1. Introduction

Silver birch (Betula pendula Roth) is a deciduous tree species native to Europe and parts of Asia. It is widely distributed and valued for its wood, which has various applications in construction, furniture making, paper production, and more. Understanding the mechanical properties of silver birch wood is essential for optimizing its utilization in different industries.

Silver birch is the third most spread forest tree species in Lithuania. Birch stands comprise 22 % of the area occupied by forest [

1]. Silver birch is the most common and perspective tree species for tree breeding in Lithuania [

2]. From 2006 in Lithuanian field trial test for genetic half-sib families wood properties evaluation, the wood hardness was added as a trait measured by Pilodyn 6J Forest device. Earlier studies selected Pilodyn device for non-destructive testing and get good negative correlation with basic wood density [

3]. Even though wood hardness is used as a trait for genetic studies the main parameters used for measuring wood quality in the industry are wood density, modulus of elasticity and bending strength [

4,

5]. Wood density is an important indicator of wood quality and is closely related to its mechanical properties [

6,

7]. The density of silver birch wood ranged from approximately 550 to 650 kg/m³ [

8]. The elastic modulus, also known as modulus of elasticity, reflects the stiffness of wood and its ability to withstand deformation under load. that the previous studies showed that the elastic modulus of silver birch wood was in a range of 10 to 15 GPa [

8,

9].

Overall, silver birch exhibits remarkable ecological plasticity and can adapt to diverse environmental conditions. Genetic studies have revealed evidence of local adaptation in silver birch populations, with certain genotypes displaying superior performance in specific habitats [

10,

11]. Understanding the genetic basis of local tree species adaptation is crucial for conservation efforts and forest management practices, particularly under the climate change situation. Several studies were focused specifically on wood quality parameters of conifer species and the influence of forest management on wood density, modulus of elasticity and stiffness [12-15]. As emphasized in the European Green Course and the EU Forest Strategy for 2030, it is appropriate to pay more attention to other tree species and their wood parameters, especially in the context of climate change [

16,

17].

This study aimed to evaluate the mechanical wood properties of silver birch (Betula pendula Roth) trees of different half-sib families.

2. Materials and Methods

The study objects were selected in the experimental plantations of the progenies of Lithuanian populations (half-sib families) of silver birch from different regions of origin (

Table 1). All selected plantations were established in 1999.

Each of the 24 populations in the experimental plantations were represented by 5 progeny families, for a total of 101 families. The experimental design included 6 blocks, and trees of each family were grown in one row of 10 trees located randomly within the block. Tree seedlings were planted in rows every 2.0-2.3 m, leaving a distance of 1.5 m between seedlings in the rows by strips using a mill (in Dubrava plantation) or using a soil plough (in Šiauliai plantation).

All standing trees in the experimental plantations were measured wood hardness with a Pilodyn 6J device (

Table 2). Wood hardness was taken as the representative traits for wood quality in tree genetic plasticity studies. Phenotypic plasticity was evaluated by the Shukla [

19] method and by calculating the ecovalences of the families and their statistical significance.

The number of measured trees per family per test was calculated to determine the average number of trees per genetic family. The adjusted sum of mean squares of a feature was calculated for each family using the SAS procedure MEANS. The total sum of mean squares was calculated as well. The Shukla ecovalence coefficient was calculated according to the following equation (1).

here,

– number of families,

- the sum of mean squares of the trait,

- the total sum of mean squares of the trait, and

- number of tests.

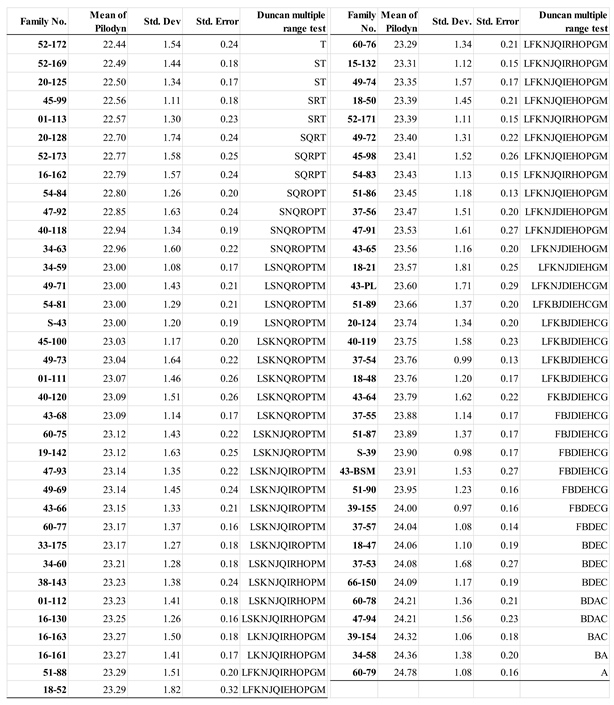

For the evaluation of wood mechanical properties, four representative half-sib families were selected by wood hardness trait of standing trees. The genetic families with not less than 30 remaining standing trees were selected. The ANOVA Duncan multiple range test was used for all selected families to ensure the significant differences between the genetic families with the hardest and softest wood. Two genetic families were selected following such principles: (1) one family with the lowest mean values of wood hardness represented the hardest wood, and one family with the highest wood hardness values to represented the softest wood; (2) one family was chosen to represent the non-plastic genetic family and one family represented the plastic genetic family, calculated by the Shukla ecovalence coefficient (

Table 2).

Table 2.

Distribution of silver birch genetic families by wood hardness measured by Pilodyn 6J. Different letters mean the significant difference between parameters by ANOVA Duncan multiple ranges at a significant level p<0.05.

Table 2.

Distribution of silver birch genetic families by wood hardness measured by Pilodyn 6J. Different letters mean the significant difference between parameters by ANOVA Duncan multiple ranges at a significant level p<0.05.

The genetic family 52-172 was identified as the family with the hardest wood, and the family 60-79 - with the softest wood (

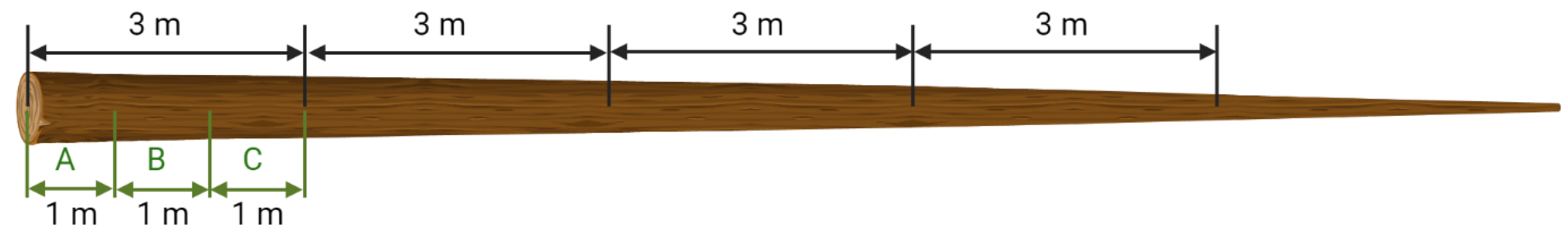

Table 2). Genetic family 51-88 was selected as representative of the non-plastic family , and family 49-69 – as representative of the plastic genetic family. According to the mentioned parameters, three model trees were selected per each genetic family in the experimental plot. The selected trees were cut and transported to the laboratory. Altogether, 24 trees were cut, 12 were sampled in Kaunas and 12 in Šiauliai experimental areas. The model tree stems were sorted into 3-meter logs across the length of the stem. Three to four representative sections were taken from each tree stem for wood mechanical properties determination. In the laboratory, 3-meter logs were divided into 1-meter sections, as shown in

Figure 1.

For each 1-meter section, the wood hardness was measured with a Pilodyn 6J device at three points (

Figure 2).

Wood samples of 50×50×1000 mm were cut from the logs. Altogether, 520 wood samples were prepared. For wood samples, wood hardness at four points, dynamic modulus of elasticity (MOEdyn), static modulus of elasticity (MOE) and bending strength (MOR) were measured.. The wood hardness and MOEdyn test schemes are shown in

Figure 3.

The wood hardness for wood samples was performed with a Pildoyn 6J device. The MOEdyn was measured by multiplying wood density and sound propagation speed according to the equation (2). The sound propagation speed was measured by ARBOTOM 3D acoustic tomography.

here:

MOEdyn - dynamic modulus of elasticity (N mm

-2);

ρ – wood density (kg m

-3);

V – wave propagation speed (m s

-1).

In the laboratory, all wood samples were tested with a Bending Testing Machine 500 kN (FORM+TEST Seidner&Co. GmbH). The tests were done following the methodology given in Standard EN 408:2006 [

20]. The samples were tested in a four-point bending test. The MOE and MOR were evaluated and calculated at 12% moisture content according to Standard EN: 384:2016 [

21]. The static modulus of elasticity was calculated according to equation (3).

here:

F1-F2 – is an increment of load on the straight-line portion of the load deformation curve, 0,2 F

max (

F2) ir 0,4 F

max (

F1), N;

ω2-ω1 – is the increment of deformation corresponding to

F2-F1, mm;

l - span, mm;

a - distance between a loading position and the nearest support, mm;

b - width of cross section, mm;

h - depth of cross section, mm.

A random wood sample was cut from each broken specimen to determine the wood density. The wood density was determined using equation (4).

here:

– wood density, kg m

-3;

– mass of the sample, kg;

– cross-section dimensions of the sample, m;

– length of the sample, m.

To determine wood density, the samples were cut near the breakage point immediately after the bending test. The moisture content was determined by the oven-dry method according to Standard EN: 13183-1:2002 [

22]. The wood density was calculated using the mass/volume ratio according to the equation (5). The values at 12% moisture content were calculated according to Standard EN 384:2016 [

21].

here:

W – moisture content, %;

m – wet sample mass, g;

m0 – dry sample mass, g.

The statistical analysis of ANOVA and correlations were performed with SAS 9.4. statistical program.

3. Results

The main values of the tree diameter at breast height (DBH), tree height, log hardness, sample hardness, wood moisture, wood density, dynamic modulus of elasticity (MOEdyn), static modulus of elasticity (MOE) and bending strength (MOR) of silver birch of different genetic families are summarized in

Table 3. Mean tree DBH of model trees varied in a range from 16.2 cm in the birch genetic family representing the soft-wood to 18.5 cm in the non-plastic genetic family. The mean height of model trees ranged from 17.0 m to 20.0 m, the tree with the largest height of 22.3 m was found in the genetic family with hard wood and the lowest height tree of 14.5 m was found in the non-plastic genetic family. The mean log hardness values between genetic families varied slightly from 17.0 mm to 18.7 mm.

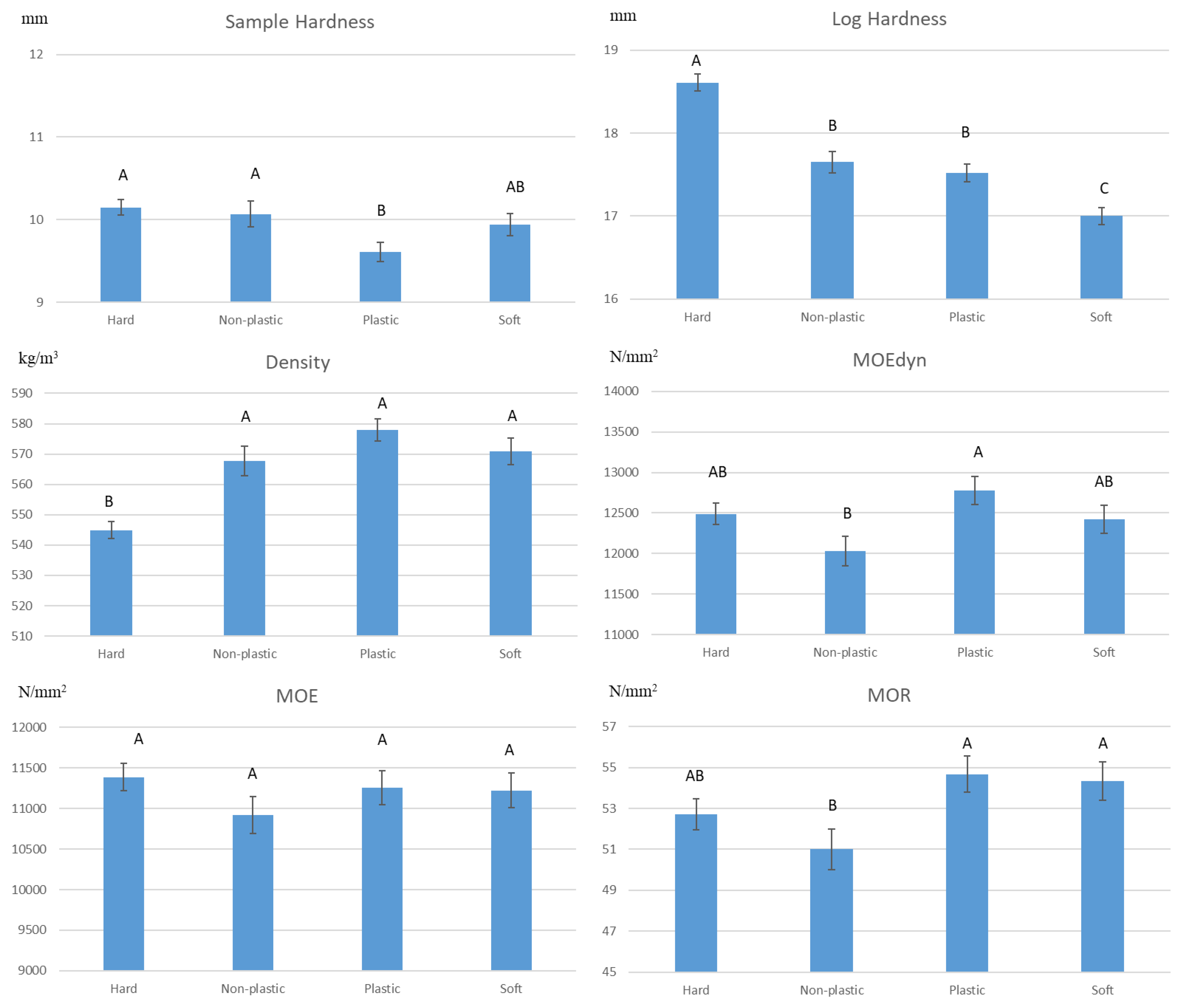

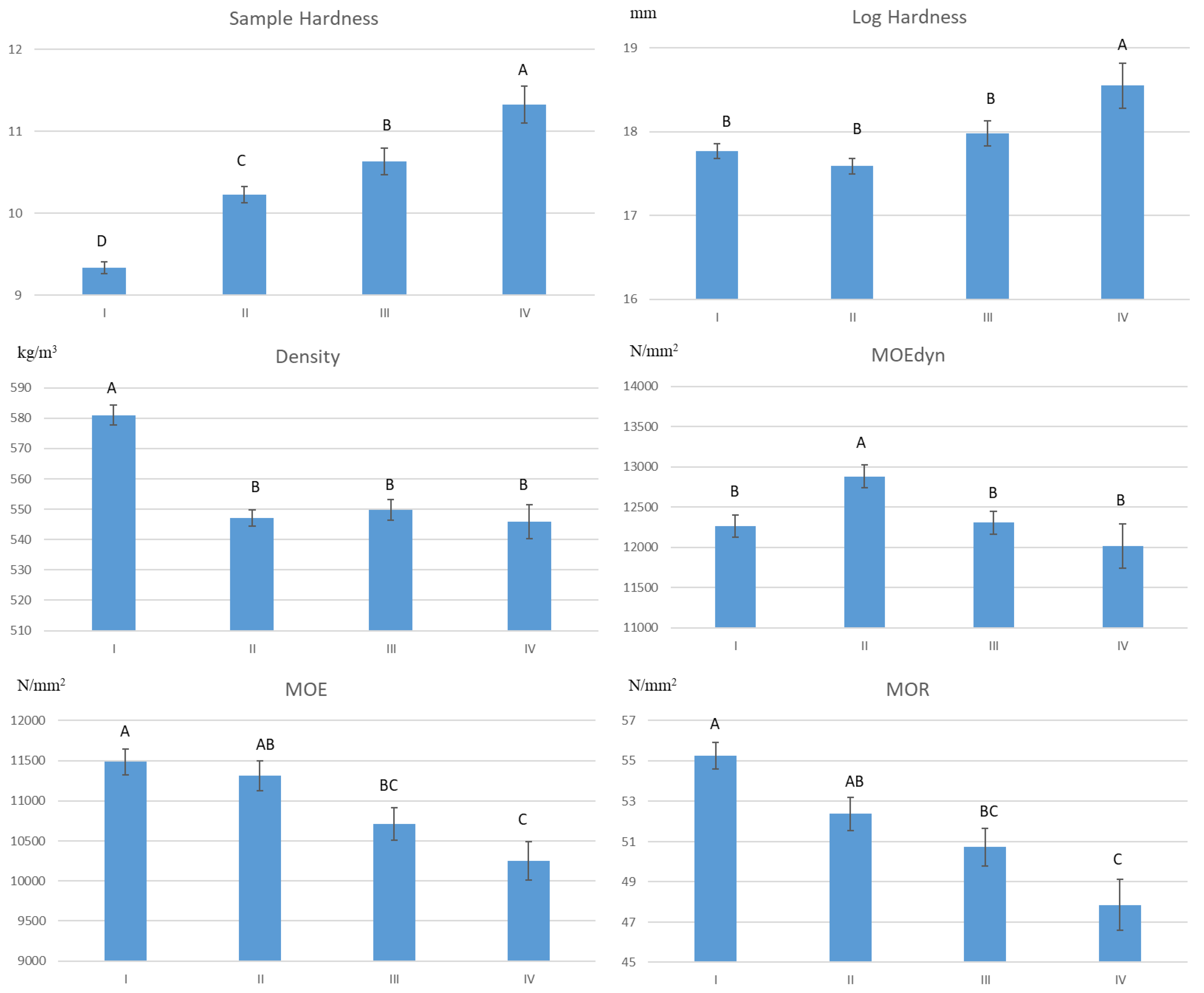

The variation of the sample hardness, wood density, MOEdyn, MOE, and MOR in relation to the genetic families is given in

Table 3 and

Figure 4. The highest sample hardness value was found in the plastic genetic family (15.5 mm), and the lowest value of sample hardness was found in the genetic family with the soft-wood (14.0 mm). The mean values of wood hardness in the samples were similar for all genetic families and varied from 9.6 mm to 10.2 mm. The mean moisture content of the samples was 9.6 %. The mean wood density ranged between 545 to 578 kg/m

3. The differences between mean MOEdyn in the studied genetic families varied in a narrow range from 12028 N/mm

2 (for non-plastic family) to 12776 N/mm

2 (for plastic family). The highest mean values of MOR were found for the plastic family, and the lowest mean values – for the non-plastic family with 6.7% difference between the genetic families. The mean MOE ranged from 10916 N/mm

2 to 11386 N/mm

2 between the genetic families.

The significantly lowest mean sample hardness was found for the plastic genetic family compared to other genetic families (

Figure 4). For the log hardness, the genetic families representing the soft-wood and hard-wood significant differedby 9%. The lowest mean wood density was found for the genetic family representing the hard-wood and this value significantly differed from other genetic families. The MOEdyn significantly differed between the plastic and non-plastic genetic families. The MOE was similar in all studied genetic families and the MOR in the non-plastic genetic family was significantly lower than in other genetic families (

Figure 4).

The wood mechanical properties of different tree stem sections are shown in

Figure 5. Analysis of the hardness of the wood sample revealed that there was a large difference between the stem sections: the hardest wood samples were in the Ist stem section. This parameter decreased significantly from the stem bottom to the top, and the diffeence between the stem sections I and IV was about 18%. The log hardness showed significant difference between the stem sections I-III and IV. The highest mean wood density was found in the stem bottom section. There were no significant differences in wood density between other stem sections. The highest mean MEOdyn was found the II stem section. The MOE and MOR showed a decreased trend from section I to section IV, which was 11% for MOE and 13% for MOR.

To compare the relations between tree and wood parameters, the Pearson correlations were analysed (

Table 4).

The strongest correlation was found between the MOE and MOR parameters (r=0.86) (

Table 4). Wood density significantly correlated with all selected parameters. The MOEdyn correlated with the MOE (r=0.48) and the MOR (r=0.41). The sample hardness strongly correlated with the wood density (r=-0.67). The Tree DBH correlated with the log hardness (r=0.36) and the sample hardness (r=-0.15). However, the wood density had weak correlations with MOEdyn (r=0.19), MOE (r=0.18) and MOR (r=0.09). Most of the evaluated parameters showed low or moderate correlations.

4. Discussion

The study results demonstrated tree genetic effect on wood qualityparameters sample and log hardness, wood density, dynamic modulus of elasticity (MOEdyn), static modulus of elasticity (MOE) and bending strength (MOR). The findings of this study showed that different half-sib families caused various responses on wood quality characteristics of Silver birch trees. Previous studies, for example that conducted in Sweden, also showed high variation in wood hardness - from 8.3 to 24.1 mm - for Silver birch standing trees [

23]. This is an even larger variation in wood hardness compared to our study log hardness parameters. These differences may be due to different tree age and specific growing conditions. Another study in Sweden showed similar mean wood hardness parameters to our study (17.4 mm) for standing trees obtained with a Pilodyn instrument for silver birch [

24].

There was a wide range of wood density parameters in the genetic progeny test plots, as shown in the Swedish studies, where average wood density values ranged from 408 to 444 kg/m

3. [

23,

24]. The wood density determined during the genetic studies in Sweden was 21-28% lower than the data from the genetic research in Lithuania. These differencies could be caused by different genetic material of trees and specific growing conditions. Other studies conducted in the 30-year-old Silver birch stands in different regions of Poland showed higher mean wood density values, which were 512 kg/m

3. Mean values of wood density have been found to increase with age, and 70-year-old trees have higher wood density than 30-year-old trees [

25].The results obtained in Poland reflect the distribution of wood density between different tree parts found in our study. Previous studies in Wales and Scotland (UK) also showed a significant effect of wood density on silver birch growth rate, with faster growing trees having significantly lower wood density compared to slow growing trees [

26]. Relationship between wood hardness and nondestructive wood quality parameter - acoustic velocity - was different in different Swedish studies. Positive relatively weak relationship was found in Jones et al. [

23] study with r values of 0.09 and 0.16. Later studies by Jones et al. [

24] showed negative correlation between the acoustic velocity and wood hardness (r=-0.18). Our study results showed negative correlation between MOEdyn calculated by acoustic velocity and wood density values with log (r=-0.20) and sample hardness (r=-0.25). Correlation in both Sweden studies showed moderate relationship between the wood hardness and wood density [

23,

24]. Similar trends were found in our study for Lithuania genetic trials. The relationship between different locations and different stand age in Sweden varied from r=-0.36 to r=-0.62.

Analysing the MOE and MOR parameters for Silver birch in Finland, the MOE was 13620 N/mm

2 and the MOR was 43,9 N/mm

2 for the wood samples with knots. Higher values were found for wood samples without knots, when the MOE was 16530 N/mm

2 and the MOR – 52.7 N/mm

2 [

27]. The mentioned study found strong correlation between MOE and MOR for all tested samples (r=0.87). In comparison to Finlad study, our results showed lower mean values for MOE and MOR of Silver birch but similar correlation between these two parameters. The lower MOE and MOR mean values in Lithuania could be caused by young tree age and measured samples from full tree height, because of high variation of wood parameters within tree. From our study results, it is clear that MOE and MOR values decreaced from tree bottom to tree top. The decreace in MOE values was found in the Silver birch stands with different growing rates in Wales and Scotland [

26]. This study showed that the mean MOE in slow grown stand was 12668 N/mm

2 and in fast grown stand 8108 N/mm

2.

The wood density - one of the main wood quality parameters - moderately strongly correlated with the MOE (r=0.67) and the MOR (r=0.66) parameters in the Finland study [

27]. Erlier study in Sweden show stronger correlations between wood density and MOE (r=0.85) [

28]. Other study from China and USA found strong correlation between the wood density and the MOE obtained using SilviScan [

29]. The authors found that the relationship between the wood density and MOE was r=0.85 for 10 different hardwood species [

29]. Our study showed weak corelation between the wood density with MOE and MOR. The relations between the mentioned parameters could be improved by increasing the number of model trees and more diverse tree age of the samples. The different results of this study may have been due to some limitations, one of which is the limited selection of model trees, as genetic trials are very valuable for genetic selection and genetic studies, and strictly regulated selection of only specific trees were alowed to use for this study. Due to limited selection of the model trees, all tree parts (sections) were taken in this study. Under these conditions, some wood quality parameters may be lower due to a certain proportion of samples from the tree top, which contain larger amount of juvenile wood, which may decrease the wood quality parameters. Different site conditions in the Silver birch genetic trials in Lithuania could also be taken as limitation of this study. Additional research is needed in the future and it is necessary to measure more model trees and more half-sib families in the future after next generation gentic trials for Silver birch would be established in Lithuania.

5. Conclusions

In this investigation, the aim was to assess the wood mechanical properties between half-sib families of Silver birch and to analyze the relationship between the wood hardness parameter and other wood properties. This study has identified high variability of different wood properties between different genetic families, although static modulus of elasticity did not show significant differences between the selected genetic families. All measured wood properties decreased from tree bottom to top of the model trees.

The wood hardness showed moderately negative correlation with wood density, and weak correlations with static modulus of elasticity and bending strength. Due to weak correlations between wood hardness and other wood mechanical properties, it is likely that dynamic modulus of elasticity would be a more appropriate trait for genetic studies. Further efforts are needed to obtain more accurate results by studying a larger number of model trees.

Author Contributions

Conceptualization, B.Š., V.B. and I.V.-K.; Formal analysis, B.Š. and I.V.-K.; Investigation, B.Š., I.V.-K., M.A., L.B., and M.Š; Methodology, B.Š., V.B., L.B., I.V.-K., and M.A.; Software, B.Š.; Supervision, B.Š. and I.V.-K.; Writing—original draft preparation, B.Š., L.B. and I.V.-K.; writing—review and editing, M.A., L.B., V.B. and M.Š. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded through the Research Council of Lithuania Postdoctoral project ID: S-PD-22-35. Silver Birch (Betula pendula Roth.) and black alder (Alnus glutinosa (L.) Gaertn) different plasticity half-sib families mechanical wood properties.

Acknowledgments

The paper presents the findings obtained through the Research Council of Lithuania Postdoctoral project ID: S-PD-22-35. Silver Birch (Betula pendula Roth.) and black alder (Alnus glutinosa (L.) Gaertn) different plasticity half-sib families mechanical wood properties.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ministry of Environment, State Forest Service. Lithuanian Statistical Yearbook of Forestry; Dagilius, R., Eigirdas, M., Kuliešis, A., Vižlenskas, D., Eds.; Lutute: Kaunas, Lithuania, 2021; p. 184. ISSN 1648-8008. [Google Scholar]

- Baliuckienė, A.; Baliuckas, V. Genetic variability of silver birch (Betula pendula L.) wood hardness in progeny testing at juvenile age. Balt For. 2007, 12, 134–140. [Google Scholar]

- Cown, D.J. Comparison of the Pilodyn and torsiometer methods for the rapid assessment of wood density in living trees. N. Z. J. For. Sci 1978, 8, 384–391. [Google Scholar]

- Høibø, O.; Vestøl, G.I.; Fischer, C.; Fjeld, L.; Øvrum, A. Bending properties and strength grading of Norway spruce: Variation within and between stands. Can. J. Forest Res. 2014, 44, 128–135. [Google Scholar] [CrossRef]

- Ruso, D.; Marziliano, P.A.; Macri, G.; Proto, A.R.; Zimbalatti, G.; Lombardi, F. Does Thinning Intensity Affect Wood Quality? An Analysis of Calabrian Pine in Southern Italy Using a Non-Destructive Acoustic Method. Forests 2019, 10, 303. [Google Scholar] [CrossRef]

- Machado, J.S.; Louzada, J.L.; Santos, A.J.A.; Nunes, L.; Anjos, O.; Rodrigues, J.; Simões, R.M.S.; Pereira, H. Variation of wood density and mechanical properties of blackwood (Acacia Melanoxylon R. Br.). Mater. Des. 2014, 56, 975–980. [Google Scholar] [CrossRef]

- Moreno-Fernández, D.; Hevia, A.; Majada, J.; Cañellas, I. Do Common Silvicultural Treatments Affect Wood Density of Mediterranean Montane Pines? Forests 2018, 9, 80. [Google Scholar] [CrossRef]

- Kollmann, F.F.P.; Côté, W.A. Principles of wood science and technology: I. Solid wood; Springer: Berlin, Heidelberg, Germany, 1968; p. 592. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Wood handbook: Wood as an engineering material. General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 2010; p. 508. [Google Scholar]

- Savolainen, O.; Pyhäjärvi, T.; Knürr, T. Gene flow and local adaptation in trees. Annu Rev Ecol Evol Syst 2007, 38, 595–619. [Google Scholar] [CrossRef]

- Kärkkäinen, K.; Savolainen, O.; Koski, V. Local adaptation in a changing world: the roles of gene-flow, mutation, and sexual reproduction. Evol. Appl. 2015, 8, 635–655. [Google Scholar] [CrossRef]

- Verkasalo, E.; Leban, J.M. MOE and MOR in static bending of small clear specimens of Scots pine, Norway spurce and European fir from Finland and France and their prediction for the comparison of wood quality. Pap. Puu-Pap Tim. 2002, 84, 332–340. [Google Scholar]

- Hautamäki, S.; Kilpeläinen, H.; Verkasalo, E. Factors and Model for Bending Properties of Sawn Timber from Finland and North-Western Russia. Part I: Norway Spruce. Balt For 2013, 19, 106–119. [Google Scholar]

- Hautamäki, S.; Kilpeläinen, H.; Verkasalo, E. Factors and Model for Bending Properties of Sawn Timber from Finland and North-Western Russia. Part II: Scots Pine. Balt For 2014, 20, 142–156. [Google Scholar]

- Šilinskas, B.; Varnagirytė-Kabašinskienė, I.; Aleinikovas, M.; Beniušienė, L.; Aleinikovienė, J.; Škėma, M. Scots Pine and Norway Spruce Wood Properties at Sites with Different Stand Densities. Forests 2020, 11, 587. [Google Scholar] [CrossRef]

- European Commission. New EU Forest Strategy for 2030. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, COM(2021) 572 Final; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- European Commission. The European Green Deal. COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Vaičys, M.; Karazija, S.; Kuliešis, A.; Rutkauskas, A. Miškų Augavietės [Forest Sites]; Lutute: Kaunas, Lithuania, 2006; p. 95. (In Lithuanian) [Google Scholar]

- Shukla, G.K. Some statistical aspects of partitioning genotype–environment components of variability. Heredity 1972, 29, 237–245. [Google Scholar] [CrossRef] [PubMed]

- EN 408:2006. Timber Structures. Structural Timber and Glued Laminated Timber—Determination of some Physical and Mechanical Properties; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- EN 384:2016. Structural timber. Determination of Characteristic Values of Mechanical Properties and Density; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- EN 13183-1:2002. Moisture Content of a Piece of Sawn Timber. Part 1: Determination by Oven Dry Method; European Committee of Standardization: Brussels, Belgium, 2002. [Google Scholar]

- Jones, G.; Liziniewicz, M.; Adamopoulos, S.; Lindeberg, J. Genetic parameters of stem and wood traits in full-sib silver birch families. Forests 2021, 12, 159. [Google Scholar] [CrossRef]

- Jones, G.; Liziniewicz, M.; Lindeberg, J.; Adamopoulos, S. Non-destructive evaluation of downy and silver birch wood quality and stem features from a progeny trial in Southern Sweden. Forests 2023, 14, 2031. [Google Scholar] [CrossRef]

- Lachowicz, H.; Bieniasz, A.; Wojtan, R. Variability in the basic density of silver birch wood in Poland. Silva Fenn 2019, 53, 9968. [Google Scholar] [CrossRef]

- Dunham, R.A.; Cameron, A.D.; Petty, J.A. The effect of growth rate on the strength properties of sawn beams of silver birch (Betula pendula Roth). Scand J For Res 1999, 14, 18–26. [Google Scholar] [CrossRef]

- Collins, S.; Fink, G. Mechanical behaviour of sawn timber of silver birch under compression loading. Wood Mater Sci Eng 2022, 17, 121–128. [Google Scholar] [CrossRef]

- Johansson, M.; Säll, H.; Lundqvist, S.O. Properties of materials from Birch–Variations and relationships: Part 2. Mechanical and physical properties. Department of building and energy technology, Linnaeus University: Växjö, Sweden, 2013, p. 43.

- Wu, Y.; Wang, S.; Zhou, D.; Xing, C.; Zhang, Y. Use of nanoindentation and silviscan to determine the mechanical properties of 10 hardwood species. Wood Fiber Sci. 2009, 41, 64–73. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).