1. Introduction

Geothermal waters are widespread in Kazakhstan due to large artesian basins with water-bearing rocks immersed in them to great depths. The size of their reserves estimates the possibilities of using geothermal waters, the presence of self-discharge, temperature indicators, the quality of groundwater and the presence of a consumer.

According to the results of more than forty years of research of hydro geothermal resources in Kazakhstan, more than a hundred exploration wells have been drilled that have uncovered thermal waters with conditioned characteristics in terms of debits, temperature and mineralisation, gas and chemical composition, and the prospects for using geothermal energy potential have been revealed [

1]. There are 3,544 underground water deposits registered. Their reserves amount to more than 42 million cubic meters of water daily. Groundwater reserves are replenished naturally by precipitation or river runoff [

2].

Currently, in Kazakhstan and many Central Asian countries, groundwater other than drinking water is hardly considered.

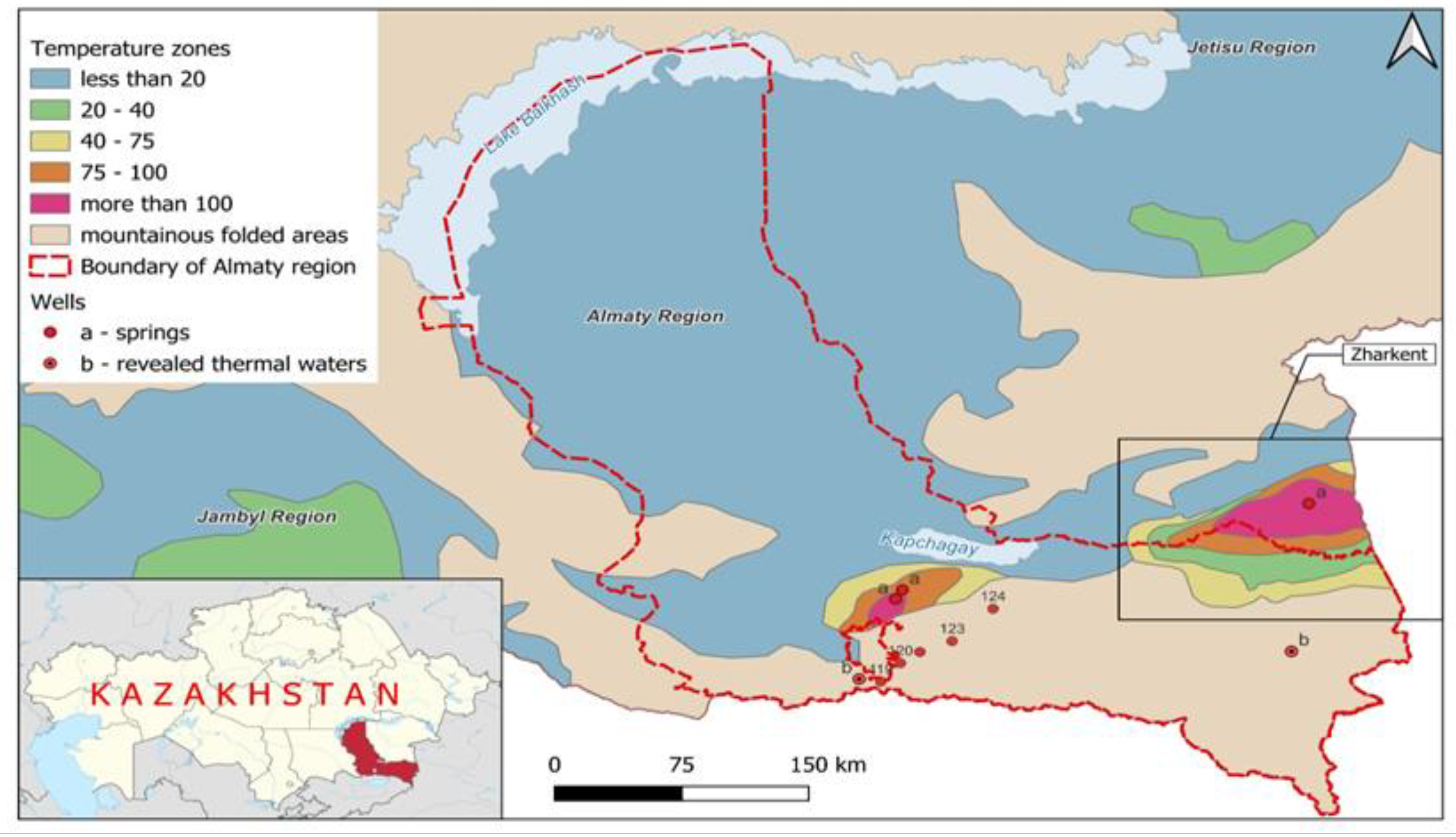

Geothermal sources in the Republic were collected and registered in the [reference from Institute of Hydrogeology and Geology named after U.M. Akhmetsafin (Almaty, Kazakhstan)] From this reference, one elaborates a territorial map of the geothermal distribution of Kazakhstan with QGIS 3.32.0,

Figure 1.

As can be seen from the plot, most high-temperature geothermal sources by occupied area are territories with electricity deficit, Southern and Western Kazakhstan regions. To this end, one is considering the possibility of using geothermal sources to generate electricity due to the energy dependence of these regions on electricity supplies from the Russian Federation and Kyrgyzstan.

In

Figure 1, the low-thermal springs with temperatures from 20-40°C are indicated on the map in green. They correspond to North Kazakhstan, the regions of Pavlodar, East Kazakhstan, Zhambyl, Kyzylorda and West Kazakhstan, and occupy a total area of 14% sq. km in the Republic, as summarised in

Table 1.

Geothermal springs with a temperature of 40-75°C marked on the map in yellow, are standard in Pavlodar, Zhambyl, Kyzylorda, Mangystau (Caspian Artesian basin) and West Kazakhstan regions and occupy a total area of 18% sq. km in the Republic (

Table 1).

Sources with a temperature of 75-100°C marked on the brown map are encountered in the Mangystau, Atyrau, and Turkistan regions and occupy a total area of 5% sq. km in the Republic (

Table 1).

Sources with a temperature of more than 100°C marked on the map in crimson colour are recorded in the Almaty (Zharkent) and Mangystau regions and occupy a total area of 2% sq. km in the Republic,

Table 1.

Geothermal sources in all these regions are used for agriculture, greenhouses, hot water supply, public buildings, private houses heating, or other uses. However, they are not used for generating electric energy. Using available geothermal sources for generating electric energy is relevant for Kazakhstan since more than 85% of electric energy is generated from thermal power plants that burn coal [

1,

3] and cause environmental damage. Kazakhstan has substantial coal reserves and has historically relied on coal-fired power plants for electricity generation. The country has also been developing its natural gas resources for power generation. Both coal and natural gas are fossil fuels that emit CO

2 when burned for electricity.

This article focuses on developing geothermal sources in promising regions of Kazakhstan.

2. Materials and Methods

2.1. Research Area

To generate electrical energy, sources with high temperatures are needed. Therefore, one will consider in more detail the areas of occurrence of groundwater with high temperature and their chemical composition.

Sources with temperature (75-100°C)

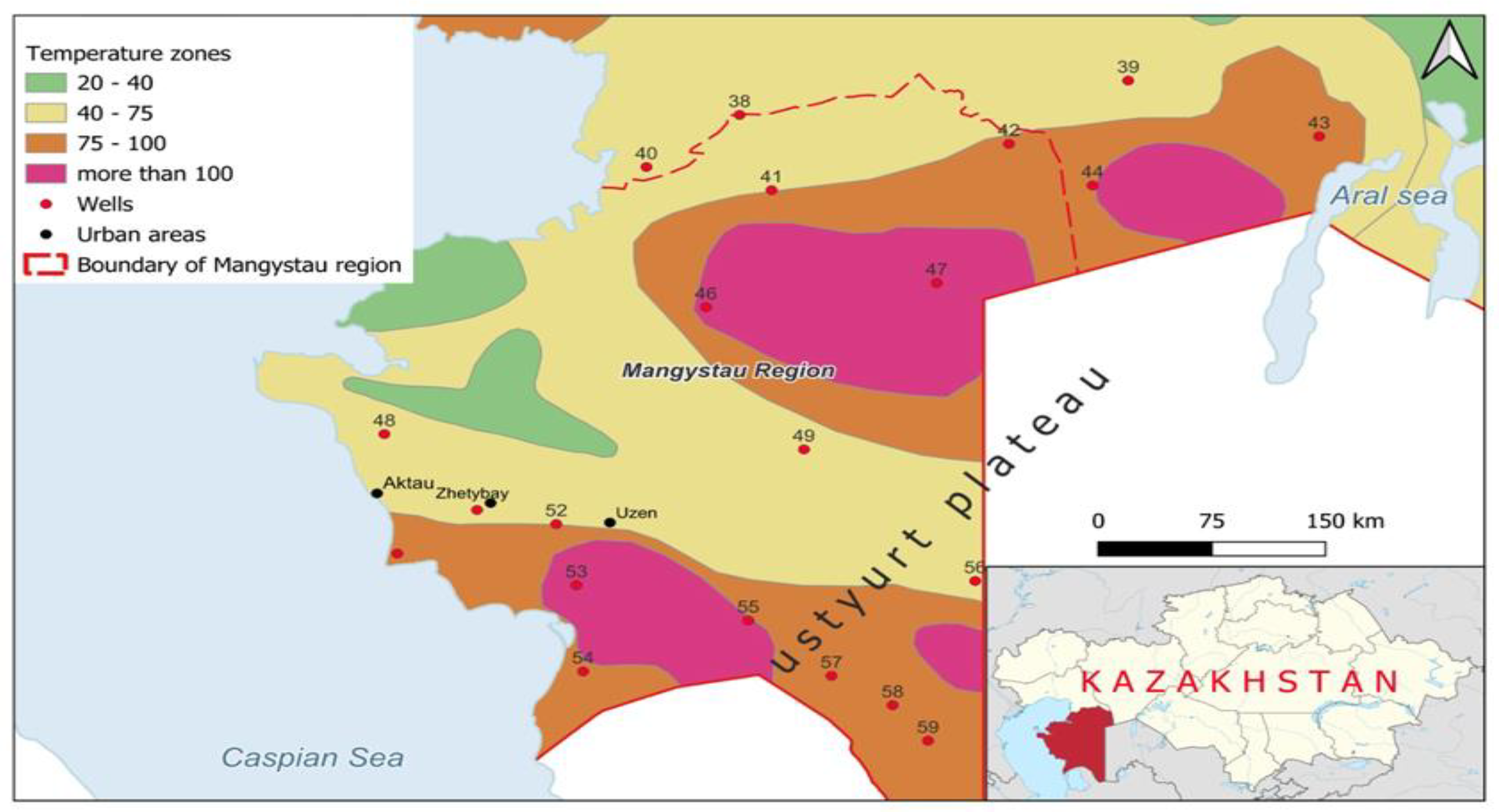

Mangystau region has significant industrial reserves of thermal waters with a constant temperature of 60-90°C in summer and winter, which can form alternative sources of heat and electricity. It is undoubtedly possible to provide residents of the Mangystau region with environmentally friendly and cheap thermal energy.

The Mangystau-Ustyurt system of artesian basins is situated in the Aral-Caspian watershed, occupying the western side of the Turan Plate. The Cretaceous and Jurassic formations are the sources of hydro geothermal resources with great potential for exploitation. Thermal waters often contain industrially significant concentrations of iodine, boron, bromine, and other essential micro-components. The Cretaceous thermometer complex is almost everywhere and can be found at a depth of up to 2000 meters or more in the bends of Mangyshlak and Ustyurt. The piezometric levels range from 160 to 250 meters below the first few tens of meters above the earth's surface. The well flow rates vary between 140 to 3500 m

3/day. The water mineralization ranges from 1 to 10 g/dm

3 in the uplift area and from 6 to 35 g/dm

3 in the Zhetybay-Uzen zone. In the bends of Mangyshlak and Ustyurt, the water mineralization ranges from 50 to 100 g/dm

3, predominantly consisting of sodium chloride. The reservoir temperature of groundwater varies from 50 to 65°C in the Zhetybay-Uzen zone and from 100 to 120°C in the North Ustyurt trough, reaching up to 120 to 150°C in the depressions of Southern Mangyshlak and Southern Ustyurt [

3].

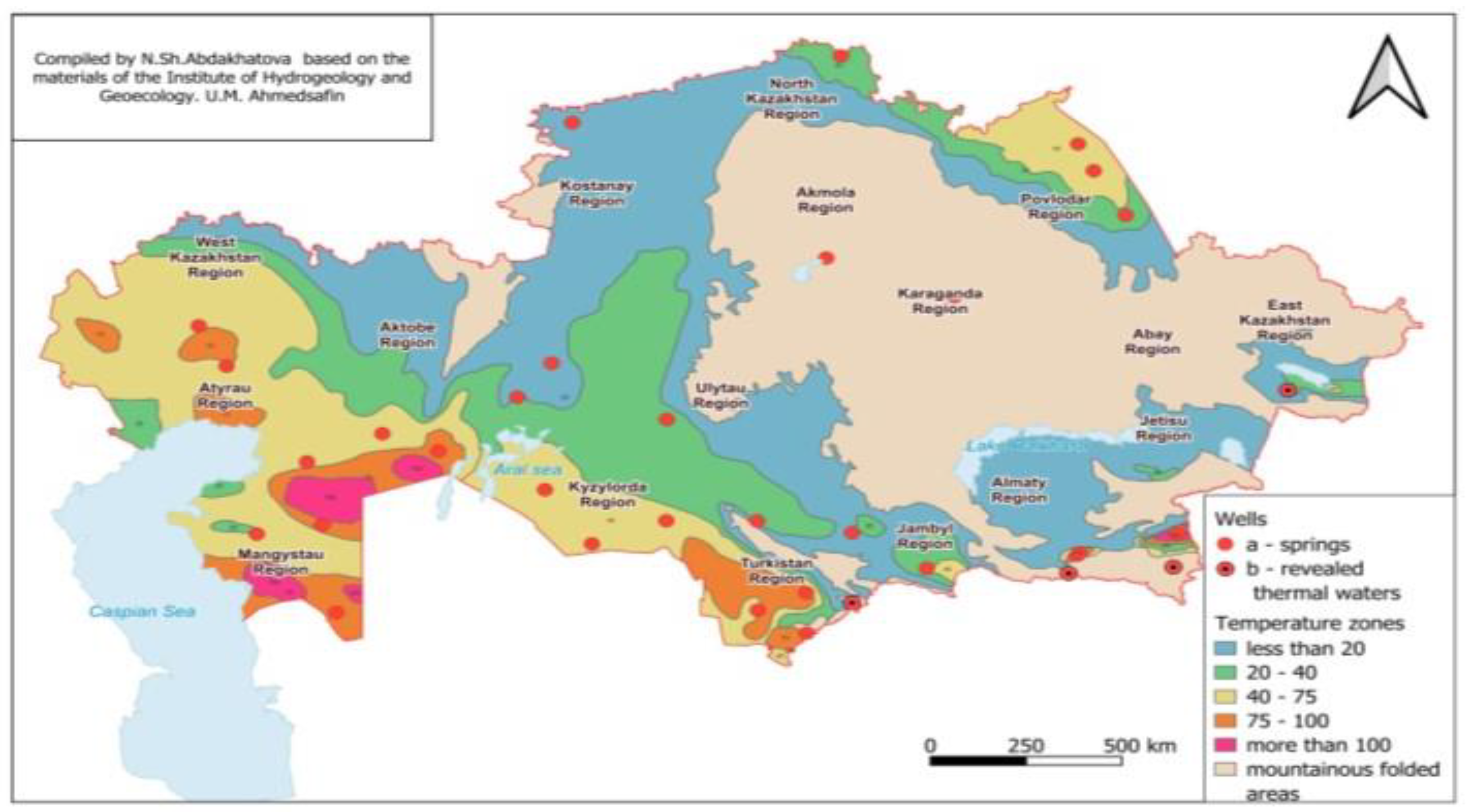

The Almaty Artesian basin is in the western part of the Ili Depression. Within this area, Neogene and Paleogene thermocautery complexes have been discovered, with depths of up to 650m and 1500-2600m in the axial part. In certain areas, groundwater comes to the surface as springs under the pressure of the earth's layers. The water discharged from the spring’s ranges from 10-500 to 800-2200m

3/day. The water mineralization ranges from 3 to 10-15 g/dm

3 and more, with sulphate-chloride and sodium chloride composition. The water temperature at a depth of 700-800m can reach up to 40°C, and at a depth of up to 2600-3000m, it can reach 75-84°C [

4].

Figure 3.

Map of geothermal waters of the Almaty region. The Zharkend area, highlighted, is in the border of Almaty region.

Figure 3.

Map of geothermal waters of the Almaty region. The Zharkend area, highlighted, is in the border of Almaty region.

The Zharkent Artesian basin is known for its thermal waters, which have high potential due to their high temperatures at the wellheads. Located in the central part of the Zharkent depression, the flow rates of wells are between 40-60 dm3/s, with temperatures exceeding 80°C. Notably, the temperature of geothermal waters in the reservoir of the Zharkent basin is the highest recorded in all of Kazakhstan. While the temperature at the wellhead ranges from 30 to 103°C, calculations indicate that the temperature at the depth of the reservoir reaches an impressive 165°C.

In the Zharkent sub-basin, geothermal waters have been discovered at depths ranging from 250-400 m in the foothills and at depths of 4,000 - 4,500 m. The flow rate of wells ranges from 120 to 12000 m3/day, with water mineralisation varying from 1.000 – 15.000 mg/l. The chemical composition of these waters varies from calcium bicarbonate to bicarbonate-sulphate-chloride sodium-calcium and sodium. The temperature of the water measured in wells varies from 20 to 103°C.

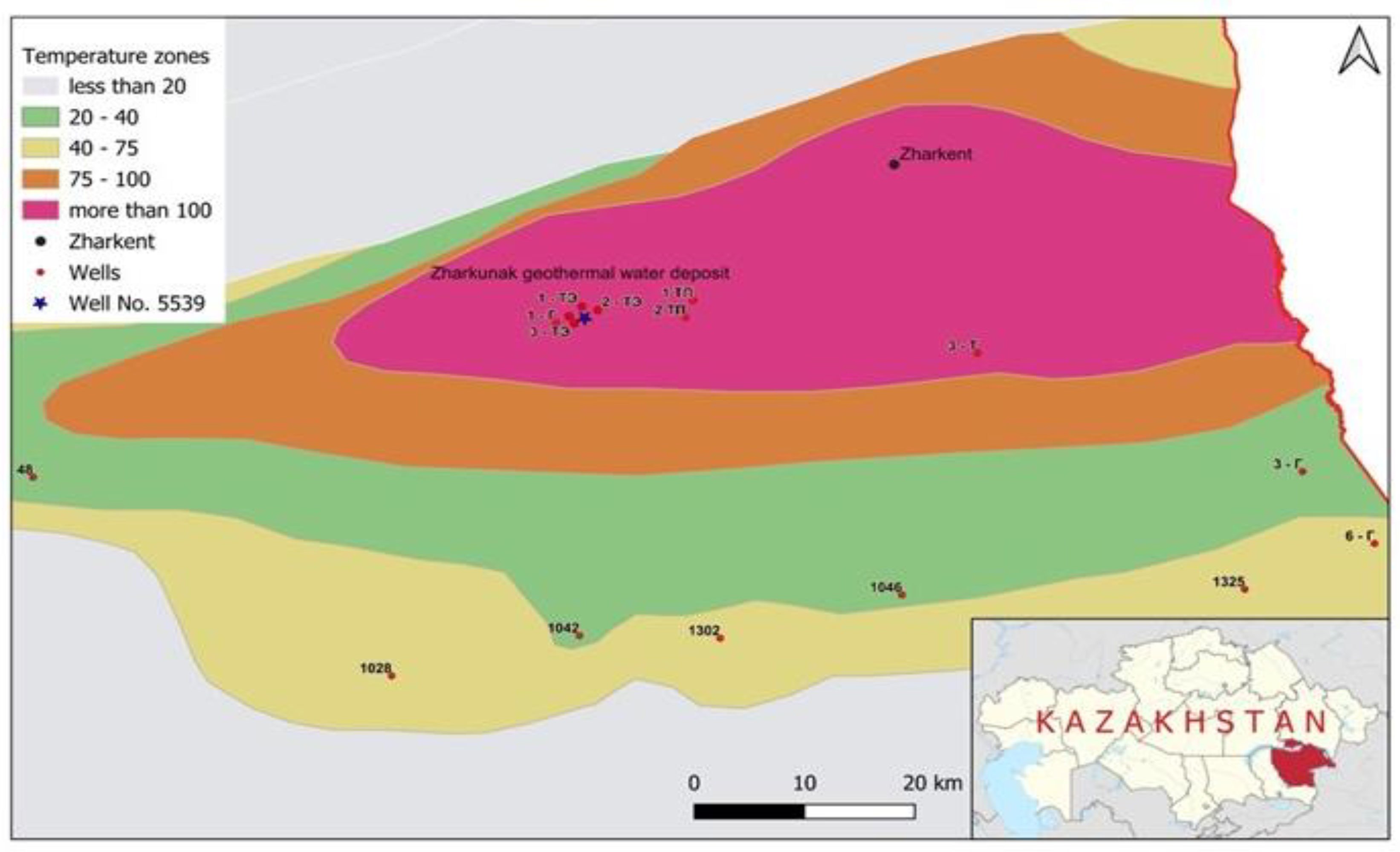

Upon review, the Almaty and Mangystau regions have some of the highest temperatures of geothermal sources. Therefore, it is worthwhile to consider geothermal sources with sufficient potential for power supply to small settlements. Specifically, the wells in some areas of the Almaty region (Zharkunak deposit, Zharkent) can be considered objects of research for the possibility of using geothermal sources for power supply, as depicted in

Figure 4 [

5,

6].

In 2015-2016, prospecting and deep exploration drilling for geothermal resources was carried out at the Zharkunak site to assess the sufficiency of geothermal resources for direct use in this area (Ministry of Energy and Mineral Resources of the Republic of Kazakhstan, 2016). This project was successful, and hot water from 2-3 wells is currently used for heating houses, hot water supply, heating greenhouses, fish farming and other needs (

Table 2) [

7].

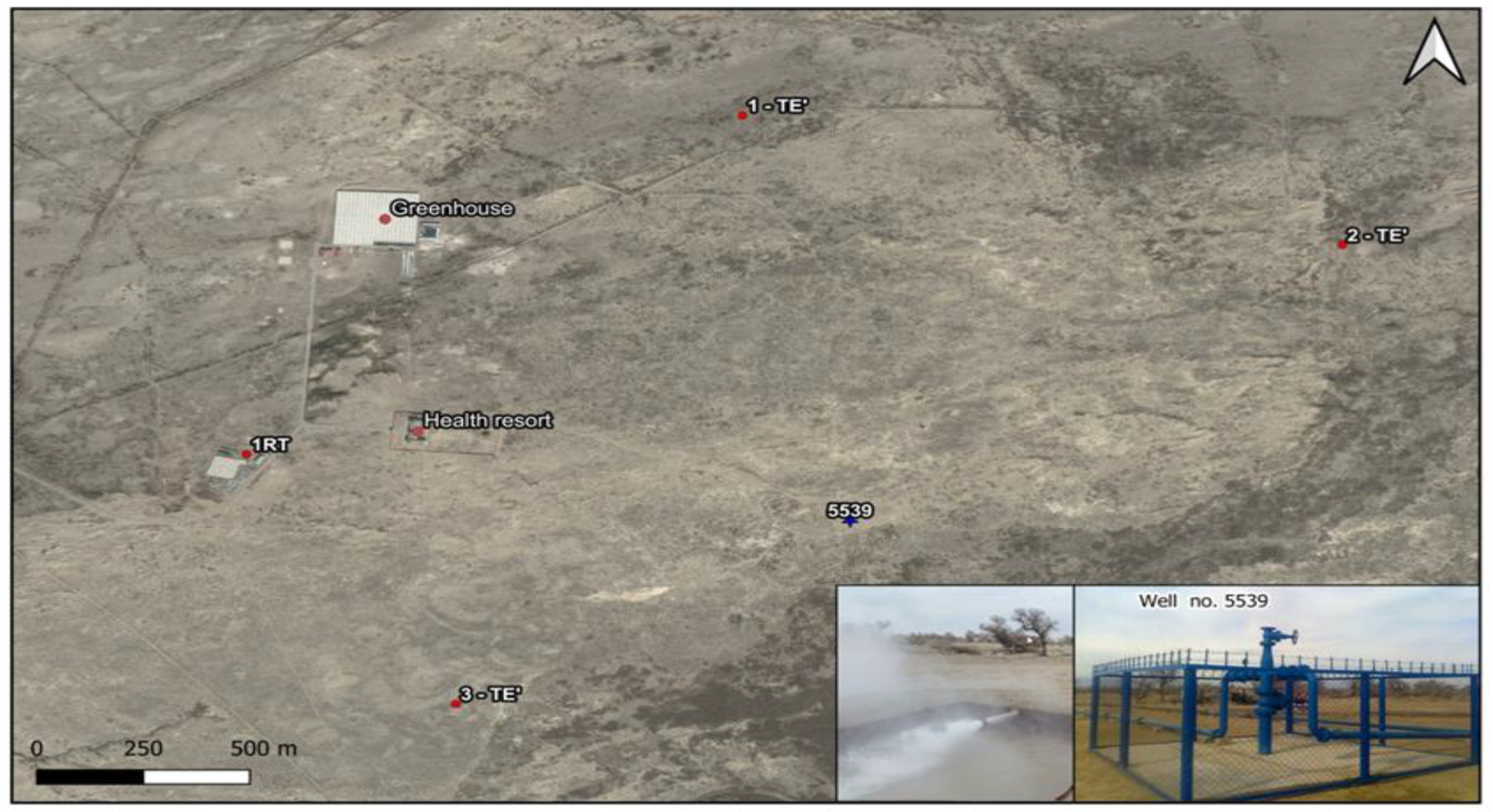

The Zharkunak geothermal water deposit refers to the central part of the Zharkent depression, including wells No. 5539 and 1RT, as well as three conditional wells included in the design scheme of the areal water intake (Wells 1-TE`, 2-TE`, 3-TE`) Well. No 5539 location – Zharkunak drilling year – 2016, (Ispolnitel` – TOO PK«GEOTERM») Contractor – Production Company "GEOTHERM" LLP" depth – 2850 m, water temperature – 103°C, flow rate – 50 l/s, aquifer – Cretaceous, water mineralisation – 0.7 g/dm

3, chemical composition – sodium bicarbonate, use – for the needs of (TOO «Kiban-Agro») Kiban-Agro LLP (greenhouses and intensive fish farming pools) [

4,

7]. Since most wells are located close to each other, geothermal sources are poorly visible on the structural map of Zharkent (

Figure 4). The reader can see in

Figure 5 the location of these sources using satellite images. The link to these images is in the

Supplementary Materials.

Based on the data shown in

Table 3, one can see that the water temperature in well No. 5539 is ideal for generating electrical energy through ORC. This well has a temperature of over 100

0C, causing the water to turn into steam as it exits the well. This steam is necessary for the turbines connected to the electric generators to rotate. In Kazakhstan, we can leverage existing self-draining geothermal wells without needing to invest significant capital costs. The production of electricity using thermal waters is dependent on mineralization and chemical composition.

Therefore, this study aims to evaluate the potential of wells in some regions of the Almaty region, specifically the central part of the Zharkent depression, Zharkunak field, and well No. 5539, for power supply using the Organic Rankine Cycle (ORC).

2.2. Research Methods

The Organic Rankine Cycle (ORC) represents an attractive technology for small-scale power production and for exploiting low-temperature heat sources [

9]. The ORC system shows higher efficiency, flexibility, and safety when compared with traditional energy systems. Furthermore, ORC guarantees low maintenance requirements, fast start-up and stop procedures and efficient partial load operations [

10].

The main difference between conventional and Organic Rankine Cycles lies in adopting an organic fluid against water vapour. Organic fluids are used in Rankine cycles at lower temperatures because they have favourable thermodynamic properties, such as lower boiling points compared to water. This allows the cycle to efficiently convert thermal energy into work at sources with lower temperatures, improving the efficiency and viability of systems like geothermal power plants and waste heat recovery in industrial processes. Organic fluids enable these systems to operate effectively where traditional water-steam cycles would not even operate.

However, the first condition is to evaluate if the site is worth it for the environmental conditions in that zone. In a continental climate like Zharkent's, summers are typically hot and dry, while winters can be extremely cold and somewhat snowy. This results in a wide range of temperatures throughout the year. For instance, during the summer months, temperatures can climb well above 30°C, occasionally reaching up to 40°C in the hottest periods. In contrast, winter temperatures can drop to -20°C for lower, especially during the coldest nights of December and January.

These temperature variations influence the thermal efficiency of the ORC system. The first concern is to evaluate the Carnot efficiency, i.e., the temperature ranges the machine will operate yearly.

The Carnot efficiency is a fundamental concept in thermodynamics. It defines the maximum possible theoretical efficiency that any heat engine can achieve during the conversion of heat into work, or more broadly, energy conversion processes. This efficiency depends solely on the temperatures of the heat source and the heat sink—respectively, the high-temperature reservoir, in our case the hot geothermal waters, from which the engine absorbs heat and the low-temperature reservoir, the atmospheric air, to which the engine expels heat. One admits the atmosphere to be the heat sink because there is no large body of water close.

where

Tc is the absolute temperature (in Kelvin) of the cold reservoir and

Th is the absolute temperature of the hot reservoir. As previously stated, the atmospheric temperature changes seasonally, reducing and increasing the overall efficiency of the ORC system. In summer, the cold reservoir may reach 40°C (313.15 K). During winter, temperatures of -10°C (263.15 K) are easily reached. For the sake of this model, one will use these two temperatures as a reference for the cold reservoir.

Table 4 shows the Carnot efficiency for the ORC system installed in the wells of the Zharkent basin, as indicated in

Table 3.

As expected, the Carnot efficiency of each well changes substantially from summer to winter. In the case of wells 48 and 3-T summer efficiency is 1.9 and 7.5 % and winter efficiency rises to 17.5 and 22.2%. The heat exchange will be much more efficient in the winter than in the summer because of the higher differences in temperature. Moreover, the real thermal efficiency of heat engines is lower than the Carnot efficiency due to practical limitations and differences between real engines and the idealized Carnot engine. These factors include irreversibility like friction, wear, turbulence, fluid resistance, heat loss, and non-ideal processes such as non-isothermal heat transfer, finite-time processes, and material limitations. The exergy destruction due to entropy production and design and operational constraints like economic and safety considerations and environmental regulations can also affect engine efficiency. Therefore, the wells that are most promising for the installation of an ORC cycle are 5539, 1-RT, and 2-TP. These wells may operate the whole year despite lower efficiency in the summer.

2.2.1. Thermodynamic Model

One selected the simplest model. It is comprised of an evaporator, turbine, condenser, and pump. The purpose of this is to assess the possibility of more than one geothermal ORC system in the Zharkent basin. There, the geothermal hot water will be directed into the evaporator, acting as the primary heat source.

The power available in the wells

To access the power in the well, one must present two hypotheses: the well pressure and the soil type. Since the well pressure is unknown, one assumes a conservative value of 125 kPa. It is unlikely to have lower static pressures for self-draining geothermal wells. The second hypothesis is the existing soil type once it conditions the heat transfer efficiency from the well to the evaporator. Thus, the ORC's efficiency is directly influenced by the geological structure of the land of the Zharkent source. Given that the land in the Zharkent source is sandy in these wells, it could boost the well-evaporator heat transfer efficiency by up to 40% [

11].

The well capacity is determined as follows:

Where:

-depends on atmospheric pressure

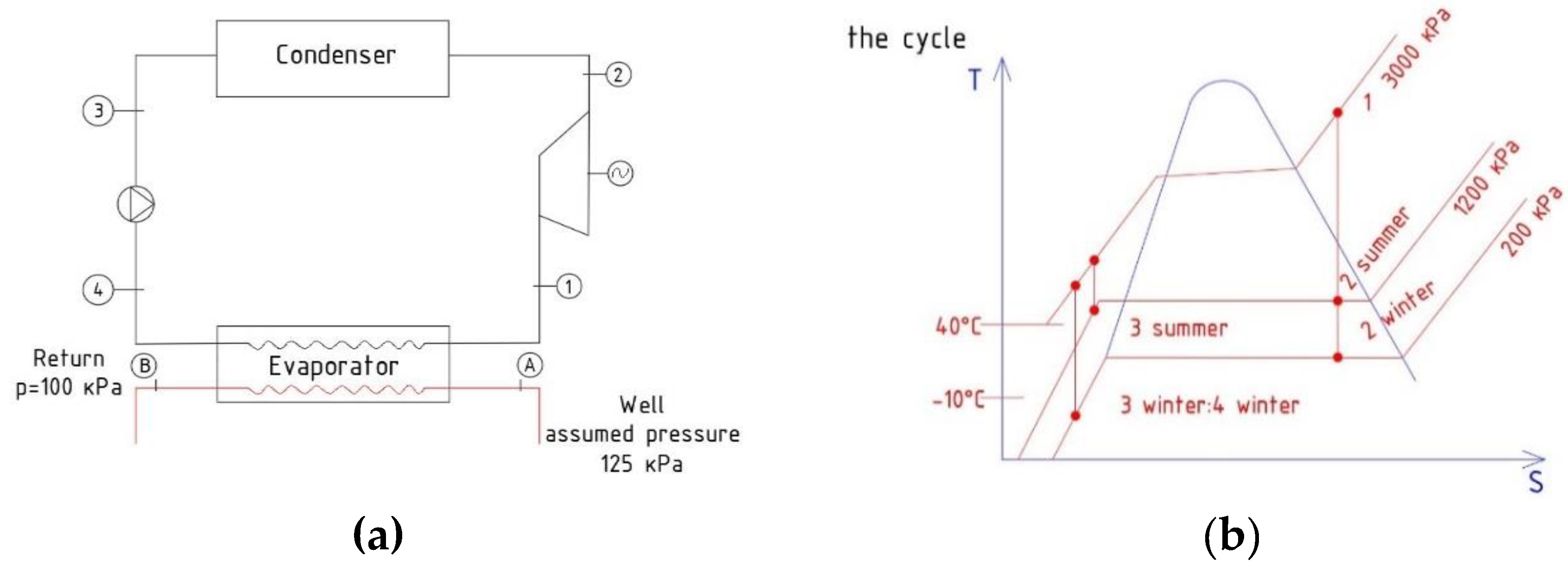

Figure 6 (a) shows the most straightforward ORC layout. Here, one will focus on evaluating each well's available power for the previously discussed two hypotheses. The available power is given by the expression in Equation (2). The heat power capacity is provided by the enthalpy gradient of the well inlet and outlet times the geothermal water mass flow. These enthalpies are related to A and B's temperature and pressure conditions, presented in

Table 5. The mass flow was calculated from the volumetric flow times the density at specific temperatures and pressure conditions, Equation (3).

Results of a thermodynamic model for an ORC with an organic liquid. R134a Under conditions Point A - p=125 kPa and Point B - p=100 kPa.

Geothermal hot water is the primary heat source and is directed into the evaporator. Inside the evaporator, the geothermal hot water flows through a series of pipes or coils, part of a closed loop containing an organic working fluid. The heat from the well will be transferred to the working fluid. The quantity of heat transferred can be estimated as indicated in Equation (4), assuming the 40% efficiency as in the second hypothesis of the model [

11].

Where: =40%

Thus, the available thermal power corresponds to that indicated in

Table 6. From the table, we conclude that well 5539 has the highest available thermal power in both summer and winter, and it is the most attractive for generating electric energy.

The power of the cycle

The evaluation of the maximum energy to be explored in the wells is indicated in

Table 6. However, the electric power extracted from the geothermal well will be a faction of that. The thermodynamic model will be presented, and the results will shed a light in the quantity of electric power yearly produced should a similar system be installed.

As the geothermal hot water circulates in the evaporator, it transfers its heat to the organic working fluid, causing it to evaporate and generate high-pressure vapour—process 4-1 in

Figure 6. This fluid is selected based on its thermodynamic properties, [

12,

13,

14] such as low boiling point and high vapour pressure, making it ideal for converting thermal energy into mechanical work. The R-134a fluid is used once its critical temperature is 10 K above the maximum well temperature. The R-134a phase change is efficient due to the evaporator's design, which maximizes heat exchange through a large surface and minimizes thermal losses [

15,

16].

The high-pressure R-134a vapour leaves the evaporator and goes into a turbine. The turbine expands and spins the blades, converting thermal into mechanical energy – Process 1-2 in

Figure 6. The fluid’s pressure and temperature drop after the turbine, but it maintains a saturated state, where vapour and liquid coexist. For summer conditions the fluid’s quality will be 97.8%, i.e. of the R134a will be vapour. For winter conditions, pressure and temperature drop will be higher thus condensing more fluid. After the turbine one will have 95.8% of the circulating R134a as vapour. A 4.2% condensate is within the acceptable operation limits of a vapour turbine.

After passing through the turbine, the R134a vapour is condensed back into a liquid by a cooling system – process 2-3. In our case, an air-cooled condenser. It is then recirculated by a pump back into the evaporator to repeat the cycle – process 3-4. The turbine is connected by a shaft to an alternator that converts the mechanical into electrical energy.

For all processes, a steady state condition has been assumed for two seasons for a system operating with R-134a. System components' pressure drops and heat losses have been neglected [

17,

18,

19].

Figure 6 (b) shows the T-s diagram of this process and the fluid’s properties are depicted in

Table 7.

A control volume at the evaporator allows the calculation of the R134a mass flow rate as depicted in Equation (5). The heat is the one provided in

Table 7 and the enthalpy are in

Table 5.

(5)

The required mass flow rate of R134a for different seasons is 0.028 kg/s in summer for well 5539 and 0.033 kg/c in winter. Also, for wells 1-RT and 2-TP in summer, 0.013 and 0.012 kg/s, and in winter, 0.015 and 0.016 kg/s

Table 8.

The vapour turbine’s maximum power is also determined by applying a control volume to the turbine. The fluid’s enthalpy is from

Table 5. For simplicity, one assumed the turbine's efficiency to be 95%. Note that this value was used to calculate the mechanical power, not the properties of point 2 of the assumed isentropic expansion.

Where: =95%

The net power of the system is given by the difference between the work obtained in the turbine expansion and pumps, calculated as indicated in Equation (7):

As expected, the work from the pumps can be ignored once calculations show it to be 0.01% from the total expansion work from the turbines.

The overall power that can be extracted from each well is thus presented in

Table 9. Based on the table, well 5539 has the highest available thermal capacity, for which the electric capacity in summer is 0.460 MW and 2.224 MW in winter. As expected, the values are significantly higher in winter than in summer because heat exchange will be much more efficient in winter due to larger temperature differences. For wells 1-TR and 2-TP, the available electric power in summer is 0.204 and 0.201MW, and in winter, 1.019 and 1.098 MW.

3. Results and Discussion

This article explores the geothermal sources of the Almaty and Mangystau regions for the possible application and generation of electric energy by ORC renewable systems. The analysis focused on the geothermal source (Zharkunak field, Zharkent), where various geothermal wells exist. A study of the energy characteristics of Organic Rankine Cycles (OCRs) for operating low-temperature heat sources was also conducted. For this purpose, R134a (freon) was chosen as the working fluid [

20].

3.1. Geothermal Electricity Generation in Almaty Region

A simple thermodynamic model enables the quantification of the mechanical power [

21] extracted from three geothermal wells in the Almaty region of Kazakhstan. The possible electricity production, E, is calculated from the energy generated by the turbines for summer and winter conditions by each machine's full power operating time, t, by the electrical efficiency, Equation (8).

In our case, one admitted the electrical efficiency to be 98%. One also hypothesized that the turbines operate 90% of the time at nominal capacity, with 10% dedicated to downtime operations or maintenance. The overall electricity production for each well is in

Table 10.

Well 5539 (

Table 8) stands out with an annual productivity of 10371 MWh of electricity, significantly surpassing the other wells. This is attributed to its notably higher temperature, as indicated in

Table 4. When we consider the total annual electric energy of wells 1-TR and 2-TP, the figure reaches 4723 and 5017 MWh, respectively. The total electric energy potential of all the wells under study is 20111 MWh, which underscores the significant potential for producing eco-friendly electricity in the Almaty region, particularly in Zharkent.

In our study, we focused on two regions that have almost identical energy characteristics. We prioritised the city of Zharkent, located in the Almaty region because it depends more on energy than the Mangystau region. The ratio between electricity production and consumption is 15.2 million kWh (output of 32.0 million kWh, consumption of 47.2 million kWh). There is an annual increase in consumption by an average of 1.2 million kWh. Moreover, the geothermal water temperature in the Zharkent reservoir is the highest recorded temperature in Kazakhstan. Therefore, we analysed a geothermal source (Zharkunak field, Zharkent, Almaty region) with several geothermal wells.

Well 5539 (

Table 8) has an annual productivity of 10371 MWh of electricity, significantly higher than the other wells. This is due to its notably higher temperature (

Table 4). When considering the total annual electric energy of wells 1-TR and 2-TP, the figure reaches 4723 and 5017 MWh, respectively. The total potential electricity of all three wells is 20111 MWh, which presents a significant potential for producing eco-friendly electricity, especially in Zharkent.

This article focused on two nearly identical regions regarding their energy characteristics. Our priority was Zharkent, located in the Almaty region, for two key reasons: the area is experiencing a growing electricity deficit, and the geothermal water temperature in the Zharkent reservoir is the highest recorded in Kazakhstan, highlighting its significant potential for geothermal energy production.

Almaty’s overall electricity deficit is 152 GWh, which is necessary for the grid to supply the region from other regions of the country. This deficit is compensated by highly pollutant coal thermal power plants [

22]. The local exploitation of known geothermal fields in the Zharkent reservoir may yield 20,1 GWh, i.e. 13, 2% of the current deficit.

4. Conclusions

This study has illustrated the potential for geothermal electricity generation in Kazakhstan's Almaty and Mangystau regions using Organic Rankine Cycle (ORC) systems. Particularly noteworthy is the Zharkunak field in the Almaty region, where the geothermal resources, highlighted by the high-temperature wells, offer a promising alternative to conventional energy sources. Among these, well 5539 stands out with its remarkably high temperature, contributing significantly to local energy supplies with an annual output of 10.3 GWh.

The combined electric power output from the geothermal wells studied in Zharkent reaches 20,1 GWh annually. This capacity is not only substantial but could also play a critical role in reducing the region's dependence on more polluting coal-fired power plants and addressing the annual increase in energy consumption.

By leveraging local geothermal resources, Kazakhstan can enhance its energy independence and security. This strategic move would reduce the need for energy imports, especially in energy-deficient areas like Almaty, and offer a sustainable and environmentally friendly alternative.

Geothermal energy, by deploying ORC systems, presents a clean, sustainable, and continuous electricity source, aligning with Kazakhstan's environmental goals and its commitments to reducing greenhouse gas emissions. This green energy solution underscores the country's potential shift towards more sustainable energy practices.

Further research is encouraged to explore the scalability of ORC systems and assess their applicability across other potential geothermal sites within Kazakhstan. Investment in the necessary infrastructure and technology to effectively harness this untapped energy source would provide not only economic benefits but also significantly contribute to environmental conservation.

In conclusion, the untapped geothermal resources in Kazakhstan, especially evident in the Almaty and Mangystau regions, represent an underutilized asset with a significant capacity to transform the country's energy matrix. Properly utilized, these resources could address the pressing challenges of energy dependency, environmental degradation, and the pursuit of economic sustainability.

Author Contributions

Conceptualization, N. A., L. F. R., and L. S.; methodology, N. A., L.F. R., and L. S.; software, A.Т., T. Zh., A. O., S.O.; validation, L. F. R., S. O. and A. T.; formal analysis, N. A., L. F. R. and L. S.; investigation, L. F. R.; resources, N. A.; data curation, L. F. R., L. S.; writing—original draft preparation, N. A., L. F. R. and L. S. ; writing—review and editing, N. A., L. F. R. and L. S.; supervision, L. F. R., O.S.; project administration, N. A.; funding acquisition, N. A.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors do not have conflicts of interest.

Nomenclature

| h |

specific enthalpy |

|

efficiency |

| P |

output power |

|

thermal power |

| T |

temperature |

|

mass consumption of geothermal water |

|

enthalpy of geothermal water at the inlet and outlet |

| Wtur

|

power of the turbine |

References

- Absametov, M.K.; Kasymbekov, D.A.; Murtazin, Y. Zh. Podzemnye vody – strategicheskiy resurs ustoychivogo razvitiya Kazakhstana [Underground water is the strategic resource of sustainable development of Kazakhstan]. Vestnik Kazakhstanskoy Akademii Estestvennykh Nauk – Herald of the Kazakhstan Academy of Natural Sciences, 2013, No 3, pp. 115–1162 [in Russian].

- Poryadin, V.I.; Akynbaeva, M.G.; Adenova, K. Fundamental’naja jekosistemnaja vzaimosvjaz’ zagrjaznenija I istoshhenija resursa presnoj vody gidrosfery. News of the National Academy of Sciences of the Republic of Kazakhstan. Series of geology and technical sciences. Izvestie NAN RK. Serija geologii i tehnicheskih nauk [Fundamental ecosystem the relationship of pollution and depletion of the fresh water of the hydrosphere. Almaty, News of the National Academy of Sciences of the Republic of Kazakhstan. Series of geology and technical sciences], 2016, 1(415), 68–78. [in Russian].

- Absametov, M.K., Murtazin, E.Zh.; Kan, S.M.; Isabekov, R.B.; Shagarova, L.V. Promy'shlenny'e vody` i ocenka zagryazneniya neftegazonosnoj sredy` regionov Kazaxstana [Industrial waters and assessment of pollution of the oil and gas environment of the regions of Kazakhstan], Institut gidrogeologii i geologii [Institute of Hydrogeology and Geology]. Almaty 2017, ISBN 978-601-228-461-5. [in Russian].

- Kalugin, O.A.; Kan, M.S.; Tleuova, T. Some features modern state of thermal mineral waters of Southern Kazakhstan. News of the national academy of sciences of the Republic of Kazakhstan Series of geology and technical sciences 2015, Volume 5, No 413(215), 105-109, ISSN 2224-5278.

- Korobkin, V.V.; Tulemisova, Zh.S. Glubinnoe stroenie i geodinamicheskie usloviya formirovaniya osadochnyh basseinov Yuzhnogo Kazakhstana (Shu-Sarysuiskogo, Pribalhashskogo, Iliiskogo) [Deep structure and geodynamic conditions for the formation of sedimentary basins in Southern Kazakhstan (Shu-Sarysu, Balkhash and Ili)]. – Geologiya i ohrana nedr [Geology and subsoil protection]. KazGEO. – 2018, No 3 (68), 2018, pp. 24–34. [in Russian].

- Baikadamova, A.M.; Jay, S. Survey of the well of the Zharkent deposit thermalny underground water (well 3-t) Engineering Journal of Satbayev University 2021, Volume 143, No 3. [CrossRef]

- Kalitov, D.K. Primery` i perspektivy` ispol`zovaniya geotermal`ny`x i promy`shlenny`x podzemny`x vod Examples and prospects of using geothermal and industrial groundwater] Kazakhstan 2018. [in Russian] https://kazaral.org/wp-content/uploads/2019/12/18.

- Absametov, M.; Sagin, J.; Adenova, D.; Smolyar, V.; Murtazin, E. Assessment of the groundwater for household and drinking purposes in central Kazakhstan. Groundwater for Sustainable Development 21(2023), 100907. [CrossRef]

- Wu, Z.; Pan, D.; Gao, N.; Zhu, T.; Xie F. Experimental testing and numerical simulation of scroll expander in a small-scale Organic Rankine Cycle system. Applied Thermal Engineering 2015; 87, 529-537. [CrossRef]

- Qiu, G. Selection of working fluids for micro-CHP systems with ORC. Renewable Energy 2012; 48: 565-57.

- Chicco, J. M.; Madrone, G. How a sensitive analysis on the coupling geology and borehole heat exchanger characteristics can improve the efficiency and production of shallow geothermal plants. [CrossRef]

- Florian, H.; Dieter, B. Thermo-Economic Evaluation of Organic Rankine Cycles for Geothermal Power Generation Using Zeotropic Mixtures. Energies 2015, 8. [CrossRef]

- Liu, Q.; Duan,Y.; Yang, Z. Performance analyses of geothermal organic Rankine cycles with selected hydrocarbon working fluids. Energy 2013; 63: 123-132. [CrossRef]

- Huan, X.; Ming-Jia, L.; Ya-Ling, H.; Wen-Quan, T. A. graphical criterion for working fluid selection and thermodynamic system comparison in waste heat recovery. Applied Thermal Engineering 2015; 89: 772-782. [CrossRef]

- Luo, X.L.; Wang, Y.P.; Liang, J.W.; Qi, J.; Su, W.; Yang, Z.; Chen, J.W.; Wang, C.; Chen, Y. Improved correlations for working fluid properties prediction and their application in performance evaluation of sub-critical Organic Rankine Cycle. Energy 2019, 174, 122–137. [CrossRef]

- Liu, Q.; Chen, R.; Yang, X.; Xiao, X. Thermodynamic Analyses of Sub- and Supercritical ORCs Using R1234yf, R236ea and Their Mixtures as Working Fluids for Geothermal Power Generation. Energies 2023, 16, 5676. [CrossRef]

- Xu, S.; Jianhui, N.; Guoyuan, M.A. Experimental Study on R1234yf Heat Pump at Low Ambient Temperature. Thermal science, 2019, Vol. 23, No. 6B, pp. 3877-3886. [CrossRef]

- Algieria, A.; Sebo, J. Energetic Investigation of Organic Rankine Cycles (ORCs) for the Exploitation of Low-Temperature Geothermal Sources – A possible application in Slovakia. Procedia Computer Science 109C (2017) 833–840. [CrossRef]

- Doaa M. A.; Hanaa M. F.; Ninet, M. A.; Hanaa, T. E. Organic Rankine Cycle Based Geothermal Energy for Power Generation in Egypt, Energy and Power Engineering, 2017, 9, 814-828. [CrossRef]

- Lemmon, EW.; Huber, M.L.; McLinden, M.O. REFPROP Reference Fluid Thermodynamic and Transport, NIST Online Databases, 2008.

- Orynbaev, S.; Tokmoldayev. A.; Abdlakhatova. N.; Zhanpeisova, A.; Tumanov. I.; Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources. Energy Harvesting and Systems 2024, 11(1): 20230082. [CrossRef]

- Kozhageldi, B.; Tulenbayev, Zh.; Orynbayev, S.; Kuttybaev, G.; Abdlakhatova, N.; Minazhova. S. Development of integrated solutions for the decentralisation of electricity supply to power-hungry regions . [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).