1. Introduction

The successful delivery of large-scale industrial construction projects often necessitates the development of requisite venues and infrastructural facilities. This undertaking presents a significant industrial project with complex logistical challenges. A central challenge lies in formulating a cohesive construction schedule, which can be categorized as a Resource-Constrained Project Scheduling Problem (RCPSP)[

1,

2]. The RCPSP is a well-studied problem in the field of project management, where the objective is to determine the optimal sequence and timing of activities. Its paradigm addresses the intricate interplay of various resources such as workspace, machinery, and manpower, all of which are subject to inherent limitations and constraints, alongside a network of tasks characterized by precedence relations and resource requisitions [

3,

4].

In the context of complex construction projects, as exemplified in this study, the RCPSP is further complicated by the need to address spatial conflicts and ensure efficient resource utilization. Spatial conflicts arise when the physical locations of concurrent construction activities overlap, leading to potential clashes and disruptions. Efficient resource utilization, on the other hand, is crucial to minimize delays and optimize project costs. Addressing these challenges is essential for the successful and timely completion of the project.

Diverse solutions have been offered to mitigate the complexities inherent in project scheduling. Notably, Primavera P6, a preeminent project management tool developed by Oracle [

5]. With over three decades of development and widespread adoption across industries, Primavera P6 has established itself as a leader in project management software. It offers robust functionality for both local deployment (P6 PPM) and scalable service provision (P6 EPPM), seamlessly integrating with Oracle databases and supporting external data import. It excels in addressing scheduling constraints such as workspace clashes, enabling the formulation of optimized schedules [

6]. However, its multifaceted functionalities require comprehensive training for proficiency.

One approach to detect spatial conflicts during construction planning is the use of Synchro 4D, a 4D simulation software [

7, chap. 6]. By integrating with project scheduling tools such as Primavera P6, Synchro 4D can import the project schedule and link it to a 3D model of the planned structures. This allows for simulating the construction sequence in 4D, enabling the visualization of potential clashes between elements. The integration of Primavera P6 planning data into the Synchro 4D model facilitates the proactive identification of spatial conflicts before they occur on the actual construction site. This capability is crucial for addressing such conflicts in complex construction projects, where the coordination of concurrent activities and resources is paramount. However, while Synchro is effective at spatial conflict detection, it has limitations in fully resolving these conflicts. The tool does not possess advanced functionalities for automatically adjusting the construction schedule or resource allocation to eliminate the identified conflicts. Consequently, project managers may need to manually manipulate the schedule or resource plans within Primavera P6 to sequence activities differently and find a feasible, conflict-free solution.

To address these challenges, we propose an integrated approach that combines data from Primavera P6 and Synchro 4D with Optimizio a heuristic scheduling tool [

8,

9,

10]. Optimizio offers several key advantages for project management and optimization including the ability to tackle complex scheduling problems, flexibility, seamless connectivity with standard industrial tools, and ease of use that eliminates the need for additional training. Through rigorous validation by domain experts, the solution demonstrates its promise for addressing real-world challenges in industrial applications.

2. Materials & Methods

2.1. Statement of the Problem

This study addresses a real-world construction scheduling challenge that extends beyond the core RCPSP formulation. While RCPSP provides a solid foundation for scheduling activities under logical dependencies and resource constraints, the use case in this study introduces additional complexities as follow:

2.1.1. Spatial Conflicts and Contractor Coordination

One such complexity involves managing spatial conflicts arising from concurrently scheduled activities within shared work areas. In the construction projects considered here, these work areas are managed by different contractors, necessitating coordination to mitigate conflicts and ensure efficient execution. Inappropriately addressed conflicts can lead to suboptimal schedules and potential delays.

2.1.2. Data Exchange and Software Integration

Another critical aspect is seamless data exchange between existing project management software. Construction projects typically involve a multitude of stakeholders and software platforms, each with its own data formats and workflows. Facilitating efficient data exchange and integration among these tools is crucial for leveraging existing project data and enabling streamlined workflows. In this study, the initial project plan was obtained from Oracle Primavera P6 Enterprise Project Portfolio Management (EPPM) cloud solution in an eXtensible Markup Language (XML) format, suitable for automated data parsing. Subsequently, building and work area information was extracted from Synchro 4D models, a popular platform for 4D BIM (Building Information Modeling) visualization and scheduling. Following data acquisition, Synchro 4D models were utilized to identify potential spatial clashes arising from concurrently scheduled activities within shared work areas based on the original schedule obtained from Primavera P6 EPPM. These spatial incompatibilities can lead to delays, increased costs, and disruptions to the overall construction process. They need to be resolved to generate a new, conflict-free schedule. However, merging the identified spatial conflicts with the updated Primavera schedule is not a straightforward task, especially in complex projects where numerous incompatibilities are found. The integration of the spatial conflict information with the revised scheduling approach presents a significant challenge that must be overcome to ensure the successful and efficient execution of the construction project.

2.1.3. Suboptimal Resource Allocation

Effective resource management is a critical aspect of successful project execution. However, this study identified instances of suboptimal resource allocation in the initial planning stages. Resources were frequently requested in excess of their available units, potentially leading to a potential bottleneck during project execution, jeopardizing timely completion and potentially impacting project delivery performance. To address this challenge, a robust methodology that seamlessly integrates resource management considerations into the project planning process is crucial for overall project efficiency and optimal results.

2.2. Problem Instance

This study evaluates the proposed solution’s effectiveness in handling complex project scheduling scenarios with diverse activity types, resource constraints, and project-specific limitations. A benchmark instance comprises 24 logically linked activities categorized into two distinct types: Level of Effort (LoE) and Task Dependent. These categories exhibit distinct characteristics regarding resource consumption, calendar utilization, and workload computation based on duration. The planning process involves the management of three types of resources: Resource A, B, and C. The initial planning revealed an over-allocation of Resource A, indicating that the demand for this resource exceeded its available capacity. Additionally, Resources B and C exhibit incompatibility, precluding their simultaneous utilization. The objective of this instance is to generate a feasible schedule that adheres to all activity precedence relationships, resource availability constraints, and project-specific limitations.

2.3. Proposed Solution

To address the complex project scheduling problem, we propose Optimizio [

8,

9,

10], an approach to model and solve complex scheduling problems. Optimizio leverages a greedy heuristic algorithm that dynamically assigns scores to unscheduled tasks at each decision point. These scores are calculated using a cost function that incorporates relevant scheduling criteria [

8]. Based on these scores and the satisfaction of constraints, our tool schedules as many feasible tasks as possible at each time step, ultimately yielding a feasible and relatively optimal schedule. The efficacity of Optimizio has been validated through extensive testing on large-scale industrial scheduling problems encompassing diverse domains [

10], including nuclear, defense, and construction industries.

Optimizio is built upon an object-oriented programming (OOP) solution that encapsulates key components of the RCPSP model through three fundamental classes:

Project Class: This class encapsulates the overall project information, including decision time step for recalculating the cost function, definition of calendars used in the planning, start and end dates of the project, etc. It also serves as a container for tasks and resources and manages the interactions between them.

Task Class: Instances of this class represent individual tasks within the project. Each task object captures task-specific attributes such as duration, precedence relationships, and resource requirements.

Resource Class: Represents available resources within the project. These resources can include personnel, equipment, materials, or any other assets that are required to complete the project tasks.

The core Optimizio platform was extended through the integration of additional modules to address specific project scheduling challenges encountered in this use case. These extensions included:

2.3.1. Connector Module

This module retrieves the initial project plan from Primavera P6 EPPM and constructs instances of the Optimizio-RCPSP classes based on the extracted data. It then fetches an Excel file containing preidentified, incompatible location pairs that were retrieved from Synchro 4D platform. These pairs represent locations that cannot be used concurrently due to scheduling constraints. The extracted data are then integrated with the established Resource class instances within the model. This ensures that the model incorporates potential spatial conflicts and facilitates informed decision-making during the planning process. To facilitate further analysis and integration with downstream processes, the module generates an XML representation of the schedule produced by the Optimizio solver. This output adheres to the Primavera P6 EPPM data format, ensuring seamless interoperability and enhancing usability for project managers and their teams.

2.3.2. Resource Incompatibility Verification Module

This extension verifies if resources assigned to tasks are compatible for concurrent utilization. It checks for resource incompatibility constraints defined within the Resource class and prevents the allocation of incompatible resources to overlapping tasks.

2.3.3. Resource Availability Verification Module

This module simulates resource unit availability throughout the project schedule. It verifies if sufficient units of each resource type are available before assigning tasks. This helps prevent resource overallocation and potential schedule delays.

The integration of the Optimizio algorithm with the latter two modules is shown in Algorithm 1.

|

Algorithm 1 Heuristic-Based Project Scheduling with Co-Activity and Resource Considerations |

Set empty list for planned tasks

while do

for each time step t do

for activities do

if predecessor relationships are respected then

if required resources are available then

if required resources have no conflict with resources already allocated to other concurrently scheduled activities then

if required resources possess sufficient capacity to accommodate the task launch then

Calculate objective score end if

end if

end if

end if

end for

Sort activities to be scheduled Execute activities based on sorted list Append finished activities to the list

end for

end while

return

|

3. Results

The entire benchmark execution achieved a runtime of approximately 0.5 seconds on a 8 core CPU. This process encompassed data retrieval from Primavera P6 EPPM and Synchro 4D to obtain the initial project plan and resource conflict information. The extracted data was then preprocessed to facilitate the generation of a RCPSP model that captured project requirements and constraints. Subsequently, a heuristic-based scheduling algorithm was employed to simulate and generate feasible project schedules. The quality and feasibility of the generated schedules were then assessed using user-defined Key Performance Indicators (KPIs). Finally, the optimized schedule was exported in an XML format compatible with Primavera P6 EPPM project management software, enabling further analysis and decision-making within the familiar project management environment.

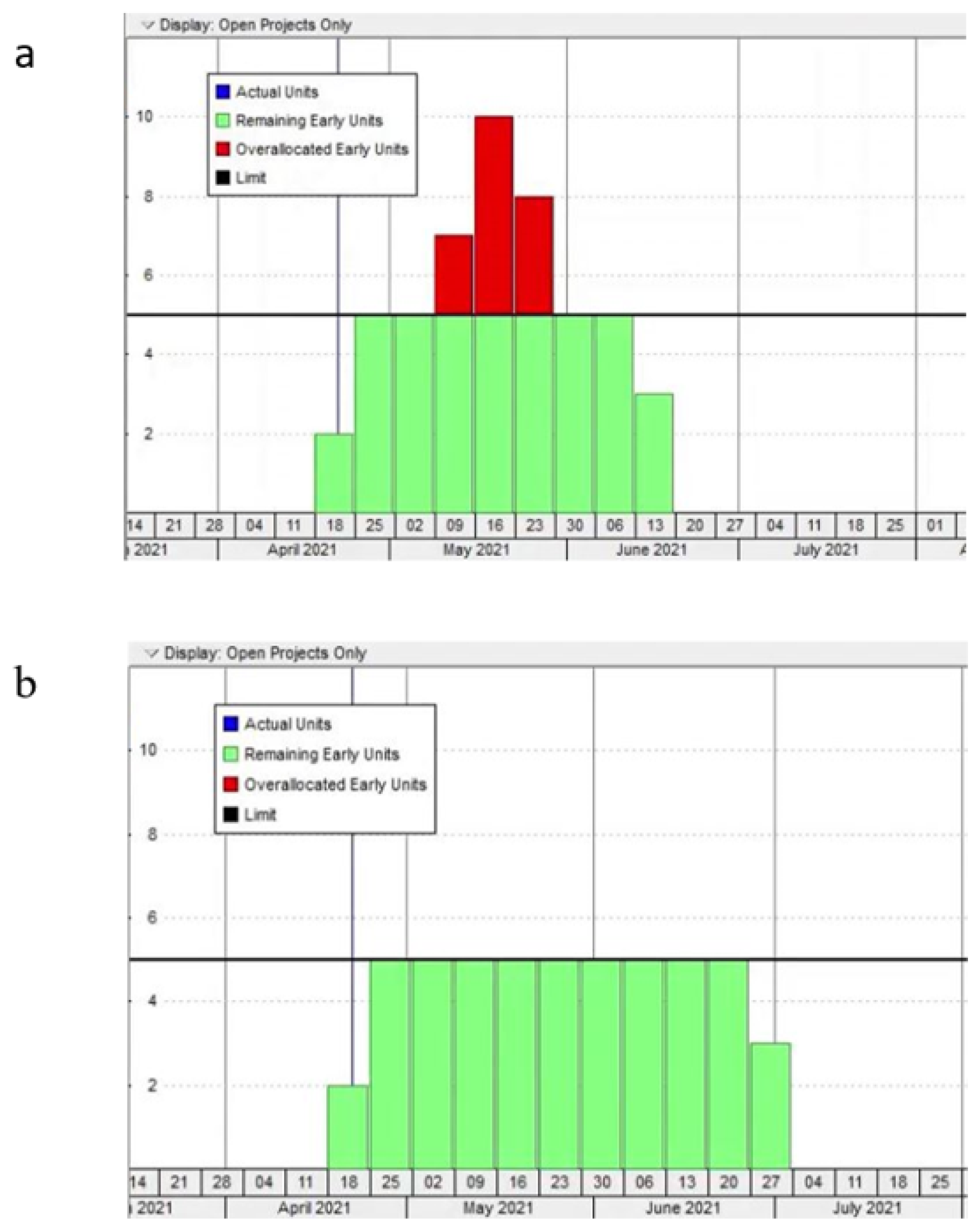

The resource overallocation identified in the initial project plan, as shown in

Figure 1a, could lead to various challenges during project execution, such as delays, conflicts, and inefficient resource utilization. By incorporating the Optimizio algorithm integrated with the resource availability verification module, the output schedule exported to Primavera P6 EPPM showed no more resource overallocation issues, demonstrating the effectiveness of the integrated scheduling optimization approach, as demonstrated in

Figure 1b.

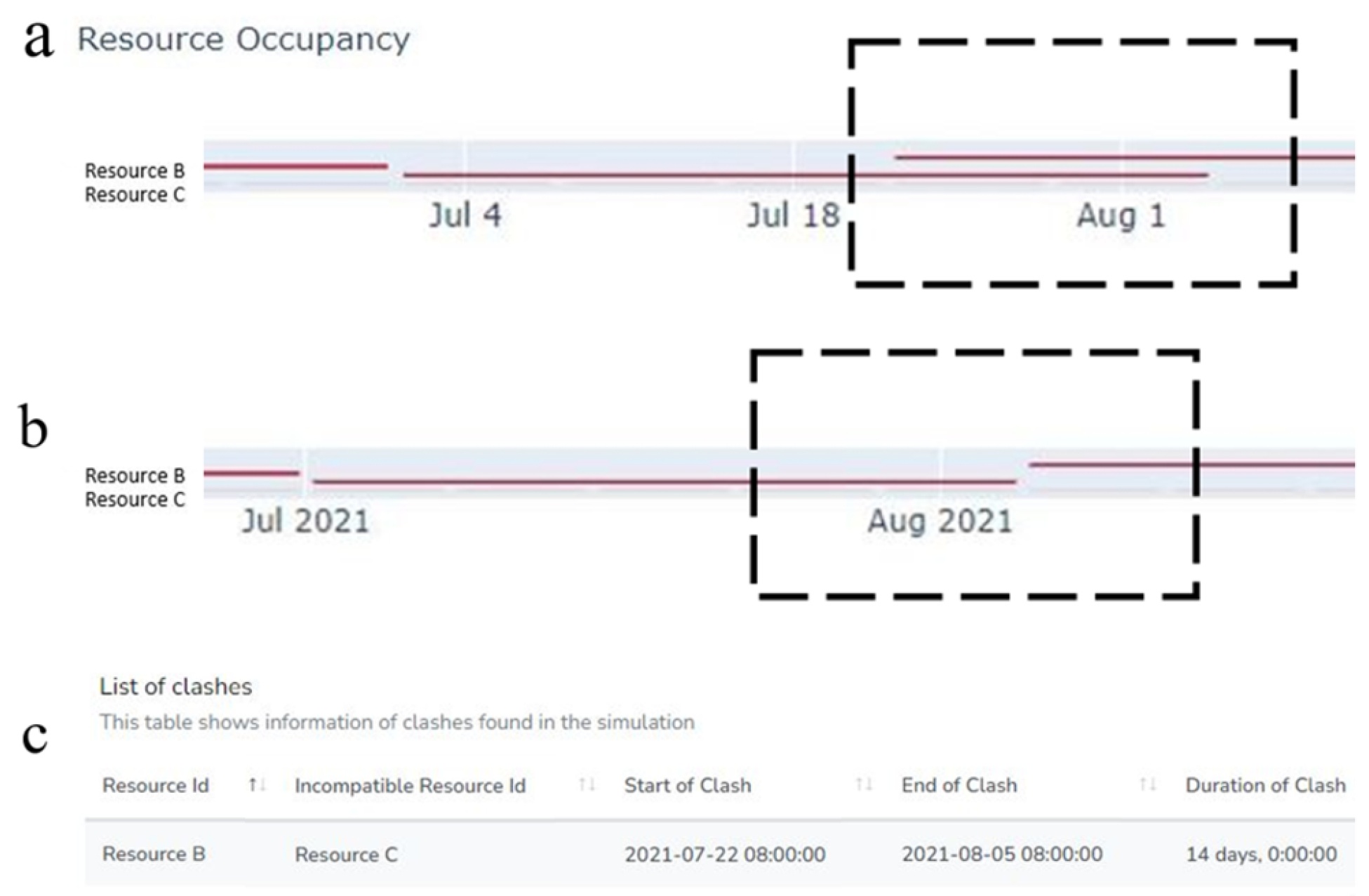

To address co-activity conflicts, the proposed approach provided insights into the scheduling simulation process. The tool provided KPIs that quantify the utilization level of each resource throughout the project schedule (

Figure 2a, 2b). Additionally, it also lists spatial conflicts found during the simulation, including the names of the resources involved and the start and end times of the clashes, along with the total duration of the conflicts (

Figure 2c).

These detailed KPIs serve as a valuable tool for project managers, enabling them to anticipate and address co-activity conflicts before they disrupt the project execution. This integration of a proactive approach into the project management workflow enhances the ability to plan, execute, and monitor projects with greater precision and confidence. Ultimately, this leads to improved project outcomes by minimizing disruptions and delays caused by unforeseen conflicts.

4. Discussion

The proposed algorithm effectively addresses conflicts arising from resource incompatibility and overallocation, as demonstrated in this work. However, its potential extends beyond these specific scenarios. The inherent modularity of the algorithm allows for adaptation to various project scheduling problems characterized by analogous constraint structures.

In this use case, two key modules were integrated within the tool. The first identifies potential conflicts stemming from resource incompatibility, while the second verifies resource availability before task execution. Even though the combined application of these modules may result in an extended overall project duration, this trade-off is justified as it demonstrably enhances the feasibility and executability of the construction schedule.

The identified spatial overlaps and resource overallocation necessitate delaying the upcoming task’s initiation to adhere to stakeholder requirements. However, the tool offers additional functionalities successfully employed in other scenarios that could be adapted here. Notably, it can compare task priorities and recommend pausing the ongoing task if it has lower priority than the upcoming one. Alternatively, a user-defined rule-based algorithm could be implemented to highlight the tool’s flexibility. This demonstrates the versatility of the proposed scheduling approach in addressing complex project management challenges.

Recognizing the widespread adoption of Primavera P6 EPPM as a leading project management software, the proposed tool offers seamless integration capabilities to enhance its usability and effectiveness within the industry. This integration enables the tool to read input directly from Primavera, ensuring that the project data and schedules are accurately captured and utilized within the proposed solution. Furthermore, the tool’s outputs, which include feasible schedules, efficient resource allocations, and conflict resolutions, can be directly exported back to Primavera P6 EPPM. This bidirectional data flow allows project managers to leverage the capabilities of the proposed tool while maintaining the familiarity and functionality of the Primavera platform.

Additionally, the tool expands its connector capabilities beyond those covered in this publication. Construction projects often involve diverse stakeholders, each utilizing different project management platforms. To accommodate this heterogeneity, an additional module was developed to facilitate the transformation of schedules from Microsoft Project, another widely used platform[

11], into a format readily interpretable by Primavera. This functionality addresses potential inconsistencies that may arise when utilizing Primavera’s built-in conversion features, ensuring seamless data exchange and fostering improved project collaboration.

To further maximize the connector capabilities, the tool offers an additional module that leverages Oracle Web Services to directly interact with project schedules within Primavera. This eliminates the need for manual data exchange through XML files. Users can simply provide their Primavera Oracle account credentials and identify the target project using elements like project object ID, ID, name, or other user-defined identifiers. This streamlines the connection process and facilitates real-time data access.

By addressing the key challenges of flexibility, domain-specific validation, and compatibility with existing tools, the scheduling approach presented in this paper offers a comprehensive solution to the complex problem of industrial project scheduling. The successful implementation and evaluation of this approach demonstrate its potential to improve resource utilization, reduce delays, and enhance the overall efficiency of industrial projects. By ensuring data continuity and transparency, this dynamic rule-based engine enriches the capabilities of project management and BIM 4D platforms, ultimately creating a digital twin of the project delivery process.

Author Contributions

Conceptualization, Khwansiri Ninpan, Lies Benmiloud Bechet and Robert Plana; Funding acquisition, Lies Benmiloud Bechet and Robert Plana; Investigation, Khwansiri Ninpan; Methodology, Khwansiri Ninpan; Project administration, Lies Benmiloud Bechet; Supervision, Francesco Vitillo, Mohamad Assaad, Lies Benmiloud Bechet and Robert Plana; Validation, Lies Benmiloud Bechet and Robert Plana; Writing – original draft, Khwansiri Ninpan and Shuzhang Huang; Writing – review & editing, Khwansiri Ninpan, Francesco Vitillo and Robert Plana.

References

- Coelho, J.; Vanhoucke, M. Going to the core of hard resource-constrained project scheduling instances. Computers & Operations Research 2020, 121, 104976. [Google Scholar] [CrossRef]

- Ding, H.; Zhuang, C.; Liu, J. Extensions of the resource-constrained project scheduling problem. Automation in Construction 2023, 153, 104958. [Google Scholar] [CrossRef]

- Wang, H.W.; Lin, J.R.; Zhang, J.P. Work package-based information modeling for resource-constrained scheduling of construction projects. Automation in Construction 2020, 109, 102958. [Google Scholar] [CrossRef]

- García-Nieves, J.D.; Ponz-Tienda, J.L.; Salcedo-Bernal, A.; Pellicer, E. The Multimode Resource-Constrained Project Scheduling Problem for Repetitive Activities in Construction Projects. Computer-Aided Civil and Infrastructure Engineering 2018, 33, 655–671. [Google Scholar] [CrossRef]

- Williams, D.L. Oracle Primavera P6 Version 8: Project and Portfolio Management; Packt Publishing Ltd, 2012.

- Aravindhan, C.; Santhoshkumar, R.; Bonny, K.; Vidhya, K.; Manishankar, S.; Dhamodharam, P. Delay analysis in construction project using Primavera & SPSS. Materials Today: Proceedings 2023, 80, 3171–3177. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons, 2018.

- Rai, A.; Atamuradov, V.; Mahe, S.; Deroui, H.; Allali, A.; Aumont, A.; Wacyk, J.G.; Plana, R. A Dynamic Heuristic Optimization for Condition-based Maintenance Planning, 2020. Published: EasyChair Preprint no. 2576.

- Rai, A.; Deroui, H.; Vacher, B.; Ninpan, K.; Aumont, A.; Vitillo, F.; Plana, R. A Modular Solution for Large-Scale Critical Industrial Scheduling Problems with Coupling of Other Optimization Problems. International Journal of Mechanical and Industrial Engineering, 2022, Vol. 16.

- Ninpan, K.; Kondratenko, K.; Huang, S.; Plancon, A.; Aumont, A.; Artaud, L.; Baker, M.; Roumili, E.; Vitillo, F.; Bechet, L.B.; Plana, R. An Extension of a Dynamic Heuristic Solution for Solving a Multi-Objective Optimization Problem in the Defense Industry. Optimization, Learning Algorithms and Applications; Pereira, A.I., Mendes, A., Fernandes, F.P., Pacheco, M.F., Coelho, J.P., Lima, J., Eds.; Springer Nature Switzerland: Cham, 2024; pp. 377–390. [Google Scholar]

- Biafore, B. Successful Project Management: Applying Best Practices, Proven Methods, and Real-World Techniques with Microsoft Project; Pearson Education, 2011.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).