2.1. Method by Measuring Minium Angular Deviation of a Prism

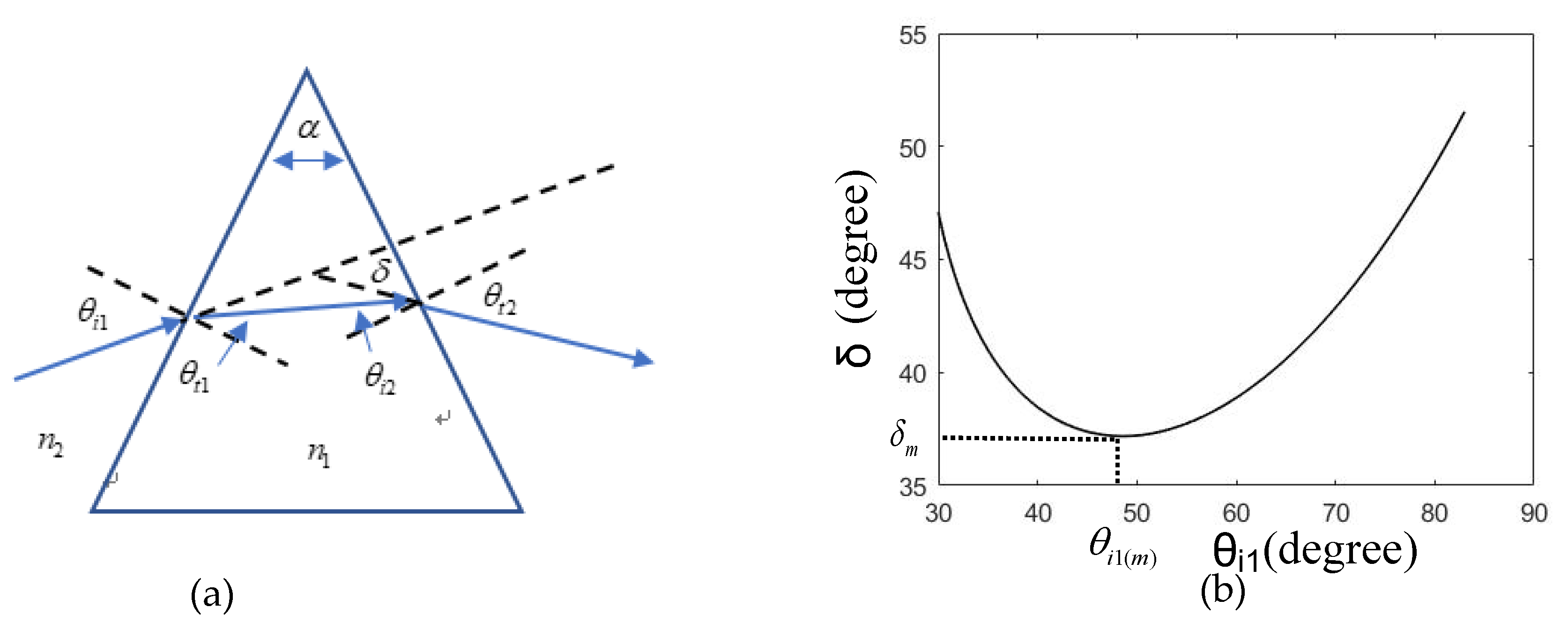

Figure 1a. shows a typical dispersing prism with an apex angle

and refractive index

n1 (at a specified wavelength of the incident light). A paralell light beam is incident from the left with an inciedent angle

at the first interface of the prism. It leaves the second interface with an angle

, which is deviated from its original incident direction with a angular deviation

. The symbols

and

indicate the refraction angle and the incident angle for the first and second refraction of the two interfaces, respectively. From the geometry of the prism triangle, we have

Using some algebra and manipulation, we find that the angular deviation

can be written as a function of

and

only. When

reaches its minimum

, the ray traverses the prism symmetrically, that is, parallel to its base (

). Under that situation, we have

where

m in the subscript indicates the minimum value for minimum

, as shown in

Figure 1(b).

Appling Snell’s law at the first refraction and assuming the medium around the prism is air or vacuum with refractive index

= 1.0, the prism’s refractive index

is

Thus, by varying

to find

and knowing

, the refractive index of the prism can be determined.

Figure 1b shows the angular deviation versus the incident for the case of

= 60

0 and n = 1.5; the minimum

is 37.2

0 at the incident angle

= 48.6

0.

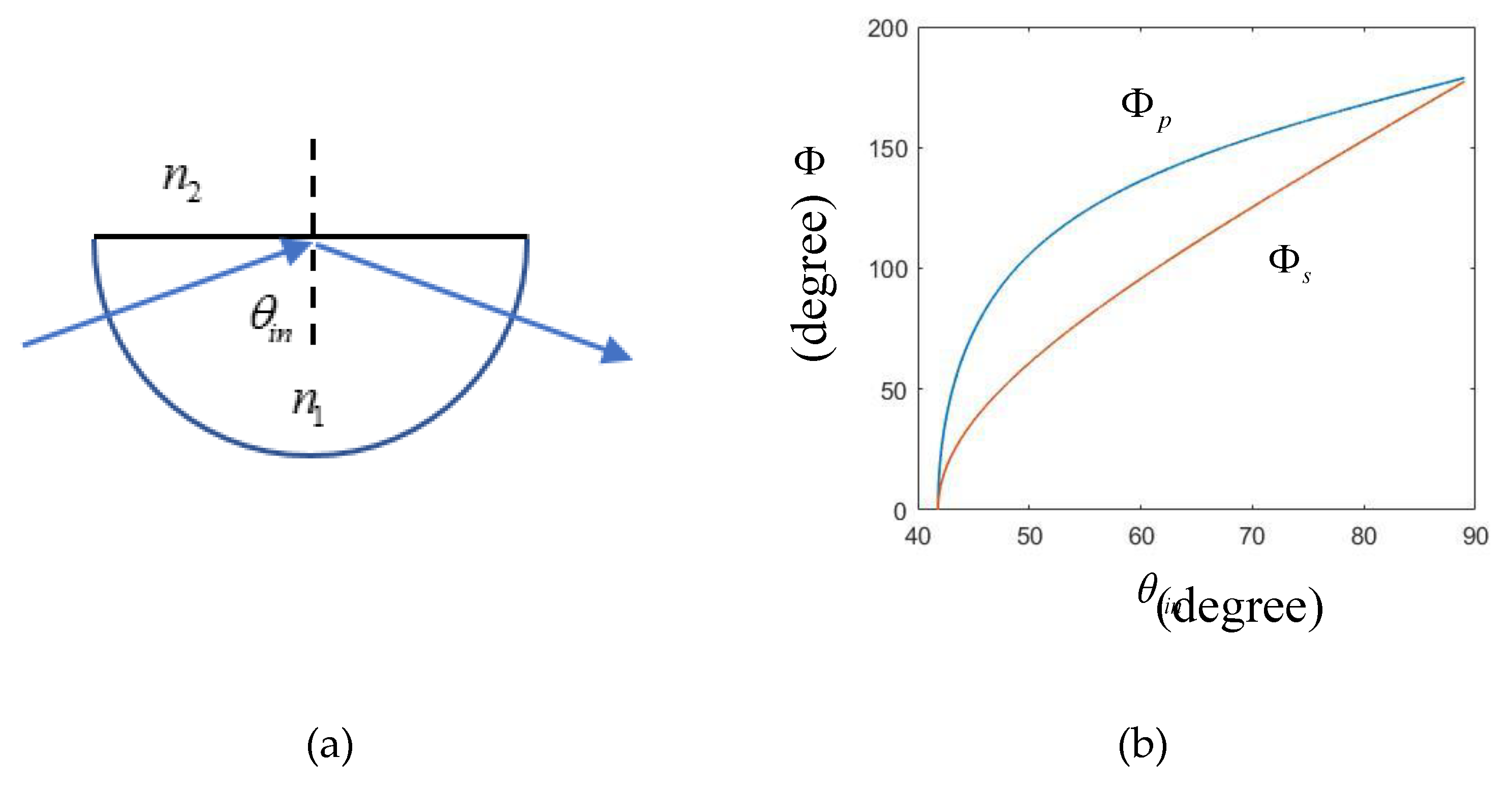

2.2. Method Measuring the Maximum Phase Change in TIR

Now we consider another schme proposed by us to measure the refractive index. Figue 2 illustrates a situation that a light beam is incident into a transparent semi-circle cylinder (or a semi-sphere) with refractive index

n1 and that of the surrounding medium is

with

. It is well known that when the incident angle is larger than the critical angle

, the total internal reflection (TIR) occurs. As TIR exists, the light beam reflects back into the same material without refracting into the medium. Here the semi-circle shape is chosen for convenience of discussion. The TIR on the top interface without considering the refraction at the boundaries of the material (i.e. when the light wave goes in and leaves the material). It is further assumed that some anti-reflection coating is applied to the boundaries (except the top surface), thus all of the incident power aimed at the center of the semi-circle with angle

is reflected and leaves the material with the same angle without taking the Fresnel loss at the boundaries into account. We also know that under TIR, the reflected light wave will gain different phase change for different polarizations as follows [

10]

where

and

are the phase changes for p and s polarizations, respectively and

is the refractive index ratio of

and

, which is less than 1.

Figure 2(b) shows

(blue line) and

(red line) versus

for the case of

and

(

n = 2/3) with the critical angle

. The phase changes start from zero at

and increase monotonically to 180

0 when

reaches 90

0, and

is larger than

in the whole interval. Because the phase differences exist for the two polarizations, there is a polarization change if the incident wave polarization is not parallel with one of the polarizations. For example, as shown in

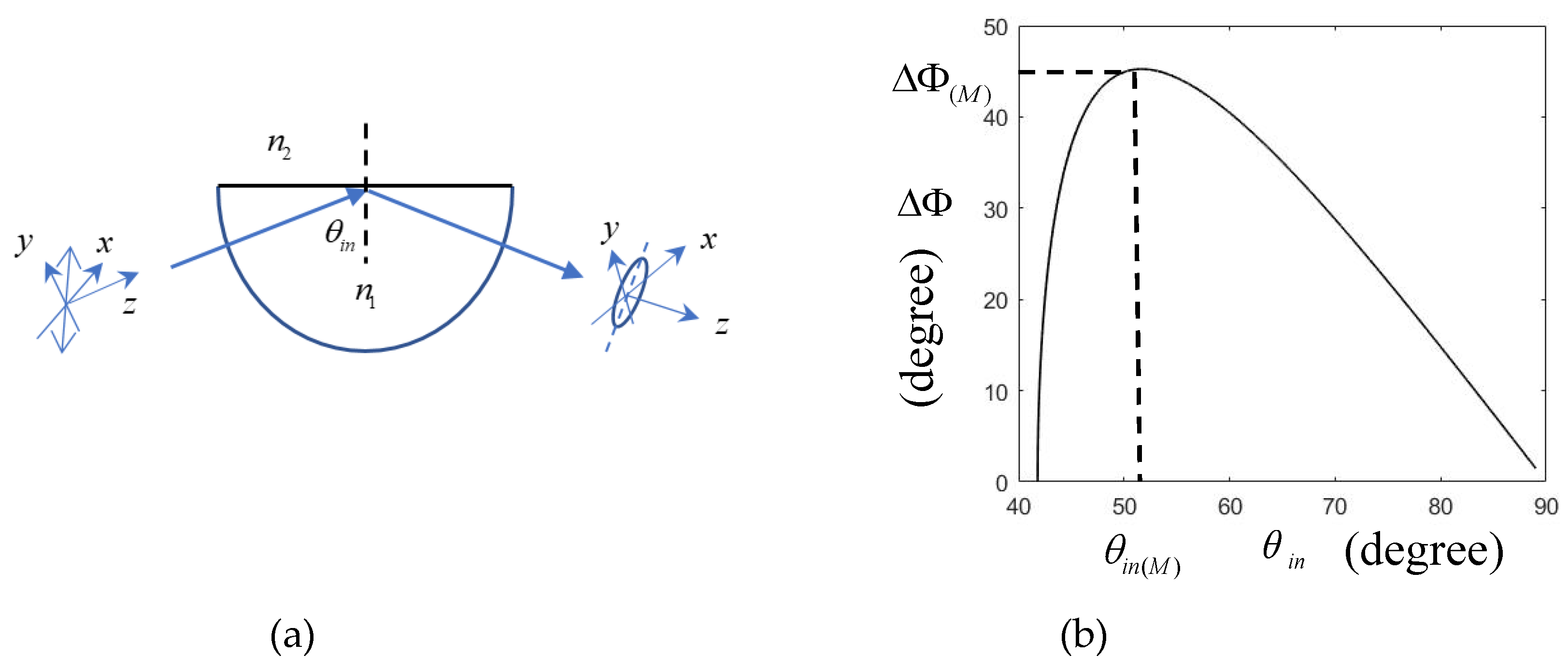

Figure 3(a), if an incident wave is linearly polarized 45

0 with respect to the

x axis, its polarization state will be an elliptical polarization after the TIR. The ellipticity depends on the incident angle and refractive index ratio

. This feature is used as a quarter wave plate that transforms a linear polarization into a circular polarization, called a Fresnel rhomb [

10]. It’s advantage over the traditional birefringent wave plate, is that it is much less wavelength sensitive. The phase difference is defined as

and it can be written as

Figure 3(b) shows

for the case of

n = 2/3 (

and

). Note that at the two incident angles 50.23

0 or 53.26

0,

reaches 45

0; thus after two TAR reflections, the total phase change accumulated is 90

0 (i.e. quarter wave), which is the Fresnel rhomb principle. It is also interesting to find that there is a maximum for the

; in this case it is

for

, where the

(M) in the subscript indicates maximum. By differentiating the right side of Equation (6) with respected to

and setting it to zero to find

, we can have

Equation (7) is of value because it gives analytical results for

and

. It is intersiting to compare

Figure 3(b) with

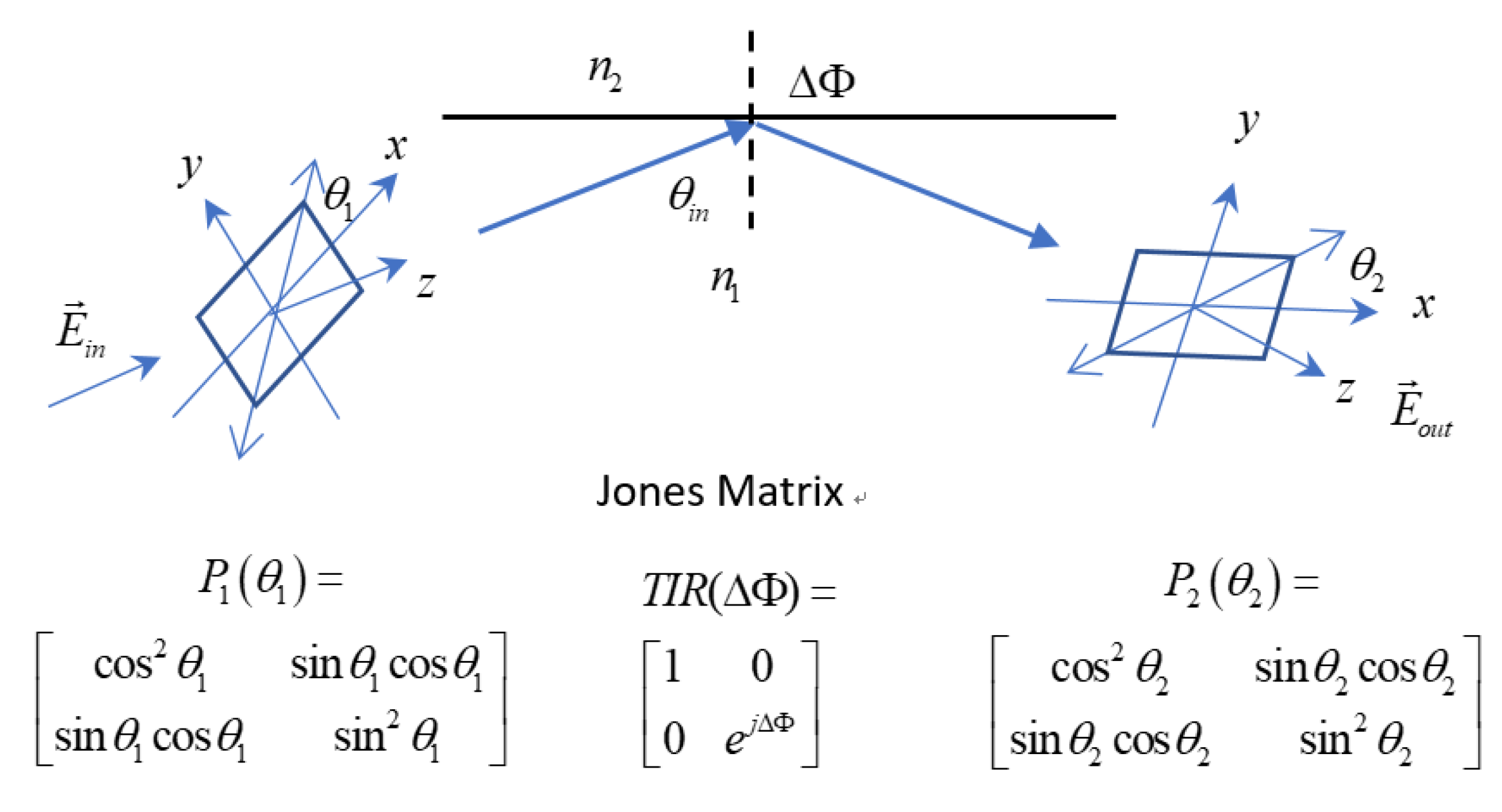

Figure 1(b), where both have extreme incident angle values for giving minimum deviation angle or maximum phase change. It is natural to expect this property can be used to measure a unknown refractive index as in the prism case. Since the phase change leads to polarization state change, we need to modify the configuration properly to detect it. Considering

Figure 4(a), without ploting the hemi-circle boundary, there are two polarizers are added outside the material and the Jones matrixes [

14] are empolyed to analyzed the polarization change. As shown in the figure, the light wave is incident along z direction. There are two polarizers P

1 and P

2 which make the angle

and

respect to their local

x coordinate respectively. The Jones matrix’s indicated in the bottom of the figure for

P1, TIR, and

P2 are

,

, and ,

respectively. Since we need to polarize the light beam at

to gain

, we can assume, without losing generality, the Jones vector of the incident light field is

, a unit vector also polarized at

and the T in the superscript is a transport operation. Using the cascade matrixes manipulation, the output field is

Finally we can get the output intensity as follows

It is noted that when

of P

2 is at the angle of 45

0 or 135

0, the output intensities are, denoted as

or

, respectively

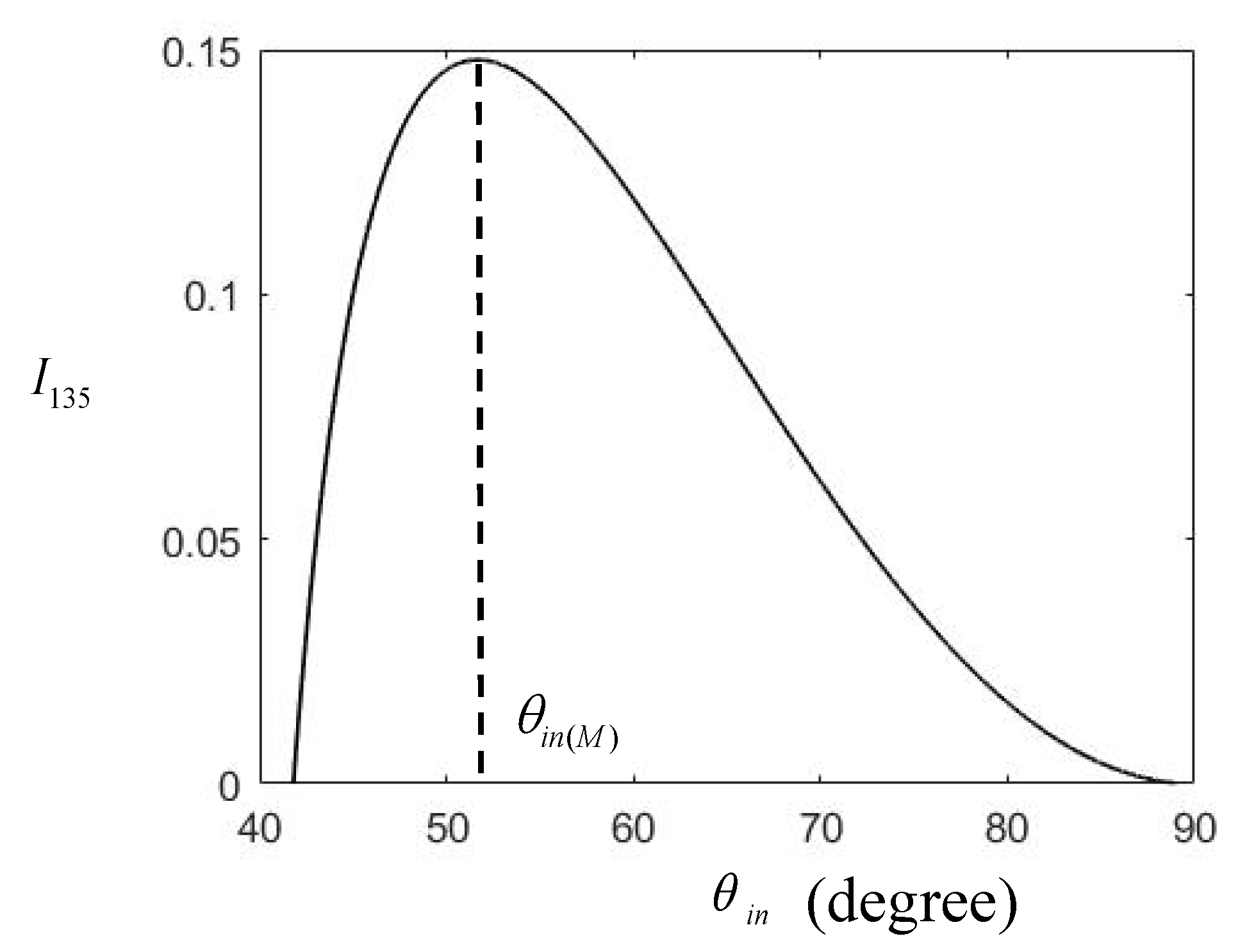

Taking

measurement as an example, if we keep increasing the incident angle

from

, and detect the intensity

, it reaches its maximum when

, as seen from

Figure 3(b) and Equation (10). This behavior is shown in

Figure 5.

Consequently, by varying the incident angle, the maximum of

can be reached to determine

, and the right half of the Equation (7) can be used to calculate

n as

Since is the refractive index ratio, we need to know the of the surrounding medium. If we take for air, the material’s refractive index is . Comparing with the scheme that determines the refractive index by finding the critical angle, which is not easy to determine exactly. This method works well by finding , which should be easier to determine more precisely because this angle is usually not close to the critical angle.

2.3. Method for Measuring Ellipticity of TIR (without Scanning the Incident Angle)

In last section we successfully find the refractive index by looking for the incident angle that gives maximum phase change in TIR. This is similar to the method in section 2.1 that looks for the incident angle that gives the minimum deviation angle. In this section we would like to introdue another possibility in which no incident angle scanning is necessary. This method may be considered an advanced or improved version. This scheme can be seen by examining Equation (6), giving that phase change only depends on the incident angle and the index ratio. Thus it is possible to find if can be find for a given without using a phase meter or an interferometer. Let us show how it proceeds.

As shown in

Figure 4 and Equation (10), this configuration can be used to measure

and

by simply rotating the

of P2 to 45 and 135 degrees, respectively. Note that by taking the square root of the ratio

/

and using Equation (6), we have

where

is the ellipticity of the polarization ellipse shown in

Figure 3(a). The ellipticity is defined as the ratio of short axis to the long axis of the polarization ellipse of the field, which is the ratio of field amplitude taken at 135 and 45 degrees, respectively. After finding

at any selected incident angle

, the refractive index ratio, from Equation (12) is obtained as

Thus, the material refractive index can be determined. The advantage of this method is that we do not need to vary the incident angle to find n. However, it is suggested to select the incident angle carefully to have a larger value (i.e. bigger ) , in order to increase the signal intensity or S/N ratio.

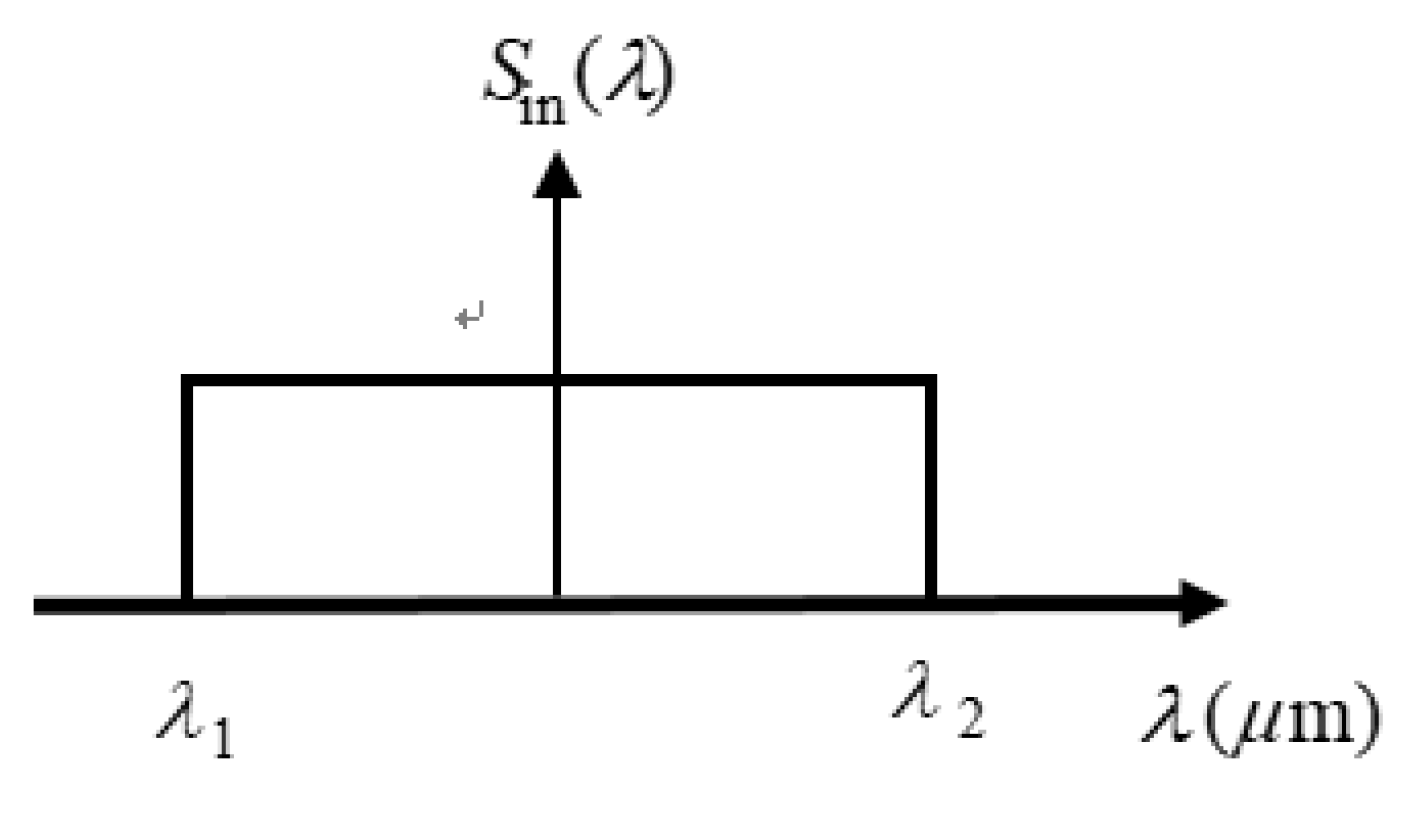

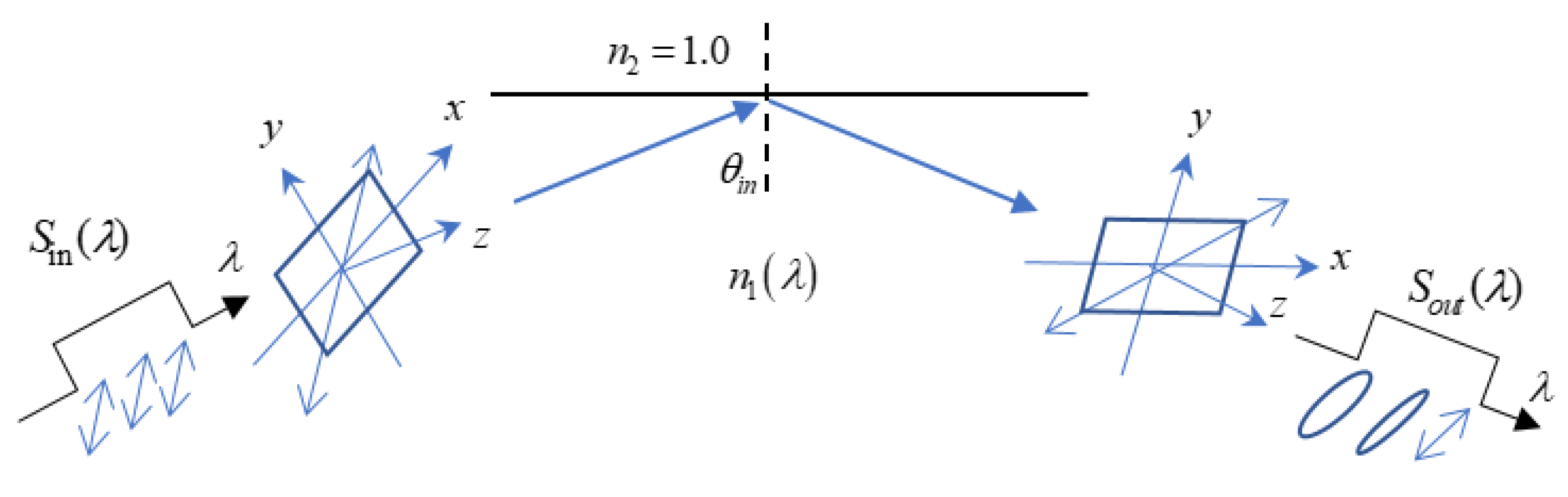

2.4. Dispersion Measurement with Polychromatic Light

In the last section we present a scheme getting the refractive index by finding ellipticity of the polarization. Here we would like to show how to use this feature to obtain the dispersion of the material by employing a polychromatic source [

15]. It is known that material dispersion is a protery such that the refractive index depends on the wavelength of the incident light wave, i.e. refractive index

is actualy a function of wavelengthe

, written as

from now on. Considering that we can prepare an incident flat-top spectrum

in the dispersion interval of interest from

to

, as shown in

Figure 6. As illustrated in

Figure 7, it is incident into a material with

and with

; thus the index ratio is

. Initially this spectrum is polarized at 45

0 as in last section; however, because of the material dispersion, each wavelength component experiences different amount of the polarization change

. Consequently, the output spectrum

has different ellipticity of polarization ellipse for different wavelengths, as shown in the right of the figure. Similarly as done in last section, this time a spectrometer is utilized to detect

by setting the polarization angle of P2 to 45 and 135 degree, and they are denoted as

and

respectively. The ellipticity dependence of

, as seen in Equation (12), is the square root of the ratio of

, that is

Consequently, as in Equation (13), the dispersion of the material is