1. Introduction

Additive manufacturing, also known as 3D printing, has developed rapidly over the past several years with dramatic increases in production and materials used. More recently, emerging Cloud-Based Additive Manufacturing (CBAM) services have made the variety of on-demand productions and access to diverse additive manufacturing resources much easier. Users only need to select and send their desired production models to 3D printing parts manufacturers online, and then the parts will be produced and sent to customers [

1]. Most of the research in this field [

2,

3,

4,

5,

6,

7] has only focused on scheduling in the production environment if it is necessary to deal with the entire process to optimize time. Planning such a store is necessary to save time. Still, it is challenging to solve the problem, especially for all processing such as receiving online orders and informing the manufacturing unit, parts production processing, and sending them to the customer.

For example, Aloui and Hadj-Hamou focused on production scheduling and the nesting problem with technological constraints. The objective was to minimize the total delay of the parts to be produced and to maximize the use rate of the additive manufacturing machines [

8]. In another research, Li et al. considered a real-time order acceptance and scheduling problem in a metal additive manufacturing production environment, where the manufacturer with multiple machines makes decisions on the acceptance and scheduling of dynamic arriving part orders simultaneously [

9]. Rohaninejad et al. investigated a scheduling problem in an additive manufacturing system with non-identical parallel selective laser melting machines [

10]. In addition, Lee and Kim proposed a two-stage meta-heuristic that can decompose the proposed problem into the part-packaging and the build-scheduling stages in additive manufacturing. This research, as well as other research conducted, shows that the scheduling done is mainly done in the production phase. While other steps such as ordering, and logistics also need scheduling and control [

11].

One of the scheduling techniques that can cover the scheduling of all phases of ordering, production, and logistics well is the Critical Chain Buffer Management (CC/BM) method. Goldratt applied the Theory of Constraints (TOC) and introduced the critical chain scheduling and buffer management methodology [

12]. This scheduling method is still used by many researchers due to its effective use [

13,

14,

15,

16,

17,

18]. This method is a competent approach to handling the activities duration risk as well as minimizing the makespan. The main idea of the approach is as follows: (1) Removing the hidden safety in activity durations to protect activities from late starting, which is called Student syndrome; (2) Preventing busy pretension by a staff named Parkinson’s law; (3) Preventing the late-finishing activities because of Murphy’s law or multitasking. These hidden safeties after removal from the former places are located following a special set of activities called a chain to preclude the activity’s delay [

19].

This research proposes a Heuristic Scheduling Algorithm (HSA) for use in CBAM with using buffer management to schedule and optimize the time in CBAM, in addition to the parts production process, it also includes the steps of receiving online orders and informing the manufacturing unit and sending them to the customer. The research question is, what effect will be using the HSA on the CBAM with an approach on CC/BM have on the steps duration of receiving online orders, parts production, and sending them to the customer?

The rest of this research is organized as follows. In the next section, an overview of the previous research related to the article is provided. The online CBAM scheduling problem is defined and modeled schematically and mathematically in the Research Methodology Section. The simulation experiment is analyzed in

Section 4.

Section 5 is related to the results and discussion. Finally,

Section 6 concludes the future research directions of the paper.

2. Research Impacts

In this research, ordering parts, producing them, and sending them to the customer in the shortest possible time will increase production and efficiency, which in turn will affect the economy. Regarding economic aspects, additive manufacturing is supposed to challenge established business models and market structures [

20].

Also, receiving orders from customers as soon as possible and without spending any time in, for example, traffic, commuting, waiting, etc. is one of the most important factors that will have a positive impact on society and people. With additive manufacturing, consumers are able not only to customize existing products but also to create and co-design their very own offerings [

21].

3. Literature Review

Much research has been done related to scheduling in AM. Oh et al. showed the status of nesting and scheduling studies applied to AM. This investigation showed how research trends have changed [

22]. While nesting-oriented problems for AM have consistently been studied, scheduling-oriented problems for AM have recently been highlighted. Alicastro et al. proposed a reinforcement learning iterated local search meta-heuristic, based on the implementation of a Q-learning variable neighborhood search, to provide heuristically good solutions at the cost of low computational expenses [

23]. Kim and Kim addressed a part-grouping and build-scheduling problem for an additive manufacturing process with non-identical parallel additive manufacturing machines [

24].

In recent years, the research conducted in this field has tried to focus mainly on CBAM. For example, Zipfel et al. investigated the customer order scheduling problem on unrelated parallel additive manufacturing machines. The discussed problem comprises the splitting of orders into jobs, the allocation of those jobs to builds, and finally the sequencing of builds on 3D printers [

25]. D’Aniello et al. discussed the design of a multi-agent system for managing and monitoring homogeneous manufacturing services in a cloud manufacturing system based on additive manufacturing technologies [

26]. Liu et al. proposed a non-cooperative game model of 3D printing services to reduce completion time, and cost and to improve service quality to improve the multi-task scheduling competitiveness of the distributed three-dimensional (3D) printing services with different types in cloud manufacturing [

27]. Wu et al. proposed a more realistic scenario of online scheduling rather than offline scheduling, in which tasks arrive randomly in CBAM [

28].

Zohrehvandi and Soltani discussed the state-of-the-art models and methods for buffer management and time optimization of projects and manufacturing industries. The results of this research showed that it is possible to implement buffer management in industries, factories, and projects and obtain satisfactory results [

29]. Bie et al. analyzed the effects of the dependence between activities on project duration performances and introduced a method for determining buffer sizes with a dependence assumption between activities [

30]. Vanhoucke used the resource-constrained scheduling approach in CC/BM to a more flexible baseline schedule to protect against unexpected events [

31]. Zhang et al. suggested the use of a dynamic buffer monitoring model based on the phase attributes of the project. The proposed method allocated a project buffer to each phase based on the duration rate and the network complexity of the phases [

32]. In another research, Zhang et al. developed a buffer sizing method based on a fuzzy resource-constrained project scheduling problem to obtain an appropriate proportionality between the activity duration and the buffer size [

33].

Peng and Lin presented a new solution for critical chain scheduling based on left shifts of activities in the theoretical framework of the critical chain method [

34]. The idea of adding a time margin to the minimal project completion time as a time buffer and using it in case of delayed occurrences was introduced by Zohrehvandi et al. [

35]. Other research conducted by Zohrehvandi et al. in the field of modeling and optimization in scheduling and project buffer management could refer to these cases [

36,

37,

38,

39].

According to the literature review done in this research, it was found that most of the research in this field has only focused on scheduling in the production environment while it is necessary to deal with the entire process to optimize time. Still, it is challenging to solve the problem, especially for all processing such as receiving online orders and informing the manufacturing unit, parts production processing, and sending them to the customer. This research deals with the entire process of optimizing time with the approach of the CCPM method and this is the novelty of this research.

4. Research Methodology

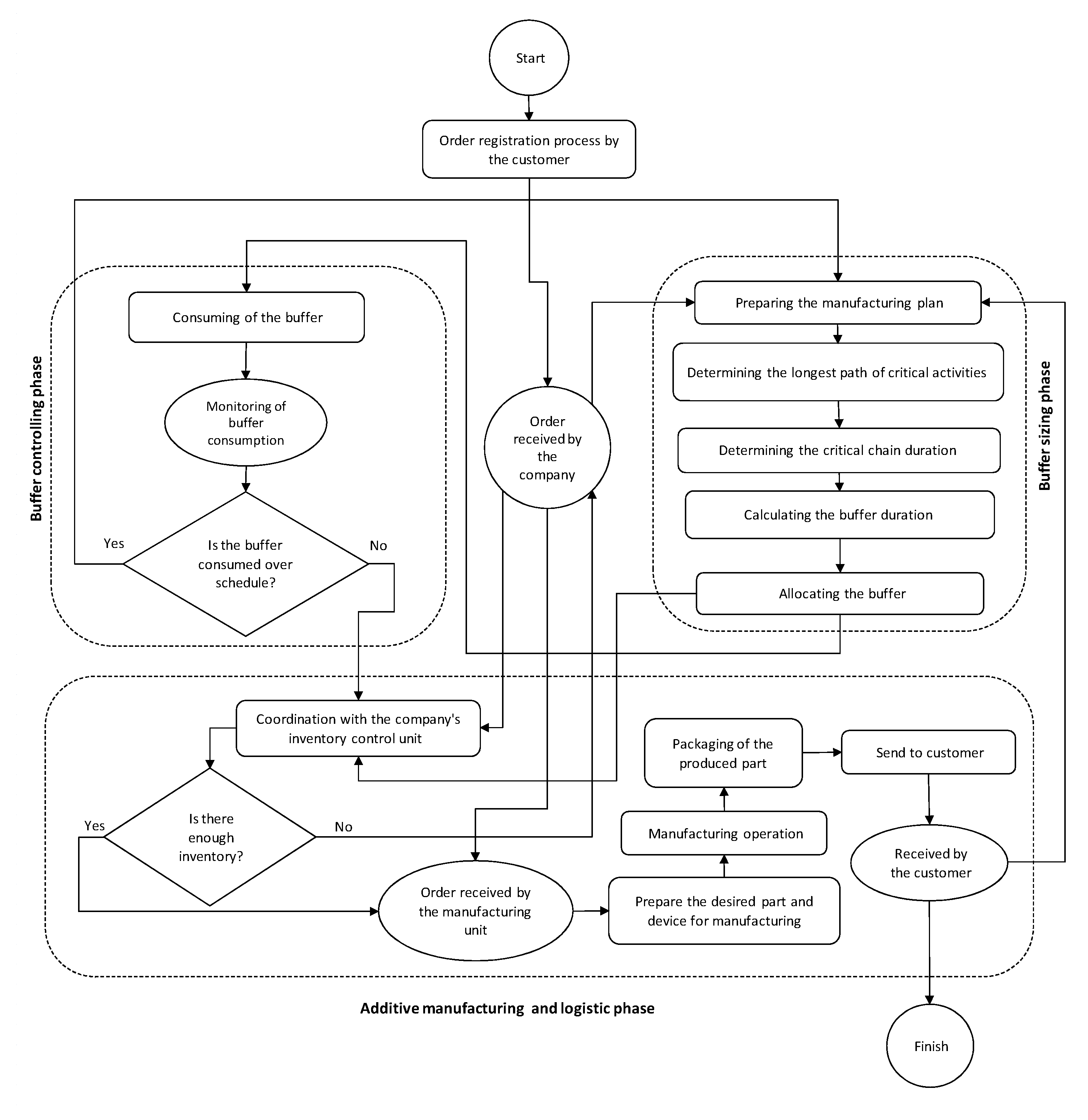

The proposed HAS in this research consists of three main phases. The buffer sizing, buffer control, and AM and logistic phases. According to this algorithm, after an order is registered by the customer online, the specifications of the ordered part will be sent to the company. Then, at the same time, they start the buffer size determination phase to determine the appropriate amount of buffer for the next activities, as well as the production and logistics phase. Necessary inquiries regarding registered orders are made from the company’s inventory control unit. Then the buffer consumption control phase also starts its activity. If the necessary materials and parts are available, the orders will be sent to the production unit, otherwise, a non-stock report will be sent. The production unit prepares the required materials and parts for the additive manufacturing operation and prepares the desired machines for the operation. Then the additive manufacturing operation is carried out according to the orders given by the customers.

During the additive manufacturing process, each part is assigned to exactly one job in one machine. Also, jobs on a machine must be processed in order. In addition, at least one part is assigned to one job in one machine and the start time of a task must be later than the arrival time of all parts assigned to the task. After the 3D printing operation, the manufactured parts are sent to the packaging unit. From packaging, logistics operations will be done to send parts to customers. During the performance of all these activities, buffer measurement operations, buffer allocation to activities, as well as buffer consumption control operations by activities continue continuously. All the steps explained in the proposed HAS in

Figure 1 are illustrated.

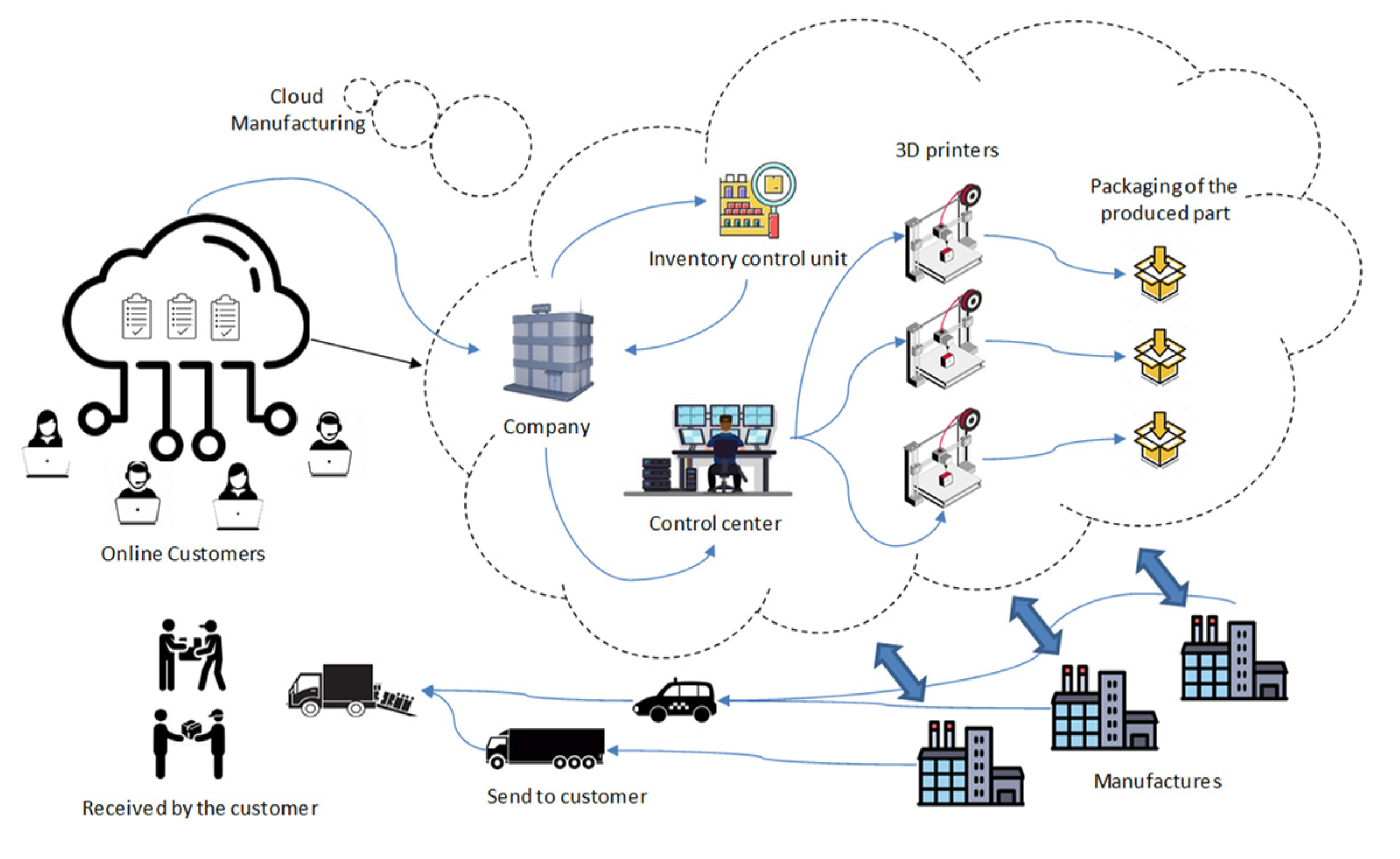

Figure 2 schematically shows the process of ordering parts by customers online in the desired cloud, receiving the order from the company, the steps of manufacturing the parts using the 3D printer method, and the steps of packaging and sending them to the customer.

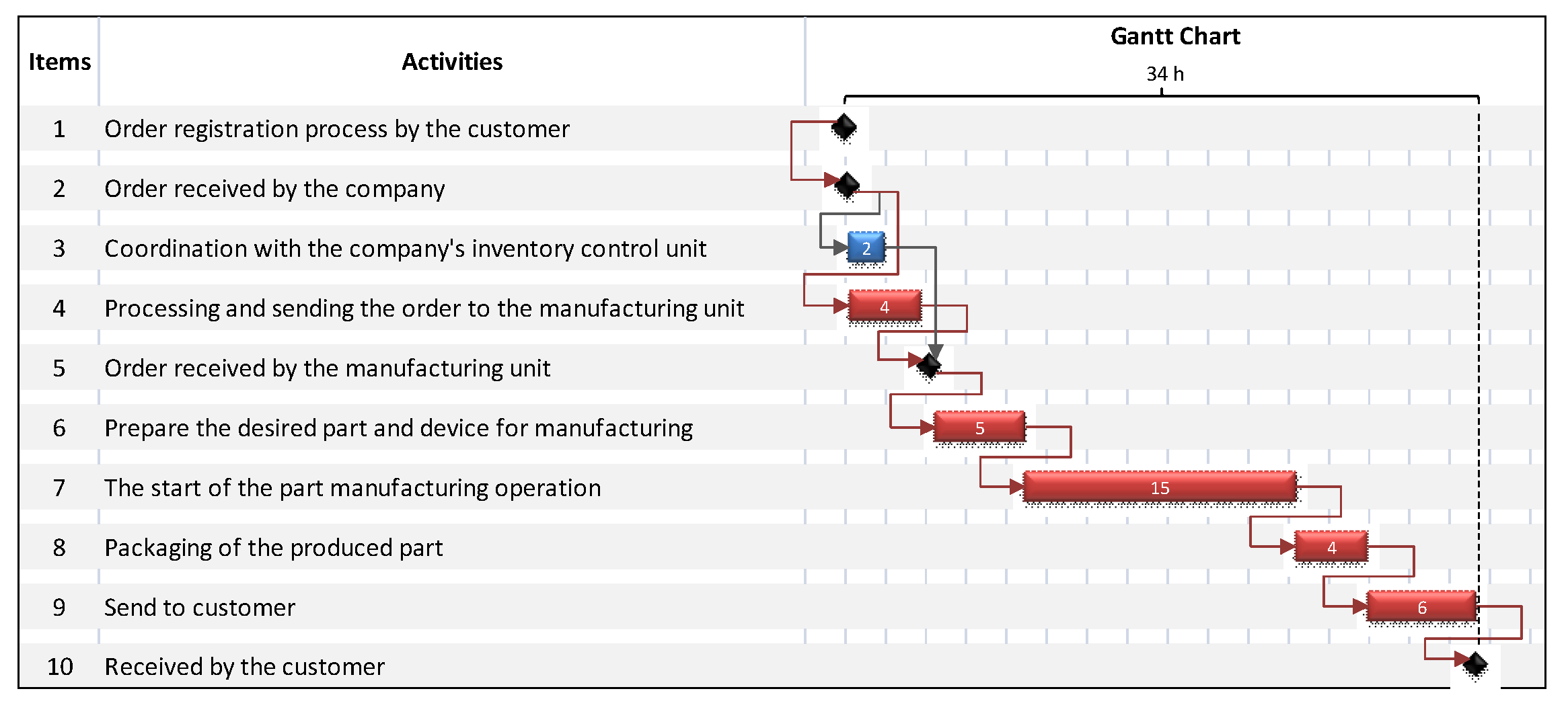

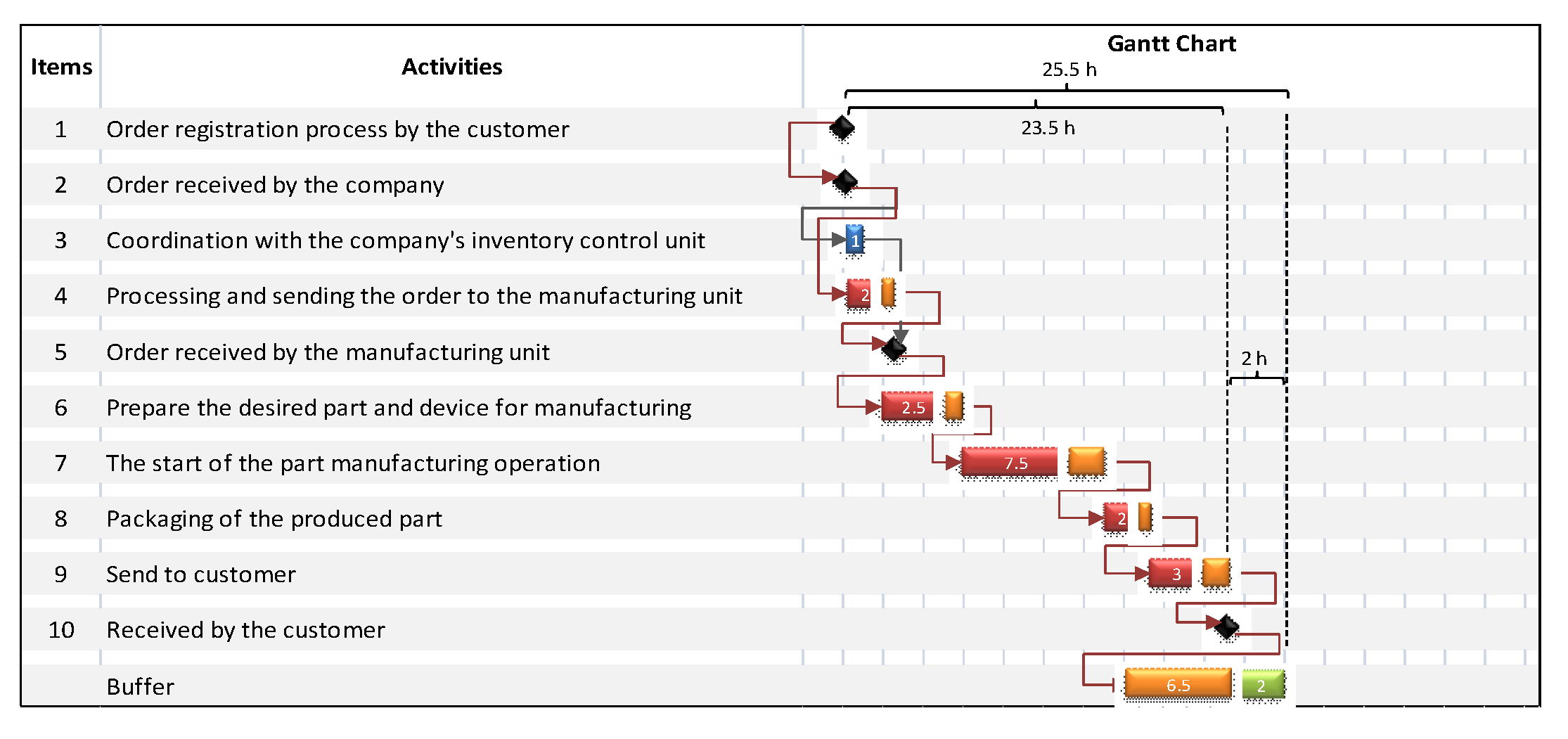

In this research, to better understand how to determine the size of the buffer, allocate the buffer to the activities, as well as how the buffer is consumed by the activities according to the CCPM method, in the algorithm presented below, the necessary explanations are given in the form of an example. The general activities from the stage of placing an order by the customer to receiving the order by the customer are given in

Figure 3. The time of each activity can be seen in the corresponding Gantt. Based on the Microsoft project software, which is widely used in activity planning, critical activities marked with red color are identified. A critical activity is an activity that does not float, and if it is delayed, it will cause a delay in the whole project. The software defines the critical path, which includes a chain of critical activities, and this chain is without a floating duration of 34 hours, which can be seen in the figure below.

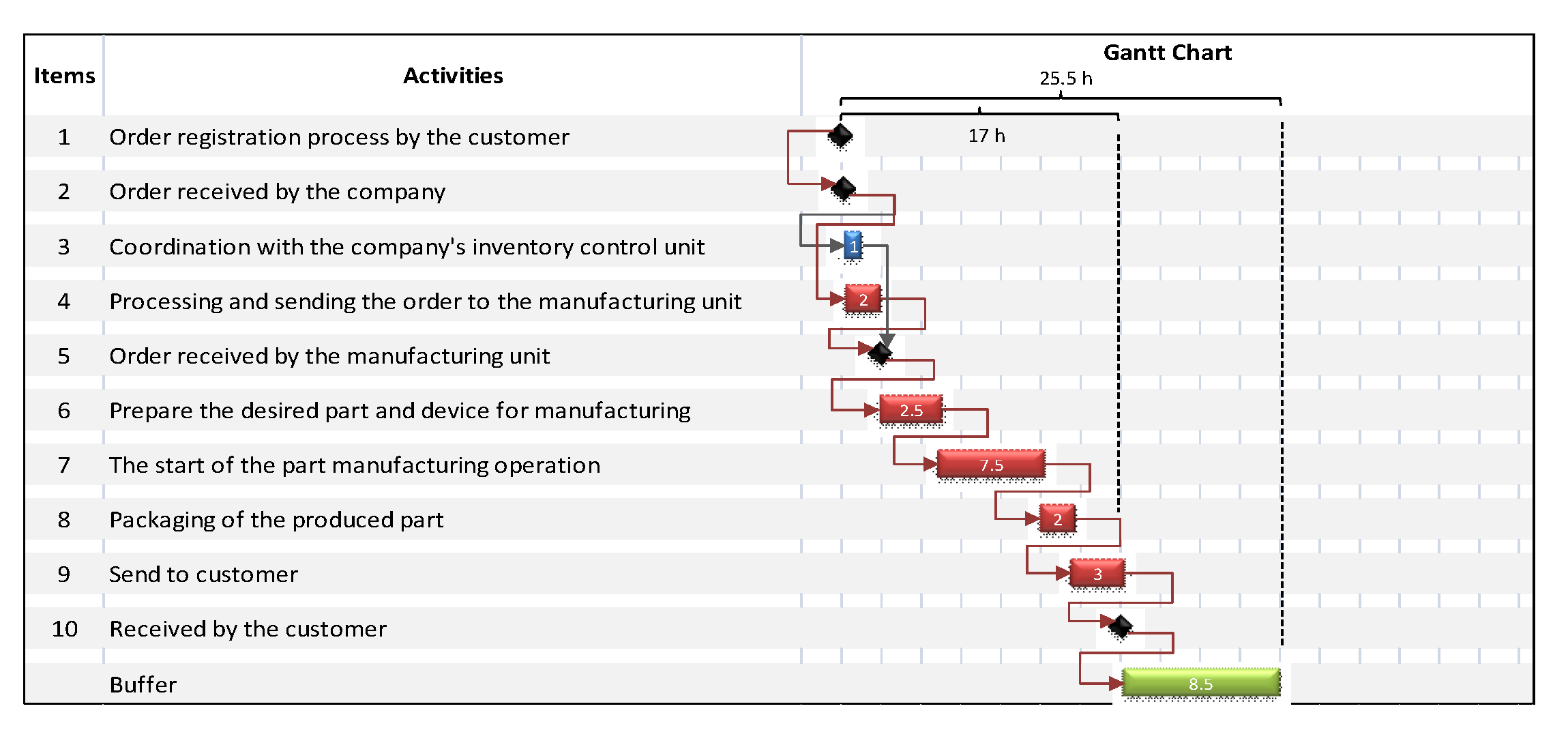

According to the algorithm presented in this research, at this stage, according to the CCPM method, the time of critical activities is halved. Therefore, the total duration or critical chain time is also halved, i.e., it is reduced from 34 hours to 17 hours. Then half of the total time of the critical chain, which is 8.5 hours, is added to the end of the critical chain as a total buffer. At this stage, the buffer is allocated to critical activities. The total time of the critical chain and the buffer is determined to be 25.5 hours, which can be seen in

Figure 4. Activities will use this allocated buffer if there is any delay.

As can be seen in

Figure 5, the critical activities in the critical chain have each used a certain amount of the allocated total buffer. In total, 6.5 hours out of 8.5 hours of the buffer amount have been consumed by the activities and 2 hours of the buffer are left. The actual completion time is 23.5 hours, which is about 30% earlier than the initial schedule of 34 hours

. In this method, these hidden safeties after removal from the former places are located following a special set of activities called a chain to preclude the activity’s delay [

19].

The indices, parameters, and variables used to formulate the problem mathematically are described below:

Indices:

Index of activity a (a ∈ A, A = {1, 2, ⋯, })

Index of part i (i ∈ I, I = {1, 2, ⋯, })

Index of job j (j ∈ J, J = {1, 2, ⋯, })

Index of machine m (m ∈ M, M = {1, 2, ⋯, })

Parameters:

The critical activity a: The duration of activity a: The ordering time of the part i: Packaging duration of part i: The quantity of the part i: Arrived time of the part i: The finishing duration of job j in the machine m: Is equal to 1 if part i is assigned to job j in machine m: Setting the time required for initialization and cleaning in machine m: The logistics time of the part i: Decision variables:

The longest path of project critical activities: The planned project buffer duration: Critical chain duration: Project plan duration: Consumed buffer: Remaining project buffer: Project completion actual time: The ordering time: Part processing time: The packaging time: Logistic time: Overall time for ordering to receive by customer: The research assumptions are as follows:

The relations between activities are finish-to-start (FS)

A machine can only produce one job at a time.

Jobs scheduled for a machine must be processed one by one in sequence.

The model is formulated as follows. In this formula, Equation (1) represents the objective function. The goal is to optimize production times, ordering, logistics, and the amount of buffer used.

Equation (2) calculates the longest path of critical activities. The duration of the critical chain is calculated through Equation (3). The buffer is calculated through Equation (4). Equation (5) calculated the buffer time and Equation (6) obtains the amount of buffer consumed.

Equation (7) specifies that each part is assigned to exactly one job in one machine. Equation (8) calculates the logistics time. In addition, Equation (9) demonstrates the ordering time. In Equation (10), the packaging time is calculated.

Equation (11) shows that jobs on a machine must be processed in order. Equation (12) determines the completion time of each task.

Equation (13) calculates the processing time. Equation (14) shows that the start time of a task must be later than the arrival time of all parts assigned to the task. Equation (15) demonstrates the overall time which consists of ordering time, part-processing time, packaging time, and logistics time. Equation (16) shows the overall time is equal to the longest path of critical activities. Also, Equation (17) calculates the project completion’s actual time.

5. Simulation Experiment

To evaluate the algorithm proposed in this research, the performance of the algorithm is simulated. The parameters used in this simulation are listed in

Table 1. It has been tried to use parameters that consider all the steps from placing the order of the part for 3D printing to receiving the part made by the customer, as well as the effect of measuring the desired buffer for activities and controlling their consumption. Necessary things should be done. For each of the parameters, a suitable range of randomly generated numbers is used as input to the algorithm. These numbers have been tried to be close to the actual values in the 3D printer industry. Each of the parameters has been tested 50 times and run in MATLAB software. In the table below, the range of values used in front of each parameter is given with its unit.

The results obtained from the simulation are given in

Table 2. According to the inputs of the proposed algorithm in

Table 1, the desired values in the decision variables were determined. The highest and lowest values obtained against each of the variables can be seen in the table below. The unit of all obtained values is hourly. The upper and lower limits as well as the values obtained between them are due to the input numbers related to the parameters that were randomly generated for simulation.

According to the results obtained from the simulation, it has been tried to make a comparison between the related cases and in fact, the necessary analysis has been done in this regard.

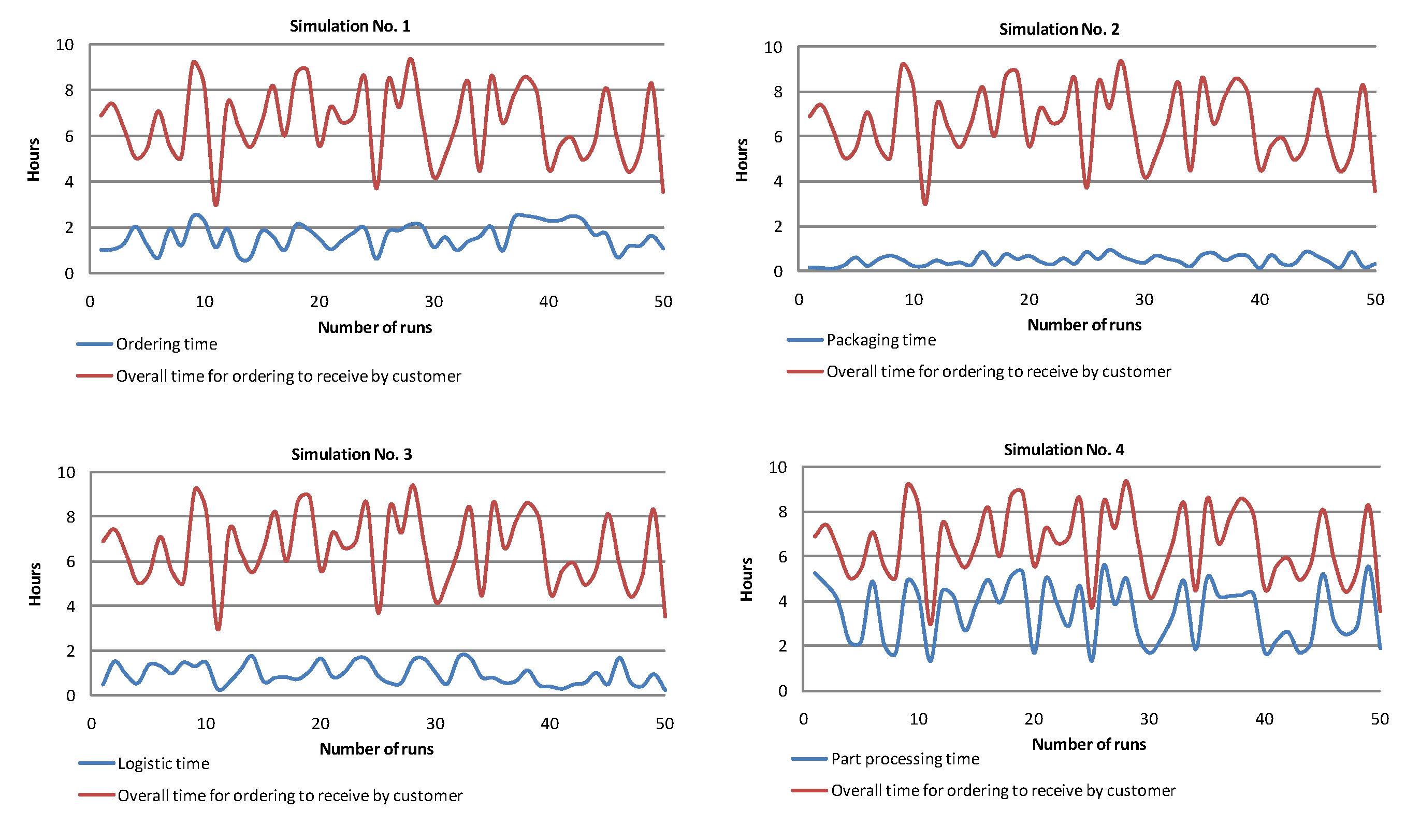

Figure 6 and

Figure 7 show the cases that can be compared with each other. In fact, in this figure, there are ten comparison diagrams of the values of the variables obtained from the simulation. Diagrams 1 to 4 in

Figure 6 show the values obtained in the simulation related to the steps of ordering the part until sending it to the customer. In graph 1, the time of ordering the part is compared with the total time of ordering until it is sent to the customer. Considering the time interval of 0.5 to 2.5 hours in the variable of ordering time compared to the time interval of 3.46 to 10.16 hours in the variable of the total time of ordering until it is sent to the customer, it shows that the effect of ordering time It is 23% on the total time from ordering to sending it to the customer.

In diagram 2, the time of packaging the part is compared with the total time of ordering until it is sent to the customer. This graph, according to the time interval of 0.08 to 1.00 hours in the packaging time variable compared to the time interval of 3.46 to 10.16 hours in the variable of the total time from ordering to sending it to the customer, shows that the impact of the packaging time on the total time from ordering to sending the part to the customer is 8%. Also, in diagram 3, the logistics time of the part is compared with the total time from ordering to sending it to the customer. This graph, according to the time interval of 0.25 to 1.80 hours in the logistics variable compared to the time interval of 3.46 to 10.16 hours in the variable of total time from ordering to sending it to the customer, shows that the influence of time the logistics of the part is 17% of the total time.

The processing time of the part is compared with the total time of ordering until it is sent to the customer in diagram 4. This graph, according to the time of 1.53 to 5.66 hours in the part processing variable compared to the period of 3.46 to 10.16 hours in the variable of the total time from ordering to sending it to the customer, shows that the effect the part processing time is 52% of the total time. After examining the simulation results in graphs 1 to 4, we conclude that in terms of time, the part processing stage, ordering stage, logistics stage, and finally the packaging stage can have the greatest impact on the total ordering time to send the part to the customer.

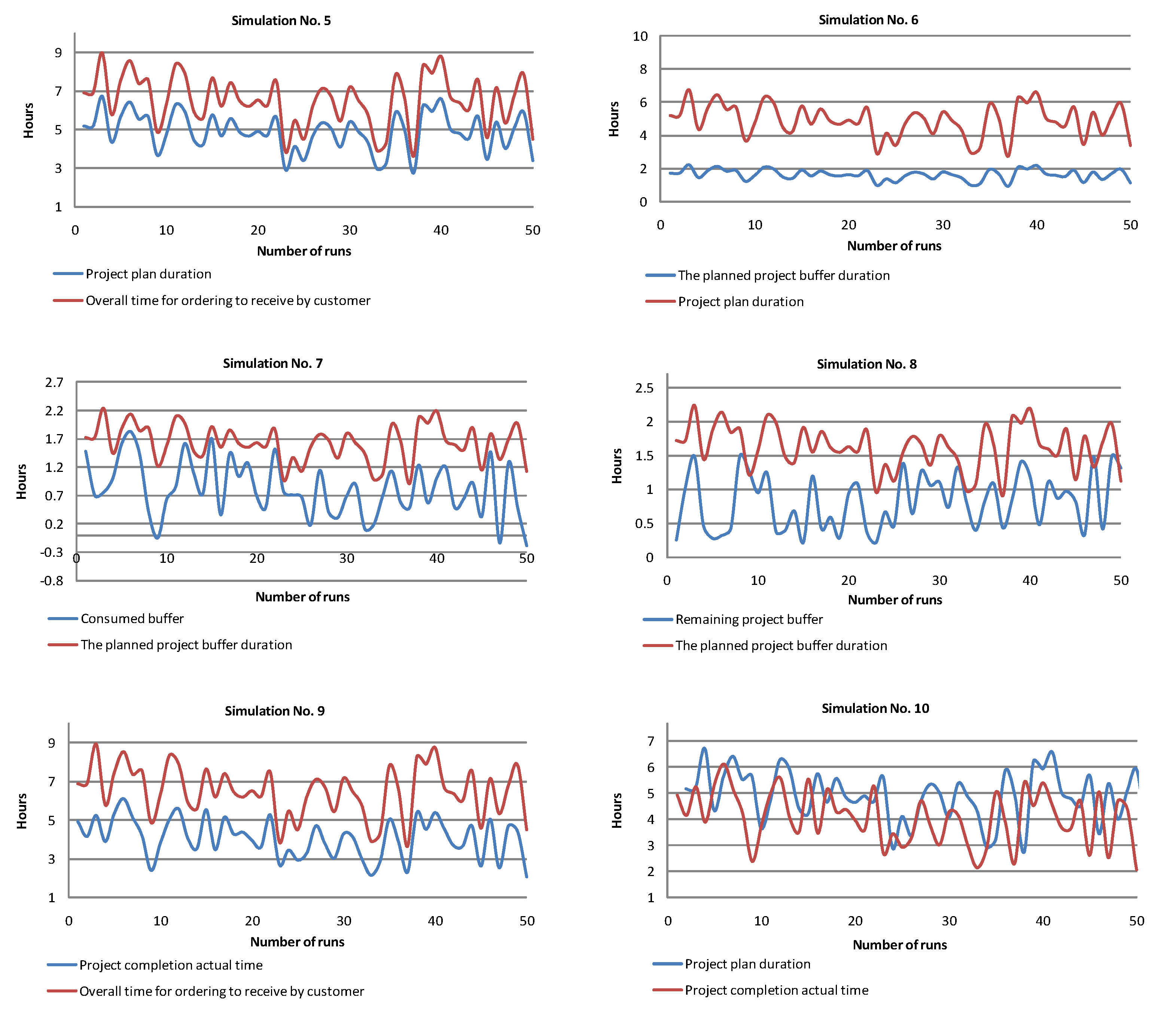

Diagrams number 5 to 10 in

Figure 7 examine the results obtained from the simulation related to the decision variables. In fact, these graphs show the effects of using the CC/BM method in order to optimize the total time of ordering parts until the logistics stage and sending the order to the customer. Necessary comparisons and analyzes are done in this section. Diagram No. 5 in

Figure 7 shows the comparison of the planned time with the total time from the order to the delivery of the product. The planned time is the time that was obtained after the implementation of the buffer management method. According to the lower and upper limit of 2.60 to 7.62 hours for the variable of planned time compared to the range of 3.46 to 10.16 of the variables of the total time of order to product delivery, it shows that the ratio of the variable of planned time to the total time variable from the order to the delivery of the product is 75%. This time reduction ratio is due to the calculation method of the buffer measurement technique.

Diagram No. 6 shows the comparison of the planned buffer time with the planned project time. The scheduled buffer time was obtained by the proposed buffer measurement method. Considering the range of 0.87 to 2.54 hours in the obtained values of the planned buffer compared to the range of 2.60 to 7.62 in the planned time variable of the project, the graph shows that the average ratio of the planned buffer time variable to the average of the planned time variable the project is 33%. In graph number 7, the consumed amount of buffer time is compared with the planned buffer time. According to the proposed algorithm, after the measured buffer was allocated to the activities, the algorithm entered the executive stage and buffer consumption control. The range of consumed buffer from -0.14 to 1.96 hours compared to the range of planned buffer from 0.87 to 2.54 hours, indicates that the average ratio of buffer consumption to the average time of planned buffer is 51%. It means that on average about half of the allocated buffers are consumed by the activities. The negative value in the buffer consumption values means that in some cases the buffer consumption value was greater than its planned value.

In chart number 8, the amount of remaining buffer time is compared with the amount of scheduled buffer time. According to the algorithm, after allocating the measured buffer to the activities and executing the algorithm, the amount of buffer needed by the activities is consumed. Some buffers may remain, and buffer overflows may occur. The remaining buffer range from 0.00 to 1.49 hours compared to the allocated buffer range from 0.87 to 2.54 hours, which shows that the average ratio of the remaining buffer time to its allocated value is 49%. It means that, on average, less than half of the allocated buffers are left. The larger the number of remaining buffers means that the activities have been completed in less time.

In chart number 9, the amount of actual time for all activities is compared with the total amount of scheduled time from the time of ordering to the delivery of the product to the customer. According to the results obtained from the simulation, the range of 1.60 to 6.64 hours in the amount of real-time done compared to the range of 3.46 to 10.16 hours in the total amount of scheduled time from the time of ordering to the delivery of the product to the customer, it shows that The ratio of the average amount of actual time done to the total amount of scheduled time from the time of ordering to the delivery of the product to the customer is 62%. It means that the use of the heuristic algorithm proposed in this research has caused the activities to be completed about 38% earlier than the original plan.

In the last diagram of the simulation done in this research, which is diagram number 10, the actual amount of time to perform all the activities is compared with the amount of planned time. The amount of planned time was calculated based on the heuristic algorithm proposed in this research. According to the obtained results, the range of results from 1.60 to 6.64 hours in the amount of real-time performed compared to the range of 2.60 to 7.62 hours in the amount of planned time, shows that the average ratio of the amount of actual time performed to the amount of program time it is 83%. It means that the use of the heuristic algorithm proposed in this research has made the desired activities be completed about 17% earlier than the planned amount of time.

6. Conclusion

In this research, a heuristic scheduling algorithm for use in cloud-based additive manufacturing with an approach to critical chain buffer management to schedule and optimize the time was proposed. The HSA proposed in this research consisted of three phases. According to the literature review done in this research, it was found that most of the research in this field has only focused on scheduling in the production environment while it is necessary to deal with the entire process to optimize time. Therefore, this research dealt with the entire process of additive manufacturing to optimize time with the approach of the CCPM method and this is the novelty of this research.

To evaluate the algorithm proposed in this research, the performance of the algorithm was simulated. It tried to use parameters that consider all the steps from placing the order of the part for 3D printing to receiving the part made by the customer, as well as the effect of measuring the desired buffer for activities and controlling their consumption. For each of the parameters, a suitable range of randomly generated numbers was used as input to the algorithm. These numbers tried to be close to the actual values in the 3D printer industry. Each of the parameters was tested 50 times and run in MATLAB software. According to the inputs of the proposed algorithm, the desired values in the decision variables were determined. The upper and lower limits as well as the values obtained between them are due to the input numbers related to the parameters that were randomly generated for simulation.

The results of simulation experiments demonstrated that the use of the heuristic algorithm proposed in this research caused the activities to be completed about 38% earlier than the original plan. In addition, it made the desired activities be completed about 17% earlier than the planned amount of time. According to the research question, using the HSA on the CBAM could optimize the entire process time of additive manufacturing.

This research can be interesting for researchers, scholars, and students who work in the field of scheduling in manufacturing, especially additive manufacturing. By making changes in the presented heuristic algorithm, they can increase the percentage of time optimization in the production process time and analyze the effects of this optimization from an economic and social point of view. They can also implement the heuristic algorithm proposed in this research as a case study in a CBAM.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Acknowledgments

We are grateful to all of those with whom I have had the pleasure to work on this and other related projects.

Declaration of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Wang, Y. , Zheng, P., Xu, X., Yang, H., & Zou, J. (2019). Production planning for cloud-based additive manufacturing—A computer vision-based approach. Robotics and Computer-Integrated Manufacturing, 58, 145-157. [CrossRef]

- Li, Q. , Kucukkoc, I., & Zhang, D. Z. (2017). Production planning in additive manufacturing and 3D printing. Computers & Operations Research, 83, 157-172. [CrossRef]

- Chergui, A. , Hadj-Hamou, K., & Vignat, F. (2018). Production scheduling and nesting in additive manufacturing. Computers & Industrial Engineering, 126, 292-301. [CrossRef]

- Kucukkoc, I. (2019). MILP models to minimise makespan in additive manufacturing machine scheduling problems. Computers & Operations Research, 105, 58-67. [CrossRef]

- Zhang, J. Zhang, J., Yao, X., & Li, Y. (2020). Improved evolutionary algorithm for parallel batch processing machine scheduling in additive manufacturing. International Journal of Production Research, 58(8), 2263-2282. [CrossRef]

- Karimi, S. , Kwon, S., & Ning, F. (2021). Energy-aware production scheduling for additive manufacturing. Journal of Cleaner Production, 278, 123183. [CrossRef]

- Kapadia, M. S., Uzsoy, R., Starly, B., & Warsing Jr, D. P. (2022). A genetic algorithm for order acceptance and scheduling in additive manufacturing. International Journal of Production Research, 60(21), 6373-6390. [CrossRef]

- Aloui, A. , & Hadj-Hamou, K. (2021). A heuristic approach for a scheduling problem in additive manufacturing under technological constraints. Computers & Industrial Engineering, 154, 107115. [CrossRef]

- Li, Q. , Zhang, D., Kucukkoc, I., & He, N. (2020). Heuristic techniques for real-time order acceptance and scheduling in metal additive manufacturing. Mathematical Modelling and Optimization of Engineering Problems, 1-24. [CrossRef]

- Rohaninejad, M. , Tavakkoli-Moghaddam, R., Vahedi-Nouri, B., Hanzálek, Z., & Shirazian, S. (2022). A hybrid learning-based meta-heuristic algorithm for scheduling of an additive manufacturing system consisting of parallel SLM machines. International Journal of Production Research, 60(20), 6205-6225. [CrossRef]

- Lee, S. J. , & Kim, B. S. (2023). Two-stage meta-heuristic for part-packing and build-scheduling problem in parallel additive manufacturing. Applied Soft Computing, 110132. [CrossRef]

- Goldratt EM (1997) Critical chain. The North River Press, New York.

- Hu, X. , Demeulemeester, E., Cui, N., Wang, J., & Tian, W. (2017). Improved critical chain buffer management framework considering resource costs and schedule stability. Flexible Services and Manufacturing Journal, 29, 159-183. [CrossRef]

- Modi, K. , Lowalekar, H., & Bhatta, N. M. K. (2019). Revolutionizing supply chain management the theory of constraints way: A case study. International Journal of Production Research, 57(11), 3335-3361. [CrossRef]

- Junqueira, V. S. V. , Nagano, M. S., & Miyata, H. H. (2020). Procedure structuring for programming aircraft maintenance activities. Revista de Gestão, 27(1), 2-20. [CrossRef]

- Xiao, L. , Bie, L., & Bai, X. (2021). Controlling the schedule risk in green building projects: Buffer management framework with activity dependence. Journal of Cleaner Production, 278, 123852. [CrossRef]

- Zhang, J., & Wang, M. (2022). Differential buffer monitoring for critical chain projects based on comprehensive activity reliability. Journal of the Operational Research Society, 1-16. [CrossRef]

- Peng, W. , Lin, X., & Li, H. (2023). Critical chain based Proactive-Reactive scheduling for Resource-Constrained project scheduling under uncertainty. Expert Systems with Applications, 214, 119188. [CrossRef]

- Roghanian, E., Alipour, M., & Rezaei, M. (2018). An improved fuzzy critical chain approach in order to face uncertainty in project scheduling. International Journal of Construction Management, 18(1), 1-13. [CrossRef]

- Weller, C. , Kleer, R., & Piller, F. T. (2015). Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. International Journal of Production Economics, 164, 43-56. [CrossRef]

- Berman, B. (2012). 3-D printing: The new industrial revolution. Business horizons, 55(2), 155-162. [CrossRef]

- Oh, Y. , Witherell, P., Lu, Y., & Sprock, T. (2020). Nesting and scheduling problems for additive manufacturing: a taxonomy and review. Additive Manufacturing, 36, 101492. [CrossRef]

- Alicastro, M. , Ferone, D., Festa, P., Fugaro, S., & Pastore, T. (2021). A reinforcement learning iterated local search for makespan minimization in additive manufacturing machine scheduling problems. Computers & Operations Research, 131, 105272. [CrossRef]

- Kim, Y. J. , & Kim, B. S. (2022). Part-grouping and build-scheduling with sequence-dependent setup time to minimize the makespan for non-identical parallel additive manufacturing machines. The International Journal of Advanced Manufacturing Technology, 1-12. [CrossRef]

- Zipfel, B., Neufeld, J. S., & Buscher, U. (2021). Customer order scheduling in an additive manufacturing environment. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems: IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, September 5–9, 2021, Proceedings, Part IV (pp. 101-109). Springer International Publishing. [CrossRef]

- D’Aniello, G. , De Falco, M., & Mastrandrea, N. (2021). Designing a multi-agent system architecture for managing distributed operations within cloud manufacturing. Evolutionary Intelligence, 14, 2051-2058. [CrossRef]

- Liu, S. , Zhang, L., Zhang, W., & Shen, W. (2021). Game theory based multi-task scheduling of decentralized 3D printing services in cloud manufacturing. Neurocomputing, 446, 74-85. [CrossRef]

- Wu, Q., Xie, N., Zheng, S., & Bernard, A. (2022). Online order scheduling of multi 3D printing tasks based on the additive manufacturing cloud platform. Journal of Manufacturing Systems, 63, 23-34. [CrossRef]

- Zohrehvandi, S. , & Soltani, R. (2022). Project scheduling and buffer management: A comprehensive review and future directions. Journal of Project Management, 7(2), 121-132. 10.5267/j.jpm.2021.9.

- Bie, L., Cui, N., & Zhang, X. (2012). Buffer sizing approach with dependence assumption between activities in critical chain scheduling. International Journal of Production Research, 50(24), 7343-7356. [CrossRef]

- Vanhoucke, M. (2013). Critical Chain/Buffer Management. Project Management with Dynamic Scheduling: Baseline Scheduling, Risk Analysis and Project Control, 187-208. [CrossRef]

- Zhang, J., Jia, S., & Diaz, E. (2018). Dynamic monitoring and control of a critical chain project based on phase buffer allocation. Journal of the Operational Research Society, 69(12), 1966-1977. [CrossRef]

- Zhang, J., Song, X., & Díaz, E. (2017). Critical chain project buffer sizing based on resource constraints. International Journal of Production Research, 55(3), 671-683. [CrossRef]

- Peng, W., & Lin, X. (2022). A heuristic for the critical chain scheduling problem based on left shifts of activities. Flexible Services and Manufacturing Journal, 1-24. [CrossRef]

- Zohrehvandi, S., Khalilzadeh, M., Amiri, M., & Shadrokh, S. (2020). A heuristic buffer sizing algorithm for implementing a renewable energy project. Automation in Construction, 117, 103267. [CrossRef]

- Zohrehvandi, S. (2022b). A Project-Scheduling and Resource Management Heuristic Algorithm in the Construction of Combined Cycle Power Plant Projects. Computers, 11(2), 23. [CrossRef]

- Zohrehvandi, S. , Vanhoucke, M., Khalilzadeh, M., Amiri, M., & Shadrokh, S. (2022a). A fuzzy project buffer management algorithm: a case study in the construction of a renewable project. International Journal of Construction Management, 1-10. [CrossRef]

- Zohrehvandi, S. , Khalilzadeh, M., Amiri, M. and Shadrokh, S. (2021), “Project buffer sizing and dynamic buffer consumption algorithm in power generation construction”, Engineering, Construction and Architectural Management, Vol. ahead-of-print No. ahead-of-print. [CrossRef]

- Zohrehvandi, S., Vanhoucke, M. and Khalilzadeh, M. (2020b), “A project buffer and resource management model in energy sector; a case study in construction of a wind farm project”, International Journal of Energy Sector Management, Vol. 14 No. 6, pp. 1123–1142. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).