1. Introduction

The global call for the development of sustainable pavement construction materials such as geopolymer cement (GPC) or binder (GPB) in recent years after a century or more of utilizing ordinary Portland cement (OPC) has brought a great transformation in the construction industry [

1,

2,

3]. This development is attributed to the implementation of regulations that will reduce the incidence of the greenhouse effect (GHE) and global warming associated with anthropogenic CO

2 emissions coupled with improvement in the performance properties of cement products [

1,

2,

4,

5,

6,

7].

Given this, the global demand for GPC or GPB has been investigated and reported to be increasing geometrically in the present Fourth Industrial Revolution (4IR) as revealed in the high number of tonnes of GPC and/or GPBs produced and marketed annually [

1]. From the global geopolymer (GP) market perspective, 6.431 billion US dollars were estimated for the year 2019 and the marketed GPC/GPBs were also statistically found to grow at a compound annual growth rate (CAGR) of 29.84%, with a forecast to attain a market size of 40.008 billion US dollars by the year 2026. The contributory factors to the CAGR include a rapid rise in construction activities in the present era [

6], the sustainability and performance qualities of the geopolymer materials [

3,

8], the need for reduction of CO

2 emitted from cement or binder materials in controlling global warming effects [

2,

3,

7], rapid infrastructure developments [

9], the role of geopolymer materials in waste management [

10], and the recovery of construction and mining industries from the impact of COVID-19 pandemic [

5,

6,

11].

From the environmental and industrial chemistry point of view, cement production has been noticed as a significant source of CO

2 emissions globally from the combustion of carbonate materials (mainly CaCO

3 and MgCO

3) under intense heat in cement ovens at temperatures between 1200 – 1500

oC to yield the clinker (the intermediate nodular cement material or product) and as one of the major contributors to global warming and climate changes [

12,

13,

14]. In a 5-year study (2015 – 2020), the emission of CO

2 from each tonne of cement produced grew by 1.8% each year, and this has made the cement industry causing 4 – 10% of CO

2 emissions globally [

4]. Other air pollutants associated with the cement production process include dust, oxides of nitrogen (as GHGs), and oxides of sulfur which also need to be reduced along with the reduction of CO

2 emissions.

Although various procedures have been developed for capturing CO

2 discharged from cement power plants, the need for developing eco-friendly cementing systems (such as GPC and GPBs) for sustainable pavement construction applications is crucial [

15,

16,

17]. Hence, reducing the global production of OPC and non-geopolymer-based binders will aid in the reduction of the amounts of CO

2 (and other cement-based pollutants) emissions from cement, construction, and mining industries towards sustainability and healthy environments.

GPC, which is commonly termed an “inorganic polymer” or a “synthetic alkali aluminosilicate material” as coined by Joseph Davidovits [

2,

3], is an innovative material derived from industrial by-products and emerging as a promising solution for achieving diverse pavement constructions [

8,

15,

16,

17]. In addition, the characteristic functionality, physicochemical composition, and formulation of GPs have made them assigned various generic and trade names such as inorganic polymers (IPs), geocement, alkali-activated materials (AAMs), aluminosilicate inorganic polymers (AIPs), alkali-bonded ceramics and hydroceramics, and inorganic phosphate cement (IPC), among others [

2,

3,

4,

8].

This critical review aims to comprehensively evaluate the application of GPC/GPB as alternative pavement construction materials based on the material properties, durability, workability, setting time and density, rheological behaviour, and thermal resistance and conductivity of GPC/GPB performance compared to the conventional OPC.

1.1. Traditional Cement and Its Environmental Imperatives

The term cement is a binding material of inorganic or organic or both in origin that can hold solid bodies together by hardening from its plastic form [

18]. Cement is an indispensable material in any construction industry and the modern-day type which is regarded as traditional or modern or ordinary Portland cement (OPC) was discovered due to the experimental work of Joseph Aspdin (a British bricklayer and builder) in 1824 by heating limestone (CaCO

3) and clay together in a lime kiln, resulting in a calcined mixture which was ground and finally mixed with water to form an inorganic binder [

18,

19]. Different forms of cement are known to exist in the global cement industries and markets, but the predominant type is the OPC [

18]. The chemistry of OPC formation reveals that the cement is obtained from the calcination of CaCO

3 and silica (SiO

2) (that is, limestone + silica + heat (1450

oC) = OPC + CO

2), according to the reaction stated below [

20].

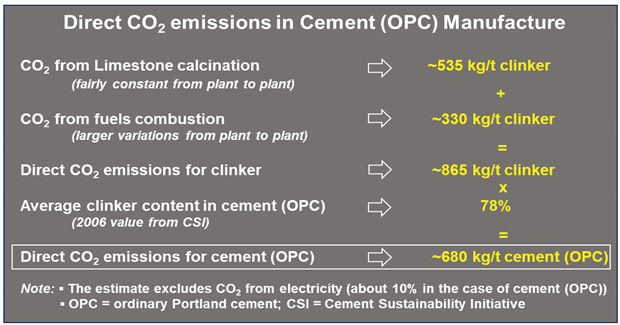

Based on the reaction equation stated above and the analysis illustrated in

Table 1, it was reported that approximately 0.54 tonnes (≈ 540 kg) of CO

2 are directly emitted for every tonne of OPC produced at a calcination temperature of 1450

oC and with the addition of 0.33 tonnes (≈ 330 kg) of CO

2 released for every carbon-containing fuel burnt to generate the calcination heat at 1450

oC needed [

20,

21]. It is quite shocking to release such amounts of CO

2 (a potent GHG) from an OPC industry on producing just 1 tonne (1000 kg) of OPC, resulting in detrimental environmental effects mainly global warming.

From

Table 1, it is established that the specific CO

2 emissions per tonne of cement produced are directly impacted by the amount of clinker in the cement. Materials such as slag, fly ash, and natural and synthetic pozzolans with cementitious qualities are being added to traditional cement or binders by many cement producers to lower the clinker level of their cement by clinker substitution and thus reduce CO

2 emissions [

21]. Despite this approach, the CO

2 emissions from traditional cement industries are still relatively higher than the expected amounts found in the environment. This effect demands greener and better-performance cement products such as GPC/GPB.

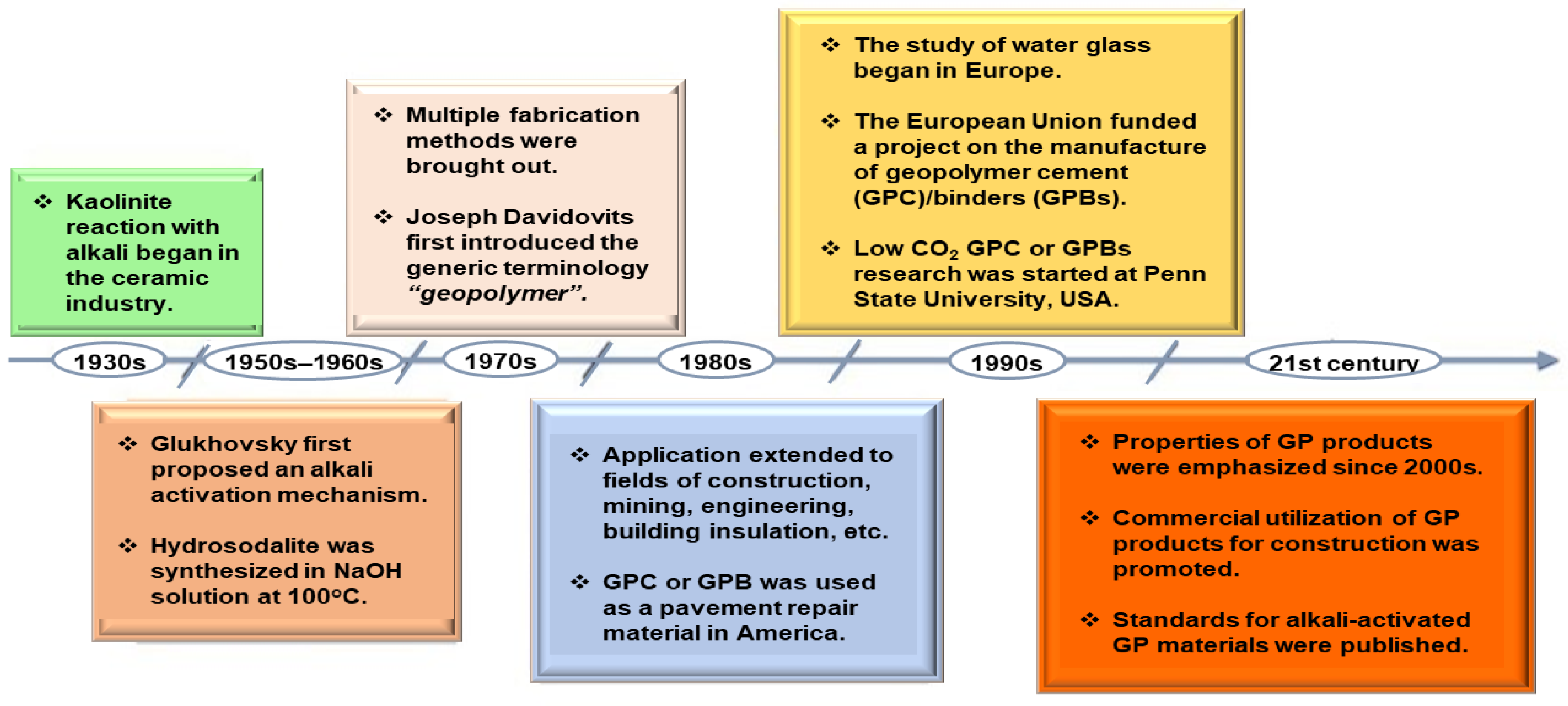

1.2. Historical Developments of Geopolymer Technology

The generic term geopolymers (GPs), which are regarded as geologically originated ceramic-like inorganic polymers formed at low temperatures (<100°C) [

22], was commercially coined in 1979 with the agreement of the Commission of the European Communities due to the modelling of zeolite geological formation although their characteristic physicochemical composition as alkali aluminosilicate binders was first introduced by Joseph Davidovits in 1976 [

22,

23,

24]. GPs comprise chains or networks of alumino-silicate mineral molecules linked with covalent bonds [

22]. Based on their composition, different molecular structural perspectives are used by both chemists and ceramicists as per the major ingredient such as kaolinite (a clay mineral) forming GPC or GPBs; for instance, a chemist considers the molecular formula of kaolinite as Si

2O

5Al

2(OH)

4, while a ceramicist sees is as Al

2O

3⋅2SiO

2⋅2H

2O [

22]. However, the structural functionality of geopolymers coupled with the geopolymerization mechanisms enables their polymeric chain unit stated as [≡Si-O-Al-(OH)

2]

n, where the covalent aluminium hydroxyl -Al-(OH)

2 side groups branched to the poly(siloxo) hexagonal macromolecule [≡Si-O-]

n [

22].

Since the 1970s, GPC, also known as GPBs, have gained international recognition as eco-friendly beneficial pavement construction materials [

27]. Apart from its replacement of OPCs, geopolymer has found wider applications in domains including civil engineering, the nuclear energy field, geotechnical engineering, and paleontological study [

25]. The summary of the timeline of geopolymer historical developments is shown in

Figure 1.

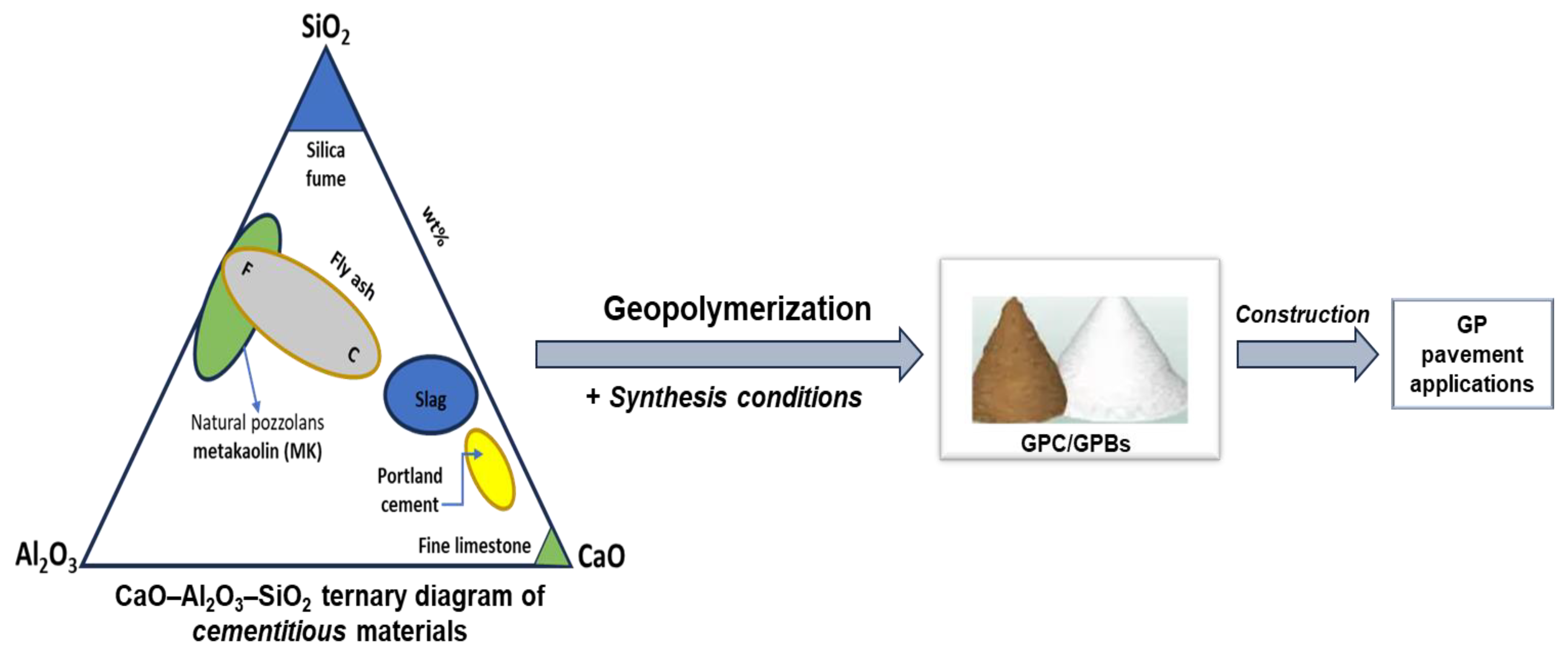

2. Geopolymer Cement/Binder Production

The production of GPC or GPBs, as found in building construction companies and ceramic industries, is based on the available cementitious materials (as seen in the CaO–Al

2O

3–SiO

2 ternary diagram of cementitious materials, synthesis conditions or influential parameters (such as temperature, pH, and alkaline activator), target products, and geopolymerization process or mechanism governing the production, as shown in

Figure 2 [

2,

4,

23]. As stated earlier, cementitious materials such as slags, fly ashes, kaolinite, zeolites, calcinated clays (such as metakaolin (anhydrous calcinated kaolin)), and finely divided pozzolans which are rich in aluminium (Al) and silicon (Si) are widely used in the production of GPC or GPBs via geopolymerization [

4,

11,

14,

22,

23,

24,

27].

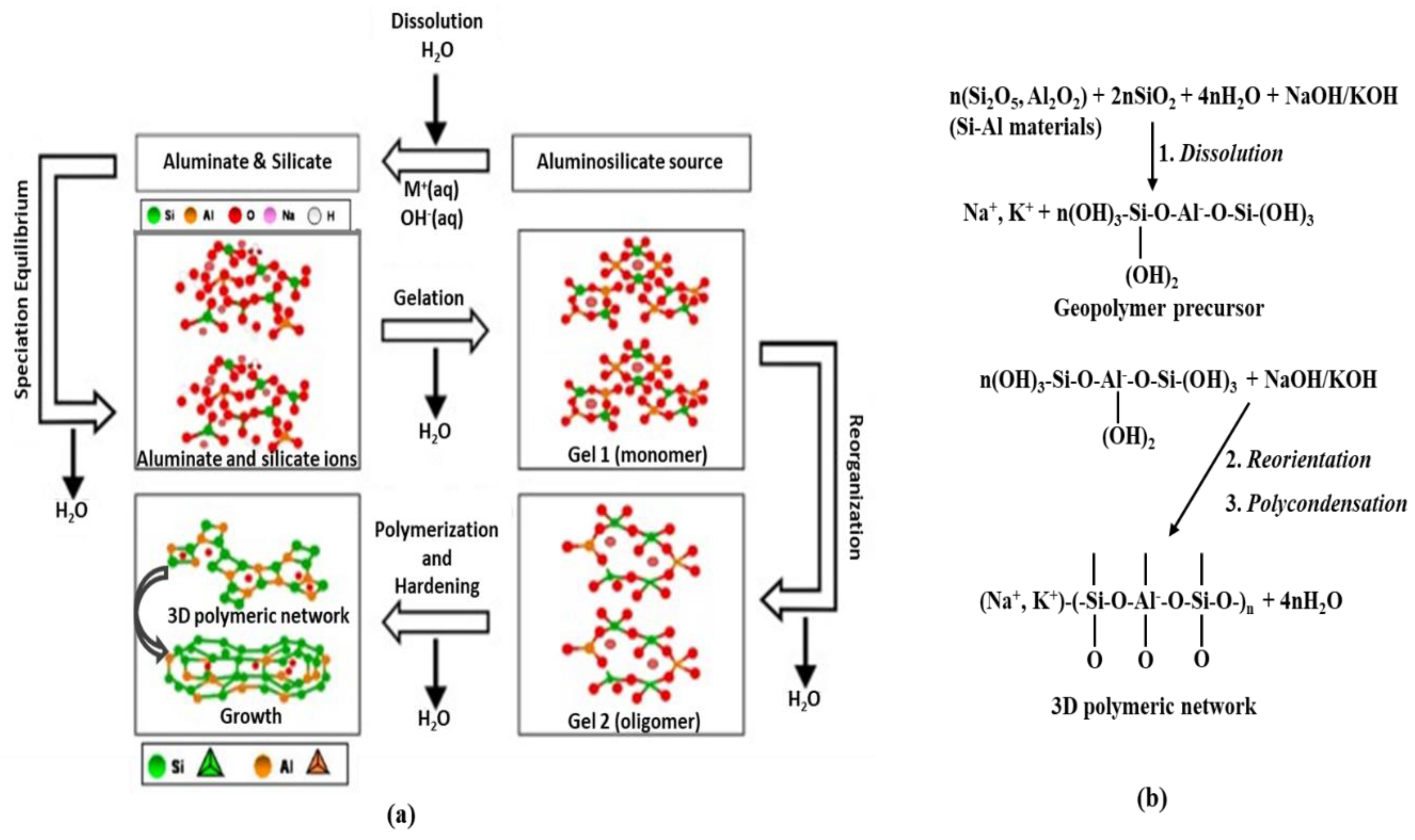

2.1. Geopolymerization Process

Geopolymerization is a process where inorganic aluminosilicate materials react to form a 3D polymeric framework or network of geopolymer cement/binders. The mechanism involves the dissolution of source cementitious materials such as metakaolin (MK) or fly ash (FA), followed by reorganization, and finally polycondensation reactions under influential parameters such as favourable temperature and alkaline activators. The required alkaline activator, usually sodium hydroxide (NaOH) or sodium silicate (Na

2SiO

3), is crucial in initiating and catalyzing the geopolymerization process [

4,

22,

23].

The mechanism of the geopolymerization process can be generally categorized into three stages, viz: (i) dissolution, (ii) reorientation or reorganization, and (iii) polycondensation, as illustrated in

Figure 3 [

15]. In the dissolution stage, alkaline activators (M

+(aq) + OH

-(aq), where M = Na or K) dissolve the solid alumino-silicate material in the presence of water to form silicate and aluminate ions under a controlled pH. The ion species then migrate to an equilibrium position with the elimination of a small amount of water and they interact by undergoing gelation/coagulation to form an aluminosilicate gel (

Gel 1). This is followed by the reorientation stage in which the group atoms in

Gel 1 reorganize themselves coupled with a partial dehydration to form

Gel 2. Finally, the polycondensation stage involves the solidification of

Gel 2 at temperatures between 20 – 1000

oC with almost full dehydration to form a 3D polymeric network of GPC or GPB.

2.2. Geopolymer Cement/Binder as Sustainable Pavement Construction Materials

Pavements, as concrete products, play a crucial role in our daily lives, serving as roads, highways, driveways, and parking lots [

29,

30,

31]. The construction of pavements remains a significant industrial application for both developing and developed nations. Pavements are categorized into two types, viz: asphalt (flexible) pavements and concrete (rigid) pavements, each consisting of distinct layers such as binder or surface, base, subbase, and subgrade [

29,

31]. The primary purpose of pavements is to distribute the load from the surface to the subgrade, enabling them to endure the applied load from vehicles or users

without excessive deformation [

29,

30,

31].

The motivation to explore geopolymers in pavement construction stems from their potential to address the environmental imperatives of traditional cement or OPC and their better construction performance over OPC. In making this possible, GPC or GPB formed through the chemical activation of aluminosilicate materials (such as (Si

2O

5,Al

2O

2)

n) offer an environmentally friendly alternative by utilizing either natural or waste and industrial by-product materials such as kaolinite (Al

2Si

2O

5(OH)

4), clays, fly ashes, red mud, or slags with improved mechanical and durability properties [

4,

7,

8,

14,

17].

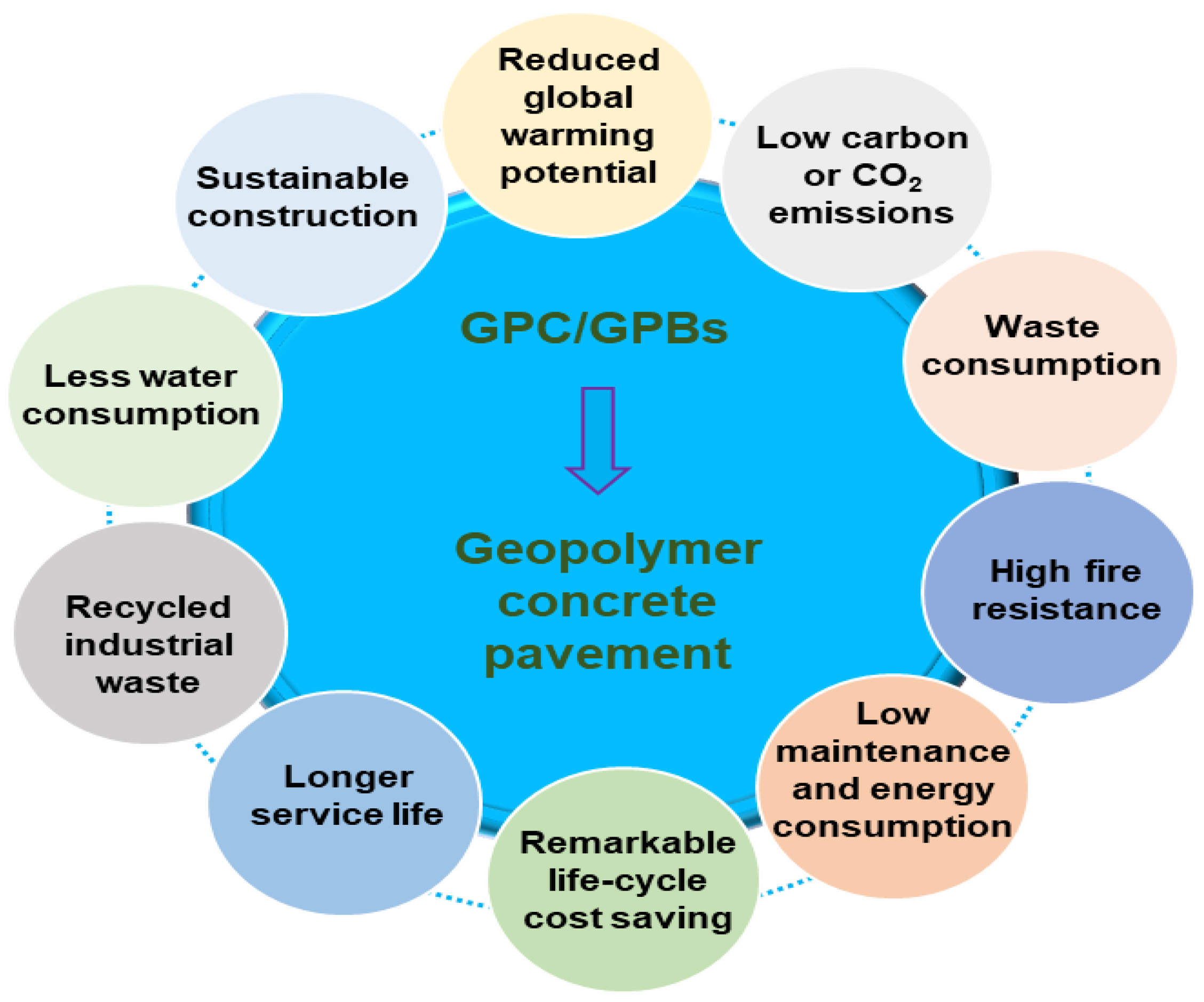

Based on their eco-friendly characteristics, the ability to replace OPC in minimizing emissions of GHGs (such as CO

2 and NO

x), and improved performance, GPC or binders as innovative cement-based materials find their usage in structural and civil engineering fields coupled with their applications in construction and mining industries in making geopolymer concrete and pavement, as illustrated in

Figure 1 [

4,

8,

9].

2.3. Types and Applications of Geopolymer Cement/Binders

The various forms of geopolymer (GP) cement or binder based on the cementitious materials used for their production and their applications are presented in

Table 2.

2.4. Comparison between GPC and OPC Based on Their Eco-Friendliness and Sustainability

GPC is globally seen as a greener alternative to OPC in various aspects based on the structural and physicochemical properties and sustainability criteria, as illustrated in

Figure 4 and

Figure 5. The important comparison between GPC and OPC as construction or building materials is presented in

Table 3 [

24,

35,

36].

3. Mechanical Properties, Durability, Workability, Setting Time and Density, Rheological Behaviour, and Thermal Resistance and Conductivity of GPC Performance compared to OPC

The greater demand for GPC, their utilization, and potential benefits in various construction activities such as pavement making have been investigated based on their mechanical properties (such as compressive strength), durability (such as chemical resistance), and general performance on comparing them to those of OPC, as indicated in

Table 4. Based on the various research conducted, for instance, the investigation made by Kurtoglu

et al., 2018 [

37], on comparing the mechanical and durability properties of SGPC (slag-based GPC) and FAGPC (fly ash-based GPC) with those of OPC, concluded that GPC is relatively better in both mechanical and durability properties than OPC in construction purposes, especially in the use of SGPC as sustainable construction materials for sewage and underground structure.

Regarding this, GPC generally offers comparable or even superior compressive strength, tensile strength, and flexural strength, and better durability properties concerning resistance to chemical attack, abrasion, and freeze-thaw cycles, leading to longer-lasting pavements. GPC concrete, as a product of GPC utilization, is found to show good resistance to cracking and reduced shrinkage due to its lower calcium content and different chemical composition,

unlike OPC concrete [

9,

26,

38].

Various factors (such as the type and composition of source materials, activators used, curing conditions, the addition of additives like fly ash or silica fume, cement/binder grade, cement/binder type, aggregate size, water-to-cement (W/C) ratio, manufacturing quality, etc.) have been shown to have impacts on GPC concrete's mechanical properties, durability, energy conversion, and performance as an alternative pavement construction material or product [

2,

3,

5,

39]. In comparison to using alkali hydroxide alone, using an alkali solution that contains both alkali hydroxide and dissolved silicate is advantageous for compressive strength [

3]. Thus, the comparable or superior mechanical properties, excellent durability, and reduced environmental impact of GPC/GPB make it an attractive alternative to OPC.

3.1. Mechanical Properties

3.1.1. Compressive Strength

This is the measure of the breaking point for a material’s strength when external pressure is applied. The GPC/GPB sample's compressive strength is determined by the mixture's flow resistance, whereas the sort, size, and weight of the material’s fibre influence both flow resistance and slump [

36]. Using fibres and proper homogeneity between the fibre and the cement matrix, high-pressure compaction can be used to boost the compressive strength (

fcs). However, the impact of various fibres on the compressive strength of geopolymer varies [

40]. Thus, the fibre constituent and other ingredients of GPC/GPB make its compressive strength superior to OPC; it’s about 1.5 times more than that of OPC concrete [

36,

40].

3.1.2. Flexural Strength

This is the three-point bending test's measurement of a material's resistance to bending without breaking. It is also known as bending strength, transverse rupture strength, or modulus of rupture. GPC often demonstrates similar flexural strength to OPC, making it a suitable material for pavements. It is reported that adding suitable reinforcements such as fibres can further enhance the flexural properties of geopolymer-based concrete [

40]. Generally, fibre-reinforced GPC has a substantially higher bending strength than unreinforced GPC [

40].

3.1.3. Fracture Toughness

This is a quantitative index that gauges a material's toughness by assessing its capacity to stop cracks from spreading. The direct tensile method, compact tensile method, wedge splitting method, and three-point bending beam method are the fracture toughness test methods commonly applied in assessing cement concretes. Based on various tests, when the crack size of a concrete sample’s material remains constant, the material's fracture toughness increases, and vice versa, and this is found to relate to the material’s fracture energy defined as the energy needed for the unit area of fracture propagation, reflecting the energy shift that occurs during the crack growth [

40,

41,

42,

43].

The fracture toughness of GPC concrete is higher than that of OPC concrete due to the presence of fibres and low calcium content. Based on the reported comparison between GPC and OPC concretes, GPC concrete was seen to have a fracture energy that was twice as high and a fracture toughness that was 20–30% higher than that of OPC concrete [

41,

42,

43]. However, the GPC’s fracture toughness increases as the fibre factor increases to a magnitude of 600 and then decreases thereafter [

40,

43].

3.1.4. Elastic Modulus

This is the measure of the stiffness or resistance of a material to its elastic deformation under subjected stress. Elastic modulus serves as a serviceability quality of a concrete material concerning its structural deformation [

38]. It is also called Young’s modulus or modulus of elasticity of a material. The elastic modulus of GPC is found to increase as compressive strength increases, showing a positive relationship between the two mechanical properties [

44]. High-strength GPC/GPB concrete shows a better comparable elastic modulus than OPC concrete over 28 days of testing [

38].

3.1.5. Shear Strength

This is the measure of a material’s ability to resist shear sliding when subjected to external pressure or forces either along the horizontal or vertical direction. The shear strength of GPC/GPB concrete is influenced by various factors such as the addition of fibres (especially mixed fibres), mix design, curing conditions, aggregate properties, and testing methods [

40]. The addition of fibres, especially mixed fibres, increase the shear strength of GPC/GPB concrete in one way or the other, making the concrete better in shear strength property than OPC concrete for various mixes and curing conditions [

44].

3.1.6. Split Tensile Strength

This is the measure that determines the tensile strength of cement concrete with the aid of a cylinder that splits across the vertical diameter of the concrete. This split cylinder method of testing and estimating the tensile strength of cement concrete is an indirect tension test that is found to be simpler and with reliable data under uniform stress [

41,

45]. Split tensile strength (

fst) is related to the compressive strength (

fcs) of concrete material and it also depicts the fracture resistance of the material [

41,

45,

46]. The relationship between

fst and

fcs of GPC concrete is given as

fst =

[

45]. Regarding this, the split tensile strength is relatively high for GPC compared to OPC under the same conditions [

41].

3.2. Durability Properties

3.2.1. Chemical Resistance

Geopolymer cement (GPC) generally provides better resistance to chemical attacks such as acid or base attack, chloride penetration, and sulfate attack which are common causes of deterioration in pavement structures [

40,

44]. The presence of fibres in GPC improves its chemical resistance, but an increase in porosity and pore size of GPs subjects them to easy deterioration by chemical attack [

40]. This attribute contributes to the long-term durability of geopolymer-based pavements. The chemical resistance of GPC concrete varies with the type and composition [

37]. Regarding this, GPC shows higher resistance to the attack by chemicals such as acids (e.g., H

2SO

4, HNO

3, and HCl), sulfates, chlorides, etc. than OPC, as illustrated in

Table 4 [

47,

48].

3.2.2. Fire Resistance

The mechanical properties, brittleness, weather tolerance, fibre reinforcement, and thermal stability of GPC concrete, among other factors, enable GPC to withstand high temperatures in the range of 1000 – 1200°C with little deterioration,

unlike OPC concrete [

49,

50]. Regarding this, GPC serves as a competitive cement-based GPC in the infrastructure and construction sectors, guaranteeing long-term durability and offering protection and safety to people's lives and property.

3.2.3. Freeze-Thaw Resistance

This refers to a material’s ability to resist the extremely damaging effects of cyclic or periodic freezing and thawing. The

freeze-thaw cycle of GPC concrete acts as an index for evaluating the durability of the associated geopolymer [

40,

44]. The physical properties of GPC concrete such as its matrix strength, pore structure, cracks, and pore saturation associated with air entrainment affect its freeze-thaw resistance. The presence of fibres in GPC and the lowering of its concrete porosity improve its concrete’s freeze-thaw cycle resistance [

40,

44]. In addition, due to its low water requirement and the pore solution with high electrolyte concentration, alkali-activated slag-based GPC concrete can withstand 300-1150 cycles of repeated freezing-thawing, whereas typical OPC concretes can only withstand less than 300 cycles [

3]. Thus, GPC concrete has a greater freeze-thaw resistance advantage than OPC concrete, as illustrated in

Table 4 [

38,

51].

3.2.4. Abrasion Resistance

This is the ability of a material surface to resist wearing away by friction or rubbing effect. It is measured by weight or mass loss in the material [

44]. The abrasion resistance of GPC concrete depends on several factors such as the material’s compactness, fibre content, surface finishing, good curing, aggregate/paste bond, mix proportions, and aggregate hardness [

50]. The addition of fibres such as polyvinyl alcohol (PVA) fibres has been studied to improve GPC concrete’s abrasion resistance [

52]. Hence, in general, GPC concrete shows a better abrasion resistance than OPC concrete [

44].

3.2.5. Fatigue Resistance

The term

fatigue resistance of a concrete material is the tendency of the material to withstand the rupturing that can be caused by the material’s repetitive static loadings by direct compression, torsion, tension, and bending beyond the strength of the material [

53]. Several static fatigue tests conducted on both GPC and OPC concrete beams showed better promising results for GPC compared to OPC [

53,

54]. Regarding this, geopolymer concrete has been seen to have superior resistance to fatigue cracking, which is crucial for heavy-loaded pavement applications [

15,

55].

3.2.6. Porosity and Air Permeability

Porosity is a measure of the number of pores present in a material such as concrete. It is an intrinsic property of cement material. For a cement material, porosity is determined as the quantity of the total volume occupied by the pores of the material sample [

56].

Air permeability of concrete material is the measure of the volume flow rate of air through the material sample.

The pore size of GPC is affected by its fibre content, vibrations, compactness, W/C ratio, etc., and it is found to be smaller than that of OPC, making the air permeability of GPC to be lower [

56,

57]. In addition, compressive strength is related to porosity, permeability of air and water, and water absorption, among others. Thus, GPC has better durability and performance than OPC based on the fewer, small-sized pores it possesses [

56,

57,

58].

3.2.7. Water Absorption and Permeability

Water absorption of a material is regarded as the quantity of water absorbed by the material. It is estimated as the ratio of the absorbed water weight to the dry material weight [

56,

59].

Water permeability refers to the measure of the degree to which water flows through a solid material under pressure [

50]. Both water absorption and permeability of GPC, for instance, are influenced by several factors such as pore size and continuity, nature of the cementitious materials, fibre content, humidity cycle, compactness, curing state, mix proportions, microcracks, and W/C ratio, and they also determine the compressive strength of any cementing material [

50,

52,

56,

59,

60]. Generally, GPC (such as FAGPC) has lower water absorption and permeability than OPC [

50,

56,

60].

3.2.8. Drying Shrinkage

This is regarded as the loss of capillary moisture from the hardened cement mixture matrix during air drying, leading to shrinkage and crack formation within the concrete. It is a crucial durability performance index that provides information on the potential cracks that can result in hardened cementitious materials [

40]. Reports have shown that fibre addition to GPC matrix on production minimizes the stress in the matrix, making it withstand drying shrinkage and better than OPC concrete [

40,

61].

3.2.9. Sorptivity

The term

sorptivity of a material is regarded as its ability to absorb and transfer fluid (such as water) through it via capillary action [

62,

63]. As a measure of concrete material, sorptivity serves as an engineering metric for concrete material’s microstructure and durability-related attributes and as an indicator of concrete resistance to being in unfavourable environments [

63]. The better physicochemical characteristic nature of GPC based on its fewer, small-sized pores, fibre-reinforced cementitious materials, low humidity cycle, high compactness, better curing state, fewer microcracks, and low W/C ratio makes it possesses lower sorptivity and better performance as a pavement construction material than OPC [

62].

3.2.10. Corrosion Performance

The term

corrosion is a process in which the properties of a material change due to a physicochemical reaction that takes place between the material and its environment. The high resistance of GPC to attacks by chemical, fire, humidity cycle, and fracture coupled with its low porosity, sorptivity, absorption, and permeability reduces its corrosion tendency, making its corrosion performance higher than that of OPC [

56,

64]. For instance, the study carried out by Farhana

et al., 2013 [

64] shows that the formation of a protective ferric oxide film on the steel of steel-reinforced GPC concrete prevents corrosion by creating an alkaline environment provided by the FAGPC. In contrast to OPC concrete, the silicate membrane on the reinforcement bar inserted in GPC concrete is tightly covered, resulting in a low corrosion rate [

64].

3.3. Workability, Setting Time, and Density

3.3.1. Workability

The term

workability of concrete means the ease with which newly mixed concrete can be placed, compacted, and finished without any segregation and homogeneity loss [

65]. It is influenced by flowability, aggregate shape, W/C ratio, water retention, strengths, moisture content, preparation, grading, adhesion, activator type, curing temperature, and superplasticizers [

3,

34,

65,

66]. It is assessed by using the slump test and compact factor test [

42,

65]. Ground granulated blast furnace slag (GGBFS) enhances the workability of cement materials. Thus, GGBFS-based GPC concrete is more workable than OPC concrete [

50,

59].

3.3.2. Setting Time

This is the amount of time needed for cement paste to harden to a specific consistency. It entails the initial and final setting time (

ts). The cement composition, W/C ratio, cementitious material reactivity, curing temperature, alkali concentration, and admixtures all affect the setting time. The setting time serves as a determinant for the workability of cement concrete; and as the curing temperature of cement concrete increases, the setting time decreases while compressive strength increases [

3,

44]. Generally, GPC (

ts: 10 – 60 min) sets faster than OPC (

ts: 30 – 300 min) [

36].

3.3.3. Density

This is the measure of compactness of a material such as cement or mortar. Factors such as fibre content, alkali concentration, cement composition, and porosity, among others, affect the density of cement concrete [

40,

67]. For instance, fibre reinforcement of GPC increases the density of GPC [

40] and GGBFS reduces concrete pore size and permeability, leading to an increase in the concrete density [

50]. Generally, the density of GPC concrete is higher than that of OPC concrete, as can be observed in the FAGPC concrete (density: 2290 – 2460 kg m

-3) compared with OPC concrete (density: 2200 – 2400 kg m

-3) [

68].

3.4. Rheological Behaviour

Rheology is a term used to describe the study of matter’s fluidity and deformation under external forces. Fluid’s rheological behaviour is categorized into viscous flow, elastic deformation, and plastic flow, and its properties are essential for material mixing, transportation, and pouring [

69]. It can be measured using a C-VOR Bohlin

® rheometer [

70]. GPC exhibits unique rheological properties that influence its workability, microstructure, durability, mechanical properties, and constructability [

3]. Despite that little investigation has been made on GPC rheological behaviour unlike OPC, it’s generally reported that GPC shows lower yield stress, higher apparent viscosity, and more complex rheological performance than OPC [

71].

3.5. Thermal Resistance, Insulation, and Conductivity

Several investigations have been carried out on the thermal behaviour of GPC compared to OPC. Regarding this, GFC shows lower thermal conductivity due to its low calcium content, among other factors, but with higher thermal resistance, stability, and insulation than OPC under the same conditions or parameters (such as density, temperature, and strength) [

72,

73]. The better thermal performance of GPC enhances its durability, mechanical properties, eco-friendliness, sustainability, engineering applications, and construction purposes, among others [

5,

40,

72,

73].

4. Environmental Impact Assessment of Geopolymer Cement/Binder

The Environmental Impact Assessment (EIA) of geopolymer cement/binder involves evaluating their environmental effects throughout their life cycle. GPC or GPB, as an alternative to traditional cement, can positively impact the environment by using industrial by-products, reducing GHG emissions, and lowering energy consumption during production. However, extracting raw materials and manufacturing processes may still have environmental consequences. Considerations include water usage, waste generation, durability, and end-of-life management. The assessment should adhere to local regulations and standards, with the understanding that the environmental impact varies based on specific formulations, production methods, and regional factors [

87,

88].

4.1. Greenhouse Gas Emissions Reduction

GPC or GPB contributes to a reduction in GHG emissions compared to OPC through several key factors. They utilize industrial by-products, lowering demand for traditional raw materials and decreasing CO

2 emissions. GP production involves lower temperatures, reducing energy consumption and carbon intensity. The absence of clinker production further lowers emissions. Additionally, factors like longer lifespan, energy-efficient manufacturing, and resistance to carbonation contribute to the overall environmental benefits of GPC or GPB. However, the actual emissions reduction depends on specific formulations, production processes, and regional conditions [

9,

66].

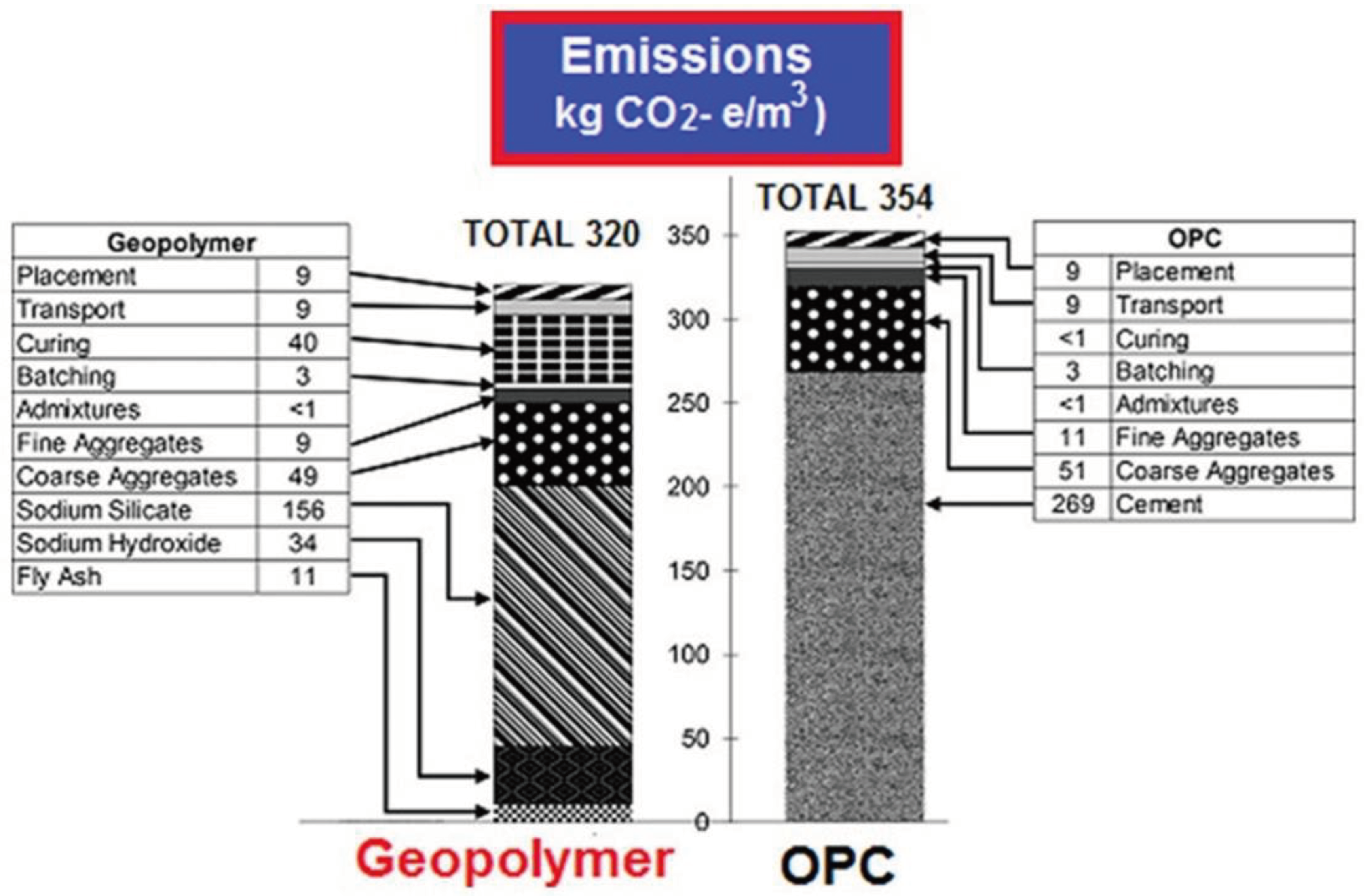

Almutairi

et al., 2021 [

9] conducted a comparison study between the CO

2-e footprints of concrete with GPC and 100% OPC concrete. The study evaluated the carbon dioxide equivalent emissions (CO

2-e) related to the sourcing of raw materials, the production of concrete, and the construction of one cubic metre of concrete in metropolitan Melbourne. Surprisingly, the CO

2 footprint of geopolymer concrete was found to be approximately 9% less than that of comparable 100% OPC concrete. Some factors were suggested to contribute to the result obtained which included the consideration of emissions from mining, treating, and transporting raw materials for alkali activating agents in geopolymers, considerable energy consumption in the production of alkali activating agents, and the requirement for high temperatures during the curing process of geopolymer concrete to attain sufficient rigidity [

89].

The graphical representation in

Figure 5 summarizes the contribution to CO

2-e emissions from various activities involved in the production and construction of one cubic meter of concrete. This comprehensive assessment spans activities from the sourcing of raw materials to the manufacturing and construction phases. The figure provides a clear overview of the carbon footprint associated with each stage, offering insights into the environmental impact of the entire lifecycle of concrete production and use. Such analyses are essential for understanding and mitigating the environmental consequences of concrete-related activities.

Comparing GPs to OPC, GPs exhibit superior mechanical properties, long-lasting performance, resilience to acids, sulfates, alkali-silica reactions, and high temperatures, as illustrated in

Table 4 [

24,

38,

48,

90,

91]. Studying the GPC derived from construction and demolition waste (CDW) aims to promote circular economy principles and reduce environmental impacts compared to OPC. For instance, the G-based geopolymer stands out with a 38% lower Global Warming Potential (GWP) than OPC.

4.2. Energy Efficiency in Geopolymer Production

In comparison to OPC paste, alkali-activated brick powder geopolymers offer benefits in terms of energy efficiency and emission reduction, potentially reducing CO

2 emissions by 40-70% and cutting energy consumption by 20-50%. However, formulations with an 8% alkali dosage in brick powder geopolymers result in high energy consumption, primarily due to the extensive use of NaOH and Na

2SiO

3. This highlights the necessity for the development of more environmentally friendly alkaline activators in future endeavours. In summary, an optimal mixture is identified with a 6% alkali dosage, a silicate modulus of 1.6, and a water-to-binder (W/B) ratio of 0.3, taking into account both functional properties and environmental considerations [

92]. Utilizing activators derived from waste materials holds the potential to cut down CO

2 emissions by 50-60% compared to commercially available sodium silicate. Waste materials rich in silica, such as silica fume, Rice Husk Ash (RHA), and waste glass, can function as activators for geopolymers, facilitating additional Si-Al linkages. These alternative activators exhibit performance like conventional sodium silicate solutions, albeit with a potential slight delay in setting time. Consequently, incorporating waste-derived activators in Autoclaved Aerated Concrete (AAC) production has the dual advantage of significantly reducing the industry's environmental impact while maintaining high performance and potentially lowering production costs. Further research is essential to fine-tune the utilization of waste materials as activators and mitigate any associated drawbacks [

93].

4.3. Resource Conservation and Waste Reduction

GPC has the potential as a sustainable substitute for regular OPC, with customizable properties. However, challenges in implementation arise from complex mixture parameters and a lack of standardized testing. Key points include GPC's workability enhancement factors, compressive strength influencers, durability aspects, bond strength considerations, and the absence of dedicated standards in the U.S. and EU. Notably, the UK's BSI PAS 8820:2016 stands out as a rare, dedicated standard for GPC, potentially serving as a model for other regions.

In future research, the adoption of alternative cementitious materials (ACMs) and GPC should consider factors such as exploring added resources for solid precursors and cost-effective alkali activators [

94].

4.3.1. Use of Industrial Waste Materials

Geopolymers (GPs), activated with alkaline solutions and utilizing industrial by-products, decrease reliance on limestone and clay for cement production [

4]. This eco-friendly approach minimizes environmental impact, lowers the carbon footprint, and enhances pavement durability, potentially reducing the need for frequent repairs. GPs contribute to a resource-efficient and sustainable construction paradigm.

In theory, any agricultural, industrial, or natural waste containing adequate silica and alumina can be employed for polymerization, with alkaline activators such as NaOH, KOH, Na

2SiO

3, and K

2SiO

3 commonly used in the GP phase, and the type of alkaline activator was observed to exert a substantial influence on the properties of the polymerization process [

95]. The primary raw materials in geopolymer consist of waste and natural materials abundant in silicon (Si) and aluminium (Al), with kaolinite being the initial substance employed in geopolymer synthesis [

23].

5. Challenges and Limitations

Geopolymer concrete, while holding promise for sustainable pavement construction, faces challenges and limitations. Issues include the absence of standardized procedures and codes, impacting regulatory approval, and the reliance on industrial by-products whose consistent sourcing can be challenging. Long-term durability assessments address concerns about factors like freeze-thaw resistance. Higher initial costs compared to conventional concrete, influenced by specialized materials and production methods, may hinder widespread adoption. Adjustments in construction practices are required due to differences in workability and setting time. Overcoming public unfamiliarity, ensuring safety in handling alkali activators, and promoting industry acceptance are needed are additional hurdles. Addressing these challenges through research, standardization, and increased awareness is crucial for the successful integration of geopolymer concrete into mainstream pavement construction [

96].

The strength superiority of GPC compared to normal concrete is acknowledged; however, its commercialization faces challenges primarily related to the conflicting and insufficiently analyzed durability properties. While conventional concrete benefits from a well-established scientific background and extensively researched durability properties, GPC lacks comprehensive analyses, leading to conflicting observations. A major hindrance in GPC commercialization is the limited understanding of the mineralogy of aluminosilicate materials, with much of the research focusing on engineering properties for bulk design mixes. To address this, there is a need for chemical limit analysis specific to aluminosilicate materials for GPC preparation. Such analysis would facilitate the assessment of different binder sources, their compositions, and their appropriateness for GPC given their variety of technical attributes. A pseudo-ternary diagram representing different binder materials and their spanning components is one suggested technique [

97]. Addressing these knowledge gaps is crucial for advancing the commercial viability of GPC.

The addition of silica fume in GPC has demonstrated potential benefits, such as increased compressive strength [

98] and enhanced resistance to acid attack [

99]. However, the viability of GPC in the long run is yet unknown. The concentration and purity of the alkaline solution, the fly ash's characteristics, the curing schedule, and the alkali activators all have a big impact on the amount of fly ash-based GPC that is produced. Variations in the Si:Al atomic ratios in alkaline solutions lead to distinct GP gels, which in turn affect the GPC's ultimate structure and ionic solution migration [

100]. Alkaline solutions also impact the hydrolyzation of fly ash and GPC porosity, controlling alkali ingression and affecting the durability and mechanical properties. Despite the ease of processing [

101] and consistent properties of metakaolin-based GPC compared to fly ash-based GPC, metakaolin has limitations: it is expensive due to energy-intensive processing, has plate-like particles affecting workability and mechanical properties, and requires elevated curing temperatures, increasing overall costs. These factors present challenges for the utilization of metakaolin in GPC, emphasizing the need for careful material selection in optimizing GPC formulations [

101,

102].

5.1. Technological Challenges

Experience in the realm of mineral processing, especially in fluid-particle interactions from worldwide research on hydrometallurgical process optimization, is essential to the creation of new cement and concretes. Reactivity must be managed by considering the phase chemistry of cement and mineral constituents such as fly ash and slag. To alter the characteristics of concrete, the best processing techniques and binder compositions require an understanding of the many glass phases found in geopolymer precursor materials. Classified fly ash and ground slag from the cement supply chain may require specific activator preparation since they aren't always compatible with the current alkaline activators for geopolymer binders. Furthermore, the unpredictability of fly ash and slag—which are frequently waste materials—especially from different sources is greater than that of OPC, a product that is under quality control. Thus, to consistently produce high-quality geopolymer concretes, online monitoring and optimization of activator types and binder components are essential [

1].

As previously mentioned, effective control of the rheology of fresh concrete is essential to facilitate its placement and finishing. The key to achieving this lies in the manipulation of colloidal interactions, primarily with chemical admixtures such as superplasticizers. It is crucial to ensure that the process of adjusting the rheological properties has no negative influence on the hardened concrete's ultimate qualities. Therefore, the judicious application of chemical admixtures becomes pivotal in striking a balance between the workability of the fresh concrete and the desired characteristics of the cured material [

103,

104]. The currently available superplasticizers in the market are specifically crafted to suit the intricate chemical reactions within the OPC system. Unfortunately, their effectiveness diminishes when applied to the geopolymer system. Similarly, the various admixtures used to regulate properties like slump, air dispersion, and water retention in the OPC system tend to be less efficient in the geopolymer system. This underscores the need to create an entirely new set of admixtures tailored for geopolymer applications. This is a serious obstacle for the emerging geopolymer sector, which must contend with the established OPC market despite its limited size. Developing specialized admixtures is essential to meet the unique requirements of geopolymers and enhance their performance in construction applications.

5.1.1. Variability in Source Materials

In the realm of geopolymer concrete technology, the presence of numerous options for binder materials and activators adds complexity to comprehending the mechanisms and parameters that contribute to strength gain. Important factors identified as affecting the process of strength gain in geopolymer concrete include the type of binder, the ratio of binder to the solution, the ratio of alkali activators, the temperature at which the concrete is cured, the length of time it takes to cure, the concentration of alkali activators, and the Si/Al ratio in both the binder material and the activators. While several of these elements have been the subject of independent research studies, it is still difficult to fully comprehend the combined influence of all these factors. The need persists for a more integrated and holistic exploration of these factors to advance the knowledge and optimization of geopolymer concrete strength development.

5.1.2. Lack of Standardized Testing Procedures

Standardization and regulation issues, including the absence of standardized testing procedures and the need to adapt building codes, hinder acceptance. Ensuring consistent and predictable material properties, optimizing mix designs, and addressing the sensitivity of geopolymer reactions to several factors are significant hurdles. Curing methods, adhesion to aggregates, and adapting construction practices for geopolymer binders pose additional challenges. The cost and availability of raw materials, workability considerations, and the necessity of educating stakeholders for public acceptance are also crucial factors. Successful implementation requires collaborative efforts to develop standards, refine technologies, and demonstrate geopolymer binders' viability in pavement construction.

5.2. Economic Challenges

FAGPC concrete offers several economic advantages over OPC concrete. The approximate cost of producing one cubic meter of geopolymer concrete was reported to be around 45 USD, which is notably lower than the cost of producing Portland cement concrete, estimated at 60 USD per cubic meter. This cost differential provides a direct economic benefit for projects opting for geopolymer concrete [

105].

A comprehensive examination of the sustainability and cost analysis of GPC in comparison to conventional OPC concrete was conducted by Manvendra Verma

et al. in 2022 [

106]. The experimental investigation delved into the physical, chemical, and mechanical properties of both GPC and OPC concretes, specifically for the M30 mix design, while also analyzing the cost and sustainability aspects. The findings reveal distinctions in properties, with GPC demonstrating advantages such as lower setting time, density, and drying shrinkage compared to OPC. Despite similar trends in compressive strength at 28 days, GPC exhibits significantly higher initial three-day strength, along with slightly superior flexural strength and splitting tensile strength. Higher GPC thermal stability up to 800°C is noted, attributed to its use of industrial solid waste. Importantly, GPC's lower embodied energy and a substantial cost reduction of up to 40% at a bulk level emphasize its potential as a more sustainable and cost-effective alternative to OPC concrete [

106].

Othe economic advantages of FAGPC concrete include a low creep, resistance to acid, sulphate, and chloride attack, and fire resistance. These economic considerations contribute to the appeal of GPC as a cost-effective and better alternative cement/binder in various construction applications.

6. Prospects and Recommendations

Ongoing research and development efforts are critical to refining the composition of geopolymer mixtures and addressing any existing challenges. Standardization is a pivotal step, as establishing industry-wide guidelines will provide a framework for consistent material composition, production processes, testing methodologies, and performance criteria. Educating and training construction professionals is essential to foster understanding and confidence in the use of geopolymer concrete. Comprehensive life cycle assessments, coupled with real-world field trials and demonstrations, are important for showcasing the sustainability as well as durability of geopolymer concrete in practical construction usage. Policy support, collaboration between stakeholders, and strategic market promotion are vital for accelerating its adoption. Emphasizing the economic benefits, such as reduced maintenance costs and extended service life, will further contribute to the mainstream acceptance of geopolymer concrete as a sustainable alternative in pavement construction.

7. Conclusion

The development of GPC presents a compelling substitute for conventional OPC. This is attributed to several advantages offered by GPC which include the ability to achieve high early strength, enhanced durability, cost-effectiveness, better performance, and a significant reduction in carbon emissions. Furthermore, it aligns with sustainability goals by minimizing waste production. The characteristics of concrete made with GPC are influenced by numerous factors, with curing conditions, temperature, and duration playing pivotal roles. Notably, GPC concrete exhibits promising fire-resistant properties, making it suitable for use in the construction industry. However, the widespread adoption of GPC concrete faces challenges, particularly in standardization. The composition of fly ash, a key component in geopolymer production, varies, making it difficult to establish universal standards for this type of concrete. To enhance practicality and ease of use on construction sites, there is a need for the development of solid geopolymers that can be conveniently mixed on-site.

GPC or binder holds paramount importance in the future of pavement construction due to its environmental sustainability and potential to mitigate challenges associated with traditional Portland cement-based concrete. By utilizing industrial by-products like fly ash or slag, geopolymer cement reduces reliance on conventional cement production, resulting in a significant reduction in carbon emissions. This eco-friendly approach aligns with the growing emphasis on sustainable construction practices and addresses the environmental impact of the construction industry. Beyond its environmental benefits, geopolymer cement offers practical advantages that can revolutionize pavement construction. The material demonstrates enhanced durability, showcasing resistance to chemical attacks, lower permeability, and reduced susceptibility to corrosion. These properties translate into longer pavement service life, reducing the need for frequent maintenance and replacements. Additionally, geopolymer concrete often exhibits high early strength, facilitating faster construction processes and quicker opening of pavements to traffic. This characteristic contributes to more efficient construction timelines and minimizes disruptions to transportation systems.

GPC also contributes to resource efficiency by repurposing industrial waste materials as valuable construction components. By doing this, the need for pristine material for manufacture is decreased, and the environmental damage caused by disposing of industrial waste is also lessened. While initial costs may vary, geopolymer concrete's potential for long-term cost benefits, stemming from its durability and reduced maintenance requirements, positions it as a cost-effective option for pavement construction.

The continuous innovation and technological advancements in geopolymer technology further enhance its appeal. Ongoing research and development efforts aim to improve its properties and expand its applicability, making geopolymer concrete an increasingly competitive and viable option for pavement construction. As awareness of environmental considerations grows, regulatory frameworks and certification systems may evolve to incentivize or mandate the use of sustainable alternatives like GPC, further bolstering its adoption in the construction industry. In conclusion, geopolymer cement emerges as a transformative and indispensable element in the future of pavement construction, offering a greener, more durable, and resource-efficient alternative to traditional cement-based materials.

Acknowledgments

The Durban University of Technology (DUT), Durban, South Africa is acknowledged for the financial support offered to ADERINTO Gbenga Emmanuel (22176502) in the form of PhD scholarship.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Van Deventer, J.S.J.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer cement. A Rev. Geopolymer Institute, Tech. Pap. 2013, 21, 1–11. [Google Scholar]

- Živica, V.; Palou, M.T.; Križma, M. Geopolymer cements and their properties: a review. Build. Res. J 2015, 61, 85–100. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Mashaan, N.; Othuman Mydin, M.A. Geopolymers: The Green Alternative to Traditional Materials for Engineering Applications. Infrastructures 2023, 8, 98. [Google Scholar] [CrossRef]

- Díaz, E.E.S.; Barrios, V.A.E. Development and use of geopolymers for energy conversion: An overview. Constr. Build. Mater. 2022, 315, 125774. [Google Scholar] [CrossRef]

- Patil, S.; Joshi, D.A.; Menon, R.; Wadhwa, L.K. 2023 Environmental Impact Assessment of fly ash and GGBS based Geopolymer Concrete in Road Construction E3S Web of Conferences vol 405 (EDP Sciences) p 3021.

- Davidovits J Geopolymer Science and Global Warming.

- Drechsler, M.; Graham, A. Geopolymers-an innovative materials technology bringing resource sustainability to construction and mining industries. Proceedings of the IQA Annual Conference 2005, 12–5. [Google Scholar]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A state-of-the-art review on the durability of geopolymer concrete for sustainable structures and infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Soundararajan, E.K.; Vaiyapuri, R. Geopolymer binder for pervious concrete. J. Croat. Assoc. Civ. Eng 2021, 73, 209–18. [Google Scholar]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–6. [Google Scholar] [CrossRef]

- Van der Zee, S.; Zeman, F. Production of carbon negative precipitated calcium carbonate from waste concrete. Can. J. Chem. Eng. 2016, 94, 2153–9. [Google Scholar] [CrossRef]

- Usha, S.; Nair, D.G.; Vishnudas, S. Geopolymer binder from industrial wastes: A review. Int. J. Civ. Eng. Technol 2014, 5, 219–25. [Google Scholar]

- Tahir, M.F.M.; Abdullah, M.M.A.B.; Abd Rahim, S.Z.; Hasan, M.R.M.; Saafi, M.; Jaya, R.P.; Mohamed, R. Potential of industrial By-Products based geopolymer for rigid concrete pavement application. Constr. Build. Mater. 2022, 344, 128190. [Google Scholar] [CrossRef]

- Hoy, M.; Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Arulrajah, A. Recycled asphalt pavement–fly ash geopolymers as a sustainable pavement base material: Strength and toxic leaching investigations. Sci. Total Environ. 2016, 573, 19–26. [Google Scholar] [CrossRef] [PubMed]

- Horpibulsuk, S.; Hoy, M.; Witchayaphong, P.; Rachan, R.; Arulrajah, A. 2017 Recycled asphalt pavement–fly ash geopolymer as a sustainable stabilized pavement material IOP Conference Series: Materials Science and Engineering vol 273 (IOP Publishing) p 12005.

- Bye, G.C. 1999 Portland cement: composition, production and properties (Thomas Telford).

- Pacheco-Torgal, F.; Labrincha, J.; Leonelli, C.; Palomo, A.; Chindaprasit, P. 2015 Handbook of alkali-activated cements, mortars and concretes.

- McLeod, R.S. Ordinary portland cement. BFF Autumn 2005, 30, 33. [Google Scholar]

- Kline, J.; Kline, C. Cement and $\hbox {CO} _ {2} $: What is Happening. IEEE Trans. Ind. Appl. 2014, 51, 1289–94. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Ceramic-like inorganic polymers. J. Ceram. Sci. Technol 2017, 8, 335–50. [Google Scholar]

- Burduhos Nergis, D.D.; Abdullah, M.; Vizureanu, P.; Tahir, M.F.M. 2018 Geopolymers and their uses IOP Conference Series: Materials Science and Engineering vol 374 (IOP Publishing) p 12019.

- Majidi, B. Geopolymer technology, from fundamentals to advanced applications: a review. Mater. Technol. 2009, 24, 79–87. [Google Scholar] [CrossRef]

- Davidovits, J. 2002 years of successes and failures in geopolymer applications. Market trends and potential breakthroughs Geopolymer 2002 conference vol 28 (Geopolymer Institute Saint-Quentin, France; Melbourne, Australia) p 29.

- Zhang, P.; Wang, K.; Li, Q.; Wang, J.; Ling, Y. Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders-A review. J. Clean. Prod. 2020, 258, 120896. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Javed, M.F.; Akbar, A.; Shah, M.I.; Aslam, F.; Alyousef, R. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Khatib, J. 2016 Sustainability of construction materials (Woodhead Publishing).

- Delatte, N. 2018 Concrete pavement design, construction, and performance (Crc Press).

- Thorpe, D.; Zhuge, Y. 2010 Advantages and disadvantages in using permeable concrete as a pavement construction material Proceedings of the 26th Annual Conference of the Association of Researchers in Construction Management (ARCOM 2010) vol 2 (Association of Researchers in Construction Management (ARCOM)) pp 1341–50.

- Tanyildizi, M.; Gökalp, İ. Joint Types and Applications in Rigid Pavements. Innov. Res. Eng. 2023, 471–96. [Google Scholar]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–67. [Google Scholar] [CrossRef]

- Davidovits, J.; Davidovits, R. 2020 Ferro-Sialate Geopolymers (-Fe-O-Si-O-Al-O-) Geopolymer Inst. Libr.

- Zhang, J.; Li, S.; Li, Z.; Gao, Y.; Liu, C.; Qi, Y. Workability and microstructural properties of red-mud-based geopolymer with different particle sizes. Adv. Cem. Res. 2021, 33, 210–23. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–90. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R. Geopolymer: Cement for low carbon economy. Indian Concr J 2014, 88, 29–37. [Google Scholar]

- Kurtoglu, A.E.; Alzeebaree, R.; Aljumaili, O.; Nis, A.; Gulsan, M.E.; Humur, G.; Cevik, A. Mechanical and durability properties of fly ash and slag based geopolymer concrete. Adv. Concr. Constr. 2018, 6, 345. [Google Scholar]

- Neupane, K.; Chalmers, D.; Kidd, P. High-strength geopolymer concrete-properties, advantages and challenges. Adv. Mater. 2018, 7, 15–25. [Google Scholar] [CrossRef]

- Dahou, Z.; Castel, A.; Noushini, A. Prediction of the steel-concrete bond strength from the compressive strength of Portland cement and geopolymer concretes. Constr. Build. Mater. 2016, 119, 329–42. [Google Scholar] [CrossRef]

- Qin, L.; Yan, J.; Zhou, M.; Liu, H.; Wang, A.; Zhang, W.; Duan, P.; Zhang, Z. 2022 Mechanical properties and durability of fiber reinforced geopolymer composites: A review on recent progressd.

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–71. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Deepar, A.J.S.; Sasi, D. 2015 Fracture properties of geopolymer concrete.

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, X.; Wang, F.; Wang, J. Mechanical properties and durability of geopolymer recycled aggregate concrete: A review. Polymers (Basel). 2023, 15, 615. [Google Scholar] [CrossRef] [PubMed]

- Ramujee, K.; PothaRaju, M. Mechanical properties of geopolymer concrete composites. Mater. today Proc. 2017, 4, 2937–45. [Google Scholar] [CrossRef]

- Lavanya, G.; Jegan, J. Evaluation of relationship between split tensile strength and compressive strength for geopolymer concrete of varying grades and molarity. Int. J. Appl. Eng. Res 2015, 10, 35523–7. [Google Scholar]

- Kwasny, J.; Aiken, T.A.; Soutsos, M.N.; McIntosh, J.A.; Cleland, D.J. Sulfate and acid resistance of lithomarge-based geopolymer mortars. Constr. Build. Mater. 2018, 166, 537–53. [Google Scholar] [CrossRef]

- Bhutta, M.A.R.; Ariffin, N.F.; Hussin, M.W.; Lim, N. Sulfate and sulfuric acid resistance of geopolymer mortars using waste blended ash. J. Teknol. 2013, 61, 1–5. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Debbarma, S.; Rashid, R.S.M. Fire resistance of geopolymer concrete: A critical review. Constr. Build. Mater. 2022, 324, 126722. [Google Scholar] [CrossRef]

- Yuksel, I. 2018 Blast-furnace slag Waste and supplementary cementitious materials in concrete (Elsevier) pp 361–415.

- Matalkah, F.; Soroushian, P. Freeze thaw and deicer salt scaling resistance of concrete prepared with alkali aluminosilicate cement. Constr. Build. Mater. 2018, 163, 200–13. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA fiber on the abrasion and cracking resistance, pore structure and fractal features of hydraulic concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Maaz, M.; Khan, R.A.; Sharma, R. 2023 Fatigue and fracture behaviour of geopolymer concrete. Mater. Today Proc.

- Deivabalan, B.; Saravanan, D. Fatigue behaviour of geopolymer concrete beam. Int. J. Res. Eng. Sci. Technol 2015, 1, 39–45. [Google Scholar]

- Rambabu, D.; Sharma, S.K.; Abdul Akbar, M. A review on suitability of using geopolymer concrete for rigid pavement. Innov. Infrastruct. Solut. 2022, 7, 286. [Google Scholar] [CrossRef]

- Razak, S.; Zainal, F.F.; Shamsudin, S.R. 2020 Effect of porosity and water absorption on compressive strength of fly ash based geopolymer and OPC Paste IOP conference series: materials science and engineering vol 957 (IOP Publishing) p 12035.

- Tepfers, R. 2012 Concrete technology–porosity is decisive Befestigungstechnik, Bewehrungstechnik und... II. ibidem-Verlag.

- Farhana, Z.F.; Kamarudin, H.; Rahmat, A.; Al Bakri, A.M.M. 2015 The relationship between water absorption and porosity for geopolymer paste Materials Science Forum vol 803 (Trans Tech Publ) pp 166–72.

- Aghaeipour, A.; Madhkhan, M. Effect of ground granulated blast furnace slag (GGBFS) on RCCP durability. Constr. Build. Mater. 2017, 141, 533–41. [Google Scholar] [CrossRef]

- Lingyu, T.; Dongpo, H.; Jianing, Z.; Hongguang, W. Durability of geopolymers and geopolymer concretes: A review. Rev. Adv. Mater. Sci. 2021, 60, 1–14. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the-art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Kulkarni, K.S.; Babu Narayan, K.S.; Yaragal, S.C. 2013 Effect of elevated temperatures on physical and residual strength properties of HPC Proc. International Conference on Innovations in Civil Engineering (ICICE-2013) pp 71–4.

- Harries, K.A.; Sharma, B. 2019 Nonconventional and vernacular construction materials: Characterisation, properties and applications (Woodhead Publishing).

- Farhana, Z.F.; Kamarudin, H.; Rahmat, A.; Al Bakri Abdullah, M.M.; Norainiza, S. Corrosion performance of reinforcement bar in geopolymer concrete compare with its performance in ordinary portland cement concrete: a short review. Adv. Mater. Res. 2013, 795, 509–12. [Google Scholar] [CrossRef]

- Lloyd, N.A.; Rangan, B.V. 2010 Geopolymer concrete: A review of development and opportunities 35th conference on Our World In Concrete & Structures, Singapore pp 25–7.

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Rahman, S.S.; Khattak, M.J. Mechanistic and microstructural characteristics of roller compacted geopolymer concrete using reclaimed asphalt pavement. Int. J. Pavement Eng. 2022, 23, 4385–403. [Google Scholar] [CrossRef]

- Al Bakri, A.M.M.; Kamarudin, H.; Binhussain, M.; Nizar, I.K.; Rafiza, A.R.; Zarina, Y. Comparison of Geopolymer Fly Ash and OPC to the Strength of Concrete.

- Wang, W.; Fan, C.; Wang, B.; Zhang, X.; Liu, Z. Workability, rheology, and geopolymerization of fly ash geopolymer: Role of alkali content, modulus, and water–binder ratio. Constr. Build. Mater. 2023, 367, 130357. [Google Scholar] [CrossRef]

- Favier, A.; Hot, J.; Habert, G.; Roussel, N.; de Lacaillerie, J.-B.d.E. Flow properties of MK-based geopolymer pastes. A comparative study with standard Portland cement pastes. Soft Matter 2014, 10, 1134–41. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Wei, Y.; Li, Z.; Farooqi, M.U. Rheological and viscoelastic characterizations of fly ash/slag/silica fume-based geopolymer. J. Clean. Prod. 2022, 354, 131629. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Snell, C.; Tempest, B.; Gentry, T. Comparison of the thermal characteristics of portland cement and geopolymer cement concrete mixes. J. Archit. Eng. 2017, 23, 4017002. [Google Scholar] [CrossRef]

- Jaya, R.P. 2020 Porous concrete pavement containing nanosilica from black rice husk ash New Materials in Civil Engineering (Elsevier) pp 493–527.

- Deepa Raj, S.; Abraham, R.; Ganesan, N.; Sasi, D. Fracture properties of fibre reinforced geopolymer concrete. Int J Sci Eng Res 2013, 4, 75–80. [Google Scholar]

- Kumar, G.; Mishra, S.S. Effect of recycled concrete aggregate on mechanical, physical and durability properties of GGBS–fly ash-based geopolymer concrete. Innov. Infrastruct. Solut. 2022, 7, 237. [Google Scholar] [CrossRef]

- Ganeshan, M.; Venkataraman, S. Interface shear strength evaluation of self compacting geopolymer concrete using push-off test. J. King Saud Univ. Sci. 2022, 34, 98–107. [Google Scholar] [CrossRef]

- Asha, G.; Antony, J. 2020 Experimental investigation on strength and durability of fly ash and GGBS based geopolymer concrete Proceedings of SECON’19: Structural Engineering and Construction Management 3 (Springer) pp 53–64.

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire resistance behaviour of geopolymer concrete: An overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- da Silva, A.C.R.; Almeida, B.M.; Lucas, M.M.; Candido, V.S.; da Cruz, K.S.P.; Oliveira, M.S.; de Azevedo, A.R.G.; Monteiro, S.N. Fatigue behavior of steel fiber reinforced geopolymer concrete. Case Stud. Constr. Mater. 2022, 16, e00829. [Google Scholar] [CrossRef]

- Katpady, D.N.; Hazehara, H.; Soeda, M.; Kubota, T.; Murakami, S. Durability assessment of blended concrete by air permeability. Int. J. Concr. Struct. Mater. 2018, 12, 1–11. [Google Scholar] [CrossRef]

- Zhou, X.M.; Slater, J.R.; Wavell, S.E.; Oladiran, O. Effects of PFA and GGBS on early-ages engineering properties of Portland cement systems. J. Adv. Concr. Technol. 2012, 10, 74–85. [Google Scholar] [CrossRef]

- Manjunatha, M.; Kvgd, B.; Vengala, J.; Manjunatha, L.R.; Shankara, K.; Patnaikuni, C.K. Experimental study on the use of human hair as fiber to enhance the performance of concrete: A novel use to reduce the disposal challenges. Mater. Today Proc. 2021, 47, 3966–72. [Google Scholar] [CrossRef]

- Asmara, Y.P.; Siregar, J.P.; Tezara, C.; Nurlisa, W.; Jamiluddin, J. Long term corrosion experiment of steel rebar in fly ash-based geopolymer concrete in NaCl solution. Int. J. Corros. 2016, 2016. [Google Scholar] [CrossRef]

- Abd Razak, R.; Abdullah, M.M.A.B.; Hussin, K.; Subaer Yahya, Z.; Mohamed, R.; Abdullah, A. Performance of Sintered Pozzolanic Artificial Aggregates as Coarse Aggregate Replacement in Concrete. Sustain. Waste Util. Bricks, Concr. Cem. Mater. Charact. Prop. Performance, Appl. 2021, 191–210. [Google Scholar]

- Bouaissi, A.; Li, L.; Abdullah, M.M.A.B.; Bui, Q.-B. Mechanical properties and microstructure analysis of FA-GGBS-HMNS based geopolymer concrete. Constr. Build. Mater. 2019, 210, 198–209. [Google Scholar] [CrossRef]

- Habert, G.; De Lacaillerie, J.B.D.; Roussel, N. An environmental evaluation of geopolymer based concrete production: reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–38. [Google Scholar] [CrossRef]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–30. [Google Scholar] [CrossRef]

- Pouhet, R.; Cyr, M. Alkali–silica reaction in metakaolin-based geopolymer mortar. Mater. Struct. 2015, 48, 571–83. [Google Scholar] [CrossRef]

- Xiao, R.; Ma, Y.; Jiang, X.; Zhang, M.; Zhang, Y.; Wang, Y.; Huang, B.; He, Q. Strength, microstructure, efflorescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J. Clean. Prod. 2020, 252, 119610. [Google Scholar] [CrossRef]

- Li, Y.; Shen, J.; Lin, H.; Lv, J.; Feng, S.; Ci, J. Properties and environmental assessment of eco-friendly brick powder geopolymer binders with varied alkali dosage. J. Build. Eng. 2022, 58, 105020. [Google Scholar] [CrossRef]

- Rathod, N.; Chippagiri, R.; Ralegaonkar, R.V. Cleaner production of geopolymer materials: A critical review of waste-derived activators. Mater. Today Proc 2023. [CrossRef]

- Martínez, A.; Miller, S.A. A review of drivers for implementing geopolymers in construction: Codes and constructability. Resour. Conserv. Recycl. 2023, 199, 107238. [Google Scholar] [CrossRef]

- Yahya, Z.; Abdullah, M.; Hussin, K.; Ismail, K.N.; Sandu, A.V.; Vizureanu, P.; Razak, R.A. Chemical and physical characterization of boiler ash from palm oil industry waste for geopolymer composite. Rev. Chim. 2013, 64, 1408–12. [Google Scholar]

- Danish, A.; Ozbakkaloglu, T.; Mosaberpanah, M.A.; Salim, M.U.; Bayram, M.; Yeon, J.H.; Jafar, K. Sustainability benefits and commercialization challenges and strategies of geopolymer concrete: A review. J. Build. Eng. 2022, 105005. [Google Scholar] [CrossRef]

- Arbi, K.; Nedeljkovic, M.; Zuo, Y.; Ye, G. A review on the durability of alkali-activated fly ash/slag systems: advances, issues, and perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–53. [Google Scholar] [CrossRef]

- Okoye, F.N.; Durgaprasad, J.; Singh, N.B. Effect of silica fume on the mechanical properties of fly ash based-geopolymer concrete. Ceram. Int. 2016, 42, 3000–6. [Google Scholar] [CrossRef]

- Živica, V.; Krizma, M. Acidic-resistant slag cement. Mag. Concr. Res. 2013, 65, 1073–80. [Google Scholar] [CrossRef]

- Rangan, B.V. Geopolymer concrete for environmental protection. Indian Concr. J. 2014, 88, 41–59. [Google Scholar]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–7. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Labrincha, J.; Leonelli, C.; Palomo, A.; Chindaprasit, P. 2014 Handbook of alkali-activated cements, mortars and concretes (Elsevier).

- Criado, M.; Palomo, A.; Fernández-Jiménez, A.; Banfill, P.F.G. Alkali activated fly ash: effect of admixtures on paste rheology. Rheol. Acta 2009, 48, 447–55. [Google Scholar] [CrossRef]

- Puertas, F.; Palomo, A.; Fernández-Jiménez, A.; Izquierdo, J.D.; Granizo, M.L. Effect of superplasticisers on the behaviour and properties of alkaline cements. Adv. Cem. Res. 2003, 15, 23–8. [Google Scholar] [CrossRef]

- Nnaemeka O F Strength characteristics of green concrete.

- Verma, M.; Upreti, K.; Vats, P.; Singh, S.; Singh, P.; Dev, N.; Kumar Mishra, D.; Tiwari, B. Experimental analysis of geopolymer concrete: a sustainable and economic concrete using the cost estimation model. Adv. Mater. Sci. Eng. 2022, 2022. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).