Submitted:

01 April 2024

Posted:

02 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Mechanics Modeling

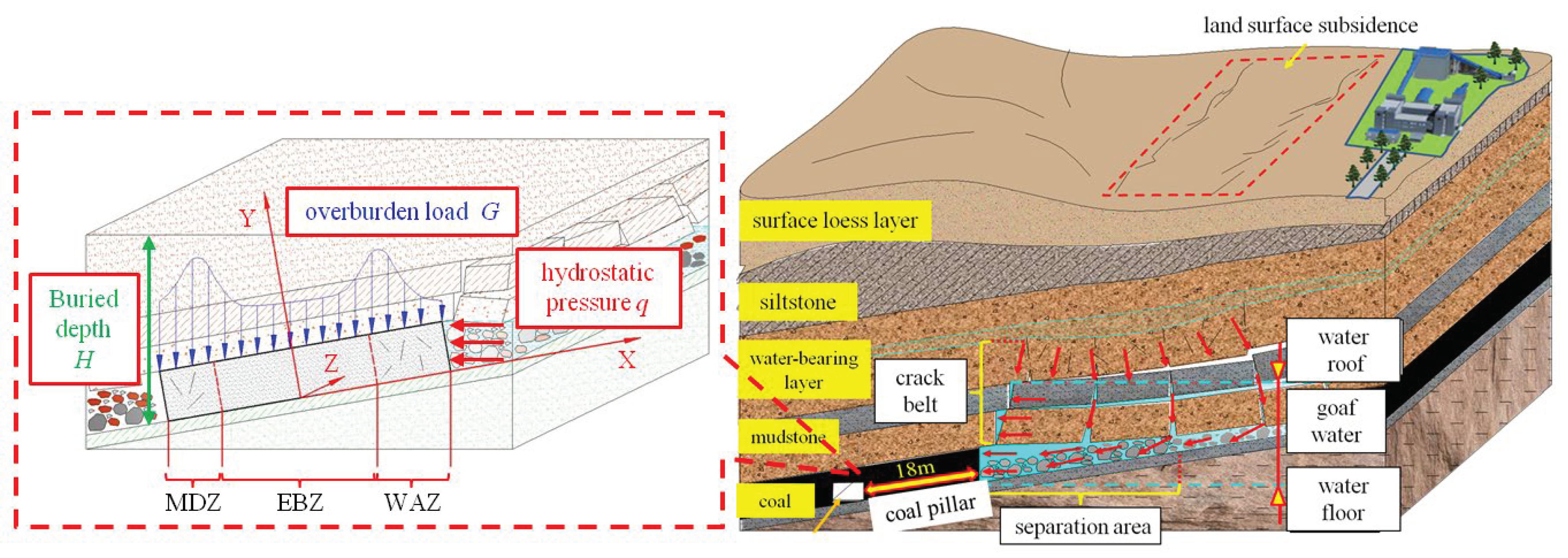

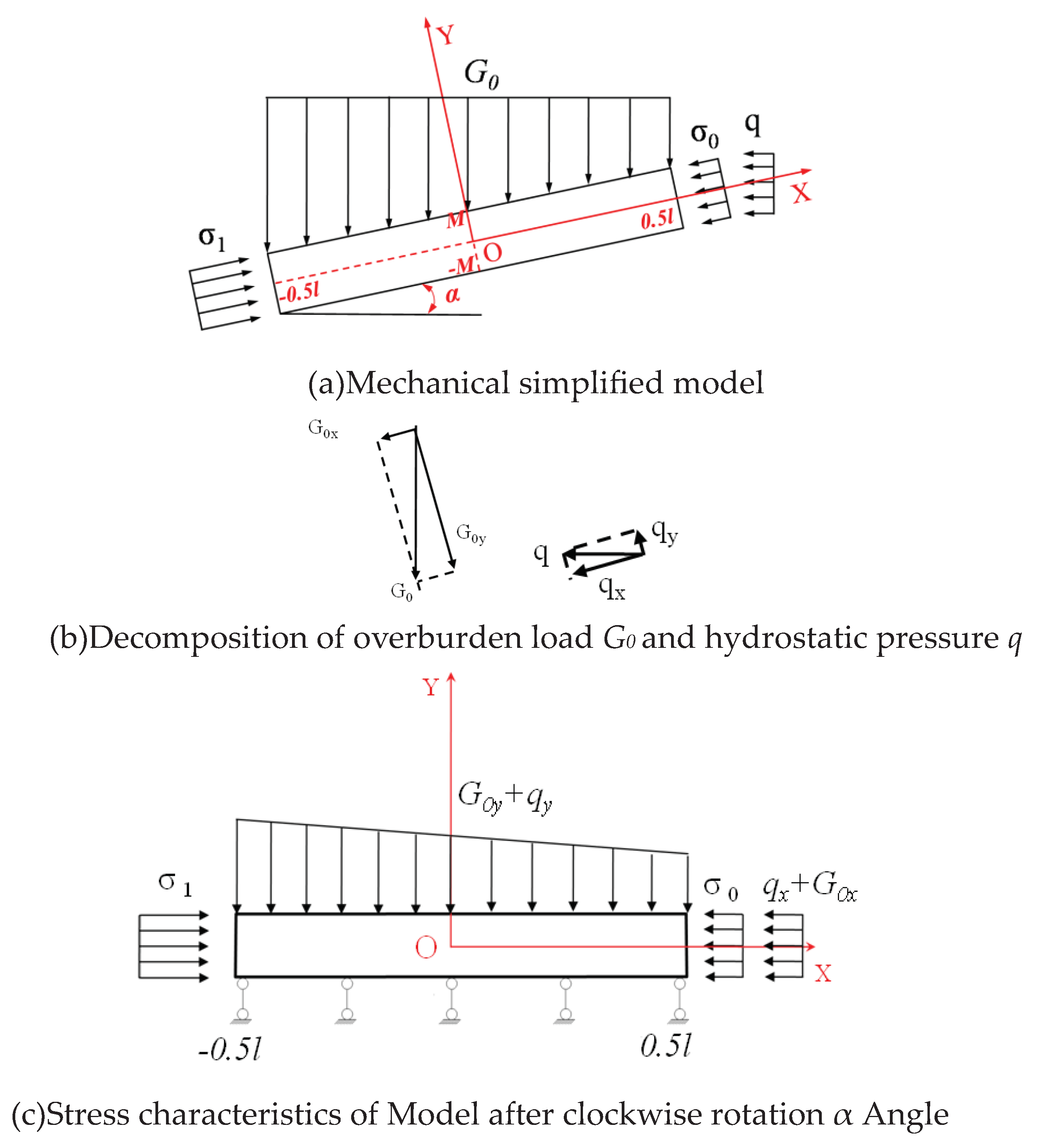

2.1. Force Analysis of Inclined Waterproof Coal Pillar

2.2. Determination of the Critical Length of the Elastic Barrier Zone

2.3. Calculation of the Critical Length of the Elastic Barrier

- (1)

- The numerator of equation (22), K1γHsinα+|q|cosα+|σ0|, is exactly the main stress σx applied to both sides of the boundary of the elastic barrier zone of the coal pillar, and the denominator, |q|sinα-K1γHcosα, is the main stress σy applied to the upper boundary of the elastic zone of the coal pillar, while the rest are the mechanical parameters of the coal pillar and its dip angle. It can be seen that the critical length of the central barrier zone is closely related to the principal stress σx in the inclination of the elastic zone of the coal pillar, the principal stress σy in the vertical direction and the inclination angle of the coal seam.

- (2)

- By analysing equations (19)-(21) and comparing them with equation (23), we can see that when the dip angle of the seam is 0°, the forces at the bottom angle of the pillar are equal and maximum, and damage can occur at any position at the bottom of the pillar. When the inclination angle α is not 0°, the internal stresses in the pillar are greater at the corners, but the stresses at the lowest horizontal part of the pillar (e.g., the lower left corner of the pillar in Figure 2a) are the greatest, and σx, σy and τxy are the maximum values at this time. Therefore, when the load on the inclined coal pillar exceeds its limit, the lowest horizontal bottom angle of the pillar should be the most vulnerable to damage.

- (3)

- In the range of inclination angle α ∈ [0°, 90°], as the inclination angle increases, the load given to the coal pillar by the residual support pressure G0 along the inclination of the seam gradually increases, while the load perpendicular to the coal pillar gradually decreases, i.e., σx is proportional to the inclination angle α, and σy is inversely proportional to the inclination angle α. Combined with equation (23), we can obtain that the critical size of the elastic barrier zone of the water barrier coal pillar presents a characteristic proportional to the inclination angle of the coal seam.

- (4)

- The destructive effect of water on the coal pillar is mainly reflected in two aspects. On the one hand is the pressure effect on the coal pillar, as can be seen from equations (23) -(25), with the increase of water pressure q, mainly reflected in the influence of the main stress σx on the tendency of the coal pillar, and the greater the water pressure, the greater the critical length. The other side is that the physical and mechanical properties of the coal rock body under water immersion will be significantly reduced, which will also affect the determination of the critical length of the elastic barrier zone of the water barrier coal pillar.

2.4. Determination of the Critical Size of MDZ and WAZ

3. Application of Critical Size Calculation for Water Barrier Coal Pillars

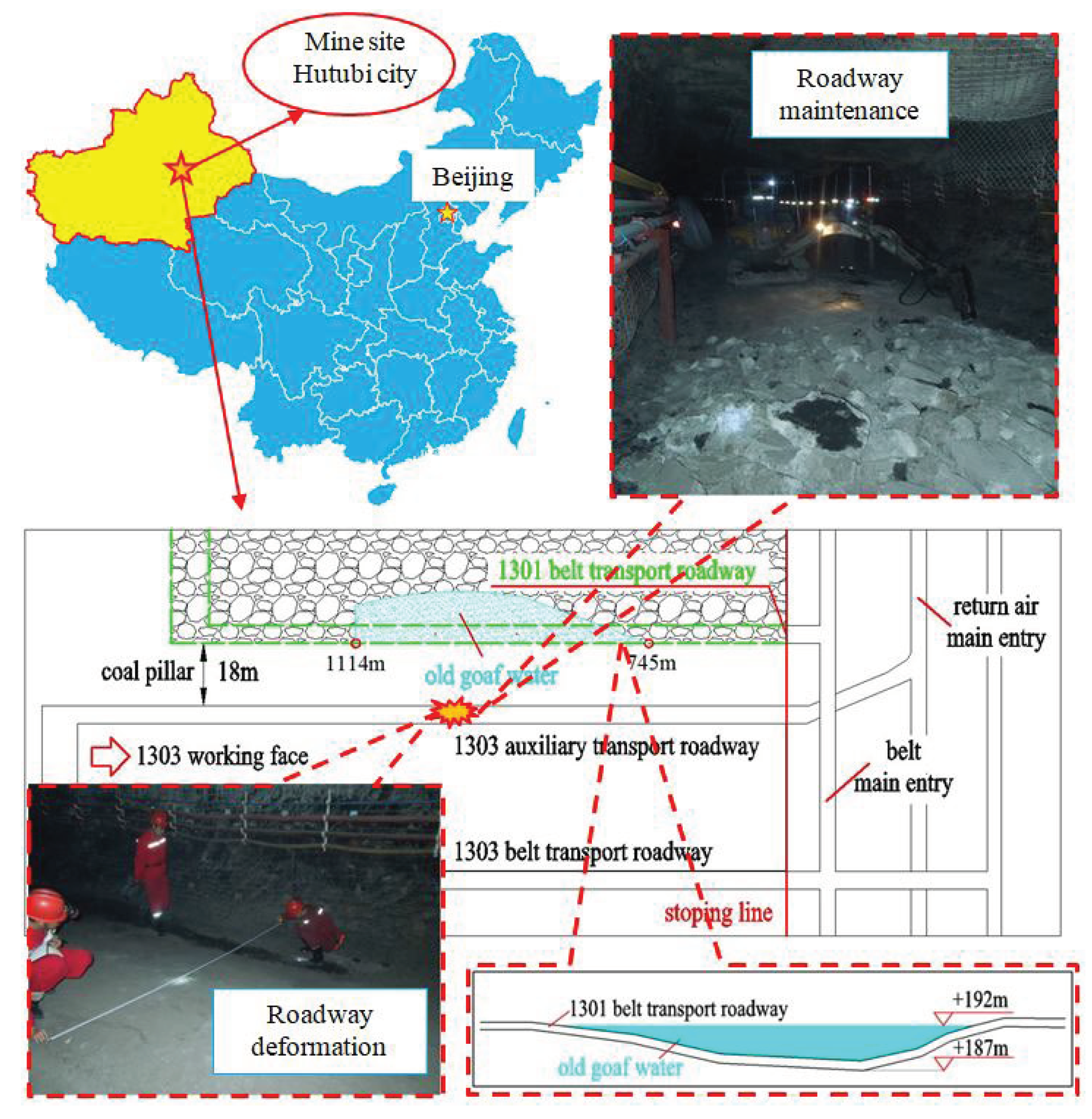

3.1. Project Overview of the Study Area

3.2. Calculation of the Critical Size of the Waterproof Coal Pillar in the Study Area

4. Elastic-Plastic Evolution of the Waterproof Coal Pillar in the Study Area

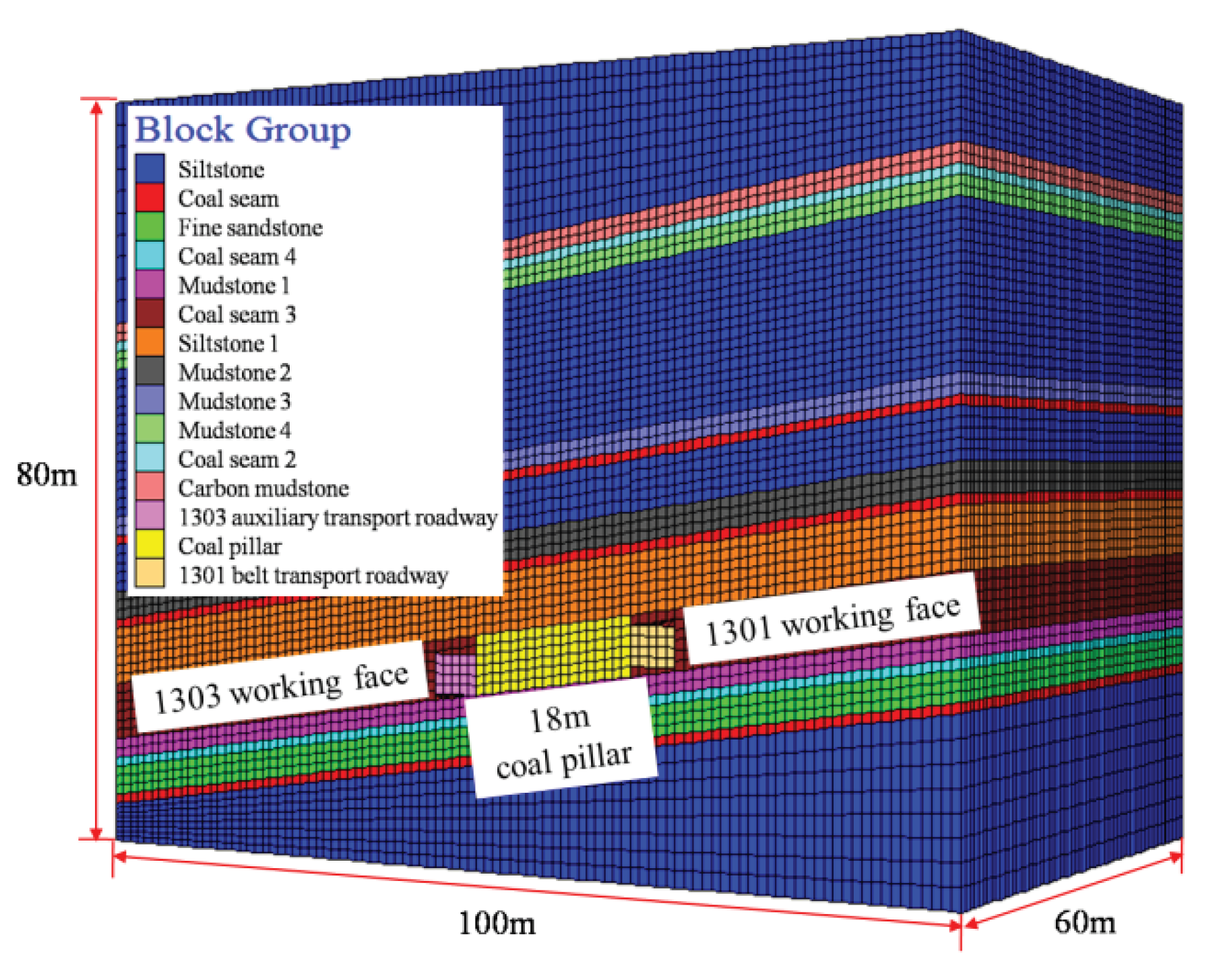

4.1. Numerical Modeling of the Study Area

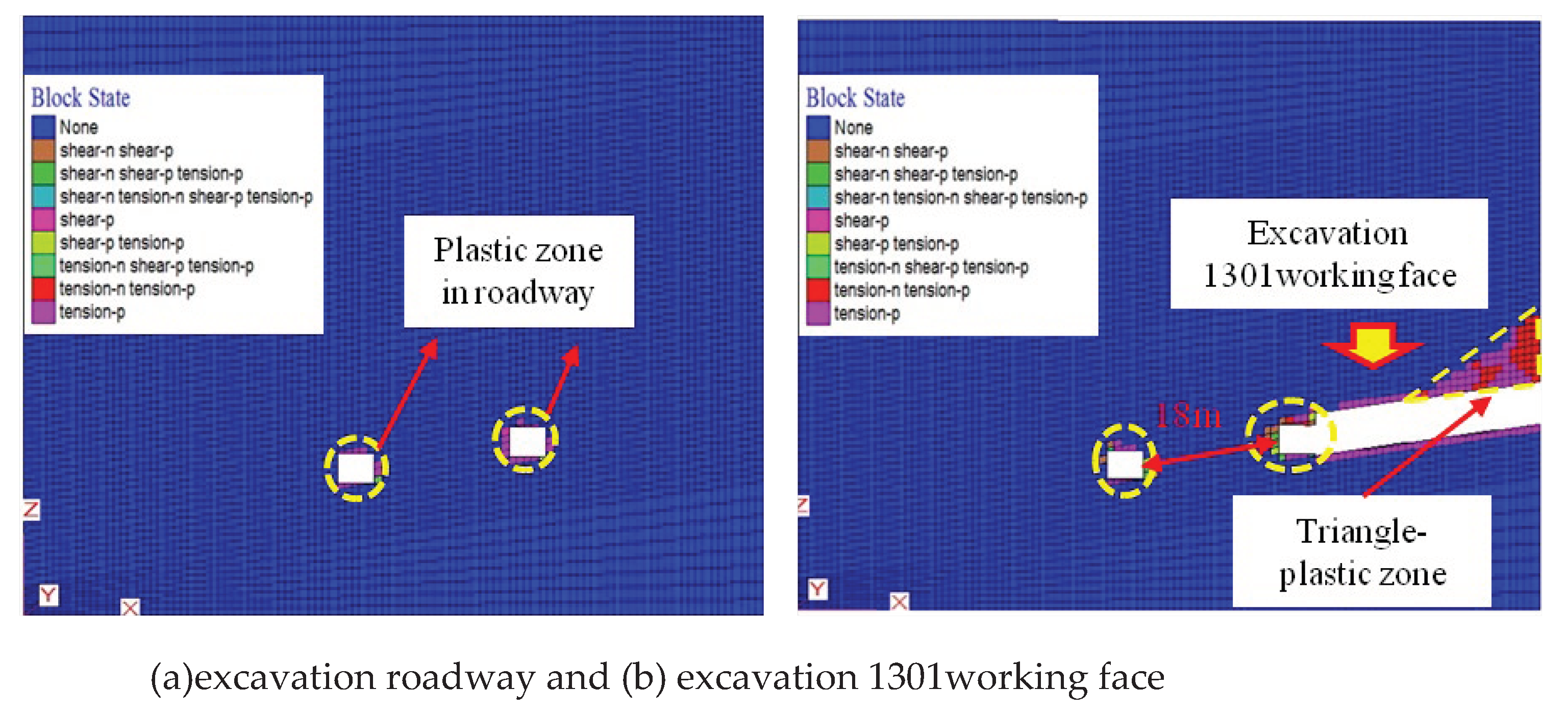

4.2. Fracture Evolution and Plastic Zone Formation Process in the Coal Pillar

5. Engineering Practice

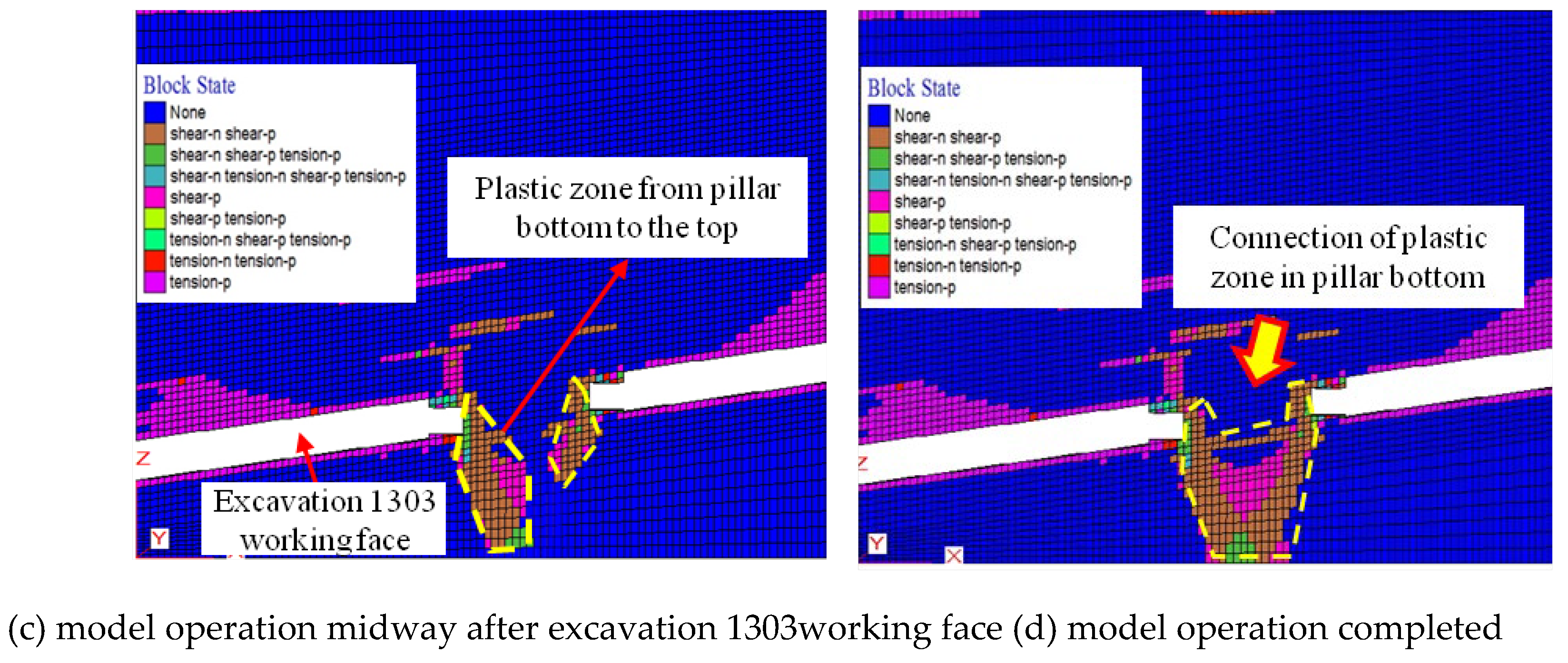

5.1. Pumping and Pressure Relief

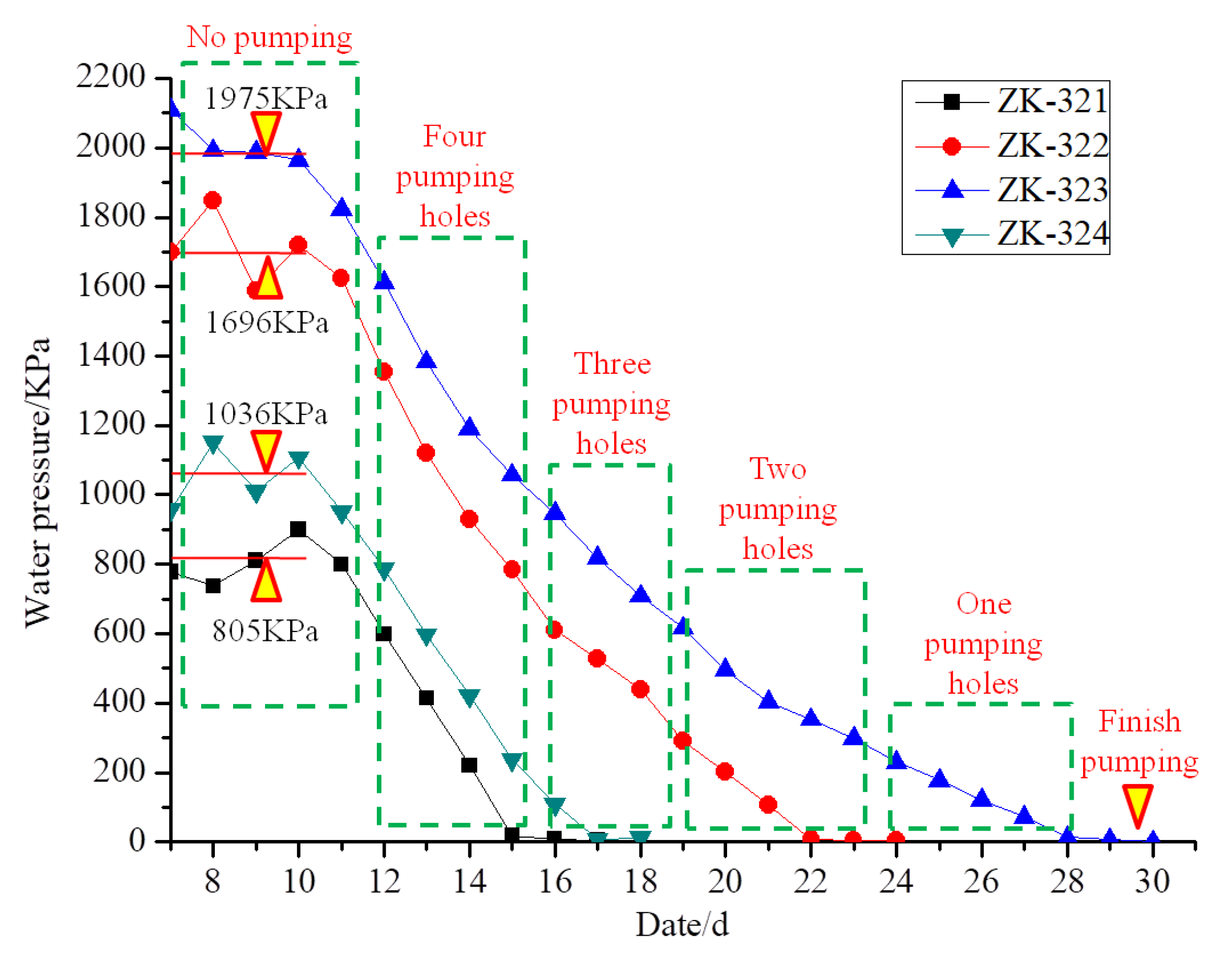

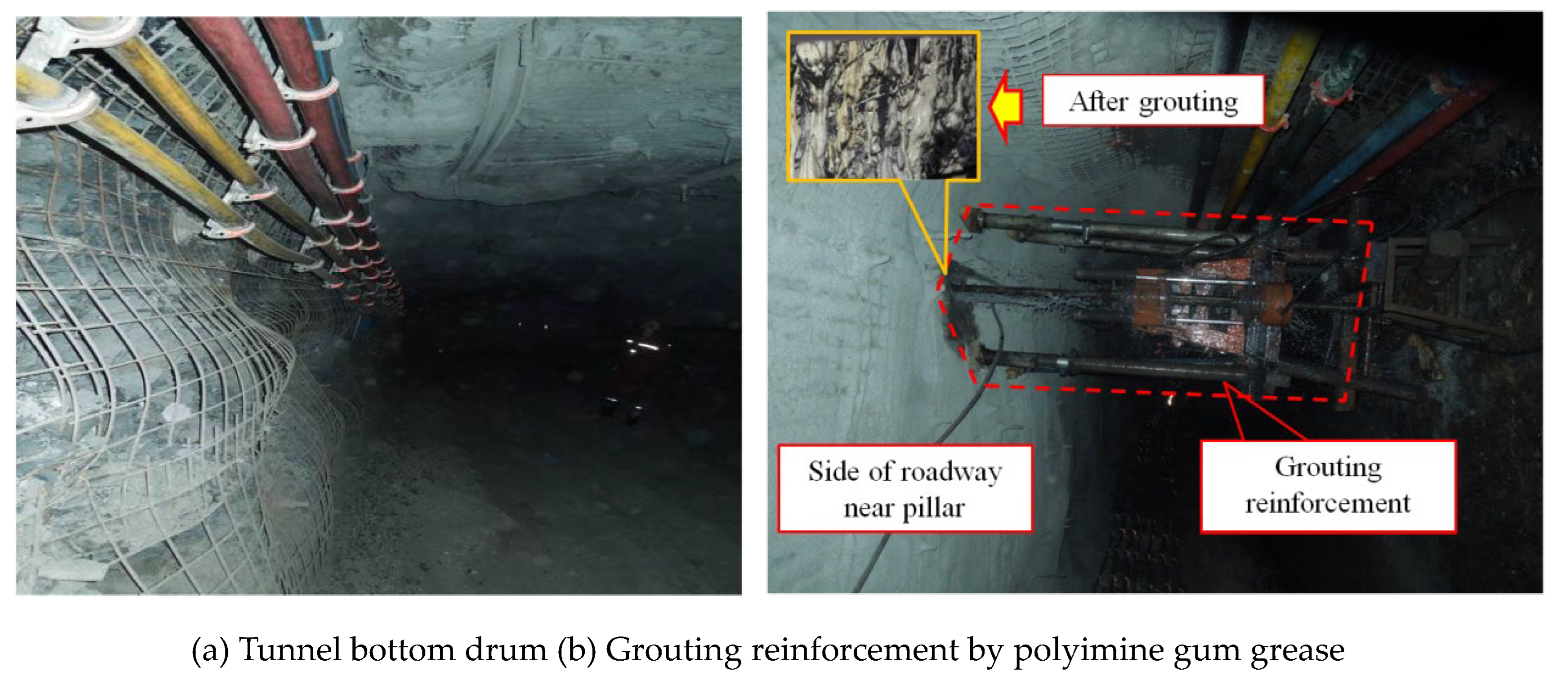

5.2. Grouting Reinforcement

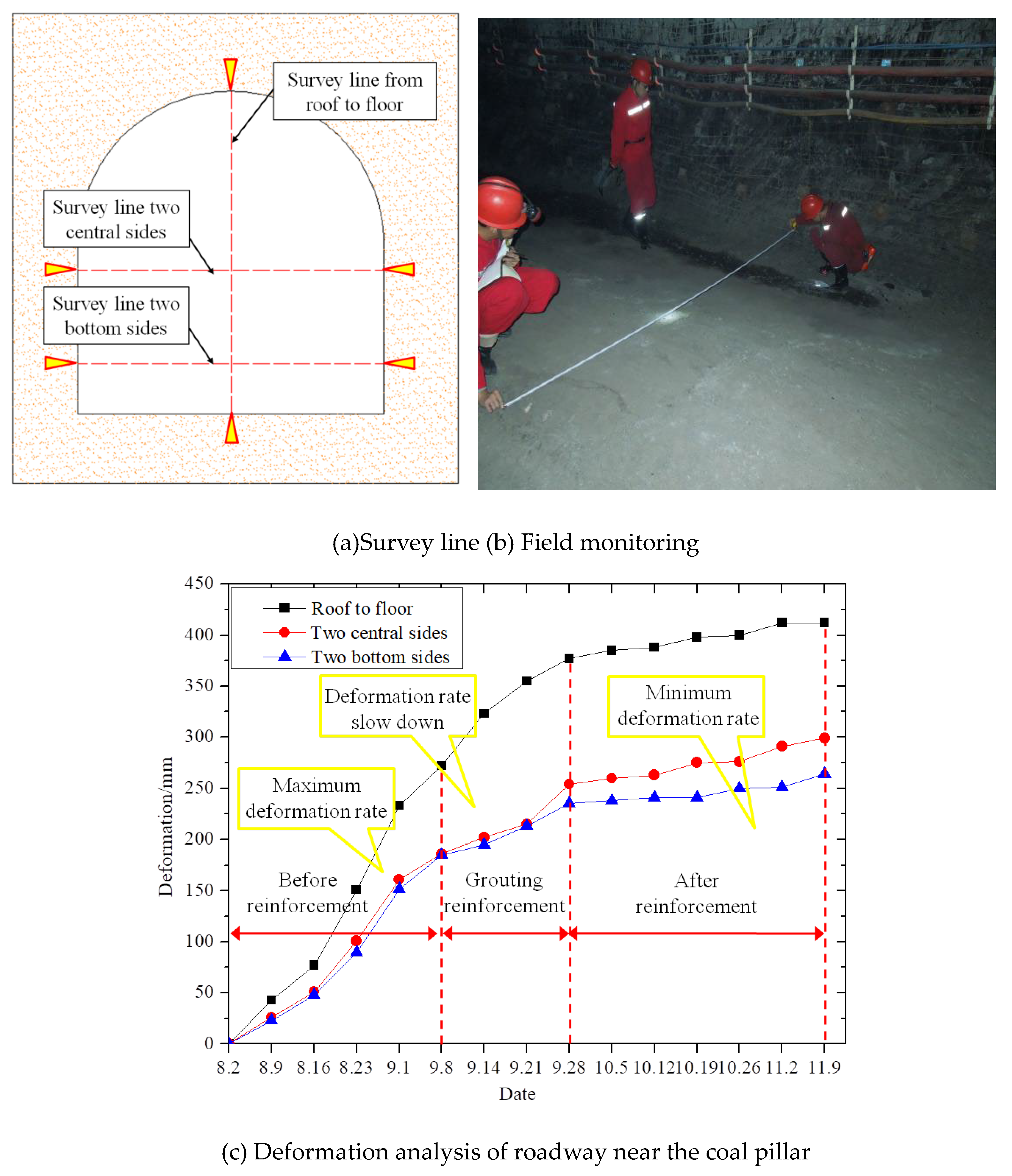

5.3. Effectiveness Test

6. Conclusions

Funding

Author contributions

Ethics Approval

Consent to publish

Data availability statement

Acknowledgment

Conflict of interest

References

- Dong, S.N. Some key scientific problems on water hazards frequently happened in China’s coal mines. Journal of China Coal Society 2010, 35, 66–71. [Google Scholar]

- Xie, H.P. Research review of the state key research development program of China: Deep rock mechanics and mining theory. Journal of China Coal Society 2019, 44, 1283–1305. [Google Scholar]

- Li, A.; Ma, Q.; Lian, Y.; Ma, L.; Mu, Q.; Chen, J. Numerical simulation and experimental study on floor failure mechanism of typical working face in thick coal seam in Chenghe mining area of Weibei, China. Environ. Earth Sci. 2020, 79, 1–22. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Ma, J. Quantitative Investigation of Tomographic Effects in Abnormal Regions of Complex Structures. Engineering 2020, 7, 1011–1022. [Google Scholar] [CrossRef]

- Liu, R.; He, Y.; Zhao, Y.; Jiang, X.; Ren, S. Statistical Analysis of Acoustic Emission in Uniaxial Compression of Tectonic and Non-Tectonic Coal. Appl. Sci. 2020, 10, 3555. [Google Scholar] [CrossRef]

- Michieka, N.M. Energy and the Environment: The Relationship Between Coal Production and the Environment in China. Nat. Resour. Res. 2013, 23, 285–298. [Google Scholar] [CrossRef]

- Sun, J.P.; Qian, X.H. Analysis of coal mine accidents in China during 2004-2015. Industry and Mine Automation 2016, 42, 1–5. [Google Scholar]

- Xue, Y.; Ranjith, P.G.; Dang, F.; Liu, J.; Wang, S.; Xia, T.; Gao, Y. Analysis of Deformation, Permeability and Energy Evolution Characteristics of Coal Mass Around Borehole After Excavation. Nat. Resour. Res. 2020, 29, 3159–3177. [Google Scholar] [CrossRef]

- Dong, L.; Hu, Q.; Tong, X.; Liu, Y. Velocity-Free MS/AE Source Location Method for Three-Dimensional Hole-Containing Structures. Engineering 2020, 6, 827–834. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Y.; Sun, D.; Zhang, Y. Implications for rock instability precursors and principal stress direction from rock acoustic experiments. Int. J. Min. Sci. Technol. 2021, 31, 789–798. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Hu, Q.; Tao, Q. Empty region identification method and experimental verification for the two-dimensional complex structure. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2021, 147, 104885. [Google Scholar] [CrossRef]

- Shang, H.F.; Ning, J.G.; Hu, S.C. Field and numerical investigations of gate road system failure under an irregular residual coal pillar in close-distance coal seams. Energy Science Engineering 2019, 7, 2720–2740. [Google Scholar] [CrossRef]

- Shi, W.G.; Zhang, J.F.; Zhang, H.M. , et al. Structural Division and Determination of Rational Width for Waterproof Partition Coal Pillar. Chinese Journal of Rock Mechanics and Engineering 2017, 36, 1227–1237. [Google Scholar]

- Cai, M.F. Key theories and technologies for surrounding rock stability and ground control in deep mining. Journal of Mining and Strata Control Engineering 2020, 02, 5–13. [Google Scholar]

- Rezaei, M.; Hossaini, M.F.; Majdi, A. A time-independent energy model to determine the height of destressed zone above the mined panel in longwall coal mining. Tunn. Undergr. Space Technol. 2015, 47, 81–92. [Google Scholar] [CrossRef]

- Shi, L.; Wang, Y.; Qiu, M.; Han, L.; Zhao, Y. Research on the required width of a fault waterproof coal pillar based on underground pressure control theory. Arab. J. Geosci. 2019, 12, 1–14. [Google Scholar] [CrossRef]

- Mu, H.W.; Bao, Y.S.; Song, D.Z. , et al. Investigation of strong strata behaviors in the close-distance multi-seam coal pillar mining. Shock and Vibration 2021, 42, 1–14. [Google Scholar]

- Xia, B.; Jia, J.; Yu, B.; Zhang, X.; Li, X. Coupling effects of coal pillars of thick coal seams in large-space stopes and hard stratum on mine pressure. Int. J. Min. Sci. Technol. 2017, 27, 965–972. [Google Scholar] [CrossRef]

- Bukowski, P. Water hazard assessment in active shafs in upper Silesian coal basin mines. Mine Water Environ 2011, 30, 302–311. [Google Scholar] [CrossRef]

- Wang, R.; Bai, J.-B.; Yan, S.; Chang, Z.-G.; Wang, X.-Y. An innovative approach to theoretical analysis of partitioned width & stability of strip pillar in strip mining. Int. J. Rock Mech. Min. Sci. 2020, 129, 104301. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, G.; Wang, X. , et al. Assessing the rock burst risk for deep shafts via distance-based multi-criteria decision making approaches with hesitant fuzzy information. Eng. Geol. 2019, 260, 105211. [Google Scholar]

- Wang, S.; Li, X.; Wang, D. Mining-induced void distribution and application in the hydro-thermal investigation and control of an underground coal fire: A case study. Process. Saf. Environ. Prot. 2016, 102, 734–756. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Z.; Chen, D.; Wang, C.; Zhang, F.; Du, Z. Study on Reasonable Roadway Position of Working Face under Strip Coal Pillar in Rock Burst Mine. Shock. Vib. 2020, 2020, 1–21. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, G.; Wang, S.; Wu, H.; Wang, S. A case study on the height of a water-flow fracture zone above undersea mining: Sanshandao Gold Mine, China. Environ. Earth Sci. 2019, 78, 122. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G. Limitations and potential design risks when applying empirically derived coal pillar strength equations to real-life mine stability problems. Int. J. Min. Sci. Technol. 2018, 29, 17–25. [Google Scholar] [CrossRef]

- Bo, L.; Chen, Y.L. Risk Assessment of Coal Floor Water Inrush from Underlying Aquifers Based on GRA–AHP and Its Application. Eng. Geol. 2016, 34, 143–154. [Google Scholar]

- Tan, Y.L.; Yu, F.H.; Chen, L. A new approach for predicting bedding separation of roof strata in underground coal mines. International Journal of Rock Mechanics and Mining Sciences 2013, 61, 183–188. [Google Scholar] [CrossRef]

- Wang, R.; Yan, S.; Bai, J. , et al. Theoretical analysis of damaged width & instability mechanism of rib pillar in open-pit high wall mining. Advances in Civil Engineering 2019, 2019, 6328702. [Google Scholar]

- Yu, W.; Wang, W.; Wu, G.; Yu, X.; Peng, W. Three Zones and Support Technique for Large Section Incline Shaft Crossing Goaf. Geotech. Geol. Eng. 2017, 35, 1921–1931. [Google Scholar] [CrossRef]

- Yu, W.; Wang, W.; Wu, G.; Yu, X.; Peng, W. Three Zones and Support Technique for Large Section Incline Shaft Crossing Goaf. Geotech. Geol. Eng. 2017, 35, 1921–1931. [Google Scholar] [CrossRef]

- Liu, R.; Ren, S.; Fan, J.; Wu, F.; William, N.T. The air-flow structure and gas dispersion behavior in gas tunnel construction through bench cut method. Therm. Sci. 2019, 23, 1417–1424. [Google Scholar] [CrossRef]

- Wang, G.; Wu, M.; Wang, R.; Xu, H.; Song, X. Height of the mining-induced fractured zone above a coal face. Eng. Geol. 2017, 216, 140–152. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, S.; Guo, W.; Liu, W. Physical Simulation of High-Pressure Water Inrush Through the Floor of a Deep Mine. Mine Water Environ. 2017, 36, 542–549. [Google Scholar] [CrossRef]

- Wang, S.; Huang, L.; Li, X. Analysis of rock burst triggered by hard rock fragmentation using a conical pick under high uniaxial stress. Tunn. Undergr. Space Technol 2020, 96, 103195. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, W.; Li, Y.; Sun, W.; Yin, D. Experimental Simulation of Fault Water Inrush Channel Evolution in a Coal Mine Floor. Mine Water Environ. 2017, 36, 443–451. [Google Scholar] [CrossRef]

- Yu, Y.; Deng, K.-Z.; Luo, Y.; Chen, S.-E.; Zhuang, H.-F. An improved method for long-term stability evaluation of strip mining and pillar design. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2018, 107, 25–30. [Google Scholar] [CrossRef]

- Liu, R. ; H. Yi; Zhao, Y.F., et al. Tunnel Construction Ventilation Frequency-control Based on Radial Basis Function Neural Network. Automation in Construction 2020, 118, 103293. [Google Scholar]

- Xie, X. ; X. B. L; Shang, X., et al. Prediction of height of water flowing fractured zone based on PCA-BP neural networks model. China Saf. Sci. J. 2017, 27, 100–105. [Google Scholar]

- Liu, B.; He, L.; Luo, L.P. Numerical Modeling on Fluid-Solid Coupling for the Water Proof Coal Pillar Design. Journal of Mining & Safety Engineering 2009, 26, 445–449. [Google Scholar]

- Russell, F.; Guy, R. Coal pillar design when considered a reinforcement problem rather than a suspension problem. Min Sci Technol. 2018, 28, 11–19. [Google Scholar]

- Liang, W.; Zhao, G.; Wu, H.; Chen, Y. Assessing the risk degree of goafs by employing hybrid TODIM method under uncertainty. Bull. Eng. Geol. Environ. 2018, 78, 3767–3782. [Google Scholar] [CrossRef]

- Meng, X.; Liu, W.; Mu, D. Influence Analysis of Mining’s Effect on Failure Characteristics of a Coal Seam Floor with Faults: A Numerical Simulation Case Study in the Zhaolou Coal Mine. Mine Water Environ. 2018, 37, 754–762. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Chen, C.F.; Wang, L. , et al. Research on Reasonable Size of Waterproof Pillar in Mining Inclined Coal Seam. Journal of Mining & Safety Engineering, 2013, 30, 735–738. [Google Scholar]

- Xie, H.P. Research review of the state key research development program of China: Deep rock mechanics and mining theory. Journal of China Coal Society 2019, 44, 1283–1305. [Google Scholar]

- Meng, Z.; Shi, X.; Li, G. Deformation, failure and permeability of coal-bearing strata during longwall mining. Eng. Geol. 2016, 208, 69–80. [Google Scholar] [CrossRef]

- Dong, S.N. Some key scientific problems on water hazards frequently happened in China’s coal mines. Journal of China Coal Society 2010, 35, 66–71. [Google Scholar]

- Xie, H.P. Research review of the state key research development program of China: Deep rock mechanics and mining theory. Journal of China Coal Society 2019, 44, 1283–1305. [Google Scholar]

| Elastic zone stress concentration factor K1 |

Plastic zone tress concentration factor K |

Dip angle of coal seam (°) |

Coal seam thickness (m) |

Rock volume force γ(KN/m3) |

Buried depth H(m) |

| 2 | 4 | 12 | 6.5 | 24.5 | 255.5 |

| Internal friction angle ϕ(°) |

Cohesion c(MPa) |

Poisson ratio υ0 |

Maximum hydrostatic pressure q(MPa) |

Strata movement angleδ (°) |

Friction factor f |

| 27.4 | 1.92 | 0.36 | 0.26 | 50 | 0.129 |

| layer | compressive strength (MPa) |

rock density (kg/m3) |

bulk modulus (GPa) |

shear modulus (GPa) |

internal friction angle ϕ(°) |

cohesion c (MPa) |

poisson ratio υ0 |

| Siltstone | 1.46 | 2360 | 7.8 | 2.8 | 29.9 | 5.35 | 0.29 |

| Fine sandstone | 1.33 | 2259 | 6.8 | 2.4 | 30 | 4.2 | 0.34 |

| Siltstone | 1.46 | 2360 | 7.8 | 2.8 | 29.9 | 5.35 | 0.29 |

| Coal seam | 0.48 | 1370 | 4.4 | 0.5 | 27.4 | 1.92 | 0.36 |

| Mudstone | 1.37 | 2397 | 6.07 | 1.37 | 29 | 3.07 | 0.28 |

| Carbon mudstone | 1.35 | 2400 | 6.8 | 1.9 | 28.6 | 4.07 | 0.28 |

| pumping holes | horizontal elevation | hole position near return air roadway | drilling parameters |

| ZK-321 | 201m | 818m | drilling depth is 19m, drilling diameter is 52mm |

| ZK-322 | 192m | 891m | |

| ZK-323 | 187m | 964m | |

| ZK-324 | 199m | 1037m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).