Submitted:

18 April 2024

Posted:

19 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

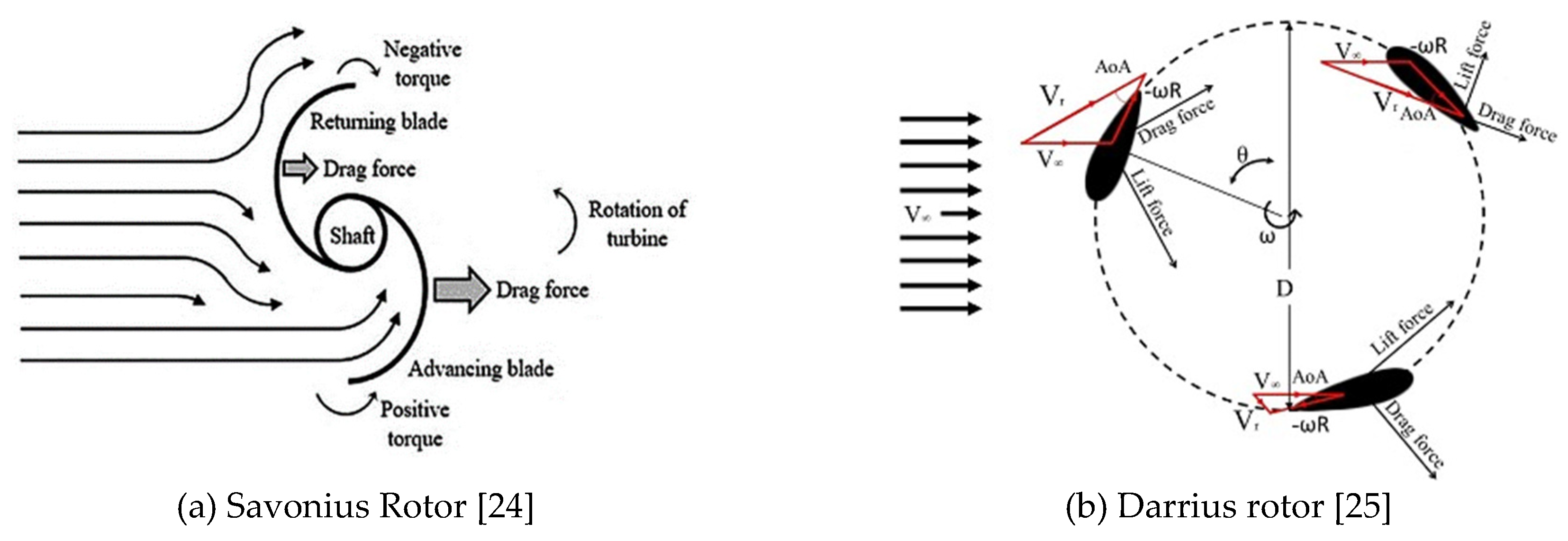

2. Fundamental Physical Principle of VAWTs

3. Mechanism of Wind Power Harvesting: Active Techniques

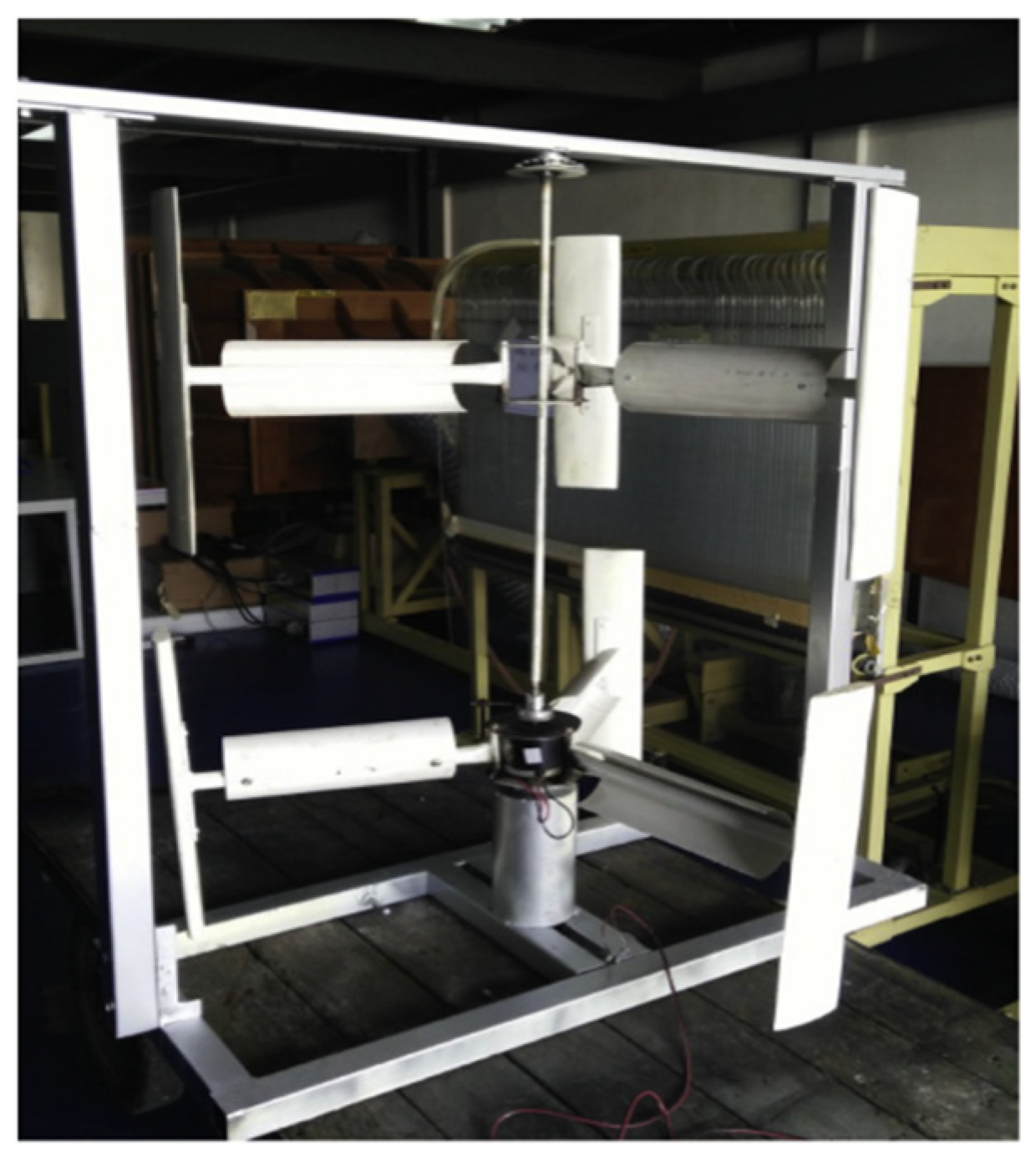

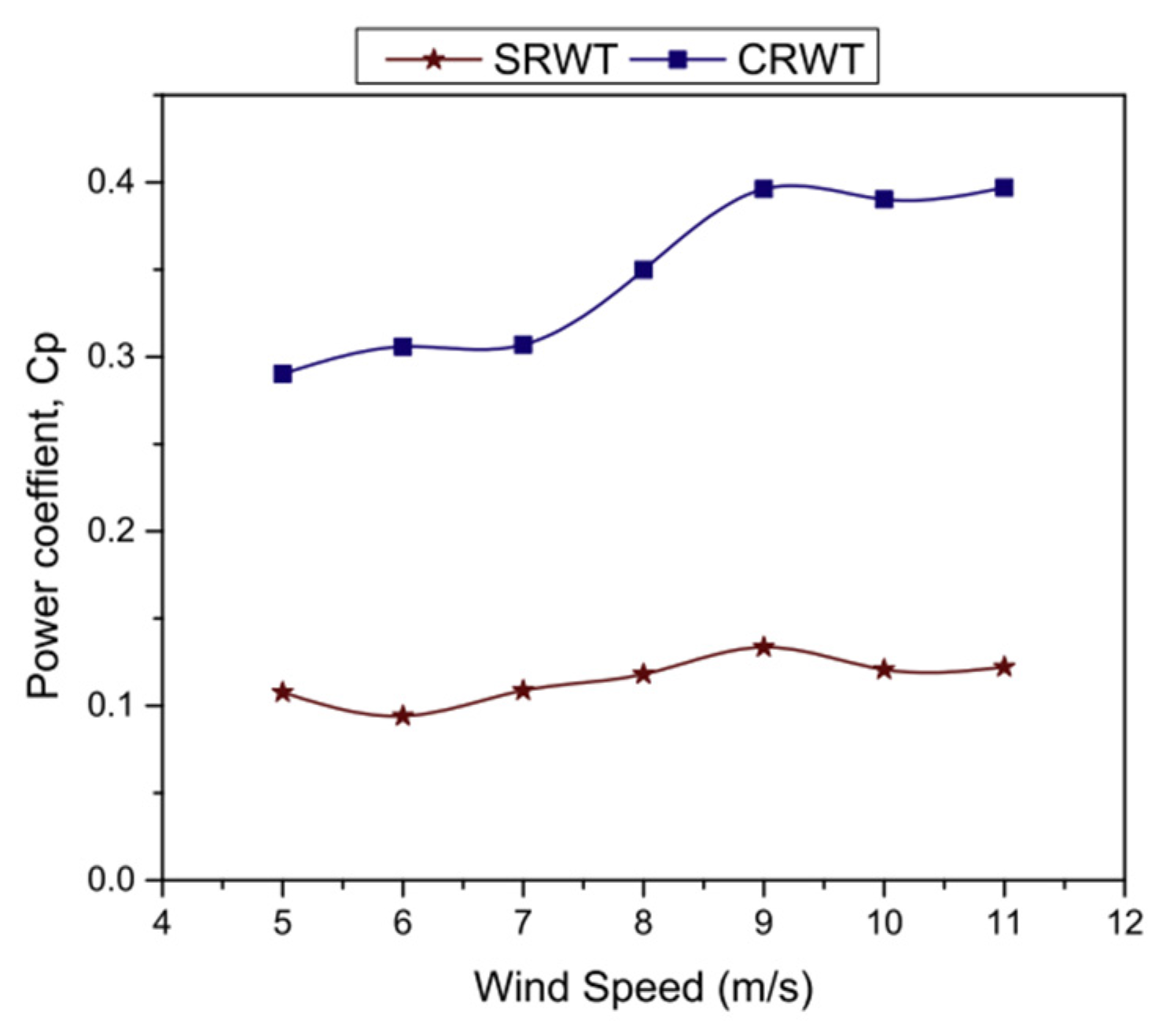

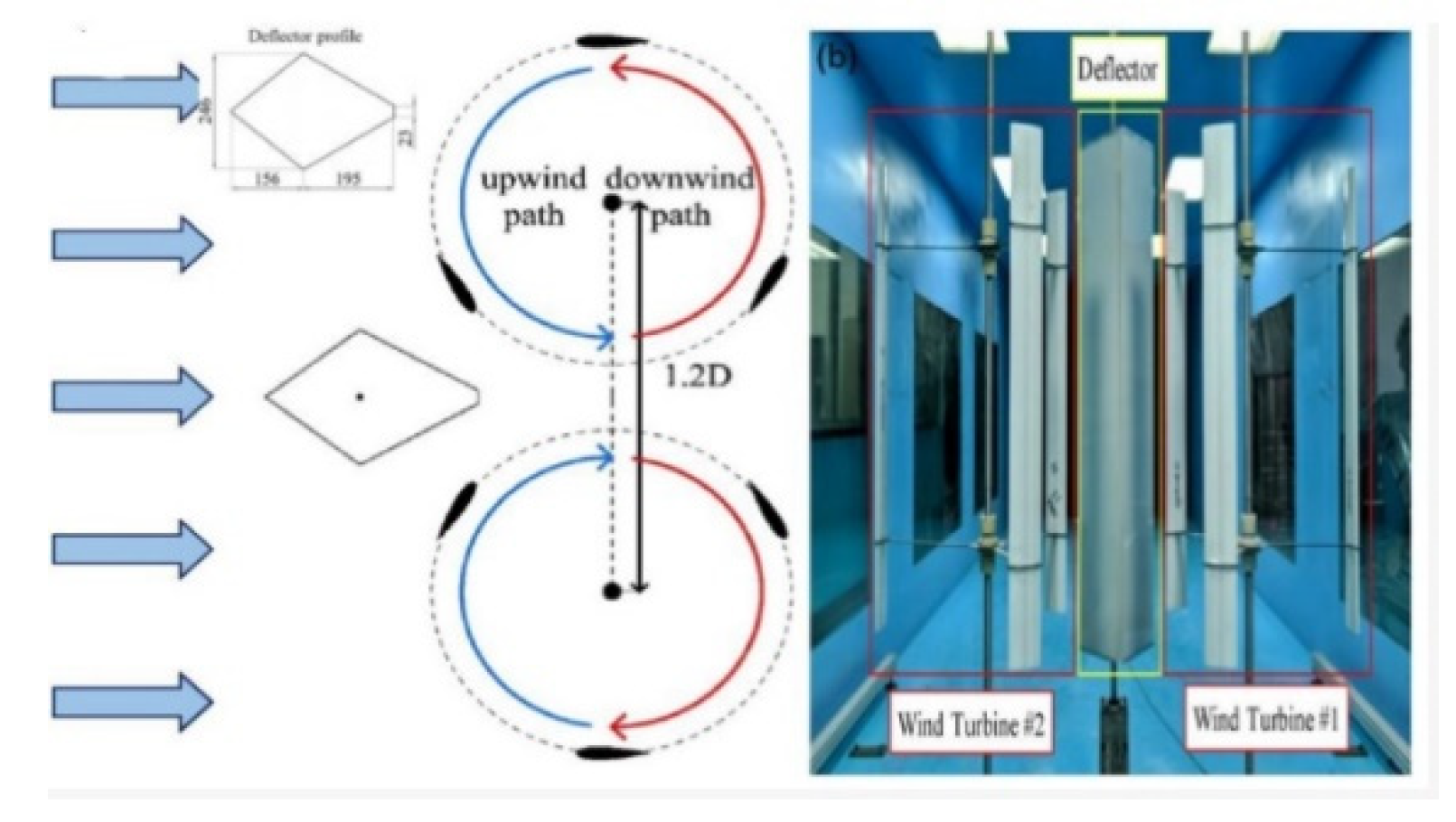

3.1. Counter-Rotating Technique

3.2. Design Parameters Affecting the Performance of VAWTs

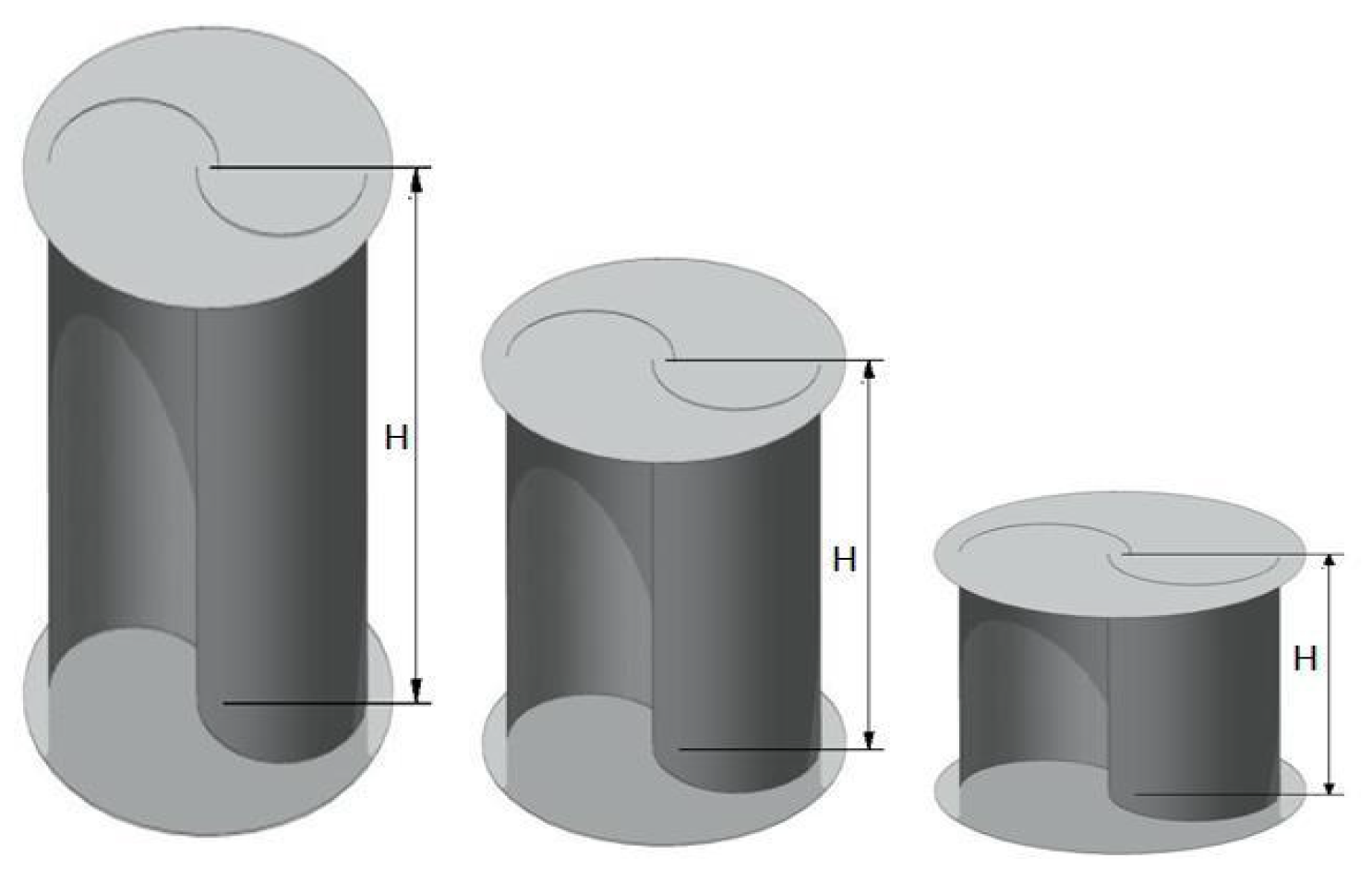

3.2.1. Aspect Ratio (AR) Effect

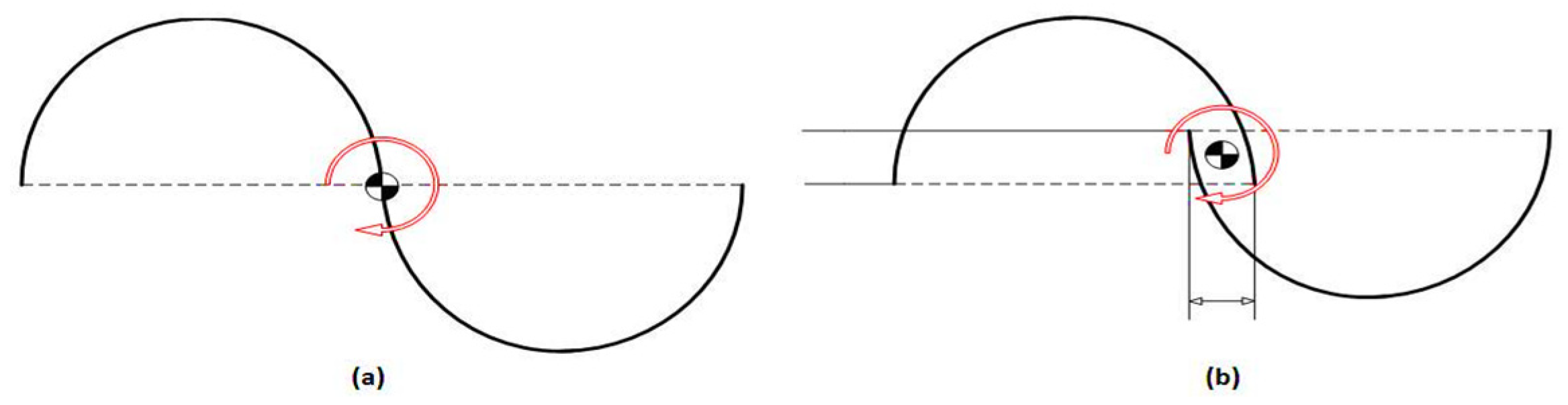

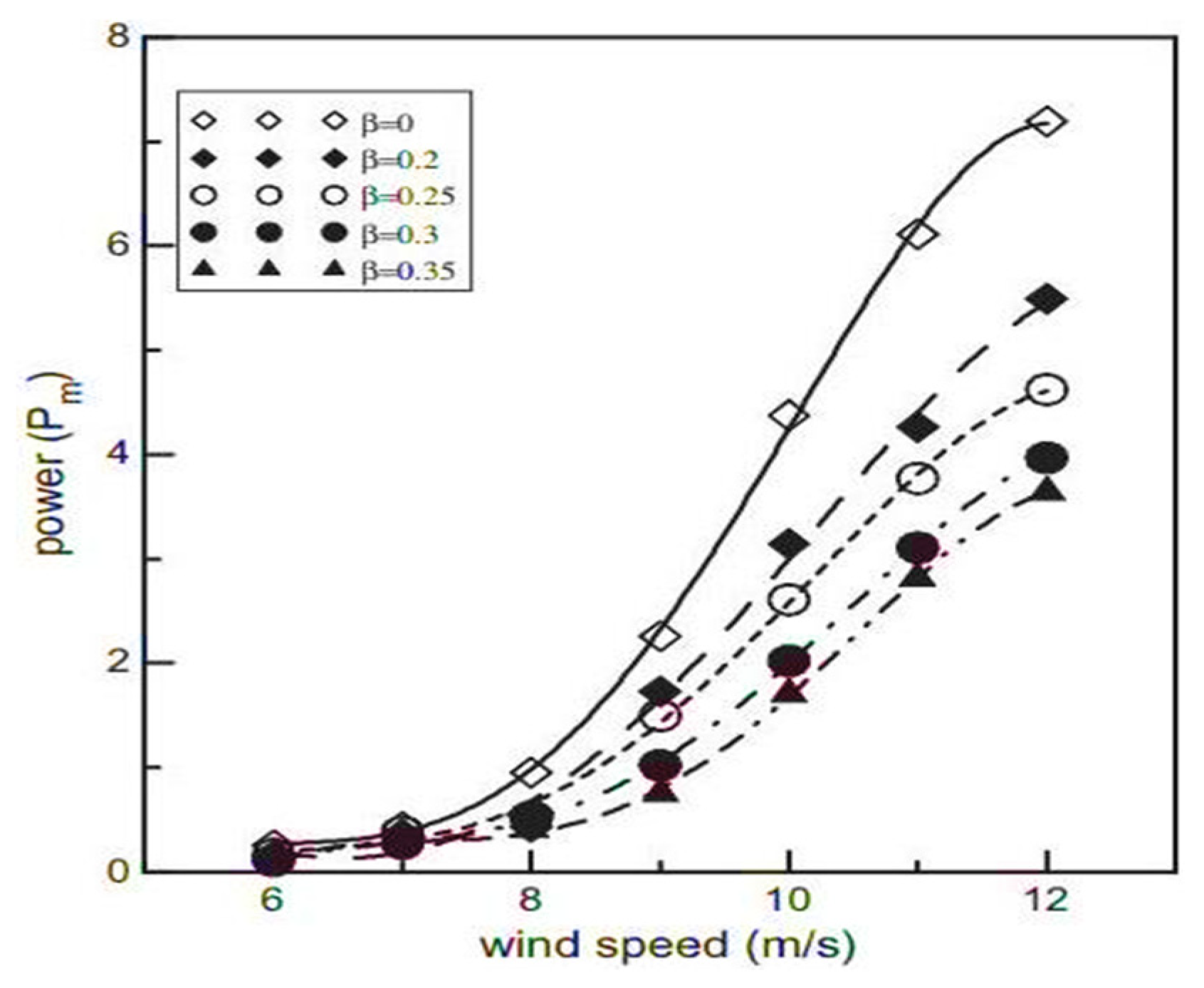

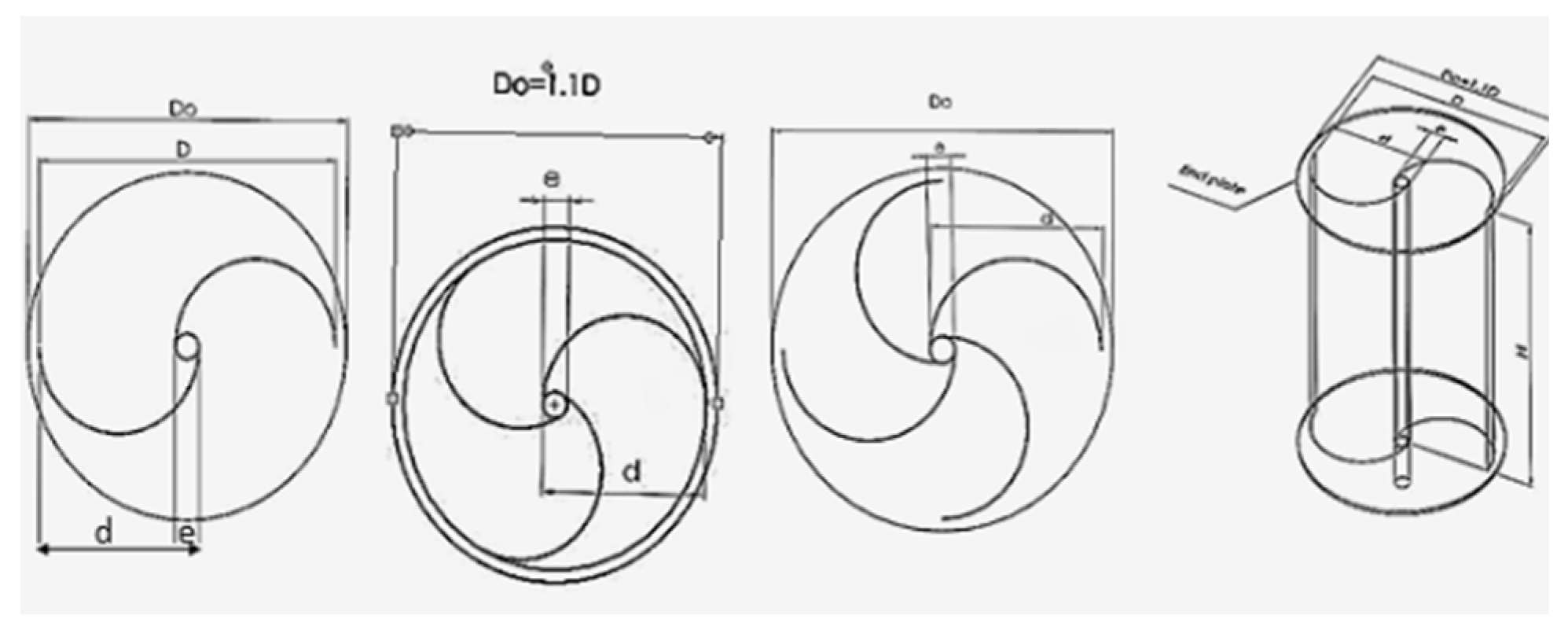

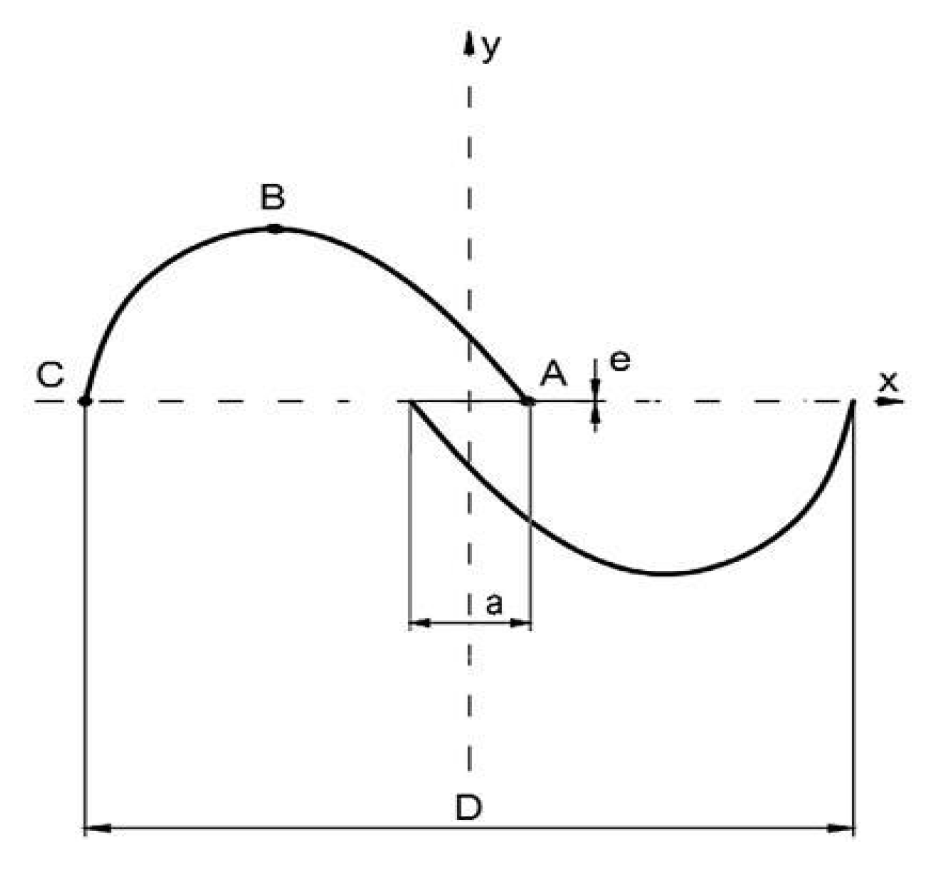

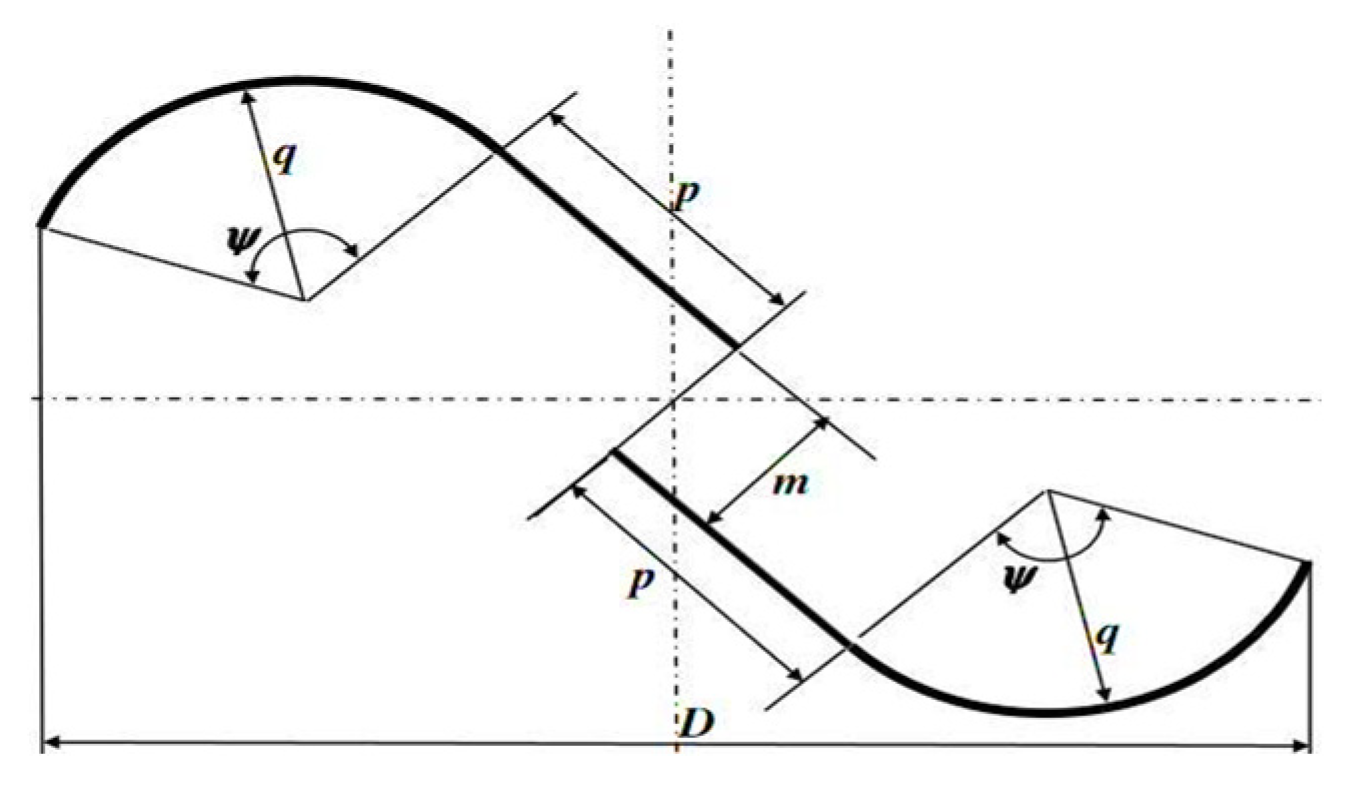

3.2.2. Overlap Ratio Effect

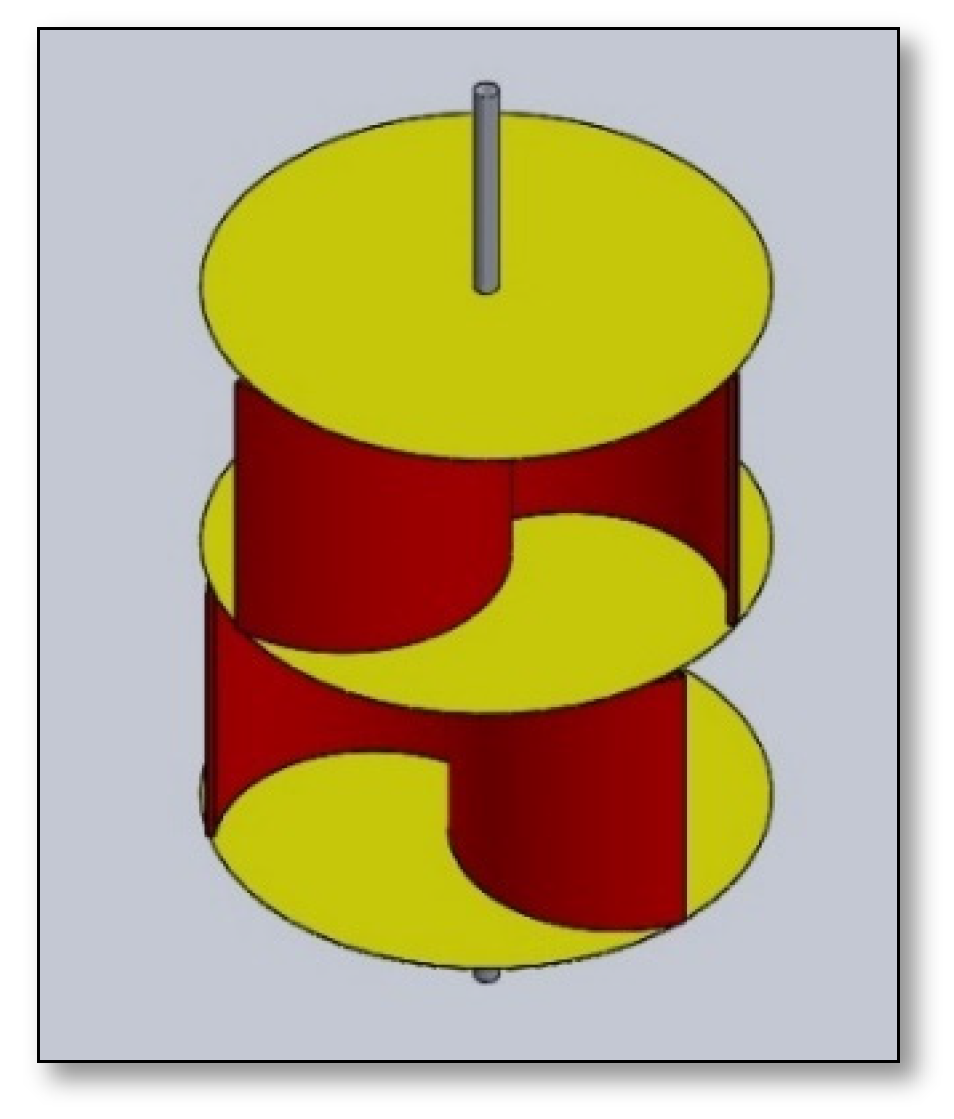

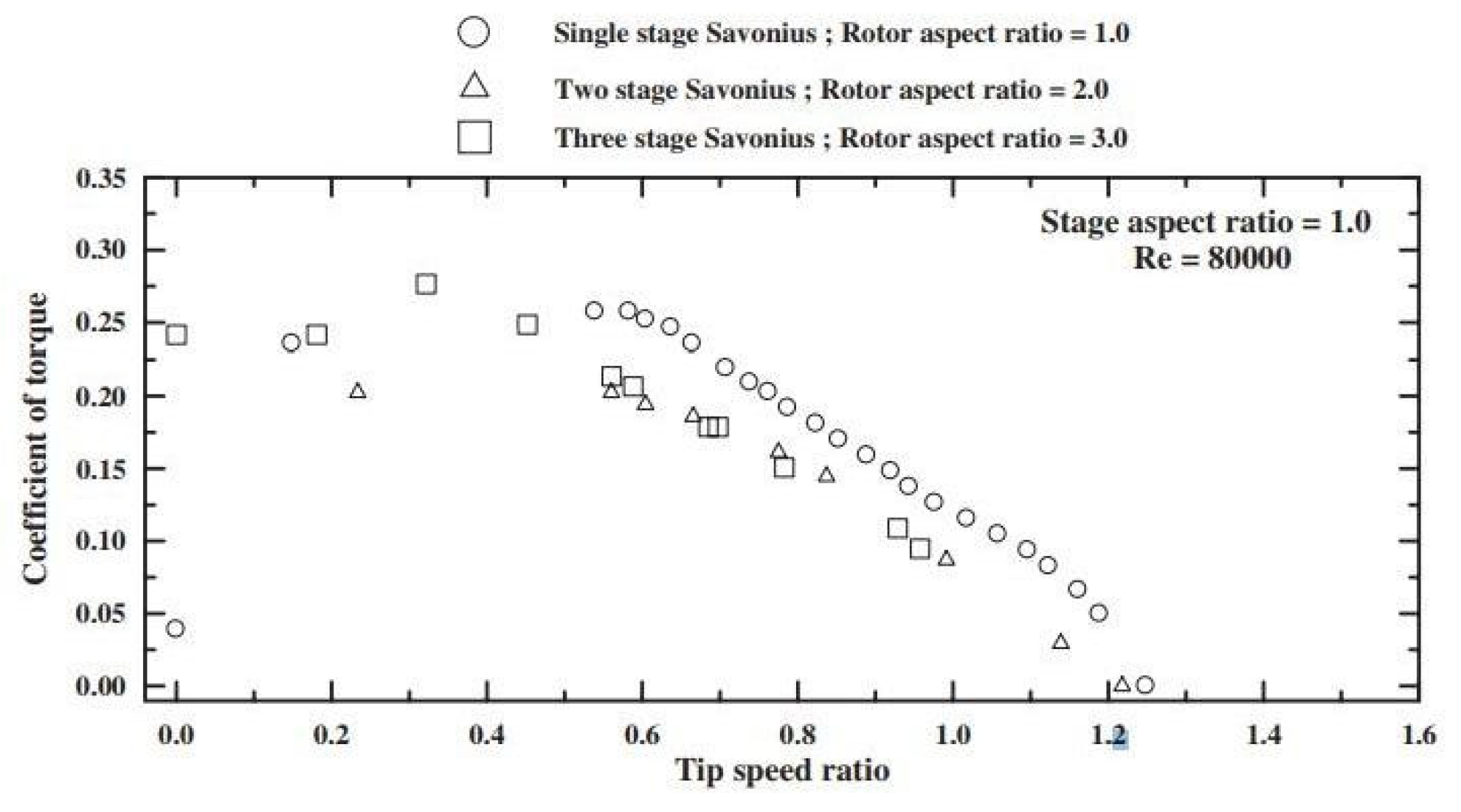

3.2.3. Multi-Staging Effect

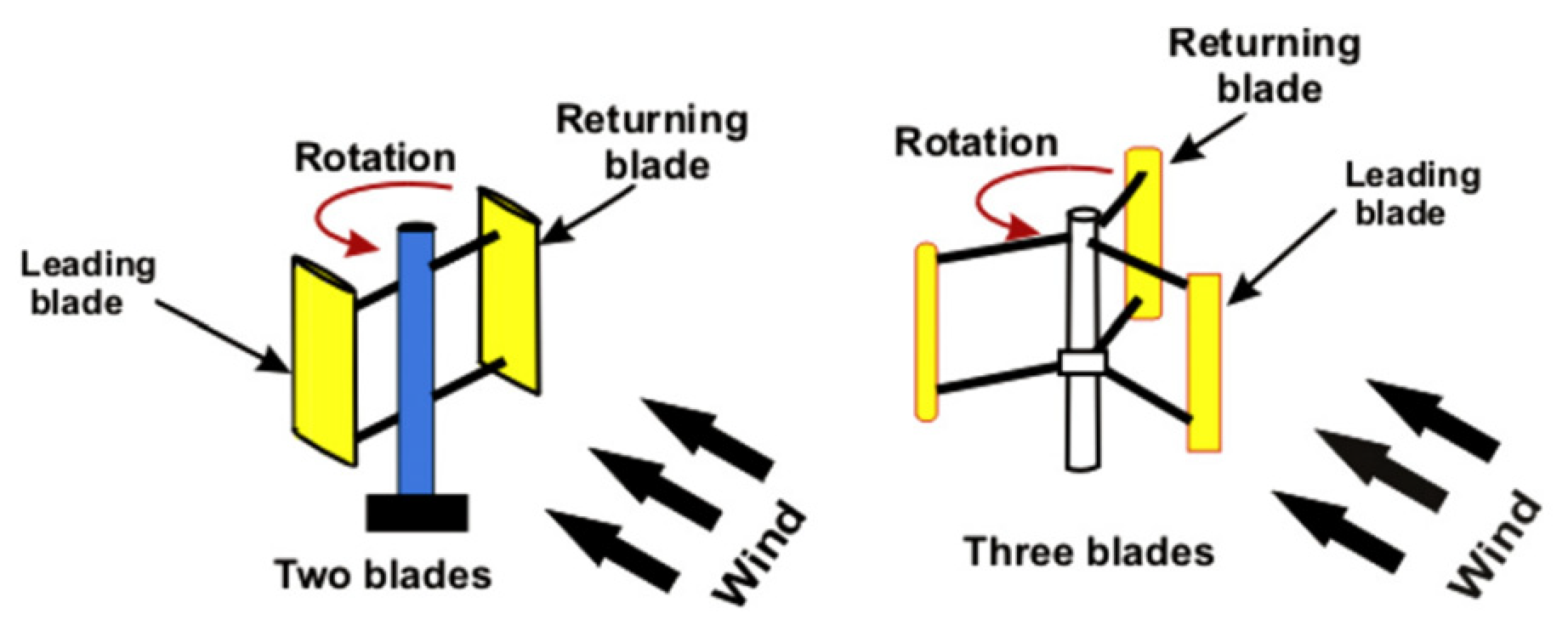

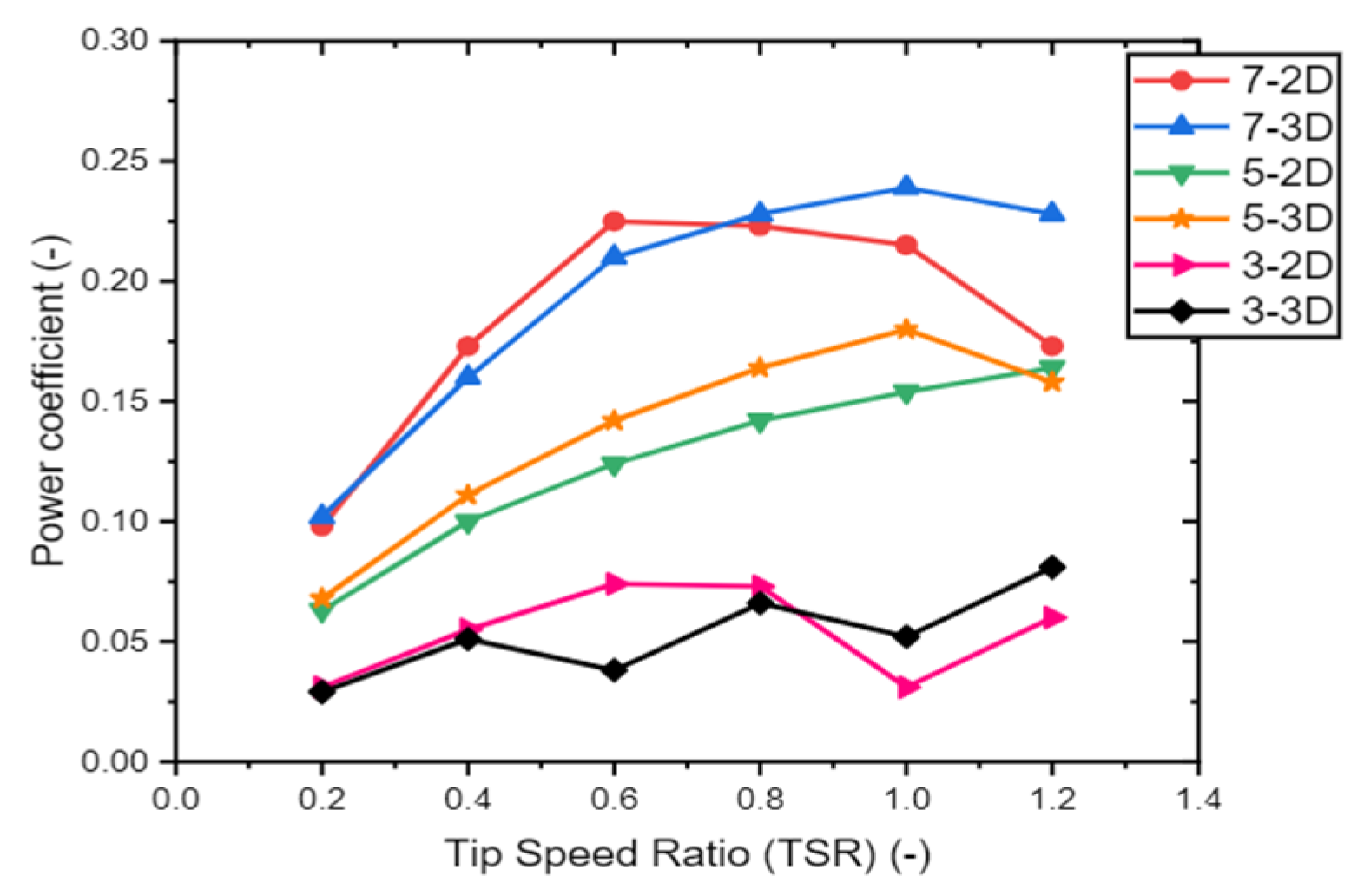

3.2.4. Effect of Number of Blades

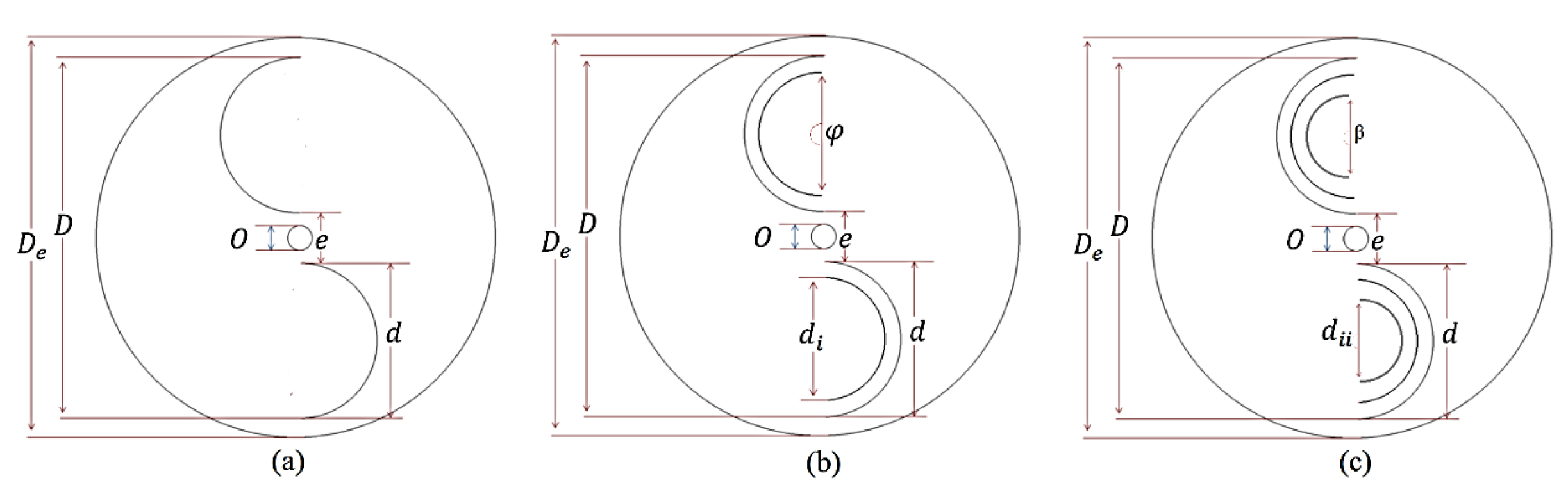

3.2.5. Effect of Inner Blades

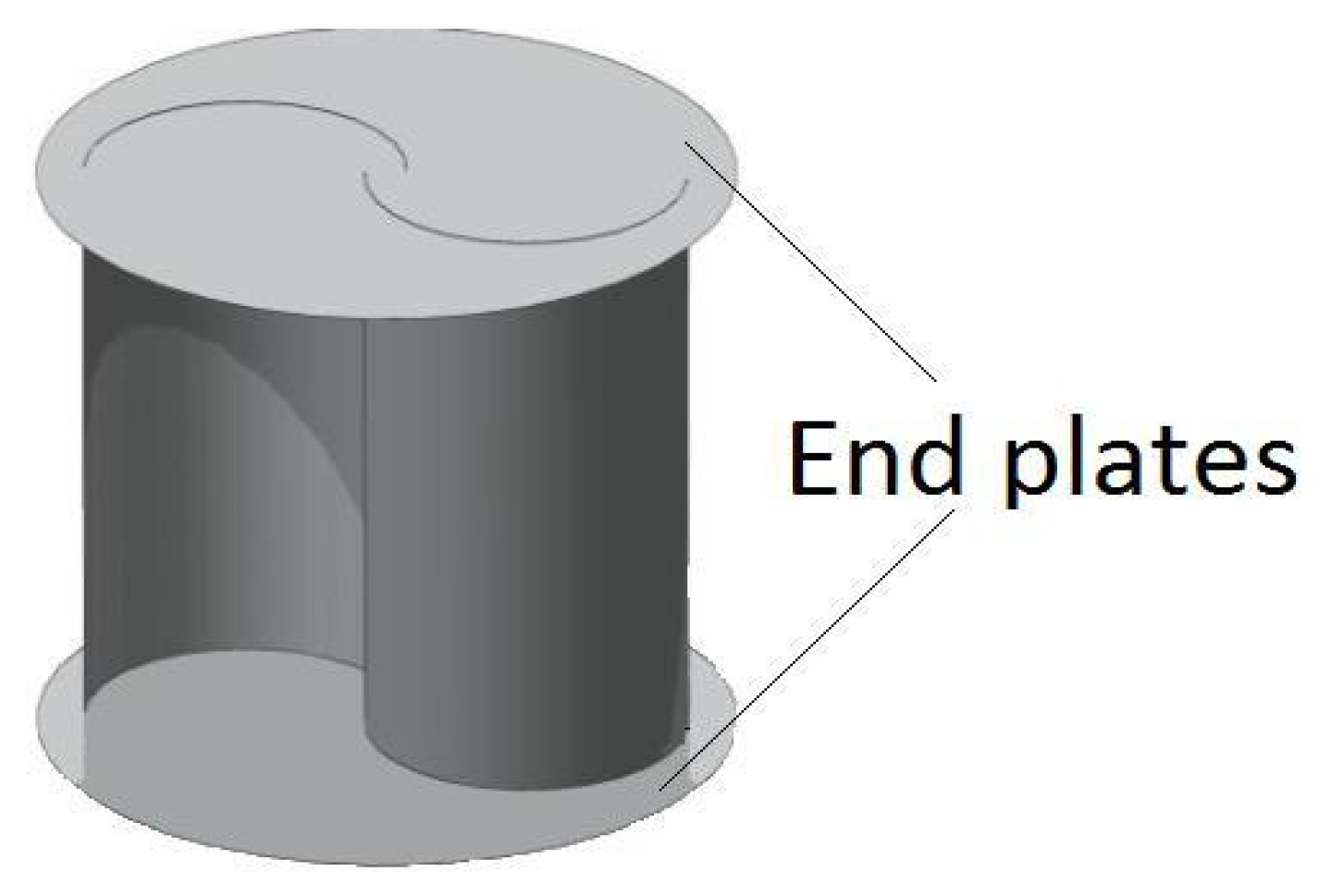

3.2.6. Effect of End Plates

3.2.7. Tip Speed Ratio (TSR) Effect

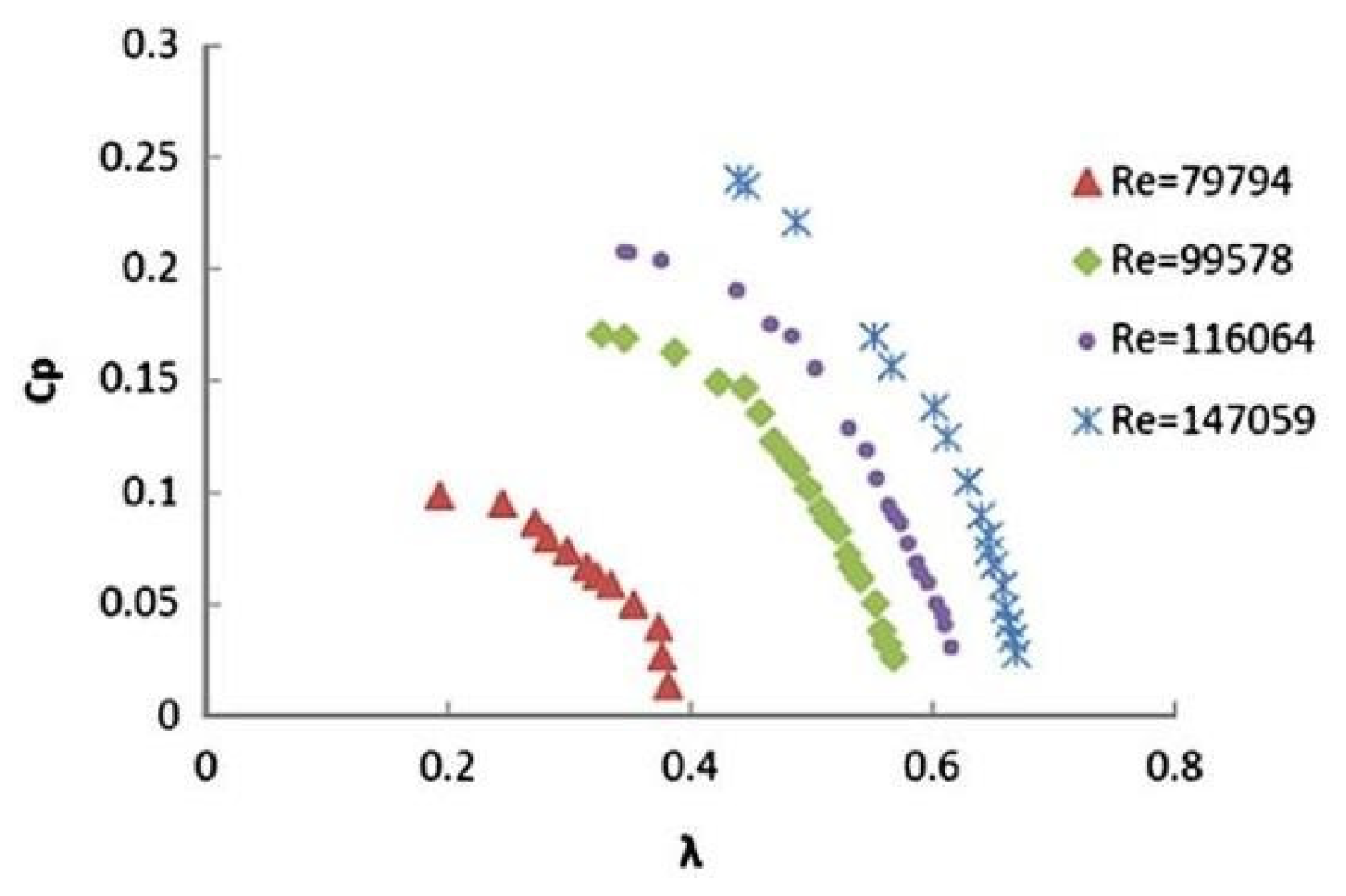

3.2.8. Effect of Reynolds Number

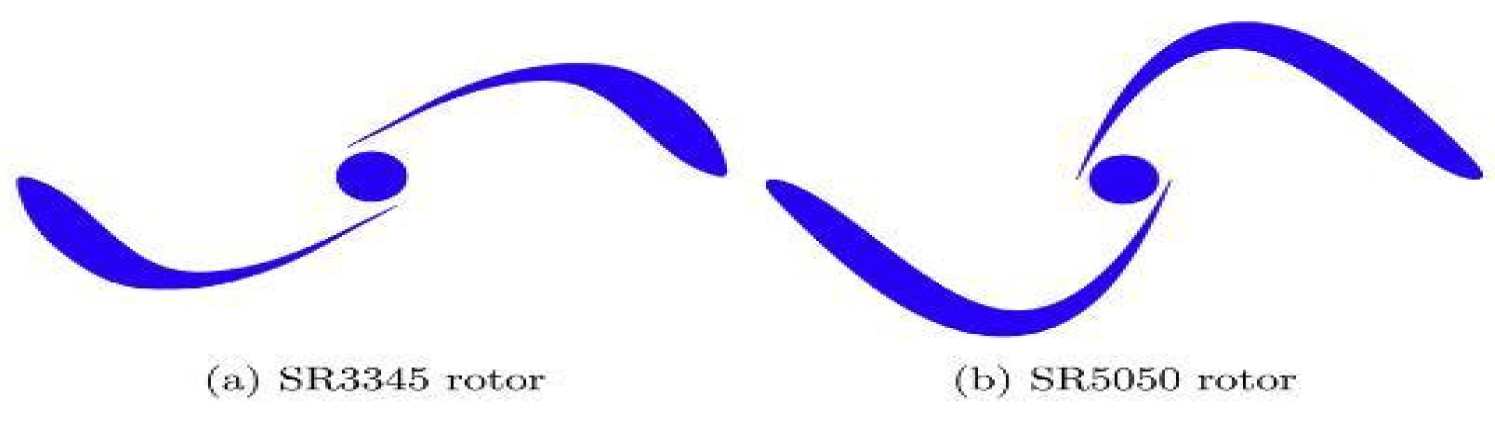

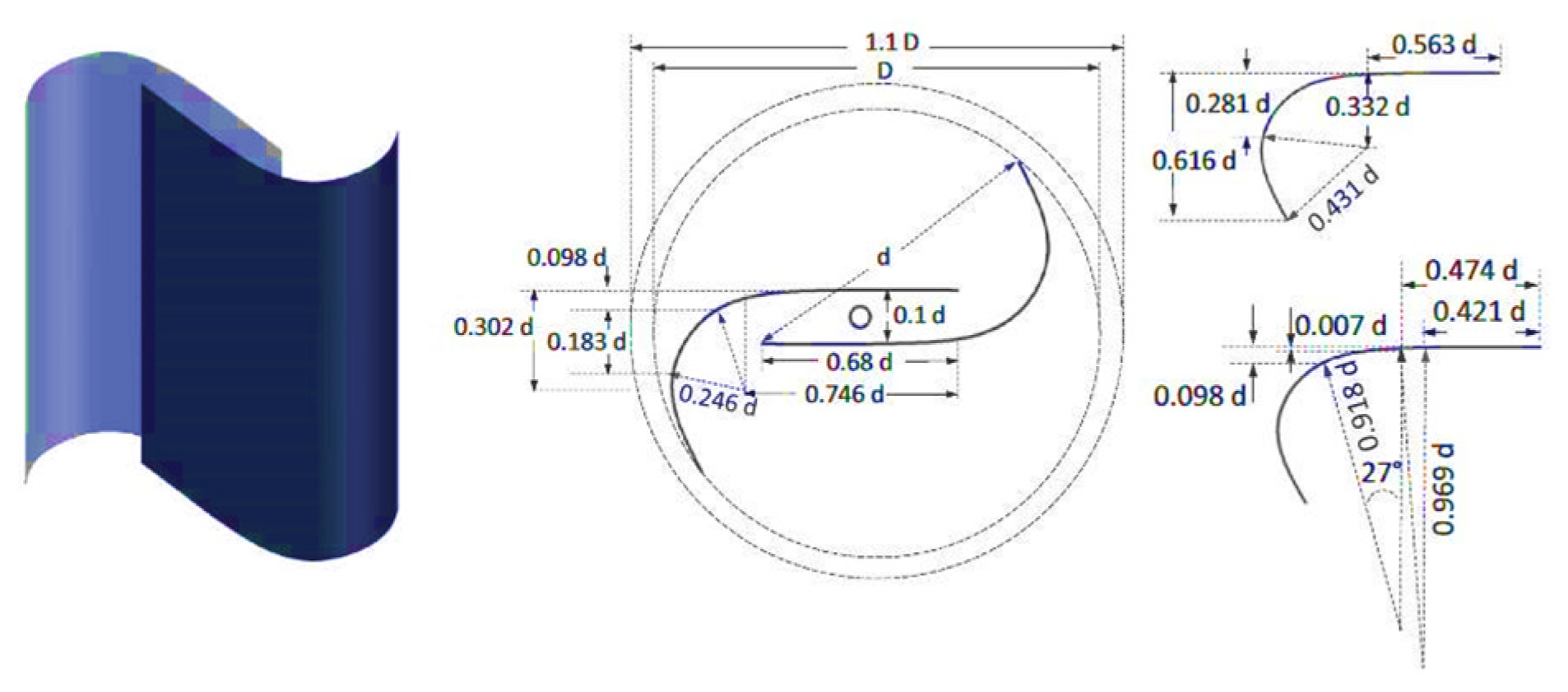

3.2.9. Effect of Blade Shape and Profile

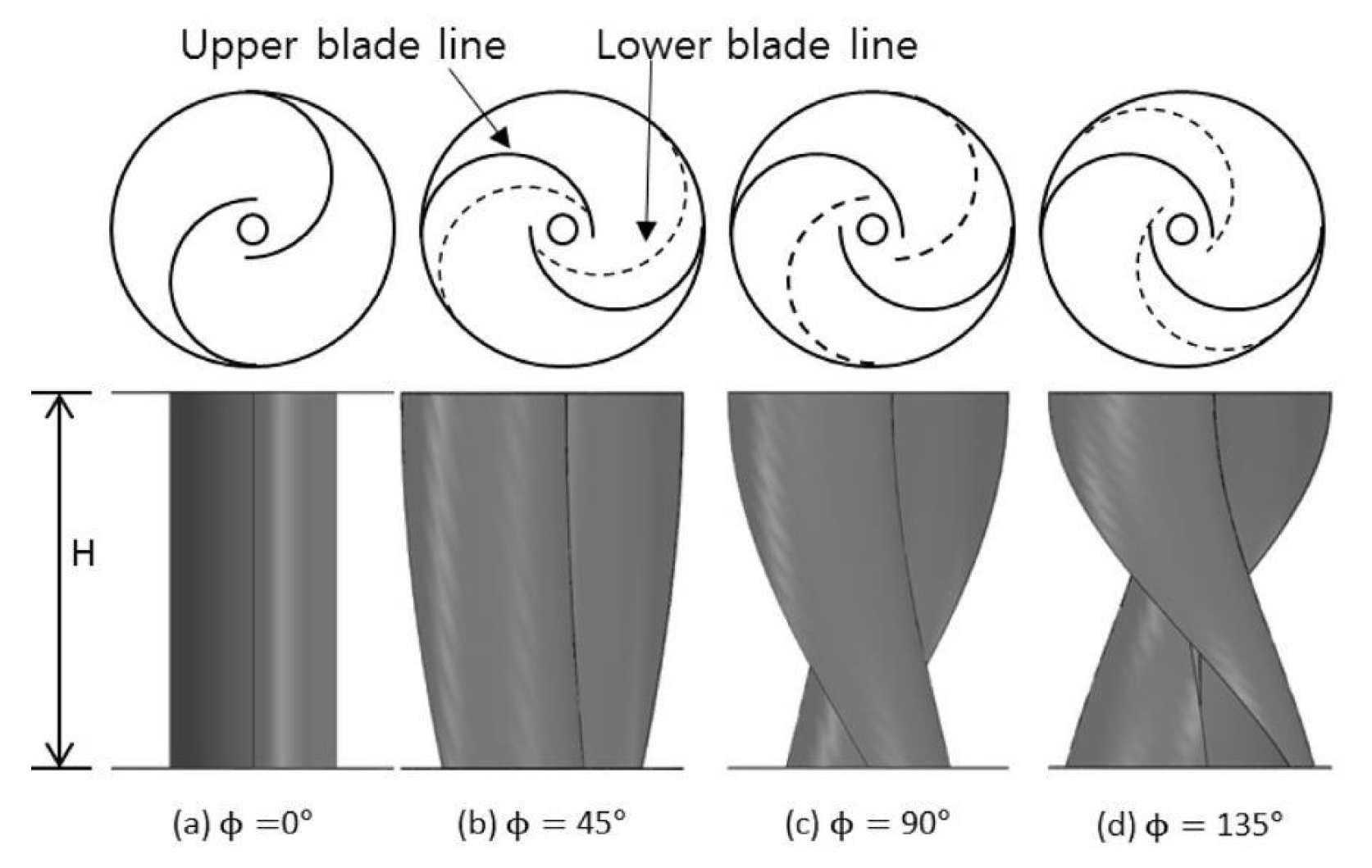

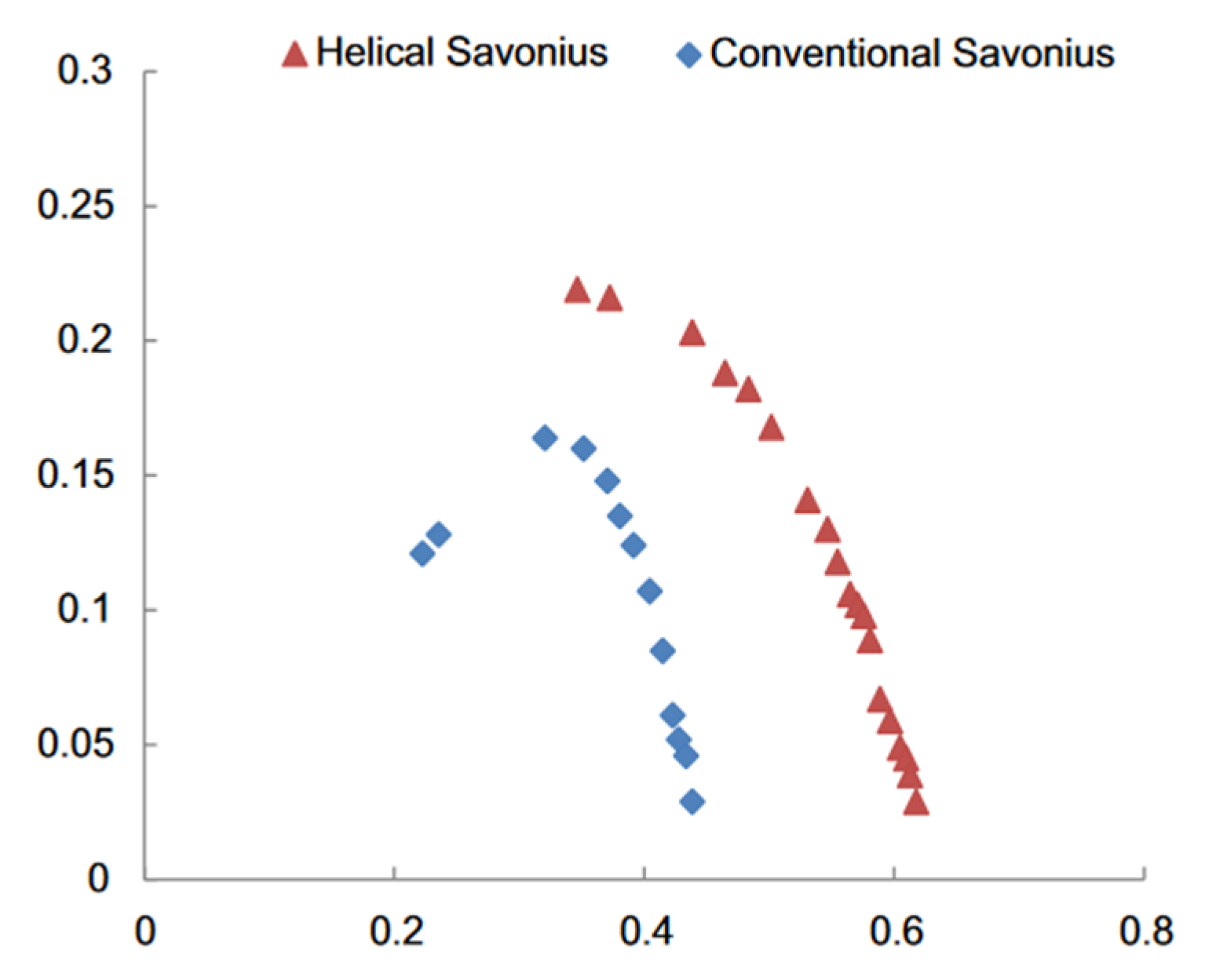

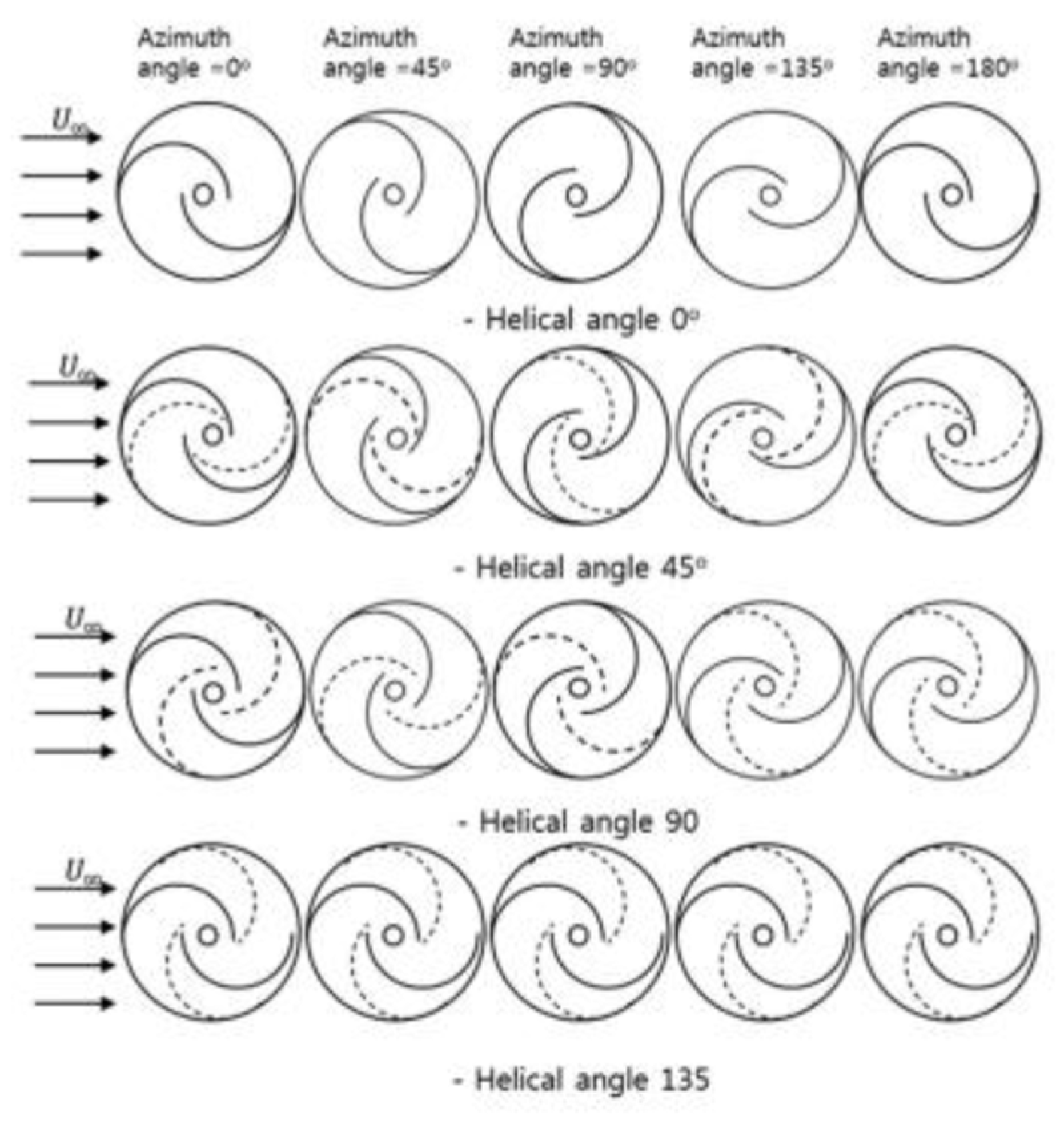

3.2.9. Angle of Twist

4. Mechanism of Wind Power Harvesting: Passive Techniques

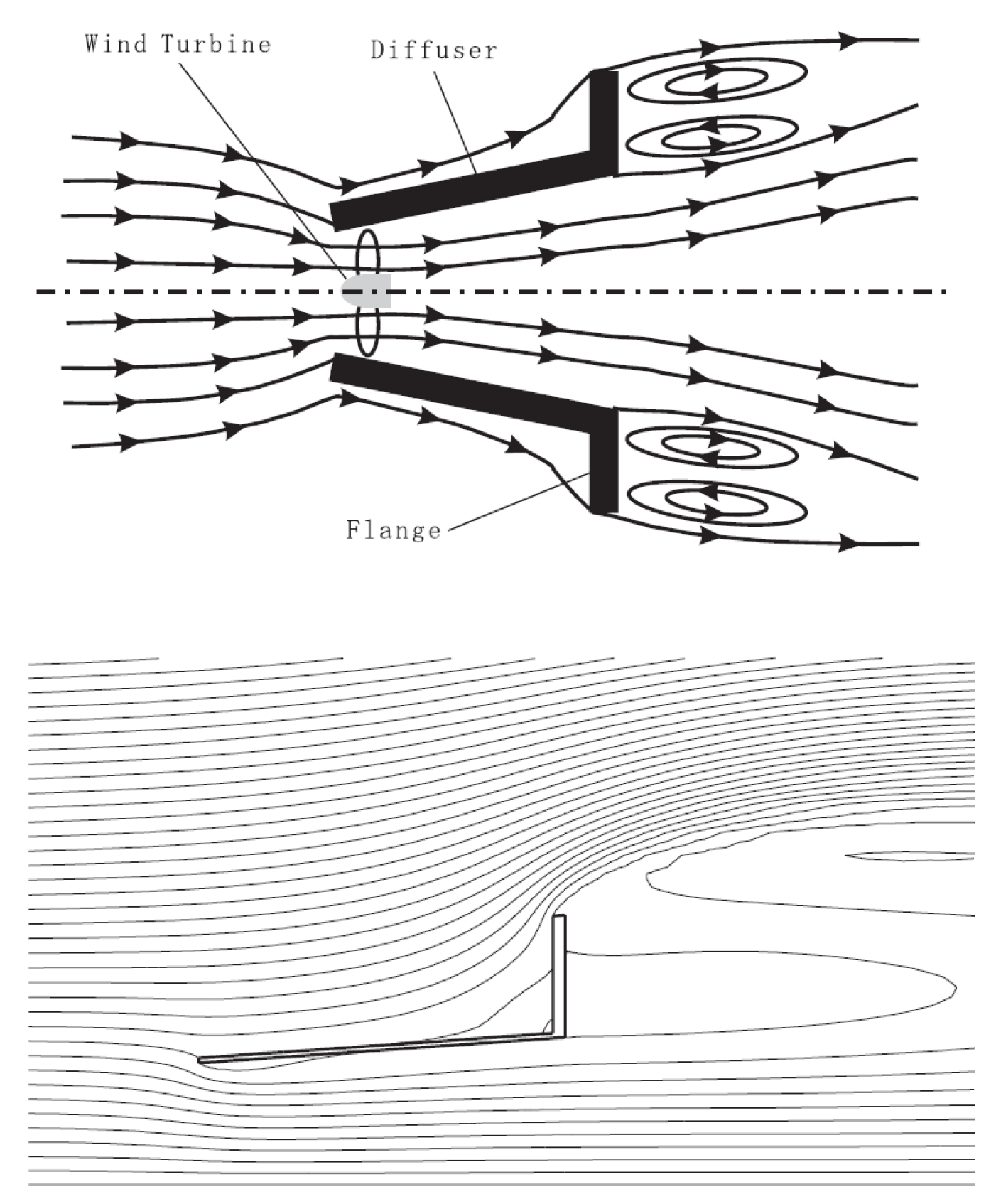

4.1. Guided-vane Technique

4.2. Guided-Vane Technique

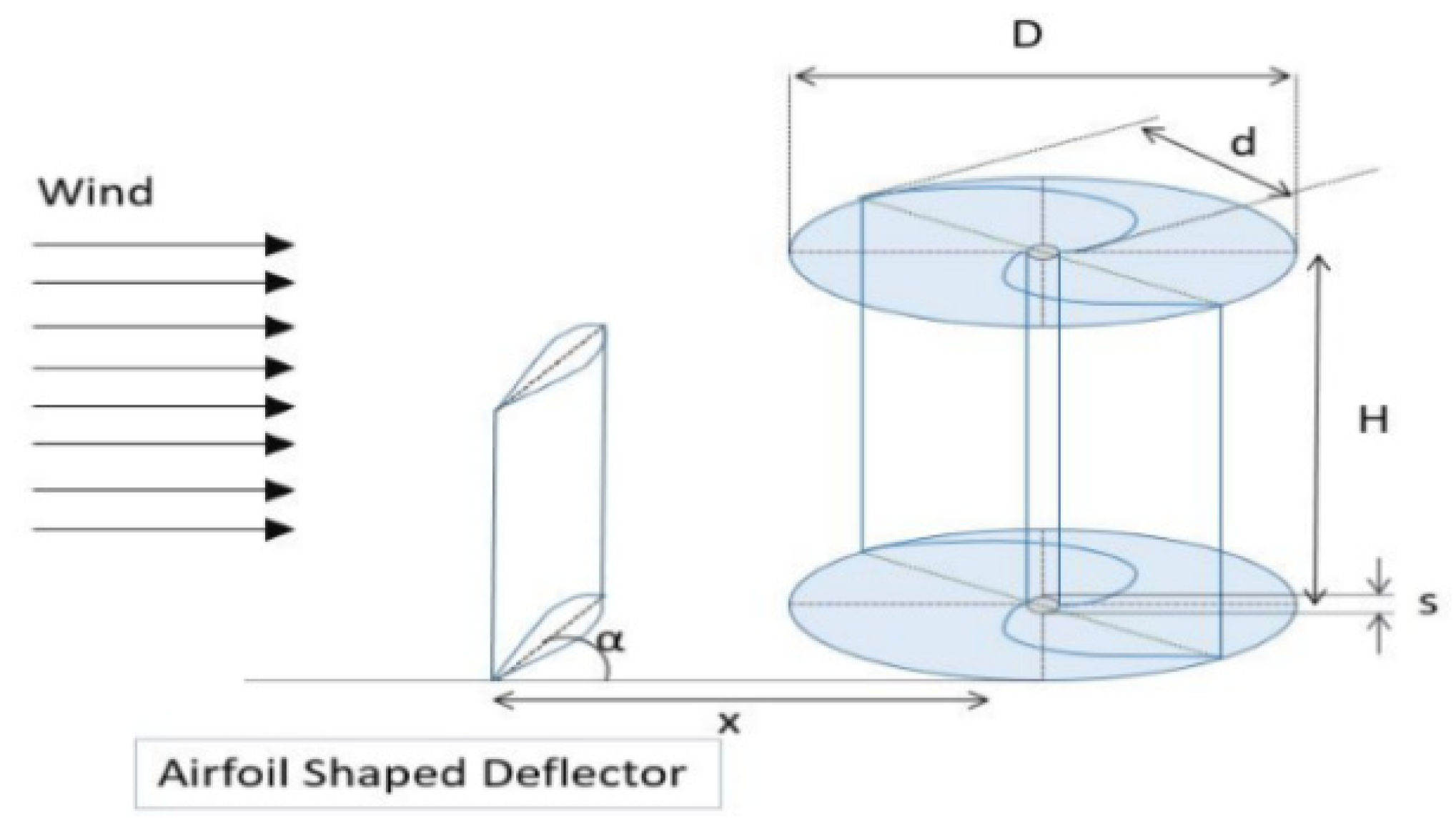

4.2.1. Airfoil-Shaped Wind Deflectors

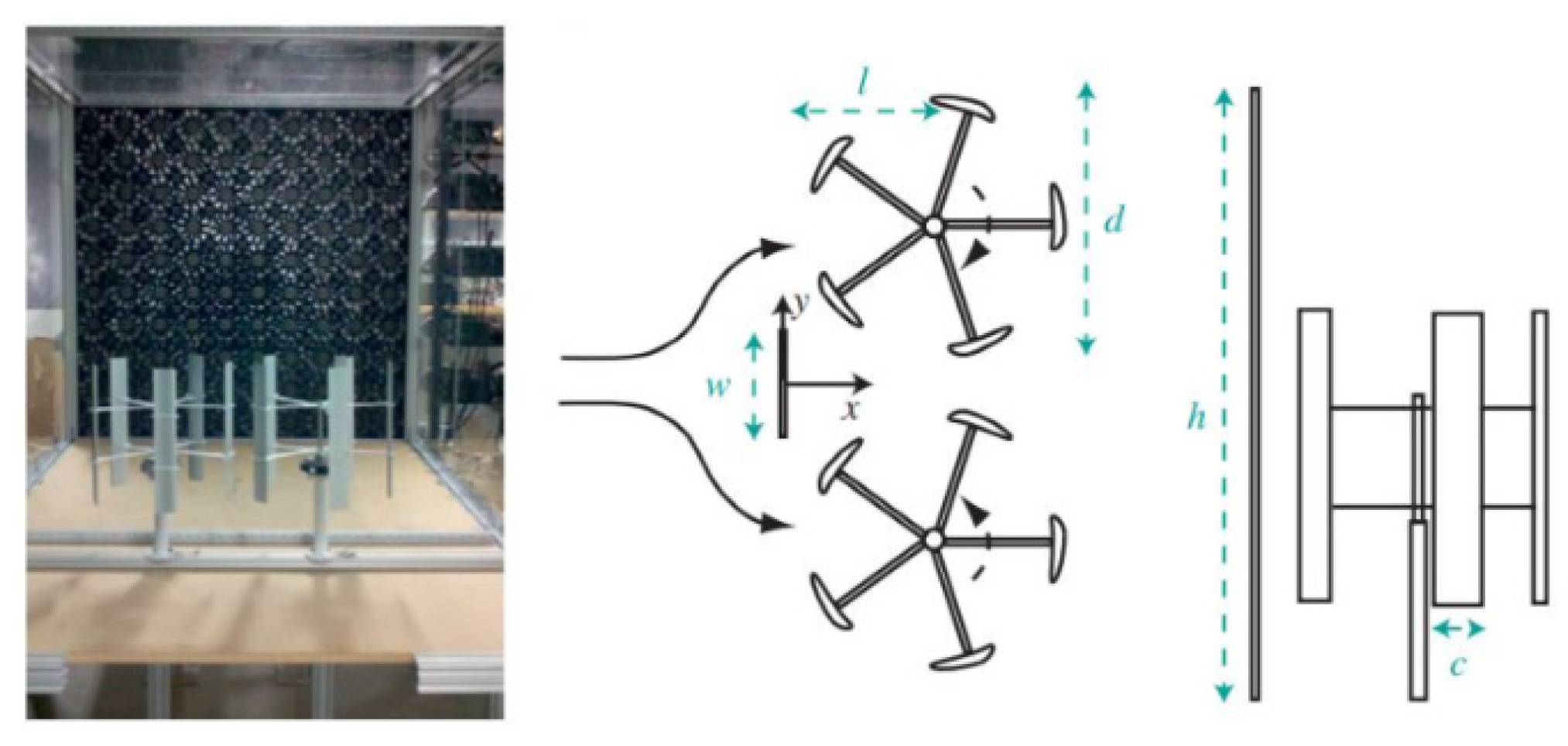

4.2.1. Compound Structured Wind Deflectors

5. Geographical Aspect of Wind Power Harvesting

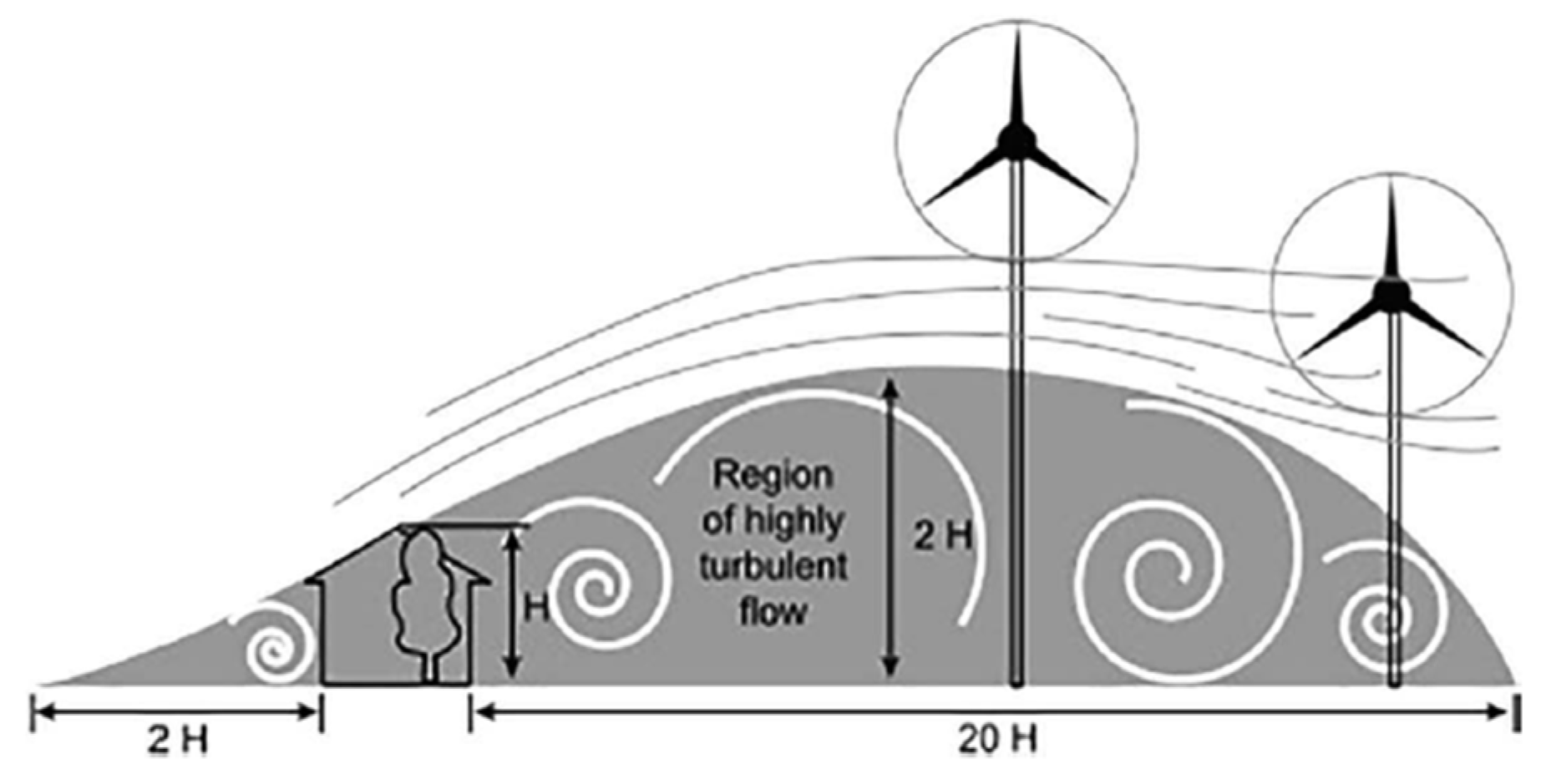

5.1. Flow Structure

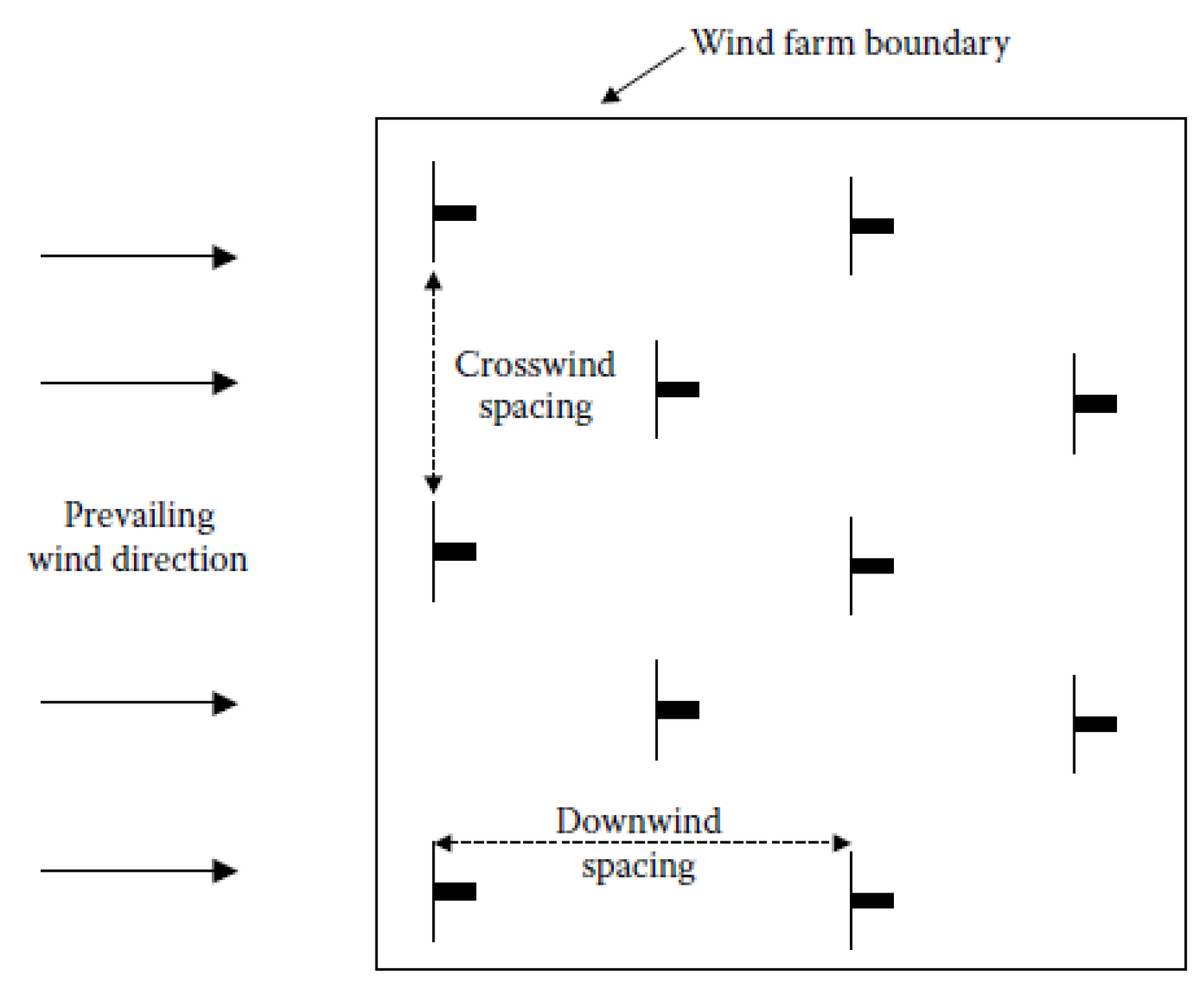

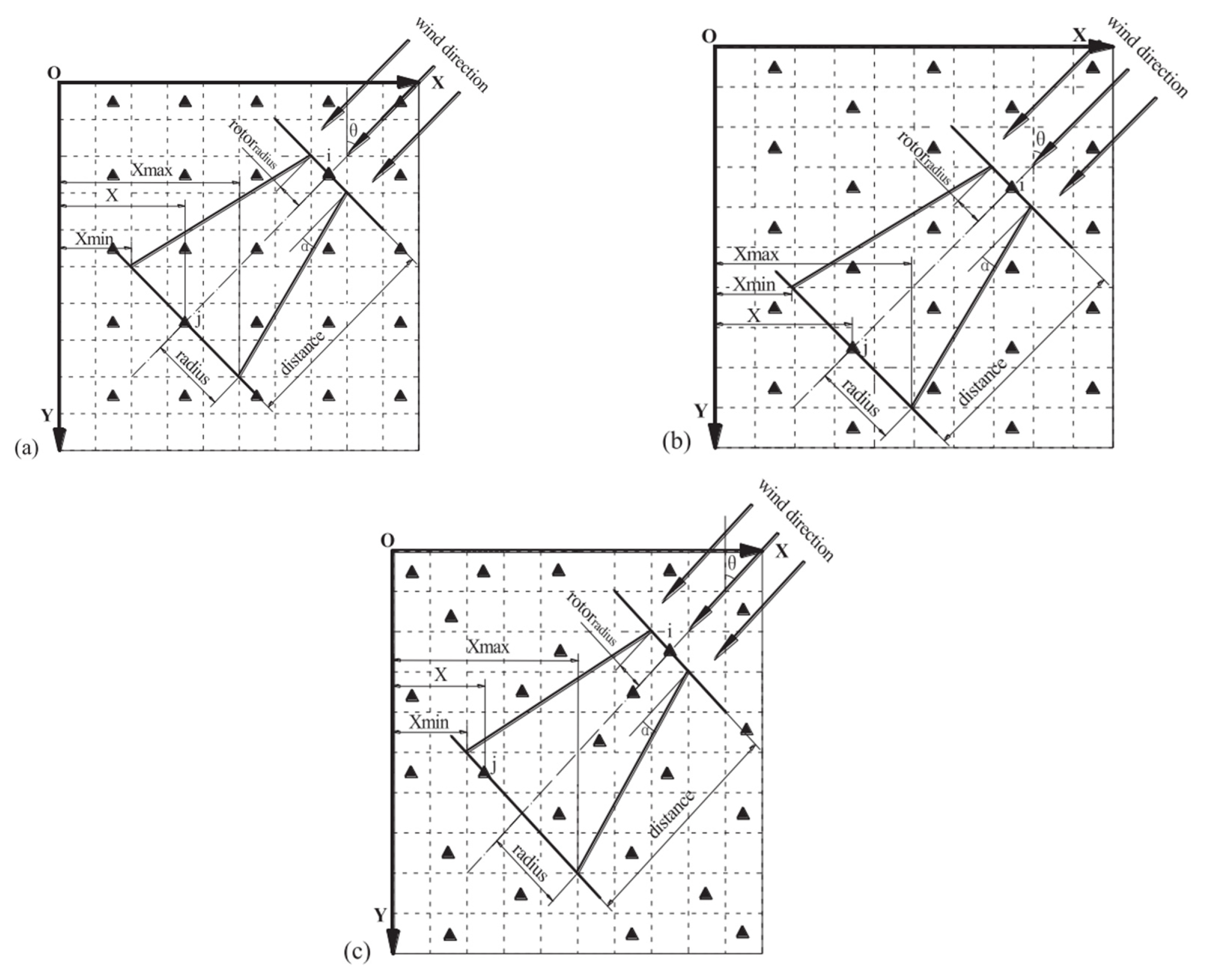

5.2. Micro-Siting

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- D. H. Didane, A. Ab Wahab, S. S. Shamsudin, and N. Rosly, “Wind as a sustainable alternative energy source in Malaysia - a review,” ARPN Journal of Engineering and Applied Sciences, vol. 11, no. 10, pp. 1–8, 2016.

- E. Hau, Wind turbines: Fundamentals, technologies, application, economics, vol. 9783642271. 2013. [CrossRef]

- M. Syahmy, M. Halmy, D. H. Didane, L. O. Afolabi, and S. Al-, “Computational Fluid Dynamics (CFD) Study on the Effect of the Number of Blades on the Performance of Double-Stage Savonius Rotor,” CFD Letters, vol. 13, no. 4, pp. 1–10, 2021. [CrossRef]

- M. Jason et al., “2D CFD Simulation Study on the Performance of Various NACA Airfoils,” CFD Letters, vol. 13, no. 4, pp. 38–50, 2021. [CrossRef]

- D. H. Didane, M. A. Z. S. Anuar, M. F. M. Batcha, K. Abdullah, M. F. M. Ali, and A. N. Mohammed, “Simulation study on the performance of a counter-rotating savonius vertical axis wind turbine,” CFD Letters, vol. 12, no. 4, pp. 1–11, 2020. [CrossRef]

- J. G. Mcgowan and J. F. Manwell, Wind Energy Explained. West Sussex: John Wiley & Sons Ltd., 2002.

- GWEC, “Global Offshore Wind Report 2023 - Global Wind Energy Council,” 2023. https://gwec.net/globalwindreport2023/ (accessed Feb. 26, 2024).

- TAKASHI TSUJI, “Renewable energy capacity on track to rival fossil fuels in 2024 - Nikkei Asia,” 2023. https://asia.nikkei.com/Spotlight/Environment/Climate-Change/Renewable-energy-capacity-on-track-to-rival-fossil-fuels-in-2024 (accessed Feb. 26, 2024).

- Goblal Wind Energy Council, “Global Wind Energy Report 2022,” 2022.

- REN21, Renewables 2022 Global Status. 2022.

- International Energy Agency, “Variability of Wind Power and Other Renewables: Management options and strategies,” 2005.

- D. H. Didane, S. Mohd, Z. Subari, N. Rosly, M. F. A. Ghafir, and M. F. M. Masrom, “An aerodynamic performance analysis of a perforated wind turbine blade,” in IOP Conference Series: Materials Science and Engineering, 2016, vol. 160, no. 1. [CrossRef]

- B. Abdulameer et al., “Review on Diffuser Augmented Wind Turbine (DAWT),” International Journal of Integrated Engineering, vol. 11, no. 1, pp. 178–206, 2019. [CrossRef]

- S. Mathew and G. S. Philip, “2.05 - Wind Turbines: Evolution, Basic Principles, and Classifications,” in Comprehensive Renewable Energy, Elsevier, 2012, pp. 93–111.

- E. Muljadi, R. M. Nelms, and V. Gevorgian, “Wind Plant Electrical Systems: Electrical Generation, Machines, Power Electronics, and Collector Systems,” National Renewable Energy Lab.(NREL), Golden, CO (United States), 2019.

- H. J. Sutherland, D. E. Berg, and T. D. Ashwill, “A Retrospective of VAWT Technology,” Security, no. January, pp. 1–64, 2012. [CrossRef]

- A. Dewan, A. Gautam, and R. Goyal, “Savonius wind turbines: A review of recent advances in design and performance enhancements,” Materials Today: Proceedings, vol. 47, pp. 2976–2983, 2021. [CrossRef]

- C. MacEachern and I. Yıldız, “1.16 Wind Energy,” 2018.

- J. V. Akwa, H. A. Vielmo, and A. P. Petry, “A review on the performance of Savonius wind turbines,” Renewable and sustainable energy reviews, vol. 16, no. 5, pp. 3054–3064, 2012. [CrossRef]

- K. A. H. Al-Gburi, F. B. I. Alnaimi, B. A. Al-quraishi, E. S. Tan, and M. M. Maseer, “A comparative study review: The performance of Savonius-type rotors,” Materials Today: Proceedings, vol. 57, pp. 343–349, 2022. [CrossRef]

- N. R. Maldar, C. Y. Ng, and E. Oguz, “A review of the optimization studies for Savonius turbine considering hydrokinetic applications,” Energy Conversion and Management, vol. 226, p. 113495, 2020. [CrossRef]

- M. Zemamou, M. Aggour, and A. Toumi, “Review of savonius wind turbine design and performance,” Energy Procedia, vol. 141, pp. 383–388, 2017. [CrossRef]

- S. J. Savonius, The S-rotor and its applications, vol. 53, no. 5. 1931.

- M. B. Salleh, N. M. Kamaruddin, and Z. Mohamed-Kassim, “The effects of deflector longitudinal position and height on the power performance of a conventional Savonius turbine,” Energy Conversion and Management, vol. 226, p. 113584, 2020. [CrossRef]

- O. S. Mohamed, A. A. Ibrahim, A. K. Etman, A. A. Abdelfatah, and A. M. R. Elbaz, “Numerical investigation of Darrieus wind turbine with slotted airfoil blades,” Energy Conversion and Management: X, vol. 5, p. 100026, 2020. [CrossRef]

- K. Appa, “Energy innovations small grant (EISG) program (counter rotating wind turbine system),” California, US, 2002.

- N. Parneix, R. Fuchs, A. Immas, and F. Silvert, “Efficiency improvement of vertical-axis wind turbines with counter-rotating lay-out. 2016,” Report Nenuphar.

- M. Neagoe, R. Saulescu, C. Jaliu, O. Munteanu, and N. Cretescu, “A Comparative Performance Analysis of Four Wind Turbines with Counter-Rotating Electric Generators,” Applied Sciences, vol. 12, no. 9, p. 4233, 2022. [CrossRef]

- G. Oprina et al., “a Review on Counter-Rotating Wind Turbines Development,” Journal of Sustainable Energy, vol. 7, no. 3, 2016.

- R. W. Y. Habash, V. Groza, Y. Yang, C. Blouin, and P. Guillemette, “Performance of a Contrarotating Small Wind Energy Converter,” ISRN Mechanical Engineering, vol. 2011, pp. 1–10, 2011. [CrossRef]

- S. N. Jung, T. S. No, and K. W. Ryu, “Aerodynamic performance prediction of a 30 kW counter-rotating wind turbine system,” Renewable Energy, vol. 30, no. 5, pp. 631–644, 2005. [CrossRef]

- D. H. Didane, N. Rosly, M. F. Zulkafli, and S. S. Shamsudin, “Performance evaluation of a novel vertical axis wind turbine with coaxial contra-rotating concept,” Renewable energy, vol. 115, pp. 353–361, 2018. [CrossRef]

- D. H. Didane, N. Rosly, M. F. Zulkafli, and S. S. Shamsudin, “Numerical investigation of a novel contra-rotating vertical axis wind turbine,” Sustainable Energy Technologies and Assessments, vol. 31, pp. 43–53, 2019. [CrossRef]

- D. H. Didane, A. Ab Wahab, S. S. Shamsudin, and N. Rosly, “Wind as a sustainable alternative energy source in Malaysia - a review,” ARPN Journal of Engineering and Applied Sciences, vol. 11, no. 10, 2016.

- D. H. Didane, S. M. Maksud, M. F. Zulkafli, N. Rosly, S. S. Shamsudin, and A. Khalid, “Experimental Study on the Performance of a Savonius-Darrius Counter-Rotating Vertical Axis Wind Turbine,” IOP Conference Series: Earth and Environmental Science, vol. 268, p. 012060, 2019. [CrossRef]

- D. H. Didane, S. M. Maksud, M. F. Zulkafli, N. Rosly, S. S. Shamsudin, and A. Khalid, “Performance investigation of a small Savonius-Darrius counter-rotating vertical-axis wind turbine,” International Journal of Energy Research, vol. 44, no. 12, pp. 9309–9316, 2020. [CrossRef]

- D. H. Didane, D. Kudam, M. F. Zulkafli, M. Faizal, M. Batcha, and A. Khalid, “Development and Performance Investigation of a Unique Dual-rotor Savonius-type Counter-rotating Wind Turbine,” International Journal of Integrated Engineering, vol. 6, pp. 89–98, 2021. [CrossRef]

- W. Vance, “Vertical axis wind rotors-status and potential,” Wind Energy Conversion Systems, 1973.

- C.-H. Lin and L. A. Klimina, “CFD simulation and analysis for Savonius rotors with different blade configuration,” 2014, vol. 1637, pp. 575–581. [CrossRef]

- S. Roy and U. K. Saha, “Review on the numerical investigations into the design and development of Savonius wind rotors,” Renewable and Sustainable Energy Reviews, vol. 24, pp. 73–83, 2013. [CrossRef]

- D. Danardono Dwi Prija Tjahjana et al., “Study on Performance Improvement of the Savonius Wind Turbine for Urban Power System with Omni-directional Guide Vane (ODGV),” Journal of Advanced Research in Fluid Mechanics and Thermal Sciences Journal homepage, vol. 55, pp. 126–135, 2019, Accessed: Mar. 27, 2020. [Online]. Available: www.akademiabaru.com/arfmts.html.

- M. A. Kamoji, S. B. Kedare, and S. V. Prabhu, “Experimental investigations on single stage modified Savonius rotor,” Applied Energy, vol. 86, no. 7–8, pp. 1064–1073, Jul. 2009. [CrossRef]

- V. J. Modi, N. J. Roth, and M. S. U. K. Fernando, “Optimum-configuration studies and prototype design of a wind-energy-operated irrigation system,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 16, no. 1, pp. 85–96, Jan. 1984. [CrossRef]

- S. Roy and U. K. Saha, “Review of experimental investigations into the design, performance and optimization of the Savonius rotor,” Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, vol. 227, no. 4, pp. 528–542, Jun. 2013. [CrossRef]

- I. B. Alit, I. A. S. Andyani, and Mirmanto, “Effect of Overlapping Ratio, Blade Shape Factor, and Blade Arc Angle to modified Rotor Savonius performances,” International Journal of Applied Engineering Research, vol. 13, 2018.

- B. D. Altan and M. Atılgan, “An experimental and numerical study on the improvement of the performance of Savonius wind rotor,” Energy Conversion and Management, vol. 49, no. 12, pp. 3425–3432, 2008. [CrossRef]

- J. V. Akwa, G. A. da Silva Júnior, and A. P. Petry, “Discussion on the verification of the overlap ratio influence on performance coefficients of a Savonius wind rotor using computational fluid dynamics,” Renewable energy, vol. 38, no. 1, pp. 141–149, 2012. [CrossRef]

- J. Ramarajan and S. Jayavel, “Numerical Study on the Performance of Savonius Vertical Axis Wind Turbine with Guide Vanes,” in Recent Advances in Computational and Experimental Mechanics, Vol—I: Select Proceedings of ICRACEM 2020, 2022, pp. 287–298.

- D. Kudam, “Performance Evaluation of a Savonius Type Counter-Rotating Wind Turbine,” Universiti Tun Hussein Onn Malaysia, 2018.

- M. H. Nasef, W. A. El-Askary, A. A. AbdEL-hamid, and H. E. Gad, “Evaluation of Savonius rotor performance: Static and dynamic studies,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 123, pp. 1–11, 2013. [CrossRef]

- U. K. Saha, S. Thotla, and D. Maity, “Optimum design configuration of Savonius rotor through wind tunnel experiments,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 96, no. 8–9, pp. 1359–1375, Aug. 2008. [CrossRef]

- T. HAYASHI, Y. LI, and Y. HARA, “Wind Tunnel Tests on a Different Phase Three-Stage Savonius Rotor,” JSME International Journal Series B, vol. 48, no. 1, pp. 9–16, 2005. [CrossRef]

- S. Frikha, Z. Driss, E. Ayadi, Z. Masmoudi, and M. S. Abid, “Numerical and experimental characterization of multi-stage Savonius rotors,” Energy, vol. 114, pp. 382–404, Nov. 2016. [CrossRef]

- C. Jian, J. Kumbernuss, Z. Linhua, L. Lin, and Y. Hongxing, “Influence of Phase-Shift and Overlap Ratio on Savonius Wind Turbine’s Performance,” Journal of Solar Energy Engineering, vol. 134, no. 1, p. 011016, 2012. [CrossRef]

- M. A. Kamoji, S. B. Kedare, and S. V Prabhu, “Experimental investigations on single stage, two stage and three stage conventional Savonius rotor,” International journal of energy research, vol. 32, no. 10, pp. 877–895, 2008. [CrossRef]

- S. Unsakul, C. Sranpat, P. Chaisiriroj, and T. Leephakpreeda, “CFD-Based Performance Analysis and Experimental Investigation of Design Factors of Vertical Axis Wind Turbines under Low Wind Speed Conditions in Thailand,” Journal of Flow Control, Measurement & Visualization, vol. 05, no. 04, pp. 86–98, 2017. [CrossRef]

- B. F. BLACKWELL, R. E. SHELDAHL, and L. V. FELTZ, “Wind Tunnel Performance Data for Two-and Three-bucket Savonius Rotors,” 1977. [CrossRef]

- B. Emmanuel and W. Jun, “Numerical Study of a Six-Bladed Savonius Wind Turbine,” Journal of Solar Energy Engineering, vol. 133, no. 4, p. 044503, 2011. [CrossRef]

- M. M. Bashar, “Computational and Experimental Study on Vertical Axis Wind Turbine in Search for an Efficient Design,” Georgia Southern University, 2014.

- B. A. Bhayo, H. H. Al-Kayiem, and N. Z. Yahaya, “Performance investigation of the S-Rotors,” IOP Conference Series: Materials Science and Engineering, vol. 100, p. 012043, Dec. 2015. [CrossRef]

- M. H. Mohamed, “Performance investigation of H-rotor Darrieus turbine with new airfoil shapes,” Energy, vol. 47, no. 1, pp. 522–530, 2012. [CrossRef]

- N. M. Ali, A. K. A. Hassan, and S. Aljabair, “Effect of conventional multistage savonius wind turbines on the performance of the turbine at low wind velocity,” Jour of Adv Research in Dynamical & Control Systems, vol. 11, no. 11, 2019. [CrossRef]

- A. Kumar and R. . Saini, “Performance parameters of Savonius type hydrokinetic turbine – A Review,” Renewable and Sustainable Energy Reviews, vol. 64, pp. 289–310, 2016. [CrossRef]

- F. Wenehenubun, A. Saputra, and H. Sutanto, “An experimental study on the performance of Savonius wind turbines related with the number of blades,” in Energy Procedia, Apr. 2015, vol. 68, pp. 297–304. [CrossRef]

- M. Al-Ghriybah, M. F. Zulkafli, D. H. Didane, and S. Mohd, “The effect of inner blade position on the performance of the Savonius rotor,” Sustainable Energy Technologies and Assessments, vol. 36, no. September, p. 100534, Dec. 2019. [CrossRef]

- M. Al-Ghriybah, M. F. Zulkafli, and D. H. Didane, “Numerical investigation of inner blade effects on the conventional savonius rotor with external overlap,” Journal of Sustainable Development of Energy, Water and Environment Systems, vol. 8, no. 3, pp. 561–576, 2020. [CrossRef]

- M. Al-ghriybah, M. Fadhli, D. Hissein, and S. Mohd, “The effect of spacing between inner blades on the performance of the Savonius wind turbine,” Sustainable Energy Technologies and Assessments, vol. 43, no. January, p. 100988, Feb. 2021. [CrossRef]

- M. Al-ghriybah, M. F. Zulkafli, D. H. Didane, and S. Mohd, “Performance of Double Blade Savonius Rotor at Low Rotational Speed,” Journal of Computational and Theoretical Nanoscience, vol. 17, no. xx, pp. 1–7, 2020. [CrossRef]

- J. P. Abraham, B. D. Plourde, G. S. Mowry, W. J. Minkowycz, and E. M. Sparrow, “Summary of Savonius wind turbine development and future applications for small-scale power generation,” Journal of Renewable and Sustainable Energy, vol. 4, no. 4, p. 042703, Jul. 2012. [CrossRef]

- B. D. Plourde, J. P. Abraham, G. S. Mowry, and W. J. Minkowycz, “Simulations of Three-Dimensional Vertical-Axis Turbines for Communications Applications,” Wind Engineering, vol. 36, no. 4, pp. 443–453, Aug. 2012. [CrossRef]

- N. Fujisawa and F. Gotoh, “Pressure measurements and flow visualization study of a Savonius rotor,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 39, no. 1–3, pp. 51–60, Jan. 1992. [CrossRef]

- S. Sivasegaram, “Secondary parameters affecting the performance of resistance-type vertical-axis wind rotors,” Wind Engineering, vol. 2, no. 1, pp. 49–58, 1978.

- K. S. Jeon, J. I. Jeong, J.-K. Pan, and K.-W. Ryu, “Effects of end plates with various shapes and sizes on helical Savonius wind turbines,” Renewable Energy, vol. 79, pp. 167–176, 2015. [CrossRef]

- S. Roy and U. K. Saha, “Wind tunnel experiments of a newly developed two-bladed Savonius-style wind turbine,” Applied Energy, vol. 137, pp. 117–125, 2014. [CrossRef]

- K. Kacprzak, G. Liskiewicz, and K. Sobczak, “Numerical investigation of conventional and modified Savonius wind turbines,” Renewable Energy, vol. 60, pp. 578–585, Dec. 2013. [CrossRef]

- Z. Zhao, Y. Zheng, X. Xu, W. Liu, and G. Hu, “Research on the improvement of the performance of Savonius rotor based on numerical study,” in 2009 International Conference on Sustainable Power Generation and Supply, 2009, pp. 1–6. [CrossRef]

- K. Golecha, T. I. Eldho, and S. V. Prabhu, “Influence of the deflector plate on the performance of modified Savonius water turbine,” Applied Energy, vol. 88, no. 9, pp. 3207–3217, Sep. 2011. [CrossRef]

- D. Darling, “Wind Power, Tip Speed Ratio,” 2014.

- C. Riley, “What’s Tip Speed Ratio (TSR)?,” 2011.

- J. Haibo, L. Yanru, and C. Zhongqing, “Renewable Energy,” in Performances of ideal wind turbine, Elsevier, 2015, pp. 658–662.

- A. Damak, Z. Driss, and M. S. Abid, “Experimental investigation of helical Savonius rotor with a twist of 180°,” Renewable Energy, vol. 52, pp. 136–142, Apr. 2013. [CrossRef]

- A. A. Najib, D. H. Didane, M. R. Behery, and H. A. Kabrein, “Comparison of 2D and 3D Simulations on Predicting the Performance of a Savonius Wind Turbine,” population, vol. 16, no. 7, pp. 71–88, 2024. [CrossRef]

- K. Mrigua, A. Toumi, M. Zemamou, B. Ouhmmou, Y. Lahlou, and M. Aggour, “CFD Investigation of A New Elliptical-Bladed Multistage Savonius Rotors.,” International Journal of Renewable Energy Development, vol. 9, no. 3, 2020. [CrossRef]

- M. Hadi Ali, “Experimental Comparison Study for Savonius Wind Turbine of Two & Three Blades At Low Wind Speed,” International Journal of Modern Engineering Research (IJMER) www.ijmer.com, vol. 3, no. 5, pp. 2978–2986, 2013.

- W. Tian, Z. Mao, B. Zhang, and Y. Li, “Shape optimization of a Savonius wind rotor with different convex and concave sides,” Renewable Energy, vol. 117, pp. 287–299, Mar. 2018. [CrossRef]

- C. Kang, F. Zhang, and X. Mao, “Comparison Study of a Vertical-Axis Spiral Rotor and a Conventional Savonius Rotor,” in 2010 Asia-Pacific Power and Energy Engineering Conference, 2010, pp. 1–4. [CrossRef]

- C. M. Chan, H. L. Bai, and D. Q. He, “Blade shape optimization of the Savonius wind turbine using a genetic algorithm,” Applied Energy, vol. 213, pp. 148–157, Mar. 2018. [CrossRef]

- N. Alom and U. K. Saha, “Influence of blade profiles on Savonius rotor performance: Numerical simulation and experimental validation,” Energy Conversion and Management, vol. 186, pp. 267–277, Apr. 2019. [CrossRef]

- N. Alom, “Influence of curtain plates on the aerodynamic performance of an elliptical bladed Savonius rotor (S-rotor),” Energy Systems, pp. 1–16, 2021. [CrossRef]

- N. Alom and U. K. Saha, “Performance evaluation of vent-augmented elliptical-bladed Savonius rotors by numerical simulation and wind tunnel experiments,” Energy, vol. 152, pp. 277–290, 2018. [CrossRef]

- M. Tartuferi, V. D’Alessandro, S. Montelpare, and R. Ricci, “Enhancement of Savonius wind rotor aerodynamic performance: A computational study of new blade shapes and curtain systems,” Energy, vol. 79, pp. 371–384, 2015. [CrossRef]

- A. Grinspan, U. K. Saha, and P. Mahanta, “Experimental investigation of twisted bladed Savonius wind turbine rotor,” International Energy Journal, vol. 5, no. 1, pp. 1–9, 2004.

- B. Deb, R. Gupta, and R. D. Misra, “Performance analysis of a helical savonius rotor without shaft at 45 twist angle using CFD,” Journal of Urban and Environmental Engineering, vol. 7, no. 1, pp. 126–133, Aug. 2013. [CrossRef]

- M. Anbarsooz, “Aerodynamic performance of helical Savonius wind rotors with 30° and 45° twist angles: Experimental and numerical studies,” Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, vol. 230, no. 6, pp. 523–534, Sep. 2016. [CrossRef]

- J.-H. Lee, Y.-T. Lee, and H.-C. Lim, “Effect of twist angle on the performance of Savonius wind turbine,” Renewable Energy, vol. 89, pp. 231–244, 2016. [CrossRef]

- S. V. Ghatage and J. B. Joshi, “Optimisation of vertical axis wind turbine: CFD simulations and experimental measurements,” The Canadian Journal of Chemical Engineering, vol. 90, no. 5, pp. 1186–1201, Oct. 2012. [CrossRef]

- R. Ricci, R. Romagnoli, S. Montelpare, and D. Vitali, “Experimental study on a Savonius wind rotor for street lighting systems,” Applied Energy, vol. 161, pp. 143–152, 2016. [CrossRef]

- U. K. Saha and M. J. Rajkumar, “On the performance analysis of Savonius rotor with twisted blades,” Renewable Energy, vol. 31, no. 11, pp. 1776–1788, 2006. [CrossRef]

- S. Frikha, “Study of the Computational Domain Effect on the Aerodynamic Structure Around a Savonius Wind Rotor,” International Journal of Fluid Mechanics & Thermal Sciences, vol. 1, no. 2, p. 20, 2015. [CrossRef]

- B. Loganathan, I. Mustary, H. Chowdhury, and F. Alam, “Effect of sizing of a Savonius type vertical axis micro wind turbine,” in Energy Procedia, Mar. 2017, vol. 110, pp. 555–560. [CrossRef]

- A. S. Saad, S. Ookawara, A. Elwardany, I. I. El-Sharkawy, and M. Ahmed, “Effect of the Number of Stages on the Performance of Savonius Vertical Axis Wind Turbines: Part II—Using Twisted Blades,” in ASME International Mechanical Engineering Congress and Exposition, 2020, vol. 84584, p. V010T10A059.

- W. T. Chong, a. Fazlizan, S. C. Poh, K. C. Pan, W. P. Hew, and F. B. Hsiao, “The design, simulation and testing of an urban vertical axis wind turbine with the omni-direction-guide-vane,” Applied Energy, vol. 112, pp. 601–609, 2013. [CrossRef]

- G. J. W. Van Bussel, “The science of making more torque from wind: Diffuser experiments and theory revisited,” in Journal of Physics: Conference Series, Jun. 2007, vol. 75, no. 1. [CrossRef]

- G. M. Lilley and W. J. Rainbird, “A Preliminary Report on the Design and Performance of a Ducted Windmill,” report 102, College of Aeronautics. Cranfield, UK., 1956.

- Y. Ohya, T. Karasudani, A. Sakurai, K. ichi Abe, and M. Inoue, “Development of a shrouded wind turbine with a flanged diffuser,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 96, no. 5, pp. 524–539, 2008. [CrossRef]

- K. Foreman, “Preliminary design and economic investigations of Diffuser Augmented Wind Turbines (DAWT),” 1981.

- B. L. Gilbert and K. M. Foreman, “Experiments with a diffuseraugmented model wind turbine,” Journal of Energy Resources Technology, Transactions of the ASME, vol. 105, no. 1, 1983. [CrossRef]

- O. IGRA, “Research and Development for Shrouded Wind Turbines,” Energy Conversion and Management, vol. 21, pp. 13–48, 1981. [CrossRef]

- D. G. Phillips, R. G. J. Flay, and P. J. Richards, “An Investigation on Diffuser Augmented Wind Turbine Design,” Department of Mechanical Engineering, vol. Doctor of, p. 370, 2003.

- K. I. Abe and Y. Ohya, “An investigation of flow fields around flanged diffusers using CFD,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 92, no. 3–4, 2004. [CrossRef]

- Y. Ohya and T. Karasudani, “A shrouded wind turbine generating high output power with wind-lens technology,” Energies, vol. 3, no. 4, pp. 634–649, 2010. [CrossRef]

- B. Kosasih and A. Tondelli, “Experimental study of shrouded micro-wind turbine,” Procedia Engineering, vol. 49, pp. 92–98, 2012. [CrossRef]

- R. A. Kishore, T. Coudron, and S. Priya, “Small-scale wind energy portable turbine (SWEPT),” Journal of Wind Engineering and Industrial Aerodynamics, vol. 116, pp. 21–31, 2013. [CrossRef]

- J. Liu, M. Song, K. Chen, B. Wu, and X. Zhang, “An optimization methodology for wind lens profile using Computational Fluid Dynamics simulation,” Energy, vol. 109, 2016. [CrossRef]

- T. A. Khamlaj and M. P. Rumpfkeil, “Analysis and optimization of ducted wind turbines,” Energy, vol. 162, pp. 1234–1252, Nov. 2018. [CrossRef]

- Y. Y. Maw and M. T. Tun, “SENSITIVITY ANALYSIS of ANGLE, LENGTH and BRIM HEIGHT of the DIFFUSER for the SMALL DIFFUSER AUGMENTED WIND TURBINE USING the NUMERICAL INVESTIGATION,” ASEAN Engineering Journal, vol. 11, no. 4, pp. 280–291, 2021. [CrossRef]

- A. M. Elsayed, “Design optimization of diffuser augmented wind turbine,” CFD Letters, vol. 13, no. 8. Penerbit Akademia Baru, pp. 45–59, Aug. 2021. [CrossRef]

- K. Layeghmand, N. Ghiasi Tabari, and M. Zarkesh, “Improving efficiency of Savonius wind turbine by means of an airfoil-shaped deflector,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 42, no. 10, p. 528, 2020. [CrossRef]

- A. H. Rajpar, I. Ali, A. E. Eladwi, and M. B. A. Bashir, “Recent development in the design of wind deflectors for vertical axis wind turbine: A review,” Energies, vol. 14, no. 16, p. 5140, 2021. [CrossRef]

- M.-H. Yang, G.-M. Huang, and R.-H. Yeh, “Performance investigation of an innovative vertical axis turbine consisting of deflectable blades,” Applied Energy, vol. 179, pp. 875–887, Oct. 2016. [CrossRef]

- Y. Yan, E. Avital, J. Williams, and J. Cui, “CFD analysis for the performance of micro-vortex generator on aerofoil and vertical axis turbine,” Journal of Renewable and Sustainable Energy, vol. 11, no. 4, 2019. [CrossRef]

- T. Yuwono, G. Sakti, F. N. Aulia, and A. C. Wijaya, “Improving the performance of Savonius wind turbine by installation of a circular cylinder upstream of returning turbine blade,” Alexandria Engineering Journal, vol. 59, no. 6, pp. 4923–4932, 2020. [CrossRef]

- M. Al-Ghriybah, M. F. Zulkafli, D. H. Didane, and S. Mohd, “Performance of the savonius wind rotor with two inner blades at low tip speed ratio,” CFD Letters, vol. 12, no. 3, pp. 11–21, 2020. [CrossRef]

- H. Aboujaoude, F. Beaumont, S. Murer, G. Polidori, and F. Bogard, “Aerodynamic performance enhancement of a Savonius wind turbine using an axisymmetric deflector,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 220, p. 104882, 2022. [CrossRef]

- M. E. Nimvari, H. Fatahian, and E. Fatahian, “Performance improvement of a Savonius vertical axis wind turbine using a porous deflector,” Energy Conversion and Management, vol. 220, p. 113062, 2020. [CrossRef]

- A. A. Majid, “Accurate and efficient forecasted wind energy using selected temporal metrological variables and wind direction,” Energy Conversion and Management: X, vol. 16, p. 100286, 2022. [CrossRef]

- C. Huang, J. Yan, D. Zhang, and Y. Zhong, “Analysis of the effect of slope on the power characteristics of wind turbines in hillside terrain,” Energy Reports, vol. 8, pp. 352–361, 2022. [CrossRef]

- J. Liu, B. Bao, J. Chen, Y. Wu, and Q. Wang, “Passively adaptive wind energy harvester featuring a double-airfoil bluff body with adjustable attack angles,” Mechanical Systems and Signal Processing, vol. 185, p. 109814, 2023. [CrossRef]

- M. E. Hasan, A. Eltayesh, M. I. Awaad, and H. M. El-Batsh, “Experimental Examination for the Electric Power Generation of a Commercial Small-scale Wind Turbine with Modified Aerodynamic Design,” Alexandria Engineering Journal, vol. 64, pp. 25–39, 2023. [CrossRef]

- W. Zhang, C. D. Markfort, and F. Porté-Agel, “Near-wake flow structure downwind of a wind turbine in a turbulent boundary layer,” Experiments in fluids, vol. 52, pp. 1219–1235, 2012. [CrossRef]

- R. Kazacoks, L. Amos, and W. Leithead, “Effect of wind flow direction on the loads at wind farm,” in Journal of Physics: Conference Series, 2019, vol. 1356, no. 1, p. 12005. [CrossRef]

- T. Uchida and G. Li, “Comparison of RANS and LES in the prediction of airflow field over steep complex terrain,” Open Journal of Fluid Dynamics, vol. 8, no. 3, pp. 286–307, 2018. [CrossRef]

- V. Nelson and K. Starcher, Wind Energy: Renewable Energy and the Environment. Third edition. | Boca Raton : Taylor & Francis, a CRC title,: CRC Press, 2018. [CrossRef]

- H. Didane, N. Rosly, M. F. Zulkafli, and S. S. Shamsudin, “Evaluation of wind energy potential as a power generation source in Chad,” International Journal of Rotating Machinery, vol. 2017, 2017. [CrossRef]

- J. O. Dabiri, “Potential order-of-magnitude enhancement of wind farm power density via counter- rotating vertical-axis wind turbine arrays Potential order-of-magnitude enhancement of wind farm power density via counter-rotating vertical-axis wind turbine arrays,” Journal of Renewable and Sustainable Energy, vol. 3, no. 043104, 2011. [CrossRef]

- V. Nelson, Wind energy: Renewable energy and the environment. CRC press, 2009.

- X. Gao, H. Yang, and L. Lu, “Investigation into the optimal wind turbine layout patterns for a Hong Kong offshore wind farm,” Energy, vol. 73, pp. 430–442, Aug. 2014. [CrossRef]

- G. Gualtieri, “A novel method for wind farm layout optimization based on wind turbine selection,” Energy conversion and Management, vol. 193, pp. 106–123, 2019. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).