Submitted:

09 April 2024

Posted:

09 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

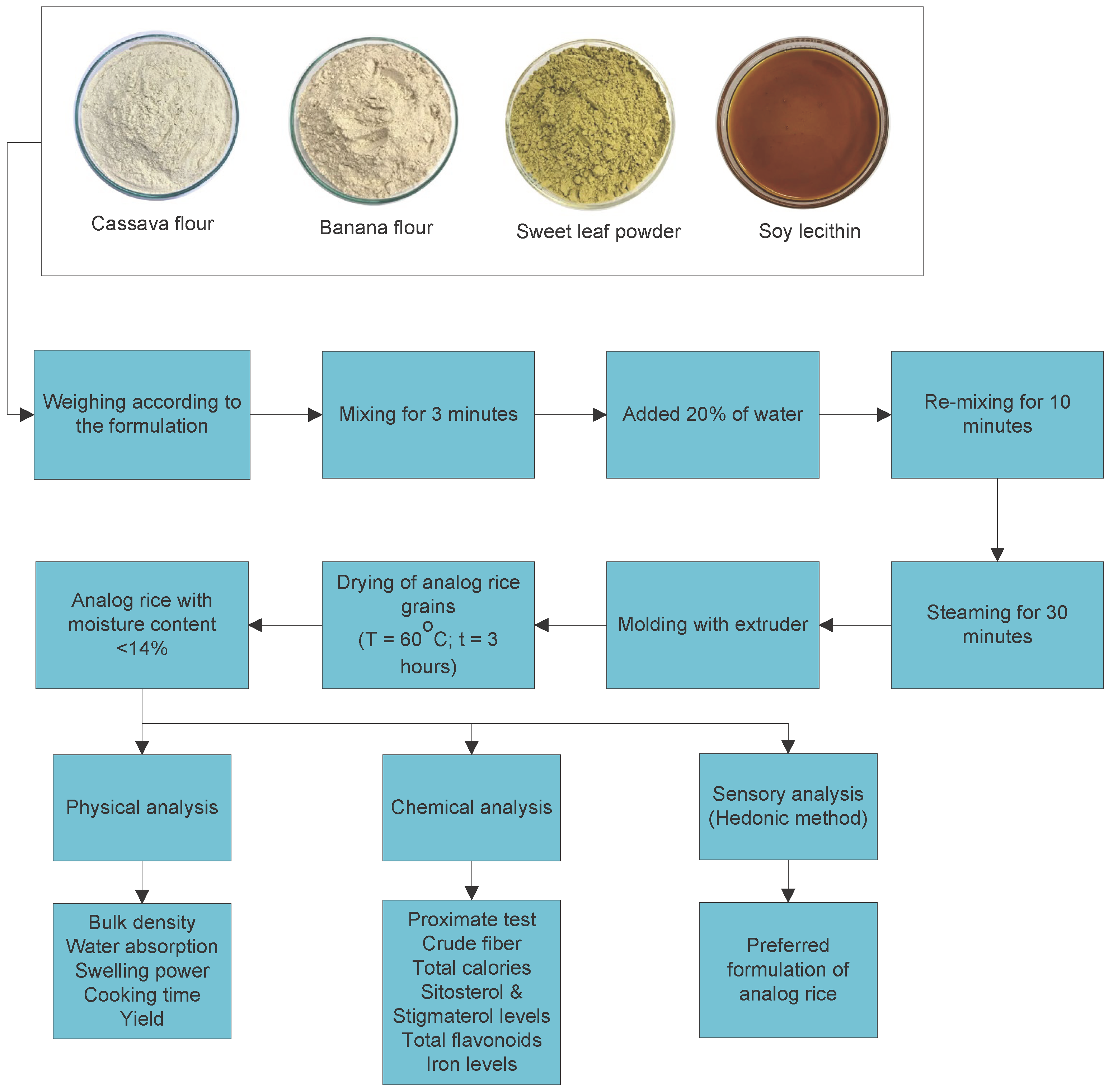

2.1. Production of Analog Rice

2.2. Physical and Chemical Analyses of Analog Rice

2.3. Sensory Analysis of Analog Rice

2.4. Statistical Analysis

3. Results and Discussion

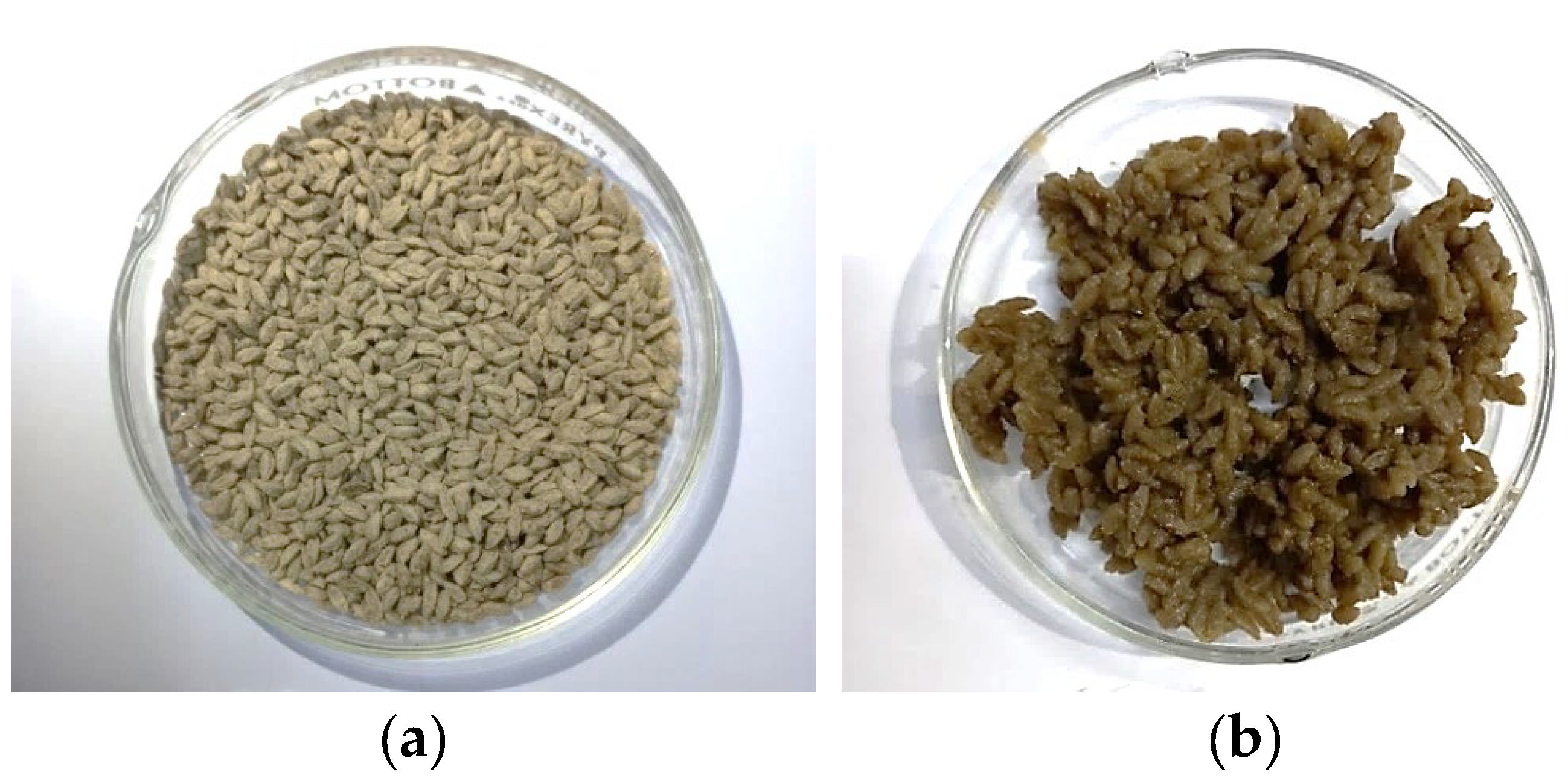

3.1. Analog Rice

3.2. Physical Properties

3.3. Proximate Content

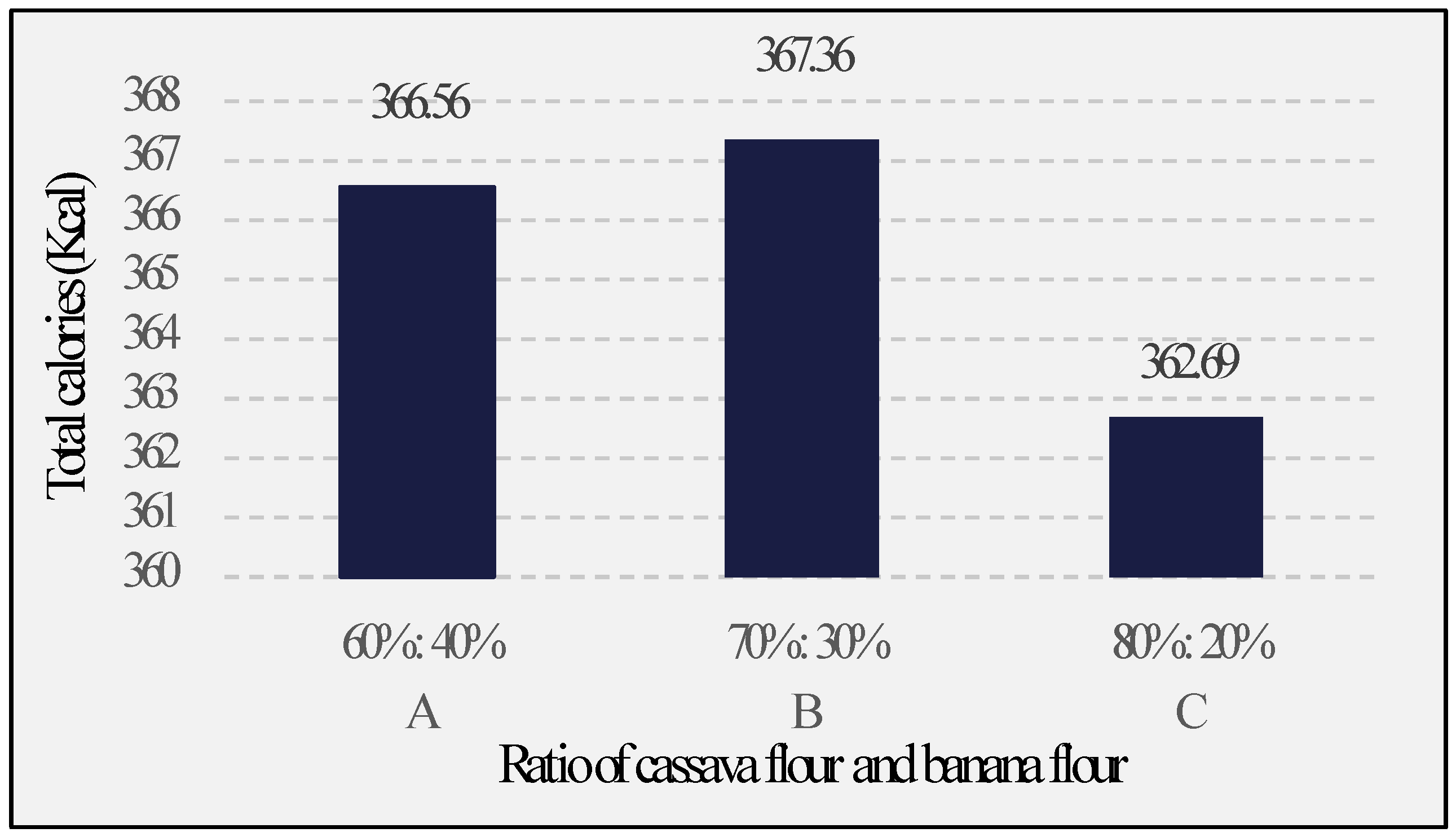

3.4. Total Calories

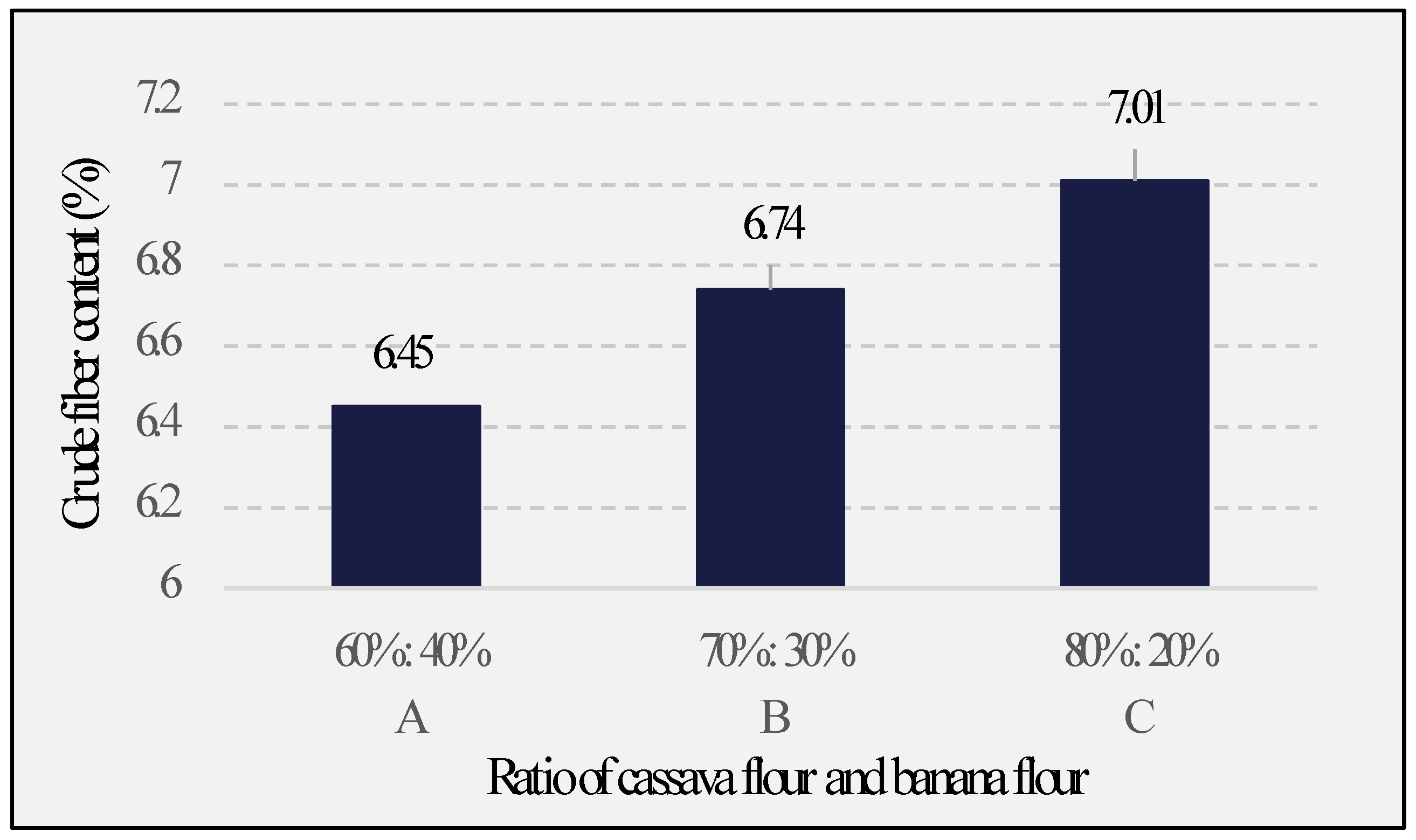

3.5. Crude Fiber Content

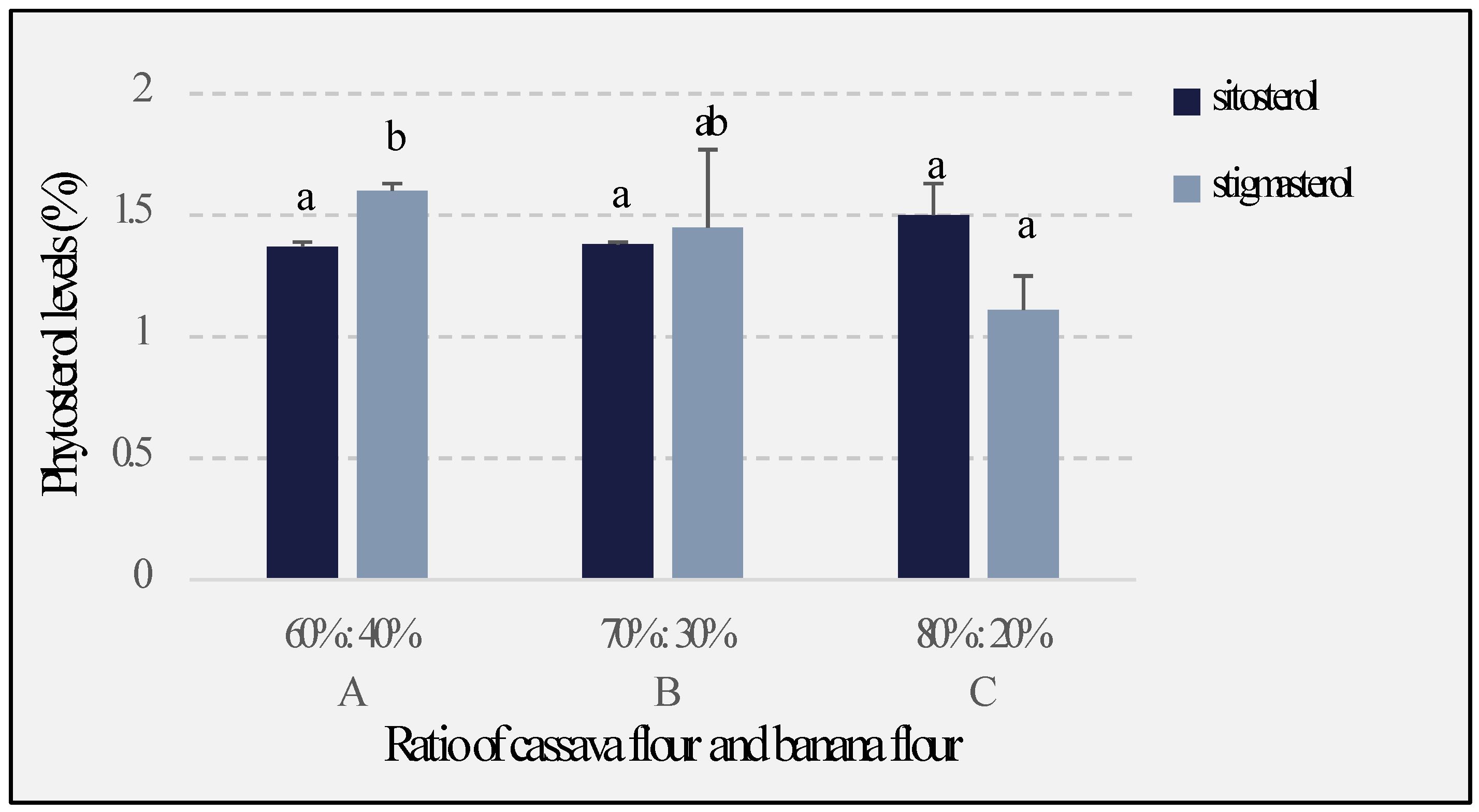

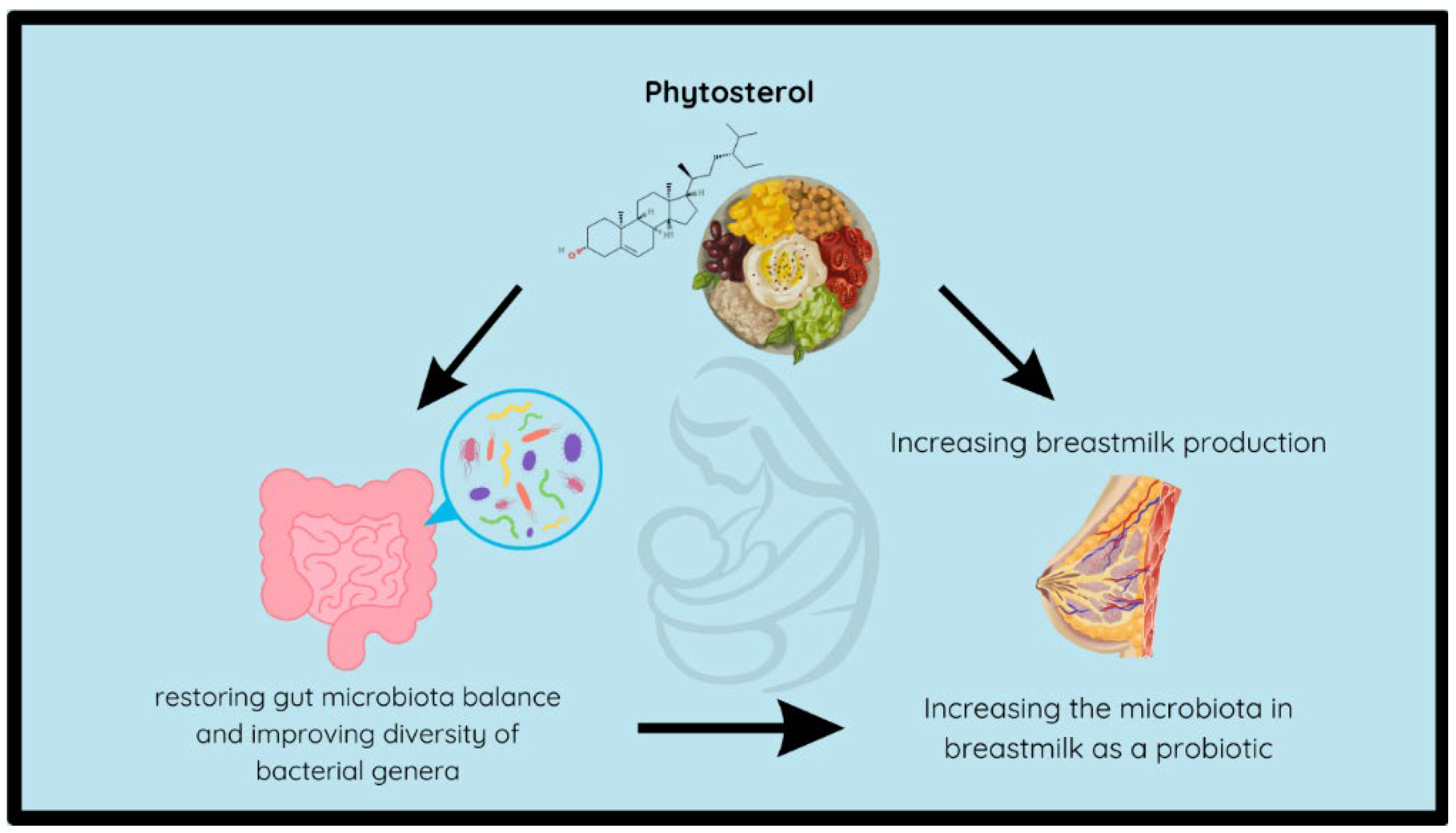

3.6. Phytosterol Levels

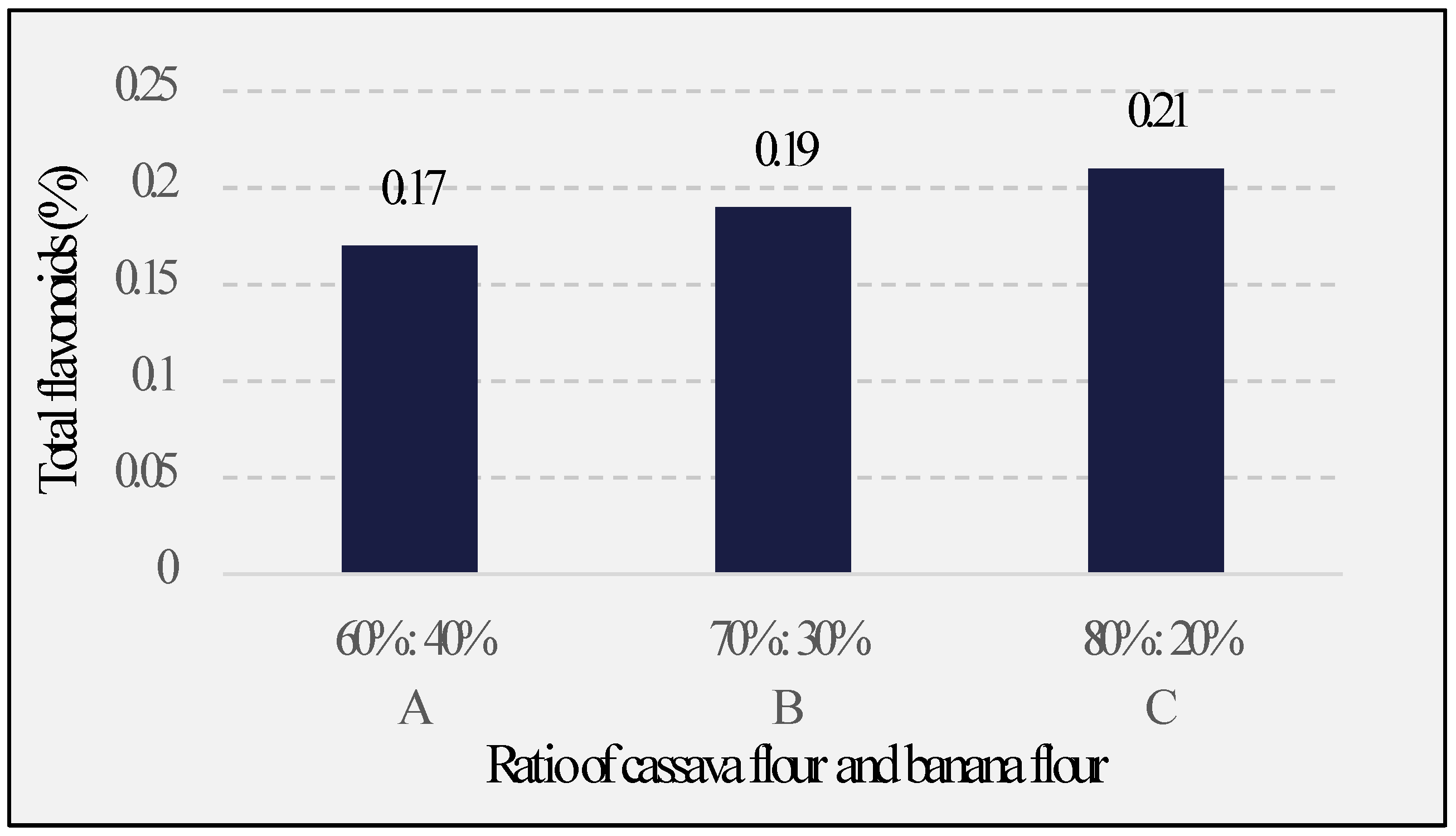

3.7. Total Flavonoids

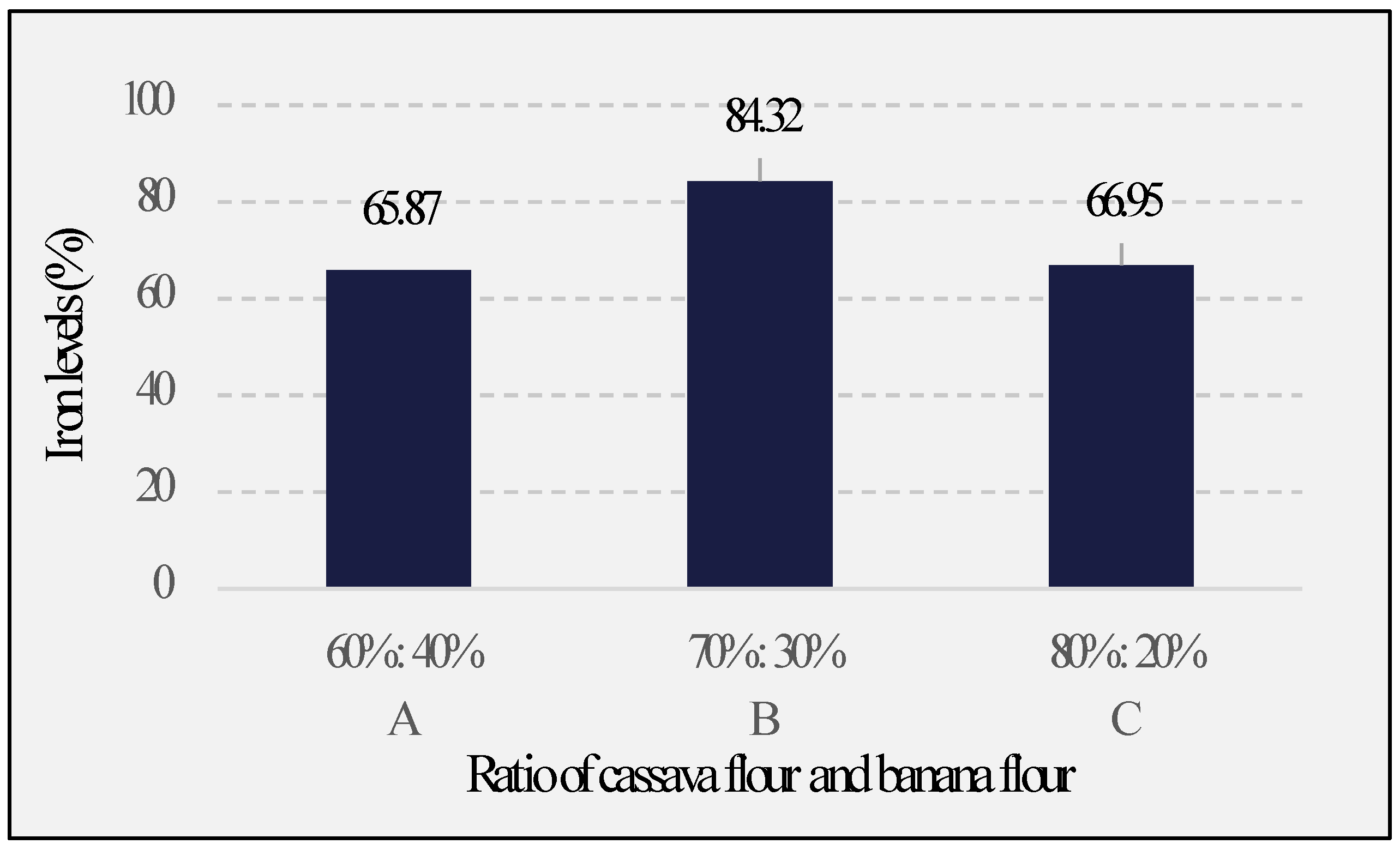

3.8. Levels of Iron (Fe)

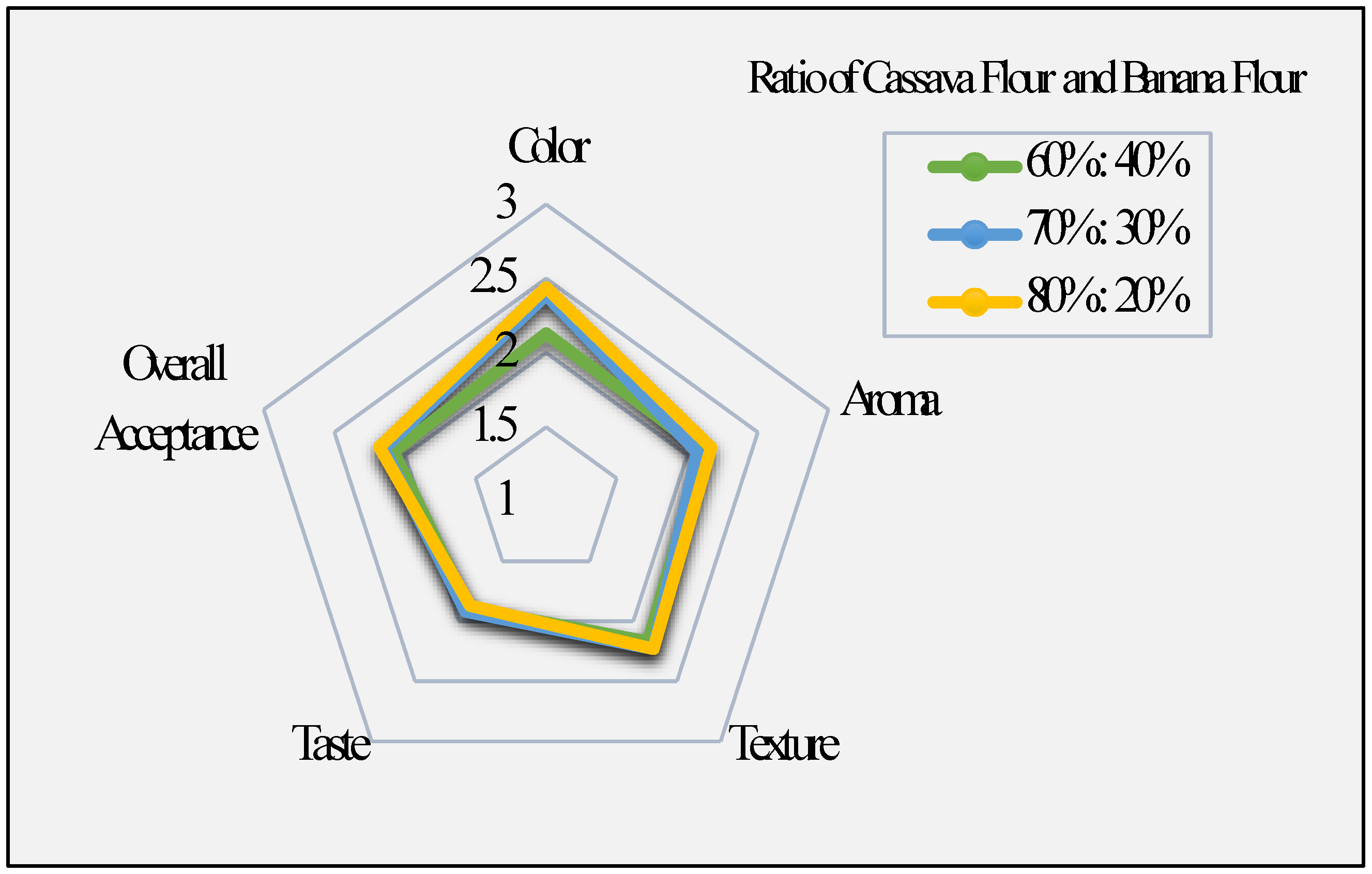

3.9. Sensory Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Budijanto, S. ; Yuliyanti Study of Preparation Sorghum Flour and Application for Analogues Rice Production. Jurnal Teknologi Pertanian 2012, 13, 177–186. [Google Scholar]

- Anggraeni, D.; Solahudin, M. ; Sutrisno Ingredients Formulation of Analogue Rice Based on Location Spesific Flour, Case Studies in the Purworejo District. IOP Conf Ser Earth Environ Sci 2020, 542, 1–9. [Google Scholar] [CrossRef]

- Ruvananda, A.R.; Taufiq, M. Analysis of Factors Affecting Rice Imports in Indonesia. KINERJA 2022, 19, 195–204. [Google Scholar] [CrossRef]

- Pudjihastuti, I.; Sumardiono, S.; Supriyo, E.; Kusumayanti, H. Quality Analog Rice Composite Flour: Modified Starch, Colocasia Esculenta, Canna Edulis Ker High Protein. In Proceedings of the AIP Conference Proceedings; 2018; Vol. 1977. [Google Scholar]

- Gunanegara, R.; Suryawan, A.; Sastrawinata, U.; Surachman, T. Efektivitas Ekstrak Daun Katuk Dalam Produksi Air Susu Ibu Untuk Keberhasilan Menyusui. Jurnal Kedokteran Maranatha 2010, 9, 104–117. [Google Scholar]

- Idris, F.P.; Kanang, B.; Adriani, F.; Asrina, A. Mother’s Behavior in Breastfeeding in Gowa Regency, South Sulawesi (Study on Mothers with Insufficient Breastmilk Production). Gac Sanit 2021, 35, S472–S474. [Google Scholar] [CrossRef] [PubMed]

- Kent, J.C.; Ashton, E.; Hardwick, C.M.; Rea, A.; Murray, K.; Geddes, D.T. Causes of Perception of Insufficient Milk Supply in Western Australian Mothers. Matern Child Nutr 2021, 17, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Mustofa; Yuliani, F. S.; Purwono, S.; Sadewa, A.H.; Damayanti, E.; Heriyanto, D.S. Polyherbal Formula (ASILACT®) Induces Milk Production in Lactating Rats through Upregulation of α-Lactalbumin and Aquaporin Expression. BMC Complement Med Ther 2020, 20, 1–8. [Google Scholar] [CrossRef]

- Soka, S.; Alam, H.; Boenjamin, N.; Agustina, T.W.; Suhartono, M.T. Effect of Sauropus Androgynus Leaf Extracts on the Expression of Prolactin and Oxytocin Genes in Lactating BALB/C Mice. Lifestyle Genom 2010, 3, 31–36. [Google Scholar] [CrossRef]

- Nugraheni, M.; Purwanti, S.; Ekawatiningsih, P. Impact of Analog Rice Derived from Different Composite Flours from Tubers, Germinated Legumes, and Cereals on Improving Serum Markers in Alloxan-Induced Diabetic Rats. Prev Nutr Food Sci 2021, 26, 296–306. [Google Scholar] [CrossRef]

- Pudjihastuti, I.; Sumardiono, S.; Supriyo, E.; Kusumayanti, H. Analog Rice Made from Cassava Flour, Corn and Taro for Food Diversification. In Proceedings of the E3S Web of Conferences; 2019; Vol. 125; pp. 1–4. [Google Scholar]

- Sumardiono, S.; Budiyono; Kusumayanti, H. ; Prakoso, N.I.A.; Paundrianagari, F.P.; Cahyono, H. Influence of Composite Flour Constituents and Extrusion Temperature in the Production of Analog Rice. Food Sci Nutr 2021, 9, 4385–4393. [Google Scholar] [CrossRef]

- Adesina, B.S.; Bolaji, O.T. Effect of Milling Machines and Sieve Sizes on Cooked Cassava Flour Quality. Nigerian Food Journal 2013, 31, 115–119. [Google Scholar] [CrossRef]

- Lu, H.; Guo, L.; Zhang, L.; Xie, C.; Li, W.; Gu, B.; Li, K. Study on Quality Characteristics of Cassava Flour and Cassava Flour Short Biscuits. Food Sci Nutr 2020, 8, 521–533. [Google Scholar] [CrossRef] [PubMed]

- Munandar, A.; Haryanti, I.; Ilham, I.; Yusuf, M.; Alwi, A.; Muhajirin, M. Community Empowerment Through Training in Processing Cassava into Cassava Flour. Lumbung Inovasi: Jurnal Pengabdian kepada Masyarakat 2022, 7, 56–64. [Google Scholar] [CrossRef]

- Bala, A.; Gul, K.; Riar, C.S. Functional and Sensory Properties of Cookies Prepared from Wheat Flour Supplemented with Cassava and Water Chestnut Flours. Cogent Food Agric 2015, 1, 1019815. [Google Scholar] [CrossRef]

- Yudanti, R.Y.; Waluyo, S. The Producing of Analog Rice Based on Banana Flour (Musa Paradisiaca). Jurnal Teknik Pertanian Lampung 2015, 4, 117–126. [Google Scholar]

- Mamuaja, C.F.; Inkiriwang, D.; Lamaega, J. Quality and Preference of Innovative Analog Rice from Purple Sweet Potato, Goroho Banana, and Baruk Sago Section. Eur. Chem. Bull 2023, 12, 1554–1561. [Google Scholar] [CrossRef]

- Kurniasari, I.; Kusnandar, F.; Budijanto, S. Physical Characteristics of Corn-Based Instant Analog Rice with Addition of κ-Carrageenan and Konjac. agriTECH 2020, 40, 64–73. [Google Scholar] [CrossRef]

- Wang, J.P.; An, H.Z.; Jin, Z.Y.; Xie, Z.J.; Zhuang, H.N.; Kim, J.M. Emulsifiers and Thickeners on Extrusion-Cooked Instant Rice Product. J Food Sci Technol 2013, 50, 655–666. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, R.A.; Lawrence, R.M. Breastfeeding: A Guide for the Medical Profession; 2022;

- Younes, M.; Aquilina, G.; Castle, L.; Engel, K.H.; Fowler, P.; Fernandez, M.J.F.; Furst, P.; Gurtler, R.; Husøy, T.; Manco, M.; et al. Opinion on the Re-Evaluation of Lecithins (E 322) as a Food Additive in Foods for Infants below 16 Weeks of Age and Follow-up of Its Re-Evaluation as Food Additive for Uses in Foods for All Population Groups. EFSA Journal 2020, 18. [Google Scholar] [CrossRef]

- Sada, Z.P.; Mahendradatta, M.; Latief, R. Physicochemical Characteristics and Anthocyanin Content of Analog Rice Made from Mocaf, Mung Beans (Vigna Radiata), and Purple Corn (Zea Mays L.). IOP Conf Ser Earth Environ Sci 2021, 807, 022061. [Google Scholar] [CrossRef]

- Rumitasari, A.; Tawali, A.; Laga, A.; Langkong, J.; Mahendradatta, M. Formulation of Analog Rice Made of White Corn (Zea Mays Ceratina) and Mung Beans (Vigna Radiata L) Flour as an Alternative Food in Maintaning a Complete Nutrition. In Proceedings of the Proceedings of The Food Ingredient Asia Conference (FiAC).

- Hasbullah, U.H.A.; Surayya, L.; Syah, I.T. Physical and Nutritional Properties of Analog Rice Based on Modified Cassava Flour and Modified Suweg Flour. Indonesian Food and Nutrition Progress 2023, 19, 9. [Google Scholar] [CrossRef]

- Sulfi, *!!! REPLACE !!!*; Nurhisna, N.I.U.; Abdullah, N.; Tawali, A.B.; Langkong, J.; Mahendradatta, M. Sulfi; Nurhisna, N.I.U.; Abdullah, N.; Tawali, A.B.; Langkong, J.; Mahendradatta, M. Formulation of Analog Rice Using Cassava (Manihot Esculenta) and Mung Bean (Vigna Radiata L.) for Breastfeeding Mothers. In Proceedings of the AIP Conference Proceedings; 2023; Vol. 2596, p. 040029.

- Amir, Y.; Hasneli, Y. ; Erika Hubungan Pemberian ASI Ekslusif Terhadap Tumbuh Kembang Bayi. Jurnal Ners Indonesia 2010, 1, 90–98. [Google Scholar]

- Mehlawat, U.; Puri, S.; Rekhi, T.K. Breastfeeding Practices among Mothers at Birth and at 6 Months in Urban Areas of Delhi-Ncr, India. Jurnal Gizi dan Pangan 2020, 15, 101–108. [Google Scholar] [CrossRef]

- Radharisnawati, N.; Kundre, R.; Pondaag, L. The Relationship Between Fulfillment of Mother’s Nutritional Needs with the Smooth Delivery of Mother’s Milk in Breastfeeding Mothers at the Bahu Community Health Center, Manado City. Jurnal Keperawatan UNSRAT 2017, 5. [Google Scholar]

- Damat, D.; Natazza, R.A.; Wahyudi, V.A. Kajian Pembuatan Beras Analog Berbasis Tepung Komposit Dengan Penambahan Konsentrasi Bubur Rumput Laut (Gracilaria Sp.) Dan Gliserol Monostearat. Food Technology and Halal Science Journal 2020, 3, 174–187. [Google Scholar] [CrossRef]

- Khalil Pengaruh Kandungan Air Dan Ukuran Partikel Terhadap Sifat Fisik Pakan Lokal: Sudut Tumpukan, Daya Ambang Dan Faktor Higroskopis. Media Peternakan Fakultas Peternakan Institut Pertanian Bogor 1999, 22, 33–42.

- Hawa, L.C.; Rhomadhona, W.; Putranto, A.W. Physicochemical Characteristics of Instant Boiled Rice: Study of Sodium Citrate Concentration and Soaking Time. Jurnal Teknik Pertanian Lampung (Agricultural Engineering University of Lampung) 2022, 11, 561–573. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemist (AOAC) Official Methods of Analysis of The Association of Official Agriculture Chemist; 16th ed.; AOAC Inernational: Virginia, 2006;

- SNI. Standar Nasional Indonesia 01-2891-1992 Cara Uji Makanan Dan Minuman; Jakarta, 1992;

- Andika, A.; Kusnandar, F.; Budijanto, S. Physicochemical and Sensory Characteristics of High Protein Multigrain Analog Rice. Jurnal Teknologi dan Industri Pangan 2021, 32, 60–71. [Google Scholar] [CrossRef]

- Lieberman, H.R.; Fulgoni, V.L.; Agarwal, S.; Pasiakos, S.M.; Berryman, C.E. Protein Intake Is More Stable than Carbohydrate or Fat Intake across Various US Demographic Groups and International Populations. Am J Clin Nutr 2020, 112, 180–186. [Google Scholar] [CrossRef]

- Pramono, Y.B.; Nurwantoro; Handayani, D. ; Mulyani, S.; Hari Wibowo, C. Physical, Chemical, Stickiness and Organoleptic Characteristics of Analog White Sweet Potato Rice with the Addition of Pumpkin Flours. IOP Conf Ser Earth Environ Sci 2021, 803. [Google Scholar] [CrossRef]

- Indrayanto, G.; Studiawan, H.; Cholies, N. Isolation and Quantitation of Manogenin and Kammogenin from Callus Cultures of Agave Amaniensis. Phytochemical Analysis 1994, 5, 24–26. [Google Scholar] [CrossRef]

- Sri Widyawati, P.; Maya Suteja, A.; Putut Suseno, T.I.; Monica, P.; Saputrajaya, W.; Liguori, C. Effect of Pigment Color Difference in Organic Rice on Antioxidant Activity. Jurnal Agritech 2015, 34, 399–406. [Google Scholar] [CrossRef]

- Nasution, M.A.; M, M.; Putra, E.D.L. Determination of Iron Content, Potassium, Calcium, and Sodium In Chinese Date Fruit (Ziziphus Jujuba Miller.) Fresh and Boiled In Atomic Adsorption Spectrophotometry. Asian Journal of Pharmaceutical Research and Development 2022, 10, 1–5. [Google Scholar] [CrossRef]

- Arifin, M.Z.; Maharani, S.; Widiaputri, S.I. UJI SIFAT FISIKO KIMIA DAN ORGANOLEPTIK MINUMAN YOGHURT NGEBOON PANORAMA INDONESIA. EDUFORTECH 2020, 5. [Google Scholar] [CrossRef]

- Budi, F.S.; Hariyadi, P.; Budijanto, S.; Syah, D. Extrusion Process Technology of Analog Rice. Food Journal 2013, 22, 263–274. [Google Scholar]

- Bhattacharya, K.R. Analysis of Rice Quality. In Rice Quality; Elsevier, 2013; pp. 431–530.

- Loebis, E.H.; Junaidi, L.; Susanti, I. Characterization of Quality and Nutrition Value of Cooked Rice Mocaf from Rice Analog. Jurnal Biopropal Industri 2017, 8, 33–46. [Google Scholar]

- Yulviatun, A.; Purnamasari, S.; Ariyantoro, A.R.; Atmaka, W. Physical, Chemical, and Organoleptic Characteristics of Rice Analog Made from Mocaf, Corn Flour (Zea Mays L.), and Mung Bean Sprout Flour (Vigna Radiata L.). Jurnal Teknologi Hasil Pertanian 2022, 15, 46. [Google Scholar] [CrossRef]

- Pudjihastuti, I.; Supriyo, E.; Devara, H.R. Pengaruh Rasio Bahan Baku Tepung Komposit (Ubi Kayu, Jagung Dan Kedelai Hitam) Pada Kualitas Pembuatan Beras Analog. Gema Teknologi 2021, 21, 61–66. [Google Scholar] [CrossRef]

- Putri, R.D.A.; Mahanani, T.A.; Simatupang, E.F.; Rohmah, K.A.N.; Lestari, I.P.; Astuti, W.; Prasetiawan, H. Synthesis of Cassava Analog Rice Fortified with Protein Tempe Flour Using Cold Extrusion Method. IOP Conf Ser Earth Environ Sci 2021, 700, 012066. [Google Scholar] [CrossRef]

- Kantrong, H.; Charunuch, C.; Limsangouan, N.; Pengpinit, W. Influence of Process Parameters on Physical Properties and Specific Mechanical Energy of Healthy Mushroom-Rice Snacks and Optimization of Extrusion Process Parameters Using Response Surface Methodology. J Food Sci Technol 2018, 55, 3462–3472. [Google Scholar] [CrossRef]

- Sasmitaloka, K.S.; Widowati, S.; Sukasih, E. Characterization of Physicochemical, Sensory, and Functional Properties of Instant Rice from Low Amylose Rice. Jurnal Penelitian Pascapanen Pertanian 2020, 17, 1–14. [Google Scholar] [CrossRef]

- Suri, S.; Singh, A. Colored Cereals: Beyond Nutritional Values. In Functionality and Application of Colored Cereals; Elsevier, 2023; pp. 47–72.

- Dogan, M.; Aslan, D.; Aktar, T.; Goksel Sarac, M. A Methodology to Evaluate the Sensory Properties of Instant Hot Chocolate Beverage with Different Fat Contents: Multi-Criteria Decision-Making Techniques Approach. European Food Research and Technology 2016, 242, 953–966. [Google Scholar] [CrossRef]

- Hailu, Y.; Maidannyk, V.A.; Murphy, E.G.; McCarthy, N.A. Improving the Physical and Wettability Properties of Skim Milk Powders through Agglomeration and Lecithination. J Food Eng 2023, 357, 111597. [Google Scholar] [CrossRef]

- Hartono, Y.; Sugiyono, S.; Wulandari, N. Formulation and Improvement of Solubility Properties of Chocolate Beverage Powder. Jurnal Teknologi dan Industri Pangan 2018, 29, 185–194. [Google Scholar] [CrossRef]

- Sumardiono, S.; Pudjihastuti, I.; Supriyo, E.; Amalia, R. Physico-Chemical Properties of Calcium-Fortified Analog Rice from Composite Flour (Cassava, Corn, and Snakehead Fish) for Osteoporosis Prevention. Journal of Vocational Studies on Applied Research 2020, 2, 10–15. [Google Scholar]

- Chandra, S.; Singh, S.; Kumari, D. Evaluation of Functional Properties of Composite Flours and Sensorial Attributes of Composite Flour Biscuits. J Food Sci Technol 2014, 52. [Google Scholar] [CrossRef]

- Li, C.; Dhital, S.; Gilbert, R.G.; Gidley, M.J. High-Amylose Wheat Starch: Structural Basis for Water Absorption and Pasting Properties. Carbohydr Polym 2020, 245, 116557. [Google Scholar] [CrossRef]

- Patty, M.D.; Murtini, E.S.; Putri, W.D.R. Physicochemical Characteristics of Starch Noodles Based on Sorghum Flour (Sorghum Bicolor L. Moench) and Sago Flour (Metroxylon Sp). Jurnal Pangan dan Agroindustri 2023, 11, 147–157. [Google Scholar] [CrossRef]

- Nilsuwan, K.; Benjakul, S.; Prodpran, T. Emulsion Stability and Properties of Fish Gelatin-based Films as Affected by Palm Oil and Surfactants. J Sci Food Agric 2016, 96, 2504–2513. [Google Scholar] [CrossRef]

- Voelker, A.L.; Verbeek, G.; Taylor, L.S.; Mauer, L.J. Effects of Emulsifiers on the Moisture Sorption and Crystallization of Amorphous Sucrose Lyophiles. Food Chem X 2019, 3, 100050. [Google Scholar] [CrossRef]

- Yussof, N.S.; Tan, C.P.; Tan, T.B.; Utra, U.; Ramli, uhammad E. Influence of Soy Lecithin and Sodium Caseinate on The Stability and in Vitro Bioaccessibility of Lycopene Nanodispersion. Food Technol Biotechnol 2023, 61, 39–50. [Google Scholar] [CrossRef]

- Zhang, P.; Hamaker, B.R. Banana Starch Structure and Digestibility. Carbohydr Polym 2012, 87, 1552–1558. [Google Scholar] [CrossRef]

- Jayanti, U.; Dasir; Idealistuti Kajian Penggunaan Tepung Tapioka Dari Berbagai Varietas Ubi Kayu (Manihot Esculenta Crantz. ) Dan Jenis Ikan Terhadap Sifat Sensoris Pempek. Jurnal Edible 2017, 6, 59–62. [Google Scholar]

- Annan, H.A.; Oduro-Yeboah, C.; Annan, T.; Akonor, P.T. Sensory Optimization of an Instant Brown Rice Cereal Containing Tigernut and Soybean. J Agric Food Res 2023, 14, 1–7. [Google Scholar] [CrossRef]

- Mandasari, R.; Amanto, B.S.; Ridwan, A. Study of Physical, Chemical, Physicochemical Characteristics and Sensory Properties Black Potato (Coleus Tuberosus) Flour Modified by Lactic Acid Solution. Teknosains Pangan 2015, 4, 1–15. [Google Scholar]

- Vamadevan, V.; Bertoft, E. Observations on the Impact of Amylopectin and Amylose Structure on the Swelling of Starch Granules. Food Hydrocoll 2020, 103, 105663. [Google Scholar] [CrossRef]

- Hu, X.; Li, Z.; Wang, F.; Mu, H.; Guo, L.; Xiao, J.; Liu, Y.; Li, X. Formation of Starch–Lipid Complexes during the Deep-Frying Process and Its Effects on Lipid Oxidation. Foods 2022, 11, 3083. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Kindelspire, J.; Krishnan, P.; Zhao, S. Microstructural, Textural, and Sensory Properties of Whole-Wheat Noodle Modified by Enzymes and Emulsifiers. Food Chem 2017, 223, 16–24. [Google Scholar] [CrossRef]

- Herawati, H.; Kusnandar, F.; Adawiyah, D.R.; Budijanto, S. Processing Technology of Artificial Rice Supporting Food Diversification. Jurnal Penelitian dan Pengembangan Pertanian 2014, 33, 87–94. [Google Scholar]

- Srihari, E.; Sri Lingganingrum, F.; Alvina, I. Rekayasa Beras Analog Berbahan Dasar Campuran Tepung Talas, Tepung Maizena Dan Ubi Jalar. Jurnal Teknik Kimia 2016, 11, 14–19. [Google Scholar]

- Budi, F.S.; Hariyadi, P.; Budijanto, S.; Syah, D. Crystallinity and Hardness of Rice Analogue Produced from Corn Flour through Hot Extrusion Processes. Jurnal Teknologi dan Industri Pangan 2017, 28, 46–54. [Google Scholar] [CrossRef]

- Hedayati, S.; Shahidi, F.; Koocheki, A.; Farahnaky, A.; Majzoobi, M. Influence of Pregelatinized and Granular Cold Water Swelling Maize Starches on Stability and Physicochemical Properties of Low Fat Oil-in-Water Emulsions. Food Hydrocoll 2020, 102, 105620. [Google Scholar] [CrossRef]

- Batista, C. de S.; dos Santos, J.P.; Dittgen, C.L.; Colussi, R.; Bassinello, P.Z.; Elias, M.C.; Vanier, N.L. Impact of Cooking Temperature on the Quality of Quick Cooking Brown Rice. Food Chem 2019, 286, 98–105. [Google Scholar] [CrossRef] [PubMed]

- Romero, H.M.; Zhang, Y. Physicochemical Properties and Rheological Behavior of Flours and Starches from Four Bean Varieties for Gluten-Free Pasta Formulation. J Agric Food Res 2019, 1, 100001. [Google Scholar] [CrossRef]

- Hedayati, S.; Mazaheri Tehrani, M. Effect of Total Replacement of Egg by Soymilk and Lecithin on Physical Properties of Batter and Cake. Food Sci Nutr 2018, 6, 1154–1161. [Google Scholar] [CrossRef] [PubMed]

- Aini, N.; Munarso, J.; Annisa, F.S.; Jayanthi, T.T. Karakteristik Beras Analog Dari Tepung Jagung-Kacang Merah Menggunakan Agar-Agar Sebagai Bahan Pengikat. Jurnal Penelitian Pascapanen Pertanian 2020, 16, 1. [Google Scholar] [CrossRef]

- Van Buren, J.B.; Puga, K.J.; Hoffman, K.C.; Nasados, J.A.; Bass, P.D.; Colle, M.J. Water Binders in Beef Patties Increase Yield and Extend Shelf Life. Transl Anim Sci 2023, 7, 1–7. [Google Scholar] [CrossRef]

- Erni, N.; Kadirman, K.; Fadilah, R. The Influence of Temperature and Length of Drying to the Chemical Characteristic and Organoleptic of Taro Flour (Colocasia Esculenta). Jurnal Pendidikan Teknologi Pertanian 2018, 1, 95–105. [Google Scholar] [CrossRef]

- Nithyalakshmi, V.; Preetha, R. Effect of Cooking Conditions on Physico-Chemical and Textural Properties of Emu (Dromaius Novaehollandiae) Meat. Int Food Res J 2015, 22, 1924–1930. [Google Scholar]

- Thielecke, F.; Nugent, A.P. Contaminants in Grain—A Major Risk for Whole Grain Safety? Nutrients 2018, 10, 1–23. [Google Scholar] [CrossRef]

- Mishra, A.; Mishra, H.N.; Srinivasa Rao, P. Preparation of Rice Analogues Using Extrusion Technology. Int J Food Sci Technol 2012, 47, 1789–1797. [Google Scholar] [CrossRef]

- Wickramasinghe, Y.W.H.; Wickramasinghe, I.; Wijesekara, I. Effect of Steam Blanching, Dehydration Temperature & Time, on the Sensory and Nutritional Properties of a Herbal Tea Developed from Moringa Oleifera Leaves. Int J Food Sci 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Y.; Cao, Y.; Huang, W.; Zhang, S.; Xia, W.; Jiang, Q. Effect of Steam Cooking on Textural Properties and Taste Compounds of Shrimp (Metapenaeus Ensis). Food Sci Technol Res 2016, 22, 75–81. [Google Scholar] [CrossRef]

- Afifah, N.; Ratnawati, L.; Indrianti, N.; Sarifudin, A. The Effect of Pre-Drying Treatments on the Quality of Dehydrated Ground Beef. IOP Conf Ser Earth Environ Sci 2021, 924, 012006. [Google Scholar] [CrossRef]

- SNI. Standar Nasional Indonesia 01-7111.1-2005 Makanan Pendamping Air Susu Ibu (MP-ASI)-Bagian 1: Bubuk Instan; Jakarta, 2005;

- The Indonesian Food and Drug Authority Rencana Aksi Nasional: Gerakan Menuju Pangan Jajanan Sekolah Yang Aman, Bermutu, Dan Bergizi; Jakarta, 2014;

- Damanik, M.; Rosmiati, R.; Permatasari, T.; Surbakti, T.A.; Ayuni, S. Ash, Protein And Salinity Analysis Of Integrated Formulation Of Herbs And Spices In Typical Simalungun “ Tinuktuk ” North Sumatera -Indonesia. International Journal of Health and Pharmaceutical 2023, 545–549. [Google Scholar] [CrossRef]

- Nurwin, A.F.; Dewi, E.N.; Romadhon, R. The Effect of Carrageenan Flour Addition on the Making of Blood Cockles (Anadara Granosa) Meatballs. Jurnal Ilmu dan Teknologi Perikanan 2019, 1, 39–46. [Google Scholar] [CrossRef]

- Ismail, B.P. Food Analysis Laboratory Manual- Ash Content Determination. Food Analysis Laboratory Manual 2017. [Google Scholar]

- Liu, K. Effects of Sample Size, Dry Ashing Temperature and Duration on Determination of Ash Content in Algae and Other Biomass. Algal Res 2019, 40, 1–5. [Google Scholar] [CrossRef]

- Butina, E.A.; Gerasimenko, E.O.; Bugaets, I.A.; Dubrovskaia, I.A. Comparative Analysis of the Physiological Value of Lecithins Obtained from Different Types of Raw Materials. Journal of Pharmaceutical Sciences and Research 2017, 9, 2493–2497. [Google Scholar]

- Asgar, A.; Musaddad, D.; Rahayu, S.; Levianny, P.S. Effect of Temperature and Drying Time on Chemical, Physical and Organoleptic Characteristics of Dry Winged Beans. IOP Conf Ser Earth Environ Sci 2022, 1024, 012004. [Google Scholar] [CrossRef]

- Sonkamble, M.; Pandhure, N. Effect of Drying Methods on Ash Contents and Moisture Content of Leafy Vegetables. International Journal of Science and Research 2015, 6, 936–938. [Google Scholar]

- Barciela-Alonso, M.C.; Bermejo-Barrera, P. Variation of Food Mineral Content during Industrial and Culinary Processing. In Handbook of Mineral Elements in Food; Wiley, 2015; pp. 163–176.

- Nurjanah; Suwandi, R. ; Aisyah, E.N.; Hidayat, T. Changes in Mineral Content and Vitamin A of Cobia (Rachycentron Canadum) Due to the Steaming Process. IOP Conf Ser Earth Environ Sci 2023, 1137, 012032. [Google Scholar] [CrossRef]

- Finirsa, M.A.; Warsidah, W.; Sofiana, M.S.J. ; Risko Physicochemical Characteristics of Analogue Rice from the Combination of Seaweeds Eucheuma Cottonii, Mocaf, and Sago. Oseanologia 2022, 1, 69–76. [Google Scholar] [CrossRef]

- Martín-Hernández, C.; Bénet, S.; Marvin-Guy, L.F. Characterization and Quantification of Proteins in Lecithins. J Agric Food Chem 2005, 53, 8607–8613. [Google Scholar] [CrossRef]

- Mortensen, A.; Aguilar, F.; Crebelli, R.; Di Domenico, A.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Lambré, C.; Leblanc, J.; et al. Re-evaluation of Lecithins (E 322) as a Food Additive. EFSA Journal 2017, 15, 1–80. [Google Scholar] [CrossRef]

- Adelina, F.; Estiasih, T.; Widyaningsih, T.D.; Harijono, H. Cassava Based Artificial Rice : A Review. Jurnal Teknologi Pertanian 2019, 20, 11–24. [Google Scholar] [CrossRef]

- Novrini, S. The Quality of Analog Corn Rice with the Addition of Several Types of Flour. J. Ilmu Pertanian 2020, 8, 267–271. [Google Scholar]

- Rasyid, M.I.; Yuliana, N.D.; Budijanto, S. Sensory and Physicochemical Characteristics of Sorghum Rice Analogue by Mixed Spices Addition. Agritech 2017, 36, 394–403. [Google Scholar] [CrossRef]

- Noviasari, S.; Kusnandar, F.; Setiyono, A.; Budijanto, S. Physical, Chemical, and Sensory Characteristics of Rice Analogue from Non Rice Ingredients. Food Journal 2017, 26. [Google Scholar]

- Septyaningsih, D.H.; Wirasti, H. ; Rahmawati; Wibowo, E.A.P. Analisis Kandungan Beras Analog Berbahan Dasar Umbi Gembili (Dioscorea Esculenta). Prosiding Seminar Nasional XI “Rekayasa Teknologi Industri dan Informasi.

- Jannah, M.; Tamrin, T.; Sugianti, C.; Warji, W. The Production and Physical Characteristics Test of Analog Rice Made from Cassava Flour Containing Protein of Shrimp. Jurnal Teknik Pertanian Lampung 2015, 4, 51–56. [Google Scholar]

- Sachriani, S.; Yulianti, Y. Analisis Kualitas Sensori Dan Kandungan Gizi Roti Tawar Tepung Oatmeal Sebagai Pengembangan Produk Pangan Fungsional. JST (Jurnal Sains Terapan) 2021, 7, 26–35. [Google Scholar] [CrossRef]

- Kusmiyati, F.; Lukiwati, D.R.; Kristanto, B.A.; Herwibawa, B. Glycemic Index of Ten Commercially Indonesian Rice Cultivars. IOP Conf Ser Earth Environ Sci 2019, 250, 012028. [Google Scholar] [CrossRef]

- Novitasari, E.; Arief, R.W. Analysis of Chemical Characteristic of Casava Flour from Klenteng and Casessart (UJ5) Varieties. Jurnal Penelitian Pertanian Terapan 2018, 18, 52–58. [Google Scholar] [CrossRef]

- Rosalina, Y.; Susanti, L.; Silsia, D.; Setiawan, R. Characteristics of Banana Flour from Bengkulu Local Banana Varieties. Industria: Jurnal Teknologi dan Manajemen Agroindustri 2018, 7, 153–160. [Google Scholar] [CrossRef]

- Anju, T.; Rai, N.K.S.R.; Kumar, A. Sauropus Androgynus (L.) Merr.: A Multipurpose Plant with Multiple Uses in Traditional Ethnic Culinary and Ethnomedicinal Preparations. Journal of Ethnic Foods 2022, 9, 10. [Google Scholar] [CrossRef]

- Handayani, S.; Setyawati, I.; Ariendha, D.S.R.; Pratiwi, Y.S.; Idyawati, S.; Fatmawati, N. The Effect of Katuk Leaf (Sauropusandrogynus L. Merr.) Biscuit Consumption toward Increasing Breastmilk Volume on the 10th Day. J Phys Conf Ser 2020, 1594, 012051. [Google Scholar] [CrossRef]

- Krisnawati, A. Soybeans as Source of Functional Food. Iptek Tanaman Pangan 2017, 12, 57–65. [Google Scholar]

- Rahayu Sihmawati, R.; Agustiyah Rosida, D. Proximate Analysis of Shredded Banana Corm With Tempeh Flour And Lechitin Fortification. STIGMA: Jurnal Matematika dan Ilmu Pengetahuan Alam Unipa 2020, 13, 1–7. [Google Scholar] [CrossRef]

- Ramu, R.; Shirahatti, P.S.; Nayakavadi, S.; R, V.; Zameer, F.; Dhananjaya, B.L.; Prasad MN, N. The Effect of a Plant Extract Enriched in Stigmasterol and β-Sitosterol on Glycaemic Status and Glucose Metabolism in Alloxan-Induced Diabetic Rats. Food Funct 2016, 7, 3999–4011. [Google Scholar] [CrossRef]

- Petrus, A.J.A. Sauropus Androgynus (L.) Merrill-A Potentially Nutritive Functional Leafy-Vegetable. Asian Journal of Chemistry 2013, 25, 9425–9433. [Google Scholar] [CrossRef]

- Bassi, G.; Sidhu, S.K.; Mishra, S. The Expanding Role of Mitochondria, Autophagy and Lipophagy in Steroidogenesis. Cells 2021, 10, 1851. [Google Scholar] [CrossRef] [PubMed]

- Kang, E.-J.; Hong, S.-H.; Lee, J.-E.; Kim, S.C.; Yang, H.-S.; Yi, P. in; Lee, S.-M.; An, B.-S. Pregnenolone Sulfate Regulates Prolactin Production in the Rat Pituitary. Journal of Endocrinology 2016, 230, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Manoppo, J.I.C.; Nurkolis, F.; Gunawan, W. Ben; Limen, G.A.; Rompies, R.; Heroanto, J.P.; Natanael, H.; Phan, S.; Tanjaya, K. Functional Sterol Improves Breast Milk Quality by Modulating the Gut Microbiota: A Proposed Opinion for Breastfeeding Mothers. Front Nutr 2022, 9, 1–6. [Google Scholar] [CrossRef] [PubMed]

- van den Elsen, L.W.J.; Garssen, J.; Burcelin, R.; Verhasselt, V. Shaping the Gut Microbiota by Breastfeeding: The Gateway to Allergy Prevention? Front Pediatr 2019, 7, 1–10. [Google Scholar] [CrossRef]

- Indrayani, D.; Shahib, M.N.; Husin, F. The Effect of Katuk (Sauropus Androgunus (L) Merr) Leaf Biscuit on Increasing Prolactine Levels of Breastfeeding Mother. Jurnal Kesehatan Masyarakat 2020, 16, 1–7. [Google Scholar] [CrossRef]

- Lutfiani, L.; Nasrulloh, N. Total Flavonoids and Antioxidant Activity of Torbangun - Katuk Food Bar on the Effectiveness of Breast Milk Production. Amerta Nutrition 2023, 7, 88–97. [Google Scholar] [CrossRef]

- Magdalena, S.; Yuwono, B.; Dharmayanti, A.W.S. The Effect of Star Gooseberry (Sauropus Androgynus (L.) Merr.) to Bleeding Time of Male Wistar Rats as an Alternative Antithrombotic Drug. e-jurnal Pustaka KesehatanPustaka Kesehatan 2015, 3, 212–216. [Google Scholar]

- Pragasam, A.; Prithvi, J.; Majalikar, P.; Tallur, P.N.; Naik, V.M. Chemical Science Review and Letters Secondary Anti-Oxidative Effect of Soya Lecithin in Bulk Soya Bean Oil. Chem Sci Rev Lett 2018, 7, 892–899. [Google Scholar]

- Choe, J.; Oh, B.; Choe, E. Effect of Soybean Lecithin on Iron-Catalyzed or Chlorophyll-Photosensitized Oxidation of Canola Oil Emulsion. J Food Sci 2014, 79. [Google Scholar] [CrossRef]

- ElGamal, R.; Song, C.; Rayan, A.M.; Liu, C.; Al-Rejaie, S.; ElMasry, G. Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products: A Comprehensive Overview. Agronomy 2023, 13, 1–21. [Google Scholar] [CrossRef]

- Gao, Y.; Xia, W.; Shao, P.; Wu, W.; Chen, H.; Fang, X.; Mu, H.; Xiao, J.; Gao, H. Impact of Thermal Processing on Dietary Flavonoids. Curr Opin Food Sci 2022, 48, 100915. [Google Scholar] [CrossRef]

- Syafarina, M.; Taufiqurrahman, I. ; Edyson Perbedaan Total Flavonoid Antara Tahapan Pengeringan Alami Dan Buatan Pada Ekstrak Daun Binjai (Mangifera Caesia). Kedokteran Gigi 2017, 1, 84–88. [Google Scholar]

- Erningtyas, C.; Amalia, R.B.; Faizah, Z. Overview of Protein and Fe Intake With The Event of Anemia In Adolescent: Systematic Review. PLACENTUM: Jurnal Ilmiah Kesehatan dan Aplikasinya 2023, 10, 170–179. [Google Scholar] [CrossRef]

- Savarino, G.; Corsello, A.; Corsello, G. Macronutrient Balance and Micronutrient Amounts through Growth and Development. Ital J Pediatr 2021, 47, 1–14. [Google Scholar] [CrossRef]

- Jorgensen, J.M.; Yang, Z.; Lönnerdal, B.; Chantry, C.J.; Dewey, K.G. Effect of Iron Supplementation during Lactation on Maternal Iron Status and Oxidative Stress: A Randomized Controlled Trial. Matern Child Nutr 2017, 13. [Google Scholar] [CrossRef] [PubMed]

- Astuti, R.; Aminah, S.; Syamsianah, A. Nutritional Composition of Soyben Tempeh Fortified with Iron and Vitamin A on Uncook and Cook Soyben Tempeh. AGRITECH 2014, 34. [Google Scholar] [CrossRef]

- Kusnadi, K.; Tivani, I.; Amananti, W. Analisa Kadar Vitamin Dan Mineral Buah Karika Dieng (Carica Pubescens Lenne) Dengan Menggunakan Spektrofotometri UV-Vis Dan AAS. Parapemikir : Jurnal Ilmiah Farmasi 2016, 5, 81–87. [Google Scholar] [CrossRef]

- Prasetyo, A.F.; -, F.; Isaura, E.R. The Difference of Iron Level Based on the Cooking Time and Methods Applied on the Tempeh and Beef Liver: An Experimental Study. Media Gizi Indonesia 2022, 17, 159–167. [Google Scholar] [CrossRef]

- Kwartiningsih, E.; Ramadhani, A.N.; Putri, N.G.A.; Damara, V.C.J. Chlorophyll Extraction Methods Review and Chlorophyll Stability of Katuk Leaves (Sauropus Androgynous). J Phys Conf Ser 2021, 1858, 012015. [Google Scholar] [CrossRef]

- Alvarez-Ramirez, J.; Vernon-Carter, E.J.; Carrillo-Navas, H.; Meraz, M. Effects of Cooking Temperature and Time on the Color, Morphology, Crystallinity, Thermal Properties, Starch-Lipid Complexes Formation and Rheological Properties of Roux. LWT 2018, 91, 203–212. [Google Scholar] [CrossRef]

- Salsabila, A.; Agustin, R.; Budiati, T. Effect of Addition Katuk Flour on Organoleptic and Physical Quality of Bread. JOFE : Journal of Food Engineering 2022, 1, 66–79. [Google Scholar] [CrossRef]

- Utari, A.C.A.; Moviana, Y.; Judiono, J.; Hastuti, W.; Fauziyyah, R.N.; Mulyo, G.P.E. Analysis Quality of Boba (Tapioca Pearl) Katuk Leaves (Sauropus Androgynus) and Mung Beans (Vigna Radiata l.) As an Alternative Snack Rich in Protein and Iron for Anemic Teenagers. Jurnal Gizi dan Dietetik 2023, 2, 38–45. [Google Scholar] [CrossRef]

- Arza, P.A.; Satriana, N.; Ilham, D. Pengaruh Penambahan Ekstrak Daun Katuk (Sauropus Androgynus L. Merr) Terhadap Mutu Organoleptik Dan Kadar Vitamin C Pada Donat. Prosiding Seminar Kesehatan Perintis E 2018, 1. [Google Scholar]

- Naknean, P.; Meenune, M. Factors Affecting Retention and Release of Flavour Compounds in Food Carbohydrates. Int Food Res J 2010, 17, 23–34. [Google Scholar]

- Arief, R.W.; Novitasari, E.; Asnawi, R. Food Diversification of Cassava as Functional Food Instead of Rice in Lampung. Planta Tropika: Journal of Agro Science 2018, 6, 62–69. [Google Scholar] [CrossRef]

- Kusmiandany, E.; Pratama, Y.; Pramono, Y.B. The Effect of Gatot (Fermented Dried Cassava) and Red Bean Ratio on Water Content and Organoleptic Characteristics of The “Gatotkaca” Analog Rice. Journal of Applied Food Technology 2019, 6. [Google Scholar] [CrossRef]

| Sample Code | Cassava Flour | Banana Flour | Katuk Leaf Powder | Soy Lecithin | Water | Total | ||

|---|---|---|---|---|---|---|---|---|

| G | %* | g | %* | %* | %* | %* | %* | |

| A | 46.20 | 60 | 30.80 | 40 | 3 | 0 | 20 | 100 |

| B | 53.72 | 70 | 22.83 | 30 | 3 | 0.25 | 20 | 100 |

| C | 61.20 | 80 | 15.30 | 20 | 3 | 0.50 | 20 | 100 |

| Physical Properties | Ratio of Cassava and Banana Flours | ||

|---|---|---|---|

| A (60% : 40%) | B (70% : 30%) | C (80% : 20%) | |

| Bulk Density (g/ml) | 0,57 ± 0,02 | 0,56 ± 0,01 | 0,55 ± 0,02 |

| Water Absorption (%) | 76,54 ± 1,78 | 75,08 ± 1,53 | 77,27 ± 1,15 |

| Swelling Power (%) | 29,45 ± 5,17 | 27,93 ± 5,01 | 31,64 ± 5,06 |

| Cooking Time (minutes) | 14,15 ± 0,09 | 14,06 ± 0,07 | 14,07 ± 0,03 |

| Yield (%) | 58,58 ± 9,25 | 61,73 ± 5,51 | 67,67 ± 1,91 |

| Proximate Properties (%) | Ratio of Cassava and Banana Flours | ||

|---|---|---|---|

| A (60% : 40%) | B (70% : 30%) | C (80% : 20%) | |

| Moisture content | 7,15 ± 0,21 | 7,36 ± 0,69 | 7,61± 0,44 |

| Ash content | 2,20 ± 0,04 | 1,54 ± 1,29 | 2,32 ± 0,10 |

| Protein content | 2,77 ± 0,15 | 2,76 ± 0,12 | 3,07 ± 0,21 |

| Fat content | 0,80 ± 0,02a | 0,60 ± 0,07b | 0,48 ± 0,06c |

| Carbohydrate content | 87,08 ± 0,29 | 87,73 ± 1,88 | 86,53 ± 0,74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).