1. Introduction

Baijiu is a unique distilled liquor in China, it is also one of the six major distilled liquors in the world, including brandy, whisky, rum, vodka, and gin. There are 12 flavor types in Chinese Baijiu, which are divided based on the brewing technology and style characteristics, including Feng-flavored baijiu, Strong -flavored baijiu etc. . It is brewed with high-quality sorghum as raw material and medium-high temperature daqu produced from barley, peas, and wheat as the starter (the core temperature is 58~60 ℃), and finally fermented in an earthen cellar. The fermentation cycle lasts one year, with cellar erection in September and cellar picking in June of the following year. The process involves cellar erection, cellar breaking, top cells, round cells, cellar insertion (May of the following year), and cellar picking. However, freshly distilled Feng-flavored baijiu is characterized by pungency and stimulation, and after storage in Mare Nectaris for a while, it becomes soft and mellow [

1]. Mare Nectaris is one of the oldest storage containers of Baijiu in China, which is mainly made by vitex negundo varvines, hemp paper, animal blood, in addition, egg whiteand, beeswax, edible oil are also the raw material of Mare Nectaris [20]. Generally, its mass is 5 tons. After pouring freshly distilled Baijiu into Mare Nectaris, it undergoes slow physical and chemical reactions (redox, condensation hydrolysis, Maillard reaction, etc.) [

2,

3,

4] and acquires a typical pleasant aroma during long-term storage.

Baijiu contains thousands of volatile compounds, the different proportions of which are the main reasons for the different styles of Baijiu . It is generally believed that many physical and chemical reactions occured during the aging process. However, the chemical reactions really determine the sensory quality of Baijiu [

5]. So far, the application of various analysis such asGC-MS, GC–IMS and other technologies have provided strong support for the study of Baijiu ; however, these technologies have some drawbacks, such as insufficient peak capacity. At present, relatively little research on Feng-flavored baijiu of different ages has been published. Liu et al. adopted GC–MS and GC–IMS to analyze the Feng-flavored baijiu, and showed that there were differences between Baijiu of different ages, a law of change of the volatile compounds had been derived preliminary [

6]. Owing to the resolution limitations of GC–MS and GC–IMS, some trace volatile compounds cannot be detected, and their impact on Feng-flavored baijiu may be overlooked. However, some crucial substances that are previously undetected, unknown, or below the detection limit of GC-MS but greatly influenced on the style features of Baijiu may be neglected due to the limited separation ability of GC-MS [

7]. GC x GC TOFMS is an advanced chromatographic separation analytical method that combines two separation techniqueswith different separation mechanisms. Nonpolar and long chromatography columns occupy the first dimension, which separates volatile compounds based on their boiling point difference. Short chromatography columns of high or moderate polarity have been used in two dimensions to further separate compounds based on their polarity differences [

8]. Compared to traditional 1D GC, 2D GC has advantages such as high scanning speed, large peak capacity, fast analysis speed, large amount of collected information, strong resolution, and short analysis time [

9].

GC×GC–TOFMS has strong qualitative capabilities and has become a powerful tool for analyzing volatile compounds in recent years [

10,

11,

12]. HS-SPME is an extensive and effective method for the pretreatment of Baijiu, and many researchers have identified a variety of volatile substances in sauce flavor, light flavor, strong flavor, fuhe flavor, and other flavors of Baijiu by HS-SPME–GC×GC–TOFMS [

13,

14,

15]. This method has greatly expanded our understanding in volatile flavor compounds of Baijiu . Ren et al. preliminary explored volatile flavor compounds in Feng-flavored baijiu by GC×GC–TOFMS [

16]. However, owing to the small number of samples, the differential compounds in aged Baijiu have not been deeply investigated.

Chemometrics is an important means of metabolomic analysis that can deeply mine large datasets and is used to analysis of complex systems [

17,

18,

19]. Many data variables, such as flavor and sense of Baijiu, exist, but the number of samples was small. The dimensions can be reduced through principal component analysis (PCA) and PLS-DA, and the relationship between the data can be intuitively displayed in low dimensions [

20,

21]. Jia et al. screened 47 compounds with significant differences in aged Baijiu using ultrahigh-pressure liquid chromatography (UHPLC)-Q-Orbitrap, they believed that the interaction between Feng flavored Baijiu and the Mare Nectaris forms honey fragrance [

22], the storage process is one of the main factors to form the style characteristics of Feng-flavored baijiu.

At present, there are few studies on flavor characteristic compounds of Fengxiang Baijiu . The identification of aged Baijiu is mainly based on sensory evaluation. This study aims to explore the differences in sensory and volatile compounds of aged Baijiu by sensory evaluation combined with instrument testing, further analyze the correlation of the key differential compounds and sensory properties, and offer a theoretical reference for flavor characteristics research on Feng-flavored baijiu.

2. Materials and Methods

2.1. Samples and Reagents

Thirty types of Feng-flavored baijiu of different ages were produced by Shaanxi Xifeng Liquor Co., Ltd, which is the typical representative enterprise of Feng flavored Baijiu . Considering the batch differences in samples of the same age, three samples were selected from different Mare Nectaris of the same age. The sample were stored in a 4°C refrigerator before detection, including A1, A2, and A3 (stored for 30 years); B1, B2, and B3 (25 years); C1, C2, and C3 (20 years); D1, D2, and D3 (18 years); E1, E2, and E3 (15 years); F1, F2, and F3 (12 years); G1, G2, and G3 (10 years); H1, H2, and H3 (8 years); I1, I2, and I3 (1 year); and J1, J2, and J3 (fresh distilled).

Normal alkanes from C7 to C30 (≥99.8%)were purchased from Sigma (St. Louis, USA). Analytical grade sodium chloride was purchased from China National Medicines Pharmaceutical Group Corporation (China), and Chromatography-grade n-hexyl-d13 alcohol (≥98.5%) was purchased from C/D/N Isotopes Inc. (Canada). Chromatography-grade anhydrous ethanol (≥99.8%) was purchased from Aladdin (China). Ultrapure water was made by Milli-Q ultrapure water machine (USA).

2.2. Volatile Compounds Analysis

2.2.1 Preparation of internal standard solution

An appropriate amount of n-hexyl-d13 alcohol was transferred to a volumetric flask, which was dissolved with 50%(v/v) ethanol solution to a final concentration of 10 mg/L, and stored in a 4°C refrigerator.

2.2.2 HS-SPME

Appropriate amount of sample was transferred to a 20ml glass test tube, which was diluted with saturated sodium chloride aqueous solution to 10% ethanol concentration (v/v) [

23]. Then, 5 mL of each diluted sample was accurately transferred to the headspace vial; 10 μL of the ISTD solution was added to each sample, and the preprocessed samples were incubated at 50 °C for 10 min. The samples were extracted using a headspace solid-phase microextracter coated with a DVB/CAR/PDMS fiber head (50/30 μm × 1 cm, Supelco, Bellefonte, USA) and kept at 60 °C for 30 min in an incubator. The extracted samples were desorbed in a GC injection port at 250 °C for 5 min and analyzed using GC×GC–TOFMS according to the set parameters; The samples above were subjected to three parallel tests to ensure the authenticity of the experimental results.

2.2.3 GC×GC–TOFMS Method

GC×GC conditions: 2D gas chromatography–high-resolution time-of-flight mass spectrometer (Pegasus GC-HRT+4D; LECO, USA). 1D column: TR

FFAP (30 m × 0.25 mm, 0.25 μm; Thermo Fisher Scientific). 2D column: Rxi-17sil M (2 m × 0.25 mm, 0.25 μm; Restek, USA). The initial temperature of the injection port was maintained 40℃ for 2 min, then increased from 40℃ to 250 °C at 5 °C/min, and maintained 250 °C for 7 min. Taking the high-purity helium (99.99%) as the carrier gas, the flowrate was 1.0 mL/min. The method of injection is non split. The modulation period was 4.0 s, and the thermal pulse period was 1.2 s in the complete 2D analysis. The temperature of the column was always 5 °C higher than that of the 1D column.

TOFMS conditions: electron bombardment source, 70 eV; ion source temperature, 250 °C; transmission line temperature, 240 ℃; detector voltage, 1984 V. The mass spectrometry scanning range was m/z 35–550, and the collection rate was 200 spectra/s.

2.3. Descriptive Sensory Analysis

Using Analytical Methods for Baijiu (GB/T 10345-2007) as a reference, a sensory panel composed of 15 professional assessors was established, including five national judges, ten provincial judges, their age ranges from 24 to 45 years old. These assessors all have keen sense of smell, they are members of the Baijiu evaluation committee of Shaanxi Xifeng Liquor Co., Ltd. and have rich experience in sensory evaluation.

The samples were described based on the flavor wheel description of Feng-flavored baijiu [

24]. The assessors were required to record the aroma and taste intensity , then rate the order from 0 (not perceivable) to 5 (strong) (e.g., 0, 0.5, 1.0...5.0). The samples were evaluated in multiple rounds, with 5 cups in each round and a pouring volume of 15–20 mL per cup. The evaluation time for each round was within 30 min, with an interval of 15 min between rounds. All samples were evaluated three times, and the obtained sensory values were averaged and plotted on a radar map. All panelists evaluated the aroma profiles of Feng-flavored baijiu.

2.4. Statistical Analysis

2.4.1. Data Processing

Data were collected using the Pegasus 4D workstation (LECO). The data analysis and processing were carried out by the instrument's built-in ChromaTOF software, automatically identifying peaks with a signal-to-noise ratio over 50 and comparing them with the NIST14 and Wiley 9 mass-spectrometry libraries to generate a peak table automatically. Compounds with halogen and silicon elements were removed, and chromatographic peaks with forward and reverse similarity greater than 700 were screened using mass spectrometry. The retention index (RI) of each volatile compound was calculated by C7–C30 n-alkanes and compared with the RI reference values in the NIST online database (

https://webbook. nist. gov/). Compounds with RI differences of 50 or less were selected. Finally, compounds with an occurrence rate greater than 50% were selected as reliable results [

25]. The content of each flavor compound was calculated by the internal standard method. The calculation method is as shown in formula (1):

2.4.2. Chemometric Analysis

Data on the Feng flavor of Baijiu collected by GC×GC–TOFMS were mined and analyzed using chemometrics. Irrelevant and redundant variables were filtered by preprocessing, thereby improving the effectiveness and accuracy of the data. Excessive missing values may pose difficulties for subsequent analyses. Variables with missing values exceeding 20% in all samples were filtered according to the 80% rule. The variables were semi-quantitatively analyzed based on internal standards; therefore, the systematic differences generated during the extraction and detection processes were reduced. To simplify the univariate and multivariate analyses, a small portion of missing values were interpolated by the K-nearest neighbor algorithm based on machine learning. The imputation value is half of the minimum peak area of the same sustance in all samples.

Variables with no statistical significance were removed by univariate analysis, and possible important compounds were preliminarily screened [

18]. Single-factor analysis of variance (ANOVA) was made by IBM SPSS. P-values were corrected by error detection rate to reduce false-positive results, and the variables were preliminarily screened based on P < 0.05 and pearson correlation coefficient |r | > 0.6. Data selected by one-way ANOVA was used to multivariate statistical analysis after scaling by unitvariance.

PCA, PLS-DA and PLSR were performed using SIMCA-P 14.1. Cluster heatmaps and radar maps were constructed using the Biodep online analysis platform (

https://www.biodeep.cn/).

3. Results

3.1. Sensory Analysis Results

The flavor of Feng-flavored baijiu of different ages was evaluated based on the sensory evaluation method and sensory evaluation radar map shown in

Figure 1.

The sensory attribute of Feng-flavored baijiu of different ages was significantly different. There was little difference between the Baijiu of fresh and stored for one year. After three years of storage, the sensory properties were changed significantly. The aroma difference of the samples stored for 10–30 years was greater than those stored for 0–8 years. With increasing age, the fresh green, newly produced and bran flavors were gradually weakened, whereas the honey, floral, aged and Mare Nectaris aromas gradually increased. The grain, fruit, alcohols and nutty aroma initially increased and then slightly weakened. Feng-flavored baijiu stored for 20 years presented the highest overall score for sensory.

The sensory flavor difference of Feng-flavored baijiu of different ages mainly depends on the volatile flavor compounds, which were detected and analyzed comprehensively in this study. In addition, the aroma and taste of each sample did not changed synchronously, as observed in the sensor analysis. The longer the storage year, the higher the overall aroma score; however, the taste score initially increased and then slightly decreased, and further in-depth research is needed.

3.2. Identification of Volatile Compounds

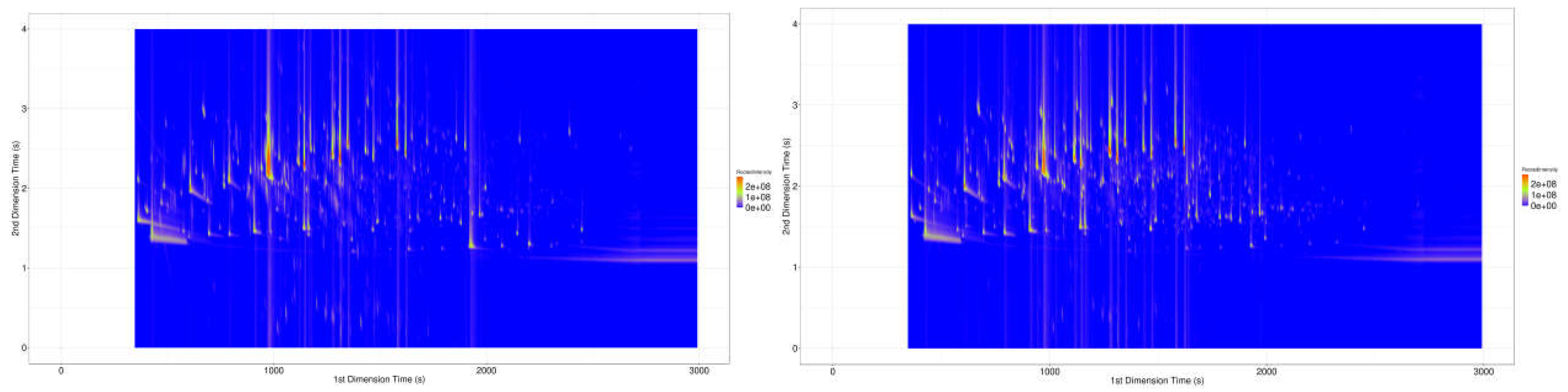

The samples of Feng-flavored baijiu were detected by HS-SPME–GC×GC–TOFMS.

90 chromatogram were extracted finally, two of the representative 2D chromatogram are shown in

Figure 2.

The amount of volatile compounds in Feng-flavored baijiu of different ages was significantly different, and the samples with longer ages had more abundant volatile components than those with shorter ages.

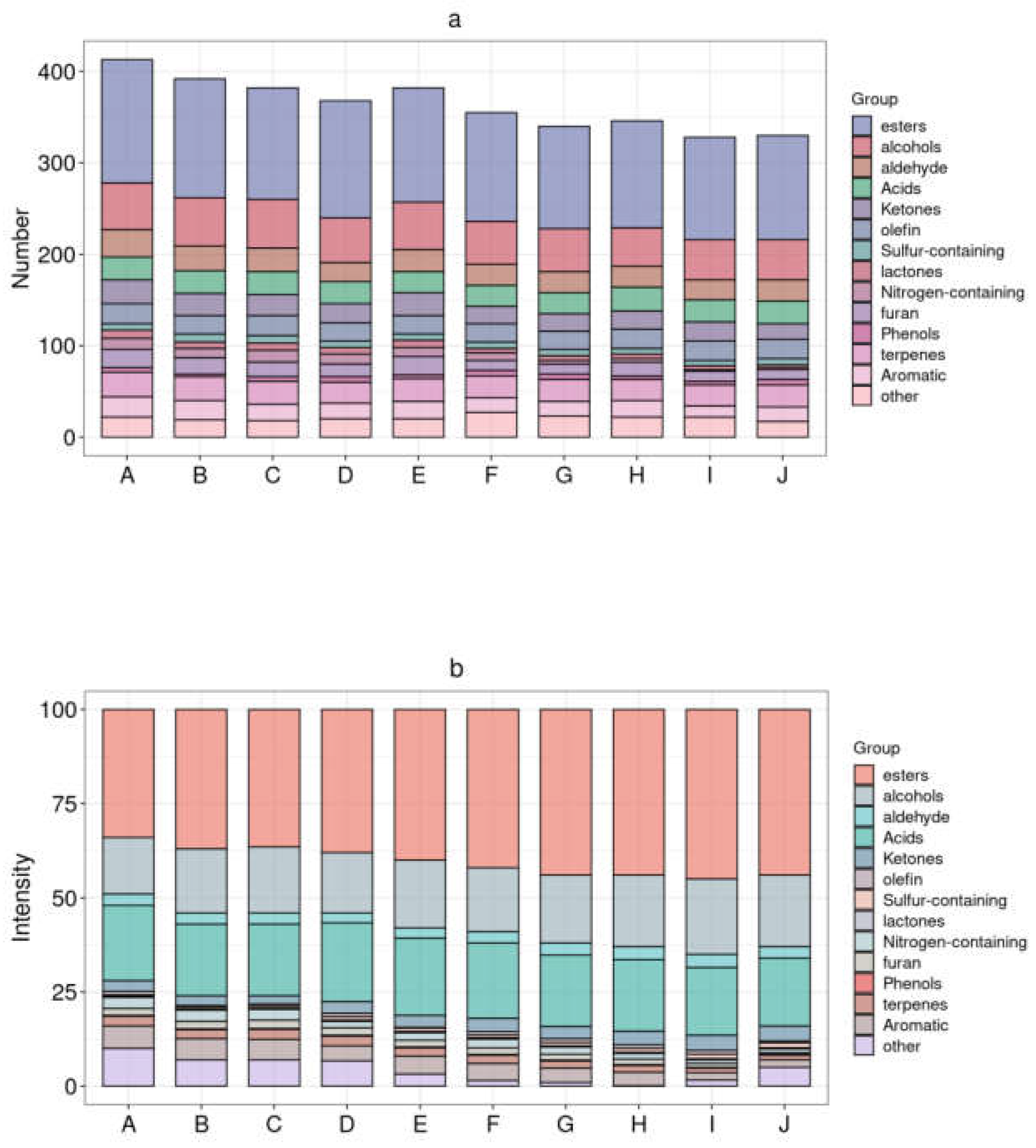

To explore the impact of the quantity and type of volatile compounds on Baijiu, 30 samples of Feng-flavored baijiu of 10 different ages were selected for analysis.

The type and quantity of volatile flavor compounds dected by GC×GC–TOFMS was much more than those dected by GC–MS. In total, 496 subtances were identified, containing 154 esters, 33 acids, 67 alcohols, 32 aldehydes, 27 ketones, 41 olefins, 13 sulfur-containing compounds, 9 lactones, 16 nitrogen-containing compounds, 20 furans, 7 phenols, 35 terpenes, 17 aromatics, and 25 other compounds. The quantity of volatile compounds increased from 330 to 413 with increasing storage time, the quantity of volatile compounds of 30 ages was ≈1.25 times that present in fresh Baijiu, as shown in

Figure 3a. The quantity of esters were highest in the samples of different ages, followed by alcohols, acids, and aldehydes. In addition, the number of compounds in Baijiu was proven to be higher during storage in Mare Nectaris, which is similar to the conclusions of other studies. In addition, with an increase in storage age, the relative contents of esters, alcohols, ketones, and sulfur-containing compounds decreased, while those of acids, olefins, nitrogen-containing compounds, furans, terpenes, aromatics, aldehydes, and other compounds tended to increase to varying degrees; the lactones and phenolic compounds did not exhibit a significant trend in proportion, as shown in

Figure 3b.

A variety of flavor compounds were detected by GC×GC–TOFMS, where 42 were identified for the first time in Feng-flavored baijiu, as shown in

Table 1.

These compounds identified for the first time mainly included medium-chain esters, phenyl ring esters, aldehydes, pyrazines, furans, terpenes, lactones, and other compounds, and their influence on the Feng-flavored baijiu needs to be further studied.

3.3. Changes in Volatile Compounds during Storage

Esters are the diverse substances of Baijiu, which endow it with rich fruit and flower fragrances and have prominent contribution to the overall aroma of Baijiu [

26]. With an increase in storage time, the total ester content significantly decreased. The content of short linear esters (C4–C12), such as ethyl acetate and hexyl hexanoate, decreased. The content of medium linear esters (C12–C15) increased first and then started to drop, while the content of long linear esters (C16–C20) such as myristic acid ethyl ester, palmitic acid ethyl ester, ethyl pentadecanoate, ethyl octadecanoate, and ethyl linoleate, initially increased and then decreased after 20 years. The contents of some branched esters, such as isoamyl nonanoate, isoamyl acetate, and trans-4-decanoate ethyl ester, did not exhibit an obvious pattern but showed an upward trend; ethyl 3-methylbutyrate, ethyl 4-methylvalerate showed a decreasing trend. Changes in the content and type of ester are one of the main reasons for the sensory changes in Feng-flavored baijiu.

Acids are important substances that influence the flavor of Baijiu and can blend the taste and stabilize the aroma. If the acid content of Baijiu is too low, its taste is weakened. Sweat and other unpleasant odors are present if its acid content is too high [

27,

28]. The content of most acids showed an upward trend [

29] as a result of the hydrolysis of esters during storage. Owing to the limitations of the GC×GC–TOFMS methods, most acids were not detected in this study. The presence of heptanoic anhydride and octanoic anhydride showed a linearly increasing trend, which may be related to the hydrolysis of esters during the aging of Baijiu .

Alcohols are the primary source of mellow sweetness and aroma, as well as the precursor of esters in Baijiu [

30]; their boiling point is low, and they are easy to volatilize, which enriches the flavor of Baijiu [

31]. Research has shown that higher alcohols (such as n-propanol, isobutanol, and sec-butanol with >3 carbon atoms) in appropriate concentrations make Baijiu soft and mellow [

26]. However, if their concentration is too high, they can impart unpleasant odors to the Baijiu and reportedly even cause dizziness. The contents and proportions of various higher alcohols are tightly related to comfortable degree after drinking. The main higher alcohols in Feng-flavored baijiu are n-propanol, sec-butanol, isoamyl alcohol, n-butanol, and isobutanol, the content of which accounted for about 85% of the total alcohol. The contents of isoamyl alcohol (365.45~1087.47 mg/L) and isobutanol (131.78~187.38 mg/L) increased, while the contents of n-propanol (452.31~234.6mg/L), n-butanol (578.89~153.65mg/L), 2-nonanol, 2-pentanol, 2-heptanol, 1-octen-3-ol, etc. decreased during storage. Some researches have demonstrated that isopentyl alcohol is a key substance that lead to the almond flavor of Feng-flavored baijiu [

32], and the ratio of n-propanol to isopentyl alcohol is the main factor determining whether dizziness occurs after drinking. This study indicated that the ratio of n-propanol to isoamyl alcohol in Feng-flavored baijiu decreased from 1.24 to 0.22 during storage, which may be one of the main reasons for the comfort experienced after drinking.

Aldehydes and ketones are important aromatic components of Baijiu, enhancing the aroma and taste of Baijiu [

33]. The main aldehydes in Feng-flavored baijiu are acetaldehyde (125.31~54.13 mg/L) and acetal (89.23~210.23 mg/L). Changes in the contents of these two substances act in improving the aging and softness. With increaseing age, the contents of benzaldehyde, phenylacetaldehyde, cinnamaldehyde, and saffron volatiles increased. It is worth mentioning that multiple aldehyde compounds were identified in samples stored for a long time. The contents of 2-octenal, 2-heptanenal, and 2-nonenal, which possess green and vegetable aromas, showed a decreasing trend, while the content of dienal aldehydes substances in particular (E, E)-2, 4-nedenal, 2, 4-hexadienal, 2, 4-decadienal, and 2-methylpentane-2-enal, which impart oil and meat flavors, showed an increasing trend during storage. Ketones, with a lower threshold value and greater aroma contribution, are mainly formed in the fatty acid beta-oxidation process and endow Baijiu with floral, fruity, and creamy flavors [

34]. The contents of vanillin acetone, isophorone, β- damadone, and acetophenone increased fluctly. Terpene compounds are important aroma compounds and physiologically active substances in Baijiu, with antibacterial, antioxidant, and other physiological functions [

35,

36].A wide variety of terpenes exist in Feng-flavored baijiu. β- caryophyllene, (+)-longifolene, and (+)-cedarol have sweet and woody aromas, and their contents changed significantly. In addition, cedarol, linalool, etc. only exist in the samples that were stored for over 10 years. These compounds may be markers of Feng-flavored baijiu of different ages, and further research is needed.

Most lactone compounds present sweet, fruity, and other aromas, and the flavor of Baijiu becomes softer after the interaction of lactone with other volatile components [

37]. The main lactone compounds detected in Feng-flavored liquor are γ-nonalactone, γ-butyrolactone, and γ-decyl lactone. Except for γ-nonalactone, the lactones were not detected in fresh Baijiu and may form slowly in the later storage stage. Furan and pyrazine compounds mainly impart a comfortable burnt and roasted aroma to Baijiu, where pyrazine compounds are a class of functional substances beneficial to human health [

38].

In this study, most furan and pyrazine compounds were detected in the samples that were stored for more than 10 years. including 2, 3, 5-trimethylpyrazine benzofuran, and 2-acetylfuran ect., and their contents increased with increasing storage time.

The content of aromatic compounds in Baijiu is very small, which account for less than 0.2% in Baijiu [

39]; however, the threshold value is lower, and the retention time of the odor is longer, which has a significant impact on Baijiu and helps to improve its quality [

40]. In this study, the p-cresol content decreased with increasing storage time. This study showed that p-cresol was related to the taste of cellar mud; therefore, it is inferred that the presence of p-cresol is one of the reasons why fresh Baijiu has an unpleasant and muddy odor, which accord with the sensory evaluation. Most of the aromatic ester compounds in Baijiu provide fruity, flowery, rose, and honey flavors, among others. In addition to phenylethyl acetate, the contents of ethyl 3-phenylpropionate, ethyl phenylacetate, phenylethyl butyrate, phenylethyl isobutyrate, ethyl benzoate, and isobutyl benzoate increased significantly during storage and are closely related to floral, honey, and fruity aromas. It is firmly concluded that the honey and sweet aromas of Feng-flavored baijiu of different ages are closely related to changes in the types and contents of aromatic esters.

3.4. Difference Analysis of Volatile Compounds in Feng-Flavored Baijiu

Missing values were filtered and deleted from all samples, and 298 compounds were obtained for the univariate analysis. The results of the one-way ANOVA indicated that 223 compounds changed significantly during storage. Pearson correlation analysis indicated that there were a total of 39 unrelated or weakly correlated compounds (| r | = 0–0.4), 42 moderately correlated compounds (| r | = 0.4–0.6), 101 strongly correlated compounds (| r | = 0.6–0.8), and 41 highly correlated compounds (| r | = 0.8–1) [

41].

A total of 143 differential compounds were preliminarily screened, which simultaneously met the three conditions of missing values less than 20%, Pearson correlation coefficient | r | > 0.6, and P < 0.05, including 45 esters, 11 alcohols, 15 acids, 19 aldehydes, 9 ketones, 7 furans, 3 phenols, 3 lactones, 4 sulfur-containing compounds, 13 aromatics, 5 terpenes, 5 nitrogen-containing compounds, and 4 other compounds.

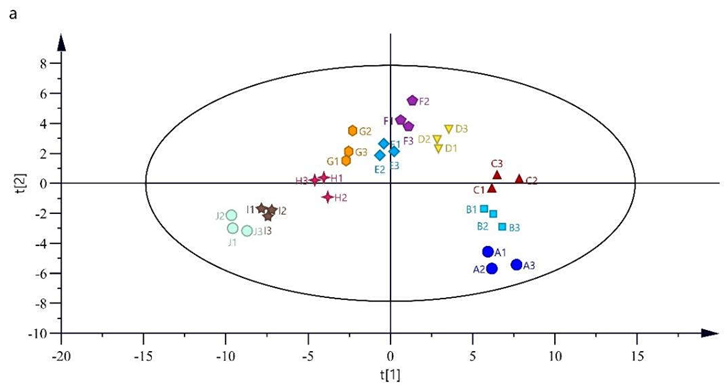

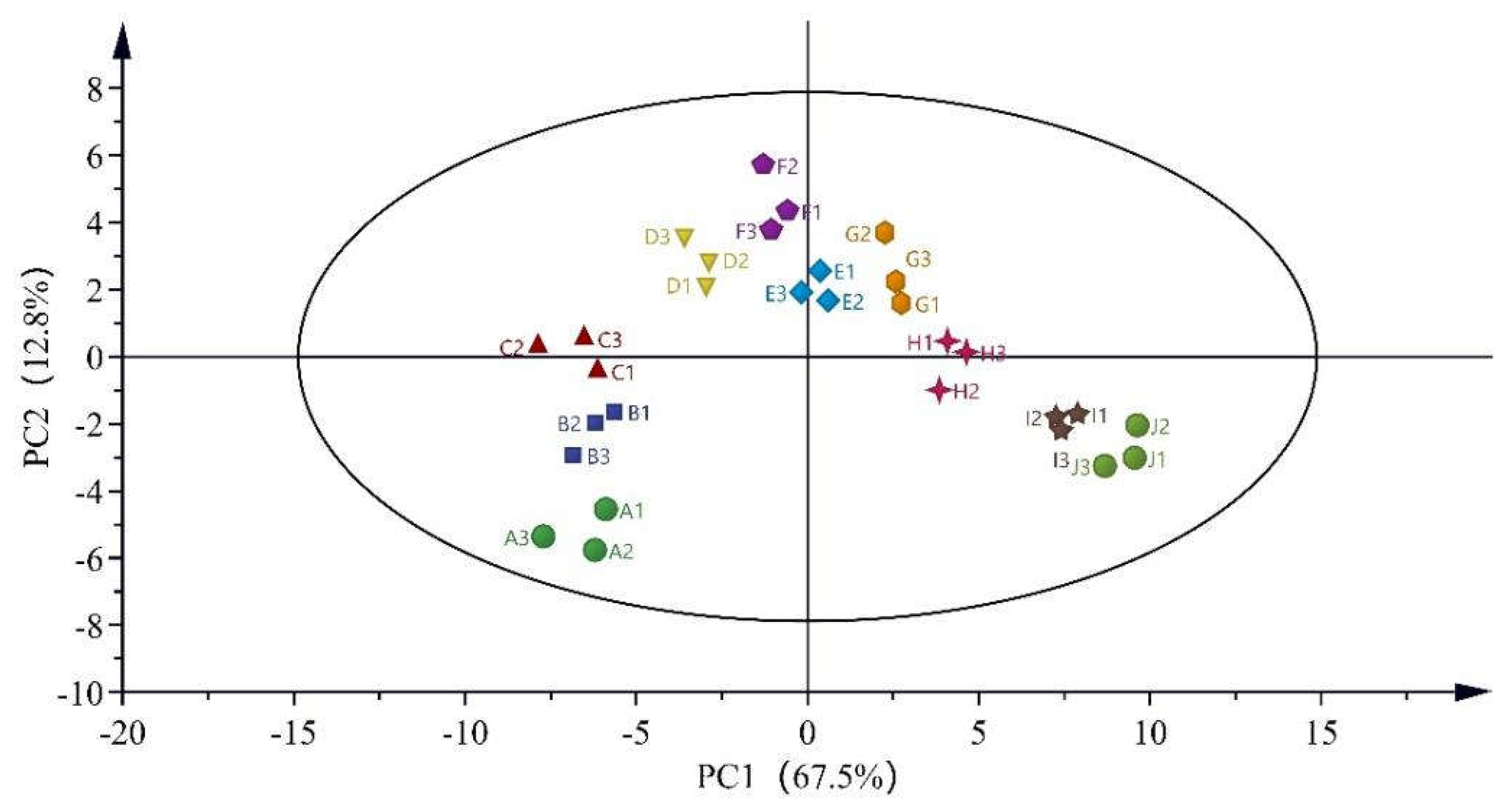

Generally, multivariate analysis in chemometrics is divided into unsupervised and supervised techniques. The former is commonly used for preliminary data exploration, including PCA and cluster analysis [

42]. Therefore, 143 important compounds selected by single-factor analysis were used for PCA to explore their differences, as shown in

Figure 4.

The PCA results showed that the cumulative contribution rates of PC1 and PC2 was 80.30%, which covers the basic information of the samples and can reflect the overall differences. The samples of different ages were separated without significant overlap, indicating that the samples of different ages could be well distinguished. The samples were divided into five groups at certain distances. The Ji and Ii are located in the fourth quadrant, and the distance is relatively close, while the Hi, Gi, and Fi are in the first quadrant. The Ei, Di, and Ci are clustered in the second quadrant, and the distances between Ei and Di are relatively close, indicating that their differences are small. The Ai and Bi, which were stored for more than 20 years, are located in the third quadrant. The farther the distance, the greater the aroma difference between each sample, which is consistent with the sensory evaluation results.

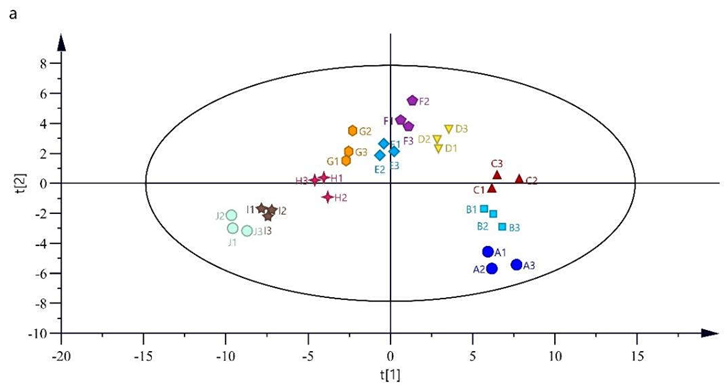

PLS-DA is a supervised modeling approach, it is usually used to screen variables that contribute significantly to sample classification by establishing a relationship model between omics data and sample categories [

25,

43]. To screen key compounds with significant differences in Feng-flavored baijiu of different ages, a PLS-DA model was established with 143 of the important compounds preliminarily screened, as shown in

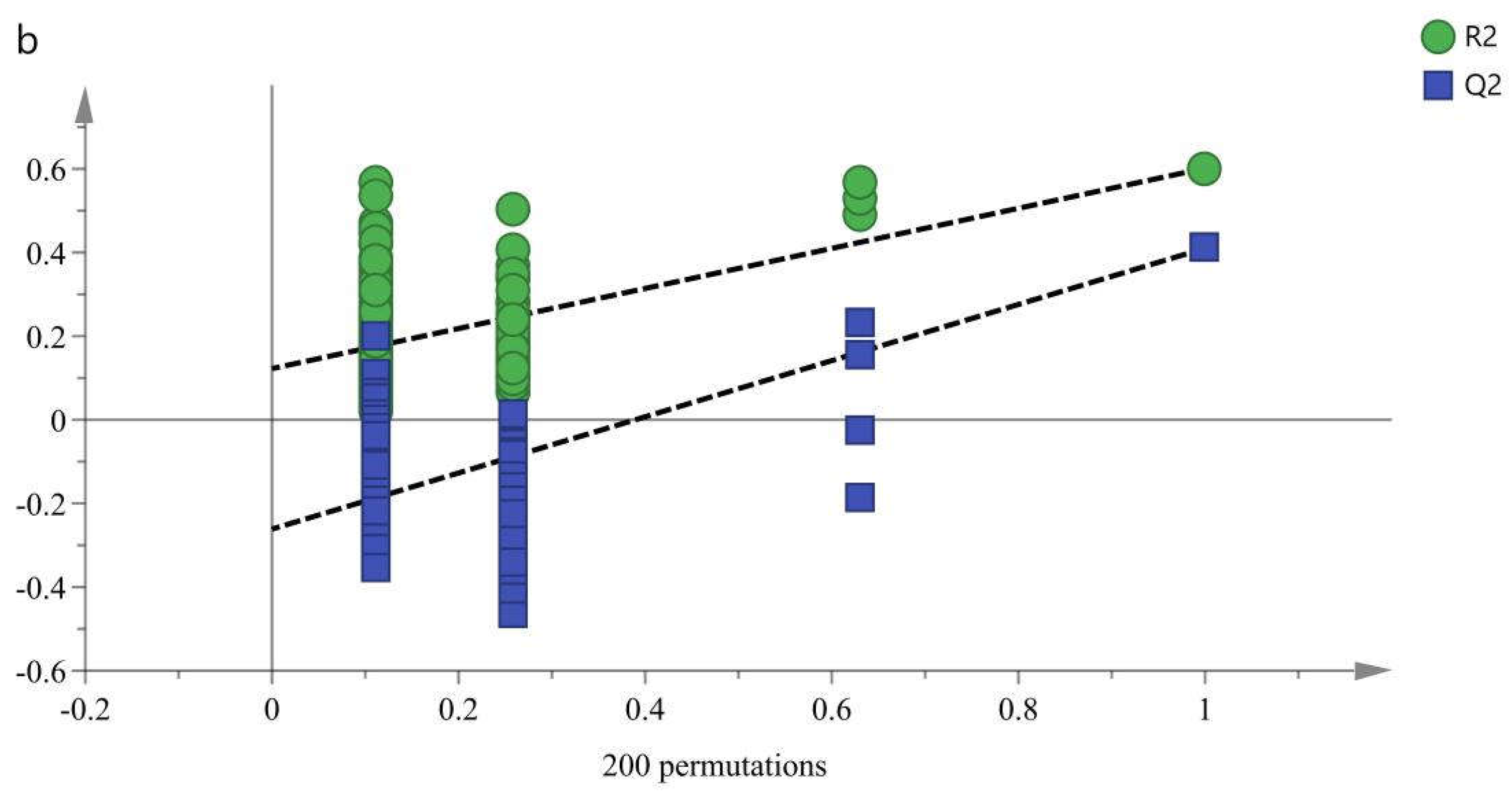

Figure 5.

Samples of different ages were separated on the score plot, indicating that the model of PLS-DA is appropriate. R2X = 0.911, R2Y = 0.934, and Q2 = 0.8570, indicating a good predictive ability (

Figure 5a).

Figure 5.

PLS-DA analysis of Feng-flavored baijiu of different ages. a) Score plot of PLS-DA and b) permutation test plot.

Figure 5.

PLS-DA analysis of Feng-flavored baijiu of different ages. a) Score plot of PLS-DA and b) permutation test plot.

To verify the reliability of the model, 200 permutation tests were performed to determine whether the model was overfitted. In the permutation test, R2Y = 0.122, Q2 = –0.261, and Q2 < 0.05, indicating that the model did not overfit (

Figure 5b).

3.5. Identification of Key Compounds Differential Feng-Flavored Baijiu of Different Ages

The contribution of each variable to different samples can be quantified by the variable importance factor (VIP) in PLS-DA and can be used to screen important characteristic compounds [

41]

. Generally, the VIP value is greater than 1, and the higher its value, the greater its ability to distinguish sample groups. Among the compounds, 65 have VIP values greater than 1; these values along with the |r| are shown in

Table 2.

To screen for the most representative compounds, the 65 potentially differential substances mentioned above were screened under the conditions of VIP > 1 and | r | > 0.7. Finally, 43 compounds were selected, containing eight esters ( ethyl acetate, butyl isovalerate, ethyl hexanoate, methyl heptanate, ethyl phenylacetate, ethyl 3-phenylpropanoic acid, ethyl isobutyrate, ethyl cinnamate, ethyl myristate, ethyl palmitate, ethyl linoleic acid, (2Z)-but-2-enoic acid ethyl ester, 3-furoate ethyl ester, (Z)-pentadecan-9-enoicacid ethylester, diethyl succinate, 9-hexadecenoicacid, ethylester and salicylic acid ethyl ester); one acid (γ- linolenic acid); two alcohols (isoamyl alcohol and phenylethanol); seven aldehydes (benzaldehyde, phenylacetaldehyde, furfural, 2-ethyl-2-hexenal, 2-butyl-2-octenal, trans-2-methyl-2-butenal, and 1, 1-diethoxyhexane); two ketones (geranylacetone and 3-decanone); three terpenes ((+)-longifolene α- fluorene, cedarol); one lactone (γ-nonalactone); two pyrazine compounds (2, 3, 5, 6-tetramethylpyrazine, 2, 3, 5-trimethylpyrazine); two sulfur-containing compounds (dimethyl disulfide and dimethyl trisulfide); one phenolic compound (p-cresol); and six other compounds (linaloyl formate, 2-acetylfuran, benzyl ether, α-terpene alcohol, indole, and 2-methylpyridine). Significant contributions to the sensory differentiation of the aged Feng-flavored baijiu may also be an age marker. Clustering heat maps of the 43 key differential compounds mentioned above are shown in

Figure 6.

In the clustering heatmap, samples of the same age were clustered together, showing that the 43 compounds effectively distinguished aged Baijiu .

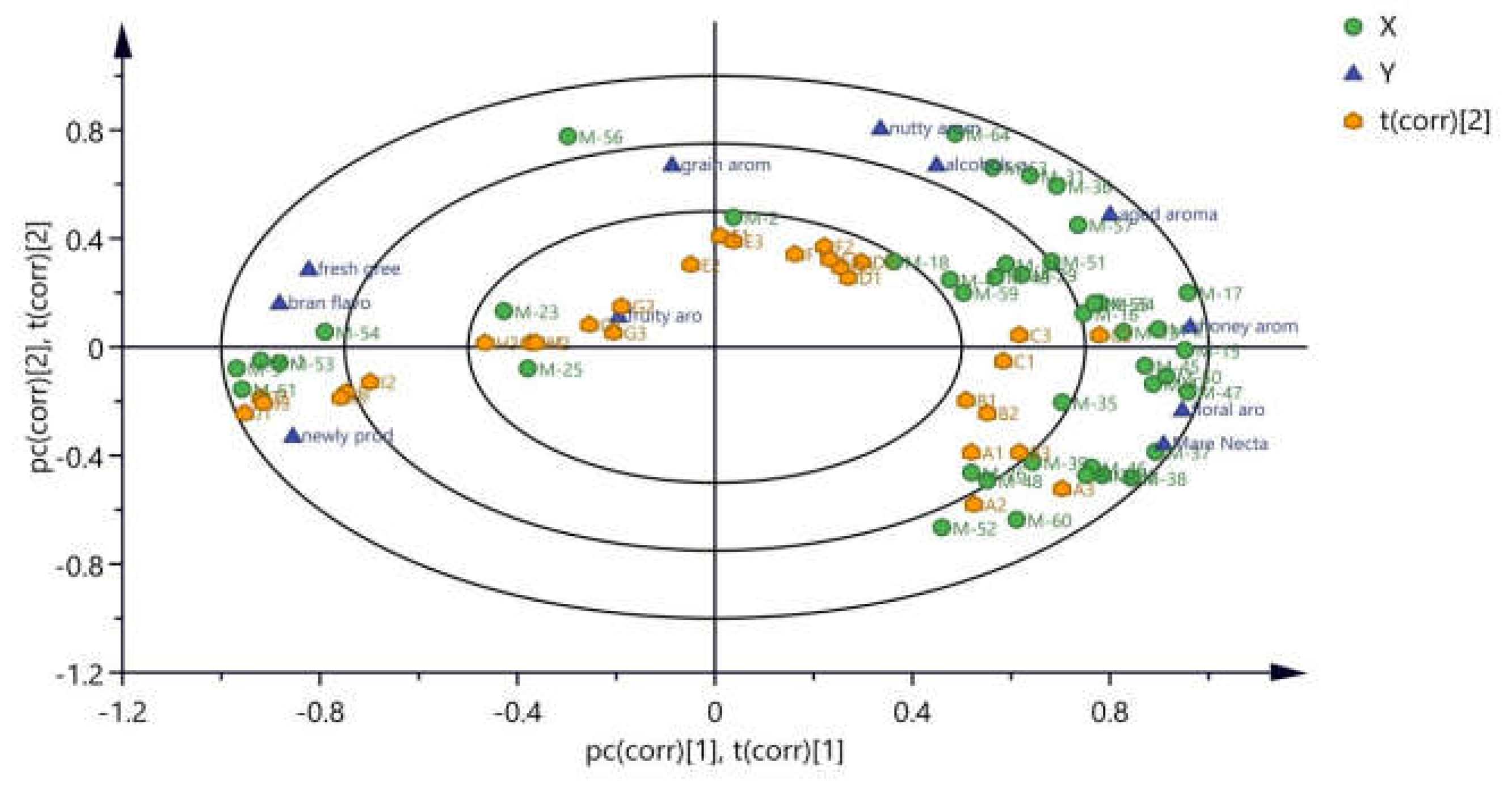

3.6. Correlation analysis of sensory evaluation and key differential compounds

A PLSR model was established based on the 43 key differential compounds in samples of different ages to further analyze the relationship of the sensory properties and key differential compounds. The X variable in the model represents the key differential compounds, and the Y variable represents flavor sensory variables, as shown in

Figure 7.

The three ellipses from the inside out represent the explained variance of 50%, 75%, and 100%, respectively. Most of the key differential compounds and sensory properties lie between 50% and 100% of the explanatory variance, indicating the model has good interpretability. There are significant differences in types of compounds and sensory properties among Feng-flavored baijiu of different ages. It can be seen that most of the compounds are highly related to the ageg Baijiu, and the fresh distilled Baijiu (Ji ), 1 year ( Ii), newly produced flavor, bran flavor, and fresh green flavor are well- and positively correlated with dimethyl disulfide, dimethyl trisulfide, furfural, methyl heptanate, etc. The samples (Hi and Gi) stored for 3 and 5 years positively correlated with fruit and grain aromas and positively correlated with butyl isovalerate, ethyl acetate, and 3-decanone. The samples (Fi, Ei, and Di) stored for 10, 15, and 18 years exhibited a good correlation with nutty, and aged aromas and were positively correlated with benzaldehyde, isoamyl alcohol, 2, 3, 5, 6-tetramethylpyrazine, 1, 1-diethoxyhexane, 2, 3, 5-trimethylpyrazine, benzyl ether, ethyl cinnamate. The samples (Ci, Bi, and Ai) stored for 20, 25, and 30 years correlated well with honey, Mare Nectaris and floral aromas. Ethyl phenylacetate, ethyl 3-phenylpropionate, phenylethyl isobutyrate, and indole correlate well with honey aroma. Vanillin, acetone, phenylacetaldehyde, ethyl myristate, and linalool formate were positively correlated with floral aroma. 2-butyl-2-octenal, ethyl linoleic acid, ethyl palmitate, (+)-longifolene, 2-ethyl-2-hexenal, cedarol, 9-hexadecenoic acid ethyl ester, γ- linoleic acid, (2Z)-buty-2-enoic acid ethyl ester, (Z)-pentadecan-9-enoic acid ethyl ester, etc. have a good correlation with the flavor of Mare Nectaris, which can be decomposed into woody, aged, oily, waxy, etc., and may be related to the materials comprising Mare Nectaris. (+)-Longifolene and cedarol have woody aromas, whereas 2-ethyl-2-hexenal, trans-2-methyl-2-butenal, 2-butyl-2-octenal, have oily aromas. In addition, the samples stored for 20, 25, and 30 years were positively correlated with bitter and sweaty compounds such as 2-methylpyridine and p-cresol. This also indicates that in addition to fruity and sweet aroma attributes, aged Baijiu has some unpleasant aromas

4. Results and Discussions

In this study, sensory descriptive analysis was devoted to analyze the sensory attributes and volatile substances of Feng-flavored baijiu were detected by HS-SPME-GC×GC-TOFMS. The research results indicated that there were notable differences in the aromas of the samples of different ages. Fresh distilled Baijiu and one-year-old both had the smell of bran and fresh greens. Samples aged 3–5 years had distinct fruity and grain aromas, while those aged 10–20 had mellow and nutty aromas, indicating their older age. The samples aged 20–30 years had significant honey, Mare Nectaris and floral aromas.

In total, 496 volatile substances were identified by HS-SPME-GC×GC–TOFMS and 42 important trace volatile compounds were discovered in Feng-flavored baijiu for the first time. It is preliminarily inferred that the increase in volatile compounds with lower content and larger aroma may be key factor in improving the quality of Baijiu . 143 compounds that are closely related to age were preliminarily screened using chemometric methods. The PCA analysis results showed that the Feng-flavored baijiu samples were well clustered according to the storage period. 65 differential compounds with VIP>1 were screened out based on PLS-DA. Combined with the VIP values and pearson correlation coefficients, 43 key differential compounds of Feng-flavored baijiu were ultimately selected out, including 18 esters, 1 acid, 2 alcohols, 7 aldehydes, 2 ketones, 3 terpenes, 1 lactone, 2 pyrazines, and 2 sulfur-containing compounds, 1 phenol, and 6 other compounds. The results also showed that esters were important substances to distinguish the aroma of aged Baijiu . The clustering heatmap analysis further confirmed the effectiveness of the 43 key substances in differential the aged Baijiu samples. A correlation evaluation model between key differential compounds and sensory properties of aged Baijiu was established using PLSR, it indicated that most of the key differential compounds were correlated with the flavor characteristic of the longer storage time samples.

Based on these results, it is preliminarily inferred that the Mare Nectaris flavor is related to terpenes, aldehydes, and long-chain esters, long chain ethyl ester, aldehydes may be important marker for distinguishing Feng-flavored baijiu of different ages. synergistic or additive effects occur in compounds with similar structures or odors that may increase or decrease certain odor intensities, such as ethyl compounds of benzene ring type. However, the influence mechanism of the proportion and composition of various compounds on the quality of Baijiu needs to be further studied

This study enriches the theoretical system of flavor chemistry and provides a reference for flavor- and sensory-oriented research on Feng-flavored baijiu, which is very important to study the quality of Feng-flavored baijiu.

Supplementary Materials

Figure 1. Production of Mare Nectaris. Figure 2. Aging of Feng-flavored baijiu in the Mare Nectaris. Figure 3. Sensory evaluation of the samples. Figure 4. Discussion in sensory evaluation.

Author Contributions

Jinmei Ren: Conceptualization, Data curation, Writing original draft, Wei Jia: Writing – review & editing, Supervision. Zhijian LI: review, Supervision.

Funding

This research was funded by the Natural Science Foundation of China (No. 31801643) and innovation capability support program project of Shaanxi province (No. 2021KJXX-37).

Institutional Review Board Statement

The sensory evaluation of this experiment is supported by the members of Baijiu evaluation committee of Shaanxi Xifeng Liquor Co., Ltd (Baijiu body design center) who are all personnel selected through professional channels and suitable for sensory evaluation.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors thank Shaanxi University of Science and Technology and Shanxi Xifeng Liquor Co., Ltd. for their support. Detection was performed by Panomix Biomedical Tech Co., Ltd (Suzhou, China).

Conflicts of Interest

Author Author Jin mei Ren was employed by Shanxi Xifeng Liquor Co., Ltd. She participated in conceptualization, design of the experiment , data curation, writing original draft in the study. The role of the company was to provide samples and sensory evaluation tests.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The authors declare that this study received funding from Shanxi Xifeng Liquor Co., Ltd. The funder had the following involvement with the study: providing samples and sensory evaluation tests.

References

- Liu, L. L.; Yang, H.; Jing, X.; Xu, C.; Zhang, Y. F.; Yan, Z. K.; Qi, Y. H. Influence of different storage containers on the aroma composition of fengxiang-type Baijiu analyzed by gas chromatography-ion mobility spectroscopy and electronic nose. Food Science 2022, 43, 257–263. [Google Scholar] [CrossRef]

- Qin, D.; He, Fei. ; Feng, S. B.; Li, H. H.; Zhang, N. Characterization of the volatile aroma compounds of Qingke Baijiu stored for different periods. Food Science 2021, 42, 99–107. [Google Scholar] [CrossRef]

- Cao, J.; Liu, K.; Zhang, A.; Yan, W.; Zheng, Y.; Zeng, Q. H- 1-NMR and viscosity studies of hydrogen bonding of Chinese rice wine. Cyta-Journal of Food 2018, 16, 776–785. [Google Scholar] [CrossRef]

- Wang, N.; Chen, S.; Zhou, Z. Characterization of volatile organic compounds as potential aging markers in Chinese rice wine using multivariable statistics. Journal of the Science of Food and Agriculture 2019, 99, 6444–6454. [Google Scholar] [CrossRef]

- Yang, H.; Liu, L. L; Jing, X.; Zhang, Y. F.; Xu, C.; Yan, Z. K.; Qi, Y. H. Analysis the difference of Feng-flavour vintage base liquor based on the derivatization-GC-MS metabonomics method. Modern Food Science and Technology 2021, 37, 295–303. [Google Scholar] [CrossRef]

- LIU Lili, YANG Hui, JING Xiong, et al. Analysis of Volatile Compounds in Aged Fengxiang Crude Baijiu Based on GC-MS and GC-IMS [J]. Science and Technology of Food Industry 2022, 43, 318–327. [CrossRef]

- Yu, H. Y.; Zheng, D. W.; Xie, T.; Xie, J. R.; Tian, H. X.; Ai, L. Z.; Chen, C. Comprehensive two-dimensional gas chromatography mass spectrometry-based untargeted metabolomics to clarify the dynamic variations in the volatile composition of Huangjiu of different ages. Food Chemistry 2022, 87:1563–1574. [CrossRef]

- Li, X.; Du, J.; Liu, Y. Q. X.; Wu, G.; Yang, L. H. M.; Qiu, K. B. Determinatin of ethyl earbamate in Baijiu by SPME combined with GC x GC-TOFMS. Food and Fermentation Industries 2023, 49, 270–274. [Google Scholar] [CrossRef]

- Gou, M.; Bi, J. F.; Chen, Q. Q.; Wu, X. Y.; Fauconnier, M. L.; Qiao, Y. N. Advances and Perspectives in Fruits and Vegetables Flavor Based on Molecular Sensory Science Food Reviews. International 2023, 39, 3066–3079. [Google Scholar] [CrossRef]

- He, X.; Jelenh, H. Comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry (GC×GC-TOFMS) in conventional and reversed column configurations for the investigation of Baijiu aroma types and regional origins. J Chromatogr A 2021, 16, 461–774. [Google Scholar] [CrossRef]

- Dymerski, T. Two-Dimensional Gas Chromatography Coupled with Mass Spectrometry in Food Analysis. Crit Rev Anal Chem 2018, 48, 252–278. [Google Scholar] [CrossRef]

- Yu, M. G.; Yang, P.; Song, H. L.; Guan, X. Research progress in comprehensive two-dimensional gas chromatography-mass spectrometry and combination with olfactometry systems in the flavor analysis field. J Food Compos Anal 2022, 114, 104790. [Google Scholar] [CrossRef]

- Yang, L.; He, J. J.; Luo, C. X.; Zhang, C. L. Analysis of volatile flavor compounds from defective product of sauce-flavor Baijiu by GC×GC-TOF-MS. China Brewing 2019, 38, 67–72. [Google Scholar] [CrossRef]

- Guan, Y. Q.; Xue, X. J.; Chen, X. J.; Du, X. F.; Yang, J. Y, ; Li, Zeng, ; Gao, Z. Y.; Cheng, W. Analysis of Volatile aroma components in Chaqu Qingxiang Baijiu by HS-SPME combined with GC×GC-TOF-MS. Liquor-making Science & Technology. 2022, 335, 117–119. [CrossRef]

- Yao, F.; Yi, B.; Shen, C.H; Tao, F.; Liu Y, M.; Lin, Z. X.; Xu, P. Chemical analysis of the Chinese liquor Luzhoulaojiao by comprehensive two-dimensional gas chromatography /time-of-flight mass spectrometry. Scientific Reports 2015, 5, 9553–9553. [Google Scholar] [CrossRef] [PubMed]

- Ren, J. M.; Chen, J. P.; Jia, W.; Li, Z. J.; Feng, Y. F.; Li, Y. L. Analysis of volatile components in Feng-flavor Baijiu by HS-SPME combined with GC×GC-TOF-MS. China Brewing 2023, 42, 231–234. [Google Scholar] [CrossRef]

- Prebihalo, S. E.; Berrier, K. L.; Freye, C. E.; Bahaghighat, H. D.; Moore, N. R.; Pinkerton, D. K.; Synovec, R. E. Multidimensional gas chromatography: Advances in instrumentation, chemometrics, and applications. Anal Chem 2018, 90, 505–532. [Google Scholar] [CrossRef] [PubMed]

- Pollo, B. J.; Teixeira, C.A.; Belinato, J.R.; Furlan, M.F.; Cunha, I.Cd.M.; Vaz, C.R.; Volpato, G.V.; Augusto, F. Chemometrics, comprehensive two-dimensional gas chromatography and "omics" sciences: basic tools and recent applications. TR Trends Anal Chem 2021, 134, 116111. [Google Scholar] [CrossRef]

- Stefanuto, P. H.; Smolinska, A.; Focant, J. F. Advanced Chemometric and Data Handling Tools for GC×GC-TOFMS.the application of chemometrics and related advanced data handling for chemical separation. Trends in analytical chemistry 2021, 139, 116251. [Google Scholar] [CrossRef]

- Wang, L.; Zhong, K.; Luo, A.; Chen, J.; Shen, Y.; Wang, X.; He, Q.; Gao, H. Dynamic changes in volatile compounds and bacterial diversity during the fourth to seventh rounds of Chinese soy sauce aroma liquor. Food Sci Nutr 2021, 9, 3500–3511. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, S.; Nie, Y.; Xu, Y. Characterization of volatile sulfur compounds in soy sauce aroma-type Baijiu and changes during fermentation using GC×GC-TOFMS, organoleptic impact evaluation, and multivariate data analysis. Food Res Int 2020, 131, 109043. [Google Scholar] [CrossRef]

- Jia, W.; Fan, Z.B.; Du, A.; Shi, L.; Ren, J. M. Characterization of key odorants causing honey aroma in Feng-flavored baijiu during the 17-year aging process by multivariate analysis combined with foodomics. Food Chemistry 2022, 374, 2–9. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y. X.; Cui, J. X.; Jiang, Z. L.; Zhao, X. H. GC × GC-ToF-MS combined with multivariate statistical methods to explore the effects of L. paracasei fermentation on bread flavor characteristics. Food Chemistry 2024, 435, 137643. [Google Scholar] [CrossRef] [PubMed]

- Ren, J. M.; Chen, J. P.; Jia, W.; Li Z., J.; Li, Y. L.; Huang, T. Construction of flavor wheel of Feng-flavor Baijiu and study on sensory characteristics. China Brewing 2023, 42, 80–85. [Google Scholar] [CrossRef]

- Liu, S. P.; Zhou, Z. L.; Yu, H. B.; Mao, L. G.; Pan, X. X.; Ji, Z. W.; Mao, J. Characterization of volatile aging markers in traditional semi-dry Huangjiu by comprehensive two-dimensional gas chromatography-time of flight mass spectrometry and chemometrics. Food Science 2023, 44, 249–258. [Google Scholar] [CrossRef]

- Guo, X. W.; Fan, E. D.; Ma, B. T.; Li, Z. X.; Zhang, Z. M.; Chen, Y. F.; Xiao, D, G. Recent progress in micro components of Chinese Baijiu. Food Science 2020, 41, 267–276. [Google Scholar] [CrossRef]

- Gao, W. J.; Fan, W. L.; Xu, Y. Characterization of the key odorants in light aroma-type Chinese liquor by gas chromatography.Olfactometry, quantitative measurements, and aroma recombination and omission studies. Journal of Agricultural and Food Chemistry 2014, 62, 5796–5804. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Tian, Z. Q.; Ma, Y. Q.; Shao, F. L.; Huang, J. L.; Wu, H.; Tian, L. Origin identification of the sauce-flavored Chinese Baijiu by organic acids, trace elements, and stable carbon isotope ratio [J]. Journal of Food Quality 2019, 2019, 7525201. [Google Scholar] [CrossRef]

- Qin, D.; Duan, J. W.; He, F.; Li, H. H.; Sun, B, G. A review of changes of flavor compounds during Baijiu aging and recent progress in artificial aging techniques. Food Science 2021, 42, 260–267. [Google Scholar] [CrossRef]

- Jia, Z. Y. Chinese liquor blending technology, 1rd ed; Chemical Industry Press: Beijing, China, 2017; pp. 125–133. [Google Scholar]

- Zhu, J. Y.; Xie, C.Y.; Li, Y. Y. Structure Analysis and Design Principles of Liquor Body. Liquor-making Science & Technology 2016, 269, 83–84. [Google Scholar] [CrossRef]

- Shen. Y, F. Chinese liquor production technology, 1rd ed; China Light Industry Press: Beijing, China, 1998; pp. 234–256. [Google Scholar]

- Zhang, M.; Yang, Y. Z.; Li, Q.; Wang, Y.; Ren, G. J. Metabolic pathway of main alcohols and aldehydes in Baijiu and its relationship with health drinking. Liquor-making Science & Technology 2017, 1, 124–128. [Google Scholar] [CrossRef]

- Juliana, M.; Aderval, L.; Diego, Batista.; Tatiana, P.; Jeremias, M.; Bruna, K.; Marcus, F.; Vinicius, M.; Hugo, S. Brazilian cheese: A survey covering physicochemical characteristics, mineral content, fatty acid profile, and volatile compounds. Food Research International 2018, 108, 18–26. [CrossRef] [PubMed]

- Scandiffio, R.; Geddo, F.; Cottone, E.; Querio, G.; Antoniotti, S.; Gallo, M. P.; E. Maffei, M.; Bovolin, P. Protective effects of (E)-β-caryophyllene (BCP) in chronic inflammation. Nutrients 2020, 12, 3273–3273. [CrossRef] [PubMed]

- KOYAMA, S.; PURK, A.; KAUR, M.; Koyama, S.; Purk, A.; Kaur, M.; Soini, H. A.; Novotny, M. V.; Davis, K.; Kao, E.; Cheng, C.; Matsunami, H.; Mescher, A. Beta-caryophyllene enhances wound healing via multiple routes. PLoS One 2019, 14, 6021–6104. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Z.; Yu, H. Y.; Tian, H. X. Flavor Contribution of Lactones in Cheese and Its Biosynthetic Regulation: a Review. Modern Food Science and Technology 2020, 36, 305–312. [Google Scholar] [CrossRef]

- Ding, H. L.; Shen, X. J.; S, C.; Xiong, Y. F.; Deng, B.; Ao, L.; Zeng, S. L, J.; Y, J.; Research progress on pyrazines in healthy functional components of Chinese Baijiu. China Brewing 2022, 41, 8–12. [CrossRef]

- Wang, X. L.; Fan, W. L.; Xu, Y. Comparison of aroma compounds in Chinese soy sauce and strong aroma type liquors by gas chromatography-olfactometry, chemical quantitative and odor activity value analysis. European Food Research and Technology 2014, 239, 813–825. [Google Scholar] [CrossRef]

- Fan, W. L.; Shen, H. Y.; Xu, Y. Quantification of volatile compounds in Chinese soy sauce aroma-type liquor by stir bar sorptive extraction and gas chromatography-mass spectrometry. Journal of the Science of Food and Agriculture 2011, 9, 1187–1198. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y, L.; Wang, C. Abnormal Frame Detection in Elevator IoT Data Collection Based on Pearson-LOF Algorithm. Control Engineering of China 2022, 29, 1457–1463. [CrossRef]

- Duan, J. W.; Cheng, W.; Lv, S. L.; Deng W., Y.; Hu, X. J.; Li, H. H.; Sun, J. Y.; Zheng, F. P.; Sun B, G. Characterization of key aroma compounds in soy sauce flavor Baijiu by molecular sensory science combined with aroma active compounds reverse verification method. Food Chemistry 2024, 443, 138487. [Google Scholar] [CrossRef]

- Zhang, X. J.; Qiu, S. Y.; Zeng, Q. J.; He, H.; Dai, Y. F.; Zhou, H. X. ; Differences in volatile compounds in maotai-flavored Baijiu produced by different processes. Food Science 2022, 43, 279–285. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).