Submitted:

02 May 2024

Posted:

03 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Background Context

1.2. The Lignocellulosic Residues from Fruit Industries

| Prunings | A (Mt/y) | B (Mt/y) | C (Mt/y) | D (Mt/y) | E (Mt/y) | F (Mt/y) | G (Mt/y) | H (Mt/y) | Average (Mt/y) |

|---|---|---|---|---|---|---|---|---|---|

| Grape | 2.90 | 1.50 | 1.28 | 1.11 | 1.19 | 1.47 | 1.58 | 0.88 | 1.29±0.23 |

| Olive | 2.40 | 1.20 | 1.14 | 1.07 | 1.15 | 1.34 | 1.43 | 0.80 | 1.16±0.19 |

| Apple | 0.20 | 0.10 | 0.09 | 0.13 | 0.12 | 0.29 | 0.28 | 0.09 | 0.16±0.08 |

| Pear | 0.10 | 0.05 | 0.05 | 0.05 | 0.03 | 0.18 | 0.17 | 0.05 | 0.08±0.05 |

| Peach | 0.20 | 0.10 | 0.16 | 0.19 | 0.14 | 0.46 | 0.42 | 0.15 | 0.23±0.13 |

| Lemon | 0.30 | 0.20 | 0.19 | 0.67* | 0.67* | 0.77* | 0.80* | 0.48 | 0.29±0.13(0.73±0.06)* |

| Almond | 0.20 | 0.10 | 0.15 | 0.12 | 0.12 | 0.22 | 0.12 | 0.09 | 0.13±0.04 |

| Hazelnut | 0.20 | 0.10 | 0.07 | 0.14 | 0.09 | 0.22 | 0.17 | 0.08 | 0.12±0.05 |

| Total | - | - | - | - | - | - | - | - | 3.46±0.37 |

| Table Legend | |||||||||

| Column name | Content and references | ||||||||

| A | Fresh prunings estimated mass by Di Blasi [20] | ||||||||

| B | Dry prunings estimated mass by Di Blasi [20] | ||||||||

| C | Dry prunings estimated mass by ITABIA [19] | ||||||||

| D | Dry prunings estimated mass by CRPA [19] | ||||||||

| E | Dry prunings estimated mass by ANPA ONR [18] | ||||||||

| F | Dry prunings mass including the contribution of the residual biomass at the end of the production cycle. Estimate by CRPA [19] | ||||||||

| G | Dry prunings mass including the contribution of the residual biomass at the end of the production cycle. Estimate by ANPA ONR [18] | ||||||||

| H | Dry residues estimated mass by ITABIA [22] | ||||||||

2. Materials and Methods

3. Results

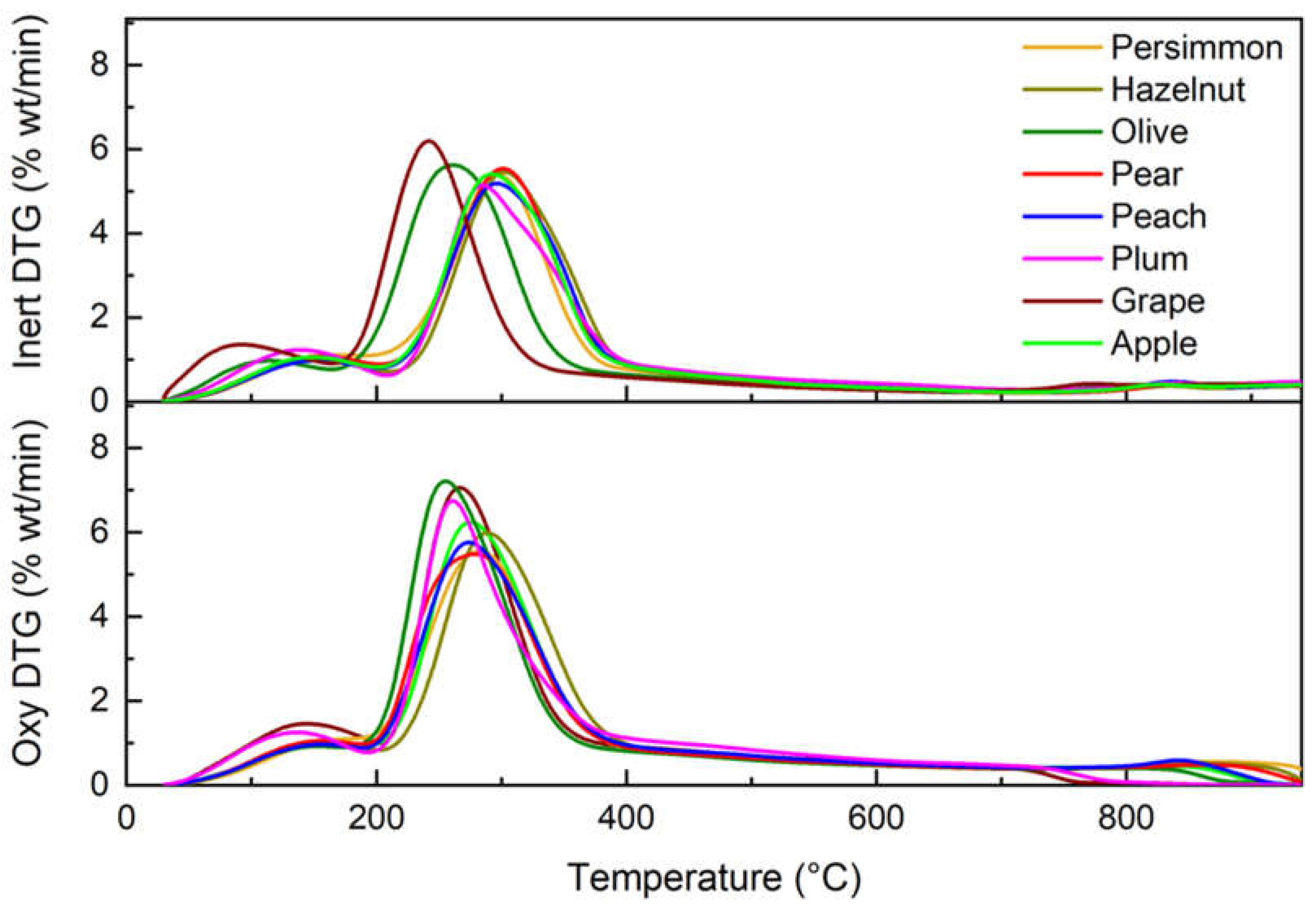

| Inert atmosphere | Oxydant atmosphere | |||||

|---|---|---|---|---|---|---|

| Samples | DTG peak temperature (°C) | DTG max (%/min) | Solid residue char + ash (%) | DTG peak temperature (°C) | DTG max (%/min) | Solid residue ash (%) |

| Pear | 290.1 | 5.82 | 6.06 | 297.2 | 5.54 | 2.42 |

| Persimmon | 283.0 | 5.54 | 8.44 | 290.7 | 5.82 | 2.77 |

| Plum | 276.5 | 5.83 | 1.78 | 254.2 | 8.11 | 1.88 |

| Peach | 286.5 | 5.57 | 5.75 | 264.9 | 6.22 | 2.96 |

| Hazelnut | 297.2 | 5.99 | 6.18 | 274.4 | 6.28 | 2.11 |

| Olive | 264.5 | 5.85 | 3.17 | 242.1 | 7.86 | 1.93 |

| Grape | 243.0 | 7.00 | 2.36 | 278.7 | 7.26 | 2.23 |

| Apple | 279.6 | 5.76 | 4.74 | 258.3 | 6.40 | 2.30 |

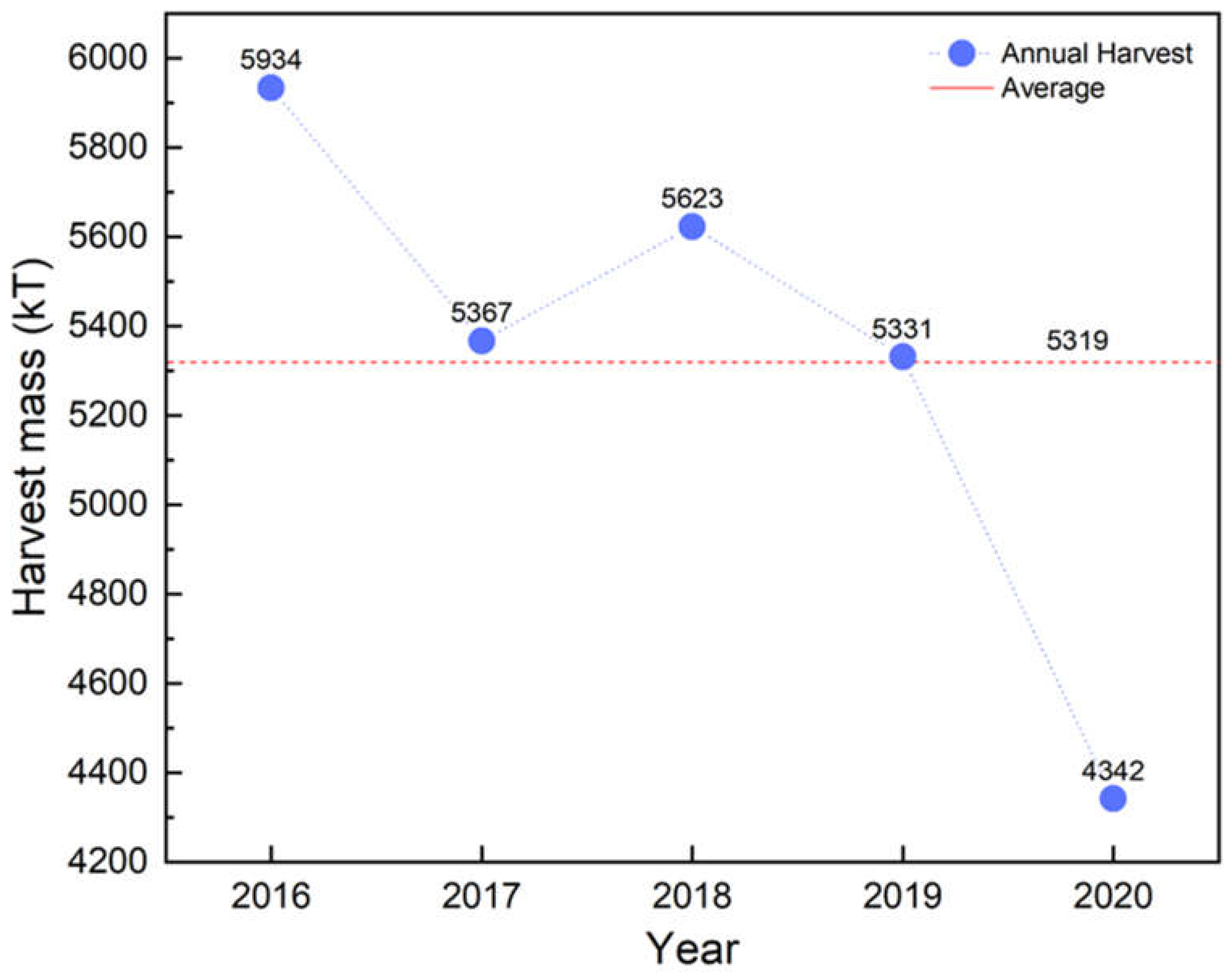

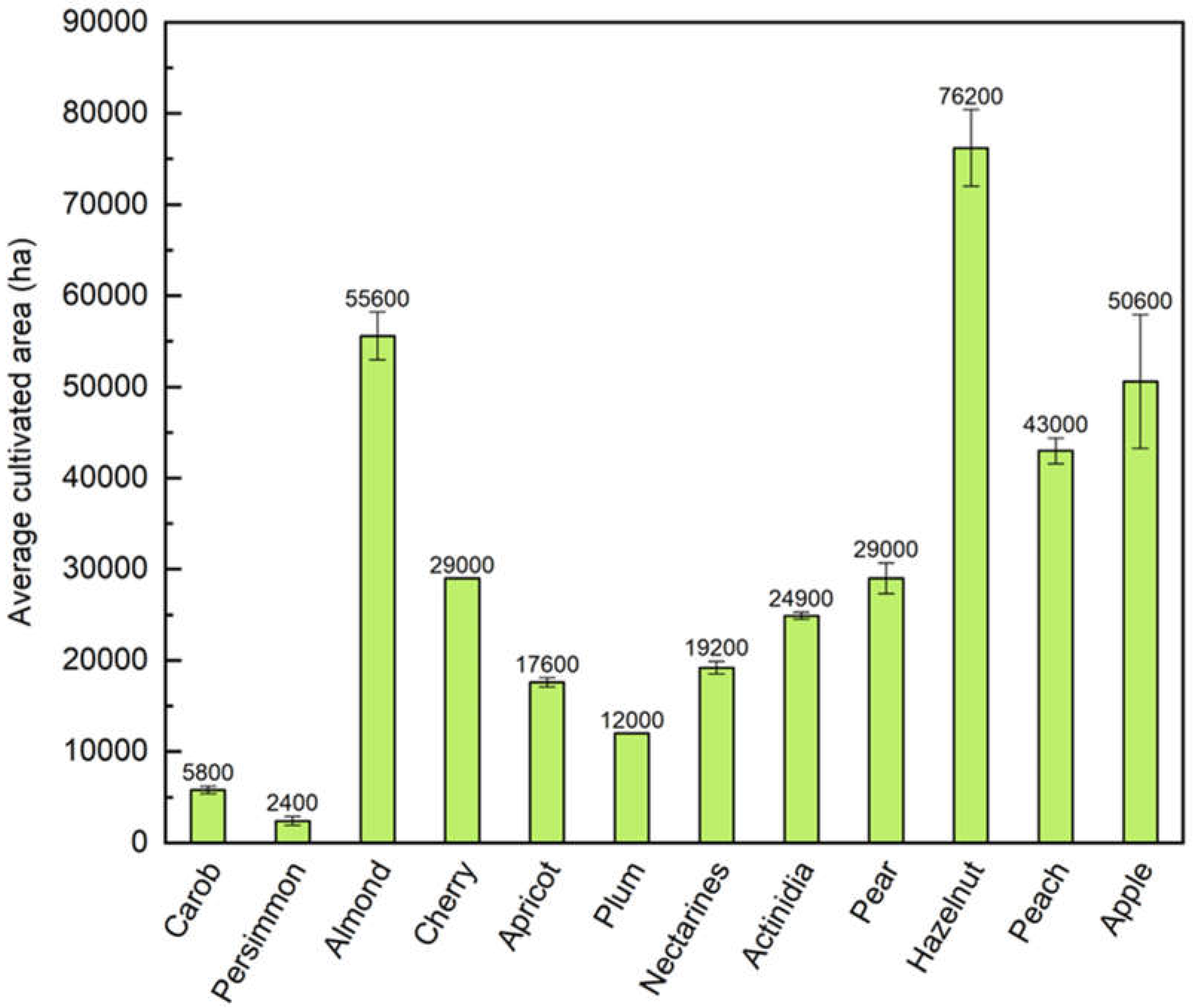

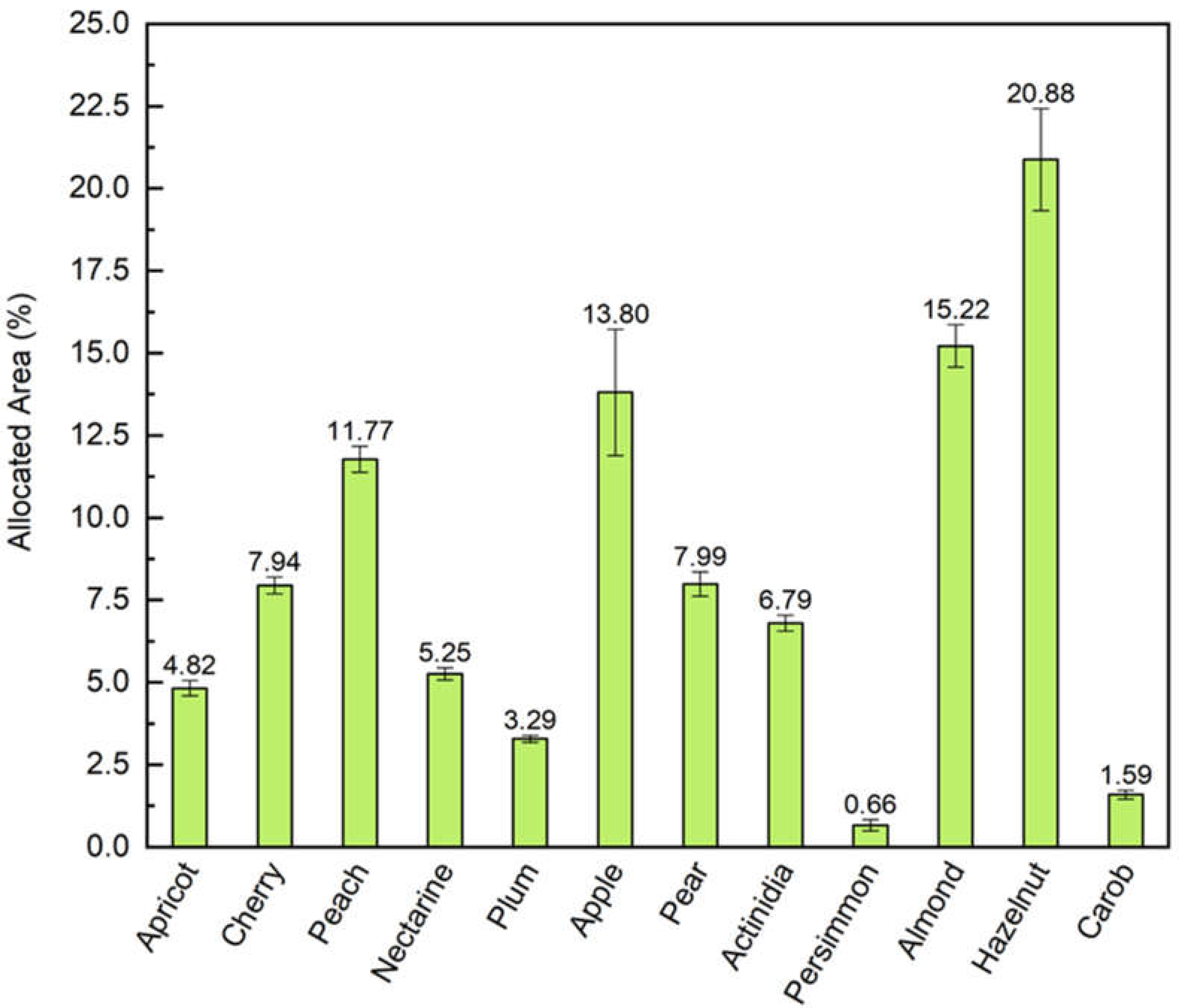

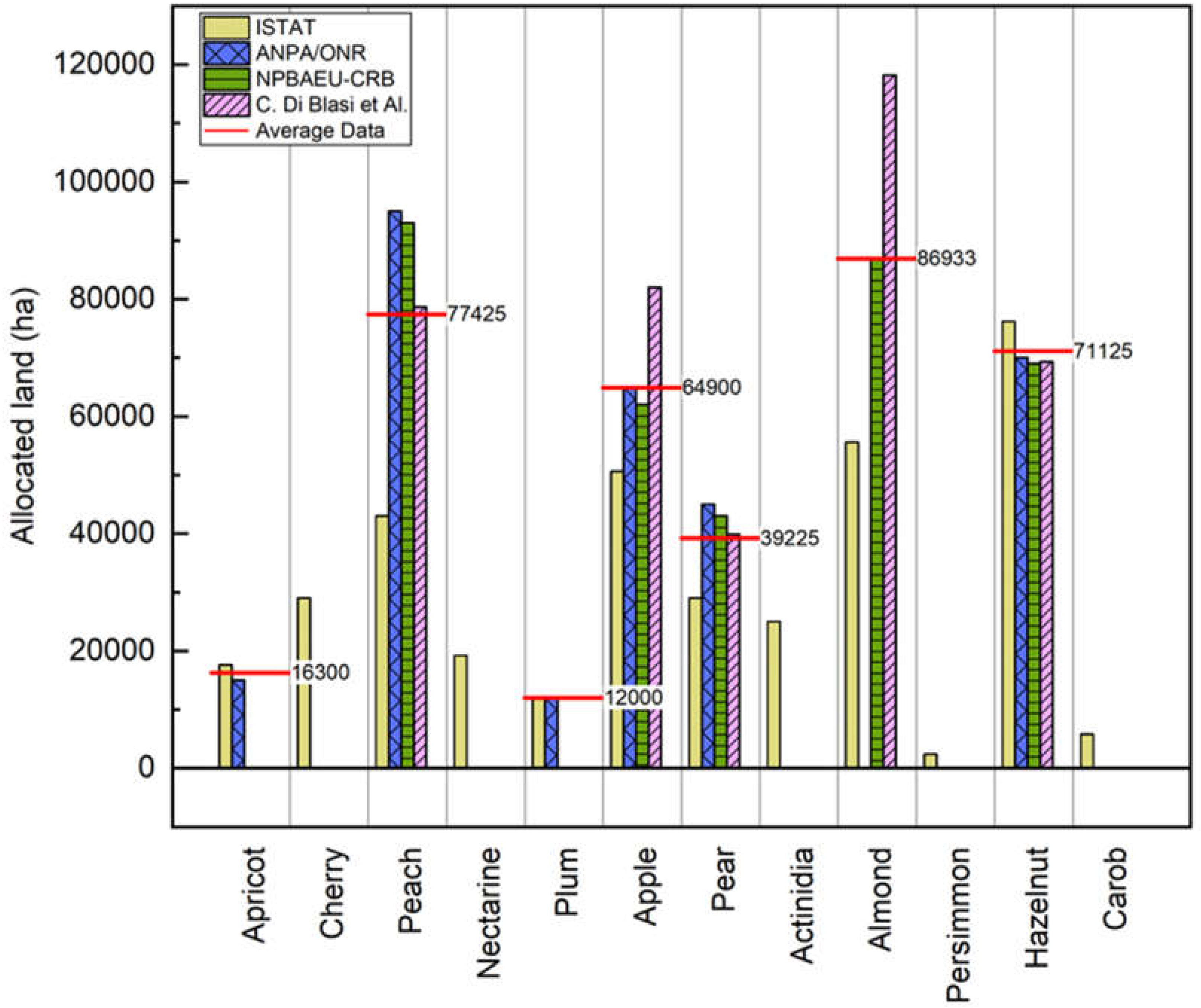

3.1. Estimation of the Potential Energy Production from Orchard Lignocellulosic Residues

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commision (EC) CDA (31-12-2021): “amending Delegated Regulation (EU) 2021/2139 as regards economic activities in certain energy sectors and Delegated Regulation (EU) 2021/2178 as regards specific public disclosures for those economic activities (Text with EEA relevance)”.

- Kaltschmitt, Martin, Wolfgang Streicher, and Andreas Wiese, eds. Renewable energy: technology, economics and environment. Springer Science & Business Media, 2007.

- Field, Christopher B., J. Elliott Campbell, and David B. Lobell. "Biomass energy: the scale of the potential resource." Trends in ecology & evolution 23, no. 2 (2008): 65-72. [CrossRef]

- Kluts, Ingeborg N., Marnix LJ Brinkman, Sierk A. de Jong, and H. Martin Junginger. "Biomass resources: agriculture." Biorefineries (2017): 13-26.

- C. Fideghelli, La frutticultura italiana alla vigilia del terzo decennio degli anni 2000, I Tempi della Terra, n. 9, pp. 22-29, 2021.

- Pari, Luigi, Vincenzo Alfano, Daniel Garcia-Galindo, Alessandro Suardi, and Enrico Santangelo. "Pruning biomass potential in Italy related to crop characteristics, agricultural practices and agro-climatic conditions." Energies 11, no. 6 (2018): 1365. [CrossRef]

- https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/fruit-and-vegetables_en [last access: 24.04.2024].

- LEGGE 13 luglio 1966, n. 615 Provvedimenti contro l'inquinamento atmosferico. G.U. n.201 del 13-08-1966.

- F. Militano, Incendi, emergenza e tutela dell'ambiente, Ali Ribelli Edizioni, 2022.

- S. Amicabile, Manuale di agricoltura. HOEPLI 2016.

- G. Vannacci, Patologia Vegetale, Edises 2021.

- Biomasse ed energia – Caratteristiche tecniche delle biomasse e dei biocombustibili. ENAMA, 2011.

- Ferronato, Navarro, Vincenzo Torretta, Marco Ragazzi, and Elena Cristina Rada. "Waste mismanagement in developing countries: A case study of environmental contamination." UPB Sci. Bull 79, no. 2 (2017): 185-196.

- Verità, Simona, and Luigi Bruzzi. "Biocombustibili ed energia pulita." Biocombustibili ed energia pulita (2013): 0-0.

- Yue, Dajun, Fengqi You, and Seth W. Snyder. "Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges." Computers & Chemical Engineering 66 (2014): 36-56. [CrossRef]

- Grant, Federica, and Laura Rossi. "The Italian observatory on food surplus, recovery, and waste: The development process and future achievements." Frontiers in Nutrition 8 (2022): 787982. [CrossRef]

- Annuario Statistico Italiano, ISTAT, 2021.

- ANPA, I. "rifiuti del comparto agro–alimentare." Studio di settore, Rapporti 11 (2001): 2001.

- Barbanera, Marco, Pietro Bartocci, and Gianluca Cavalaglio. "Documento propedeutico alla redazione del Piano Nazionale Biocarburanti e Biomasse-II Edizione-Aggiornamento 2011." (2011).

- Di Blasi, Colomba, V. Tanzi, and M. Lanzetta. "A study on the production of agricultural residues in Italy." Biomass and Bioenergy 12, no. 5 (1997): 321-331. [CrossRef]

- Gonzalez-Salazar, Miguel Angel, Mirko Morini, Michele Pinelli, Pier Ruggero Spina, Mauro Venturini, Matthias Finkenrath, and Witold-Roger Poganietz. "Methodology for estimating biomass energy potential and its application to Colombia." Applied Energy 136 (2014): 781-796. [CrossRef]

- Flamini, Riccardo. "L’utilizzo dei sottoprodotti della filiera viti-vinicola per la produzione di bioenergie: studio della cellulosa, emicellulosa e Monosaccaridi estraibili dai sarmenti di vite e dalle vinacce per la produzione di bioetanolo di seconda generazione." la valorizzazione dei sottoprodotti nell’ambito agro-zootecnico, industriale ed energetico (2013): 85.

- Zivkovic, Milovan, Mirko Urosevic, Snezana Oljaca, Mico Oljaca, Kosta Gligorevic, Ivan Zlatanovic, and Ranko Koprivica. "Aspects of using potential energy products of biomass after pruning fruit and grape plantations in the Republic of Serbia." Poljoprivreda i Sumarstvo 59, no. 1 (2013): 167.

- https://www.arera.it/it/docs/08/003-08een.htm [last access: 24.04.2024].

- https://www.terna.it/it/sistema-elettrico/statistiche/pubblicazioni-statistiche [last access: 24.04.2024].

- Giannoni, Tommaso, Mattia Gelosia, Alessandro Bertini, Giacomo Fabbrizi, Andrea Nicolini, Valentina Coccia, Paola Iodice, and Gianluca Cavalaglio. “Fractionation of Cynara cardunculus L. by Acidified Organosolv Treatment for the Extraction of Highly Digestible Cellulose and Technical Lignin.” Sustainability 13, no. 16 (2021): 8714. [CrossRef]

- Stolarski, Mariusz Jerzy, Paweł Dudziec, Michał Krzyżaniak, and Ewelina Olba-Zięty. "Solid biomass energy potential as a development opportunity for rural communities." Energies 14, no. 12 (2021): 3398. [CrossRef]

- Monarca, D., M. Cecchini, M. Guerrieri, and A. Colantoni. "Conventional and alternative use of biomasses derived by hazelnut cultivation and processing." In VII International Congress on Hazelnut 845, pp. 627-634. 2008. [CrossRef]

- Bilandzija, Nikola. "Energy potential of fruit tree pruned biomass in Croatia." Spanish Journal of Agricultural Research 10, no. 2 (2012): 292-298. ISSN 1695-971X, ISSN-e 2171-9292.

- Di Giacinto, Simone. "Modello di campionamento per le biomasse residuali: il caso del nocciolo nella provincia di Viterbo. Stima dei quantitativi di potature, caratterizzazione chimica, fisica ed energetica della biomassa e prospettive di utilizzo." (2014).

- Zambon, Ilaria, Fabrizio Colosimo, Danilo Monarca, Massimo Cecchini, Francesco Gallucci, Andrea Rosario Proto, Richard Lord, and Andrea Colantoni. "An innovative agro-forestry supply chain for residual biomass: Physicochemical characterisation of biochar from olive and hazelnut pellets." Energies 9, no. 7 (2016): 526. [CrossRef]

- Velázquez-Martí, Borja, Isabel López-Cortés, Domingo Salazar-Hernández, and Ángel Jesús Callejón-Ferre. "Modeling the calorific value of biomass from fruit trees using elemental analysis data." Biomass Volume Estimation and Valorization for Energy (2017): 271-292. [CrossRef]

- Şenol, Halil. "Biogas potential of hazelnut shells and hazelnut wastes in Giresun City." Biotechnology reports 24 (2019): e00361. [CrossRef]

- Mamaní, Arminda, Yolanda Maturano, Victoria Mestre, Laura Montoro, Liliana Gassa, Cristina Deiana, and Fabiana Sardella. "Valorization of olive tree pruning. Application for energy storage and biofuel production." Industrial Crops and Products 173 (2021): 114082. [CrossRef]

- Yuan, Yufeng, Bo Jiang, Hui Chen, Wenjuan Wu, Shufang Wu, Yongcan Jin, and Huining Xiao. "Recent advances in understanding the effects of lignin structural characteristics on enzymatic hydrolysis." Biotechnology for Biofuels 14 (2021): 1-20. [CrossRef]

- Fabbrizi, Giacomo, Tommaso Giannoni, Leonardo Lorenzi, Andrea Nicolini, Paola Iodice, Valentina Coccia, Gianluca Cavalaglio, and Mattia Gelosia. "High Solid and Low Cellulase Enzymatic Hydrolysis of Cardoon Stems Pretreated by Acidified γ-Valerolactone/Water Solution." Energies 15, no. 7 (2022): 2600. [CrossRef]

- https://dgsaie.mise.gov.it/consumi-petroliferi [last access: 24/04/2024].

- Procentese, Alessandra, Francesca Raganati, Giuseppe Olivieri, Maria Elena Russo, Marco De La Feld, and Antonio Marzocchella. "Agro food wastes and innovative pretreatments to meet biofuel demand in Europe." Chemical Engineering & Technology 42, no. 5 (2019): 954-961. [CrossRef]

- Holmatov, Bunyod, Joep F. Schyns, M. S. Krol, P. W. Gerbens-Leenes, and Arjen Y. Hoekstra. "Can crop residues provide fuel for future transport? Limited global residue bioethanol potentials and large associated land, water and carbon footprints." Renewable and Sustainable Energy Reviews 149 (2021): 111417.

| Proximate analysis (wt.% d.b.) | Ultimate Analysis (wt.% d.b.) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Species | Moisture (%) | Volatile Matter (%) | Fixed Carbon (%) | Ash (%) | Nitrogen content (%) | Carbon content (%) | Hydrogen content (%) | HHV (MJ/kg) | LHV (MJ/kg) |

| Pear | 11.63±0.01 | 76.26±0.04 | 20.24±0.02 | 3.50±0.02 | 0.4±0.2 | 42.9±0.8 | 6.10±0.14 | 18.03±0.05 | 16.8±0.7 |

| Persimmon | 9.87±0.03 | 74.8±0.3 | 20.8±0.2 | 4.4±0.1 | 0.39±0.03 | 42.9±0.6 | 6.10±0.05 | 18.63±0.09 | 17.4±0.7 |

| Plum | 15.40±0.01 | 77.3±0.2 | 19.9±0.2 | 2.82±0.03 | 0.03±0.01 | 41.1±0.7 | 6.3±0.2 | 17.32±0.09 | 16.1±0.5 |

| Peach | 9.30±0.03 | 76.9±0.1 | 18.33±0.08 | 4.71±0.07 | 0.23±0.04 | 42.6±0.6 | 6.05±0.09 | 17.55±0.01 | 16.3±0.6 |

| Hazelnut | 10.39±0.05 | 77.4±0.1 | 20.03±0.07 | 2.59±0.07 | 0.16±0.03 | 43.8±0.8 | 6.1±0.1 | 17.56±0.01 | 16.3±0.6 |

| Olive | 10.75±0.07 | 77.9±0.4 | 19.1±0.4 | 2.99±0.05 | 0.19±0.02 | 42.5±1.1 | 6.3±0.4 | 17.1±0.4 | 15.9±0.2 |

| Grape | 17.83±0.07 | 76.9±0.1 | 19.5±0.1 | 3.65±0.01 | 0.05±0.01 | 40.67±0.05 | 5.34±0.07 | 18.23±0.02 | 17.1±0.5 |

| Apple | 10.23±0.09 | 77.50±0.08 | 18.97±0.07 | 3.53±0.02 | 0.22±0.01 | 43.9±0.3 | 5.85±0.02 | 17.5±0.2 | 16.3±0.4 |

| Species content (mg/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Elements | Apple | Grape | Olive | Hazelnut | Peach | Plum | Persimmon | Pear |

| Cadmium (Cd) | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Chromium (Cr) | 0.5±0.1 | 1.7±0.3 | 0.6±0.2 | 1.1±0.1 | 0.7±0.1 | 1.8±0.2 | 0.4±0.1 | 0.9±0.1 |

| Copper (Cu) | 5.0±0.5 | 197.2±0.6 | 21.2±0.1 | 79.9±0.8 | 5.7±0.2 | 20.0±0.4 | 3.0±0.2 | 4.0±0.9 |

| Nickel (Ni) | 1.1±0.2 | 36.4±0.6 | 2.6±0.1 | 21.2±0.2 | 0.9±0.1 | 1.0±0.3 | 0.9±0.2 | 3.9±0.4 |

| Lead (Pb) | 1.4±0.2 | 0.7±0.1 | 1.8±0.2 | 1.2±0.3 | 0.8±0.3 | 1.2±0.4 | 0.6±0.1 | 0.9±0.2 |

| Zinc (Zn) | 46.0±0.4 | 0.7±0.2 | 13.1±0.3 | 25.4±0.6 | 32.4±0.4 | 51.0±0.7 | 18.1±0.6 | 30.3±0.5 |

| Species | Hemicellulose (%) | Cellulose (%) | Lignin (%) |

|---|---|---|---|

| Pear | 16.45 ± 0.12 | 34.60 ± 0.22 | 19.90 ± 1.21 |

| Persimmon | 14.98 ± 0.14 | 35.55 ± 0.52 | 28.24 ± 0.79 |

| Plum | 16.25 ± 0.15 | 36.73 ± 0.48 | 24.26 ± 1.25 |

| Peach | 12.70 ± 0.07 | 38.38 ± 0.63 | 23.31 ± 2.21 |

| Hazelnut | 16.78 ± 0.09 | 39.88 ± 0.17 | 22.98 ± 1.12 |

| Olive | 15.52 ± 0.16 | 40.00 ± 0.59 | 23.12 ± 0.98 |

| Grape | 12.93 ± 0.24 | 40.33 ± 0.25 | 22.93 ± 1.14 |

| Apple | 13.70 ± 0.14 | 40.90 ± 0.47 | 25.31 ± 1.06 |

| Species | Dry residue mass (Mt/y) | LHV (Mj/kg) | Cellulose Content (%) | Equivalent Electrical Energy (GWh) | Bioethanol (Mt/y) |

|---|---|---|---|---|---|

| Grape | 1.29±0.23 | 17.13 ± 0.54 | 40.33 ± 0.25 | 2823.60±503.4 | 0.20±0.03 |

| Olive | 1.16±0.19 | 15.88 ± 0.20 | 40.00 ± 0.59 | 2353.77±385.5 | 0.18±0.03 |

| Apple | 0.16±0.08 | 16.26 ± 0.37 | 40.90 ± 0.47 | 332.43±166.2 | 0.030±0.015 |

| Pear | 0.08±0.05 | 16.77 ± 0.69 | 34.60 ± 0.22 | 171.43±107.1 | 0.010±0.006 |

| Peach | 0.23±0.13 | 17.38 ± 0.72 | 38.38 ± 0.63 | 510.78±288.7 | 0.030±0.017 |

| Hazelnut | 0.12±0.05 | 16.28 ± 0.63 | 39.88 ± 0.17 | 249.63±104.0 | 0.020±0.008 |

| Total | 3.04±0.34 | 6441.62±731.7 | 0.48±0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).