Among the organic electrically conductive materials, polyacetylene (i.e., -[CH]

n-) has been the first intrinsically conductive polymer to be developed. Initially, only the cis- and trans-isomers with undoped conductivity values of respectively 10

-11 and 10

-6 ohm·cm

-1 were studied. In the first synthesis scheme, polyacetylene (PA) was obtained by Zielgler-Natta polymerization of acetylene [

1]. In particular, a polymeric film resulted on the surface of the glass reactor by exposing the acetylene gas to a titanium salt catalyst. Nowadays, several chain and step polymerization methods for the PA synthesis are known (e.g., ring-opening metathesis polymerization from precursor, reverse Diels-Alder reaction processes, modified-Ziegler homogeneous, radiation polymerization) [

1]. Other less used approaches for the PA synthesis are the dehydroalogenation of polymers [

2] and polyvinyl alcohol (PVOH) thermal-dehydration [3-5]. The dehydrochlorination of poly(vinyl chloride) by treatment with a very strong base (e.g., t-BuO

-K

+) in a polar medium has been the first example of methods based on reducing a plastic precursor, however this elimination reaction never reaches completion and hence it is unsuitable for producing a highly electrically-conductive material. Differently, the PVOH thermal-dehydration for PA films synthesis [

3,

4] has shown great technological potentialities because it leads to a high conversion yield.

We have found that extended polyenic groups, (-CH=CH-CH=CH-)n, are generated in polyvinyl alcohol (PVOH) molecules by exposing this polymer to a very common chemical-dehydrating agent, known as absolute sulfuric acid (H2SO4). If this chemical-dehydration treatment is prolonged for enough time, even whole PA molecules (i.e., -[CH=CH]n-) can be obtained reacting the precursor polymer at room temperature. To the best of our knowledge, such an easy and very effective reaction scheme for PVOH conversion to PA, based on chemical-dehydration of the precursor polymer by H2SO4, has never been described in the literature. A great potentiality of the proposed approach is the possibility to control the conversion degree of this heterogeneous reaction and to stop the process of solid PVOH reduction to PA at a desired conversion degree.

At quite high concentrations, sulfuric acid contains a small percentage of sulfuric anhydride (SO

3) and this

in situ generated chemical specie results an extremely strong dehydrating agent. As well known, absolute sulfuric acid is capable to act on alcohols and polyols at 140-180°C for generating olefinic and polyene groups [

6]; also carbohydrates are readily converted to carbon materials by dehydration with absolute sulfuric acid at room temperature [

7]. Similarly, sulfuric acid can act on the hydroxyl groups present in the linear PVOH molecules for generating extended polyenic groups in the molecular chain and even whole PA molecules. In this case, an hydrocarbon is obtained instead of a carbon material because PVOH has an hydrogen content higher than carbohydrates; indeed, one H

2O molecule per each carbon atom is contained in carbohydrates (carbohydrate formula: C

m(H

2O)

n, with m=n or very close) and therefore elemental carbon results by their dehydration. Concerning the exact chemical specie acting as dehydrating agent in these reduction processes, a compound named pyrosulfuric acid (H

2SO

4.xSO

3) and also known as disulfuric acid (ySO

3.H

2O) is present in highly concentrated sulfuric acid. Differently, dilute or mildly concentrated H

2SO

4 aqueous solutions do not contain sulfuric anhydride (SO

3) and consequently these solutions do not cause PVOH dehydration but only a mild chemical cross-linking process with condensated sulfate bridge formation [

8].

When the PVOH semi-crystalline powder (Aldrich, MW=89,000-98,000, 99+% hydrolyzed) was dispersed into pure H2SO4 (J.T. Baker, 95-97%) at room temperature, the dehydration reaction took place immediately, according to the white powder color change to brown/black. However, in order to simplify the reduced polymer removal from the very aggressive liquid medium at dehydration process end, this heterogeneous reaction was preferentially performed by reacting PVOH in form of films. Indeed, in this case, the reduced film can be mechanically separated from the liquid phase simply by using a plastic sieve. In particular, PVOH films with the desired thickness (ca. 0.5mm) were prepared by solution-casting technique. The PVOH powder was dissolved in boiling distilled water and the obtained stable aqueous solution was cast in a Petri dish. After water evaporation, the achieved films were cut in small pieces and successively dried in oven (3h at 60°C). During the heterogeneous reaction, with polymeric films dipped in H2SO4 without stirring, the formation of extended polyenic groups in PVOH caused a slow darkening of the initially transparent and colorless films. In particular, the films were swollen by sulfuric acid and became first brown and then reddish-black colored. Such darkening process can be attributed to the formation of chromophoric groups in the PVOH films with nonselective absorption in visible spectral region. Chromophores consisted of conjugated carbon-carbon double bonds and isolated olefinic groups in the macromolecular system. When the dark films were removed from the reaction medium, they had a gel consistency for the significant swelling due to the adsorbed sulfuric acid.

At beginning of the chemical dehydration process, the brown colored PVOH films resulted also slightly fluorescent, with a blue emission, when observed under the UV-light of a mercury-vapor lamp (TLC lamp, 365nm). Such fluorescence phenomenon has been already described in the literature for thermally-dehydrated PVOH films [

9] and it could be ascribed to the formation of isolated and slightly-conjugated carbon-carbon double bonds (i.e., dienes, trienes, etc.).

In a typical preparation, after one week at room temperature, the PVOH film swollen by H

2SO

4 was mechanically removed from the polyene/H

2SO

4 liquid system and, in order to completely remove sulfuric acid from the film, it was washed repeatedly first by distilled water and then by ethanol in presence of ultrasounds. During the reduced film drying in air, a significant volume decrease was observed.

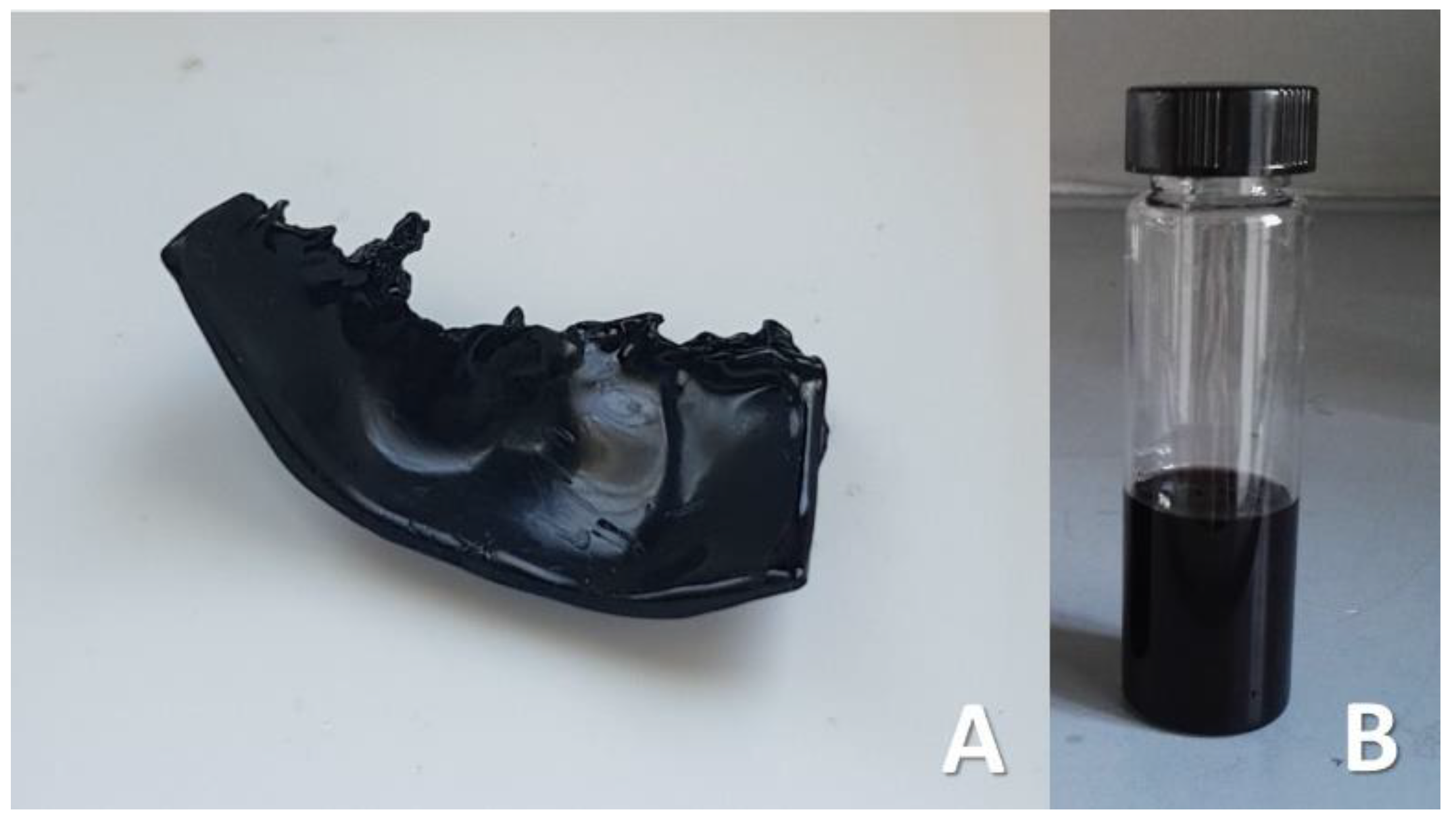

Figure 1a shows a piece of dehydrated PVOH film after these washing and drying treatments. In addition, overtime a little amount of sulfuric acid was released from the solid phase probably because of a progressive crystallization process taking place in the material. The dry reaction product resulted electrically conductive (it behaved as a highly resistive solid material, as tested by a LCR meter, UT612, Uni-Trend, China) and had a brittle consistency. Such a behaviour should suggest the presence of trans-PA as predominant isomeric form in the system.

In addition to PVOH dehydration at solid-state, a small fraction of this polymer (probably low-molecular-weight polymeric molecules and oligomers) were dissolved in the viscous liquid (absolute H

2SO

4), thus leading to a progressively increasing coloration of this liquid phase. Also the liquid reactive medium appeared first reddish-brown and then reddish-black colored. As visible in

Figure 1b, after a few days at room temperature the sulfuric acid appeared black for the presence of reduced oligomers dissolved in the liquid phase. This remaining part of the produced PA can be separated from the reactive medium by diluting it with water. In particular, the reactive medium was added drop-by-drop under magnetic stirring to some distilled water (typically 80ml of liquid medium was dissolved in 300ml of distilled water) and a PA flocculation process was observed. The obtained flocculated polymer suspension was easily separated by filtration under vacuum on paper filter (Whatman 25 filter papers, hydrophilic membrane). In order to completely remove the residual sulfuric acid contained in the separated solid, it was washed repeatedly by distilled water and ethanol and then recovered from the filter by a spatula and dried in air.

Since the synthesized PA is insoluble in all types of organic solvents (e.g., chloroform, acetone, ethanol), its characterization has been carried out at solid state. In particular, the degree of PVOH conversion to polyene molecules was investigated by ATR analysis (PerkinElmer Frontier, FT-IR Spectrometer) of the solid reaction product. This spectroscopical analysis is very sensible to the presence of adsorbed water molecules, which produces a strong and broad signal at 3300cm

-1 and a medium-intensity signal at 1630cm

-1 and these two signals are capable to obscure some important sample absorptions. Therefore, the reaction product was accurately dried before ATR-mode analysis by mildly heating the sample under vacuum at 40°C for 8h and then at 60°C for 3h. The ATR spectrum of the pure dehydrated product is shown in

Figure 2a. The incomplete reduction of the polyalcohol to an unsaturated hydrocarbon is readily noticed because of the presence of residual hydroxyl groups (OH) absorption in this ATR spectrum. Indeed, these groups produce the characteristic intense and broad absorption band due to the O-H stretching vibration, which is centred at 3398cm

-1. Such absorption is accompanied by the small intensity absorption band due to C-O stretching vibration at 1041cm

-1 and a less intensive OH bending vibration band located at 1250cm

-1. The IR resonance at 2934cm

-1 is generated mainly by the terminal methyl groups, that are present also in the PA molecules but also by the stretching of methylene and methine groups bonding the residual hydroxyls. As for the case of -OH stretching, this signal is strongly reduced compared to the case of the pristine PVOH spectrum (see spectra comparison in

Figure 2b). However, the IR spectrum shows also clear evidences of the formation of conjugated olefinic groups. Indeed, the IR spectrum of the dehydration product contains the four main characteristic absorption bands generated by conjugated olefinic groups: the carbon-carbon double bond (C=C) stretching vibration, the C-C single bond stretching vibration, the in-plane and out-of-plane olefinic (vinyl) =C-H bending vibrations [10-16]. In particular, the C=C stretching vibration band appears at a wavenumber of ca. 1632cm

-1 and it is characterized by an absorption of medium intensity. This band extents on a wide spectral region (from ca. 1602cm

-1 to ca. 1705cm

-1) because the conjugation phenomenon variously extends in the linear polymer chains and even isolated C=C are present in these molecules. In particular, the wavenumber of the carbon-carbon double bond absorption band decreases with the extent of conjugation since the bond order (i.e., force) reduces. On the other hand, owing to the same conjugation phenomenon, the C-C single bond stretching absorption appears at higher wavenumber (i.e., 1387cm

-1), with an absorption band of quite high intensity. Very intensive absorption bands are also generated by the in-plane =C-H bending resonance that is visible at 1200 cm

-1 and out-of-plane =C-H bending absorption that is located at 851cm

-1. In general, polyenes might also show a band for the vinyl =C-H bond stretching, which should appear at ca. 3080cm

-1, however in our PA sample such band is probably obscured by the broader absorption bands appearing at ca. 3000cm

-1, that are generated by the stretching vibration of residual hydroxyls. The CH

3- and -CH

2- bending vibrations appear at 1039cm

-1. According to the literature [10-14], the carbon-carbon double bond (C=C) has also a bending vibration, however it is located outside the infrared spectral region we have explored (i.e., below 400cm

-1). According to this IR spectral assignment, the chemically synthesized compound should correspond to a cis-rich PA sample with some residual alcoholic chain portions (PVOH) in its molecule. The produced PA molecular structure should be mostly consisting of cis-PA, also because the cis-alkenes have a non symmetric structure, and therefore they are capable to absorb more strongly than trans-alkenes at 1632cm

-1, as observed in our sample.

The comparison between FT-IR spectra of pristine and dehydrated PVOH, shown in

Figure 2b, clearly evidences as the most intensive absorptions bands of two compounds do not correspond, thus indicating a substantial PVOH chemical transformation. Indeed, the most important signals in the pristine PVOH spectrum that disappear after dehydration are the following: (i) strong and broad absorption band generated by the O-H stretching vibration located at 3277cm

-1; (ii) C-O stretching vibration located at 1088cm

-1; (iii) O-H bending vibration located at 1330cm

-1; (iv) CH

2/CH

3 stretching vibrations located at 2910/2942cm

-1; C-H bending vibration band at 1420cm

-1 [

17]. Therefore, the PVA dehydration process has caused variations in the bands intensity and position and the appearance of completely new absorption bands corresponding mostly to a cis-rich PA sample. Similarly, the PVOH dehydration process produces a radical change in the polymeric material optical properties. Indeed, the perfectly transparent and colorless PVOH film, whose optical absorption spectrum (measured by PerkinElmer, Lambda 850) showed no absorption peak above 250nm (thus indicating the absence of conjugated double bonds as defects in the original sample), acquires a strong absorption band in the visible spectral region after dehydration and this band is centered at ca. 410nm. The observed UV-Vis absorption band corresponds exactly to the optical behavior usually ascribed to PA [

18].

PA is potentially useful as polymer principally for its very good electrical conductivity; however, owing to the insolubility in all organic solvents, this polymer cannot be easily processed, for example, in form of ink to produce coatings films or filaments to be used for technological applications like electrical wires, sensors, electrodes, etc. However, PA could have also a number of non-electrical applications [19-22], where it is used as powder or granular material. For example, owing to the presence of a very large number of carbon-carbon double bonds, PA can be used for drug delivery, as adsorbent for organic substances, oxygen scavenger, hydrogen storage medium (in a transition-metal decorated form), etc. The here described very simple chemical reaction scheme allows to produce high quality PA films or powders to be used for non-electrical applications. In addition, this approach could be used also for reusing a plastic waste; indeed, PVOH is an appealing target for recycling because it is a high-production-volume polymer.

References

- Olabisi, Olagoke, and Kolapo, Adewale, eds. Handbook of thermoplastics. Vol. 41. CRC press, 2016. Cap. 34.

- S.E. Eusyukov, Yu P. Kudryavtsev, Yu V. Korshak, “Chemical dehydroalogenation of halogen-containing polymers”, Russian Chemical Reviews 60(4)(1991)373-390.

- I. Yu. Prosanov, N.F. Uvarov, “Electrical properties of dehydrated polyvinyl alcohol”, Physics of the Solid State 54(2)(2012)421-424.

- I. Yu. Prosanov, A.A. Matvienko, “Study of PVA thermal destruction by means of IR and Raman spectroscopy”, Physics of the Solid State 52(10)(2010)2203-2206.

- I. Yu. Prosanov, A.A. Matvienko, B.B. Bokhonov, “Influence of urea on polyvinyl alcohol molecular superstructure formation”, Physics of the Solid State 53(6)(2011)1302-1306.

- D.J. Ward, D.J. Saccomando, G. Walker, S.M. Mansell, “Sustainable routes to alkenes: applications of homogeneous catalysis to the dehydration of alcohols to alkenes”, Catal. Sci. Technol. 13(9)(2023)2638-2647.

- D.A. Dolson, R. Battino, T.M. Letcher, K.H. Pegel, N. Revaprasadu, “Carbohydrate dehydration demonstration”, J. Chem. Edu. 72(10)(1995)927.

- B.S. Minhas, D.G. Peiffer, J.L. Soto, D.L. Stern, “Process for the recovery of sulfuric acid using polymeric membranes, PTC patent, WO 2004/074811 A2 (2 September 2004).

- J. Yang, P. Li, B. Zhao, K. Pan, J. Deng, “Electrospinning chiral fluorescent nanofibers from helical polyacetylene: preparation and enantioselective recognition ability”, Nanoscale Adv. 2(2020)1301-1308.

- H. Shirakawa, S. Ikeda, “Infrared spectra of poly(acetylene)”, Polymer Journal, 2(2)(1971)231-244.

- F. Cataldo, “A spectroscopic study of polyacetylene prepared by using Rh(I) catalysts”, Polymer 35(24)(1994)5235-5240.

- J.-Y. Kim, J.-T. Kim, M.-H. Kwon, D.-K. Han, S.-J. Kwon, “ATR-infrared spectroscopic study of n-doped polyacetylene films”, Macromolecular Research 15(1)(2007)5-9.

- H.W. Gibson, S. Kaplan, R.A. Mosher, W.M. Prest, R.J. Weagley, “Isomerization of polyacetylene films of the Shirakawa type-spectroscopy and kinetics”, Journal of the American Chemical Society, 108(22)(1986)6843-6851.

- B. Alvarez, A. Sarmiento-Santos, E. Vera-Lopez, “Acetylene polymerization in plasma of direct current” Journal of physics: Conference Series, 1386(2019)012044.

- Huan Li, G. Chen, P.N. Duchesne, P. Zhang, Y. Dai, H. Yang, B. Wu, S. Liu, C. Xu, N. Zheng, “A nanoparticulate polyacetylene-supported Pd(II) catalyst combining the advantages of homogeneous and heterogeneous catalysts”, Chinese Journal of Catalysis 36(2015)1560-1572.

- A. Sarmiento-Santos, J.A. Gomez-Castano, B. Alvarez-Luna, W. Redondo-Lancheros, J. Garcia-Zuniga, “Formation of polyacetylene films on copper substrate by abnormal glow discharge”, Revista UIS Ingenierias 22(3)(2023)189-196.

- N. Jamil, H. Husin, A.W. Alfida, Z. Aman, Z. Assan, “Characterization and preparation of polyvinyl alcohol (PVA) as inhibitor in formation of hydrates”, International Journal of Current Science, Engineering & Technology (2018)578-584.

- W. Zhao, Y. Yamamoto, S. Seki, S. Tagawa, “Formation of conjugated double bonds in poly(vinyl alcohol) film under irradiation with -rays at elevated temperature”, Chemistry Letters (1997)183184.

- H. Lee, W. Ih Choi, J. Jhm, “On hydrogen storage in metal-decorated trans-polyacetylene”, Journal of Alloys and Compounds 446-447(2007)373-375.

- J. Liang, C. Song, J. Deng, “Optically active microspheres constructed by helical substituted polyacetylene and used for absorption of organic compounds in aqueous systems”, ACS Appl. Mater. Interfaces 6(21)(2014)19041-19049.

- M. Chen, G. Hu, T. Shen, H. Zhang, J.Z. Sun, B.Z. Tang, “Applications of polyacetylene derivatives in gas and liquid separation”, Molecules 28(2023)2748.

- H. Li, G. Chen, P.N. Duchesne, P. Zhang, Y. Dai, H. Yang, B. Wu, S. Liu, C. Xu, N. Zheng, “A nanoparticulate polyacetylene-supported Pd(II) catalyst combining the advantages of homogeneous and heterogeneous catalysts”, Chinese Journal of Catalysis 36(2015)1560-1572.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).