Submitted:

01 May 2024

Posted:

03 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Phases of a Life Cycle Assessment

- Goal and scope: this is the first and most crucial step, serving as the foundation of the LCA. In this phase, the system boundaries and the functional unit of analysis are defined, including the reasons for conducting the study. This method enables researchers to compare two or more products or systems using a consistent measurement approach. As a result, the functional unit needs to be clearly defined and measurable. System boundaries determine which processes, whether directly or indirectly related to the product or device, are included in the study;

- Life cycle inventory (LCI): data are gathered and stored in this phase. LCI analysis collects data on the materials and energy used throughout the project according to the boundaries established in the previous step. This inventory phase is critical for identifying and quantifying the inputs and outputs of the system, laying the groundwork for the subsequent impact assessment;

-

Life cycle impact assessment (LCIA): this phase encompasses several sub-steps:

- Impact assessment: calculation of environmental impacts based on LCI data;

- Classification: data are aggregated into separate impacts;

- Characterization: the relative contributions of materials/emissions in one of the impact categories are quantified;

- Standardization and valuation: these independent steps allow for a detailed analysis of the size of each impact. Both actions are subjective, with valuation considered more subjective than standardization.

- Interpretation and improvement recommendations: the results are interpreted, and some tools for improvement are described. This final phase aims to explain the impact assessment's results and the priorities for improvement.

1.2. Software and Databases for Life Cycle Assessment

- OpenLCA [16]: developed by GreenDelta in 2006, OpenLCA is an open-source tool for LCA and sustainability assessment. Its accessibility without license cost makes it a popular choice for conducting comprehensive environmental analyses;

- Building for Environmental and Economic Sustainability (BEES) [17]: created by the National Institute of Standards and Technology (NIST) in the USA, BEES is an online tool for evaluating environmentally preferable building products, integrating both cost and environmental performance considerations;

- GaBi [18]: this software suite offers LCA modeling and reporting capabilities augmented by extensive content databases. It includes intuitive data collection and reporting tools, facilitating detailed environmental impact analyses;

- SimaPro [19]: with a three-decade presence and recognition in industry and academia, spanning over 80 countries, SimaPro is renowned for providing science-based information, ensuring complete transparency, and avoiding black-box processes.

1.3. Product Environmental Footprint

2. Materials and Methods

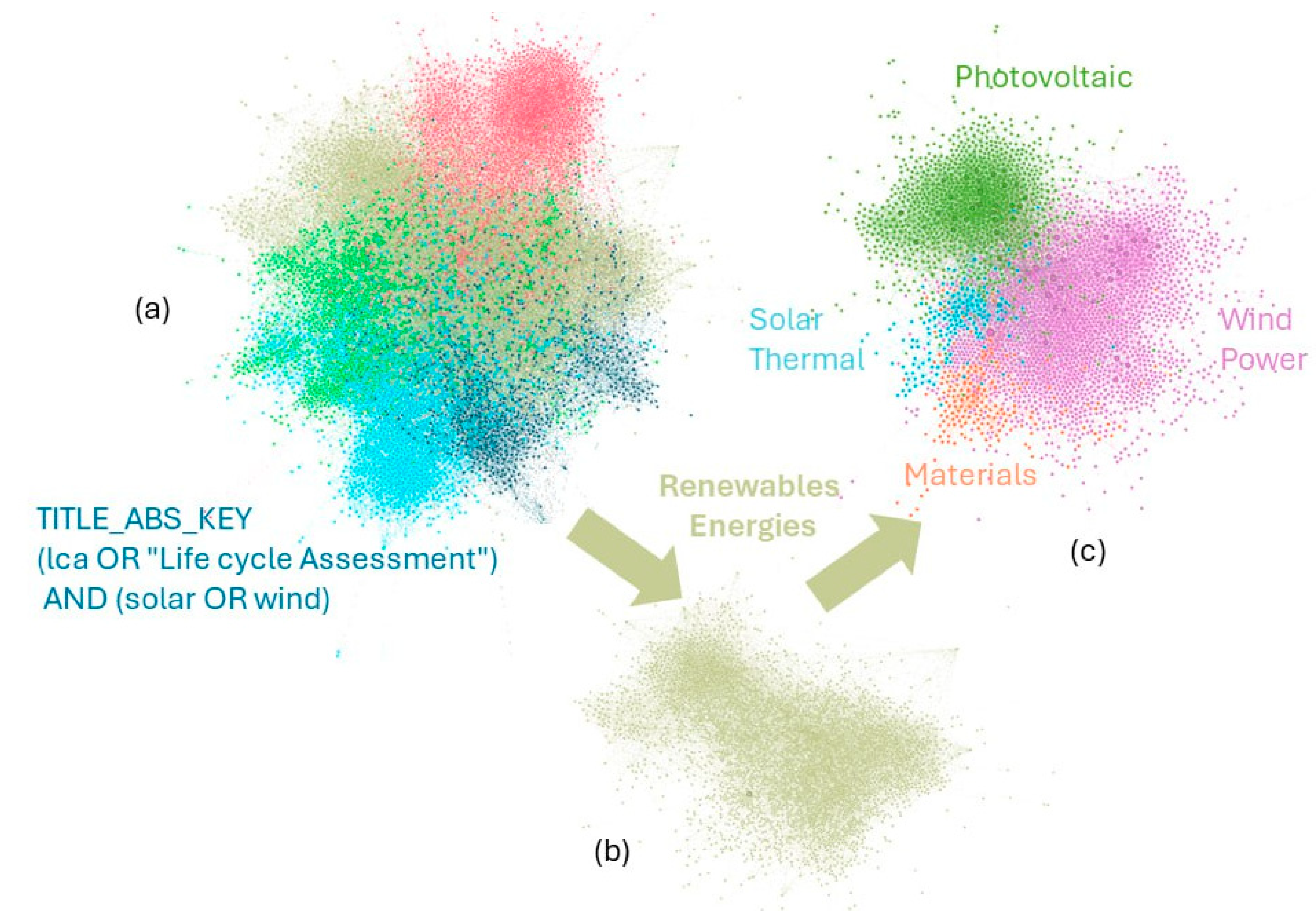

3. State-of-the-Art

- Material cultivation and fabrication: this stage is the most extensive, involving resource extraction and processing, which encompasses the mining, refining, and purifying silicon and other essential metals and minerals for the cells, glass, frame, inverters, and other required electronics. This phase also includes petroleum extraction for plastics and natural gas extraction used in heating, covering every material process needed to create the photovoltaic (PV) module and other electronics up to the point of transportation to the operation site. Wind energy involves extracting and processing metals and petroleum for components like steel, plastics, internal wiring, turbine blades, gears, rotors, nacelle, and tower construction;

- Construction: this phase entails on-site assembly and the transportation of materials. For PV systems, this includes the transport and installation of panels along with the balance-of-system (BOS) components such as mounting structures, cabling, interconnection components, and inverters. During this stage, greenhouse gas (GHG) emissions arise from processing BOS materials and the fossil fuels consumed in transport and assembly. For wind power, this stage also involves significant use of cement and iron rebar for supporting structures and the installation of cabling and substations;

- Operation and maintenance: PV systems' operation involves ongoing maintenance, occasional part replacements, and cleaning of the modules. Wind systems require similar maintenance, regularly replacing parts like blades and gear components and replenishing consumables such as filters and hydraulic oil for turbine lubrication. This direct stage includes the activities necessary to ensure the systems function efficiently over their operational life;

- Decommissioning represents the end-of-life (EoL) cycle, focusing on dismantling, disposal, recycling, and potential land reclamation. This stage is critical for reducing future GHG emissions. In wind energy, for example, while the foundation pads may be left in place or reused, most materials, such as steel towers, plastics, and fiberglass blades, are recyclable, which can significantly offset future emissions.

3.1. Photovoltaic Community

3.2. Wind Power Community

3.3. Solar Thermal Community

3.4. Materials Community

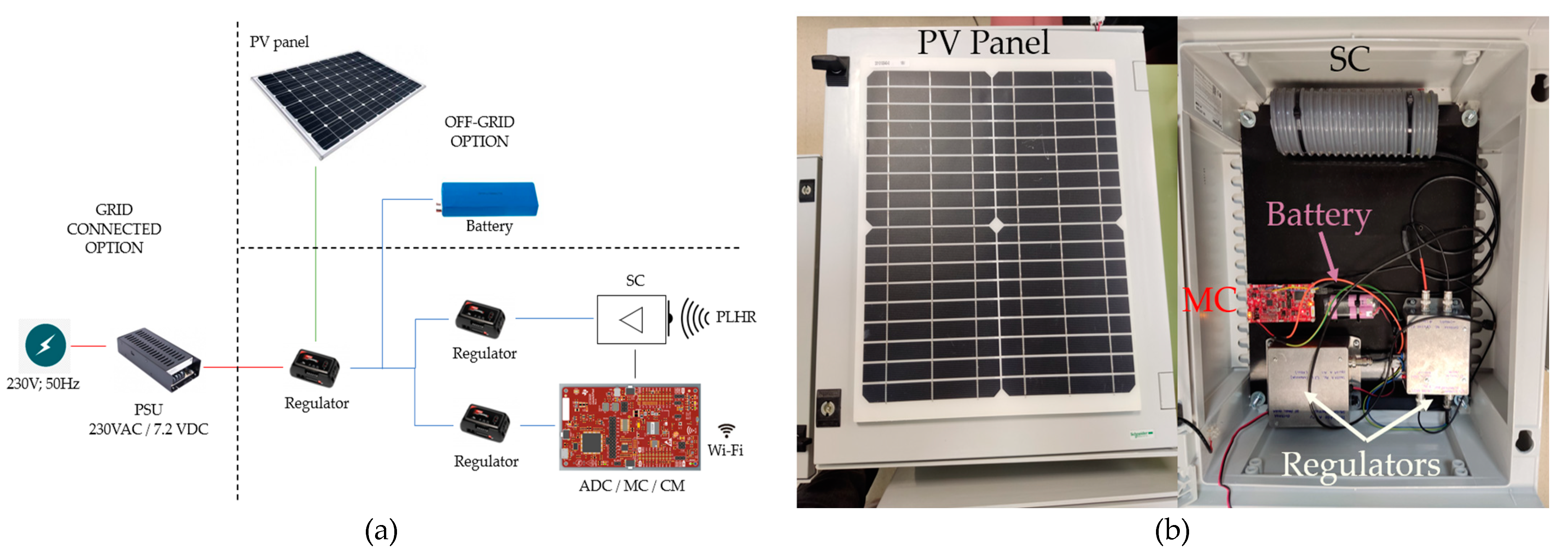

4. Case Study

4.1. Goal and Scope

4.2. Life-Cycle Inventory

- 20 meters of three-conductor cable, 1.5 mm², 60 g/m;

- 12 cylindrical connectors, 1.5 mm²;

- Two-pole circuit breaker;

- 230 VAC/7.2 VDC power supply unit (PSU).

- PV panel from PowerFilm, model MP7.2-150F, 0.037 m²;

- Two rechargeable Lithium-Ion batteries, 6.7 Ah, 7.2 V.

- 20 years for the PV module and electrical components (cable, circuit breaker, connectors);

- Ten years for electronic components (PSU);

- Eight years for batteries.

- Transoceanic shipment from China to a Spanish seaport (9,000 km);

- Semi-truck transport from Algeciras Port, Spain, to a warehouse in Almeria, Spain (339 km).

- Transoceanic shipment from the USA to a Spanish seaport (6,000 km);

- Semi-truck transport from Algeciras Port, Spain, to Almeria, Spain (339 km).

4.3. Life Cycle Impact Assessment

4.4. Interpretation and Improvement Recommendations

5. Future Perspectives and Challenges

5.1. Photovoltaic

5.2. Wind Power

5.3. Solar Thermal

5.4. Materials

5.5. Data Quality and Accessibility Challenges

5.6. Methodological Variability and Comparison Difficulties

5.7. Integrating Life Cycle Assessment with Decision-Making Processes

5.8. Technological and Regulatory Advancements

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stoppato, A. Life Cycle Assessment of Photovoltaic Electricity Generation. Energy 2008, 33. [Google Scholar] [CrossRef]

- Nations, U. World Urbanization Prospects. The 2018 Revision. Methodology. Department of Economic and Social Affairs, Population Division 2018.

- Walker, S.; Coleman, N.; Hodgson, P.; Collins, N.; Brimacombe, L. Evaluating the Environmental Dimension of Material Efficiency Strategies Relating to the Circular Economy. Sustainability 2018, 10, 666. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment: Theory and Practice; 2017.

- Varun; Bhat, I.K.; Prakash, R. LCA of Renewable Energy for Electricity Generation Systems-A Review. Renewable and Sustainable Energy Reviews 2009, 13.

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life Cycle Assessment of Electricity Production from Renewable Energies: Review and Results Harmonization. Renewable and Sustainable Energy Reviews 2015, 42. [Google Scholar]

- Cheng, B.; Lu, K.; Li, J.; Chen, H.; Luo, X.; Shafique, M. Comprehensive Assessment of Embodied Environmental Impacts of Buildings Using Normalized Environmental Impact Factors. J Clean Prod 2022, 334, 130083. [Google Scholar] [CrossRef]

- Ludin, N.A.; Mustafa, N.I.; Hanafiah, M.M.; Ibrahim, M.A.; Asri Mat Teridi, M.; Sepeai, S.; Zaharim, A.; Sopian, K. Prospects of Life Cycle Assessment of Renewable Energy from Solar Photovoltaic Technologies: A Review. Renewable and Sustainable Energy Reviews 2018, 96. [Google Scholar]

- Jungbluth, N. Life Cycle Assessment of Crystalline Photovoltaics in the Swiss Ecoinvent Database. Progress in Photovoltaics: Research and Applications 2005, 13.

- Hellweg, S.; Milà i Canals, L. Emerging Approaches, Challenges and Opportunities in Life Cycle Assessment. Science (1979) 2014, 344, 1109–1113. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ Sci Technol 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Heijungs, R.; Settanni, E.; Guinée, J. Toward a Computational Structure for Life Cycle Sustainability Analysis: Unifying LCA and LCC. Int J Life Cycle Assess 2013, 18, 1722–1733. [Google Scholar] [CrossRef]

- International Organization for Standardization ISO 14040.; Ginebra, Suiza, 2006;

- International Organization for Standardization ISO 14044.; Ginebra, Suiza, 2007;

- de Saxcé, M.; Rabenasolo, B.; Perwuelz, A.; Quesne, A. Development, Documentation of Life Cycle Inventories (LCI) and LCA Databases Organisation. In Proceedings of the International Workshop on Green Supply Chain GSC’ 2012, June 21-22; 2012.

- GreenDelta OpenLCA Software Available online:. Available online: http://openlca.org (accessed on 31 May 2021).

- NIST. BEES Software. Available online: https://www.nist.gov/services-resources/software/bees (accessed on 31 May 2021).

- Sphere Solutions GaBi Software Available online:. Available online: http://gabi-software.com (accessed on 31 May 2021).

- SimaPro SimaPro Software Available online:. Available online: http://simapro.com (accessed on 31 May 2021).

- Millet, D.; Bistagnino, L.; Lanzavecchia, C.; Camous, R.; Poldma, T. Does the Potential of the Use of LCA Match the Design Team Needs? J Clean Prod 2007, 15, 335–346. [Google Scholar] [CrossRef]

- Nakano, K.; Hirao, M. Collaborative Activity with Business Partners for Improvement of Product Environmental Performance Using LCA. J Clean Prod 2011, 19, 1189–1197. [Google Scholar] [CrossRef]

- Hollerud, B.; Bowyer, J.; Howe, J.; Pepke, E.; Fernholz, K. A Review of Life Cycle Assessment Tools. Dovetail Partners, Inc. 2017.

- Miah, J.H.; Koh, S.C.L.; Stone, D. A Hybridised Framework Combining Integrated Methods for Environmental Life Cycle Assessment and Life Cycle Costing. J Clean Prod 2017, 168. [Google Scholar]

- European Commission. 2013/179/EU: Commission Recommendation of 9 April 2013 on the Use of Common Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations.; Brussels, Belgium, 2013;

- Lehmann, A.; Bach, V.; Finkbeiner, M. EU Product Environmental Footprint—Mid-Term Review of the Pilot Phase. Sustainability 2016, 8, 92. [Google Scholar] [CrossRef]

- Bach, V.; Lehmann, A.; Görmer, M.; Finkbeiner, M. Product Environmental Footprint (PEF) Pilot Phase—Comparability over Flexibility? Sustainability 2018, 10, 2898. [Google Scholar] [CrossRef]

- Manfredi, S.; Allacker, K.; Pelletier, N.; Schau, E.; Chomkhamsri, K.; Pant, R.; Pennington, D. Comparing the European Commission Product Environmental Footprint Method with Other Environmental Accounting Methods. Int J Life Cycle Assess 2015, 20, 389–404. [Google Scholar] [CrossRef]

- Wu, Y.; Su, D. LCA of an Industrial Luminaire Using Product Environmental Footprint Method. J Clean Prod 2021, 305, 127159. [Google Scholar] [CrossRef]

- Pyay, S.; Thanungkano, W.; Mungkalasiri, J.; Musikavong, C. A Life Cycle Assessment of Intermediate Rubber Products in Thailand from the Product Environmental Footprint Perspective. J Clean Prod 2019, 237, 117632. [Google Scholar] [CrossRef]

- Corradini, G.; Pierobon, F.; Zanetti, M. Product Environmental Footprint of a Cross-Laminated Timber System: A Case Study in Italy. Int J Life Cycle Assess 2019, 24, 975–988. [Google Scholar] [CrossRef]

- Kuo, T.; Lee, Y. Using Pareto Optimization to Support Supply Chain Network Design within Environmental Footprint Impact Assessment. Sustainability 2019, 11, 452. [Google Scholar] [CrossRef]

- Novas, N.; Alcayde, A.; Khaled, D. El; Manzano-Agugliaro, F. Coatings in Photovoltaic Solar Energy Worldwide Research. Coatings 2019, 9. [Google Scholar]

- de la Cruz-Lovera, C.; Perea-Moreno, A.-J.; de la Cruz-Fernández, J.L.; G. Montoya, F.; Alcayde, A.; Manzano-Agugliaro, F. Analysis of Research Topics and Scientific Collaborations in Energy Saving Using Bibliometric Techniques and Community Detection. Energies (Basel) 2019, 12, 2030. [CrossRef]

- Wiedemann, S.; McGahan, E.; Murphy, C.; Yan, M.-J.; Henry, B.; Thoma, G.; Ledgard, S. Environmental Impacts and Resource Use of Australian Beef and Lamb Exported to the USA Determined Using Life Cycle Assessment. J Clean Prod 2015, 94, 67–75. [Google Scholar] [CrossRef]

- Portillo, F.; García, R.M.; Alcayde, A.; Gázquez, J.A.; Fernández-Ros, M.; Novas, N. Prospective Environmental and Economic Assessment of a Sensor Network. Sustainability 2021, 13, 10306. [Google Scholar] [CrossRef]

- Muñoz, I.; Portillo, F.; Rosiek, S.; Batlles, F.J.; Martínez-Del-Río, J.; Acasuso, I.; Piergrossi, V.; De Sanctis, M.; Chimienti, S.; Di Iaconi, C. Prospective Environmental and Economic Assessment of Solar-Assisted Thermal Energy Recovery from Wastewater through a Sequencing Batch Biofilter Granular Reactor. J Clean Prod 2019, 212, 1300–1309. [Google Scholar] [CrossRef]

- Pehnt, M. Dynamic Life Cycle Assessment (LCA) of Renewable Energy Technologies. Renew Energy 2006, 31. [Google Scholar] [CrossRef]

- Nugent, D.; Sovacool, B.K. Assessing the Lifecycle Greenhouse Gas Emissions from Solar PV and Wind Energy: A Critical Meta-Survey. Energy Policy 2014, 65. [Google Scholar] [CrossRef]

- Gong, J.; Darling, S.B.; You, F. Perovskite Photovoltaics: Life-Cycle Assessment of Energy and Environmental Impacts. Energy Environ Sci 2015, 8. [Google Scholar] [CrossRef]

- Gerbinet, S.; Belboom, S.; Léonard, A. Life Cycle Analysis (LCA) of Photovoltaic Panels: A Review. Renewable and Sustainable Energy Reviews 2014, 38. [Google Scholar]

- Peng, J.; Lu, L.; Yang, H. Review on Life Cycle Assessment of Energy Payback and Greenhouse Gas Emission of Solar Photovoltaic Systems. Renewable and Sustainable Energy Reviews 2013, 19. [Google Scholar]

- Yu, Z.; Ma, W.; Xie, K.; Lv, G.; Chen, Z.; Wu, J.; Yu, J. Life Cycle Assessment of Grid-Connected Power Generation from Metallurgical Route Multi-Crystalline Silicon Photovoltaic System in China. Appl Energy 2017, 185. [Google Scholar] [CrossRef]

- Hou, G.; Sun, H.; Jiang, Z.; Pan, Z.; Wang, Y.; Zhang, X.; Zhao, Y.; Yao, Q. Life Cycle Assessment of Grid-Connected Photovoltaic Power Generation from Crystalline Silicon Solar Modules in China. Appl Energy 2016, 164. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Solano-Olivares, K.; Martínez, E.; García, E.O.; Santoyo, E. Life Cycle Assessment for a Grid-Connected Multi-Crystalline Silicon Photovoltaic System of 3 KWp: A Case Study for Mexico. J Clean Prod 2021, 316. [Google Scholar] [CrossRef]

- Bhandari, K.P.; Collier, J.M.; Ellingson, R.J.; Apul, D.S. Energy Payback Time (EPBT) and Energy Return on Energy Invested (EROI) of Solar Photovoltaic Systems: A Systematic Review and Meta-Analysis. Renewable and Sustainable Energy Reviews 2015, 47. [Google Scholar]

- Sherwani, A.F.; Usmani, J.A. ; Varun Life Cycle Assessment of Solar PV Based Electricity Generation Systems: A Review. Renewable and Sustainable Energy Reviews 2010, 14. [Google Scholar]

- Raugei, M.; Bargigli, S.; Ulgiati, S. Life Cycle Assessment and Energy Pay-Back Time of Advanced Photovoltaic Modules: CdTe and CIS Compared to Poly-Si. Energy 2007, 32. [Google Scholar] [CrossRef]

- Sumper, A.; Robledo-García, M.; Villafáfila-Robles, R.; Bergas-Jané, J.; Andrés-Peiró, J. Life-Cycle Assessment of a Photovoltaic System in Catalonia (Spain). Renewable and Sustainable Energy Reviews 2011, 15. [Google Scholar]

- Song, Z.; Watthage, S.C.; Phillips, A.B.; Heben, M.J. Pathways toward High-Performance Perovskite Solar Cells: Review of Recent Advances in Organo-Metal Halide Perovskites for Photovoltaic Applications. J Photonics Energy 2016, 6. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, X.; Yuan, Z. Life-Cycle Assessment of Multi-Crystalline Photovoltaic (PV) Systems in China. J Clean Prod 2015, 86. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Chai, J.; Xue, B.; Zhao, F.; Wang, X. Environmental Influence Assessment of China’s Multi-Crystalline Silicon (Multi-Si) Photovoltaic Modules Considering Recycling Process. Solar Energy 2017, 143. [Google Scholar] [CrossRef]

- Turconi, R.; Boldrin, A.; Astrup, T. Life Cycle Assessment (LCA) of Electricity Generation Technologies: Overview, Comparability and Limitations. Renewable and Sustainable Energy Reviews 2013, 28. [Google Scholar]

- Kannan, R.; Leong, K.C.; Osman, R.; Ho, H.K.; Tso, C.P. Life Cycle Assessment Study of Solar PV Systems: An Example of a 2.7 KWp Distributed Solar PV System in Singapore. Solar Energy 2006, 80. [Google Scholar] [CrossRef]

- Latunussa, C.E.L.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an Innovative Recycling Process for Crystalline Silicon Photovoltaic Panels. Solar Energy Materials and Solar Cells 2016, 156. [Google Scholar] [CrossRef]

- Fthenakis, V.M. End-of-Life Management and Recycling of PV Modules. Energy Policy 2000, 28. [Google Scholar] [CrossRef]

- Wiedmann, T.O.; Suh, S.; Feng, K.; Lenzen, M.; Acquaye, A.; Scott, K.; Barrett, J.R. Application of Hybrid Life Cycle Approaches to Emerging Energy Technologies - The Case of Wind Power in the UK. Environ Sci Technol 2011, 45. [Google Scholar] [CrossRef]

- Tahtah, A.; Raouti, D.; Meziane, R. Economic and Ecological Evaluation and Optimization of the Life Cycle of a Wind Farm. International Journal of Environmental Science and Technology 2023, 20. [Google Scholar] [CrossRef]

- Mendecka, B.; Lombardi, L. Life Cycle Environmental Impacts of Wind Energy Technologies: A Review of Simplified Models and Harmonization of the Results. Renewable and Sustainable Energy Reviews 2019, 111. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Assessing the Life Cycle Environmental Impacts of Wind Power: A Review of Present Knowledge and Research Needs. Renewable and Sustainable Energy Reviews 2012, 16. [Google Scholar]

- Ardente, F.; Beccali, M.; Cellura, M.; Lo Brano, V. Energy Performances and Life Cycle Assessment of an Italian Wind Farm. Renewable and Sustainable Energy Reviews 2008, 12. [Google Scholar]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life Cycle Assessment of Onshore and Offshore Wind Energy-from Theory to Application. Appl Energy 2016, 180. [Google Scholar] [CrossRef]

- Chipindula, J.; Botlaguduru, V.S.V.; Du, H.; Kommalapati, R.R.; Huque, Z. Life Cycle Environmental Impact of Onshore and Offshore Wind Farms in Texas. Sustainability (Switzerland) 2018, 10. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Wang, Z.; Li, S.; Li, J.; He, G.; Li, Y.; Liu, Y.; Piao, S.; Gao, Z.; et al. Potential Contributions of Wind and Solar Power to China’s Carbon Neutrality. Resour Conserv Recycl 2022, 180. [Google Scholar] [CrossRef]

- Lian, J.; Hou, G.; Cai, O.; Xu, K. Assessing the Life Cycle Risks of Offshore Wind Turbines with Suction Bucket Foundations. J Clean Prod 2022, 362. [Google Scholar] [CrossRef]

- Chen, J.; Mao, B.; Wu, Y.; Zhang, D.; Wei, Y.; Yu, A.; Peng, L. Green Development Strategy of Offshore Wind Farm in China Guided by Life Cycle Assessment. Resour Conserv Recycl 2023, 188. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, L. The GHG Intensities of Wind Power Plants in China from a Life-Cycle Perspective: The Impacts of Geographical Location, Turbine Technology and Management Level. Sustainability (Switzerland) 2023, 15. [Google Scholar] [CrossRef]

- Xu, L.; Pang, M.; Zhang, L.; Poganietz, W.R.; Marathe, S.D. Life Cycle Assessment of Onshore Wind Power Systems in China. Resour Conserv Recycl 2018, 132. [Google Scholar] [CrossRef]

- Yang, J.; Chang, Y.; Zhang, L.; Hao, Y.; Yan, Q.; Wang, C. The Life-Cycle Energy and Environmental Emissions of a Typical Offshore Wind Farm in China. J Clean Prod 2018, 180. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life Cycle Assessment of a Multi-Megawatt Wind Turbine. Renew Energy 2009, 34. [Google Scholar] [CrossRef]

- Lechón, Y.; De La Rúa, C.; Sáez, R. Life Cycle Environmental Impacts of Electricity Production by Solarthermal Power Plants in Spain. Journal of Solar Energy Engineering, Transactions of the ASME 2008, 130. [Google Scholar] [CrossRef]

- Piemonte, V.; Falco, M. De; Tarquini, P.; Giaconia, A. Life Cycle Assessment of a High Temperature Molten Salt Concentrated Solar Power Plant. Solar Energy 2011, 85. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. Concentrating Solar Systems: Life Cycle Assessment (LCA) and Environmental Issues. Renewable and Sustainable Energy Reviews 2017, 78. [Google Scholar]

- Gobio-Thomas, L.B.; Darwish, M.; Stojceska, V. Environmental Impacts of Solar Thermal Power Plants Used in Industrial Supply Chains. Thermal Science and Engineering Progress 2023, 38. [Google Scholar]

- Corona, B.; San Miguel, G.; Cerrajero, E. Life Cycle Assessment of Concentrated Solar Power (CSP) and the Influence of Hybridising with Natural Gas. International Journal of Life Cycle Assessment 2014, 19. [Google Scholar] [CrossRef]

- Ehtiwesh, I.A.S.; Coelho, M.C.; Sousa, A.C.M. Exergetic and Environmental Life Cycle Assessment Analysis of Concentrated Solar Power Plants. Renewable and Sustainable Energy Reviews 2016, 56. [Google Scholar]

- Burkhardt, J.J.; Heath, G.A.; Turchi, C.S. Life Cycle Assessment of a Parabolic Trough Concentrating Solar Power Plant and the Impacts of Key Design Alternatives. Environ Sci Technol 2011, 45. [Google Scholar] [CrossRef]

- Whitaker, M.B.; Heath, G.A.; Burkhardt, J.J.; Turchi, C.S. Life Cycle Assessment of a Power Tower Concentrating Solar Plant and the Impacts of Key Design Alternatives. Environ Sci Technol 2013, 47. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Mao, T.; Sui, J.; Jin, H. Life Cycle Assessment (LCA) Optimization of Solar-Assisted Hybrid CCHP System. Appl Energy 2015, 146. [Google Scholar] [CrossRef]

- Oró, E.; Gil, A.; de Gracia, A.; Boer, D.; Cabeza, L.F. Comparative Life Cycle Assessment of Thermal Energy Storage Systems for Solar Power Plants. Renew Energy 2012, 44. [Google Scholar] [CrossRef]

- Burkhardt, J.J.; Heath, G.; Cohen, E. Life Cycle Greenhouse Gas Emissions of Trough and Tower Concentrating Solar Power Electricity Generation: Systematic Review and Harmonization. J Ind Ecol 2012, 16. [Google Scholar] [CrossRef]

- Gmelin, H.; Seuring, S. Determinants of a Sustainable New Product Development. J Clean Prod 2014, 69. [Google Scholar] [CrossRef]

- Pell, R.; Tijsseling, L.; Goodenough, K.; Wall, F.; Dehaine, Q.; Grant, A.; Deak, D.; Yan, X.; Whattoff, P. Towards Sustainable Extraction of Technology Materials through Integrated Approaches. Nat Rev Earth Environ 2021, 2. [Google Scholar]

- Karthika, P.; Dinesh, G.K.; Sathya, V.; Karthika, S.; Sinduja, M.; Kiruthiga, S.; Kannojiya, S.; Priya, P.S.; Prasad, S.; Soni, R. Current Scenario on Conventional and Modern Approaches Towards Eco-Friendly Electronic Waste Management. In Microbial Technology for Sustainable E-waste Management; 2023.

- Seck, G.S.; Hache, E.; Bonnet, C.; Simoën, M.; Carcanague, S. Copper at the Crossroads: Assessment of the Interactions between Low-Carbon Energy Transition and Supply Limitations. Resour Conserv Recycl 2020, 163. [Google Scholar] [CrossRef]

- Ghosh, A.; Dhiman, S.; Gupta, A.; Jain, R. Process Evaluation of Scandium Production and Its Environmental Impact. Environments - MDPI 2023, 10.

- RACHID, S.; TAHA, Y.; BENZAAZOUA, M. Environmental Evaluation of Metals and Minerals Production Based on a Life Cycle Assessment Approach: A Systematic Review. Miner Eng 2023, 198. [Google Scholar]

- Surup, G.R.; Kaffash, H.; Ma, Y.; Trubetskaya, A.; Pettersen, J.B.; Tangstad, M. Life Cycle Based Climate Emissions of Charcoal Conditioning Routes for the Use in the Ferro-Alloy Production. Energies (Basel) 2022, 15. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Friedrich, B. Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-based Carbon: A Review. Minerals 2021, 11. [Google Scholar]

- Novas Castellano, N.; Garcia Salvador, R.M.; Portillo Rodriguez, F.; Fernandez-Ros, M.; Gazquez Parra, J.A. Renewable Energy: The Future of Photovoltaic Energy. In Living With Climate Change; 2024.

- Pauer, E.; Wohner, B.; Tacker, M. The Influence of Database Selection on Environmental Impact Results. Life Cycle Assessment of Packaging Using GaBi, Ecoinvent 3.6, and the Environmental Footprint Database. Sustainability 2020, 12, 9948. [Google Scholar] [CrossRef]

- European Union Directive 2014/24/EU of the European Parliament and of the Council of 26 February 2014 on Public Procurement. Official Journal of the European Union 2014, 94, 65–242.

- European Union Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Official Journal of the European Union 2010, L 153, 13–35.

- Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. Official Journal of the European Union 2012, L 315, 1–56.

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated Life-Cycle Assessment of Electricity-Supply Scenarios Confirms Global Environmental Benefit of Low-Carbon Technologies. Proc Natl Acad Sci U S A 2015, 112. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability Assessment of Energy Systems: Integrating Environmental, Economic and Social Aspects. J Clean Prod 2014, 80. [Google Scholar] [CrossRef]

- Hunter, LP. Total Energy Use in the Production of Silicon Solar Cells from Raw Materials to Finished Product. In Proceedings of the 12th IEEE PV Specialists Conference.; New York, November 15 1976; pp. 347–352.

- Fthenakis, V.M.; Kim, H.C. Photovoltaics: Life-Cycle Analyses. Solar Energy 2011, 85. [Google Scholar] [CrossRef]

- Pacca, S.; Sivaraman, D.; Keoleian, G.A. Parameters Affecting the Life Cycle Performance of PV Technologies and Systems. Energy Policy 2007, 35. [Google Scholar] [CrossRef]

- (Mariska) de Wild-Scholten, M.J. Energy Payback Time and Carbon Footprint of Commercial Photovoltaic Systems. Solar Energy Materials and Solar Cells 2013, 119, 296–305. [Google Scholar] [CrossRef]

- Hsu, D.D.; O’Donoughue, P.; Fthenakis, V.; Heath, G.A.; Kim, H.C.; Sawyer, P.; Choi, J.K.; Turney, D.E. Life Cycle Greenhouse Gas Emissions of Crystalline Silicon Photovoltaic Electricity Generation: Systematic Review and Harmonization. J Ind Ecol 2012, 16. [Google Scholar] [CrossRef]

- Cong, N.; Song, Y.; Zhang, M.; Wu, W. Life Cycle Assessment of Carbon Reduction Potential of EoL Wind Turbine Blades Disposal Scenarios in China. Environ Impact Assess Rev 2023, 100. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Assessment of Sustainability Indicators for Renewable Energy Technologies. Renewable and Sustainable Energy Reviews 2009, 13. [Google Scholar]

- Hondo, H. Life Cycle GHG Emission Analysis of Power Generation Systems: Japanese Case. In Proceedings of the Energy; 2005; Vol. 30.

- Maheswari, H.; Yudoko, G.; Adhiutama, A.; Agustina, H. Sustainable Reverse Logistics Scorecards for the Performance Measurement of Informal E-Waste Businesses. Heliyon 2020, 6. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems Thinking for Life Cycle Sustainability Assessment: A Review of Recent Developments, Applications, and Future Perspectives. Sustainability (Switzerland) 2017, 9. [Google Scholar]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A Survey of Unresolved Problems in Life Cycle Assessment. Int J Life Cycle Assess 2008, 13. [Google Scholar] [CrossRef]

- Saadah, Y.; Abuhijleh, B. Decreasing CO2 Emissions and Embodied Energy during the Construction Phase Using Sustainable Building Materials. International Journal of Sustainable Building Technology and Urban Development 2010, 1. [Google Scholar] [CrossRef]

- Pacca, S.; Sivaraman, D.; Keoleian, G.A. Parameters Affecting the Life Cycle Performance of PV Technologies and Systems. Energy Policy 2007, 35. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies (Basel) 2020, 13, 252. [Google Scholar] [CrossRef]

- Garrett, P.; Rønde, K. Life Cycle Assessment of Wind Power: Comprehensive Results from a State-of-the-Art Approach. International Journal of Life Cycle Assessment 2013, 18. [Google Scholar] [CrossRef]

- Shahabian, A.; Fadai, A.; Peruzzi, T. Future of Life-Cycle Assessment in a Smart and/or Sustainable World. In; 2019.

- Ghisellini, P.; Passaro, R.; Ulgiati, S. Environmental and Social Life Cycle Assessment of Waste Electrical and Electronic Equipment Management in Italy According to EU Directives. Environments - MDPI 2023, 10. [Google Scholar] [CrossRef]

| Impact category and reference unit | Sensor connected to the grid | Sensor connected to a PV panel |

|---|---|---|

| Acidification (mol) | 1.22 E-2 | 1.48 E-3 |

| Climate change (kg CO2 eq.) | 2.09 E0 | 2.71 E-1 |

| Ecotoxicity, freshwater (Items) | 7.47 E-1 | 9.62 E-2 |

| Eutrophication marine (kg) | 1.84 E-3 | 2.97 E-4 |

| Eutrophication, freshwater (kg) | 1.05 E-5 | 5.11 E-6 |

| Eutrophication, terrestrial (kg) | 1.99 E-2 | 3.06 E-3 |

| Human toxicity, cancer (Items) | 1.32 E-8 | 1.94 E-9 |

| Human toxicity, non-cancer (Items) | 3.83 E-7 | 4.21 E-8 |

| Ionizing radiation, human health (kBq) | 2.46 E-1 | 3.35 E-2 |

| Land use (Items) | 7.05 E0 | 8.15 E-1 |

| Ozone depletion (kg) | 2.89 E-10 | 8.45 E-10 |

| Particulate Matter (Items) | 1.29 E-7 | 2.05 E-8 |

| Photochemical ozone formation – human health (kg) | 5.59 E-3 | 8.30 E-4 |

| Resource use, fossils (kg) | 2.99 E1 | 3.87 E0 |

| Resource use, minerals, and metals (kg) | 1.74 E-4 | 8.71 E-6 |

| Water use (m3) | 1.05 E0 | 5.94 E-2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).