Submitted:

11 April 2024

Posted:

12 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

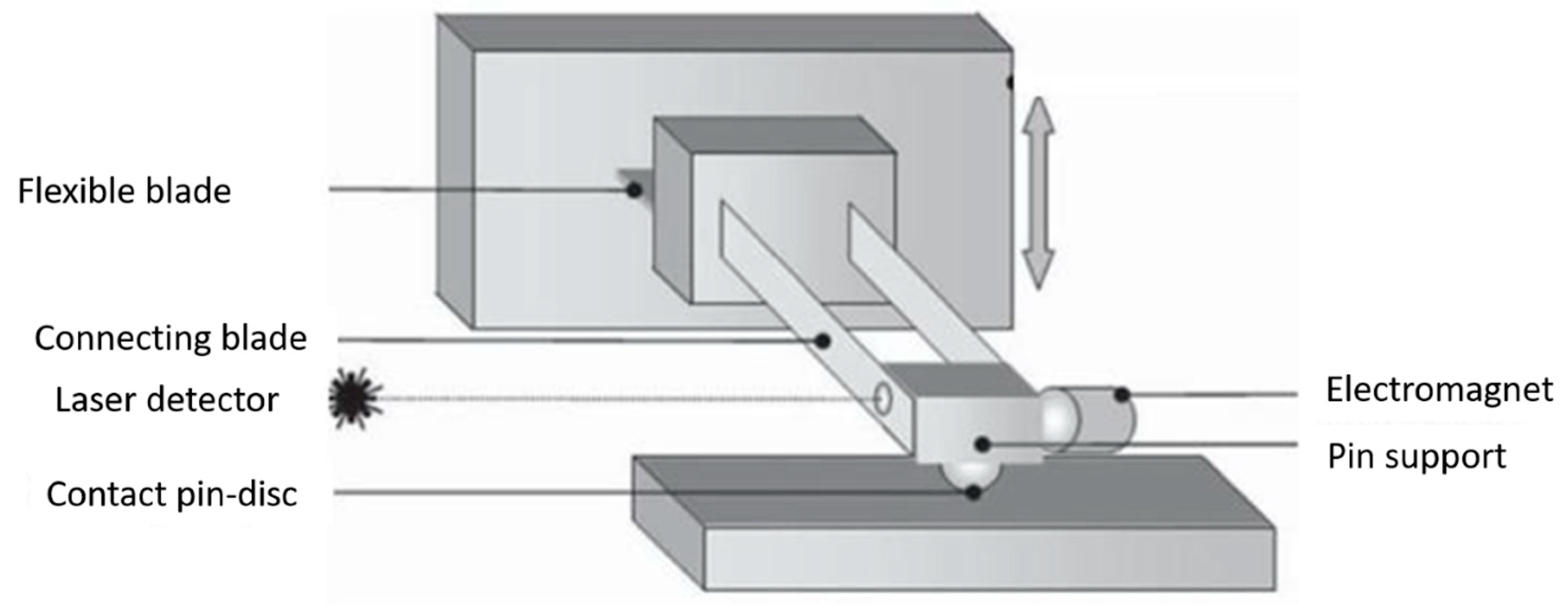

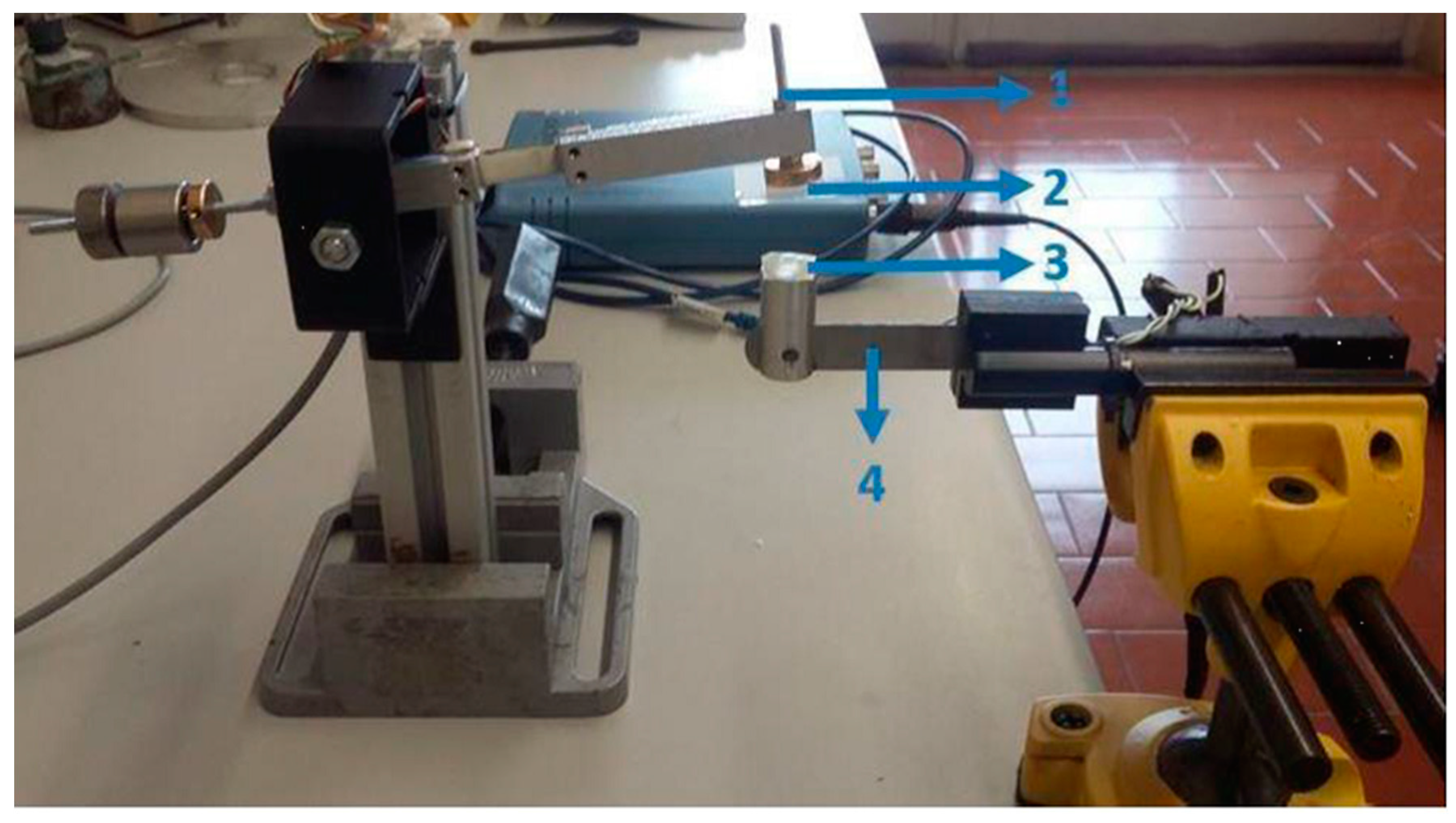

2. Materials and Methods

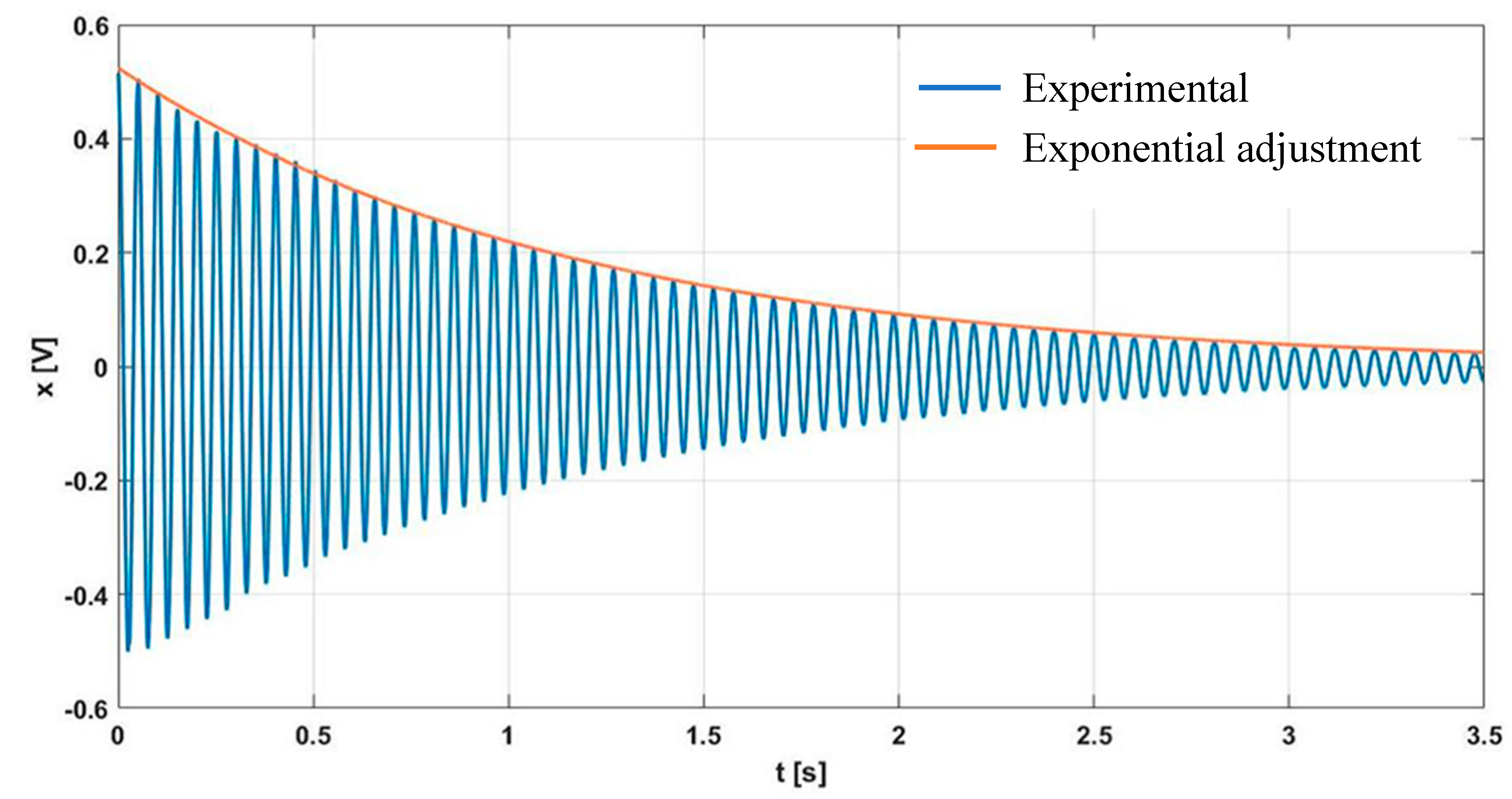

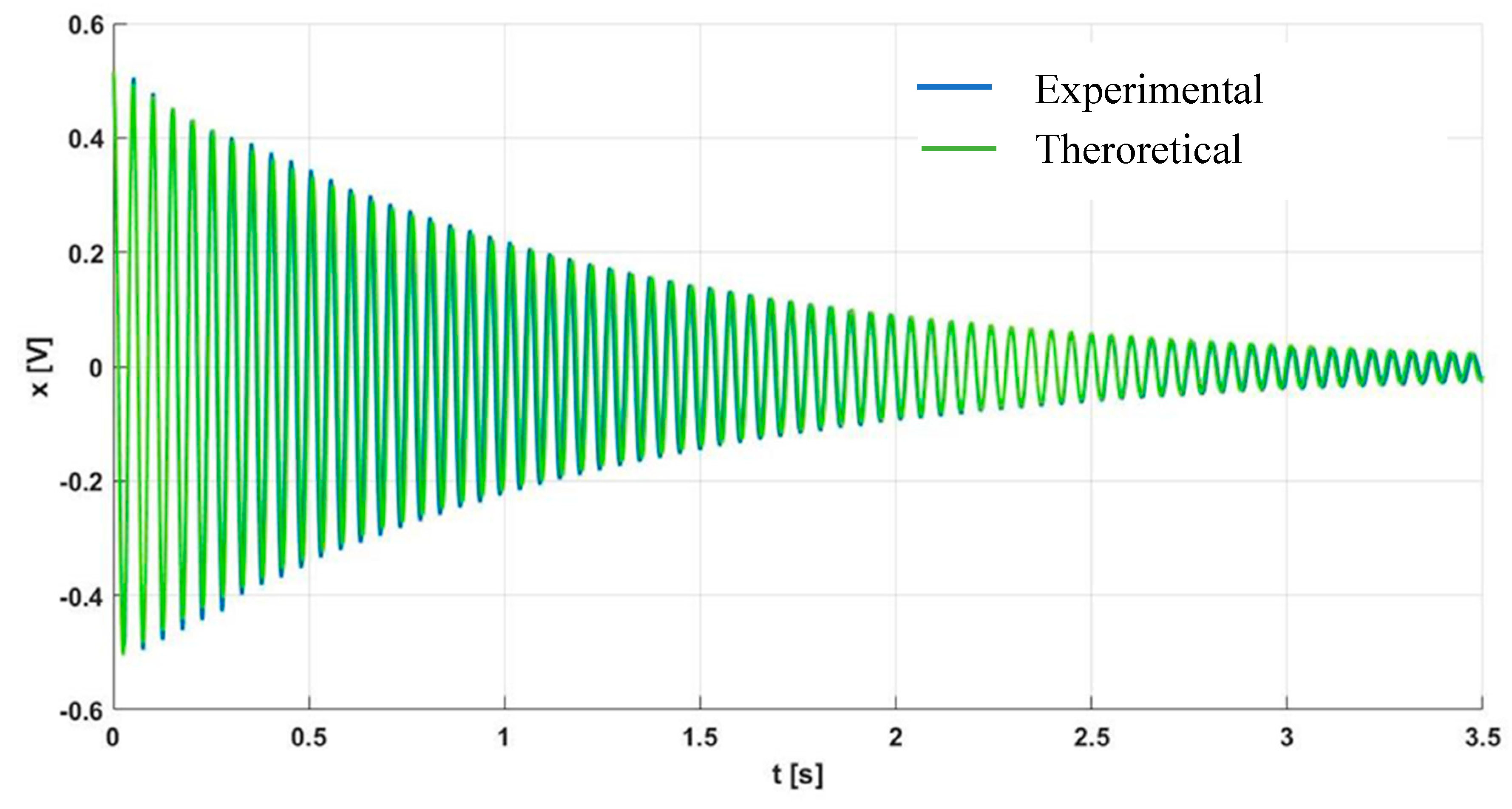

2.1. Methodology

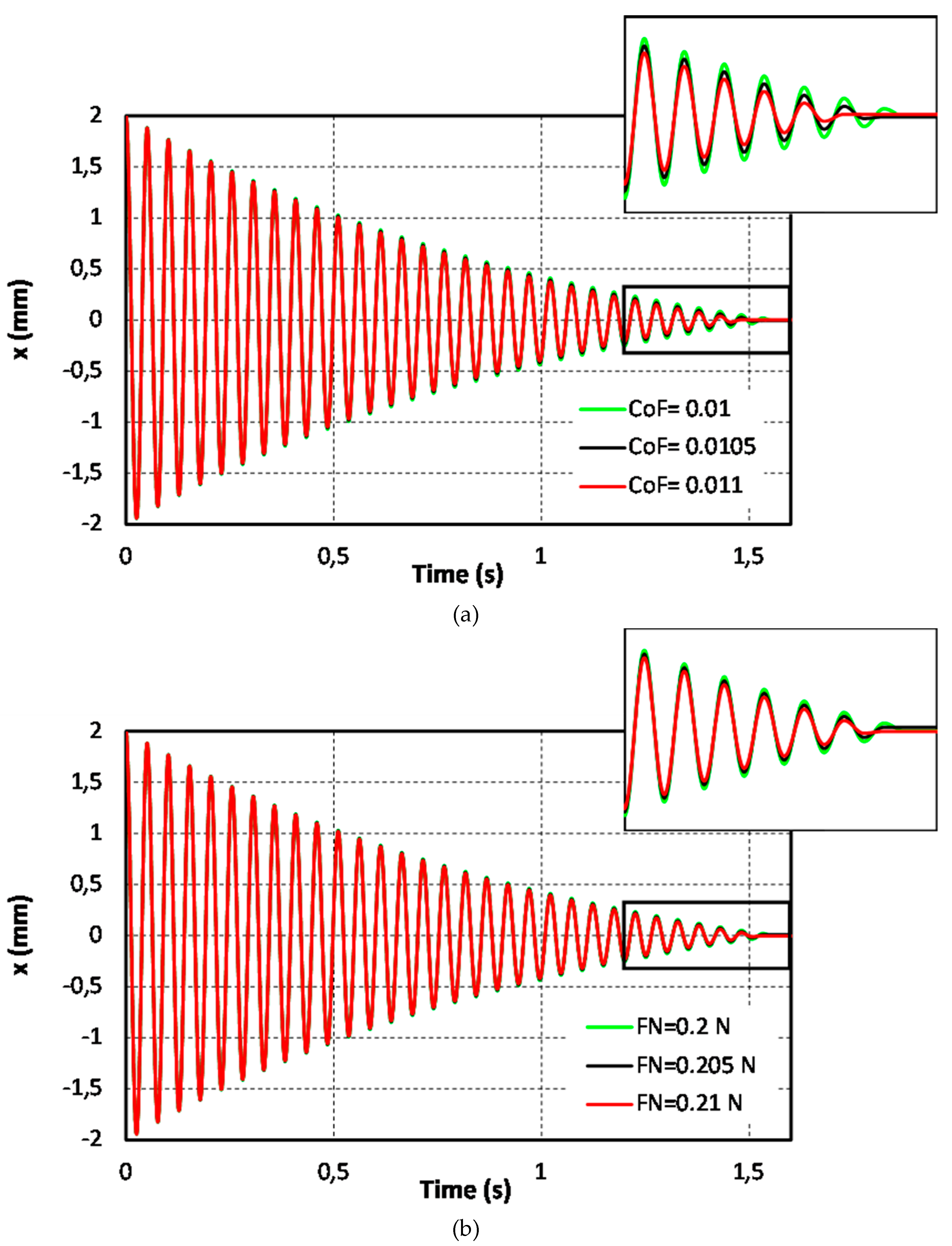

Reverse Analysis

2.2. Specimens

3. Results

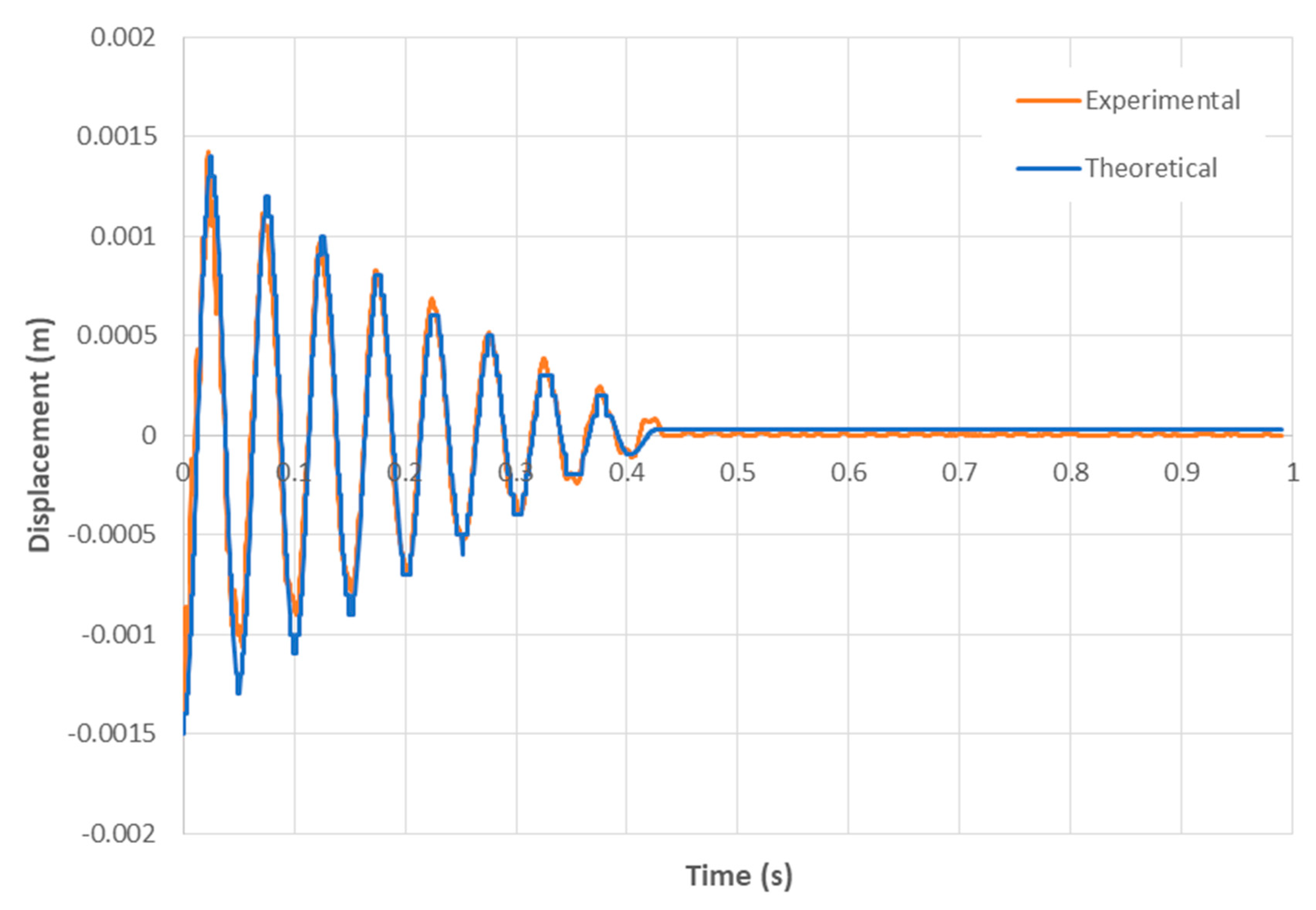

3.1. Physical Constants of the System

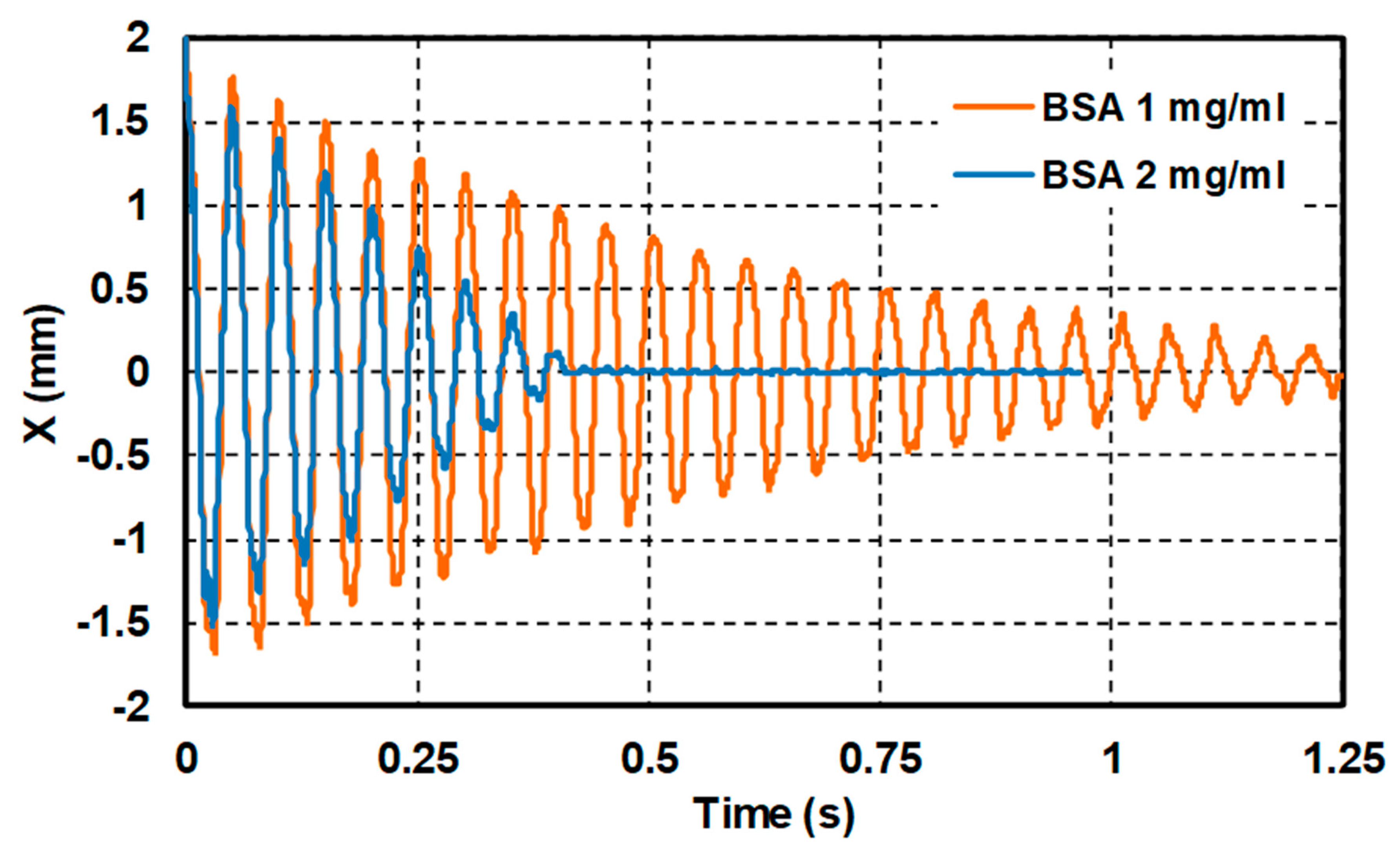

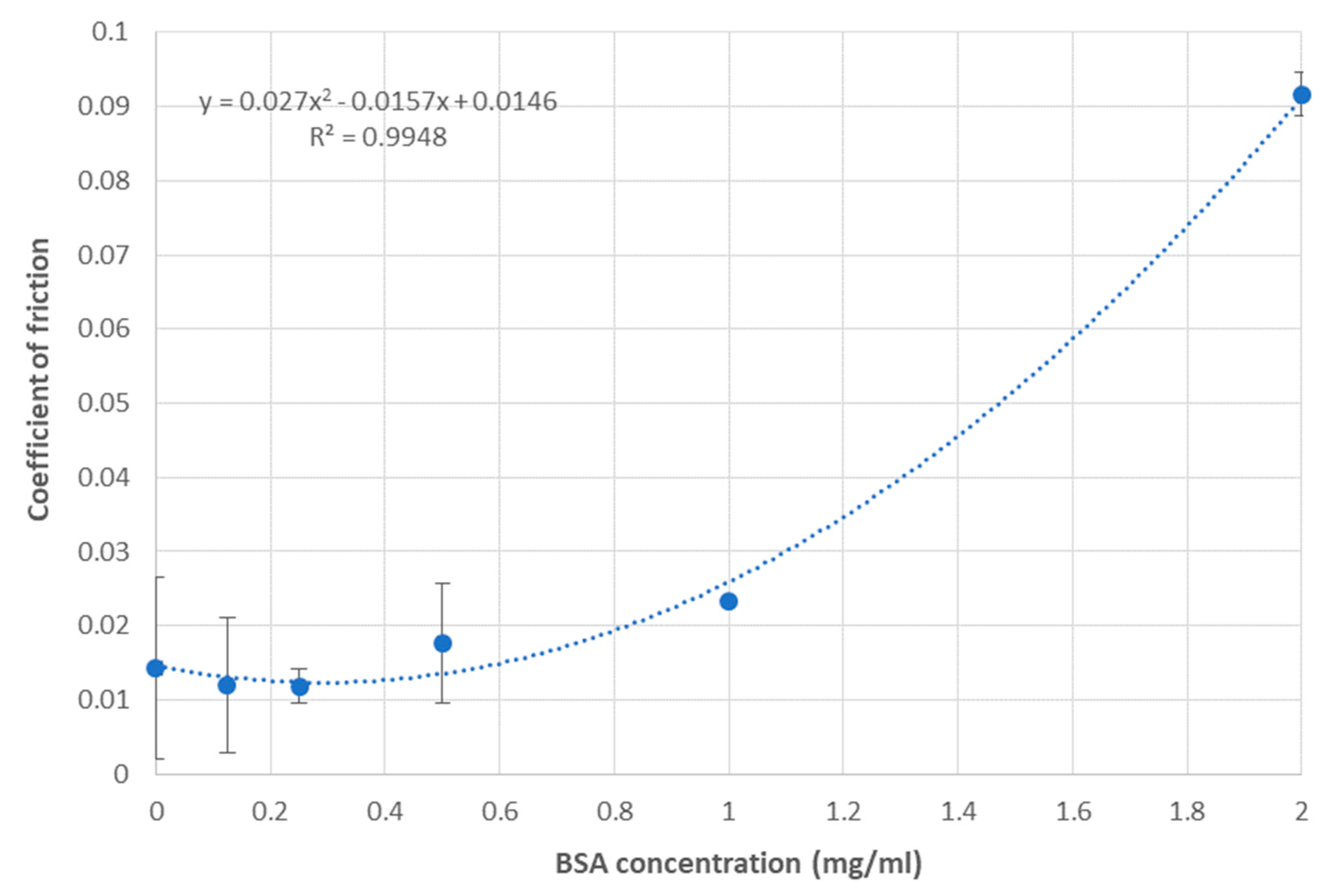

3.2. Effect of BSA Concentration

5. Conclusions

- This technique has sufficient sensitivity for biologically relevant conditions, namely low pressures and sliding speed;

- Changes in the properties of CLs caused by factors such as protein accumulation can be correlated with in vivo comfort and are mainly reflected in the friction coefficient values obtained between the contact lens and the eyelid;

- An increase in BSA content results in an increase in friction values.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dunn, A.C.; Tichy, J.A.; Urueña, J.M.; Sawyer, W.G. Lubrification Regimes in Contact Lens Wear During a Blink. Tribology International 2013, 63, 45–50. [Google Scholar] [CrossRef]

- Kwon, K.-A.; Shipley, R.J.; Edirisinghe, M.; Ezra, D.G.; Rose, G.; Best, S.M.; Cameron, R.E. High-speed Camera Characterization of Voluntary Eye Blinking Kinematics. Journal of The Royal Society Interface 2013, 10, 20130227. [Google Scholar] [CrossRef] [PubMed]

- Sterner, O.; Aeschlimann, R.; Zurcher, S.; Scales, C.; Riederer, D.; Spencer, N.D.; Tosatti, S.G.P. Tribological Classification of Contact Lenses: From Coefficient of Friction to Sliding Work. Tribol Lett 2016, 63, 9. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Randall, N.X.; Li, L. A study of the Frictional Properties of Senofilcon-A Contact Lenses. Journal of the Mechanical Behavior of Biomedical Materials 2011, 4, 1336–1342. [Google Scholar] [CrossRef] [PubMed]

- Rennie, A.C.; Dickrell, P.L.; Sawyer, W.G. Friction Coefficient of Soft Contact Lenses: Measurements and Modeling. Tribology Letters 2005, 18, 4. [Google Scholar] [CrossRef]

- Dunn, A.C.; Urueña, J.M.; Huo, Y.; Perry, S.S.; Angelini, T.E.; Sawyer, W.G. Lubricity of Surface Hydrogel Layers. Tribol Lett 2013, 49, 371–378. [Google Scholar] [CrossRef]

- Roba, M.; Duncan, E.G.; Hill, G.A.; Spencer, N.D.; Tosatti, S.G.P. Friction Measurements on Contact Lenses in their Operating Environment. Tribol Lett 2011, 44, 387–397. [Google Scholar] [CrossRef]

- Mann, A.; Tighe, B. Ocular Biotribology and the Contact Lens: Surface Interactions and Ocular Response. In Biomaterials and Regenerative Medicine in Ophthalmology; Woodhead Publishing: London, UK, 2016; pp. 45–74. [Google Scholar]

- “Lentes de contacto 365,” [Online]. Available online: https://www.lentesdecontacto365.pt/bausch-lomb-lubrificante (accessed on 30 October 2018).

- Nairn, J.A.; Jiang, T.-B. Measurement of the Friction and Lubricity Properties of Contact Lenses. Proceedings of ANTEC'95, Boston, 1995.

- Silva, D.; Fernandes, A.C.; Nunes, T.G.; Colaço, R.; Serro, A.P. The Effect of Albumin and Cholesterol on the Biotribological Behavior of Hydrogels for Contact Lenses. Acta Biomaterialia 2015, 26, 184–194. [Google Scholar] [CrossRef] [PubMed]

- Urueña, J.M.; Dunn, A.C.; Sawyer, W.G. Contact Lens Boundary Lubrification and Friction Reduction with Hyaluronic Acid. Tribology Lubrification Technology 2011, 67, 2. [Google Scholar]

- Samson, M.; Chan, A.; Iwabuchi, Y.; Subbaraman, L.; Jones, L.; Schmidt, T. In Vitro Friction Testing of Contact Lenses and Human Ocular Tissues: Effect of Proteoglycan 4 (PRG4). Tribology International 2015, 89, 27–33. [Google Scholar] [CrossRef]

- Su, C.-Y.; Lai, C.-C.; Yeh, L.-K.; Li, K.-Y.; Shih, B.-W.; Tseng, C.-L.; Fang, H.-W. The Characteristics of a Preservative-free Contact Lens Care Solution on Lysozyme Adsorption and Interfacial Friction Behavior. Colloids and Surfaces B: Biointerfaces 2018, 171, 538–543. [Google Scholar] [CrossRef] [PubMed]

- Den Hartog, J.P. Forced Vibrations with Combined Coulomb and Viscous Friction. Trans ASME 1931, 53, 107–115. [Google Scholar] [CrossRef]

- Rigaud, E.; Perret-Liaudet, J.; Belin, M.; Joly-Pottuz, L.; Martin, J.-M. An Original Dynamic Tribotest to Discriminate Friction and Viscous Damping. Tribology International 2010, 43, 320–329. [Google Scholar] [CrossRef]

- Carvalho, A.L.; Vilhena, L.M.; Ramalho, A. , Study of the frictional behaviour of soft contact lenses by an innovative method. Tribology International 2021, 153, 106633. [Google Scholar] [CrossRef]

- Vilhena, L.; Ramalho, A. , Assessment of friction in aged soft contact lenses by an innovative method. Journal of the Mechanical Behaviour of Biomedical Materials 2023, 145, 106036. [Google Scholar] [CrossRef] [PubMed]

- https://www.sigmaaldrich.com/PT/en/technical-documents/technical-article/cell-culture-and-cell-culture-analysis/cell-culture-media-preparation/albumin-from-bovine-serum.

| pI in Water at 25 °C | Fatty Acid Depleted - 5.3, Endogenous Material - 4.7; 4.9 |

|---|---|

| pH of 1% Solution | 5.2-7 |

| Optical Rotation | [α] 259 : -61°; [α] 264 : -63° |

| Stokes Radius (r s ) | 3.48 nm |

| Sedimentation constant, S 20,W X 10 13 | 4.5 (monomer), 6.7 (dimer) |

| Diffusion constant, D 20,W X 10 7 | 5.9 |

| Partial specific volume, V 20 | 0.733 |

| Intrinsic viscosity, η | 0.0413 |

| Frictional ratio, f/f 0 | 1.30 |

| Overall dimensions, Å | 40 X 140 |

| Refractive index increment (578 nm) X 10 -3 | 1.90 |

| Optical absorbance, A279 nm (1 gram/liter) | 0.667 |

| Mean residue rotation [ m' ] 233 | 8443 |

| Mean residue ellipticity | 21.1 [θ] 209 nm ; 20.1 [θ] 222 nm |

| Estimated α-helix, % | 54 |

| Estimated β-form % | 18 |

| 𝒌[𝑵/𝒎] | 𝒘𝒏 [𝒓𝒂𝒅/𝒔𝟐] | 𝝃 | 𝒎 [𝒈] | 𝒄 [𝑵.𝒔/𝒎] |

|---|---|---|---|---|

| 265 | 123.10 | 7.14x10-3 | 17.49 | 0.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).