1. Introduction

The mechanical gearbox is the cornerstone of variable-speed transmission systems, playing a pivotal role in aligning the torque and rotational velocity between the prime mover and the driven load. Its widespread adoption is attributed to its exceptional torque density and versatile gear ratios. However, the reliance on physical contact for power transmission in mechanical gears introduces significant tribological challenges. These challenges manifest as elevated costs associated with lubrication, cooling, and maintenance [

1]. Empirical evidence underscores the fact that tooth abrasion critically undermines the reliability of mechanical gears, often emerging as a primary cause of system failures [

2]. This vulnerability significantly restricts their application in industries such as food, pharmaceuticals, and chemicals, where the operational environment demands higher standards of cleanliness and system integrity. In situations where a clear separation between power input and output is required, mechanical gears may not meet these strict requirements.

Magnetic gears (MGs) are emerging as superior alternatives to traditional mechanical gearboxes, offering a host of benefits that include higher efficiency, reduced noise, and intrinsic self-protection features [

3,

4]. These advantages stem from MGs’ ability to inherently provide overload protection through the physical separation of input and output rotors, a critical feature that significantly enhances transmission reliability [

5]. Unlike mechanical gears, which rely on the direct meshing of teeth on the master and slave wheels for motion and power transmission, MGs utilize the coupling of magnetic fields between permanent magnets affixed to these wheels, a principle that is also finding applications in the design of electric motors, such as the permanent-magnet field-modulation machines [

6,

7]. The initial phase of MG research focused on developing magnetic gear topologies by drawing parallels with the traditional designs of mechanical gears. This foundational work has led to the development of a diverse array of MG types over the past two decades. Classifying MGs by their operating principles reveals a variety including coaxial permanent-magnet (PM) coaxial MGs, reluctance MGs [

8], cycloidal MGs [

9], and planetary MGs [

10]. When categorized by structural characteristics, the range expands to radial-type magnetic gears (RMGs), axial-type magnetic gears (AMGs), linear MGs [

11], and tubular MGs [

12]. Notably, RMGs and AMGs have attracted significant research interest for their potential to directly replace mechanical gearboxes in practical engineering applications. While RMGs are celebrated for their adaptability, certain applications may find them less suitable due to strict spatial constraints. In these instances, AMGs present an advantageous alternative, boasting higher torque density and a reduced axial length compared to RMGs [

13]. The distinction between Axial Magnetic Gears (AMGs) and Radial Magnetic Gears (RMGs) is primarily rooted in the orientation of permanent magnet magnetization and the nature of their coupling surfaces. Specifically, RMGs feature magnets that are magnetized in the radial direction and utilize the radial outer circular surface for coupling. Conversely, AMGs employ an axial magnetization direction, with coupling occurring at the axial outer end surface. This fundamental difference renders AMGs particularly advantageous in applications where weight reduction is paramount, such as in aerospace technologies [

14].

The historical development of AMGs was marked by a significant milestone in 1987 when Tsurumoto K. and Kikuchi S. introduced an axial magnetic gear with an involute shaped permanent magnet, arranged in a circular pattern on a base disc, achieving a 3:1 gear ratio using SmCo5 permanent magnets. This design was revolutionary in that it transitioned the coupling region from a radial to an axial cross-section [

15], subsequently undergoing further optimizations by Tsurumoto K. [

16,

17]. The application of axial magnetic gears, particularly in centrifugal equipment as investigated by Klaui [

18] and Meisberger [

19], has demonstrated the potential to achieve high torque densities through experimental testing. Innovations aimed at enhancing torque density have included the development of a flux-focusing axial magnetic gear, although this design was challenged by the issue of flux leakage [

20,

21]. An alternative approach involved employing a Halbach array to augment torque density [

22]. Afsari’s introduction of a magneto-resistive linkage-type axial magnetic gear presented a design that not only reduced the number of required permanent magnets but also aimed to enhance gear reliability [

23]. Despite these advancements, the design faced limitations in significantly boosting gear torque and exhibited magnetic leakage in slower-rotating rotors. Furthermore, the performance evaluation of AMGs necessitates the construction of complex three-dimensional models, a process that is notably time-consuming and has thus limited the proliferation of research and development in this area [

24,

25]. The axial-direction force exerted by AMGs also poses substantial challenges to their fabrication, complicating the design process further. Another overarching concern for both types of magnetic gears is the extensive reliance on permanent magnets (PMs), which considerably inflates manufacturing costs due to the materials used.

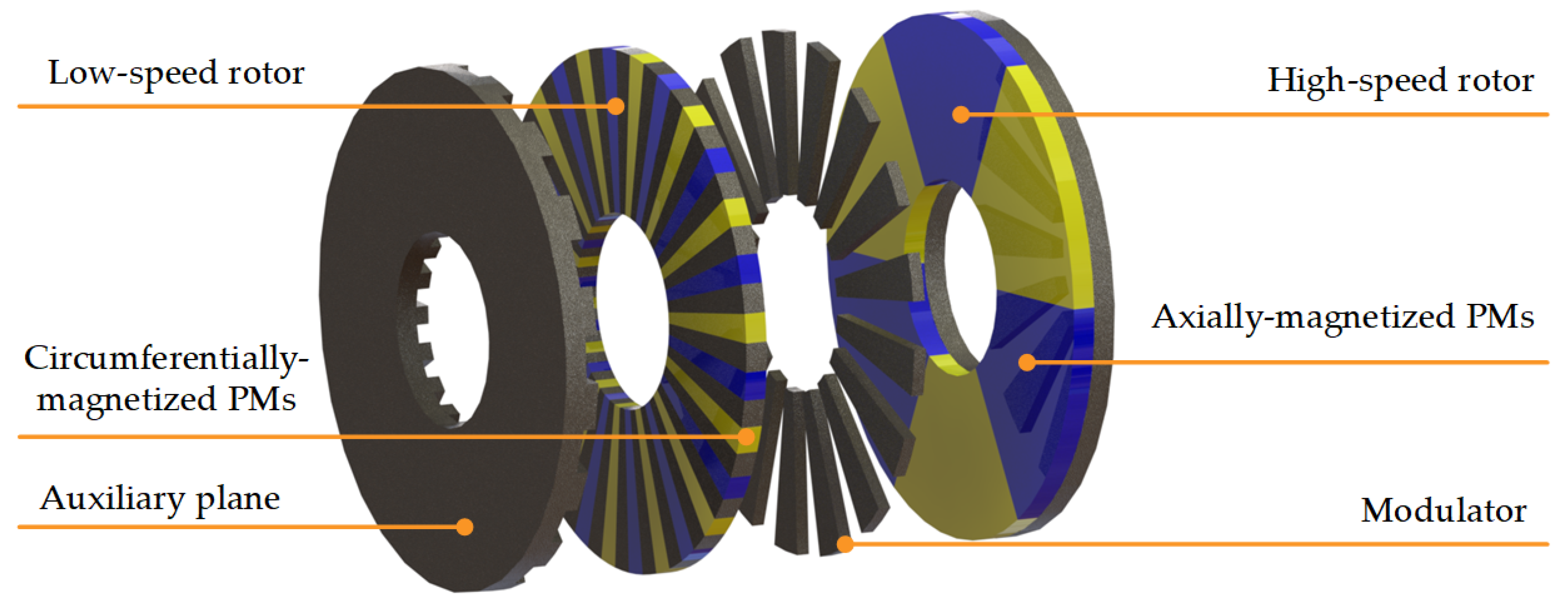

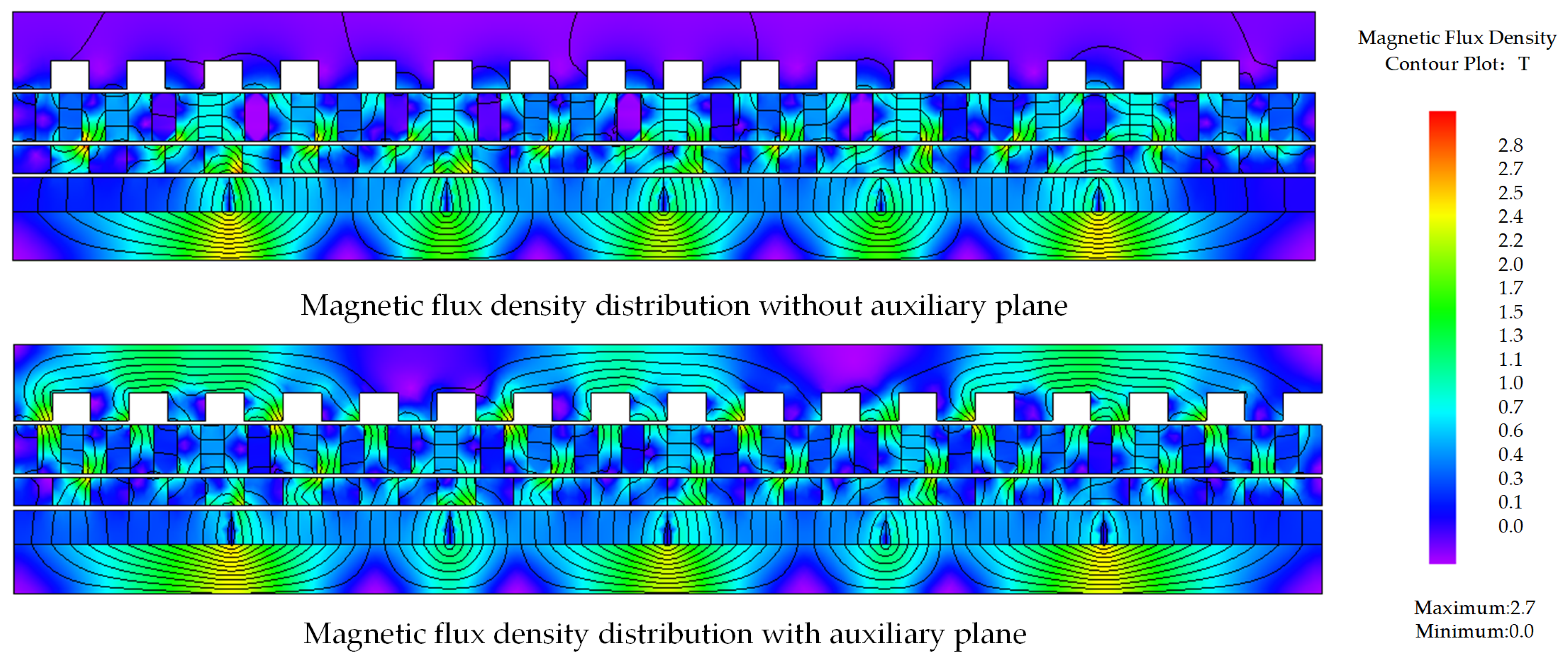

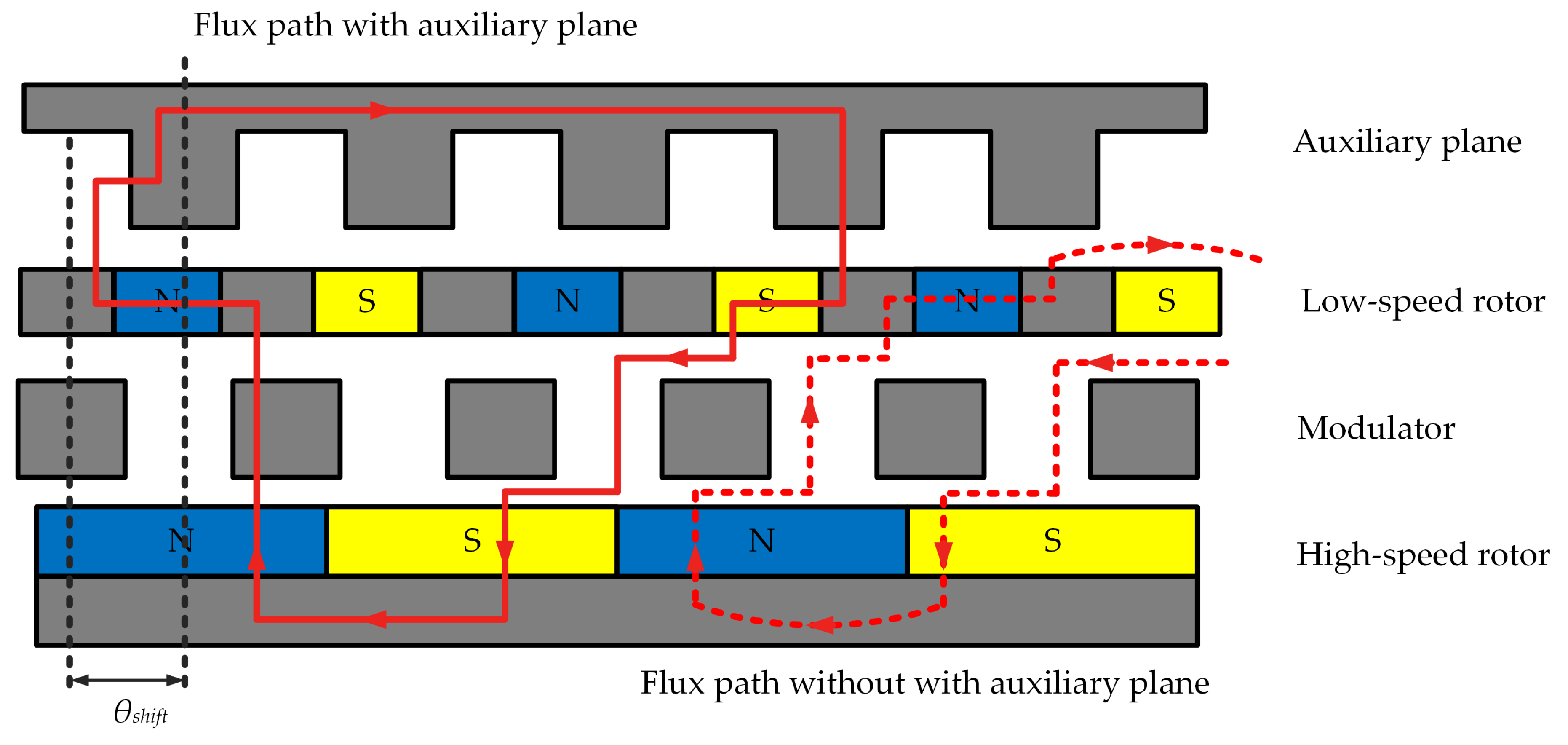

In addressing the limitations identified in existing Axial Magnetic Gear (AMG) designs—namely, the insufficient improvement in torque density and the consequential cost implications stemming from the extensive use of permanent magnets (PMs)—this paper introduces a innovative approach. We propose the integration of an iron-made flux-enhancing plate to the exterior of AMGs, a novel addition designed to significantly elevate the output torque. This innovative concept is meticulously analyzed through the examination of flux path variations, pre and post the implementation of the auxiliary flux-enhancing plane, elucidating the underlying principle of flux enhancement.

Subsequently, the performance metrics of three distinct AMG configurations are rigorously compared to demonstrate the superiority of our proposed structure. This comparison not only showcases the enhanced torque density achieved through our design but also highlights an unprecedented improvement in the PM utilization factor. By ingeniously augmenting the magnetic flux efficiency within the gear system, our approach effectively mitigates the challenges associated with high PM usage, thereby addressing both the performance and cost-efficiency concerns.

3. Optimization Process

There are two important indexes for the evaluation of AFS-AMGs, namely the torque density with respect to the total volume

, and torque density with respect to the volume of PMs

. They can be defined as [

30]:

where

and

are the inner and outer radii of the AFSAMG, respectively.

L is the axial length of the AFS-AMG, and

is the total volume of PMs in the AFS-AMG.

Given the substantial computational demands of executing a single instance of AFS-AMG in FEA software, the application of a genetic algorithm-based optimization method for AFS-AMGs is rendered impractical. Consequently, the paper opts for a parameter sweep method for the optimization process. This approach involves the sequential optimization of the geometrical parameters associated with AFS-AMGs. By methodically altering each parameter within a specified range and evaluating the resulting performance metrics, the optimal configuration can be identified with greater efficiency and less computational expense.

3.1. Pole-Pair Combination Selection

To make AMGs with different pole-pair combinations comparable to one another, the gear ratio range is settled at the first stage. Since gear ratio G should not be integer to avoid large torque ripple [

31,

32], its value is set within the range between four to five in this paper. Additionally, since iron bars are required to inserted between each circumferentially-magnetized PMs, Plow cannot be too large to prevent manufacture difficulties. Hence, the possible pole-pair combinations for AFS-AMGs are listed in

Table 2.

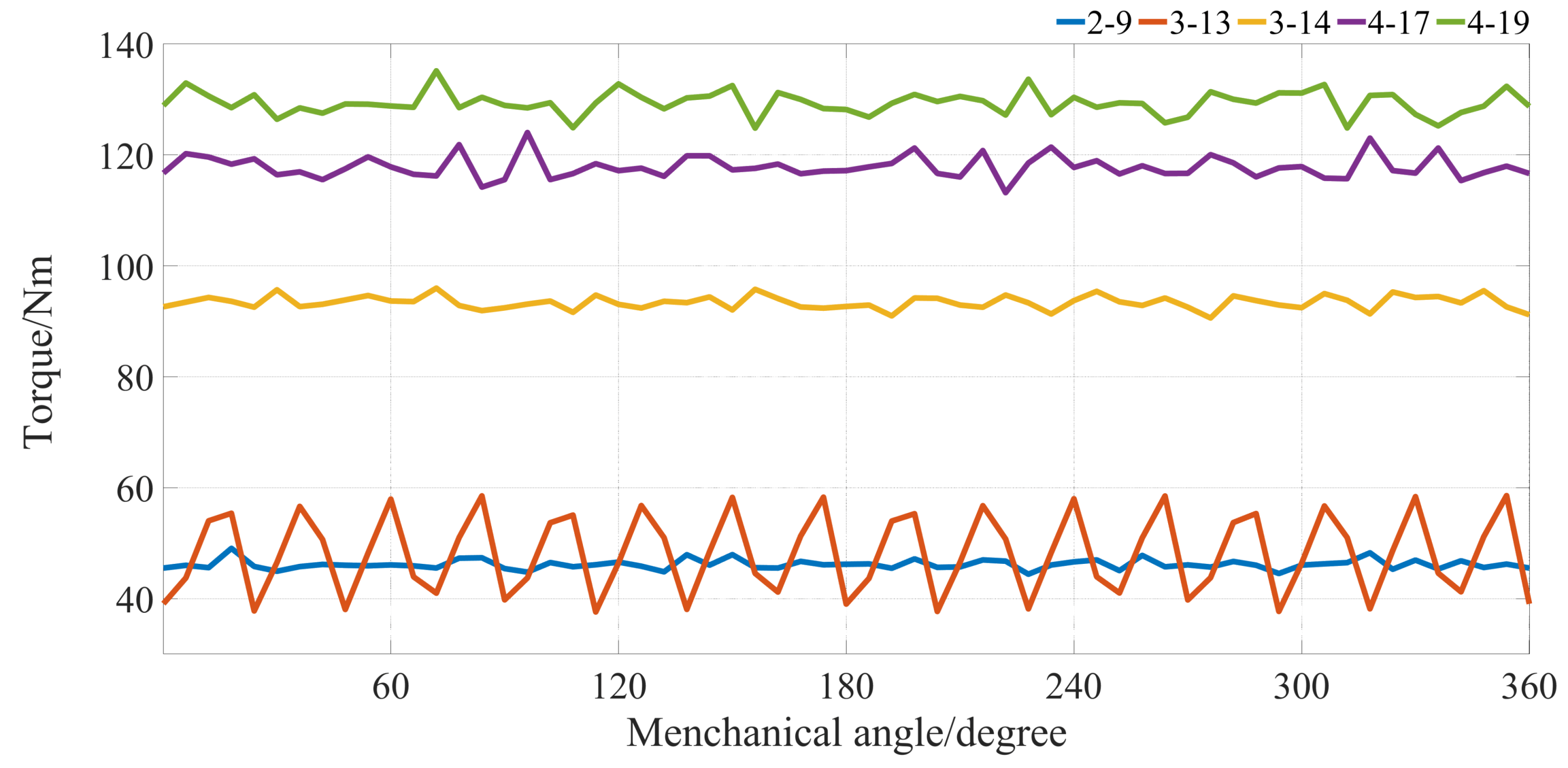

Figure 5 depicts the electromagnetic torque waveforms on the low-speed rotor of AFS-AMG with different pole-pair combinations with the same geometrical size. Since the volume of the whole AFS-AMG and PMs do not change with the pole-pair combination variation, it is enough to use Tlow as the judgement standard. It can be observed that 4-19 pole-pair combination has the largest torque, and a relatively low torque ripple. Hence, the 4-19 pole-pair combination of AFS-AMGs is chosen for further geometrical parameter optimization.

3.2. Air-Gap Length Optimization

Another point of concern within the design of AFS-AMG systems pertains to the optimization of the air-gap length, denoted as . An excessively large significantly elevates the magnetic reluctance, consequently diminishing the torque density of the system. Conversely, a minimal complicates the manufacturing process and substantially amplifies the axial force exerted between each plane, potentially compromising structural integrity. To streamline both design and manufacturing processes, the air-gap lengths between the four planes within the AFS-AMG configurations are uniformly established.

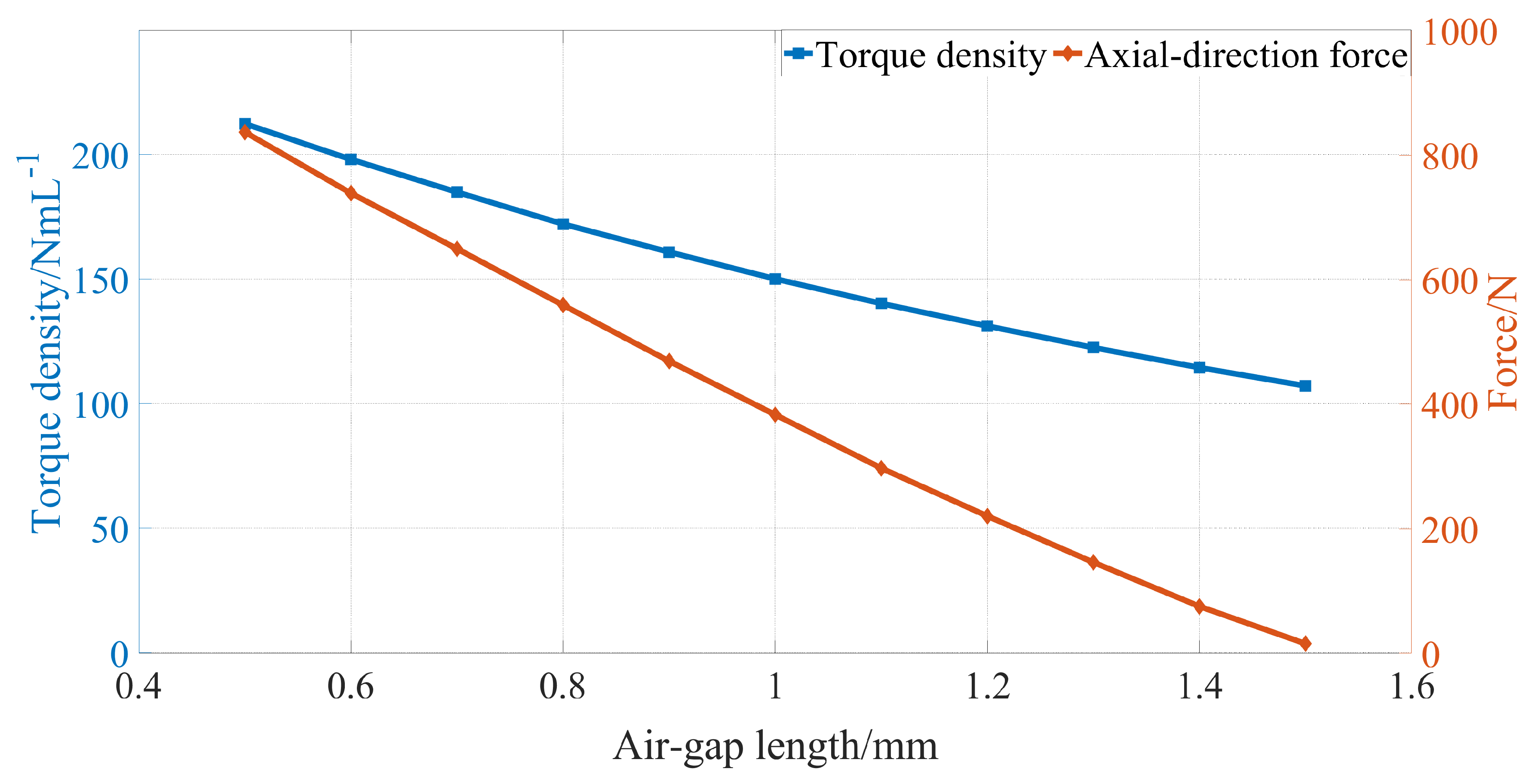

As illustrated in

Figure 6, the variation of the total tangential torque,

, along with the axial-direction force on the modulator,

, as functions of the air-gap length, are presented. Given that the volume of the permanent magnets (PM) remains constant irrespective of variations in air-gap length, the PM-related torque,

, is not depicted. The graphical analysis reveals a decline in both

and

with the increment of air-gap length. For this study, an air-gap length of 0.6 mm is selected as an optimal compromise, considering factors such as manufacturing precision and the material strength of the modulator in practical engineering applications. This decision highlights the important balance between achieving high performance and maintaining ease of manufacturing and durability in AFS-AMG system design.

3.3. PM and Modulator Thickness Optimization

The thickness of PMs plays a crucial role in determining the magnitude of MMF, which, in turn, significantly impacts the magnetic flux density across the air gap, as delineated in Equation (

3). Moreover, the thickness of the modulator pieces and the auxiliary plane teeth critically influences the extent of magnetic saturation within the silicon steel. This saturation level is a key determinant of the torque density in AFS-AMGs. To streamline the optimization procedure, we propose equalizing the thicknesses of the circumferentially-magnetized PMs located on the low-speed rotor and the axially-magnetized PMs. This unified thickness parameter is denoted as

. Similarly, to facilitate a simplified optimization framework, the thicknesses of the modulator pieces and the auxiliary plane teeth are also standardized and represented by

.

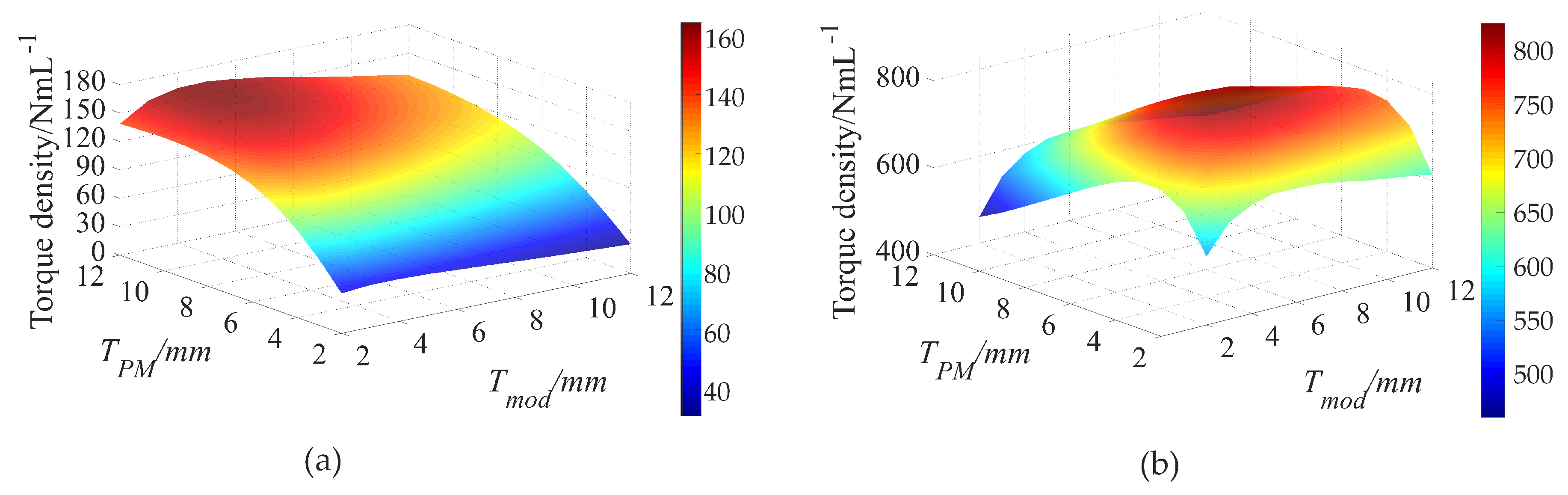

Figure 7 depicts the variations of torque density per volume and torque density per PM volume with respect to

and

. It can be observed that the variation trend of

and

are in conflict with one another. For instance, the peak value of

total occurs when the value of

is

, but the peak value of

occurs when the value of

is

. Hence, a trade off must be made to balance the conflict of

total and

. In this paper, the AFS-AMG with

is selected, where

and

.

3.4. Back Iron Thickness Optimization

The thickness of back iron of the high-speed rotor and auxiliary plane will influence the magnetic saturation, which further affect the electromagnetic torque. To simplify the optimization process, the thickness of the back iron of the high-speed rotor and auxiliary plane are set equal, which is represented by

.

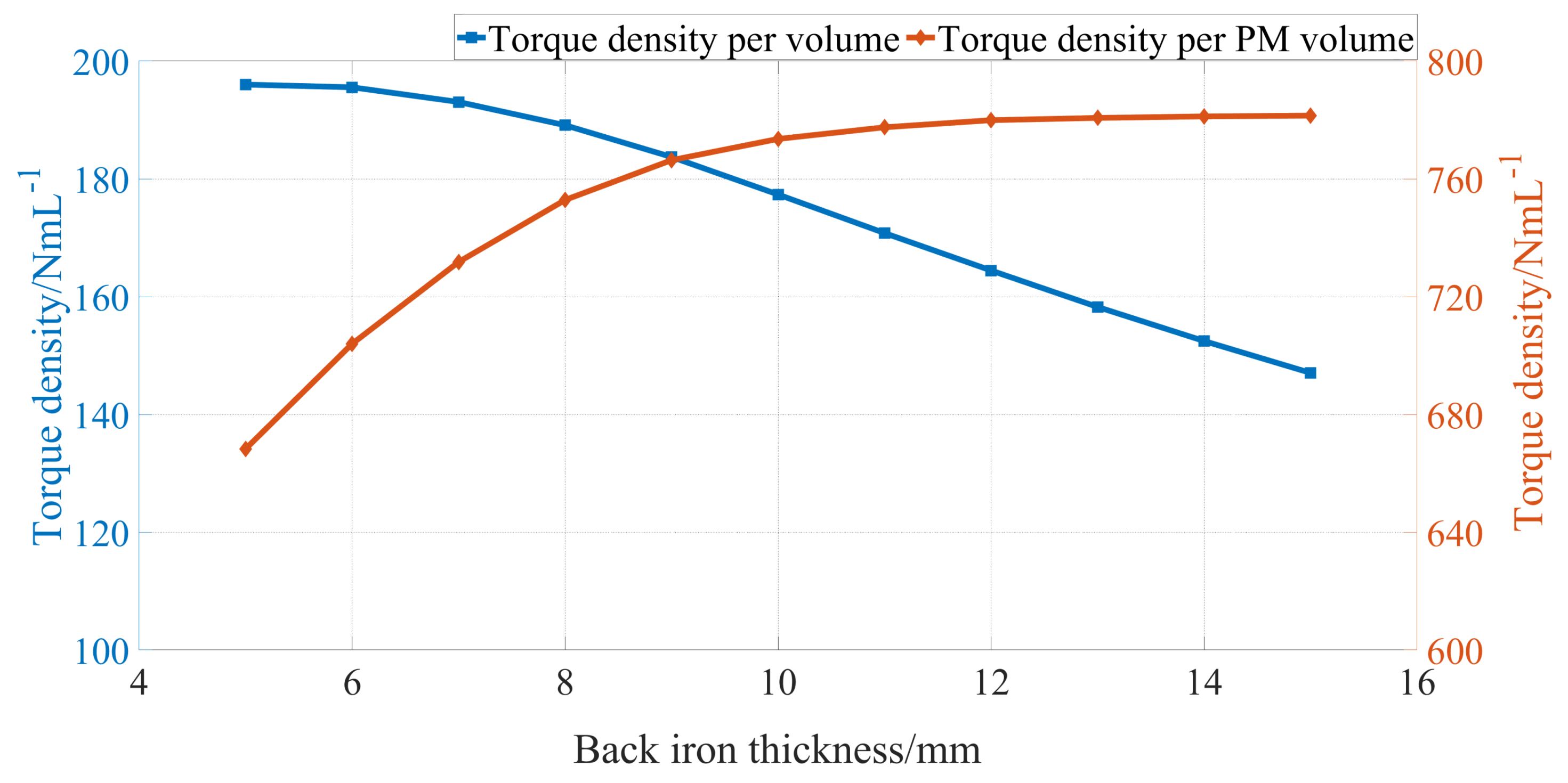

Figure 8 depicts the variations of torque density per volume and torque density per PM volume with respect to

. It can be observed that the variation trends of and

are in conflict with each other. However, the increasing gradient of becomes smaller when the value of

is above

. Hence, in this paper,

is set as

.

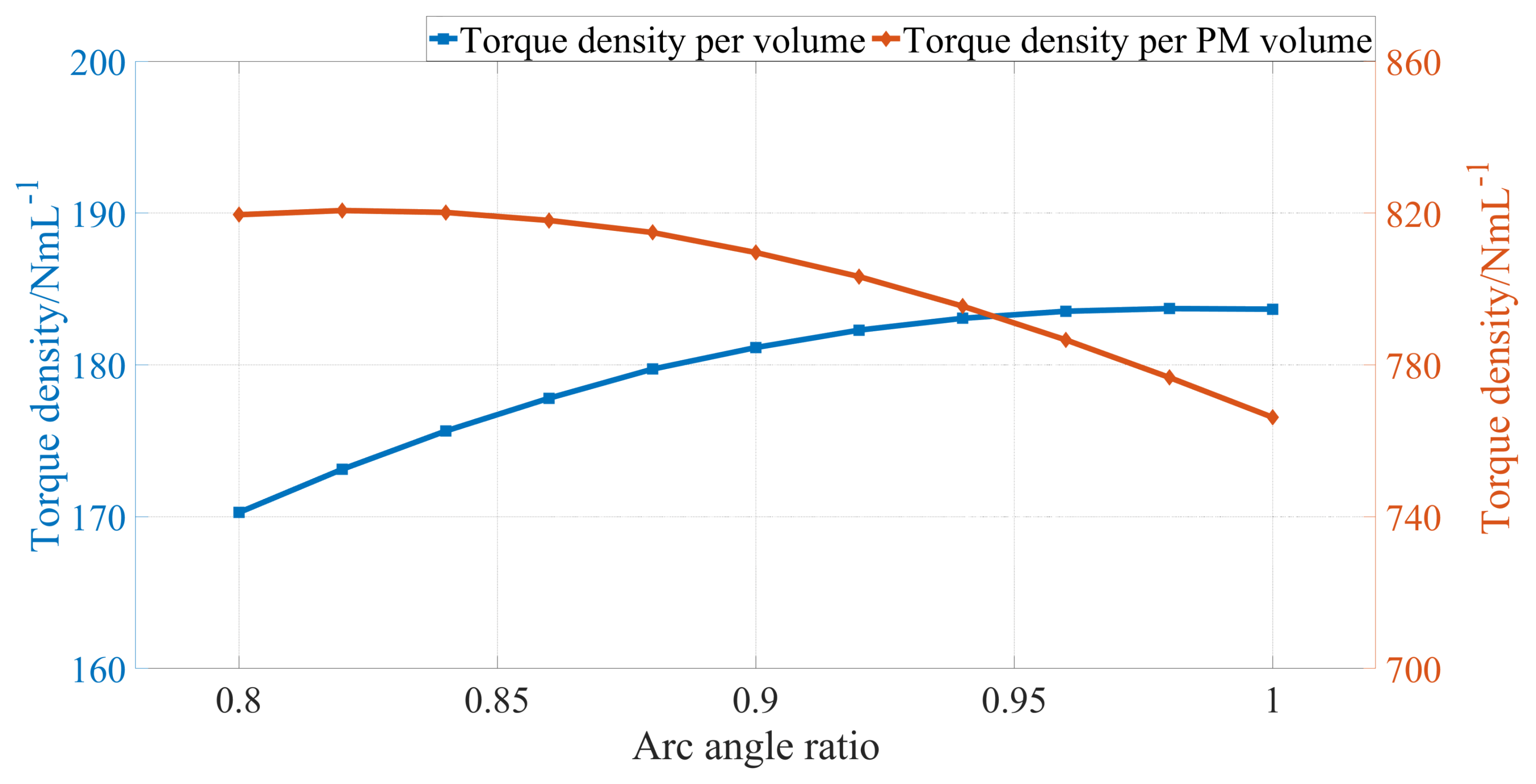

3.5. High-Speed Rotor PM Arc Angle Ratio Optimization

For the PMs on the low-speed rotor, they are adjacent with the silicon steel part to form a complete plane. If these PMs and silicon steel are not stuck with each other tightly, the mechanical strength of the low-speed rotor will be affected. However, the PMs on the high-speed rotor are stuck to the back iron, so there could be intervals between each PM block. The arc angle ratio

of the high-speed rotor PMs is defined as:

Figure 9 depicts the variations of torque density per volume and torque density per PM volume with respect to the arc angle ratio

. It can be observed that the variation trend of

and

are in conflict with one another. The decreasing trend of

becomes prominent when

is above 0.9 , while the increasing trend of becomes indistinctive when

is above 0.9 . Hence,

is chosen as 0.9 in this paper.

4. Electromagnetic Performance Evaluation

To prove the superiority of the AFS-AMG, three AMGs with the same inner and outer radii, similar PM and silicon steel amount are constructed in FEA software JMAG to compare their performances, whose parameters are provided in

Table 3. The MG input torque is on the high-speed shaft, therefore the output power is:

where the bracketed torque and power loss terms denote that they are functions of the high-speed rotor input speed

.The loss within the AMG can be separated into:

where

is the iron core loss and

is the eddy current loss.

The following formula can be used to calculate the core loss, which includes the eddy current loss and hysteresis loss caused by the laminated structure of electrical steel sheets [

33]:

where

and

represent the eddy current loss and hysteresis loss coefficients, respectively. The magnetic flux frequency is denoted by f, and

represents the harmonic magnetic flux density.

The calculation of eddy current loss is very important because the generation of eddy current loss can lead to thermal demagnetization. The eddy current loss of PM can be expressed as the integral of the eddy current density [

34]:

Here,

represents the conductivity of each material,

represents the eddy current density, and V represents the volume of the material.

The efficiency was calculated by using :

where

is the output power and

is the power loss.

The corresponding simulation result values are provided in

Table 4.

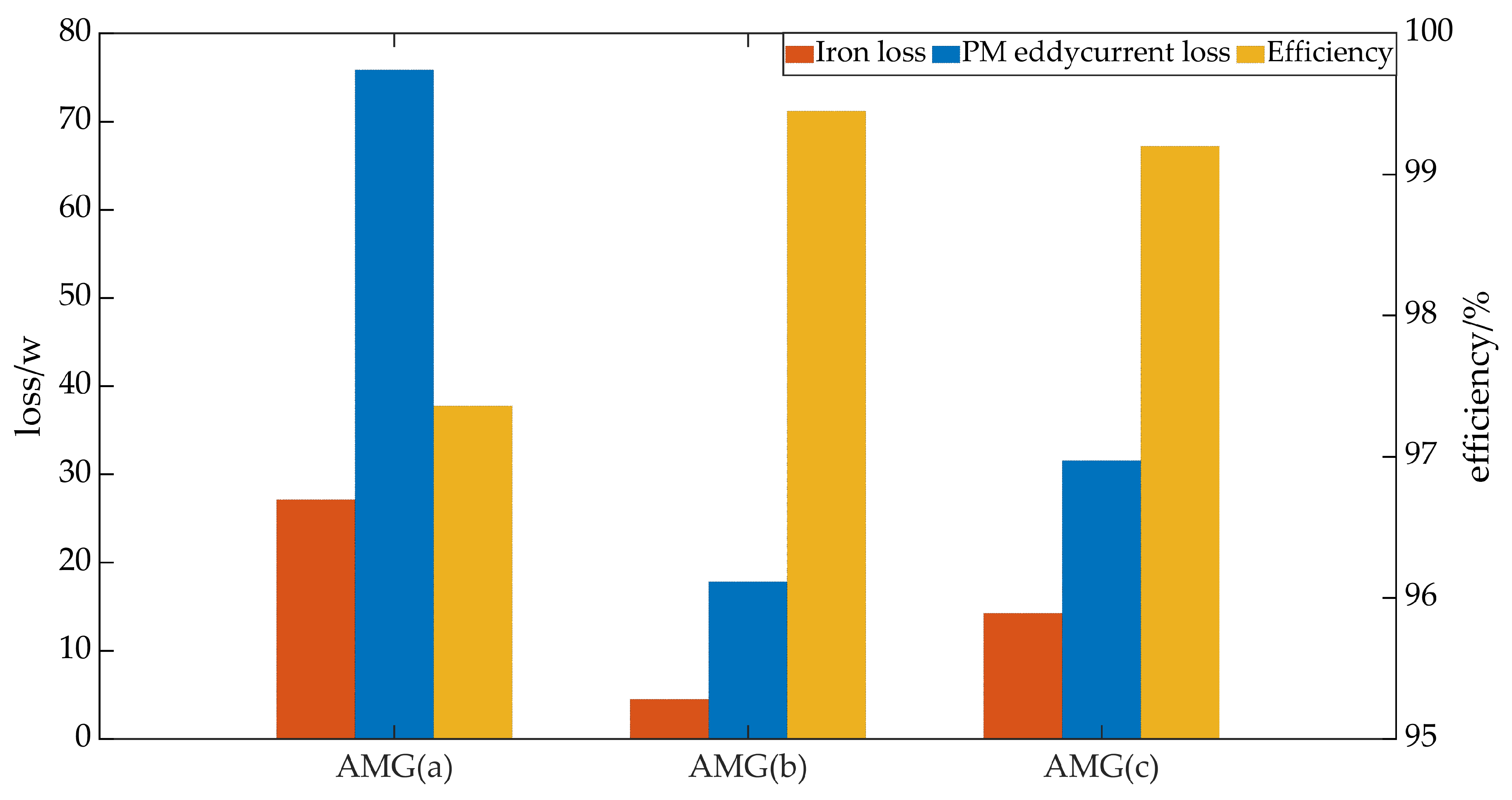

In the study of AMGs, particularly in analyzing their performance metrics, it’s essential to consider the iron losses and permanent magnet (PM) eddy current losses as pivotal factors affecting overall efficiency.

Figure 10 compares the performance of the AMGs visually. Among the different configurations examined, AMG(a) exhibits the highest iron and PM eddy current losses, with values reaching 27.15W and 75.86W, respectively. In contrast, AMG(c) demonstrates a significant reduction in both iron and PM eddy current losses, recorded at 14.25W and 31.58W, respectively, thus offering an improvement over AMG(a). The most efficient configuration in terms of minimizing losses is found in AMG(b), where the iron and PM eddy current losses are identical to those in AMG(c), at 14.25W and 31.58W, respectively. When evaluating the overall efficiency, AMG(a) ranks the lowest with an efficiency of 97.36%. Meanwhile, AMG(c) achieves a higher efficiency of 99.2%, which is only slightly below the efficiency of AMG(b) at 99.45%.

The air gap density of an AMG contains not only the radial and tangential components, but also the axial component.The axial component of the air gap density (axial air gap density) is the most important component of the air gap density and has the greatest influence on the torque capacity of an AMG.Based on the air gap density distribution of an axial magnetic gear and using the Maxwell stress tensor method to calculate the torque, the torque and axial force of an AMG can be expressed as:

where,

is the vacuum permeability;

and

are the axial and tangential components of the air gap magnetic density at different radii in the axial magnetic gear, respectively.

and

are the inner and outer diameters of the axial magnetic gear, respectively.

Of course, the torque and axial force of the high speed rotor are only related to the magnetic density distribution in the air gap of the high speed rotor, and the torque and axial force of the low speed rotor are only related to the magnetic density distribution in the air gap of the low speed rotor. Since the air gap magnetic density at different radii of axial magnetic gear is not the same, in order to simplify the calculation of AMG torque, the air gap magnetic density at the average radius

is used to replace the air gap magnetic density at different radii, where the calculation formula of the AMG torque and axial force can be converted to:

The axial component

and the tangential component

of the air gap magnetic density at the mean radius Rm are expressed as follows:

where,

and

are Fourier coefficients;

and

are the initial angles of the axial and tangential components of each harmonic wave flux density contained in the air gap flux density at radius

, respectively.

So, the calculation formula of the AMG torque can be expressed as:

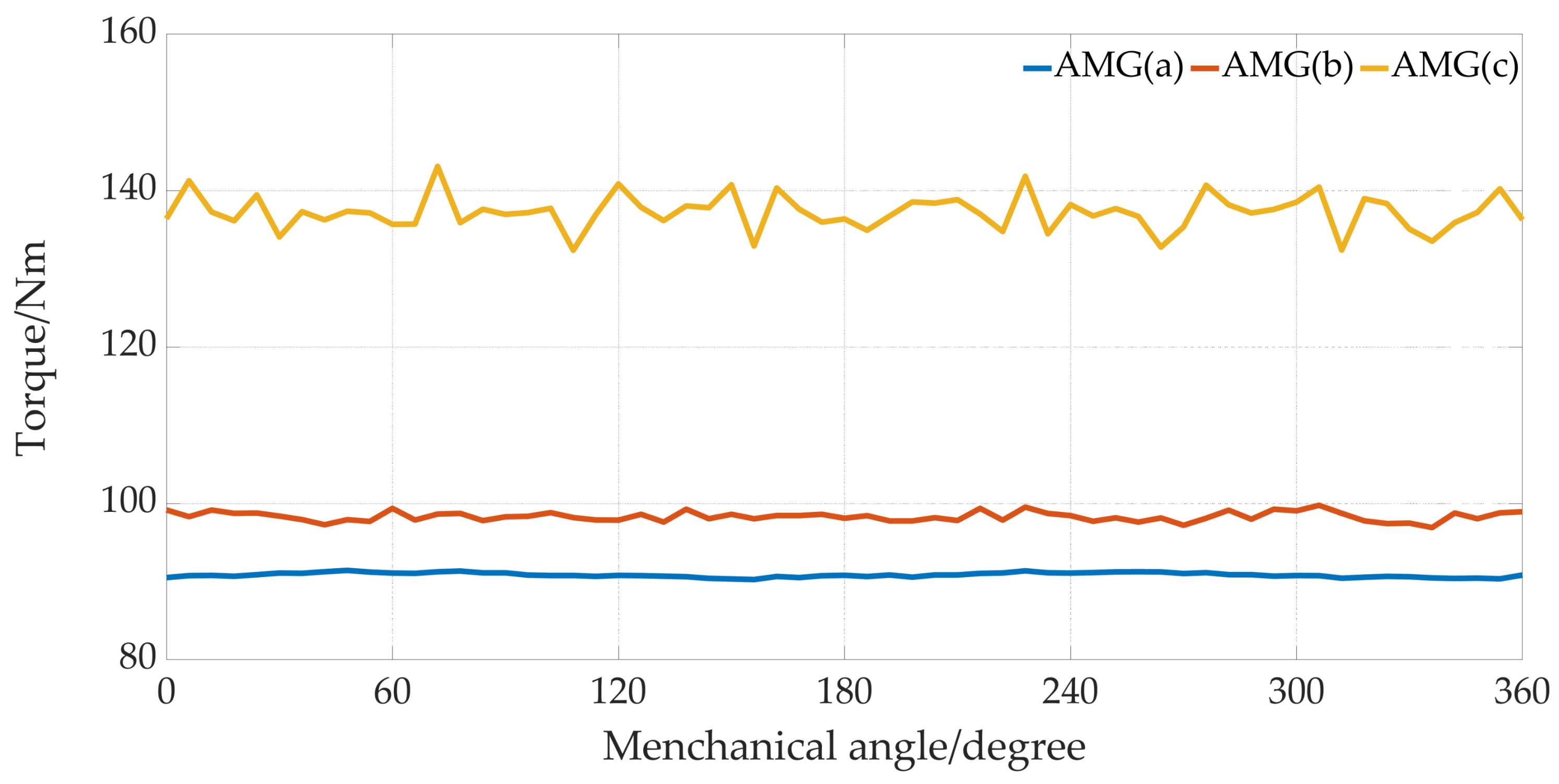

The electromagnetic torque waveforms on the low-speed rotor for the three AMGs are depicted in

Figure 11. It can be observed that the AFS-AMG (c) has the largest torque density per PM volume. The PM utilization factor of AFS-AMG is 2.15 times of that in AMG (a), and 1.40 times of that in AMG (b). Additionally, AFS-AMG has a higher efficiency compared with conventional AMGs, namely AMG (a).

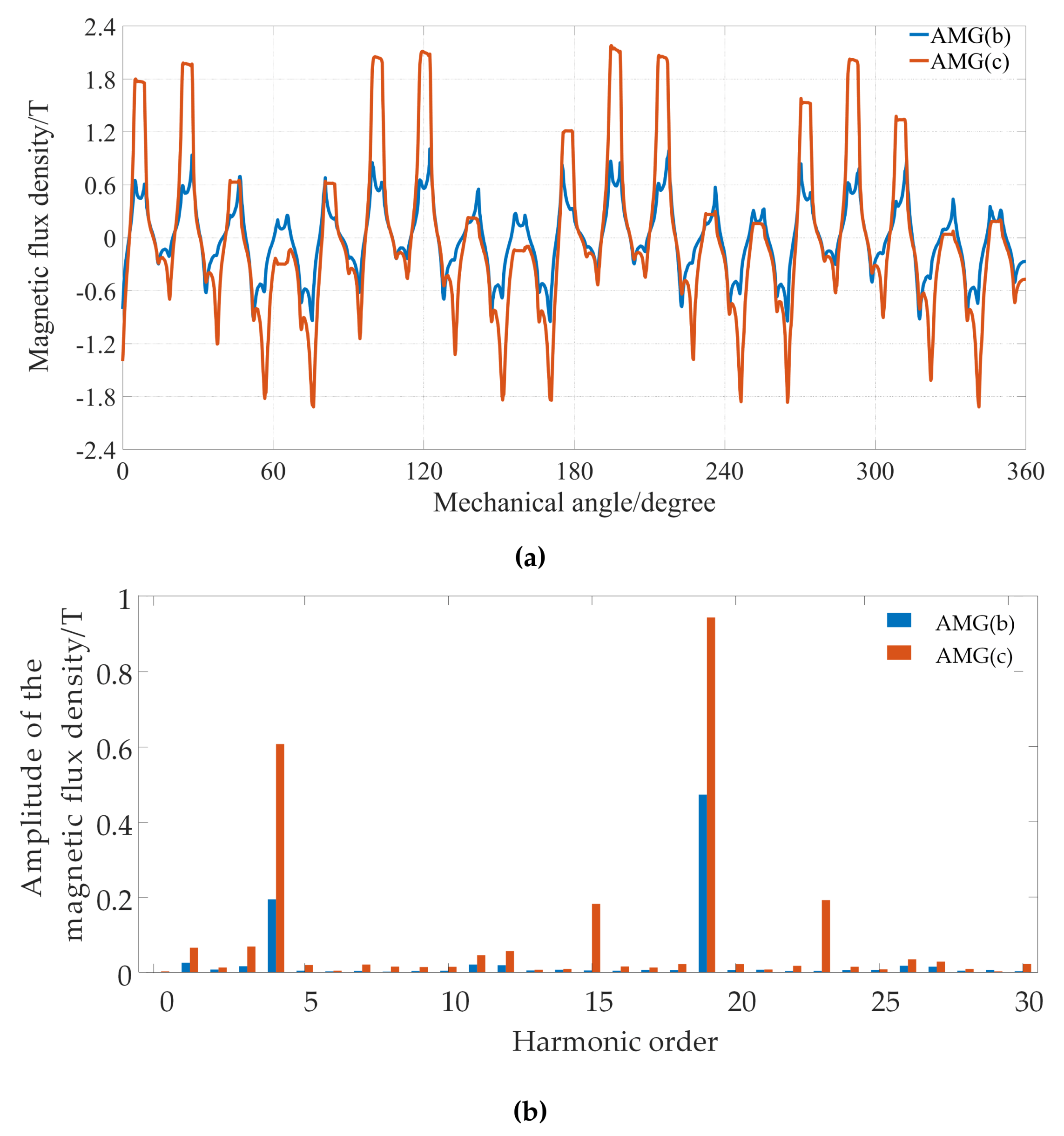

The axial component magnetic flux density distributions on the air region between the auxiliary plane and low-speed rotor and their corresponding Fast Fourier Transform (FFT) of the AMG (b) and (c) with the radius being 60 mm are depicted in

Figure 12. It can be observed that for AMG (c), namely the AFS-AMG, the amplitudes of working harmonics, namely 4th and 19th harmonics, are much larger than that in AMG (b), leading to a torque increase.

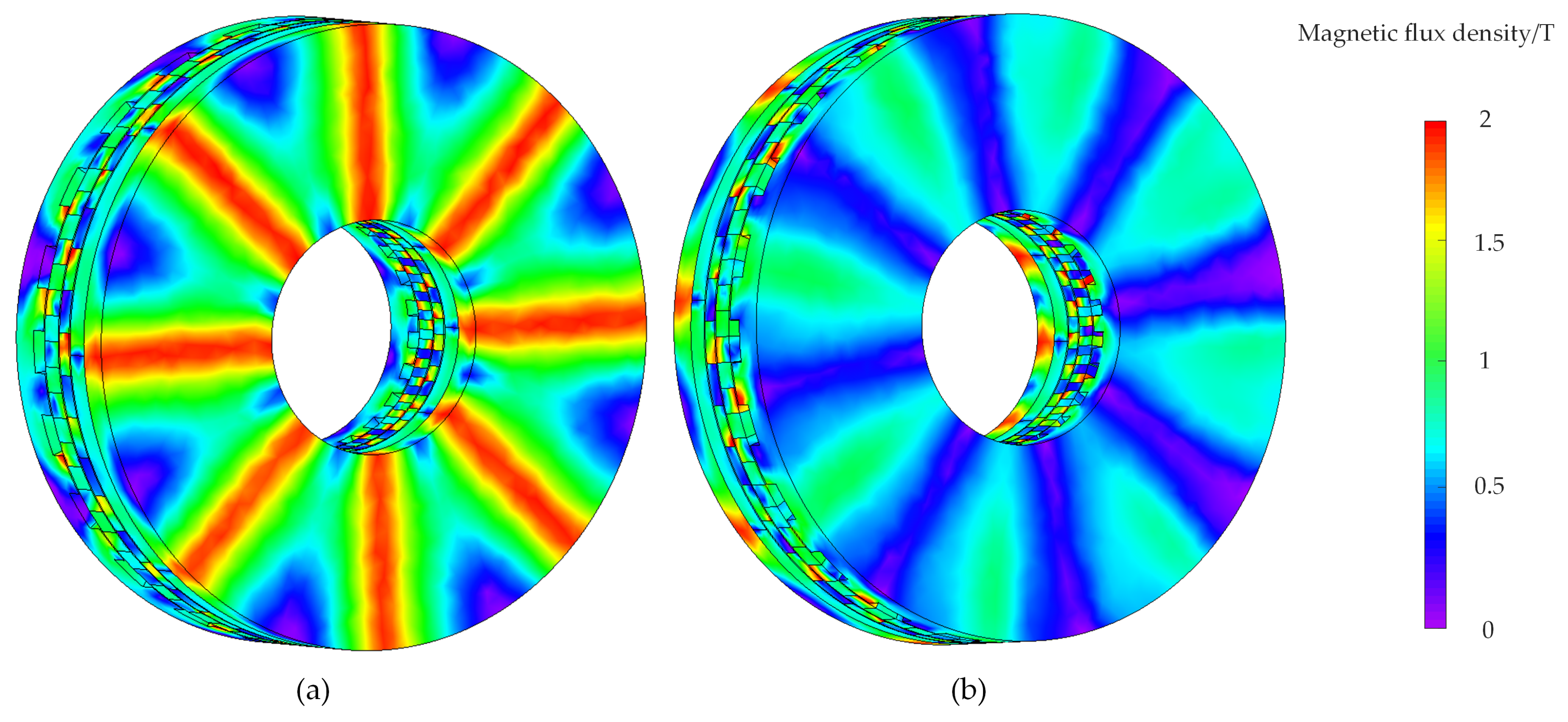

The magnetic field distribution of the proposed AMG viewed from the less-PM face and more-PM face is shown in

Figure 13. It can be observed that the back iron is more easily saturated on the less-PM side, while the auxiliary plane has lower magnetic field density.

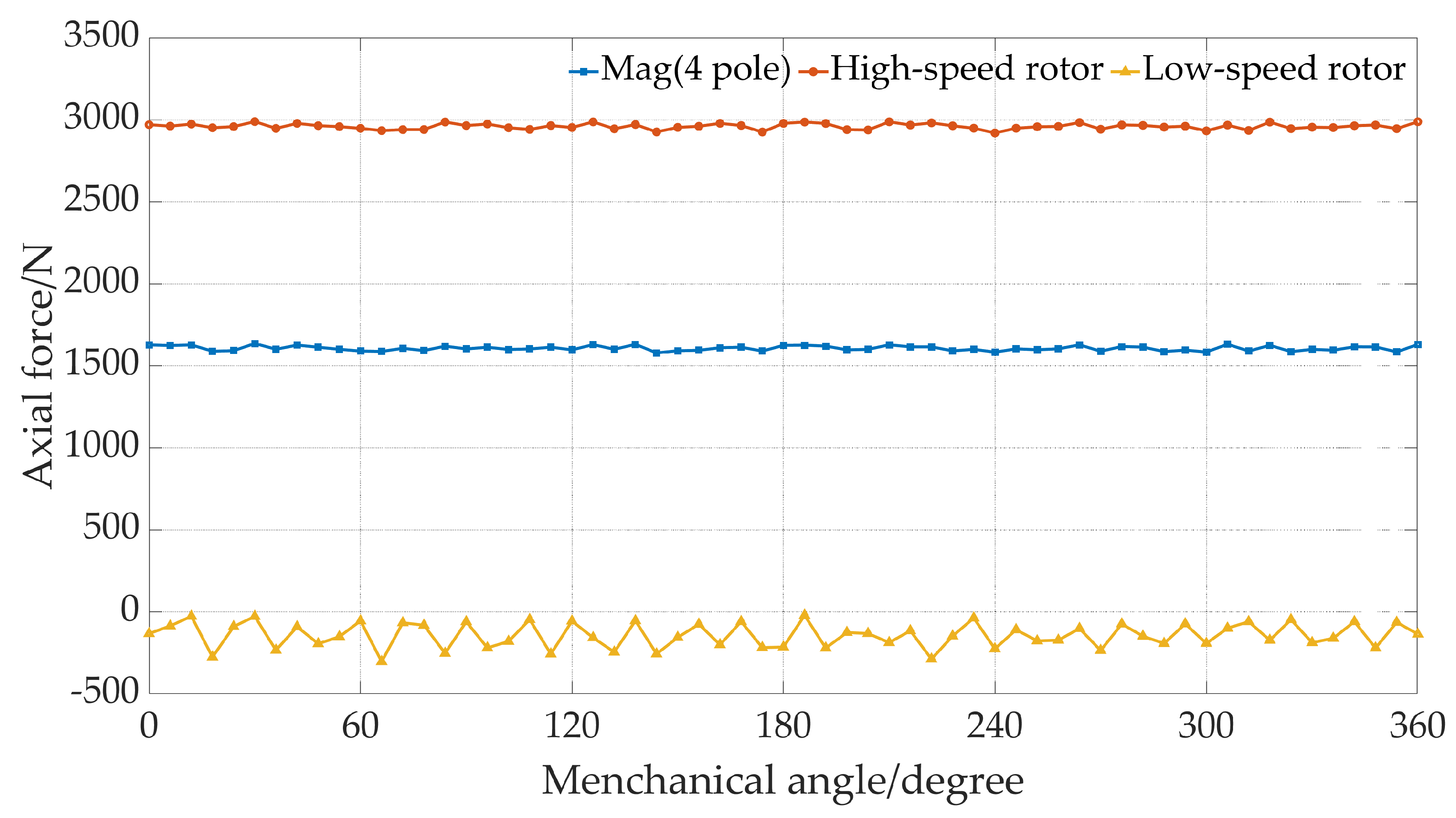

Figure 14 illustrates the axial forces exerted on all components of the AMG, encompassing both the low-speed rotor and the high-speed rotor. Notably, the axial force experienced by the low-speed rotor is relatively significant, reaching 2960 N. Consequently, the axial forces acting on the magnetic steel (N-pole) and the back iron are computed separately for a detailed analysis. Given that the North pole comprises four pieces of magnetic steel, the axial force exerted on each piece is approximately 400 N. This value falls within the tolerance limits of the manufacturing process, indicating its feasibility. In contrast, the average axial force on the high-speed rotor is quantified at around 123 N, a comparatively lower value. This discrepancy is attributed to the minimal variation in the magnetic field associated with the low-speed rotor.

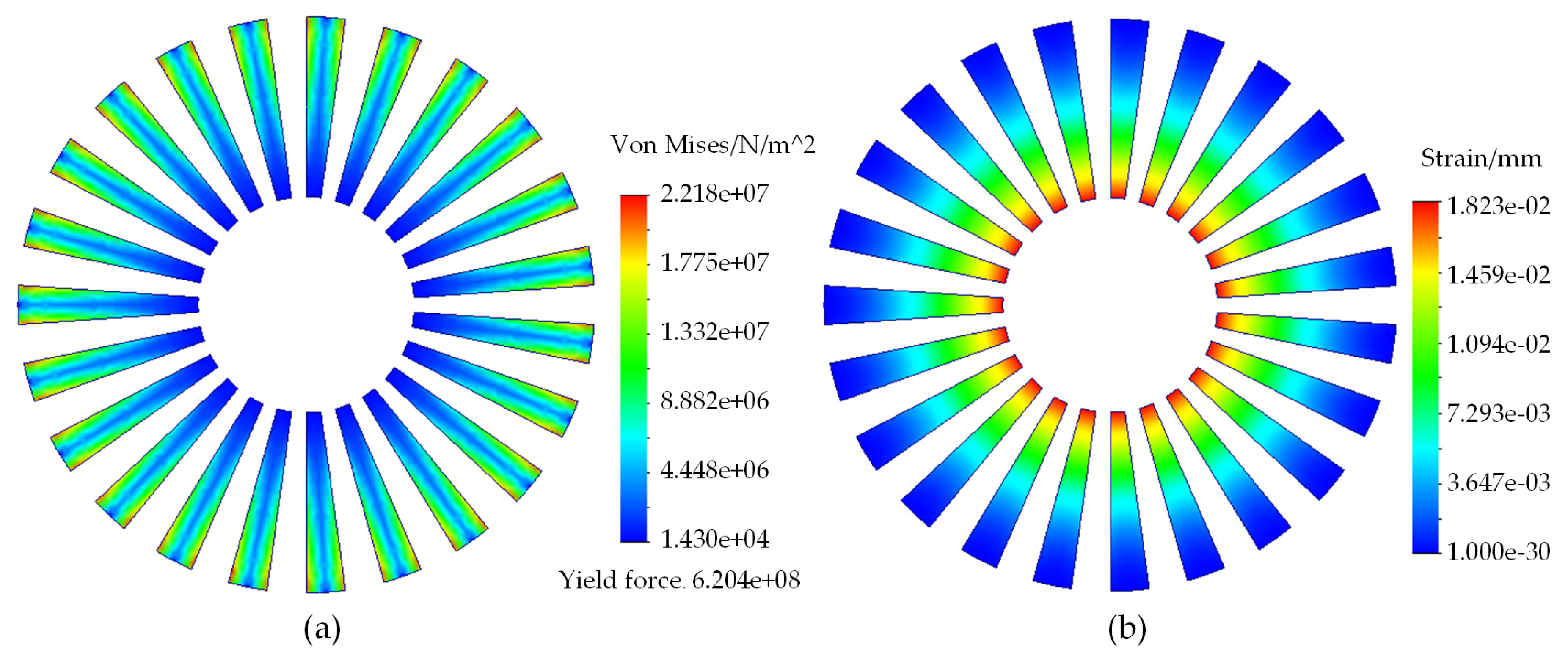

The attraction between the two rotors is accompanied by strain on the modular-poles. To analyze the results, the stress and strain on the modular poles were calculated using FEA based on equations (2) and (3).

Stress is defined as the force per unit area, where

F is the applied force and

A is the area. Strain, on the other hand, is the elongation per unit length, where

is the modified length and

L is the existing length. The analysis results are presented in

Figure 15, which shows that the stress on the modular-pole is

, a value that is below the yield force

) of the material used in the modular-pole. The strain is approximately

. The air gap between the modular-pole and the two rotors is

. The analysis results indicate that the deformation rate of the magnetic gear is within the allowable range.

6. Outlook

Although some aspects of axial magnetic gearing have been investigated in this paper, there are many issues that need to be investigated in greater depth, which can be summarised in the following two areas:

(1) Prototyping and Experimental Validation: While simulation results are promising, the next step involves prototyping and rigorous testing under real-world conditions. This will provide invaluable data on the performance, durability, and potential limitations of the AFS-AMG, guiding further refinements.

(2) Temperature field analysis: This paper does not analyze the temperature field of the AFS-AMG, and further accurate calculation of the temperature field is required. These factors should be comprehensively considered in order to better establish and apply the transmission system of the AFS-AMG.

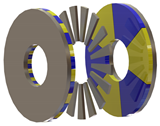

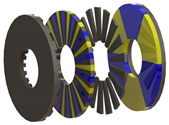

Figure 1.

Explosive view of the proposed AFS-AMG.

Figure 1.

Explosive view of the proposed AFS-AMG.

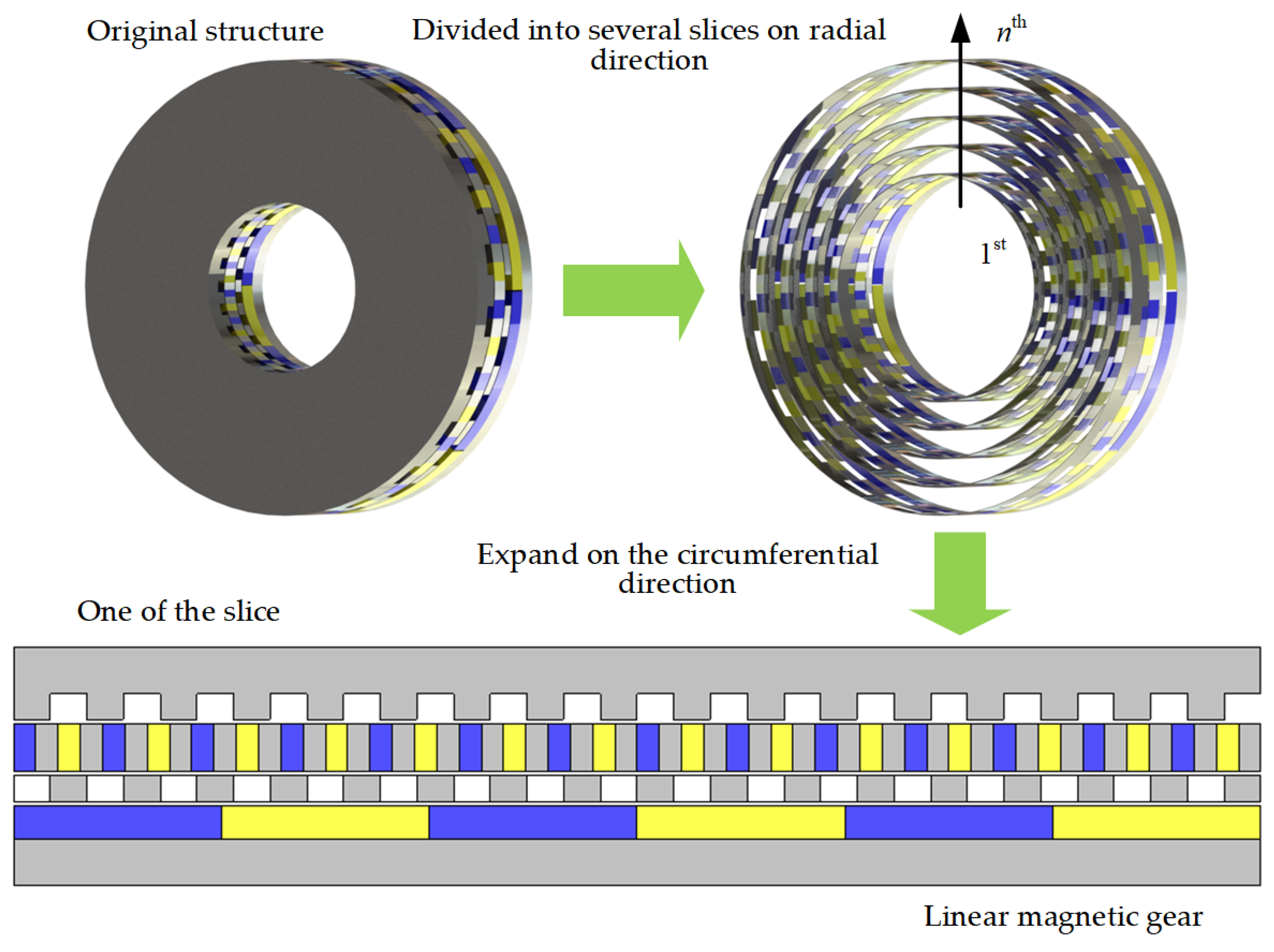

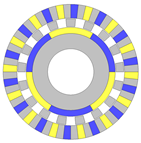

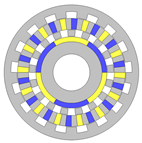

Figure 2.

Analysis simplification of the AFS-AMG.

Figure 2.

Analysis simplification of the AFS-AMG.

Figure 3.

The magnetic flux density distribution of the AFS-AMG with and without the auxiliary plane.

Figure 3.

The magnetic flux density distribution of the AFS-AMG with and without the auxiliary plane.

Figure 4.

The magnetic flux path illustration of the AFS-AMG with and without the auxiliary plane.

Figure 4.

The magnetic flux path illustration of the AFS-AMG with and without the auxiliary plane.

Figure 5.

The torque waveforms on the low-speed rotor of AFS-AMGs with different pole-pair combinations.

Figure 5.

The torque waveforms on the low-speed rotor of AFS-AMGs with different pole-pair combinations.

Figure 6.

Variation of torque density per volume and axial-direction force on the modulator with respect to air-gap length in AFS-AMGs.

Figure 6.

Variation of torque density per volume and axial-direction force on the modulator with respect to air-gap length in AFS-AMGs.

Figure 7.

Variation of torque density with respect to the thickness of modulator teeth and PMs: (a) ; (b) .

Figure 7.

Variation of torque density with respect to the thickness of modulator teeth and PMs: (a) ; (b) .

Figure 8.

Variation of torque density with respect to the thickness of back iron in AFS-AMGs.

Figure 8.

Variation of torque density with respect to the thickness of back iron in AFS-AMGs.

Figure 9.

Variation of torque density per PM volume with respect to PMs’ arc angle ratio on the high-speed rotor in AFS-AMGs.

Figure 9.

Variation of torque density per PM volume with respect to PMs’ arc angle ratio on the high-speed rotor in AFS-AMGs.

Figure 10.

Comparison of the three different AMGs.

Figure 10.

Comparison of the three different AMGs.

Figure 11.

Torque waveforms of the three different AMGs.

Figure 11.

Torque waveforms of the three different AMGs.

Figure 12.

Magnetic flux density distribution on the circumferential direction with radius being 60 mm: (a) Axial component; (b) the corresponding FFT.

Figure 12.

Magnetic flux density distribution on the circumferential direction with radius being 60 mm: (a) Axial component; (b) the corresponding FFT.

Figure 13.

Magnetic field distribution of the proposed AMG: (a)From less-PM face; (b) From more-PM face.

Figure 13.

Magnetic field distribution of the proposed AMG: (a)From less-PM face; (b) From more-PM face.

Figure 14.

Axial force of the proposed AMG.

Figure 14.

Axial force of the proposed AMG.

Figure 15.

Stress analysis of modulator teeth: (a) Stress; (b) Strain.

Figure 15.

Stress analysis of modulator teeth: (a) Stress; (b) Strain.

Table 1.

Mapping relations between RMGs and AMGs.

Table 1.

Mapping relations between RMGs and AMGs.

Table 2.

Possible pole-pair combinations of AFS-AMGs.

Table 2.

Possible pole-pair combinations of AFS-AMGs.

|

|

G |

| 2 |

9 |

4.5 |

| 3 |

13,14 |

4.33,4.67 |

| 4 |

17,19 |

4.25,4.75 |

Table 3.

Mapping relations between RMGs and AMGs.

Table 3.

Mapping relations between RMGs and AMGs.

| Symbol |

Parameter |

Value |

|

Low-speed rotor PM pole pairs number |

19 |

|

High-speed rotor PM pole pairs number |

4 |

| Q |

Modulation pieces number |

23 |

|

Outer radius of the AFS-AMG |

80 mm |

|

Inner radius of the AFS-AMG |

30 mm |

|

Air-gap length |

0.6 mm |

|

Thickness of PMs on low-speed and high-speed rotors |

7 mm |

|

Thickness of modulator pieces and auxiliary plane teeth |

5 mm |

|

Thickness of the back iron of high-speed rotor and auxiliary plane |

9 mm |

|

Arc angle ratio of high-speed rotor PMs |

0.9 |

|

Rotating speed of low-speed rotor |

400 r/min |

|

Rotating speed of high-speed rotor |

1900 r/min |

Table 4.

Simulation result values of the AMGs.

Table 4.

Simulation result values of the AMGs.

| Symbol |

AMG (a) |

AMG (b) |

AMG (c) |

|

90.85 |

98.32 |

137.09 |

|

135.51 |

194.87 |

181.14 |

|

375.56 |

580.53 |

809.60 |

| Torque ripple

|

1.28 |

2.89 |

7.82 |

| Iron loss/W |

27.15 |

4.53 |

14.25 |

| PM eddy current loss/W |

75.86 |

17.86 |

31.58 |

| Efficiency/% |

97.36 |

99.45 |

99.20 |