Photovoltaics (PV) offer the major environmental benefits that go along with it: it reduces carbon emissions overall, operates quietly and cleanly, produces no waste or spent fuel, and is well appreciated for its fashionable appearance. However, there are also other environmental problems, like as the availability of raw materials and the substantial acreage requirement for chargers that rely on sunshine.

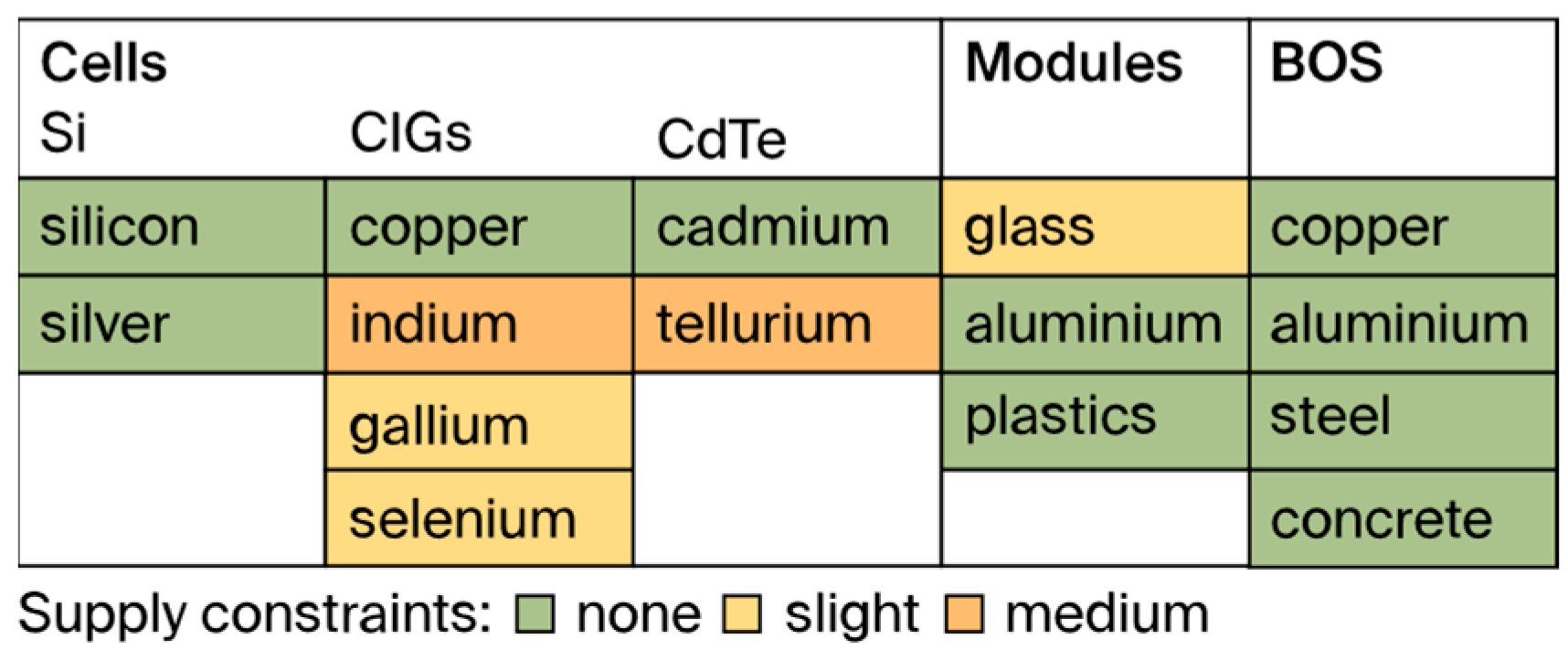

Let's start by talking about raw materials. It is evident that everything will be OK as long as photovoltaics (PV) continue to rely on silicon solar cells in the future. Silica, which is as abundant as beach sand almost everywhere, is possibly the most common element found outside of Earth. Thankfully, it is also essentially harmless and won't eventually run out. While silicon itself seems amazing, this is not to argue that the other materials used to create silicon photovoltaic modules are limitless or without problems. Since the critically important new forms of sunlight-based cells—primarily Copper Indium Gallium Selenide (CIGS) and cadmium telluride (CdTe)—have lately been discussed in previous sections of the postulation [

1], the issue isn't as evident as silicon. Nevertheless, a 2004 analysis by the highly regarded National Renewable Energy Laboratory (NREL) of the US Department of Energy (DOE) was largely comforting. The paper evaluated the required "strength" materials for solar cell manufacturing, additional materials for PV module integration, and "ware" materials for balance-of-framework (BOS) components such as backing structures and roof mountings. An increase in annual PV sales in the USA to 20 GWp by 2050 was the scenario considered [

2]. From then on, it looked at the amount of various materials with the degrees of production that are currently occurring globally to establish the rate of development necessary year until 2050. The conclusion reached was that, while the aforementioned scenario wouldn't necessarily result in problems with asset accessibility, things would change if development proceeded more quickly or, conversely, if global creation were to reach 100 GWp/year.

As one might anticipate, silicon sunlight-based cells are accepted as appropriate, with no concerns expressed either silicon or the silver used to screen-print cell associations. Deficits in tellurium may limit CdTe cells, although shortages in gallium and selenium may limit CIGS cells more than limitations in indium [

4]. Happening to PV modules and BOS parts, the main minor concern is the enormous measures of glass required; this isn’t on the grounds that unrefined components would run out, but instead on the grounds that creation limit would have to increment fundamentally on an overall scale to stay aware of PV’s requests. In summary, tellurium and indium, and less so gallium and selenium, are the "claim to fame" elements that really need to be prioritized.

1.2. Environmental and Societal Cost

The conventional understanding of "cost" blatantly ignores the effects on society and the environment that all energy production techniques—whether they rely on coal, oil, gas, nuclear, or renewable sources—have [

6]. A limited financial perspective on contemporary cycles evaluates everything in terms of money, with the exception of many viewpoints that sound judgment dictates should be considered in any objective assessment of worth. For instance, the "cost" of producing power in thermal energy stations has typically been calculated without accounting for accident or health risks; in contrast, the "cost" of supplying power in coal-fired plants has not been evaluated in light of their unwelcome commitment to an unnatural weather change; and due to wind power, the value of the surrounding environment has not been considered.

There are two main factors that contribute to this obvious stupidity. To begin with, it is challenging to measure and evaluate elements such as safety, security, environmental preservation [

7], and scene grandeur using a conventional accounting framework. Although appropriate instruments and ways for consolidating them are still in the early stages of development and recognition, it is widely acknowledged that they are valuable and frequently have a higher value than cash. This is unquestionably essential to undertake since many of the problems we are presently facing stem from the tendency of traditional bookkeeping "to know the cost of everything and the benefit of nothing."

The second defense deals with the pressing consideration of the external expenses associated with energy production. Since the majority of these expenses include an environmental or social component, they are typically viewed as being outside the purview of the energy economy and coming within the purview of society at large [

8]. This ought to be achievable financially through fees or ecologically with a reduction in lifestyle. They take precedence over an organization's internal operating expenses, which include salaries for staff, fuel, buildings and equipment, and other expenses that are directly related to the business and have an impact on its main objective. If Earth is viewed as an endless "source" of raw materials and a never-ending "sink" for pollution and waste products, it is quite simple to ignore the expenses associated with space travel [

9]. For instance, it is improbable that the pioneers of steam transportation in the 1800s or the designers of the first supersonic commercial aircraft in the 1900s were very concerned about environmental concerns and supersonic explosions. One of the most significant current trends is the growing belief that external costs ought to be factored into circumstances, whether local or national and increasingly global ones. In other words, external expenses should be taken into account and covered by the company or companies that are accountable. The saying "the polluter should pay" is still relevant today.

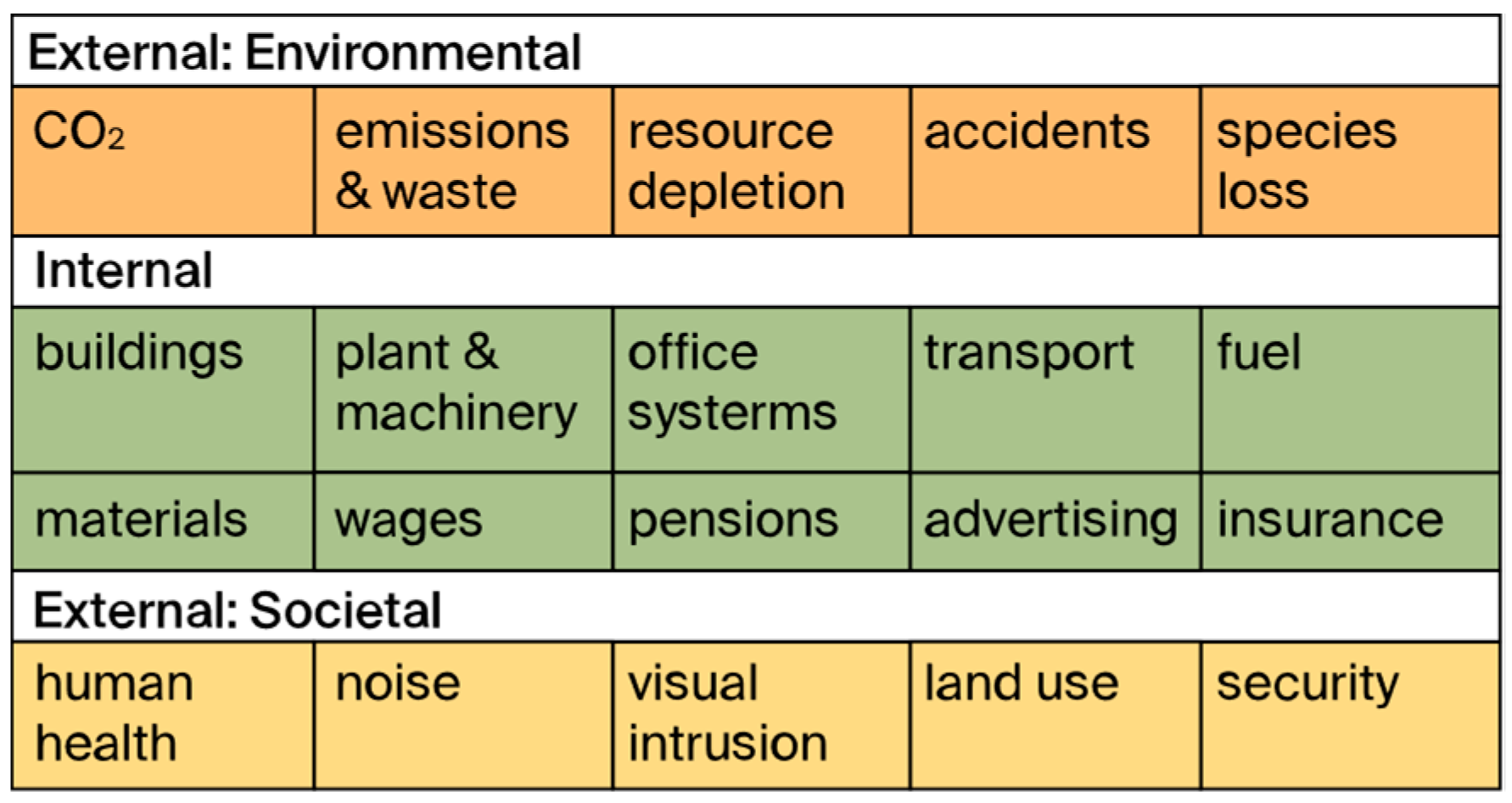

A comprehensive list of the internal and external consumptions associated with contemporary assembly is shown in

Figure 2. Despite the fact that there is a great deal of overlap between the two, the external ones—which stand for overall costs or burdens on society—are divided into the environmental and humanistic categories. Internal expenses [

10] are directly funded by the group or organization itself and cover a wide variety of goods and services, from labor compensation to designs. The distinction between internal and external costs is not always clear since many items that a company purchases, such gasoline and materials, also have significant "outer" expenses for the time it takes to assemble and deliver them. An accurate assessment of the environmental costs associated with the growth of electricity should consider all major actions and services "from support to grave," regardless of whether they are provided on- or off-site. It goes without saying that this is a difficult task.

One of the intriguing challenges facing the renewable power age is the manner that many of its benefits, such as photovoltaics, stem from avoiding external consumptions and are hence obscured by conventional bookkeeping techniques. Renewable energy sources often result in extremely low carbon dioxide discharges, little pollution, minor noise, and very little risk to life or property, in addition to areas of strength for having support [

11]. PV is entitled to these advantages. Nevertheless, when lawmakers and financial experts discuss photovoltaics, the avoidance or reduction of external costs is rarely brought up. Thankfully, environmental life cycle analysis is becoming more and more important to energy experts and government advisors, who are using it to more realistically weigh the benefits and drawbacks of competing technologies. Without a doubt, the PV people group ought to be proactive in refuting out-of-date assumptions on the wider advantages of its innovation.

Putting forward two main points is important. Regardless, there are significant differences between monetary compensation and energy restitution. The former is mostly a financial issue, whereas energy restitution is far more concerned with the environment. The last option is concerned with providing a long-term payback schedule for the capital and support costs (including energy consumption) incurred by a framework. Second, the environmental benefits of a quick restoration phase rely on the continuing energy mix of the nation or nations in question. If the majority of the required energy is provided by coal-consuming power plants, it is more harmful than, say, hydroelectricity [

12]. Given this, it is plausible to argue that certain large-scale life-cycle studies conducted in the early years of the new century painted a bleak picture of PV's effects on the environment and human welfare. This was primarily because the phones and modules were expected to be produced using energy derived from petroleum derivatives. A subsequent analysis, on the other hand, represents external costs and advances in PV design accurately, leading to fundamentally more optimistic conclusions.

The market for power-producing solar photovoltaic (PV) systems has recently expanded significantly. According to the most recent data available, 102.4 GW of network-associated photovoltaic boards were established globally in 2018. This amount is the same as the total PV limit that was available in 2012 (100.9 GW). As a result, the total solar power limit that was imposed was 400 GW in 2017 and increased to above 500 GW in 2018 [

13]. The major participants are the US, China, India, and Japan. Not quite the previous year, China introduced 44 GW (16% under 2017), India introduced 8.3 GW (16% under 2017), and Japan brought 6.6 GW (8% under 2017). These were the other major backers. The primary country with a consistent introduction of new solar power was the US (10.6% in 2017 and 2018). Australia gained 295% in market share from the previous year to add 5.3 GW in 2018, making it the world's fifth-largest market.

The European Union (EU) took the lead in accomplishing the binding targets of reducing greenhouse gas emissions and other environmental effects associated with the use of non-renewable energy sources, as well as switching from petroleum derivatives to renewable energy sources. The EU intends to expand the use of solar technology in the near future in accordance with the new 32% renewables goal in 2030 (the maximum power introduced in Europe in 2018 was 11.3% GW, which was 21% more than the cap imposed in 2017) [

14]. In light of the previous year, the EU displayed a crucial pattern: Compared to 2017, there were larger installations in 22 out of 28 EU markets, and the total solar limit linked to the framework increased to 8.2 GW (37% more than in 2017). A great deal of effort has been completed to enhance PV implementation in the environmental domain as well. As a result, PV innovation is more ecologically friendly than petroleum goods in many impact classes; nonetheless, environmental effects are still a part of its life cycle.

As a result, it's critical to weigh the benefits of using PVs in terms of energy and the environment while taking the life cycles of the frameworks into account. A useful standard method for achieving this goal is the life cycle assessment (LCA) [

15], which takes into account the effects on the environment, the main sources of energy consumption (both renewable and non-renewable), the depletion of resources, and outflows over the course of an innovation's entire life cycle.

The Existence Cycle Assessment (LCA) is a “objective method for surveying the energy and environmental burdens connected with an interaction or movement [

16]” that determines the energy and materials expected as well as the trash delivered into the environment.

1.3. PV Technology Description

One of the intriguing challenges facing the renewable power age is the manner that many of its benefits, such as photovoltaics, stem from avoiding external consumptions and are hence obscured by conventional bookkeeping techniques. Renewable energy sources often result in extremely low carbon dioxide discharges, little pollution, minor noise, and very little risk to life or property, in addition to areas of strength for having support [

11]. PV is entitled to these advantages. Nevertheless, when lawmakers and financial experts discuss photovoltaics, the avoidance or reduction of external costs is rarely brought up. Thankfully, environmental life cycle analysis is becoming more and more important to energy experts and government advisors, who are using it to more realistically weigh the benefits and drawbacks of competing technologies. Without a doubt, the PV people group ought to be proactive in refuting out-of-date assumptions on the wider advantages of its innovation.

Putting forward two main points is important. Regardless, there are significant differences between monetary compensation and energy restitution. The former is mostly a financial issue, whereas energy restitution is far more concerned with the environment. The last option is concerned with providing a long-term payback schedule for the capital and support costs (including energy consumption) incurred by a framework. Second, the environmental benefits of a quick restoration phase rely on the continuing energy mix of the nation or nations in question. If the majority of the required energy is provided by coal-consuming power plants, it is more harmful than, say, hydroelectricity [

12]. Given this, it is plausible to argue that certain large-scale life-cycle studies conducted in the early years of the new century painted a bleak picture of PV's effects on the environment and human welfare. This was primarily because the phones and modules were expected to be produced using energy derived from petroleum derivatives. A subsequent analysis, on the other hand, represents external costs and advances in PV design accurately, leading to fundamentally more optimistic conclusions.

The market for power-producing solar photovoltaic (PV) systems has recently expanded significantly. According to the most recent data available, 102.4 GW of network-associated photovoltaic boards were established globally in 2018. This amount is the same as the total PV limit that was available in 2012 (100.9 GW). As a result, the total solar power limit that was imposed was 400 GW in 2017 and increased to above 500 GW in 2018 [

13]. The major participants are the US, China, India, and Japan. Not quite the previous year, China introduced 44 GW (16% under 2017), India introduced 8.3 GW (16% under 2017), and Japan brought 6.6 GW (8% under 2017). These were the other major backers. The primary country with a consistent introduction of new solar power was the US (10.6% in 2017 and 2018). Australia gained 295% in market share from the previous year to add 5.3 GW in 2018, making it the world's fifth-largest market.

The European Union (EU) took the lead in accomplishing the binding targets of reducing greenhouse gas emissions and other environmental effects associated with the use of non-renewable energy sources, as well as switching from petroleum derivatives to renewable energy sources. The EU intends to expand the use of solar technology in the near future in accordance with the new 32% renewables goal in 2030 (the maximum power introduced in Europe in 2018 was 11.3% GW, which was 21% more than the cap imposed in 2017) [

14]. In light of the previous year, the EU displayed a crucial pattern: Compared to 2017, there were larger installations in 22 out of 28 EU markets, and the total solar limit linked to the framework increased to 8.2 GW (37% more than in 2017). A great deal of effort has been completed to enhance PV implementation in the environmental domain as well. As a result, PV innovation is more ecologically friendly than petroleum goods in many impact classes; nonetheless, environmental effects are still a part of its life cycle.

As a result, it's critical to weigh the benefits of using PVs in terms of energy and the environment while taking the life cycles of the frameworks into account. A useful standard method for achieving this goal is the Life cycle assessment (LCA) [

15], which takes into account the effects on the environment, the main sources of energy consumption (both renewable and non-renewable), the depletion of resources, and outflows over the course of an innovation's entire life cycle.

A Life Cycle Assessment (LCA) is a “objective method for surveying the energy and environmental burdens connected with an interaction or movement [

16]” that determines the energy and materials expected as well as the trash delivered into the environment.

1.4. Types of PV Cells

The ongoing advancement of photovoltaic innovation aims to improve cell performance, reduce module market costs, and streamline production processes in terms of cost and speed. Solar cells may be created by layering materials that hold light in at least one layer. The main scenario refers to single intersection cells, which are relatively easy to construct but less effective; surprisingly, different setups, or multi-intersections, are more complex and perform better because they have multiple cycles for charge partition and retention [

20]. The components and innovations used in PV frameworks' solar cells set them apart. PV cell developments are frequently arranged according to three ages:

Undefined silicon (a-Si), cadmium telluride (CdTe) and cadmium sulfide (Cds), copper indium gallium selenide (CIGS)/copper indium selenide (CIS), gallium ar-senide (GaAs), and couple/multi-intersections modules in view of Si are among the materials utilized in the second era of thin-film solar cells;

The third era (sometimes referred to as the future) alludes to novel non-silicon based advancements and new idea gadgets, such as color-sharpened solar cells (DSSC), quantum spot (QD) cells, perovskite solar cells (PSC), natural/semi-natural PV boards (OPV), and PSCs.

The development of PV innovation throughout several generations was driven by the desire to increase the expense/benefit ratio. Even with the advancements, original photovoltaics still have high creation costs (between 200 and 500 US dollars per square meter) and limited potential for further reduction (to 150 US dollars per square meter), as a significant portion of the cost is attributed to the quantity of materials needed and the specific techniques in question. Also, the majority of these assembly procedures consume a significant amount of energy [

21], which has a big impact on the life cycle outflow factors of the devices. Fascinatingly, devices from the second generation achieve modest production while generating minimal area costs (between 30 and 110 US dollars per square meter). This is achieved by using low-cost fabrication techniques (such as fume testimony, modifying, and so on) and reducing the amount of material needed. As second-generation devices need less energy to assemble than original devices, lower discharge variables should follow if second-generation devices are able to provide higher performance execution than justify their massive scope creation [

22]. Finally, the third era presents the opportunity to maintain the benefits of thin film production techniques with respect to energy and the environment, while increasing efficiency well beyond that of the first and second ages (by means of optional energy transformation instruments) and lowering creation costs (which are typically between 40 and 150 US dollars/m2 for the most productive devices).

The use of renewable energy sources in place of petroleum products only helps to advance real, global advancement in the economic and social spheres. This makes it feasible to reject the conventional wisdom that links a nation's financial progress and energy use to an increase in the emissions of substances that deplete the ozone layer [

23]. Due to the continuous concern about environmental change and the desire to lessen the negative effects that the usage of conventional petroleum derivatives has on the environment and human well-being, renewable assets are becoming more and more important in global economies.

Although renewable energy innovations have eventually been included into a variety of force supply frameworks, their exceptional features should be taken into account to provide consistent coordination and accelerate the infiltration of these technologies [

24]. This is especially clear when it comes to the erratic and variable nature of renewable energy sources, which provide a challenge to the electrical energy framework's changing requirements due to variations in the amount of electricity generated during the day, week, and season. According to power lattice administrators, the term "dispatch capacity" refers to the ability of power to be dispatched upon request in response to market demands. Dispatched age frameworks provide for the tracking of several key performance indicators, such as response time, creation accessibility, age term, realistic age-level upper and lower bounds, and slope rate from one age level to the next. Other considerations to take into account include the area of the renewable energy assets and the limit factor. When renewable energy sources are integrated into power supply companies, they may be used even more efficiently.

As nations strive for cleaner energy advancement focuses on reducing their reliance on petroleum derivatives, energy capacity becomes a fundamental role in dealing with the receipt of renewable energy sources. In this particular scenario, there is a great deal of interest in the impact that capacity advancements have on venture costs and the environment [

25].

One of the commercial renewable energy innovations is Solar Thermal Energy (STE), which is produced in the concentrating solar power (CSP) facilities. STE generates power with the use of mirrors that enable the convergence of solar rays at temperatures between 400 and 1000 °C. The interaction's ultimate goal is to power an intensity motor—typically a steam turbine—which generates energy for the electrical framework. Though it is seldom used in crossover activities or coordinated with nuclear power stockpile, STE provides solid limit and dispatchable power upon request [

26]. STE is a renewable invention that can guarantee a steady supply of energy and follow market trends. As a result, it can replace power plants that use petroleum products and help achieve a 100% renewable energy supply.

There is still uncertainty regarding these power offices' potential effects on the environment, even though they have been thoroughly examined from a variety of angles. There aren't many exams in the writing, and none of them provide a thorough overview of a CSP office. Piemonte et al., for instance, introduced a novel solar innovation that combines a concentrating solar power (CSP) with an assister biomass burner in order to compare the results and life cycle assessments (LCAs) of other energy advancements, such as gas and heavy oil power plants (information taken from writing). Oró et al. considered the environmental effects of three elective Thermal Energy Storage (TES) frameworks for solar power plants. These frameworks featured reasonable intensity stockpiling using both fluid and strong warm stockpiling medium (liquid salts and high temperature concrete) and dormant intensity stockpiling employing Phase Change Material (PCM). Lalau et al. focused solely on the effects of the stockpiling framework while comparing the environmental effects of an innovative stockpiling framework named "thermocline/Cofalit and liquid salt" with those of a traditional CSP stockpiling innovation called "two tanks/liquid salt" [

27]. Whitaker et al. assessed water use, Cumulative Energy Demand (CED), Energy Payback Time (EPBT), and Greenhouse Gas (GHG) discharges for a hypothetical pinnacle CSP project located in the US. The characteristics of the plant were derived from previous studies on liquid salt pinnacle plant designs overseen by Sandia National Laboratories in connection with functioning plant demonstration projects carried out by the National Renewable Energy Laboratory (NREL). Pelay et al.'s LCA covered a hypothetical pinnacle CSP plant with a Rankine power cycle and Thermal Chemical Energy Storage (TCES) using calcium hydroxide. When comparing the LCA to the reference plant without capacity, the increased environmental impact resulting from the TCES framework was considered to be quite negligible. These inventors discovered that standard component libraries, such as Ecoinvent, LCA Food DK, and USA Info Result Data set, were inadequate for the study of force plants due to a lack of knowledge.