1. Introduction

The Firefighters Protective Clothing (FPC) belongs to the category of Personal Protective Equipment (PPE) [

1]. The FPC has to provide required protection against the risks which occurs in the work place. In the case of the FPC it should protect against dangerous factors occurring while firefighting and other rescue operations such as roadway operations, aircraft fires, emergency medical, or flood. It is a crucial feature and requirement of the FPC. However, some other aspects should be also taken into consideration, especially the ergonomics and comfort [

2]. Each kind of emergency operation can pose completely different risks [

3]. Due to this fact depending on the operation the firefighter should be equipped with different types of protective clothing. The basic type is so-called structural firefighting protective clothing. It is designed for actions during rescue operations, firefighting and other activities undertaken by firefighters. Extreme heat exposure combined with high physical exertion can injure a firefighter.

The process of heat flow in the chain: firefighter body-protective clothing- surroundings can work in two modes of firefighter's work [

4]:

in the first mode the environment without the influence of high temperature or normal mode; at this time, the firefighter is performing work that is not related to firefighting,

in the second mode, the firefighter is in the high ambient temperature zone or when performing fire extinguishing operations.

In the first normal mode the temperature of ambient air is lower than the temperature firefighter's body, and the humidity in the space of the underwear is less than 100% (protective clothing is relatively dry). During intensive effort in stress conditions the temperature of firefighter's body increases, and the natural processes of thermoregulation in human body are activated, cooling the body through breathing and sweating, and then evaporation of sweat from the skin. Moisture exchange occurs through contact and evaporation of moisture from the surface of human body. In the process of moisture exchange the thermal insulation layer of the protective clothing becomes wet due to the perspiration of the firefighter. In order to create comfortable working conditions in normal mode it is necessary to remove both heat and moisture from the under-clothing space to outside.

During the second mode the heat transfer occurs differently because the ambient temperature is significantly higher than the temperature firefighter's body and the humidity in the under-clothing space is even 100%. The heat exchange is directed towards the firefighter's body, which causes the temperature inside the clothing to rise, which in turn increases the firefighter's body temperature. In air saturated with water vapor, water cannot evaporate, moisture condenses on the surface of the body, so sweat amount increases, but sweat does not evaporate. Therefore, the thermoregulation of the firefighter's body almost stops and is carried out only by breathing. Protective clothing becomes wet, and because of this the thermal protection properties are significantly reduced, and a condition is created where thermal shock and burns are possible.

When the firefighter performs operational and tactical tasks involving increased heat flow the normal duration of protective effectiveness of FPC is reduced. The decrease of protective performance is caused by increased humidity of the multilayer material of the FPC due to liquid sweat remaining inside the materials. Taking above into consideration it should be stated that a designing the FPC and materials for it is a difficult challenge. In such situation it is necessary to make a compromise between two significant simultaneously opposite factors – maximum fulfilment the thermal protection and while minimizing the heat stress. Protection against fire and flame is absolutely the most important task of the FPC. However, its impact on metabolic heat stress cannot be ignored [

5].

There are numerous research works aimed at an investigation and optimization of materials used in the FPC and multilayer assemblies for the FPC [

6,

7,

8,

9]. Usually, the FPC is a multilayer textile set consisting of various types of textile materials such as woven and nonwoven fabrics, in some cases also knitted fabrics. In many scientific works the FPC is presented as a three-layered assembly containing the following layers: the outer shell, moisture barrier, and thermal insulator [

10,

11,

12,

13,

14,

15]. The outer shell layer material is made of non-flammable fabric intended for protection against an open fire and mechanical impact. It should also protect against toxic substances. The moisture barrier layer is made of polymer material to protect against the negative effects of external moisture and wind, whereas the thermal barrier layer is made of materials with low thermal conductivity to protect against thermal effects. Considering the FPC as a three-layer assembly is not entirely correct. The mentioned layers: outer shell, moisture barrier, and thermal barrier are the basic components. The outer shell is usually covered by special impregnation, whereas the thermal insulation nonwoven is protected by the lining creating a two-layer set [

12]. The number of layers and their comfort-related properties influence the heat and moisture exchange between the firefighter’s body and surrounding.

The complete firefighter’s outfit in action consists of even six layers, including underwear, which are barriers to the dangerous external factors. Unfortunately, they are also barriers to the transfer of metabolic heat and sweat produced by the human body. Sweat transfer from human body is taken into consideration in standards describing the requirements for firefighters protective clothing. However, the standard only takes into account the water-vapor resistance Ret. According to the standard the water-vapor resistance of the FPC should not exceed 45 m2Pa/W. The parameter describes an ability of the FPC to transfer the sweat in the form of vapor. The EN-469:2021 standard [

16] does not contain the requirements concerning the liquid moisture transport. The research works published till now very rarely cover the issue of sweat condensation on the firefighter’s skin and the transport of liquid sweat through firefighters protective clothing [

17,

18,

19]. Meanwhile, the transport of condensed (liquid) sweat is a very significant factor influencing the thermo-physiological comfort of clothing usage by firefighters during firefighting and other rescue operations. Sweating during the hard activity in stress and/or hot conditions is intensive. Some amount of sweat cannot be evaporated due to high water-vapor resistance of multilayer protective clothing for firefighters. This leads to sweat condensing on the skin surface. In such case it is necessary that the liquid sweat is transported through the material of the FPC to the outer layer, and next evaporated to environment. Due to this fact it is necessary to take into account the liquid moisture transport while selecting the materials for the FPC. Currently, there are testing methods that allow for such an assessment, for instance the Moisture Management Tester [

20,

21,

22,

23] by SDL Atlas. It is an instrument enabling the measurement of textile materials in the range of liquid transport properties in the following aspects [

20,

21]:

time of moisture absorption – it is determined for both surfaces of measured specimen: inner and outer,

transfer of liquid moisture in one direction: from the inner surface to outer,

speed of spreading the liquid moisture on both fabric surfaces.

The aim of presented work was to investigate the multilayer sets of textile materials for the FPC in the aspect of the properties which describes the fabrics in the aspect of transport the liquid moisture. In the presented work the measurements of liquid moisture transport properties have been performed for the entire multilayer sets for the FPC and for individual materials applied in each layer of the multilayer sets.

2. Materials and Methods

Four variants of multilayer textile sets (Sample Sets) for the FPC were the objects of the investigations. Each of them was composed of three main layers: next to the skin layer, internal thermal-insulation layer, and layer creating the outer shell. The multilayer sets have been taken from the Polish industry. They are commercially available multilayer textile packages developed especially for the FPC. The manufacturers of the investigated materials confirmed that their protective properties have been checked and certified according to appropriate standards. In the frame of presented work only the liquid moisture transport properties of the multilayer sets were the objects of measurements and analysis.

The raw material composition and mass per square meter of each layer of the set of materials investigated in the research are presented in the

Table 1. The data have been provided by the manufacturers. However, it was not allowed to present more detailed data of particular components due to the competitiveness on the market.

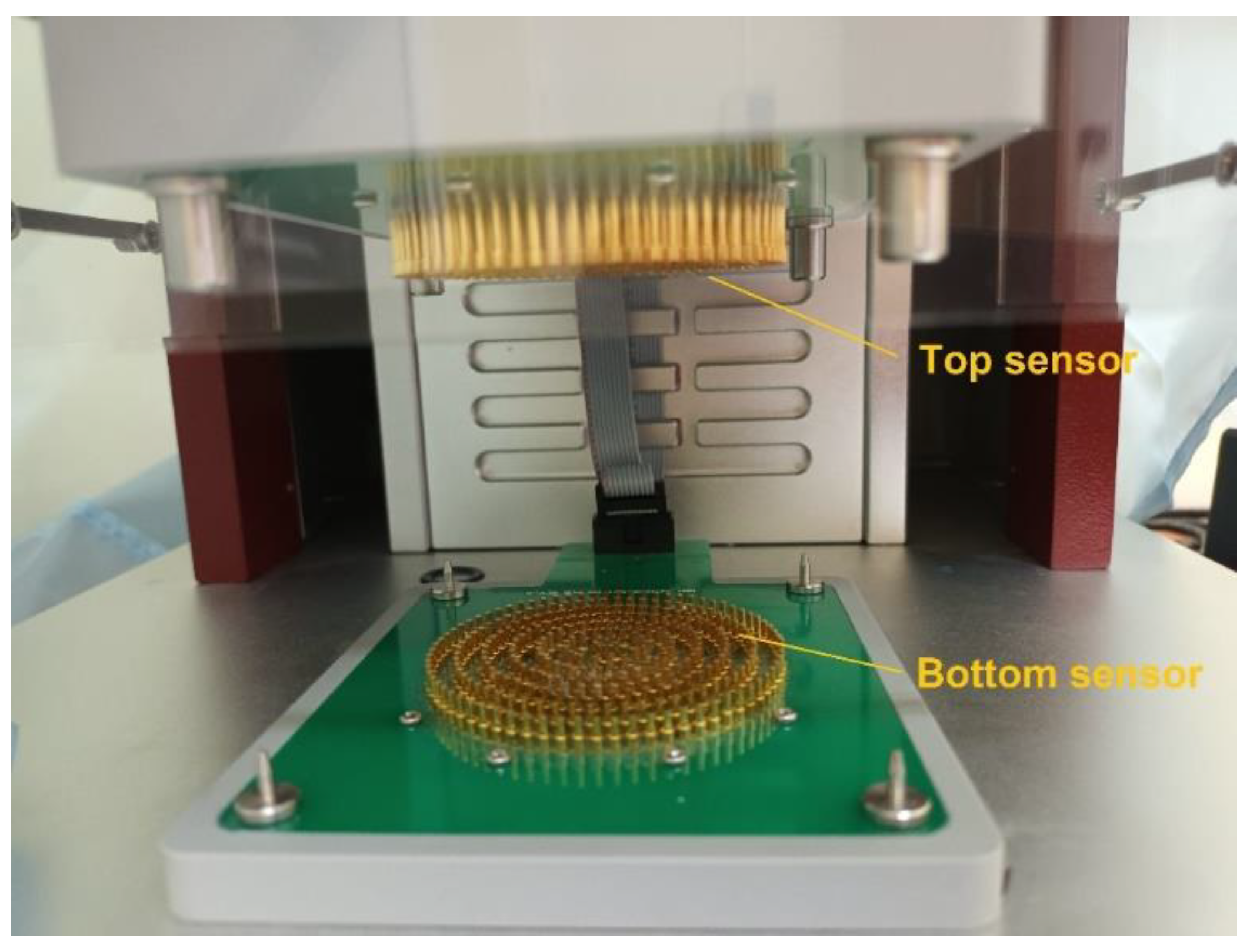

The presented above materials (

Table 1) have been investigated using the Moisture Management Tester M290 (

Figure 1) by the SDL Atlas company (US). This device possesses two electric sensors: upper and lower (

Figure 2). The electric signal is converted into moisture data. While testing the measured specimen is located between the sensor as you can see below.

The measurement is carried out following the procedure described in The AATCC standard and device instruction manual [

20,

24]. A precisely determined quantity of testing solution is dispensed drop by drop onto the upper surface of the measured sample. The upper surface of measured specimen represents the surface of the material that is closest to the user's body during clothing use. Then the liquid is transferred onto the measured sample in three directions:

spreading centrally on the upper surface,

transfer from the upper to the bottom surface,

spreading on the bottom surface of measured sample.

Measurements have been performed according to the standardized [

24].

Measurements by means of the MMT have been done for the entire multilayer sets, and next for the inner and middle layer of the sets. The results of measurement have been analysed statistically using the nonparametric post-hoc tests: Kruskal-Wallis ANOVA and Median tests in the TIBC® Statistica™. The nonparametric tests have been applied since the normality assumption has not been confirmed.

3. Results and Discussion

3.1. Liquid Moisture Transport of Sample Sets

The liquid moisture transport properties of four types of multilayer textile sets (Sample Sets) for the FPC are presented in the

Table 2 and

Table 3 [

25].

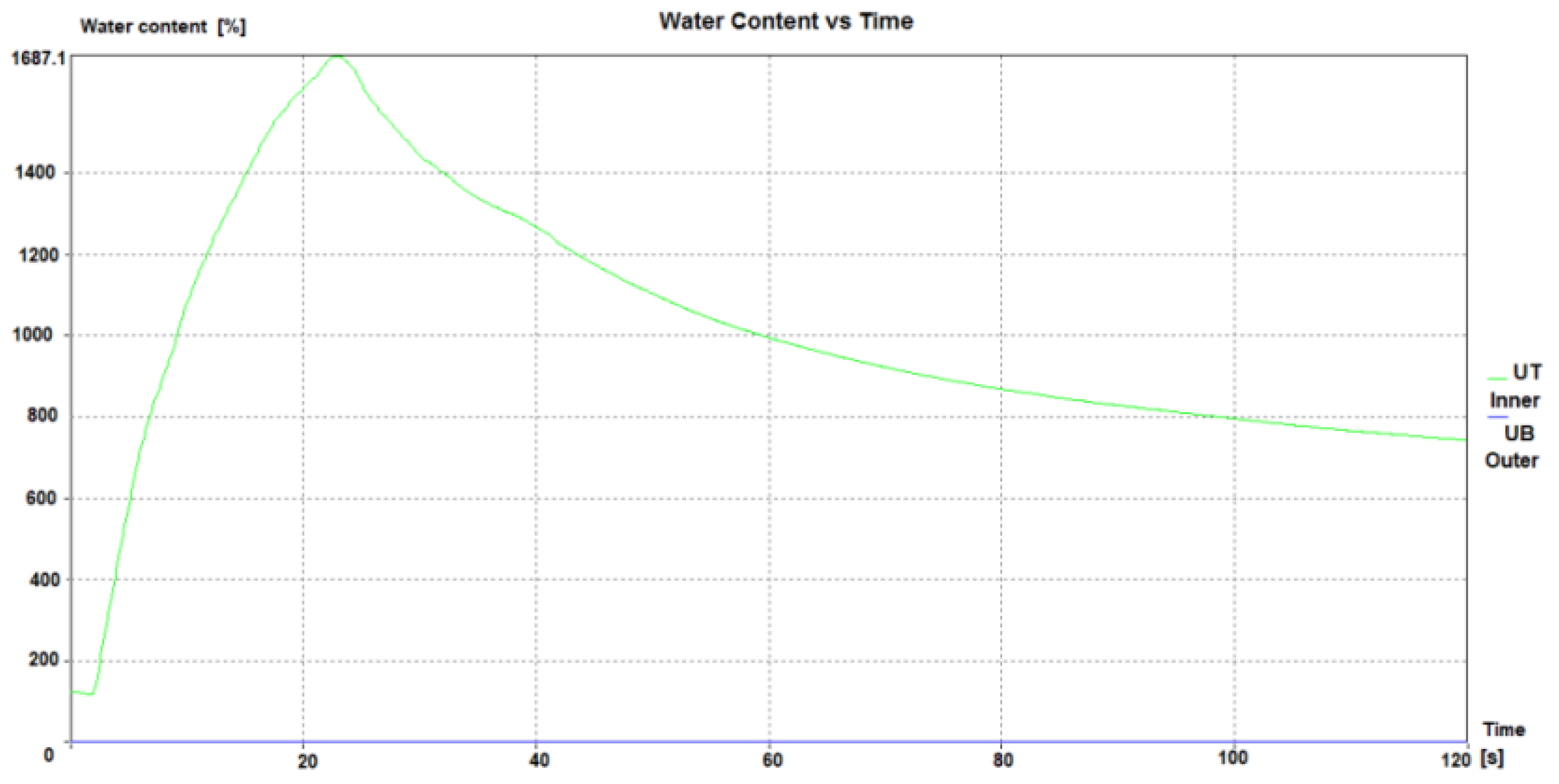

Among all parameters provided by the MMT instrument two of them are the most important. They are: R – accumulative one-way transport index, and OMMC – Overall Moisture Management Capacity. Both parameters describe the sample as a whole, while the remaining parameters determined concern particular sides of the sample. Both parameters: R and OMMC are calculated on the basis of other parameters measured by the device according to the algorithms elaborated by the MMT manufacturer.

The R parameter represents a difference between the accumulative moisture content of bottom surface and top surface related to time [

21]. The interpretation is the following: the higher value of the R parameter is the better liquid moisture transport and in the same way the better management of moisture [

20,

25]. Investigations showed that in all cases the values of the R parameter are negative. It means that the entire multilayer material sets for the FPC are not able to transfer the liquid moisture.

The Overall Moisture Management Capacity (OMMC) is a parameter indicating the overall ability of measured material to transport a moisture in liquid state. Generally, the OMMC is calculated from the values of the absorption rate for the bottom surface (BAR), the spreading speed for the bottom surface (SSB), and the accumulative one-way transport index (R). The value of the OMMC parameter can be in the interval from 0 till 1. The higher value is the better ability of measured specimen to transport the liquid moisture. The Overall Moisture Management Capacity of the textile sets being tested is 0 (

Table 3). In all cases the liquid was not visible on the outer layer of the sets [

18].

Other parameters provided by the MMT instrument also confirm a lack of liquid moister management ability of the measured textile sets. For the bottom surface the values of such parameters as: absorption rate (BAR), spreading speed (SSB), maximum wetted radius (MWRB) are 0 (

Table 2 and

Table 3). Whereas, the value of the wetting time for the bottom surface (WTB) was 120 s, i.e. total measurement time by means of the MMT. It means that the liquid moisture does not reach the outer layer of the multilayer sets and thus it is not drained outside the clothing (

Figure 3). Due to this fact, all Sample Sets for the FPC being investigated should be included into the "water-proof materials" class.

Analysis of the samples after the test has shown that for all four multilayer textile sets being investigated moisture transport occurred only on the first and second layers. Due to this fact, in next step of the investigations the first (inner) and second (middle) layers have been measured separately.

3.2. Liquid Moisture Transport in Inner Layer of the Multilayer Textile Sets for the FPC

Measurement of entire textile sets for the FPC showed that the one-way transport of liquid moisture occurred only in the materials creating the first (inner) layer of the multilayer packages. Therefore, there was a need to assess the liquid moisture transport properties of the inner layer in the textile sets for the FPC. The investigated inner layers were connected to their thermal insulation barrier by stitching and glue. The liquid moisture transport properties of the inner layers of four types of multilayer textile sets for the FPC are presented in the

Table 4 and

Table 5.

Based on the presented results, it is justified the statement that the inner layers in the multilayer textile sets (SS) for the FPC differ from each other in the range of all parameters measured by the MMT.

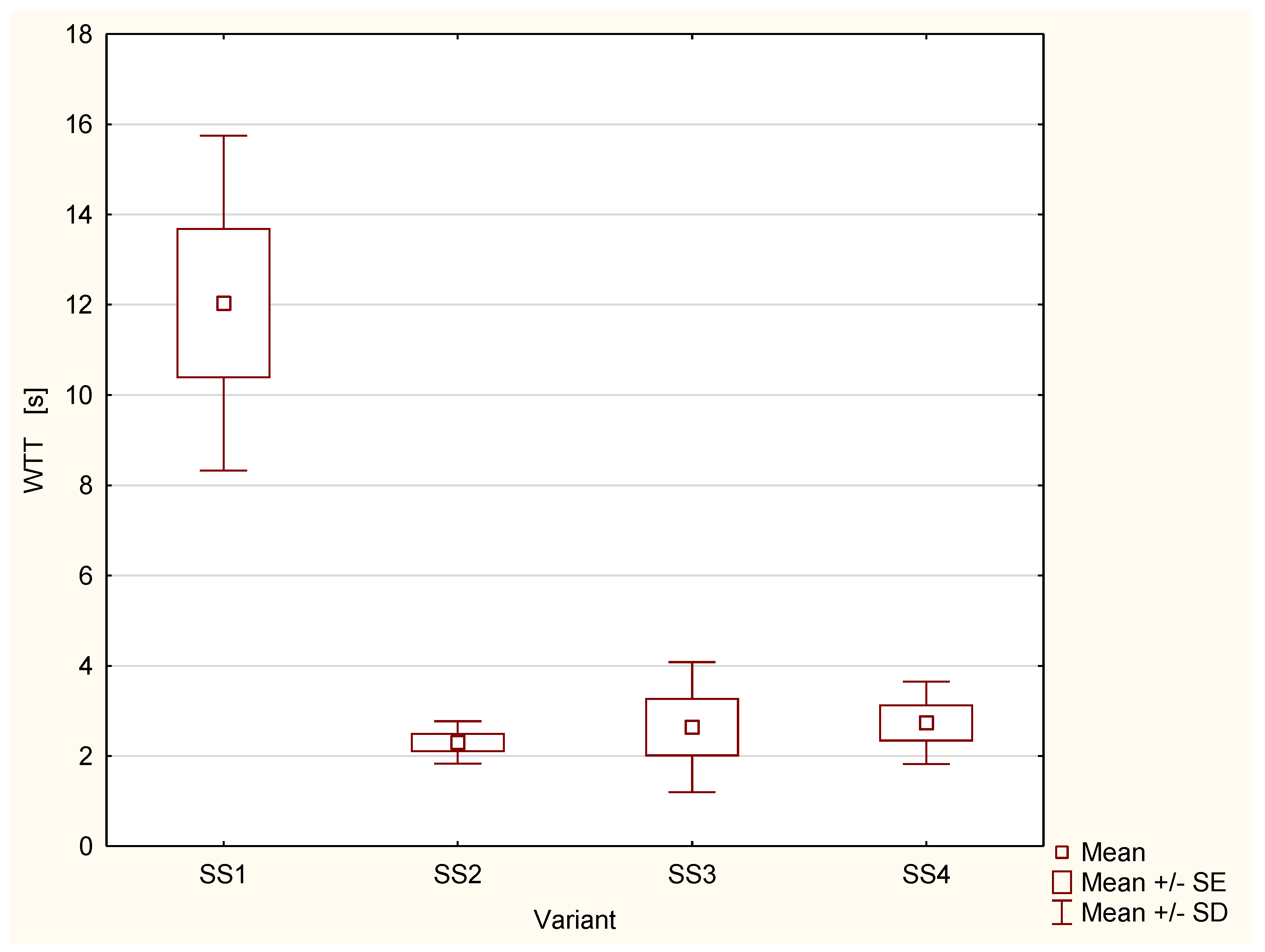

The longest wetting time for the top surface occurred for the SS1 variant (WTT = 12.04 s). For rest of the investigated inner layers of the SSs the wetting time was significantly shorter and at the same level: for the SS2 = 2.30 s, for the SS3 = 2.64 s and for the SS4 = 2.74 s (

Figure 4). The WTT parameter determines the time from the start of the test at which the upper and lower surfaces of the measured sample begin to wet [

25,

26]. The shorter wetting time is the better ability of fabric to manage the liquid moisture. This follows from the fact that wetting determines transport of liquid under the influence of capillary forces. For the bottom surface the results are more differentiated than that for the top surface. The longest wetting time was stated for the SS2 variant (WTB = 60.88s), next for the SS1 (WTB = 39.31 s), the SS3 (WTB =37.98 s), and finally for the SS4 (WTB = 6.40 s). Considering the values of the WTT and WTB parameters the SS4 variant should be assessed as the best from the wetting of both surfaces.

Statistical analysis using the Kruskal Wallis test confirmed that the differences between the values of the WTT for particular fabric variants are statistically significant at the significance level 0.05. In the case of the wetting time for the bottom surface the differences have been assessed as statistically insignificant. It is due to a very large dispersion of results for particular variants.

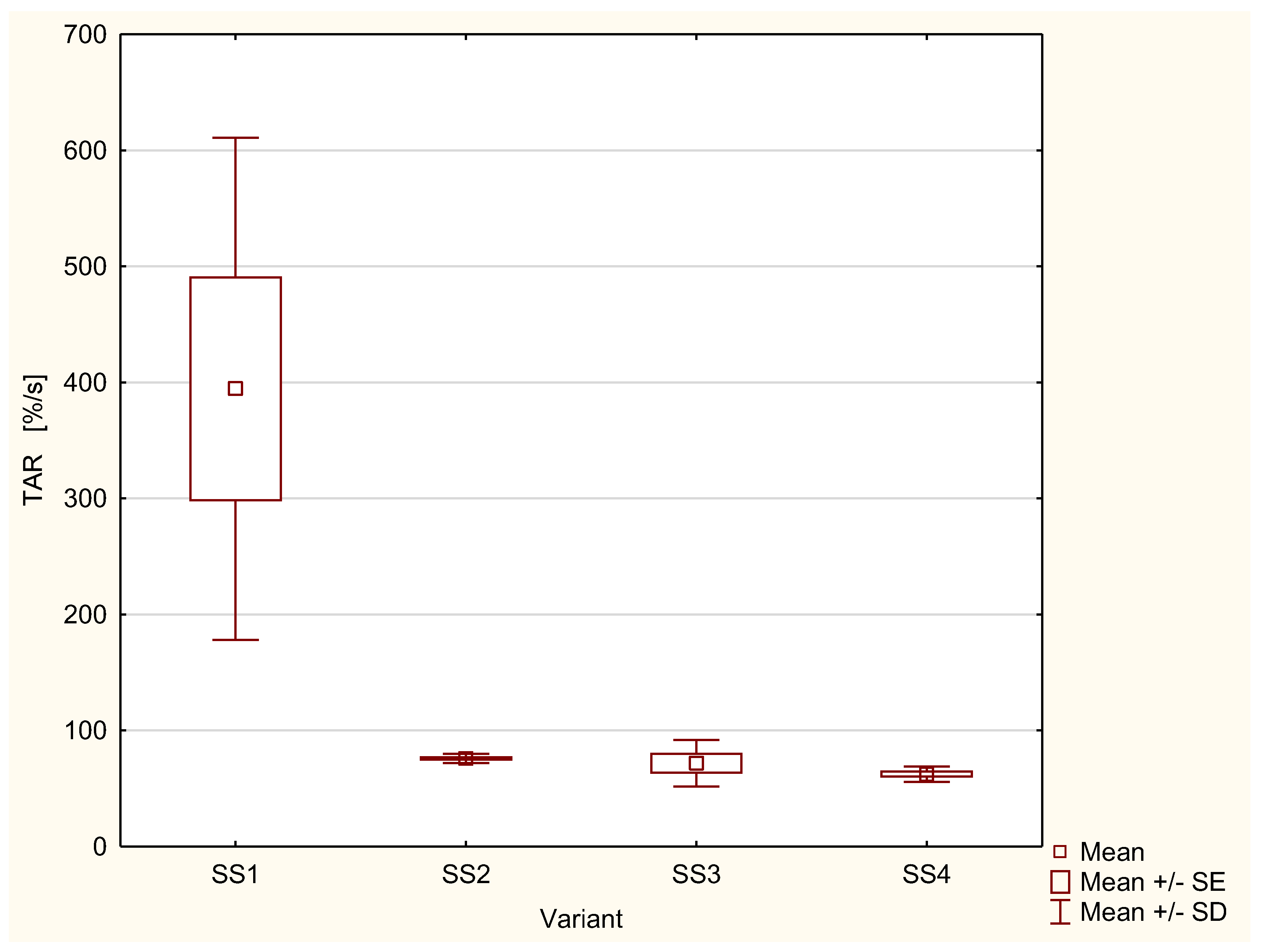

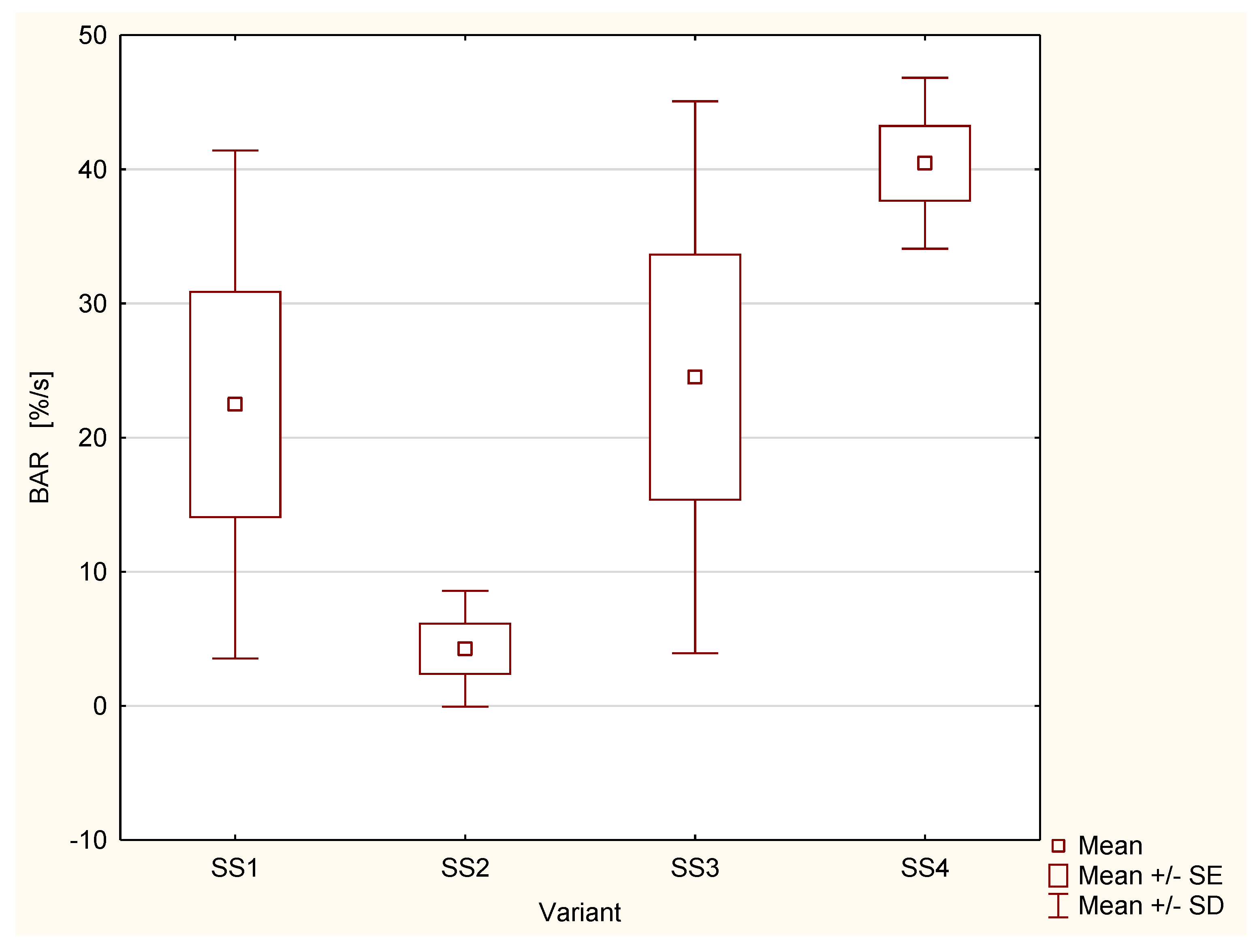

Absorption rate (AR) is next parameter provided by the MMT device. The parameter represents the average speed of liquid absorption of both material surfaces during the initial change of water content while test performance [

15]. The absorption of liquid restricts the movement of liquid in capillars between the fibres and yarns. Greater absorption of liquid limits the spreading it on a surface. Great absorption rate of the top surface (TAR) causes that the liquid moisture is retained inside the fibres if the inner surface. At the same time, it is not discharged to the external surface. This means that the liquid sweat is not transported effectively to the outer (bottom) surface of fabric. It causes that in clothing made of such material the liquid sweat is not transferred outside of clothing. This is unfavorable for draining a liquid sweat from the wearer's skin to the outside, and at the same time of thermo-physiological comfort. Very high absorption rate of the top surface (

Figure 5) was noted for the inner layer of the SS1 variant (TAR = 394.30 %/s). The lowest value of the TAR parameter occurred for the variant SS4 (TAR = 62.34 %/s). In all cases it was also observed that the absorption rate of the top surface is significantly higher than that for the bottom surface (

Table 4). It means that the top surface, being the inner (next to skin) layer of clothing, absorbs the liquid sweat much faster than the bottom surface being the outer layer of clothing (

Figure 6). It restricts the evaporation of liquid sweat from the outer surface of clothing to the environment.

Statistical analysis showed that differences between the values of the absorption rate of the top surface are statistically insignificant. In the case of the bottom surface the differences between the values of the BAR parameter for measured samples are statistically significant.

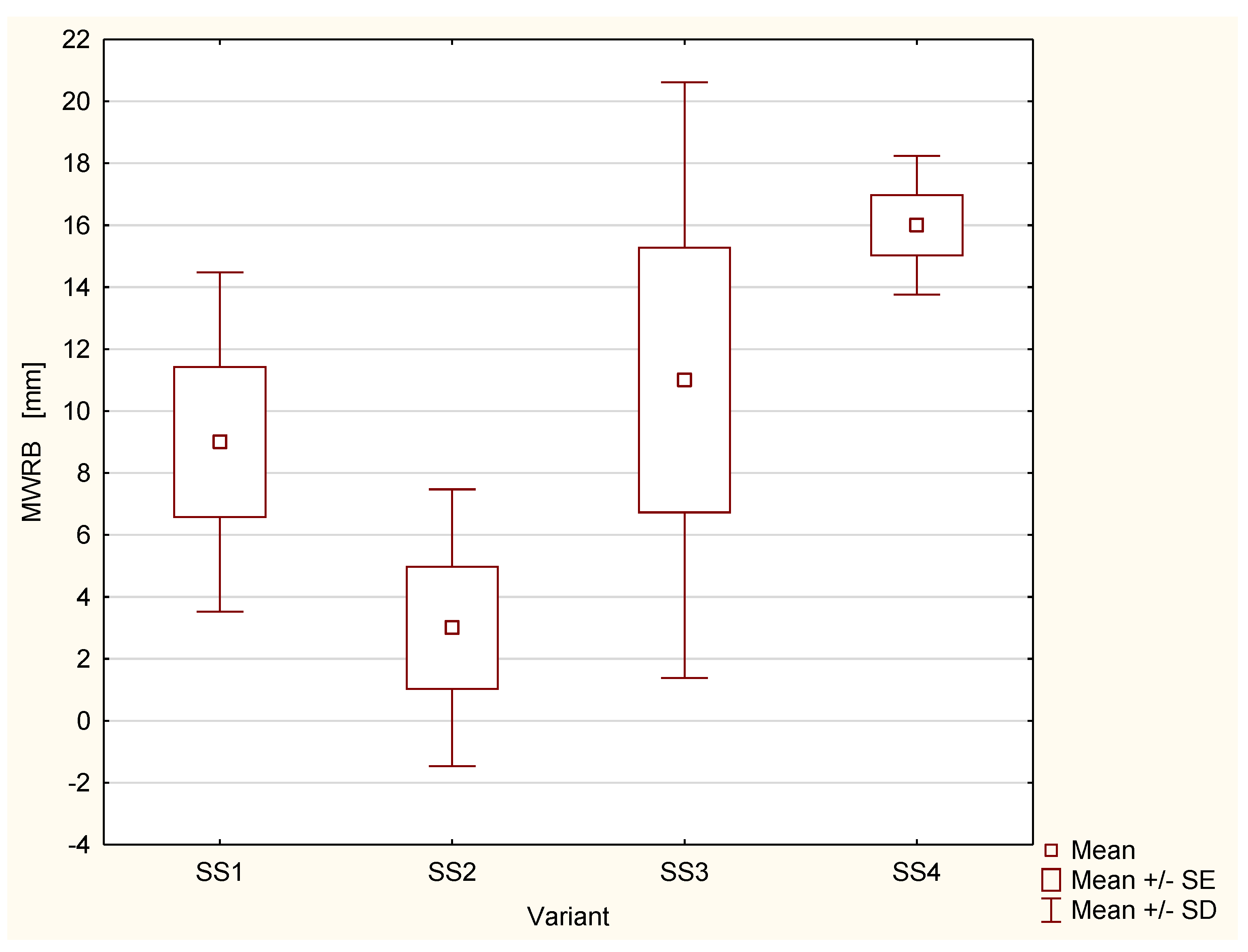

The maximum wetted radius is defined as the maximum radius of ring on the sensor on which the liquid is detected be almost one pin of sensor. Greater maximum wetted radius means better spreading the liquid on the surface. Great area of the liquid trace on the fabric surface creates favorable conditions for evaporation of liquid. The maximum wetted radius on the bottom surface (MWRB) is more significant for physiological comfort than that on the top surface (MWRT). Greater area of liquid trace on the bottom (outer) surface of the investigated fabric leads to more intensive evaporation of liquid sweat from the underclothing space into ambient air

In the case of the inner layers of the investigated multilayer sets in three cases – variants SS2, SS3 and SS4 the maximum wetted radius for the top (inner) surface is greater than that for the bottom (outer) surface (

Table 4). This is not favorable relationship from the point of view of physiological comfort. The worst relation was observed for the SS2 variant. For this variant the maximum wetted radius for the top surface is great (MWRT = 30 mm) whereas for the bottom surface is very small (MWRB = 3 mm). The maximum wetted radius directly influences the evaporation of liquid from the outer surface of fabric. In the case of this parameter (

Figure 7) the greatest values were observed for the variant SS4 (MWRB = 16 mm), and next – the SS3 variant (MWRB = 11mm).

In both cases, i.e. the MWRT and MWRB parameters the differences between their values for the investigated fabric variants are statistically significant.

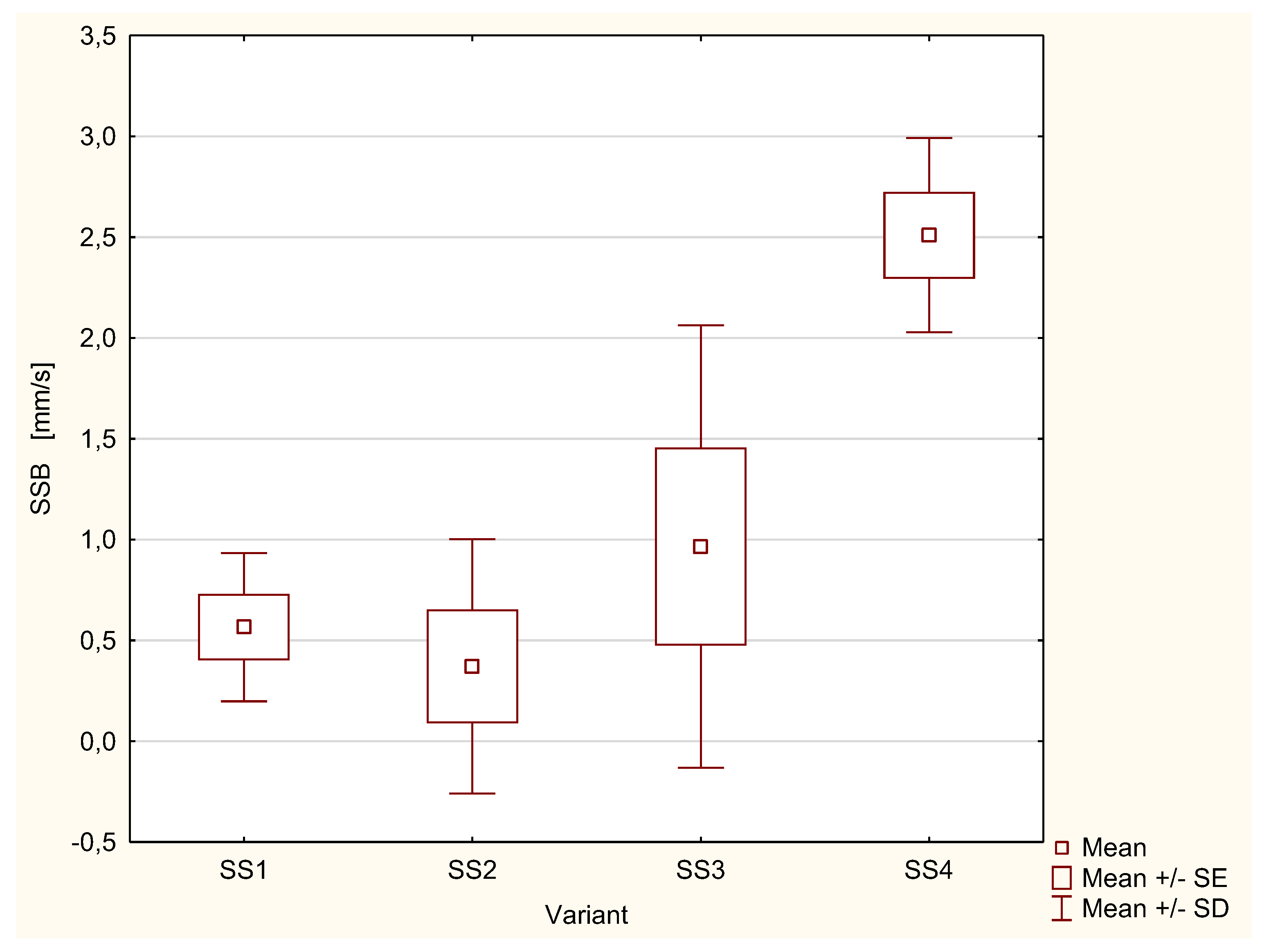

The spreading speed (SS) represents the accumulated rate of wetting the individual surface from the center of the specimen to the maximum wetted radius [

25,

26]. Higher spreading speed means better conditions for liquid evaporation. This parameter is important especially for the bottom surface of clothing. In the case of the investigated samples the values of the SS parameter are very diversified (

Table 4). For the SS1 variant the spreading speed is very low for both surfaces (SST = 0.48 mm/s, SSB = 0.57 mm/s). The highest value occurred for the top surface of the SS2 variant (SST = 13.41 mm/s), and next for the top surface of the SS2 variant (SST = 7.76 m/s). But for both cases the spreading speed for the bottom surface was very low: for the SS3 variant the SSB value is 0.97 mm/s and for the SS2 – 0.37 mm/s (

Figure 8). The very small spreading speed for the bottom surface is unfavorable for the evaporation of the liquid sweet from the outer surface, and in the same time for the physiological comfort. The highest value of the spreading speed for the bottom surface occurred for the SS4 variant (SSB = 2.51 mm/s). For the SS4 variant the disproportion between the spreading speed of the top and bottom surfaces is the smallest in comparison to other variants (

Table 5).

The differences in values of spreading speed for both surfaces are also significant what was confirmed by statistical test. The two-sided comparisons showed that the significant difference occurs between the SS2 and SS4 variants.

In all cases the value of the R parameter (accumulative one-way transport index) are negative (

Table 5). It means that the investigated materials creating the inner layer of the multilayer sets for the FPC are not good from the point of view of evaporation of liquid sweat and physiological comfort of clothing wearer. Due to the great dispersion of the R results, the differences between particular fabric variants have been assessed as statistically insignificant.

According to the value of the OMMC parameter (

Table 5) the fabrics are classified to 5 classes from very poor (OMMC = 0.0 - 0.2) to excellent (OMMC > 0.8). Among all investigated fabrics creating the inner layer of the multilayer sets for the FPC only the SS1 variant can be classified as poor (OMMC = 0.21) but the value of the OMMC parameter is practically on the board between the very poor and poor classes. The rest of investigated materials were classified as very poor, wherein the value of the OMMC parameter for the SS1 variant is very close to the border value between the very poor and poor classes. In the case of the OMMC, the influence of the SS variant on the parameter values was assessed as statistically significant. The two-sided comparison showed that statistically significant difference occurs between the SS2 and SS4 variants. In the case of the inner layers applied as a lining of the FPC each of them was classified as a "fast absorbing and slow drying" according to the MMT manufacturer’s rules. The results of the analysis confirmed that the liquid moisture can be transported through the inner layer of the multilayer textile sets for the FPC, and the existence of moisture transport through the middle layer should be investigated too.

3.3. Liquid Moisture Transport of Middle Layer of Multilayer Sets for the FPC

The liquid moisture transport properties of the middle (thermal insulating) layer of the textile sets for the FPC are shown in the tables 6 and 7.

As can be seen from the

Table 6 and

Table 7, in almost all cases of the middle layer in the textile sets, the parameters characterizing the bottom surface: absorption rate (BAR), minimum wetted radius (MWRB) spreading speed (SSB) and Overall Moisture Management Capacity (OMMC) showed values equal to 0. The exception here is the SS1 variant. For this variant the minimum wetted radius (MWRB) is 5 mm and the absorption rate (BAR) is 3.85 %/s. It means that some amount of liquid was transferred to the outer surface. However, the accumulative one-way transport index (R) for the middle layer of the multilayer sets for the FPC has very large negative values for all investigated variants. The results obtained from the MMT indicate that liquid moisture transport does not occur through the middle layer in the multilayer textile sets for the FPC. Therefore, it means that the transport of liquid moisture from the human body stops against this middle layer. The middle layer in the multilayer textile set for the FPC is the layer responsible for the water barrier of the FPC and is classified as a "water-repellent fabric" according to the MMT classification. During the MMT test of the middle layers the liquid moisture was spread mostly on the upper (inner) surface of the layer. (including propositions, lemmas, corollaries etc.)

4. Conclusions

For the physiological comfort of firefighter in rescue action the transport of sweat produced by the firefighter’s body is very important. The Firefighter Protective Clothing (FPC) is composed of several layers. Each of them creates a barrier for the water-vapour. Due to this fact at intensive sweating conditions some amount of sweat produced by the firefighter’s body is not evaporated from the human skin to the environment. It condenses on skin surface and causes unpleasant feeling and discomfort. In such situation the transport of sweat in the form of liquid is necessary to ensure the physiological comfort and optimal effectiveness of firefighters in action.

Measurements of entire multilayer textile sets for the FPC in the range of the liquid moisture transport showed that the liquid moisture was not observed on the outer layer of the multilayer sets. Liquid moisture was observed only in the inner, next to skin layer of the sets. It causes that liquid moisture remains inside the multilayer fabric sets and accumulates during the usage of the firefighter protective garment. Measurement of individual layers of the multilayer sets for the FPC demonstrated that the transport of liquid sweat occurs only through the first (inner, next o skin) layer of the multilayer sets. However, the inner layers of the multilayer sets transfer the liquid sweat in a way classified as poor according to the rules suggested by the Moisture Management Tester (MMT) producer. The highest value of the OMMC parameter occurred for the inner layer of the SS4 variant (0.21), and the lowest (0.01) for the inner layer of the SS2 variant.

While design the multilayer textile sets for the FPC the aspect of liquid swat transport trough materials used in the FPC should be taken into consideration. Additionally, it should be taken into account that the FPC is used together with the underwear. The underwear creates additional barrier for the liquid sweat transport and influences the liquid sweat transport through the inner layer of the multilayer sets for the FPC.

Author Contributions

Conceptualization, M.M.; methodology, M.M.; formal analysis, M.M. and S.O.; investigation/measurement, S.O.; data curation, M.M. and S.O.; writing—original draft preparation, M.M and S.O.; writing—review and editing, M.M.; visualization, M.M.; supervision, M.M.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Regulation (EU) 2016/425 of the European Parliament and of the Council of 9 March 2016 on personal protective equipment and repealing Council Directive 89/686/EEC, Official Journal of the European Union, 31. 03. 2016.

- Rossi, R. Firefighting and its influence on the body. Ergonomics 2003, 46, 1017–1033. [Google Scholar] [CrossRef] [PubMed]

- Firefighter Personal Protective Equipment. Chapter 6 in Essential of firefighting, IFSTA International Fire Service Training Association, https://www.ifsta.org/sites/default/files/web-assets/36922-manual-ch6. (accessed on 4 April 2024).

- Сoрoкин, В.; Никифoрoв, А.Л.; Шарабанoва, И.Ю.; Циркина, О.Г. 2018; 1.

- Rossi, R. Interactions between Protection and Thermal Comfort. In: Textiles for Protection, Ed. Scott R.A., Woodhead Publishing in Textiles, Cambridge England, 2005, chapter 10, pp. 233–260.

- Houshyara,S. ; Padhyea, R.; Troynikova, O.; Nayaka, R.; Ranjanb, S. Evaluation and improvement of thermo-physiological comfort properties of firefighters’ protective clothing containing super absorbent materials. The Journal of The Textile Institute 2015, 106, 1394–1402. [Google Scholar] [CrossRef]

- Krzemińska, S.; Szewczyńska, M. Analysis and Assessment of Hazards Caused by Chemicals Contaminating Selected Items of Firefighter Personal Protective Equipment – a Literature Review. Safety 2020, 56, 92–109. [Google Scholar] [CrossRef]

- Fanglong, Z.; Weiyuan, Z.; Minzhi, C. Investigation of Material Combinations for Fire-fighter’s Protective Clothing on Radiant Protective and Heat-Moisture Transfer Performance. Fibres and Textiles in Eastern Europe 2007, 15, 72–75. [Google Scholar]

- Rathour, R.; Das, A.; Alagirusamy, R. Impact of repeated radiative heat exposure on protective performance of firefighter’s protective clothing. Industrial Textiles 2022, 52, 1–30. [Google Scholar] [CrossRef]

- Roy, P.K.; Rajput, P.; Meena, M. Structural Firefighting Suits : Futuristic Materials and Designs for Enhanced Comfort. Trends in Textile Engineering and Fashion Technology 2020, 6, 000633. [Google Scholar] [CrossRef]

- Renard, M.; Puszkarz, A.K. Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography. Materials 2022, 15, 5417. [Google Scholar] [CrossRef] [PubMed]

- Młynarczyk, M. Characteristics of Specialised Firefighter Clothing Used in Poland – the Thermal Parameters. Fibres & Textiles in Eastern Europe 2020, 28, 65–70. [Google Scholar]

- Keiser, C.; Becker, C.; Rossi, R. Moisture Transport and Absorption in Multilayer Protective Clothing Fabrics. Textile Research Journal 2008, 70, 604–613. [Google Scholar] [CrossRef]

- Nayak, R. , Houshyar, S.; Padhye, R. Recent trends and future scope in the protection and comfort of fire-fighters’ personal protective clothing. Fire Science Reviews 2014, 3, 1–19. [Google Scholar] [CrossRef]

- Mandal, S.; Martin Camenzind, M.; Annaheim, S.; Rossi, R. Firefighters’ Protective Clothing and Equipment. In Firefighters’ Clothing and Equipment. Performance, Protection, and Comfort. Ed. Song G., Wang F., CRC Press.Taylor & Francis Group, Broken Sound Parkway 2019, pp. 91–134.

- EN-469:2021 Protective clothing for firefighters - Performance requirements for protective clothing for firefighting activities.

- Nayak, R.; Kanesalingam, S.; Houshyar, S.; Wang, L; , Padhye, R. ; Vijayan, A. Evaluation of thermal, moisture management and sensorial comfort properties of superabsorbent polyacrylate fabrics for the next-to-skin layer in firefighters’ protective clothing. Textile Research Journal 2018, 88, 1077–1088. [Google Scholar] [CrossRef]

- Kamińska, D.; Sukhbat, O.; Matusiak, M. Investigation of The Moisture Transport in Protective Clothing For Firefighters. In Proceedings of the 10th Central European Conference, 2019., Lodz October 22-23.

- Matusiak, M.; Sukhbat, O. Transport of liquid sweat through the multilayer textile assembly, In Clothing-Body Interaction Symposium, Berlin 23. 20 March.

- 20. M290 MMT Moisture Management Tester, 2017.

- Matusiak, M. Moisture Management Properties of Seersucker Woven Fabrics of Different Structure. Fibres & Textiles in Eastern Europe 2019, 27, 43–50. [Google Scholar]

- Barros de Vasconcelos, F.; Monteiro de Barros, LM.; Borelli, C.; Gomes de Vasconcelos, F. Moisture Management Evaluation in Double Face Knitted Fabrics with Different Kind of Constructions and Fibers. Journal of Fashion Technology &Textile Engineering. [CrossRef]

- Matusiak, M. , Sukhbat, O. Liquid Moisture Transport in Stretched Knitted Fabrics. Autex Research Journal 2023, 23, 466–473. [Google Scholar] [CrossRef]

- AATCC Test Method 195-2011 Liquid Moisture Management Properties of Textile Fabrics.

- Sukhbat, O. Shaping the Physiological Comfort Performance of Multilayer Clothing Assemblies for Firefighters, PhD thesis, Lodz University of Technology, Lodz 2023.

- Matusiak, M.; Sukhbat, O. Influence of Stretching on Liquid Transport in Knitted Fabrics. Materials 2023, 16, 2126. [Google Scholar] [CrossRef] [PubMed]

- Sathish Kumar, T.; Ramesh Kumar, M.; Prakash, C.; Senthil Kumar, B. Study on Moisture Management Properties of Plated Interlock Knitted Fabrics. Journal of Natural Fibers 2022, 19, 7330–7337. [Google Scholar] [CrossRef]

Figure 1.

Moisture Management Tester MMT M290.

Figure 1.

Moisture Management Tester MMT M290.

Figure 2.

Top and bottom sensors of the MMT M290.

Figure 2.

Top and bottom sensors of the MMT M290.

Figure 3.

Exemplary results from the Moisture Management Tester – Water Content vs. Time for the multilayer textile set No.1 (SS1): green line – top surface, blue line – bottom surface.

Figure 3.

Exemplary results from the Moisture Management Tester – Water Content vs. Time for the multilayer textile set No.1 (SS1): green line – top surface, blue line – bottom surface.

Figure 4.

Wetting time for top surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 4.

Wetting time for top surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 5.

Wetting time for top surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 5.

Wetting time for top surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 6.

Absorption rate of the bottom surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 6.

Absorption rate of the bottom surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 7.

Absorption rate of the bottom surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 7.

Absorption rate of the bottom surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 8.

Spreading speed of the bottom surface of the investigated inner layers of the multilayer sets for the FPC.

Figure 8.

Spreading speed of the bottom surface of the investigated inner layers of the multilayer sets for the FPC.

Table 1.

Characteristic parameters of sets of clothing materials for the firefighter.

Table 1.

Characteristic parameters of sets of clothing materials for the firefighter.

| Sample Set |

Layer |

A kind

of material |

Raw

material

composition |

Mass per square meter

g/m2

|

| SS1 |

Outer shell |

Woven fabric |

99 aramid/1 ASF |

210 |

| Moisture barrier |

Knitted fabric

laminated |

PES

PU laminate |

80 |

| Lining |

Woven fabric |

Cotton FR |

275 |

| Thermal barrier |

Nonwoven |

aramid |

| SS2 |

Outer shell |

Woven fabric |

98 meta-aramid/ASF |

210 |

| Moisture barrier |

Laminate/nonwoven |

PTFE/aramid |

165 |

| Lining |

Woven fabric |

50 aramid/50 VI FR |

125 |

| Thermal barrier |

Felt |

aramid |

50 |

| SS3 |

Outer shell |

Woven fabric |

58 para-aramid/40 PBI/2 ASF |

205 |

| Moisture barrier |

Laminate/nonwoven |

PTFE/aramid |

100 |

Thermal barrier

(lining and felt) |

Quilted |

aramid |

170 |

| S4 |

Outer shell |

Woven fabric |

99 aramid /1 ASF |

210 |

| Moisture barrier |

Laminate |

65 aramid/35 PU |

120 |

| Thermal barrier |

Knitted fabric |

aramid+FR |

270 |

| Lining |

Woven fabric |

50 aramid/50 VI |

Table 2.

The liquid moisture transport parameters of multilayer textile sets for the firefighter’s protective clothing.

Table 2.

The liquid moisture transport parameters of multilayer textile sets for the firefighter’s protective clothing.

| Sample Set |

WTT

(s) |

WTB

(s) |

TAR

(%/s) |

BAR

(%/s) |

MWRT

(mm) |

MWRB

(mm) |

| SS1 |

Mean |

34.07 |

119.61 |

271.42 |

0.00 |

4.00 |

0.00 |

| SD |

47.15 |

0.88 |

264.13 |

0.00 |

2.24 |

0.00 |

| CV |

1.38 |

0.01 |

0.97 |

0.00 |

0.56 |

0.00 |

| SS2 |

Mean |

2.43 |

120.00 |

80.36 |

0.00 |

30.00 |

0.00 |

| SD |

0.64 |

0.00 |

4.77 |

0.00 |

0.00 |

0.00 |

| CV |

0.26 |

0.00 |

0.06 |

0.00 |

0.00 |

0.00 |

| SS3 |

Mean |

7.49 |

120.00 |

107.68 |

0.00 |

19.00 |

0.00 |

| SD |

8.10 |

0.00 |

113.02 |

0.00 |

8.94 |

0.00 |

| CV |

1.08 |

0.00 |

1.05 |

0.00 |

0.47 |

0.00 |

| SS4 |

Mean |

3.24 |

120.00 |

61.99 |

0.00 |

29.00 |

0.00 |

| SD |

0.16 |

0.00 |

1.89 |

0.00 |

2.24 |

0.00 |

| CV |

0.05 |

0.00 |

0.03 |

0.00 |

0.08 |

0.00 |

Table 3.

The liquid moisture transport parameters of multilayer textile sets for the firefighter’s protective clothing, continuation.

Table 3.

The liquid moisture transport parameters of multilayer textile sets for the firefighter’s protective clothing, continuation.

| Sample Set |

SST

(mm/sec) |

SSB

(mm/sec) |

R

(%) |

OMMC

(-) |

| SS1 |

Mean |

0.35 |

0.00 |

-804.94 |

0.01 |

| SD |

0.26 |

0.00 |

481.07 |

0.02 |

| CV |

0.75 |

0.00 |

0.60 |

2.24 |

| SS2 |

Mean |

7.24 |

0.00 |

-951.73 |

0.00 |

| SD |

1.92 |

0.00 |

35.20 |

0.00 |

| CV |

0.27 |

0.00 |

0.04 |

0.00 |

| SS3 |

Mean |

8.30 |

0.00 |

-1353.1 |

0.00 |

| SD |

9.97 |

0.00 |

216.92 |

0.00 |

| CV |

1.20 |

0.00 |

0.16 |

0.00 |

| SS4 |

Mean |

4.63 |

0.00 |

-962.94 |

0.00 |

| SD |

0.22 |

0.00 |

34.57 |

0.00 |

| CV |

0.05 |

0.00 |

0.04 |

0.00 |

Table 4.

The liquid moisture transport parameters of the inner layer of multilayer textile sets for the firefighter’s protective clothing.

Table 4.

The liquid moisture transport parameters of the inner layer of multilayer textile sets for the firefighter’s protective clothing.

| Sample Sets |

WTT

(s) |

WTB

(s) |

TAR

(%/s) |

BAR

(%/s) |

MWRT

(mm) |

MWRB

(mm) |

SS1

inner layer |

Mean |

12.04 |

39.31 |

394.39 |

22.48 |

7.00 |

9.00 |

| SD |

3.71 |

47.34 |

216.43 |

18.93 |

2.74 |

5.48 |

| CV |

0.31 |

1.20 |

0.55 |

0.84 |

0.39 |

0.61 |

SS2

inner layer |

Mean |

2.30 |

60.88 |

75.89 |

4.26 |

30.00 |

3.00 |

| SD |

0.47 |

54.38 |

3.87 |

4.32 |

0.00 |

4.47 |

| CV |

0.20 |

0.89 |

0.05 |

1.01 |

0.00 |

1.49 |

SS3

inner layer |

Mean |

2.64 |

37.98 |

71.74 |

24.50 |

29.00 |

11.00 |

| SD |

1.44 |

45.71 |

20.14 |

20.57 |

2.24 |

9.62 |

| CV |

0.55 |

1.20 |

0.28 |

0.84 |

0.08 |

0.87 |

SS4

inner layer |

Mean |

2.73 |

6.40 |

62.34 |

40.45 |

30.00 |

16.00 |

| SD |

0.91 |

1.15 |

6.61 |

6.37 |

0.00 |

2.24 |

| CV |

0.33 |

0.18 |

0.11 |

0.16 |

0.00 |

0.14 |

Table 5.

The liquid moisture transport parameters of the inner layer of multilayer textile sets for the firefighter’s protective clothing, continuation.

Table 5.

The liquid moisture transport parameters of the inner layer of multilayer textile sets for the firefighter’s protective clothing, continuation.

| Sample |

SST

(mm/sec) |

SSB

(mm/sec) |

R

(%) |

OMMC

(-) |

S1

inner

layer |

Mean |

0.48 |

0.57 |

-168.88 |

0.18 |

| SD |

0.16 |

0.37 |

594.09 |

0.20 |

| CV |

0.34 |

0.65 |

3.52 |

1.10 |

S2

inner layer |

Mean |

7.76 |

0.37 |

-1026.4 |

0.01 |

| SD |

1.88 |

0.63 |

37.44 |

0.02 |

| CV |

0.24 |

1.70 |

0.04 |

2.24 |

S3

inner layer |

Mean |

13.41 |

0.97 |

-849.57 |

0.08 |

| SD |

46.11 |

1.10 |

736.61 |

0.07 |

| CV |

3.44 |

1.14 |

0.87 |

0.87 |

S4

inner layer |

Mean |

5.07 |

2.51 |

-598.44 |

0.21 |

| SD |

0.98 |

0.48 |

58.13 |

0.03 |

| CV |

0.19 |

0.19 |

0.10 |

0.14 |

Table 6.

The liquid moisture transport parameters of the middle layer of multilayer textile sets for the firefighter’s protective clothing.

Table 6.

The liquid moisture transport parameters of the middle layer of multilayer textile sets for the firefighter’s protective clothing.

| Sample |

WTT

(s) |

WTB

(s) |

TAR

(%/s) |

BAR

(%/s) |

MWRT

mm) |

MWRB

(mm) |

S1

middle

layer |

Mean |

8.28 |

61.07 |

248.55 |

3.85 |

5.00 |

5.00 |

| SD |

0.99 |

4.30 |

175.93 |

0.08 |

0.00 |

0.00 |

| CV |

0.12 |

0.07 |

0.71 |

0.02 |

0.00 |

0.00 |

S2

middle

layer |

Mean |

13.34 |

120.00 |

294.73 |

0.00 |

5.00 |

0.00 |

| SD |

3.11 |

0.00 |

269.83 |

0.00 |

0.00 |

0.00 |

| CV |

0.23 |

0.00 |

0.92 |

0.00 |

0.00 |

0.00 |

S3

middle

layer |

Mean |

7.16 |

120.00 |

75.80 |

0.00 |

5.00 |

0.00 |

| SD |

0.73 |

0.00 |

11.99 |

0.00 |

0.00 |

0.00 |

| CV |

0.10 |

0.00 |

0.16 |

0.00 |

0.00 |

0.00 |

S4

middle

layer |

Mean |

7.16 |

120.00 |

258.60 |

0.00 |

5.00 |

0.00 |

| SD |

0.07 |

0.00 |

198.00 |

0.00 |

0.00 |

0.00 |

| CV |

0.01 |

0.00 |

0.77 |

0.00 |

0.00 |

0.00 |

Table 7.

The liquid moisture transport parameters of the middle layer of multilayer textile sets for the firefighter’s protective clothing. continuation.

Table 7.

The liquid moisture transport parameters of the middle layer of multilayer textile sets for the firefighter’s protective clothing. continuation.

| Sample |

SST

(mm/sec) |

SSB

(mm/sec) |

R

(%) |

OMMC

(-) |

S1

middle

layer |

Mean |

0.59 |

0.08 |

-1162.2 |

0.00 |

| SD |

0.07 |

0.01 |

25.37 |

0.00 |

| CV |

0.12 |

0.07 |

0.02 |

0.00 |

S2

middle

layer |

Mean |

0.38 |

0.00 |

-1039.6 |

0.00 |

| SD |

0.09 |

0.00 |

58.38 |

0.00 |

| CV |

0.23 |

0.00 |

0.06 |

0.00 |

S3

middle

layer |

Mean |

0.68 |

0.00 |

-1023.2 |

0.00 |

| SD |

0.07 |

0.00 |

31.33 |

0.00 |

| CV |

0.10 |

0.00 |

0.03 |

0.00 |

S4

middle

layer |

Mean |

0.68 |

0.00 |

-926.50 |

0.00 |

| SD |

0.01 |

0.00 |

29.05 |

0.00 |

| CV |

0.01 |

0.00 |

0.03 |

0.00 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).