Submitted:

21 April 2024

Posted:

23 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

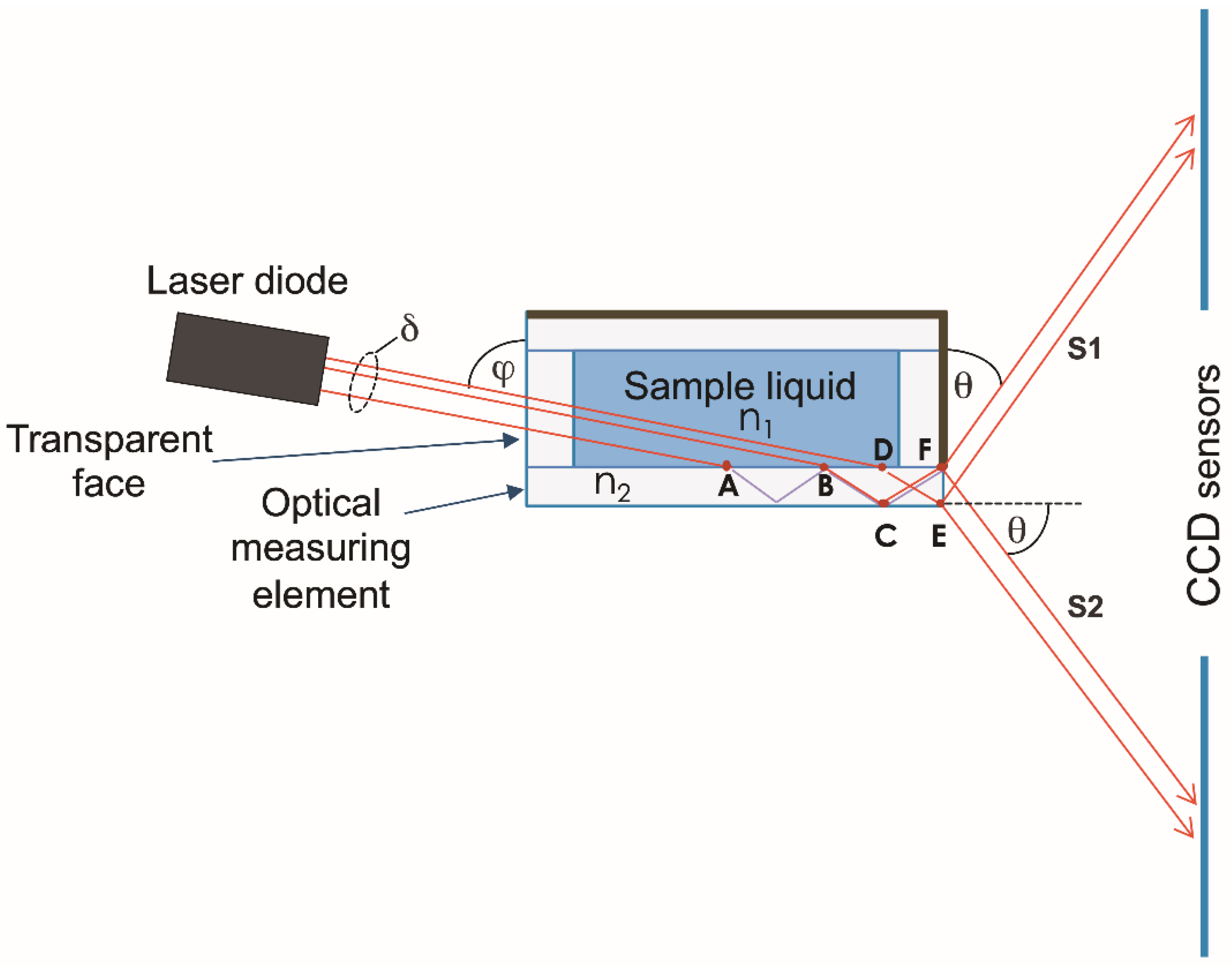

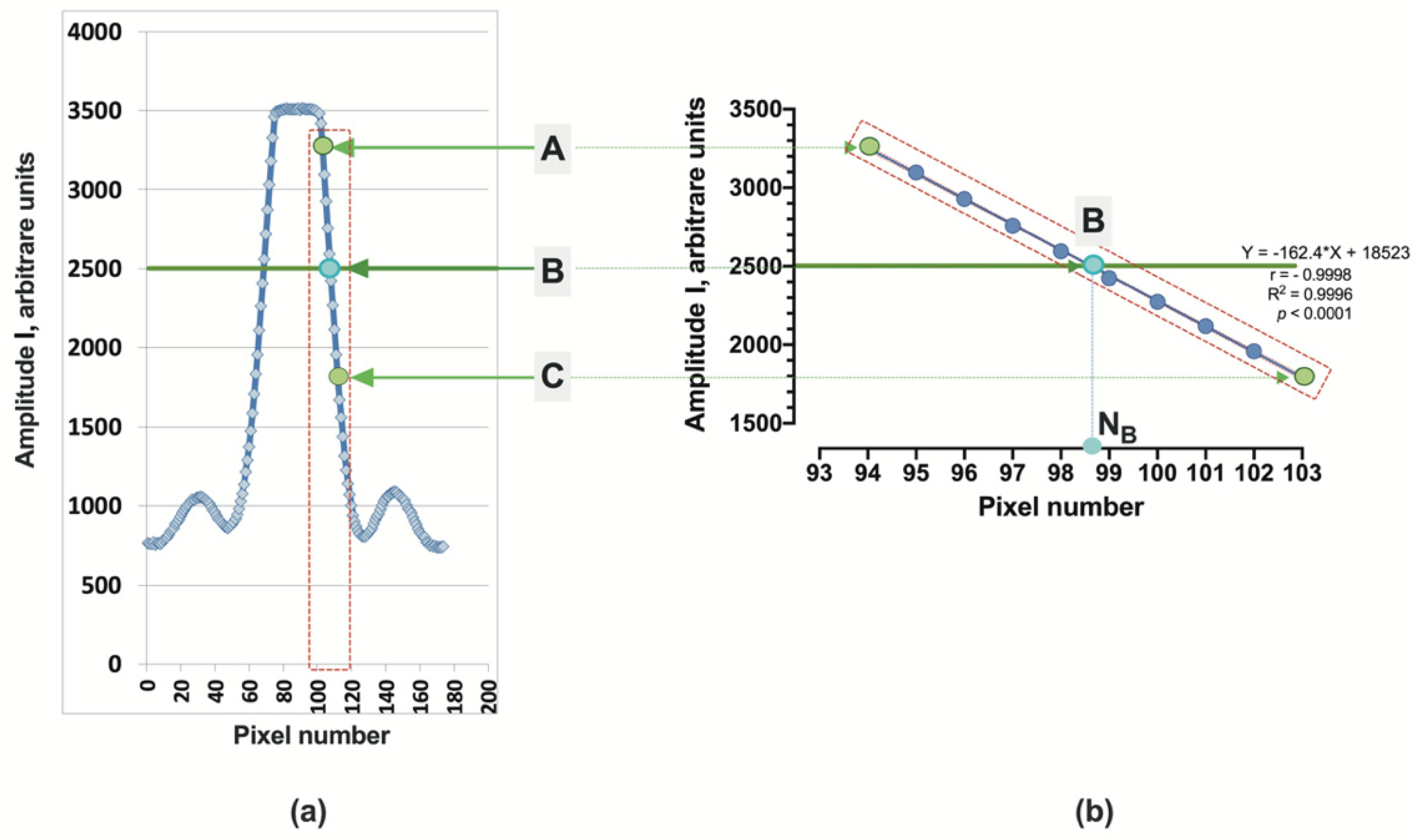

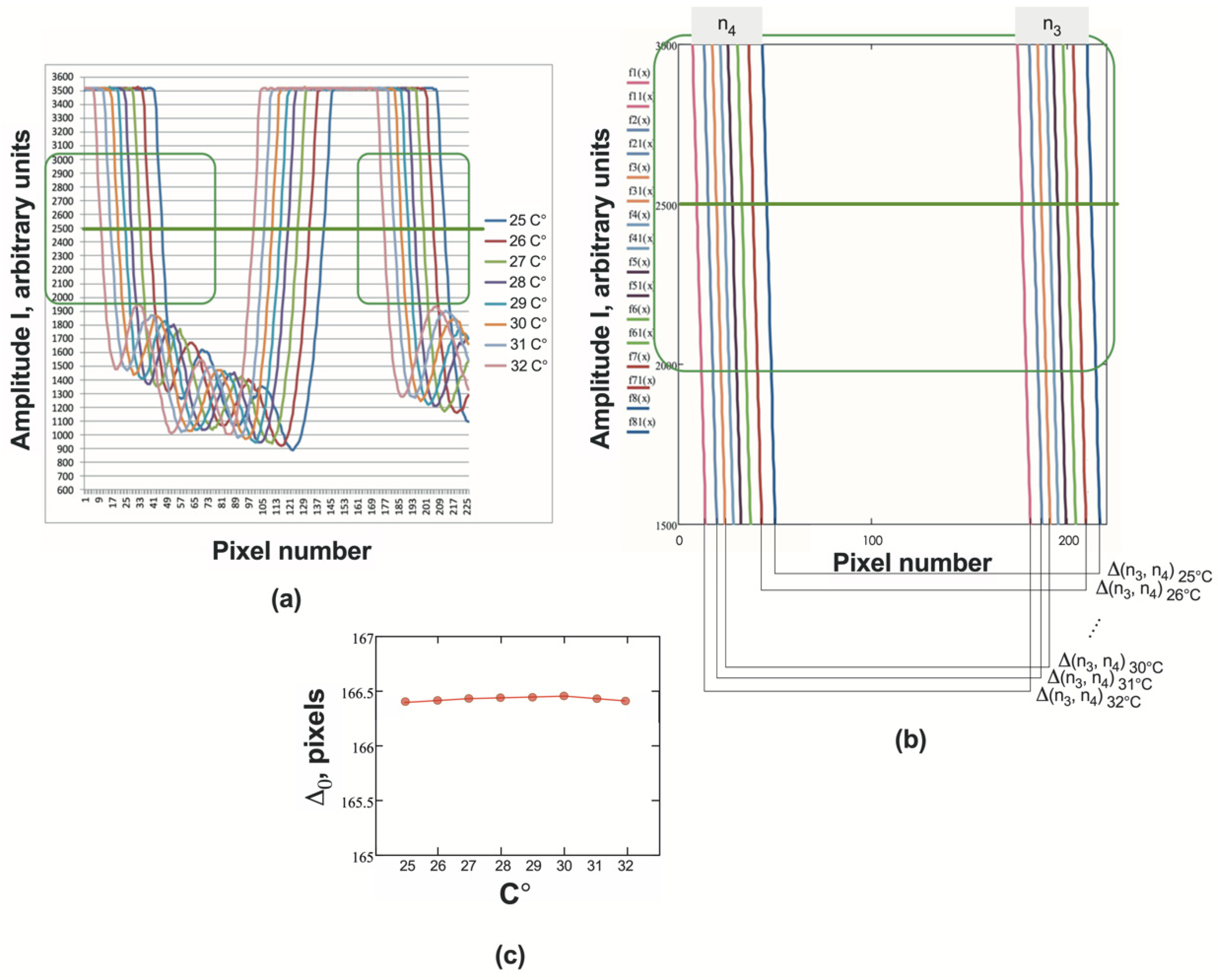

2. Principles of RI Measurement

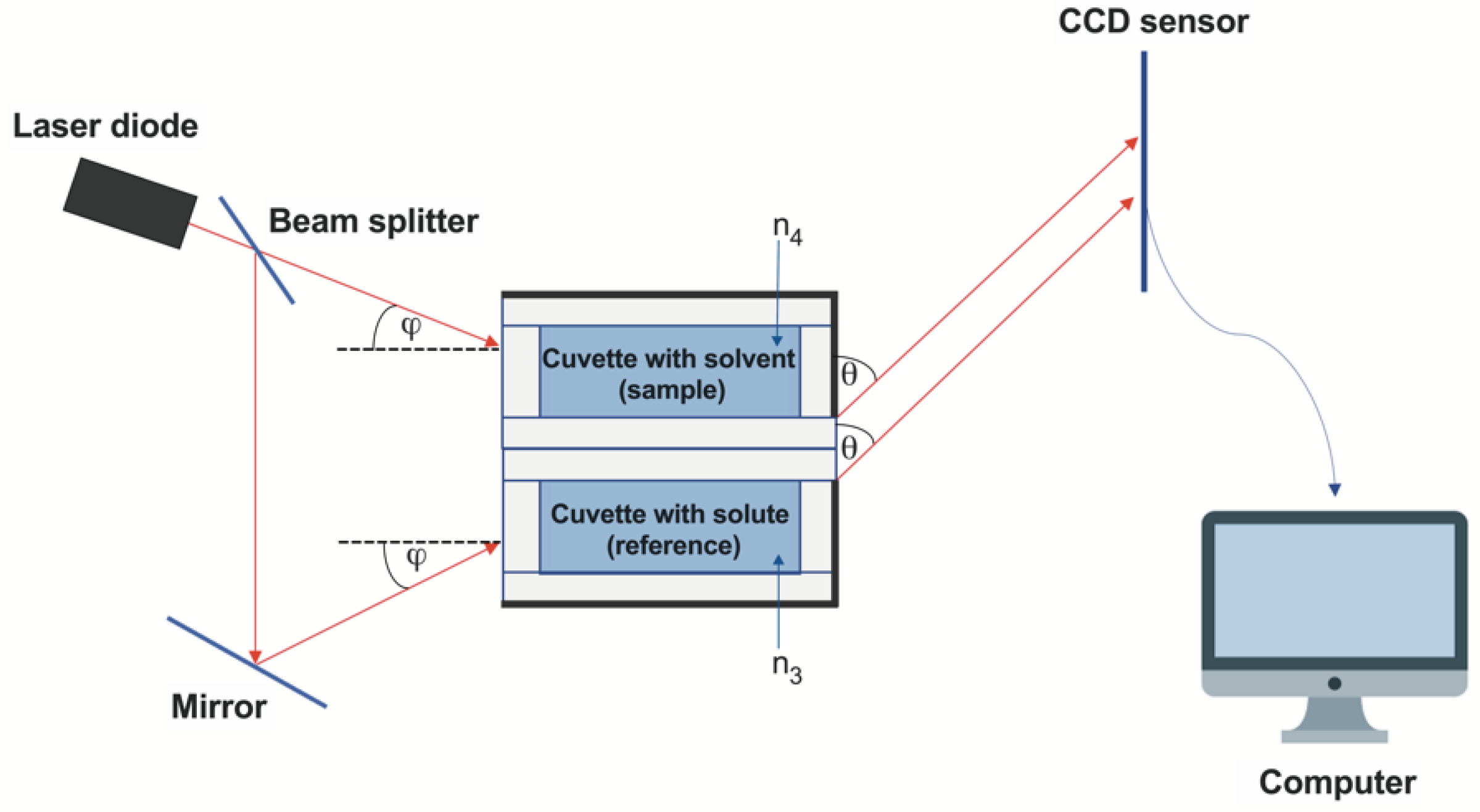

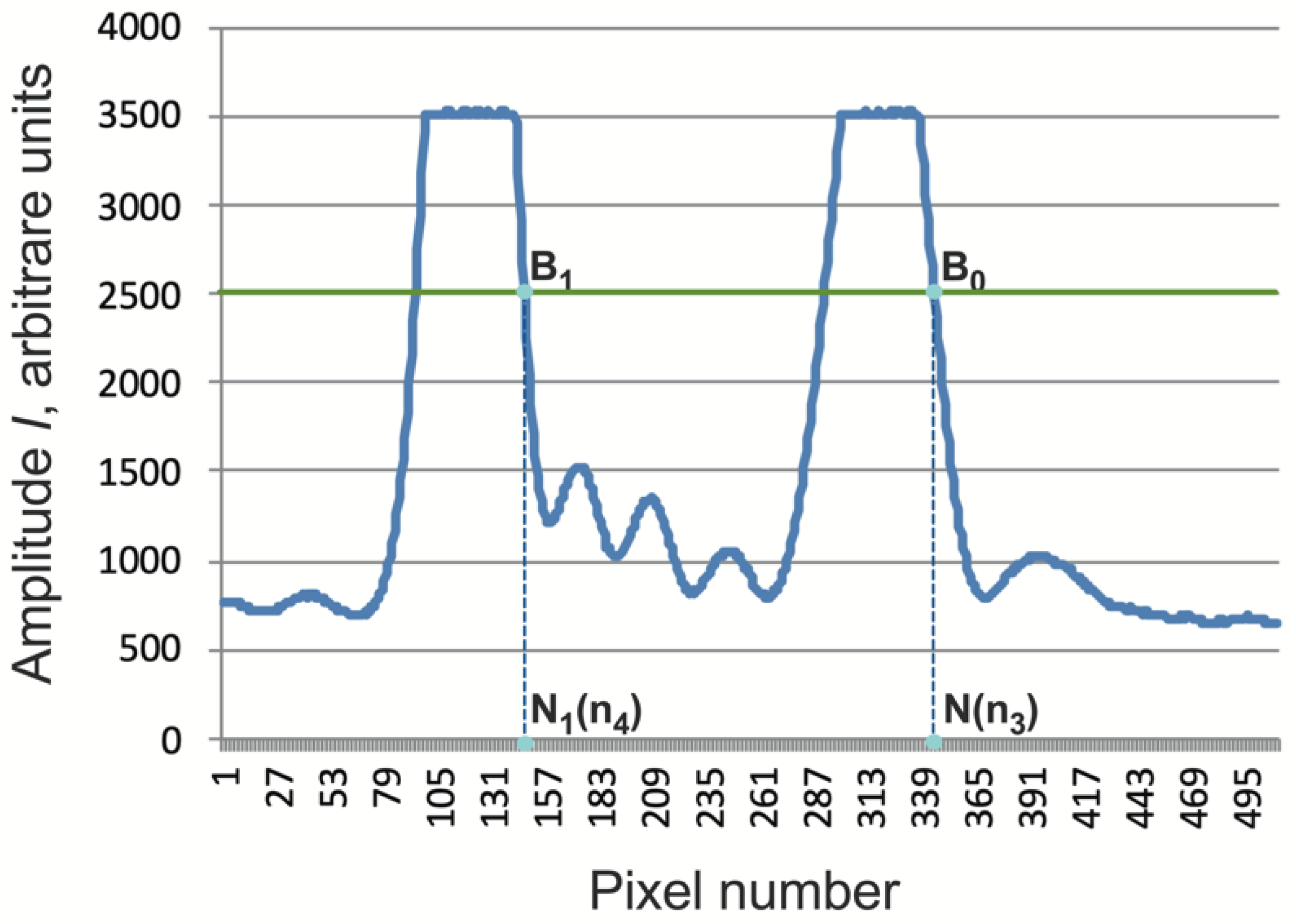

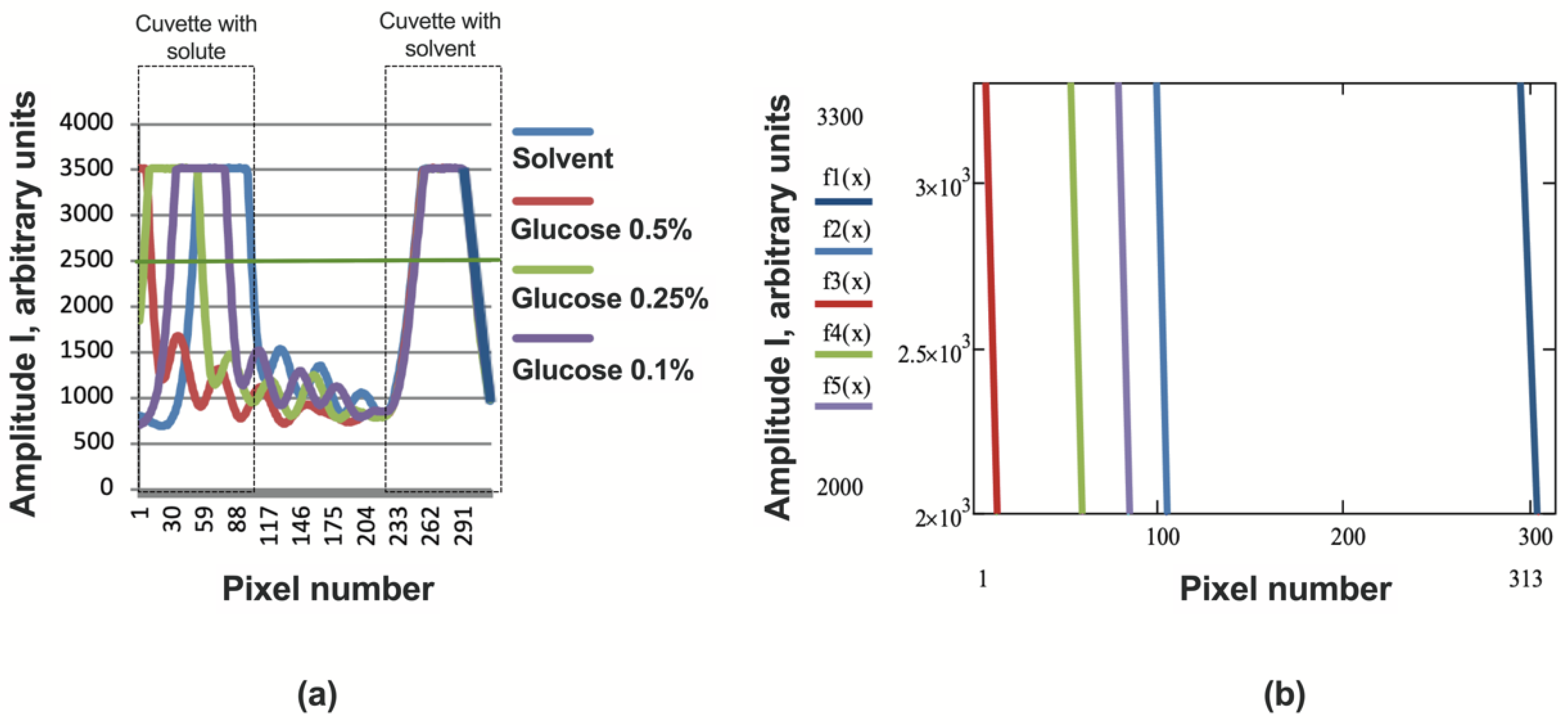

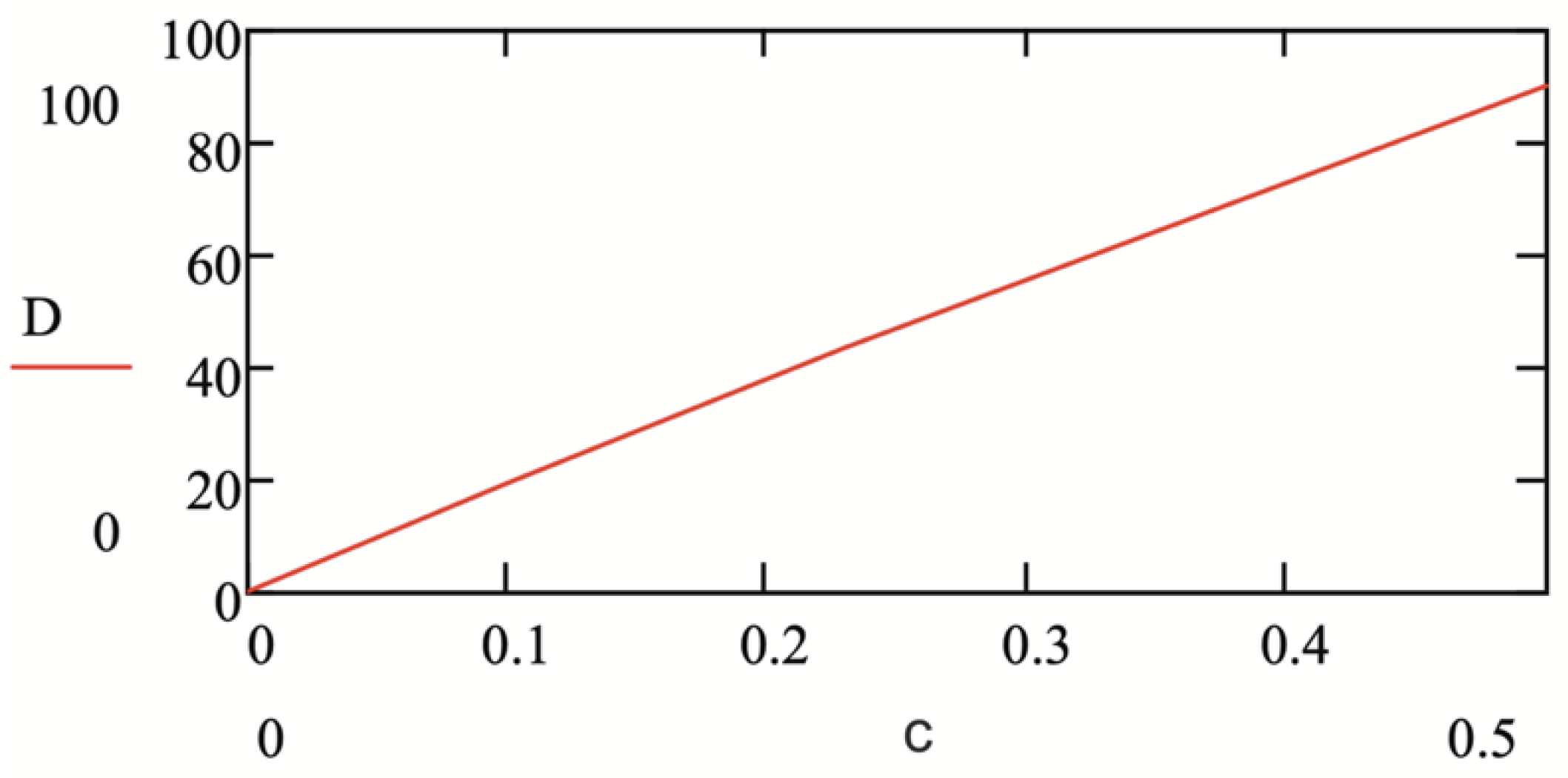

3. Design of Differential Refractometer and Preliminary Results

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shyam Singh. Refractive Index Measurement and its Applications. Physica Scripta 2002, 65, 167-180. [CrossRef]

- Meeten, G. H. Refractive Index Measurement. In Measurement, Instrumentation and Sensors Handbook; Webster, J. G., Ed; CRC Press LLC: 2000 Corporate Blvd., N.W., Boca Raton, FL 33431, USA, 1999, pp. 1680-1689.

- Longhurst, R.S. General and Physical Optics, 3rd ed.; Addison-Wesley Longman Ltd., London, UK, 1974; pp. 677.

- Vilitis, O.; Shipkovs, P. and Merkulov, D. Determining the refractive index of liquids using a cylindrical cuvette. Meas. Sci. Technol. 2009, 20, 117001. [CrossRef]

- Kozlov, V.; Merkulov, D. and Vilitis, O. New method for measuring refractive index of liquids. Proceedings of SPIE 2001, 4318, 89-92. [CrossRef]

- Kozlov, V.; Heinlaan, M. and Merkulov, D. Measurement of the concentration of functionalized polymer nanoparticles using light refraction. Proceedings of Intern.Conf. “Medical physics in the Baltic States”, Kaunas, Lituania, 2019; pp. 134-136.

- Brice, B. A. and Halwer, M. A differential refractometer. J. Opt. Soc. Am. 1951, 41, 1033.

- García-Valenzuela, A. Beam refraction and displacement in a differentia refractometer with an absorbing samplе. Opt. Lett 2009, 34, 2192-2194. [CrossRef]

- Misto; Purwandari, E.; Supriydi; Arkundato, A.; Rohman, L. and Cahyono, B.E. Analyses of Concentration and Wavelength Dependent Refractive Index of Sugar Solution Using Sellmeier Equation. J. Phys.: Conf. Ser. 2021, 1825, 012030.

- McClimans, М.; LaPlante, С.; Bonner, D. and Bali, S. Real-time differential refractometry without interferometry at a sensitivity level of Applied Optics 2006, 45, 6447-6486.

- Koutsoumpos, S.; Giannios, P.; Triantis, D. and Moutzouris, K. Critical angle differential refractometry of lossy media: a theoretical study and practical design issues. Instruments 2019, 3, 36. [CrossRef]

- Zilio, S. C. A simple method to measure critical angles for high-sensitivity differential refractometry. Optics Express 2012, 20, 1862-1867.

- www.wyatt.com.

- Gong, X.; Ngai, N. and Wu, C. A portable, stable and precise laser differential refractometer. Rev.Sci.Instr. 2013, 84, 114103. [CrossRef]

- GESAMP. Sources, fate and effects of microplastics in the marine environment: a global assessment (Kershaw, P. J., ed.). IMO/ FAO/UNESCO-IOC/UNIDO/WMO/IAEA/ UN/UNEP/UNDP Joint group of experts on the scientific aspects of marine environmental protection. Reports and studies GESAMP 2015, 93:96.

- Toussaint, B.; Raffael, B.; Angers-Loustau, A.; Gilliland, D.; Kestens, V.; Petrillo, M.; Rio-Echevarria, I.M. and Van den Eede, G. Review of micro- and nanoplastic contamination in the food chain. Food Additives & Contaminants: Part A 2019, 36, 639-673. [CrossRef]

- SAPEA. Science Advice for Policy by European Academies.. A Scientific Perspective on Microplastics in Nature and Society. Berlin: SAPEA 2019. [CrossRef]

- Besseling, E.; Redondo-Hasselerharm, P.; Foekema, E.M. and Koelmans, A.A. Quantifying ecological risks of aquatic micro- and nanoplastic. Critical Reviews in Environmental Science and Technology 2019, 49, 32-80. [CrossRef]

- de Sá, L.C.; Oliveira, M.; Ribeiro, F.; Rocha, T.L. and Futter, M.N. Studies of the effects of microplastics on aquatic organisms: What do we know and where should we focus our efforts in the future? Science of the Total Environment 2018, 645, 1029–1039.

- Silva, A.B.; Bastos, A.S.; Justino, C.I.L.; da Costa, J.P.; Duarte, A.C. and Rocha-Santos, T.A.P. Microplastics in the environment: Challenges in analytical chemistry -A review. Analytica Chimica Acta 2018, 1017, 1-19.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).