Submitted:

08 April 2024

Posted:

09 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

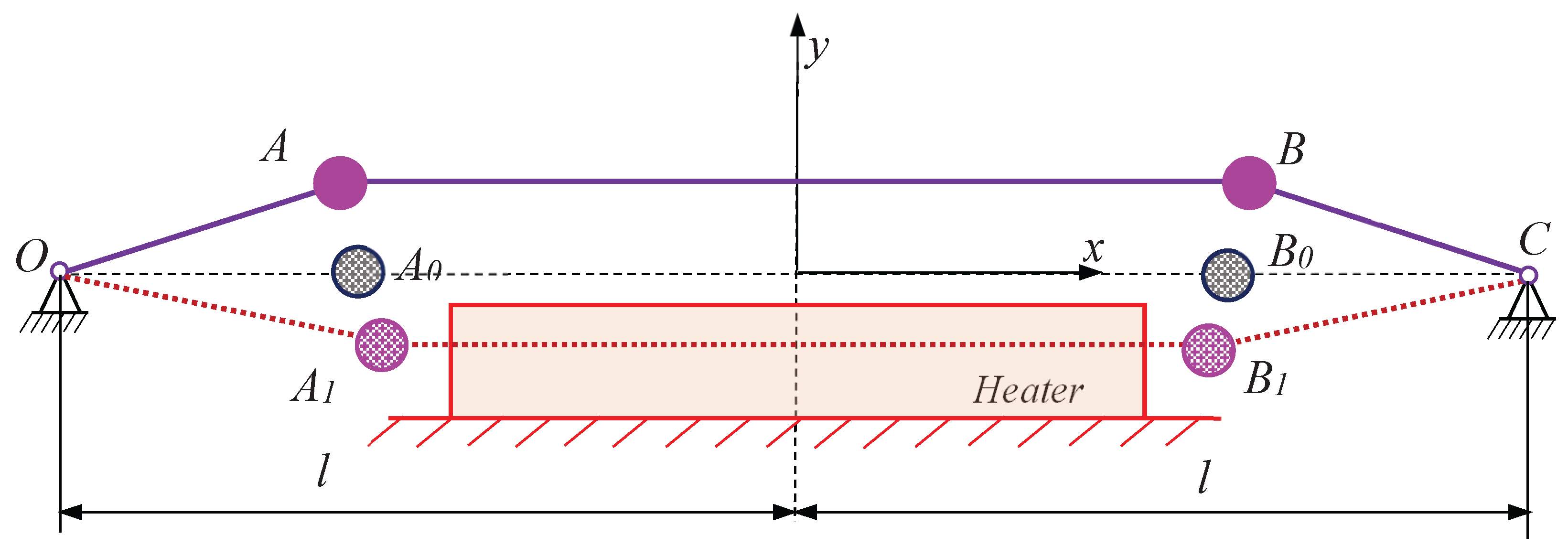

2. Design Concept of the Self-Excited Thermomechanical Oscillator

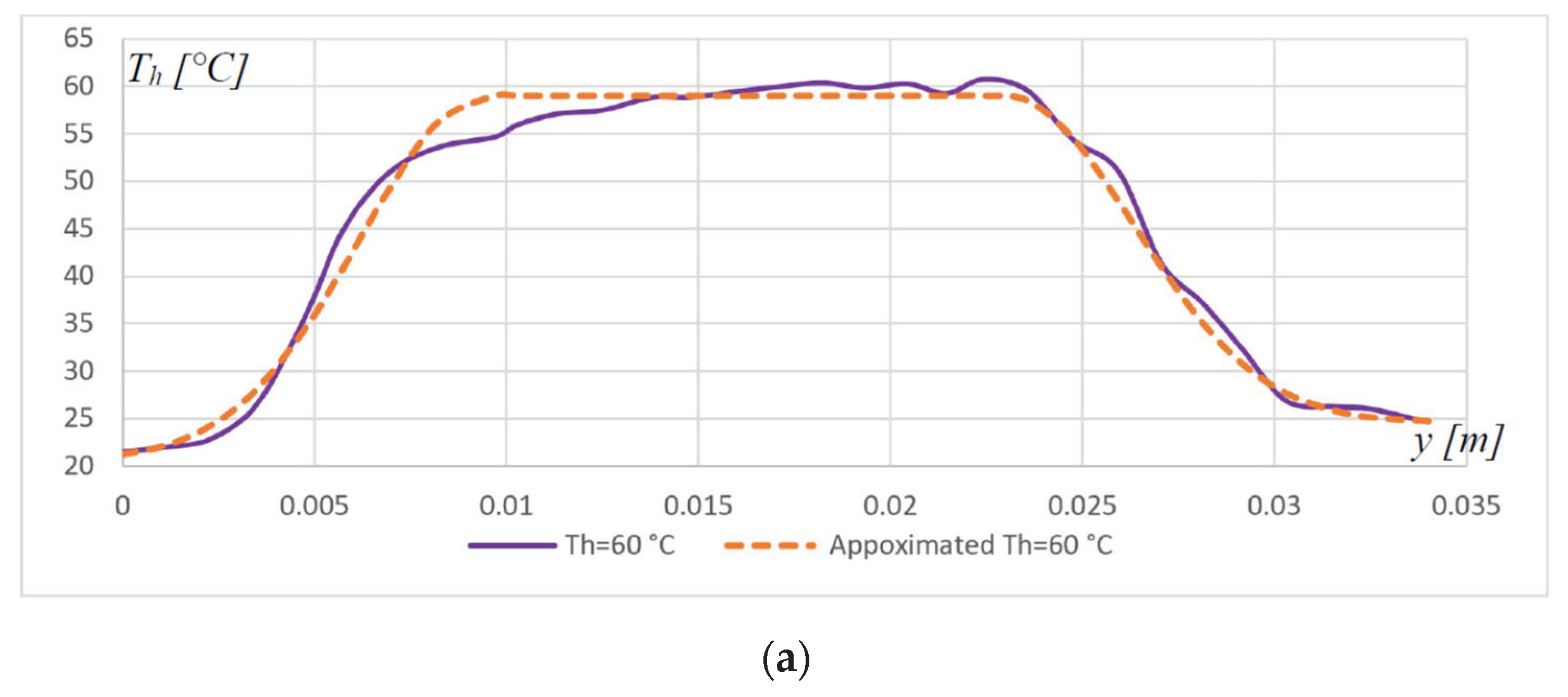

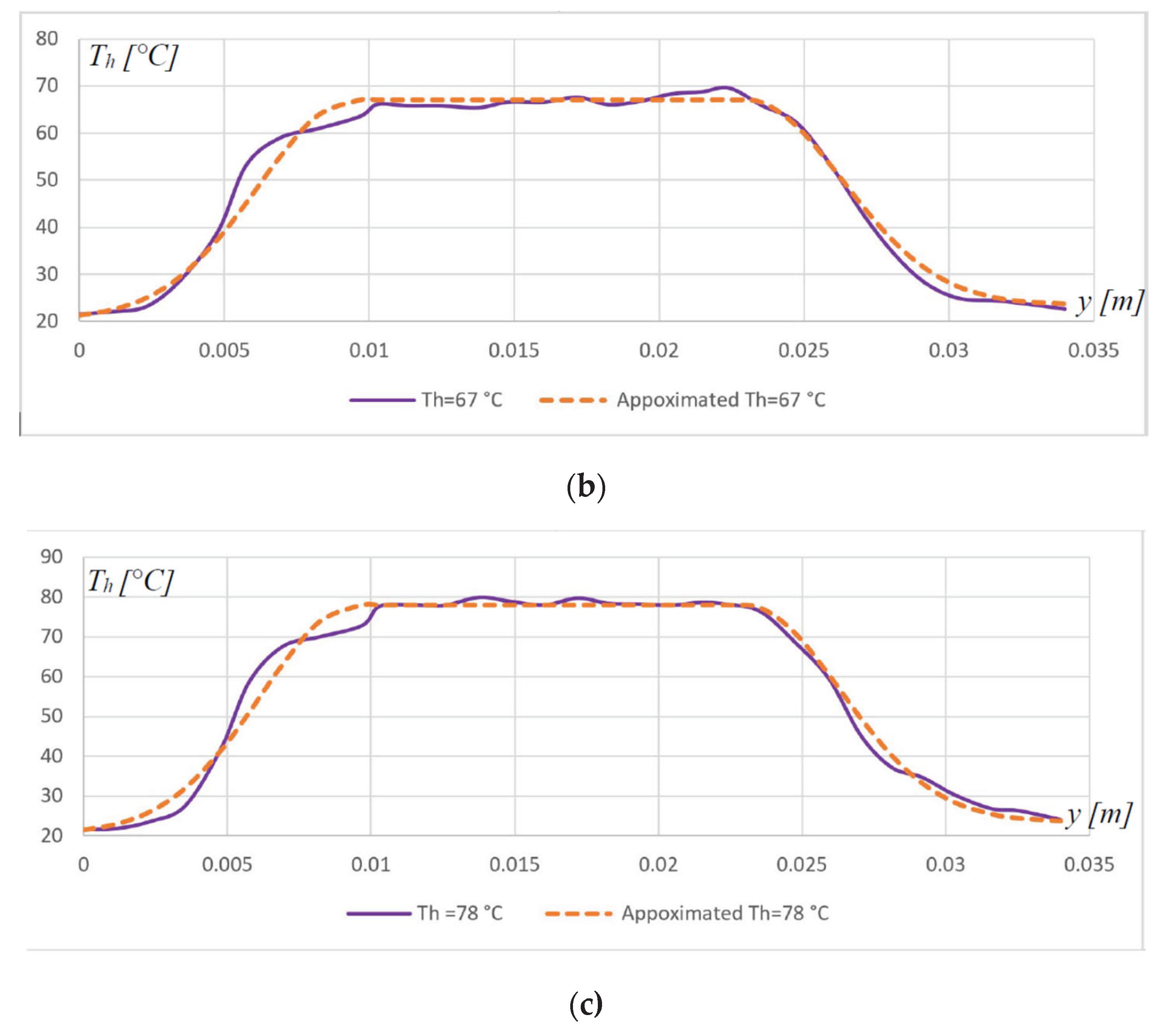

3. Building a Dynamic Model and Determining the Input Data for Its Solution

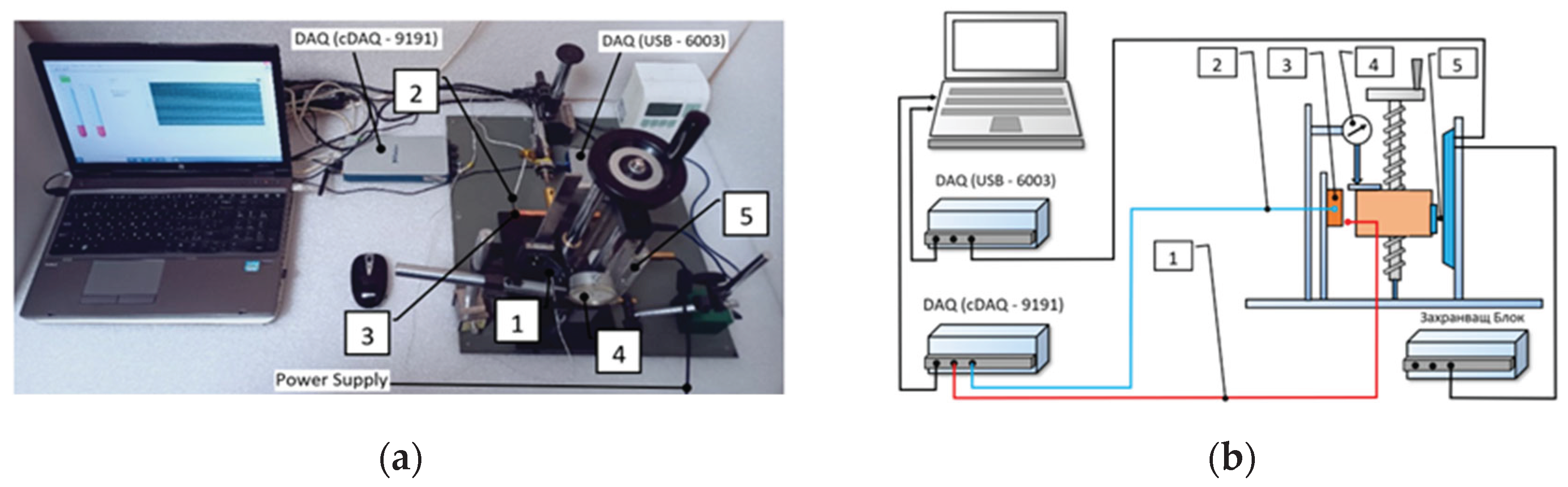

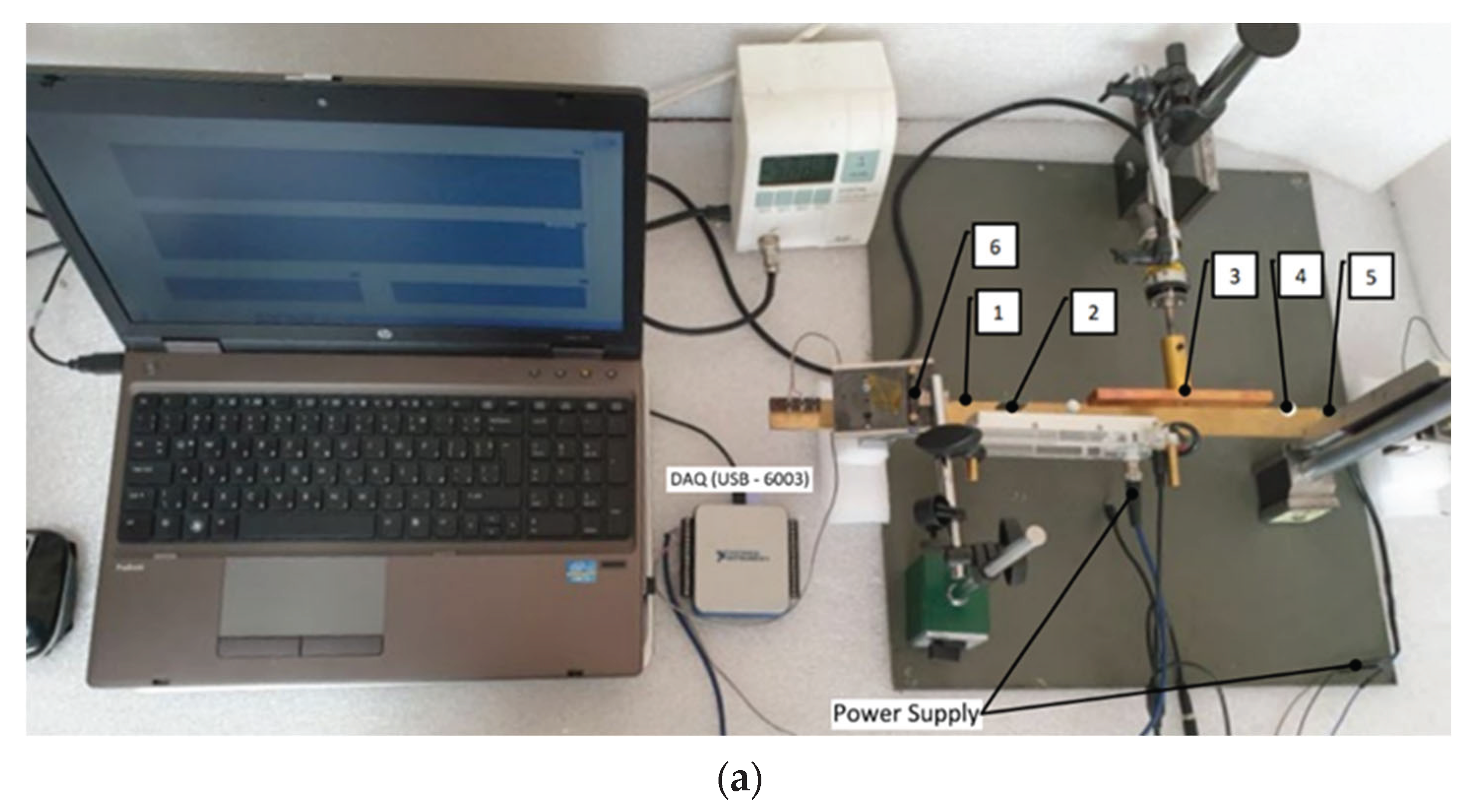

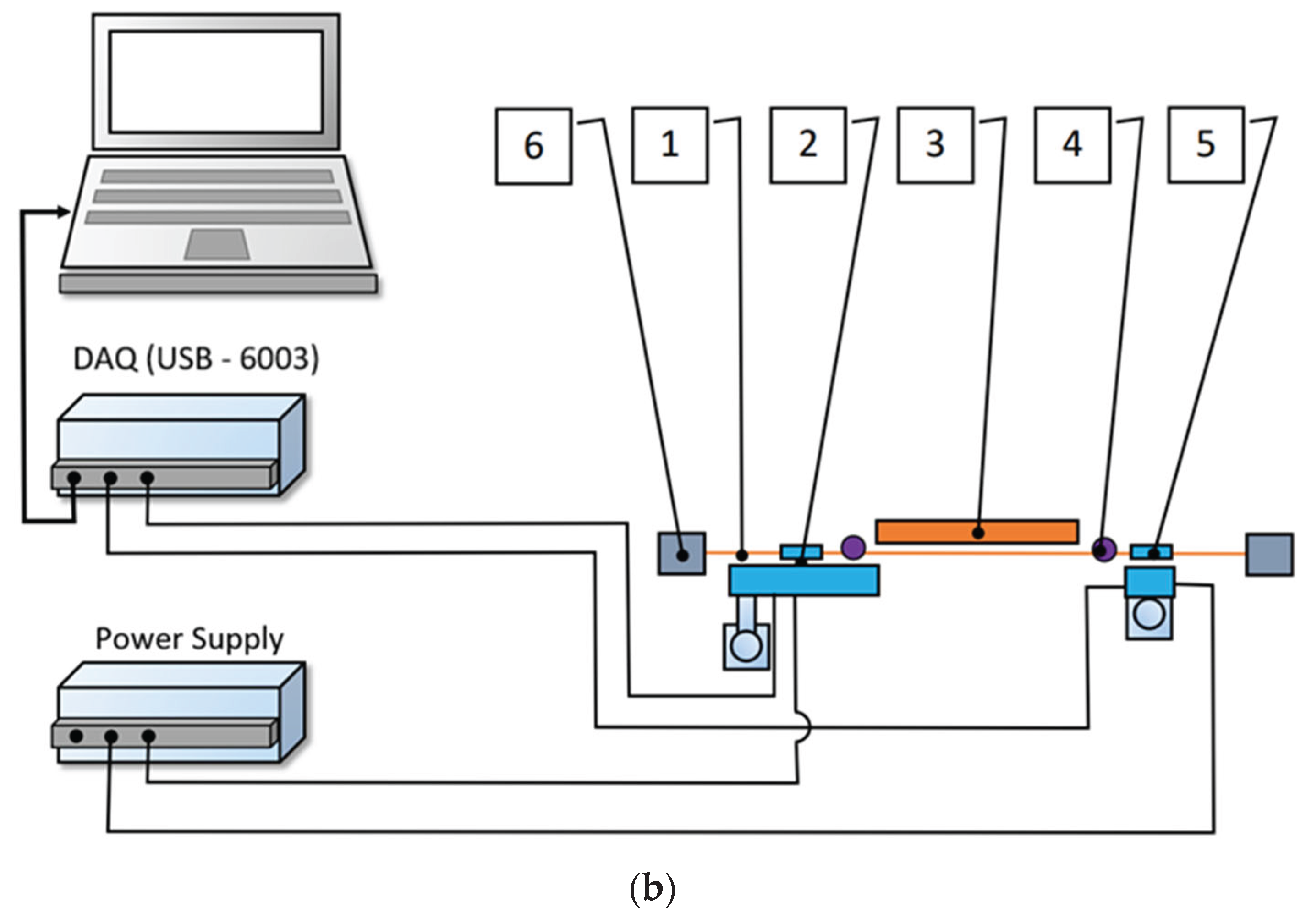

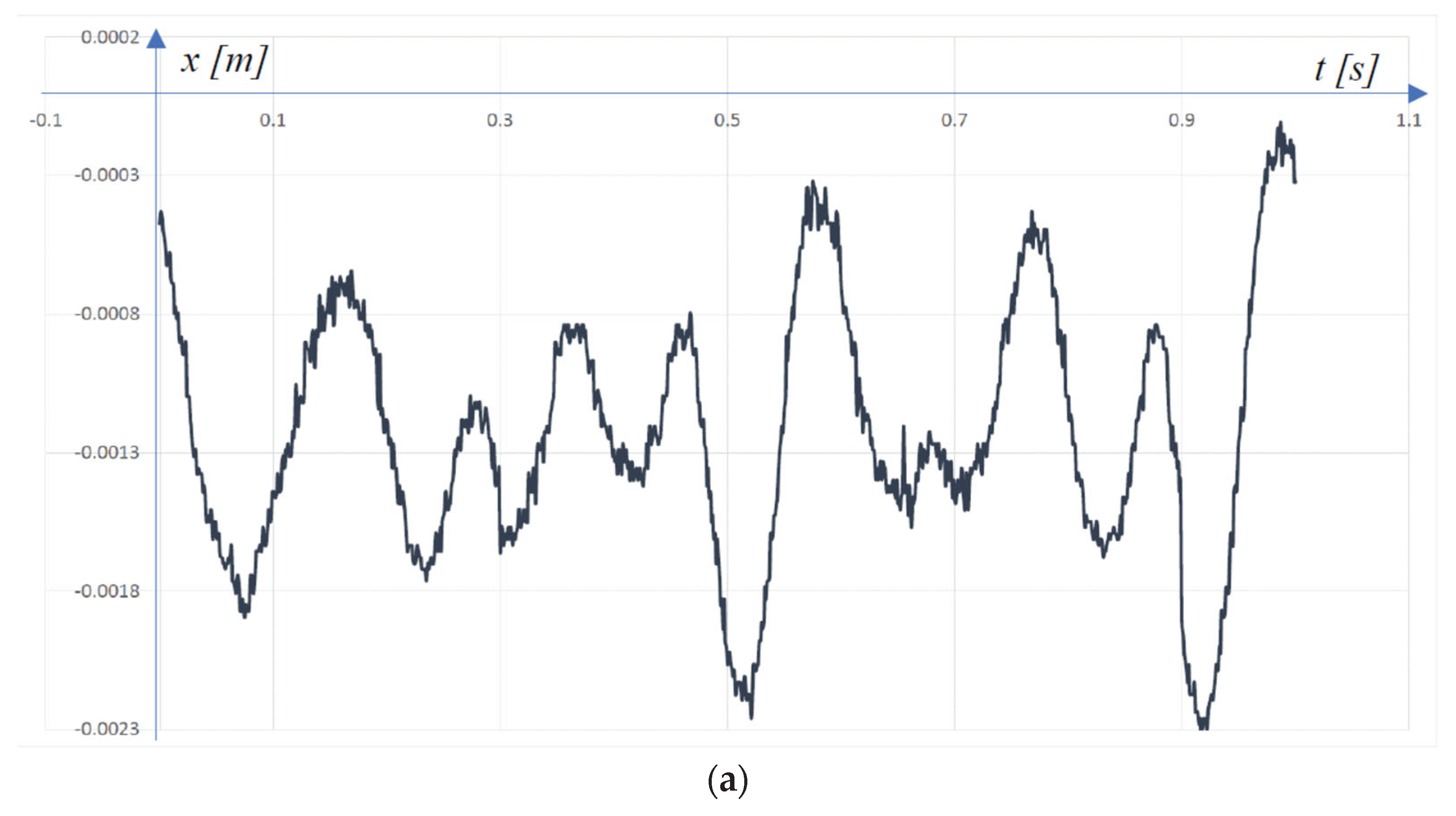

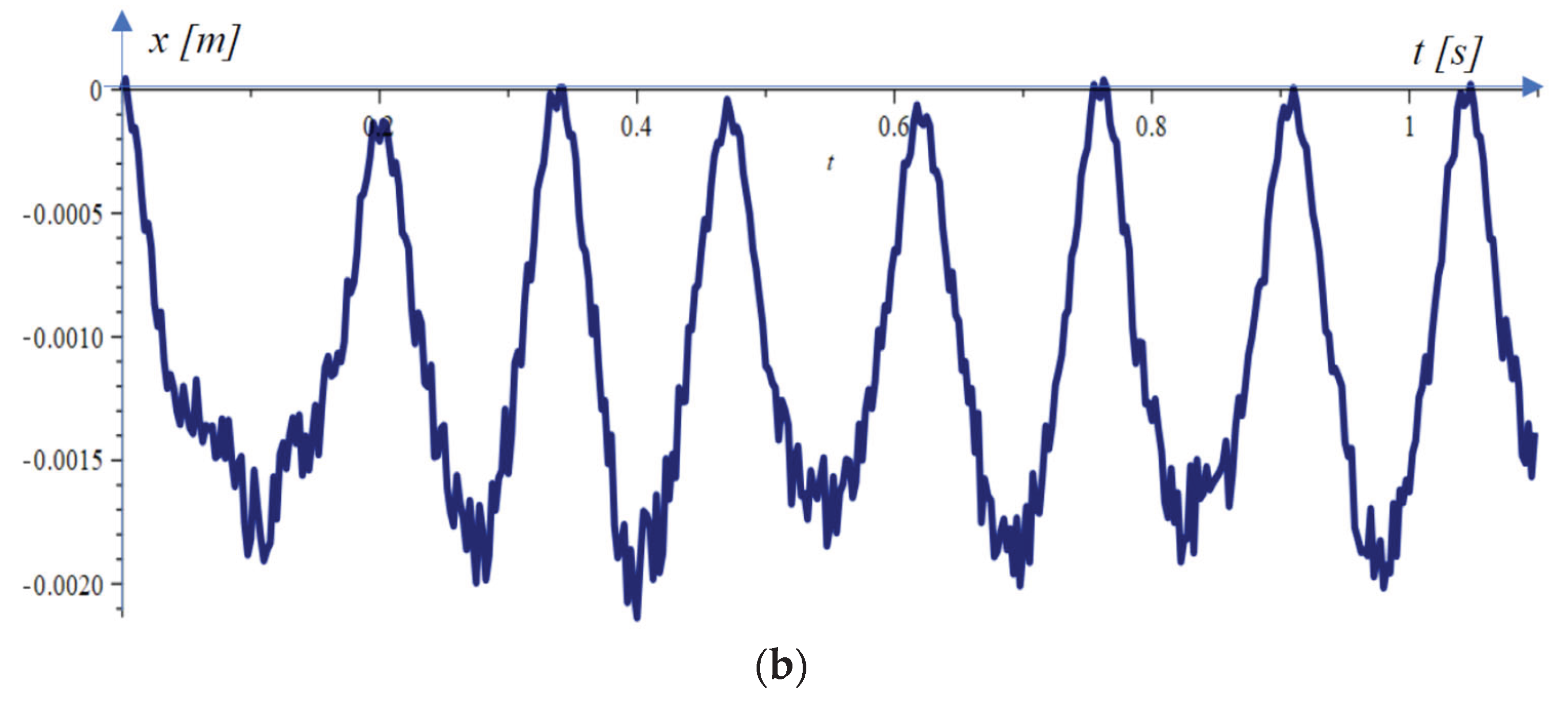

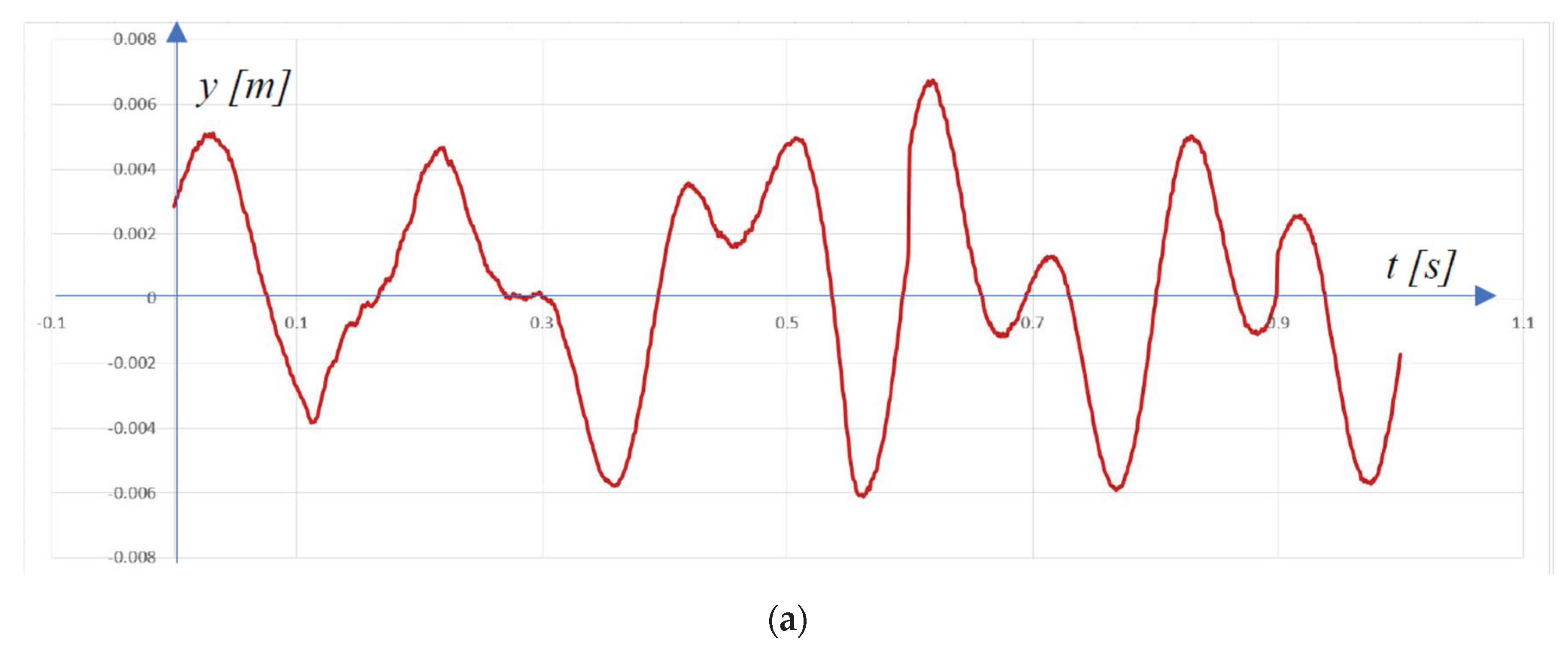

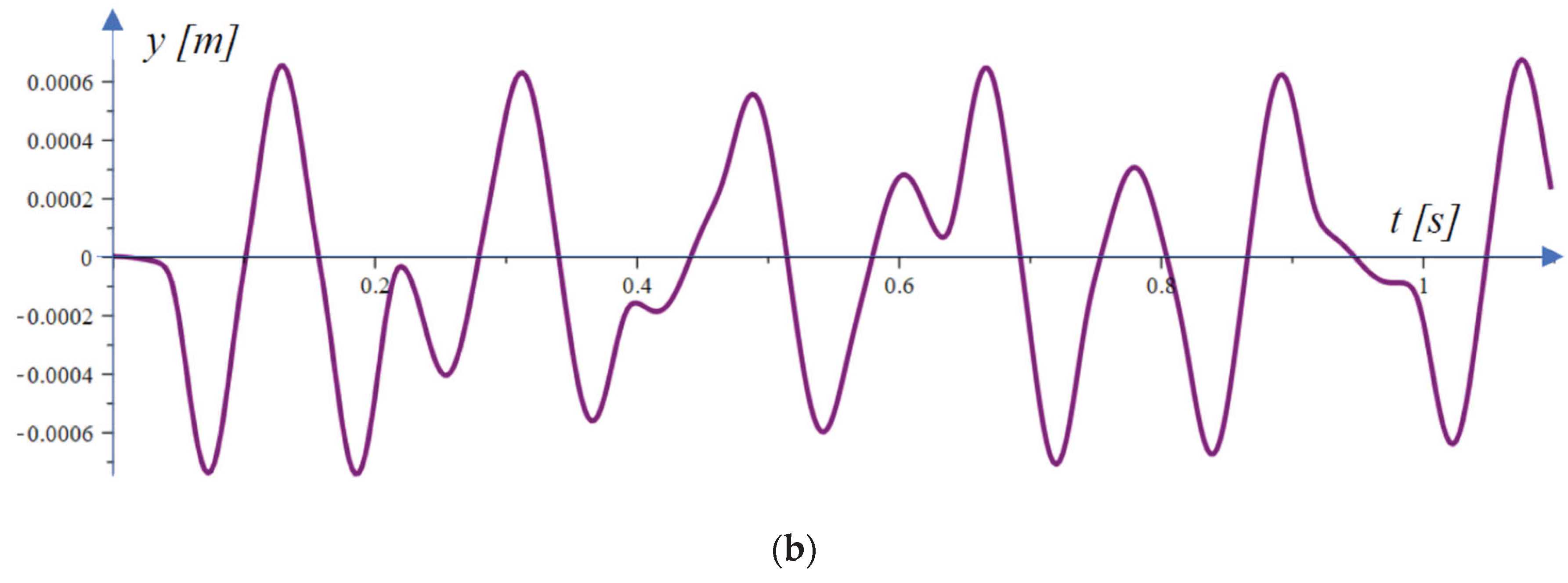

4. Conducting the Experiments and Comparing the Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kroger, M.; Neubaer, M.; Popp, K. Experimental investigation on the avoidance of self-excited vibrations. Philosophical Transactions of the Royal Society A 2008, 366, 785–810. [Google Scholar] [CrossRef] [PubMed]

- Ding, W. Modeling and Control. In Self-Excited Vibration; Springer: Berlin, Heidelberg, 2010. [Google Scholar]

- Papangelo, A.; Putignano, C.; Hoffmann, N. Self-excited vibrations due to viscoelastic interactions. Mechanical Systems and Signal Processing 2020, 144, 106894. [Google Scholar] [CrossRef]

- Nesis, E.I.; Nesis, S.E. Thermomechanical and thermoacoustic self-excited oscillations. Journal of Engineering Physics 1988, 55, 1178–1194. [Google Scholar] [CrossRef]

- Khvol’son, O.D. Physics Course; vol. 3, Berlin, 1923.

- Awrejcewicz, J.; Pyryev, Y. Thermo-mechanical model of frictional self-excited vibrations. International Journal of Mechanical Sciences 2005, 47, 1393–1408. [Google Scholar] [CrossRef]

- Astashev, V.K.; Korendyasev, G.K. Thermomechanical model of the occurrence of oscillations in metal cutting. Journal of Machinery Manufacture and Reliability 2012, 41, 189–193. [Google Scholar] [CrossRef]

- Fel’dshtein, V.A. Thermomechanical Self-Excited Oscillations of Current-Carrying Conductors. Journal of Applied Mechanics and Technical Physics 2017, 58, 1091–1098. [Google Scholar] [CrossRef]

- Toda, A.; Tomita, C.; Hikosaka, M.; Hibno, Y.; Miyayji, H.; Nonomura, C.; Suzuki, T.; Ishihara, H. Thermo-mechanical coupling and self-excited oscillation in the neck propagation of PET films. Polymer 2002, 43, 947–951. [Google Scholar] [CrossRef]

- Weng, W.; Anstie, J.D.; Abbott, P.; Fan, B.; Stace, T.M.; Luiten, A.N. Stabilization of a dynamically unstable opto-thermo-mechanical oscillator. Physical Review A 2015, 91, 063801. [Google Scholar] [CrossRef]

- Blocher, D.; Rand, R.H.; Zehnder, A.T. Analysis of laser power threshold for self oscillation in thermo-optically excited doubly supported MEMS beams. International Journal of Non-Linear Mechanics 2013, 57, 10–15. [Google Scholar] [CrossRef]

- Pandey, M.; Aubin, K.; Zalalutdinov, M.R.; Reichenbach, B.A.; Zehnder, T.; Richard, R.H.; и Craighead, H.G. Analysis of Frequency Locking in Optically Driven MEMS Resonators, Journal of Microelectromechanical Systems 2006,15, 6, pp. 1546-1554.

- Pandey, M.; Rand, R.H.; Zehnder, A.T. Frequency Locking in a Forced Mathieu-van der Pol-Duffing System. Nonlinear Dynamics 2008, 54, 3–12. [Google Scholar] [CrossRef]

- Wei, L.; Kuai, X.; Bao, Y.; Wei, J.; Yang, L.; Song, P.; Zhang, M.; Yang, F.; Wang, X. The Recent Progress of MEMS/NEMS Resonators. Micromachines 2021, 12, 724. [Google Scholar] [CrossRef] [PubMed]

- Miller JM, L.; Shin, D.D.; Kwon, H.-K.; Shaw, W.S.; Kenny, T.W. Spectral narrowing of parametrically pumped thermomechanical noise. Applied Physics Letters 2020, 117, 033504. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Li, M.-H.; Li, S.-S. CMOS-MEMS Resonators and Oscillators: A Review. Sensors and Materials 2018, 30, 733–756. [Google Scholar]

- Pillai, G.; Li, S.-S. Piezoelectric MEMS Resonators: A Review. IEEE Sensors Journal 2021, 21, 12589–12605. [Google Scholar] [CrossRef]

- Mitrev, R.; Todorov, T.; Fursov, A.; Ganev, B. Theoretical and Experimental Study of a Thermo-Mechanical Model of a Shape Memory Alloy Actuator Considering Minor Hystereses. Crystals 2021, 11, cryst11091120. [Google Scholar] [CrossRef]

- Elahinia, M.H. Shape Memory Alloy Actuators: Design, Fabrication, and Experimental Evaluation, Toledo: John Wiley & Sons, Ltd., 2016, p. 621.

- Sohn, J.W.; Ruth, S.J.; Yuk, D.-G.; Choi, S.-B. Application of Shape Memory Alloy Actuators to Vibration and Motion Control of Structural Systems: A Review. Applied Sciences 2023, 13, 995. [Google Scholar] [CrossRef]

- Todorov, T.; Mitrev, R.; Yatchev, I.; Fursov, A.; Ilin, A.; Fomichev, V. A Parametric Study of an Electrothermal Oscillator Based on Shape Memory Alloys, 2020 21-st International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, 2020, pp.1-4.

- Wang, L.; Melnik, R. Nonlinear dynamics of shape memory alloy oscillators in tuning structural vibration frequencies. Mechatronics 2012, 22, 1085–1096. [Google Scholar] [CrossRef]

- Mitrev, R.; Atamas, E.; Goncharov, O.; Todorov, T.; Iatcheva, I. Modeling and study of a novel electrothermal oscillator based on shape memory alloys, In 9th International Scientific Conference “Techsys 2020” – engineering, technologies and systems 14-16 May, Plovdiv, 2020 IOP Conf. Ser.: Mater. Sci. Eng. 2020, 878, 012059.

- Rusinek, R.; Rekas, J. Modelling of shape memory alloy oscillator and its application to middle ear structural reconstruction, Proceedings of the 22nd International Conference on Computer Methods in Mechanics 13–16 September, Lublin, AIP Conference Proceedings 2018, 1922(1):100017.

- Kumari, N.; Rakotondrabe, M. Design and Development of a Lead-Freepiezoelectric Energy Harvester for Wideband, Low Frequency, and Low Amplitude Vibrations. Micromachines 2021, 12, 1537. [Google Scholar] [CrossRef]

- Yang, F.; Shi, Y.; Liu, J.; Wang, Z.; Tian, X. Design and Experimental Study of Shape Memory Alloy and Piezoelectric Composite Power Generation Device. Micromachines 2023, 14, 1434. [Google Scholar] [CrossRef]

- Wang, X.; Qin, Q.; Lu, Y.; Mi, Y.; Meng, J.; Zhao, Z.; Wu, H.; Cao, X.; Wang, N. Smart Triboelectric Nanogenerators Based on Stimulus-Response Materials: From Intelligent Applications to Self-Powered Systems. Nanomaterials 2023, 13, 1316. [Google Scholar] [CrossRef] [PubMed]

- Namli, O.; Taya, M. Design of piezo-SMA composite for thermal energy harvester under fluctuating temperature. Journal of Applied Mechanics 2011, 78, 031001. [Google Scholar] [CrossRef]

- Todorov, T.S.; Fursov, A.S.; Mitrev, R.P.; Fomichev, V.V.; Valtchev, S.S.; Il’in, A.V. Energy Harvesting With Thermally Induced Vibrations in Shape Memory Alloys by a Constant Temperature Heater. IEEE/ASME Transactions on Mechatronics 2022, 27, 475–484. [Google Scholar] [CrossRef]

- Reddy, A.R.; Umapathy, M.; Ezhilaras, D.I.; Uma, G. Piezoelectric energy harvester with shape memory alloy actuator using solar energy. IEEE Trans. Sustain. Energy 2015, 6, 409–1415. [Google Scholar]

- Mitrev, R.; Todorov, T.; Fursov, A.; Fomichev, V.; Il‘in, A. A Case Study of Combined Application of Smart Materials in a Thermal Energy Harvester with Vibrating Action. Journal of Applied and Computational Mechanics 2021, 7, 372–381. [Google Scholar]

- Todorov, T.; Nikolov, N.; Todorov, G.; Ralev, Y. Modelling and Investigation of a Hybrid Thermal Energy Harvester, In ICoEV Sofia 2017 MATEC Web of Conferences, 2018, 148, 12002.

- Fursov, A.S.; Todorov, T.S.; Krylov, P.A.; Mitrev, R.P. On the Existence of Oscillatory Modes in a Nonlinear System with Hystereses. Differential Equations 2020, 56, 1081–1099. [Google Scholar] [CrossRef]

- Fursov, A.S.; Mitrev, R.P.; Krylov, P.A.; Todorov, T.S. On the Existence of a Periodic Mode in a Nonlinear System. Differential Equations 2021, 57, 1076–1087. [Google Scholar] [CrossRef]

- Wang, L.; Melnik, R.V.N. Nonlinear dynamics of shape memory alloy oscillators in tuning structural vibration frequencies. Mechatronics 2012, 22, 1085–1096. [Google Scholar] [CrossRef]

- Dynalloy, Inc., “Technical Characteristics of Flexinol Actuator Wire”, Dynalloy, Inc.: Irvine, CA, USA, 2018. [Онлайн]. Available: https://www.dynalloy.com/pdfs/TCF1140.pdf. [21 12 2023].

- Mitrev, R.; Todorov, T.; Fursov, A.; Fomichev, V.; Il‘in, A. A Case Study of Combined Application of Smart Materials in a Thermal Energy Harvester with Vibrating Action. J. Appl. Comput. Mech. 2021, 7, 372–381. [Google Scholar]

- Mitrev, R.; Todorov, T. A Case Study of Experimental Evaluaton of the Parameters of Sape Memeory Alloy Wires, In TechSys 2021 - Engineering, Technologies and Systems, AIP Conference Proceedings, Plovdiv 2022, 2449(1).

- Miller JM, L.; Ansari, A.; Heinz, D.B.; Chen, Y.; Flader, I.B.; Shin, D.D.; Villanueva, L.G.; Kenny, T.W. Effective quality factor tuning mechanisms in micromechanical resonators. Appl. Phys. Rev. 2018, 5, 041307. [Google Scholar]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Half-support distance | l | 0.026 | m |

| NiTi filament half length | ls | 0.25 | m |

| Mass of a sphere | m | 0.012 | kg |

| Gravity acceleration | g | 9.81 | m/s2 |

| Lengths of NiTi filament end sections |

|

0.14 | m |

| Length of the middle section of the NiTi filament | 0.24 | m | |

| Diameter of NiTi filament | ds | 0.00025 | m |

| Young’s modulus for NiTi in fully twinned martensite | 21.7 | GPa | |

| Young’s modulus for NiTi in partially twinned martensite | 0.56 | GPa | |

| Young’s modulus for NiTi in detwinned martensite | 11.1 | Gpa | |

| Young’s modulus for NiTi in austenite | 55.5 | Gpa | |

| Yield strain for twinned NiTi in martensite | 0.0024 | ||

| Minimum strain of twinned NiTi in martensite | 0.0044 | ||

| Starting austenite temperature of NiTi | AS | 55.99 | °C |

| Final austenite temperature of NiTi | 64.05 | °C | |

| Starting martensitic temperature of NiTi | 25.4 | °C | |

| Final martensitic temperature of NiTi | 21.44 | °C | |

| Austenite correction temperature | 0.01 | °C | |

| Austenite coefficient | 1.95 | ||

| Martensitic correction temperature | 0.01 | °C | |

| Martensitic coefficient | 2.17 | ||

| Start position of maximum temperature | 0.0095 | m | |

| End position of maximum temperature | 0.023 | m | |

| Room temperature | 20 | °C | |

| Maximum temperature of NiTi filament | 70 | °C | |

| Longitudinal damping coefficient | βx | 0.00042 | kg/s |

| Transverse damping coefficient | βy | 0.0014 | kg/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).