The scientific methodology used resort to the inductive method which has as its starting point with observation of particular facts to, through their association, establish generalizations that allow the formulation of theory. Therefore, the work consists of carrying out observations and data analysis. With visits to the damaged house, to take the maximum information registered in photos and collecting information in personal communications, from the persons which were present during the fire. Then, the observed and analysed data were laboratory tested to consistently identify characteristics that lead to the ignition and propagation of the fire.

Laboratory tests to simulat the accident conditions, using similar materials and condition were performed, in order to demonstrate the potential for ignition of a beam in contact with the hot gases from the fireplace. K type thermocouples connected to the NI CDAQmx acquisition system via a NI9213 board, which allowed continuous recording of the temperatures reached throughout the tests, with a resolution of 1 second, were used with the program FLEXllogger from National Instruments. Additionally, the test was recorded in the infrared and visible range with the FLIR infrared (IR) camera, model SC660.

Results and Discussion

On June 21, 2021, after authorization from the court, the team moved to the incident place, the owners couple were waiting for us. After arriving at the location where the owners were. It was not possible to travel by car, we walked to the house, through narrow streets that were difficult to access. We started by interviewing the owners, who informed us that they are married, unemployed and have three children, so the loss of their home puts them in a difficult situation in socio-economic terms. They reported that the damaged house had been rebuilt between March and August 2020, by the builder from a nearby city (Leiria), without requiring a license, as its construction was prior to 1920. The owners lived in Lisbon but decided to move to the interior (Arganil) and rebuild an old family house, and to that end they used a digital platform, where they found the construction company.

The fire in the house took place on December 25, 2020, a Friday, when they had already been living in the house for more than a month. On the 24th, Christmas Eve, the family was together in the house and in addition to the household, there were other family members, including lady’s brother. On this day and taking into account the cold that can be felt at this time, the fireplace was on and continued to burn on the 25th, more than 48 hours. On the 25th, at around 4pm they felt that there was smoke, so they opened the windows. This fireplace already existed in the house before it was rebuilt, so it was only requested that the exterior structure be enlarged. The fireplace is located in the living room, on the upper floor of the house. A new roof was also placed on the house, maintaining the central wooden structure, that is, replacing the roof with a sandwich panel and inside it was fitted with a wooden false ceiling (lining). It should be noted that we consider it relevant to mention that we noticed the insertion of a beam in the fireplace chimney all the way to the inside, up to the area where hot combustion gases pass through, as can be seen in

Figure 1. To feed the fireplace, the couple used Pine firewood, mostly, but also oak and olive.

After opening the windows, the smell of smoke seemed to have eased, however, at around 6pm the brother of the owner, who was on the lower floor, decided to go take a shower, and to do so he went up to the upper floor, passed through the living room living room and went to the bathroom, which was next to the fireplace room. As he passed through the room he heard a kind of crackling sound from the fire and looking at the chimney he saw sparks coming out. Thus, he noticed that the roof was on fire and at that moment they still had electricity, he immediately called owner and they started to leave the house, between 6:30 pm and 7:30 pm. A neighbor, called the firefighters (Volunteer Firefighters of Coja, Arganil), according to the records with the alarm at 7:35 pm, who arrived at the scene 45 minutes later, with 22 operators involved in fighting the flames. The family members were already abroad, couple the, the 3 children and a brother. The owner, removed the gas bottles (

Figure 2) to a more distant land and the fuel from a generator.

Figure 2.

Location where the gas cylinders were removed.

Figure 2.

Location where the gas cylinders were removed.

Table 1.

Data from fire.

Alert

|

17:35PM |

Ignition cause

|

Fireplace, with technical flaws and connection to the ceiling lining |

| Equipment involved in the ignition |

Fireplace |

| Source of heat |

pine firewood |

| Extension |

The entire house |

| Factors contributing to ignition |

Wooden beams inside the fireplace chimney, stone-lined plasterboard wall between the chimney and the wooden lining, with sandwich panels on the ceiling. |

| Ignition place |

Living room |

| Operational people |

22 elements of the firefighters |

Based on this study, with the elements collected and analysis of the data collected, we consider that the ignition occurred next to the fireplace, which was turned on and burning with woody material, with the wooden beam inside the fireplace and with the false ceiling covered with wood, as shown in

Figure 3.

The cause of the ignition appears to be directly linked to the insertion of the wooden beam into the chimney structure (with dimensions of 11cm x 5cm), where it came into contact with the hot combustion gases, with temperatures exceeding 600ºC. Wood, as it is a natural polymer, when subjected to fire, undergoes depolymerization and carbonization, altering its mechanical properties, depending on the temperature reached and the time of exposure to the heat to which it was subjected. The following table shows the changes that we can observe with increasing temperature in wood.

Shafler (1973) says that woody materials undergo pyrolysis at temperatures in the order of ~300ºC. Therefore, this practice of embedding the beams, or the carelessness of not removing them, during the reconstruction, seems to be a serious failure (either of these two actions) that will certainly have led to the outcome of the fire. We also remember that an additional barrier to the release of heat was created, with the outer layer built around the chimney, which would have promoted the accumulation of heat near the lining and wooden beams, as there was rock wool insulation at the top. mineral. Commonly known as sandwich panels were placed on the roof, thin metal sheets with highly combustible polymeric material inside, which would have promoted the rapid spread of the fire across the roof (

Figure 4,

Figure 5 and

Figure 6)

Carrying out laboratory tests simulating the accident conditions, using similar materials and conditions

In order to demonstrate the potential for ignition of a beam in contact with the hot gases from the fireplace, tests were carried out in the fire laboratory at the University of Coimbra. In the absence of widespread and standardized tests for this type of accident, the site conditions were replicated, using a vertical combustion tunnel in the laboratory, where wood chips similar to those used in a conventional fireplace were ignited and burned. calorific value of approximately 20 MJ/kg. A wooden beam measuring 11cm x 5cm was inserted through a hole in one of the sides, at a height of 2m from the base and the burning area, as at the accident site.

Figure 7 shows the vertical combustion tunnel, with the wooden beam being tested.

The wooden beam was instrumented with type K thermocouples and connected to the NI CDAQmx acquisition system via a NI9213 board, which allowed continuous recording of the temperatures reached throughout the test, with a resolution of 1 second, using the FLEXllogger program from National Instruments. Additionally, the test was recorded in the infrared and visible range.

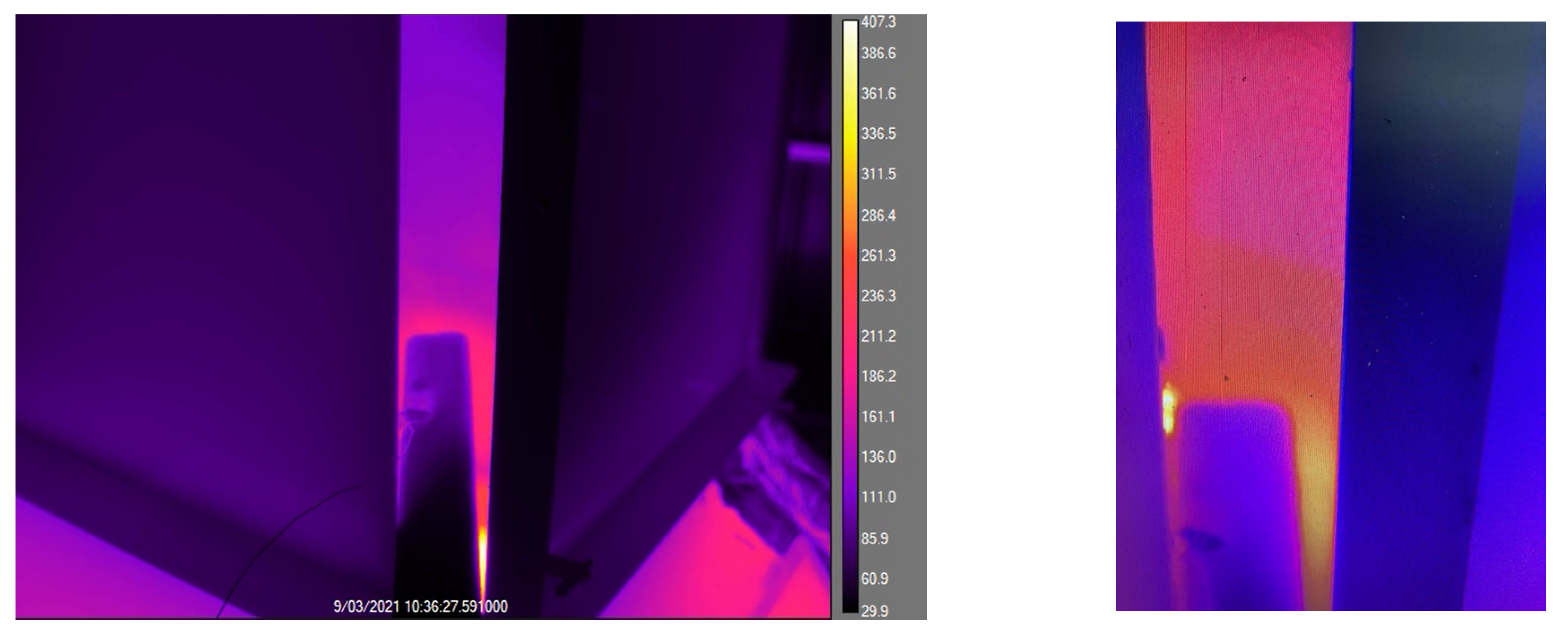

Figure 7 shows a general image of the test with the FLIR infrared (IR) camera, model SC660.

Figure 8.

General image of the test with the infrared camera.

Figure 8.

General image of the test with the infrared camera.

The infrared camera, model SC660, from FLIR, allowed the spatial monitoring of all recorded temperatures and the extraction of frames, which quickly allows the evolution of the test to be clarified at any time.

The recording of temperatures made it possible to identify that temperatures exceeding 360ºC were reached in the wooden beam, as can be seen in the following figures, in the yellow areas ,

Figure 9.

After carrying out the test, which lasted around 40 minutes, the beam was analyzed and photographed, so clearly burned areas could be seen that had combusted, despite not having had contact with the flames and only with the gases. hot, as in the case of the chimney

Figure 10.

After carrying out this test and its analysis, it was verified that it was possible for the beam to start the combustion process, that is, in the chimney there were conditions to start a fire. Additionally, in the house we had the continuity of fuels, through the wooden lining on the ceiling, the electrical cables and the sandwich panels on the building's roof, as well as the chimney lining with the plasterboard support structure and stones, with connection to the wooden structure.