1. Introduction

Albeit its economic and social relevance, the construction sector in the European Union (EU) consumes a great amount of resources, with figures up to 50% of all extracted materials [

1], and produces vast quantities of waste, accounting for 37.5% of the total [

2]. Moreover, the built environment is responsible for 40% of the total energy consumption and 36% of all CO2 emissions in the EU [

3].

Among some of the most commonly employed construction materials are concrete and steel. Understanding the properties and constraints of materials is essential to both the design and future construction and use; however, evaluating the environmental impact has become equally critical as climate change and sustainability concerns increase. Thus, the use of Life Cycle Assessment (LCA) databases allows for the assessment and comparison of construction materials’ environmental performance through the use of indicators such as embodied energy or CO

2 emissions. For instance, the Ecoinvent database [

4] indicates that steel has an embodied energy of 27.90 MJ/kg and emissions of 1.71 kg CO2/kg. Similarly, values of 0.618 MJ/kg and 0.112 kg CO2/kg are reported for concrete [

4].

Nowadays, similar to other economic sectors, construction is veering towards practices within material selection, construction methods, operational efficiency, and end-of-life strategies that regard social and environmental wellbeing to further sustainability. In this regard, the European Green Deal [

5] promotes the use of timber as a means to reduce the environmental pressure of the construction industry.

Although the use of timber is not new, approaches to alleviate some of the inherent limitations of wood (i.e., dimensions, strength, stability, fire resistance, etc.) through the development of wood-engineered products [

6,

7] and various technological advances [

8,

9] are propelling its current popularity. Moreover, another factor driving the increase in use is the comparatively better environmental profile with respect to other construction materials [

10]. As a renewable resource, timber can be continually sourced from sustainably managed forests, which contributes to the maintenance and expansion of forested areas, thereby mitigating deforestation and promoting ecological quality [

11]. Since it originates from a photosynthetic organism, uptake of carbon occurs during its growth due to biomass conversion with approximately 1.5 t CO

2/m

3 of wood [

12]. Thus, sequestration or carbon storage could be considered in the manufacture of timber, provided that the harvested tree is used in long-life cycle products such as construction materials. Moreover, the use of timber in substitution of other more environmentally damaging materials constitutes an additional benefit in CO

2 mitigation since the manufacturing emissions of the replaced construction material are avoided. After sawing, lumber is naturally or forced-dried to achieve dimensional stability and planed according to use or processing into other wood-engineered products. Undoubtedly, these operations pose a negative impact on the environment. Although precise figures vary for the different wood products, both carbon emissions and embodied energy are significantly lower in timber construction [

10,

13,

14].

Among the wood-engineered materials, this research work focuses on glued laminated timber (also known as glulam). This construction material is composed of layers of sawn lumber bonded together, with the grain running parallel to the length of the structural element. This manufacturing allows for large spans and variable cross-sections, as well as high strength-to-weight ratios. Nevertheless, the different strength classes (e.g., from GL 20h to GL 32h for homogeneous glulam [

15]) exhibit specific mechanical performances relating to the wood species. For instance, lower strength classes could be associated with softwoods (

Thuja plicata,

Picea sitchensis,

Abies magnifica,

Abies grandis,

Abies concolor,

Abies procera,

Abies amabilis, etc.), whereas greater strength classes are connected to

Pinus sylvestris,

Larix decidua,

Pseudotsuga menziesii, etc. [

16].

In this regard, the scientific community has predominantly centered its attention on the study of a single strength class, and the interest has not been uniformly distributed among them. Conversely, it is worth mentioning the research by Baranski et al. [

17], who addressed the optimization of different beam geometries as well as different qualities of glulam (i.e., GL 22h, GL 24h, GL 26h, GL 28h, GL 30h, and GL 32h).

From the literature analysis, GL 24h stands out as the most evaluated class, with a greater incidence on bending elements such as beams. In the context of structure optimization, two investigations could be highlighted. Firstly, Jelušiˇ and Kravanka [

18] assessed the optimization design of timber floor joists for a given imposed load and span of the structure. Then, De Vito et al. [

19], who developed a topology optimization of Douglas Fir GL 24h beams, considering the orthotropic nature of wood and the layering manufacture. Whereas Kilincarslan and Turker [

20] considered the strengthening of the GL 24h spruce timber column-beam connection with carbon fiber-reinforced polymer through experimental evaluation. Wang et al. [

21] evaluated the stiffness of GL 24h timber from Scotch pine beam-column joints with bolted connections and introduced a stiffness prediction method. Moreover, in the current state of transition to more sustainable materials, there are also some examples of the hybrid use of GL 24h with inert materials. Regarding the association with concrete, Fu et al. [

22] studied the optimization of the bonding performance between prefabricated concrete and GL 24h timber from spruce. Similarly, Giv et al. [

23] studied the effect of adhesive type on the bending behavior of the GL 24h timber-concrete composite panel. Ferrara et al. [

24] conducted real-scale experiments on the mechanical performance of a GL 24h timber-concrete composite floor supported at two edges. Gomez-Ceballos et al. [

25] presented a numerical method for the analysis of the mechanical behavior of GL 24 h Douglas beams reinforced with ultra-high-performance fiber-reinforced concrete. For the timber-steel conjunction, Ching et al. [

26] developed a topology optimization framework for trusses made of GL 24h timber and steel that aims to reduce global warming potential.

Several authors have also assessed the GL 28h class, mostly in the context of reinforced elements such as tendons or steel bars. For instance, De Luca and Marano [

27] tested the failure of pre-stressed GL 28h spruce timber reinforced with steel bars. Also for European spruce, McConnell et al. [

28] tested Gl28h timber with steel tendons in post-tensioning conditions. In regards to optimization, Mam et al. [

29] engaged on GL 28h bracing structures. For a timber-timber composite with glulam ribs and cross-laminated timber flanges, Suárez-Riestra et al. [

30,

31] tested the GL 28h from

Picea abies and proposed an estimation model for the long-term behavior of the composite.

Amid the less studied strength classes, it should be mentioned the investigation carried out by Jelušič [

32], who proposed an optimization approach to variable cross-section beams of GL 30h timber, as well as the research performed on GL 32h timber by Šilih et al. [

33] for timber trusses and Simón-Portela [

34] for an entire timber roof structure.

Despite the current clear focus on specific strength classes, the complete consideration of the strength class range within the material selection could benefit the optimization of the timber volume required for a specific structure, which is one of the objectives of this research work. In this regard, there is an extensive literature on reducing material consumption in the design of steel and concrete structures; some examples could be found in [

35,

36,

37]. Albeit more limited, optimization approaches have also been made for timber construction such as beams [

17,

32,

34] and trusses [

18,

33,

38,

39].

Additionally, the consideration of the use of the strength classes could also result in advantages from a sustainability standpoint since a greater variety of wood species would be considered for construction purposes. It should be noted that besides their performance and classification within a strength class, the available tree species for selection would also be motivated by their intrinsic characteristics (e.g., climatic adaptation, growing rate [

34], etc.) as well as the final acquisition cost of the material. In this regard, research shows that tree species richness can enhance wood productivity while maximizing ecosystem functioning [

40,

41,

42]. Notwithstanding, to adequately supply the increasing demand for wood as a construction material, the source material must originate from responsibly managed forests.

Therefore, the present investigation assesses the influence of glulam strength classes in timber construction. Specifically, on the design of a timber roof structure consisting of timber double-tapered beams and purlins, according to Eurocode 5 [

43] requirements. To that end, an optimization tool based on genetic algorithms has been developed, and based on the results, several equations have been proposed to determine the optimal geometry (width and height) of the structural elements (beams and purlins) as well as their spatial configuration given the roof length, span, snow load, and strength class. Similarly, a general equation has been found to predict the optimum volume required for the roof structure considering the different strength classes, which would promote efficient use of resources and economic advantages while complying with structural and safety requirements.

4. Conclusions

This research work focused on the optimization of roof structures comprised of glulam beams and purlins of different strength classes and exposed to varying snow loads. The developed genetic algorithm tool, along with the structural calculation program, was employed to generate 1792 optimal roof structures with dimensions (i.e., roof length and span) and load conditions (i.e., snow loads below 3 kN/m

2) typical of European construction. From a systematic statistical analysis, several predictive equations were proposed as a reliable method for optimizing timber roof design in accordance with Eurocode 5 [

43]. Firstly, the predictive model could be used to optimize the beam width and height as well as their spatial arrangement as a function of the roof dimensions, loads, and the desired strength class. Additionally, the developed model also enabled the determination of the overall optimal timber volume required for a roof structure as a function of the strength class. Although this approach seeks the material usage reduction and economic savings, ultimately could assist in the promotion of the use of alternative wood species.

Among the findings, it was found that double tapered beams exhibited their optimal inclination angle at 5º, leading to a 30% reduction in the total timber volume used for the roof structure compared to an inclination of 10º. The optimal spacing between purlins coincided with the maximum set value, i.e., that allowed by the roofing material. This suggests an interest in considering non-traditional roofing materials as a future optimization strategy.

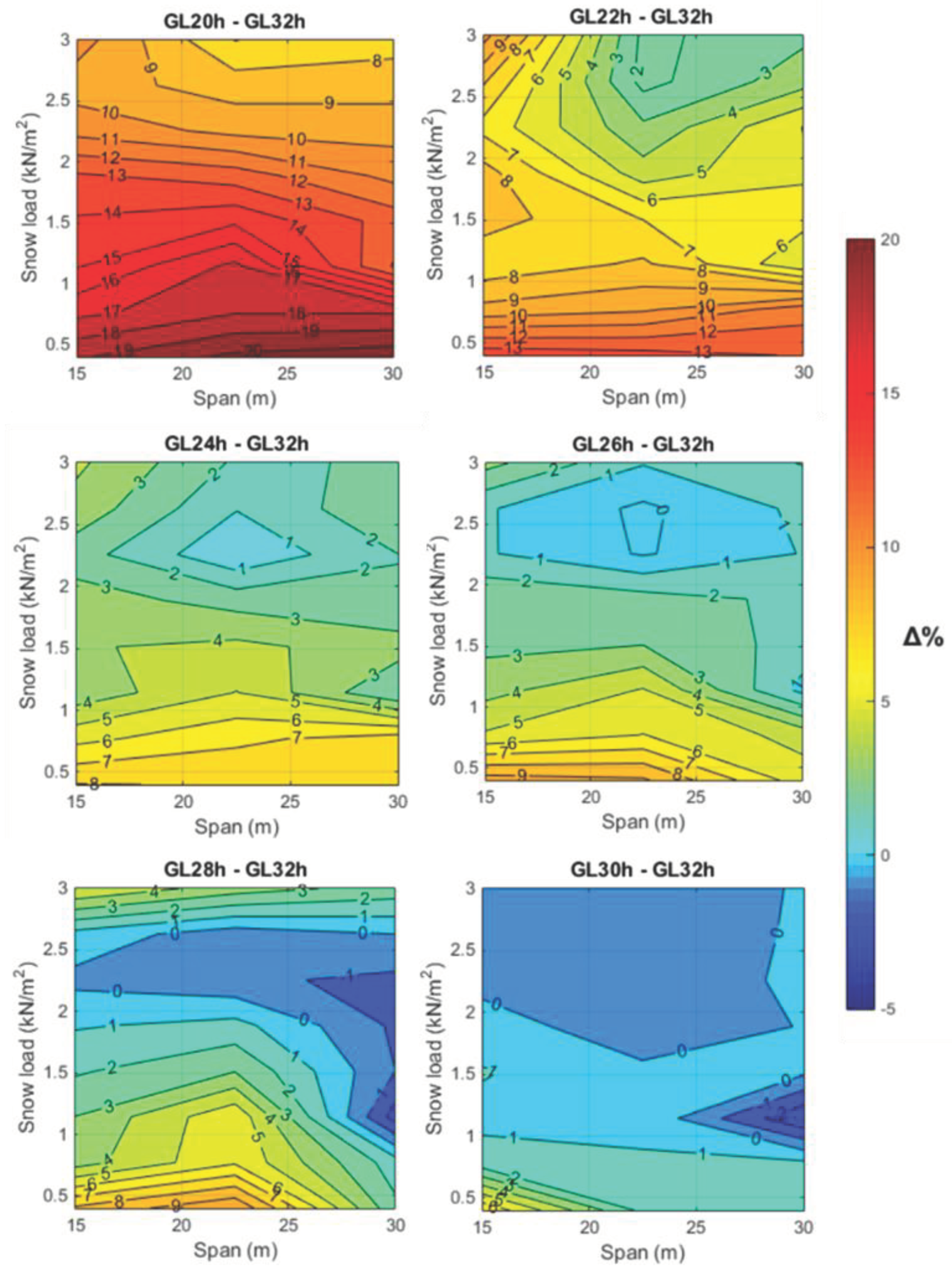

For structures exposed to snow loads greater than 2.5 kN/m2, a similar timber volume requirement, with at most a 3% difference, was noticed for most strength classes (GL 24h, GL 26h, GL 28h, GL 30h, and GL 32h). Thus, suggesting the existence of a broad range of wood species that effectively could rival the most commonly employed (GL 24h and GL 32h). Similarly, for snow loads greater than 1 kN/m2, GL 30h and GL 32h classes also resulted in similar consumption of timber volumes (up to a 1%). Across all strength classes, the largest differences in volume occur at span values close to 15 m and for the lower snow loads, with differences up to 20% for GL 20h compared to GL 32h. In any case, a strong relationship exists between the increase in the timber volume and the reduction in the strength class or the modulus of elasticity.