1. Introduction

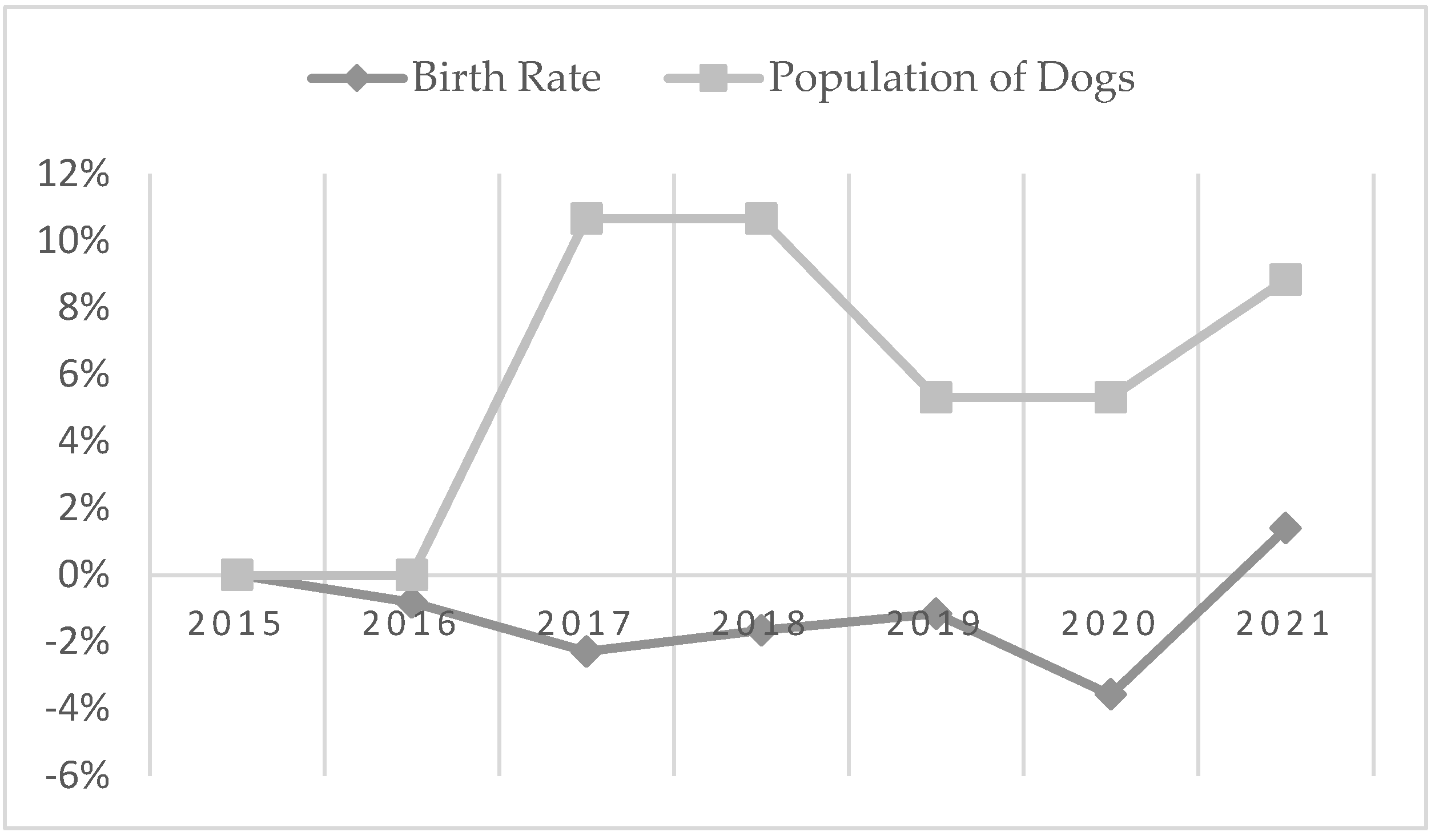

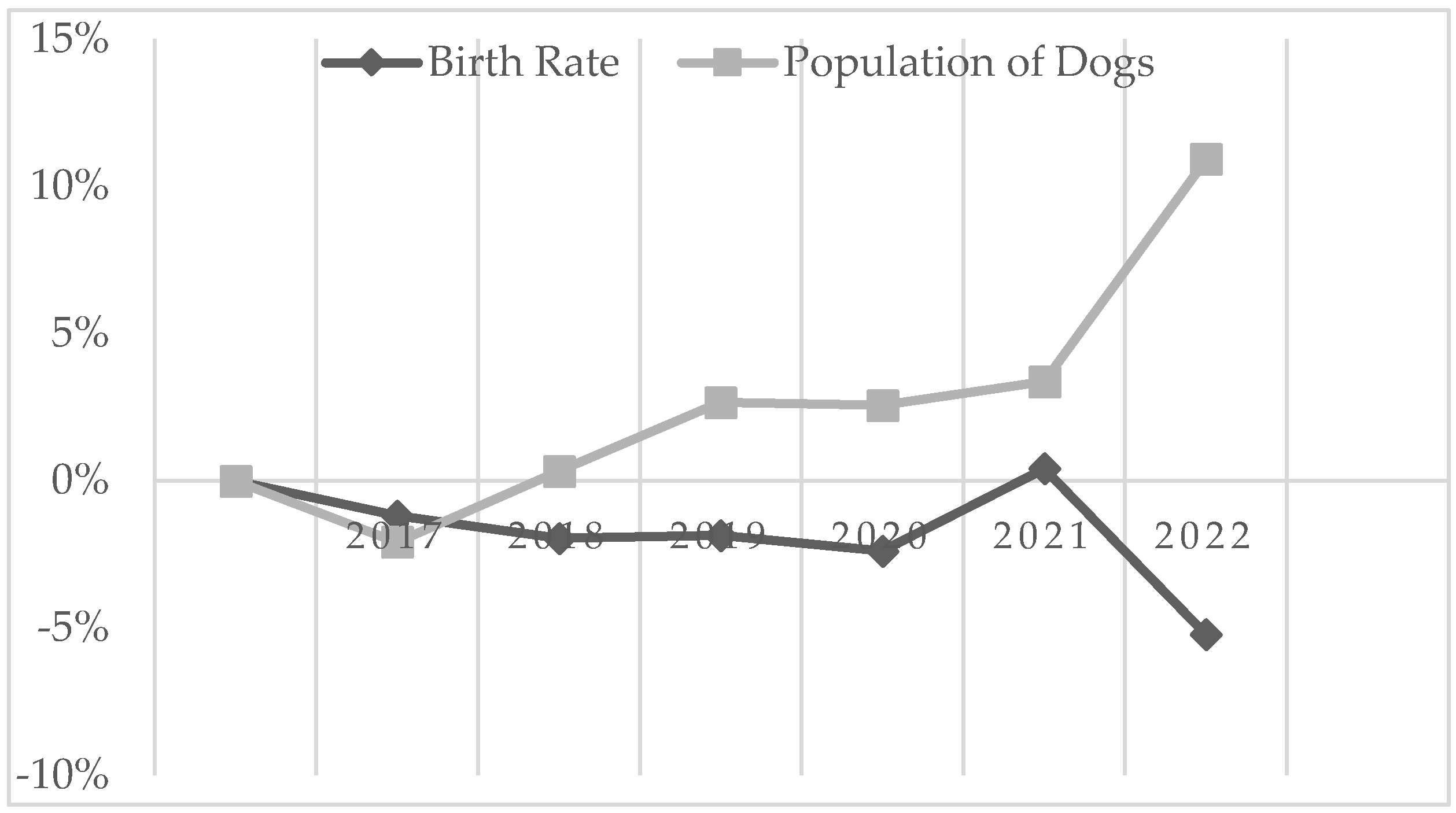

Owning domestic pets has gradually become a popular lifestyle while birth rate is declining throughout the world. Financial considerations and responsibilities contribute a lot to the phenomenon of low fertility rate but high dog population nowadays. Raising a child comes with significant financial commitments, including expenses related to healthcare, education, and general upbringing, along with time and responsibilities for taking care of the child [

1]. Thus, some individuals or couples decide to keep dogs as family members or companions instead of giving birth since the money and time for owning a dog is generally lower than raising a child. Europe, for instance, 90 million European households own at least one pet, which account for near a half of Europe while the annual birth rate is decreasing gradually from 4.3 million to 3.9 million that shown on

Figure 1 [

2] and

Table 1 [

3]. From the

Figure 2 [

4] and

Table 2 [

5], annual birth rate in the United States from 2015 to 2020 is declining from 4 million to 3.7 million while the dog population is increasing continuously from 54 million to 69 million, which has the same phenomenon with Europe. In Hong Kong, survey report illustrated by the Census and Statistics Department in 2019 stated that almost 250,000 households are keeping cats or dogs and more than 60% are dog keepers, which amounts to over 220,000 dogs [

6]. According to the increasing of pets, variety of pet food products is well developed and pet food industry is growing significantly at the same time, which 10.2 million tons of pet food are sold in 2022 with reaching the sale of 27.7 billion EUR and the annual growth rate is 3.1% in Europe market (average value over the past three years) [

7].

Due to the characteristics of loyalty and companionship, dogs are equally treated as family members nowadays [

8,

9,

10], health and well-being of dogs are of utmost importance to their caregivers, thereby their awareness to dog food quality and safety is risen. Pet food safety indicates a significant challenge in types of biological, chemical and physical hazards in the food. In the past decades, there have been many hazards on pet food such as toxic metal, mycotoxin, salmonella and high sodium phosphorus content. Nowadays, some pet food products are over the daily reference value in different hazards, yet, several testing techniques like Inductively Coupled Plasma Optical Emission spectroscopy (ICP-OES), High-Performance Liquid Chromatography (HPLC), Liquid Chromatography–Mass Spectrometry (LC-MS) and Atomic Adsorption Spectroscopy (AAS) are able to detect those hazards.

Specific authorities, regulations and laws for pet food products are enacted in various countries. In fact, Hong Kong lacks a mechanism to monitor imported or local pet food at present, which means there is no legal protection for pets and pet owners [

11]. By summarizing worldwide authorities and regulations for overseeing the safety of dog food, suggestions for Hong Kong Government to develop regulations to supervise the safety of dog food are expressed and advised. For further information, please refer to Part 4 and Table 11. As a result, the following study provides reviews on existing pet food market, challenges and suggestions for Hong Kong Government to illustrate the urgency and necessity for having a monitoring mechanism to control and guarantee the dog food selling in Hong Kong are safe, nutritious and in high quality.

2. Review of Existing Dog Foods

2.1. Types of Dog Food

Dog food product is a subset of animal feed which should be able to provide “taste, aroma or nutritive value” [

12] and the three major nutrient components of dog food are protein, carbohydrates and fat [

13]. Commercial dog food products, can simply as a treat made by raw meat and complicated as a 60-plus ingredients with multi-steps process biscuit, which can be divided into three main types, including dry dog food, also known as kibble, semi-moist dog food, wet dog food, and raw dog food (sold as treats or usually made by the pet owners) [

14]. Each of them have particular production process and consist of various ingredients. The comparison between those four types of dog food is shown on

Table 3.

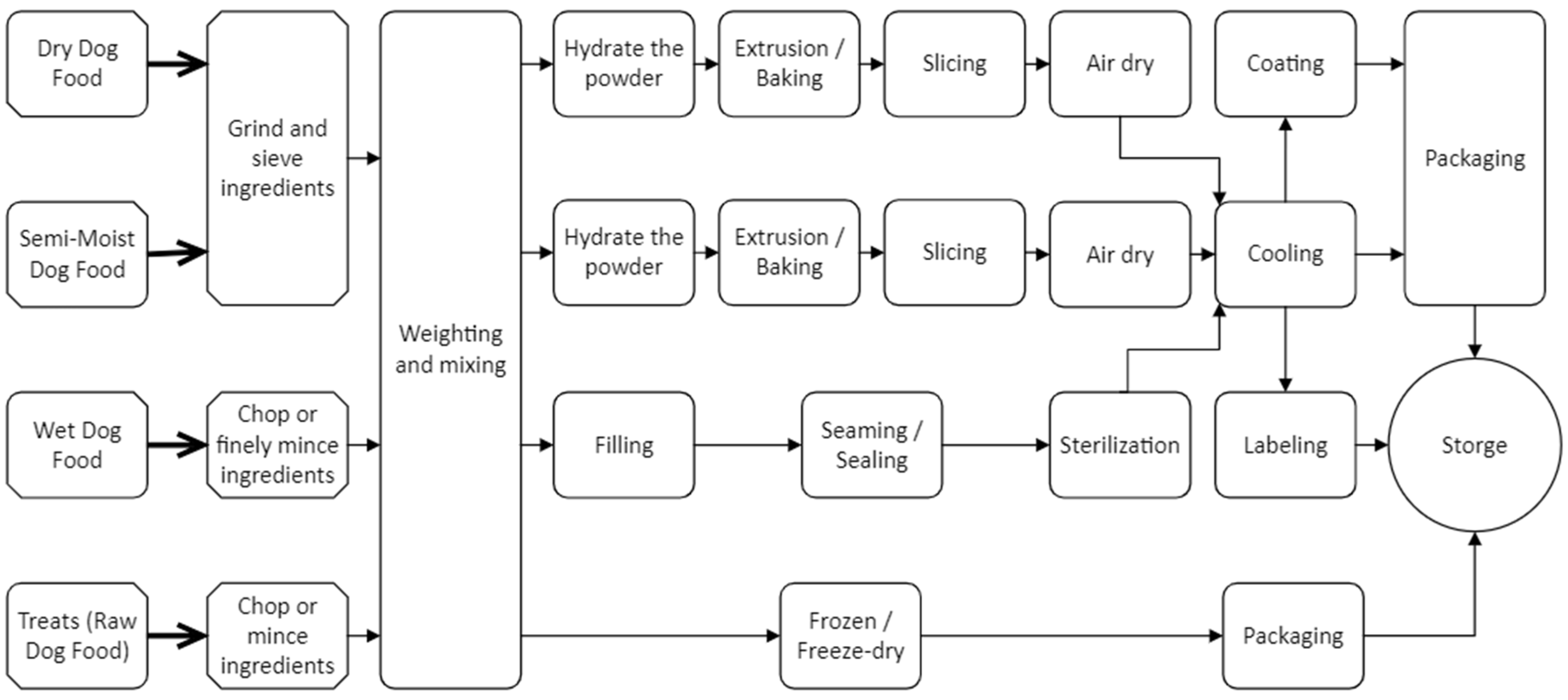

2.2. Production Process

The initial preparation for all pet food production is to select meat, vegetables, grains, and other components based on the desired recipe and nutritional requirements. Ingredients are typically inspected for quality and may undergo cleaning, and cutting or grinding processes to break down the raw ingredient into smaller size for further processes. Afterwards, treated ingredients are going to be mixed according to a specific recipe or formulation [

20]. This step ensures the ingredients are evenly distributed and blended. The comprehensive production flow of various pet foods is shown on

Figure 3.

The production process of dry and semi-moist dog food is similar, the ground and mixed ingredient powder need to be hydrated to a dough state by combining with water, steam, and wet ingredients before extrusion or baking. Extrusion is a cooking method where a food substance is compelled to move through a die under high temperature, pressure, and shear conditions [

21]. For semi-moist dog food, the temperature and cooking time are different from dry pet food as their moisture is disparate [

22]. When the dough exits the extruder, the rotary cutter slices the cooked dough into a pre-specified size and shape. The cut dry kibbles and semi-moist products are sent to air dried and cooled after cooking. However, the dry kibbles process to coating while semi-moist dog products process to packaging after extrusion or baking [

23]. The dry kibbles often go into a rotating drum where they receive a uniform coating of flavor enhances to improve taste, and preservatives to extend the food’s shelf life and prevent spoilage. Subsequently, the products are going to be packed according to the specified weight and the packaging is properly sealed to avoid any potential contamination during storage and distribution [

24].

Figure 3.

The production process of various dog food [

17,

22,

23].

Figure 3.

The production process of various dog food [

17,

22,

23].

The production process of wet dog food is less complex, the treated raw ingredients are directly filled into various packages such as cans, pouches, or trays after weighing and formulating. The filled products are then sealed or seamed and enter a cooking and sterilization process [

20]. Once the products are cooked, they are cooled down, and then the cans are labeled. Following this, the products are going to be stored.

Ingredients for producing raw dog food are usually frozen or freeze-dried immediately after being treated and formulated. Next, the products are packed and sealed before being stored [

25].

Apart from the captioned processing step for all four types of dog food, in-house quality control and assurance is also an essential step during each production procedure. A comprehensive quality management system can ensure the dog food is safe for consumption which complies with the regulations, and the consistency of the products by doing different tests including microbiological and physical tests during each production step [

26]. The dog food that passes all tests should be a certified safe food for dogs and able to be distributed.

2.3. Ingredients

Selecting high quality ingredients is the first crucial step for producing nutritious and safe dog food. To make sure the pet food can deliver adequate and balanced nutrients to dogs, the product development scientists and manufacturers formulated various ingredients by choosing them from different nutrient categories including protein, carbohydrates and fiber, fat, vitamins, and minerals. In addition, factors in selecting ingredients are nutrient level, palatability, availability, functionality, digestibility, and cost [

13]. Typical ingredient examples of different nutrients are listed in

Table 4.

3. Hazards

3.1. Special Toxic Food

There are a lot of toxic elements that posed a risk to dogs if they are present in their food or environment. Most of the toxic food is very common to humans like chocolate, grapes and garlic. However, these food is toxic to dog. In this day and age, most of the pet owners already know that dogs cannot eat chocolate. In fact, the dose makes the poison.

| |

Poisonous Substance |

Symptoms |

| Alcohol |

Alcohol |

Deaths, respiratory failures, seizures, drowsiness, losing body coordinate |

| Cherries |

Cyanide |

Deaths, breathing complications, and pupils’ dilapidation |

| Chocolate |

Theobromine and caffeine |

Seizures, high blood pressure, fast breathing, internal bleeding and fatal |

| Coffee and Tea |

Caffeine |

Vomiting, seizures, heart arrhythmias, abdominal discomfort and diarrhea |

| Grapes and Raisins |

Grapes |

Shivers, decreased appetite, lethargy, kidney failure and deaths |

| Nuts |

Nuts |

Lack of muscle control, vomiting, lethargy and seizures |

| Onions and Garlic |

Thiosulphate |

Anemia |

| Rhubarbs |

Rhubarbs |

Kidney failures and digestion complications |

| Xylitol |

Xylitol |

Loss of coordination, vomiting, and liver failures |

3.2. Dog Food Safety Hazard Analysis

3.2.1. Chemical

3.2.1.1. Heavy Metals

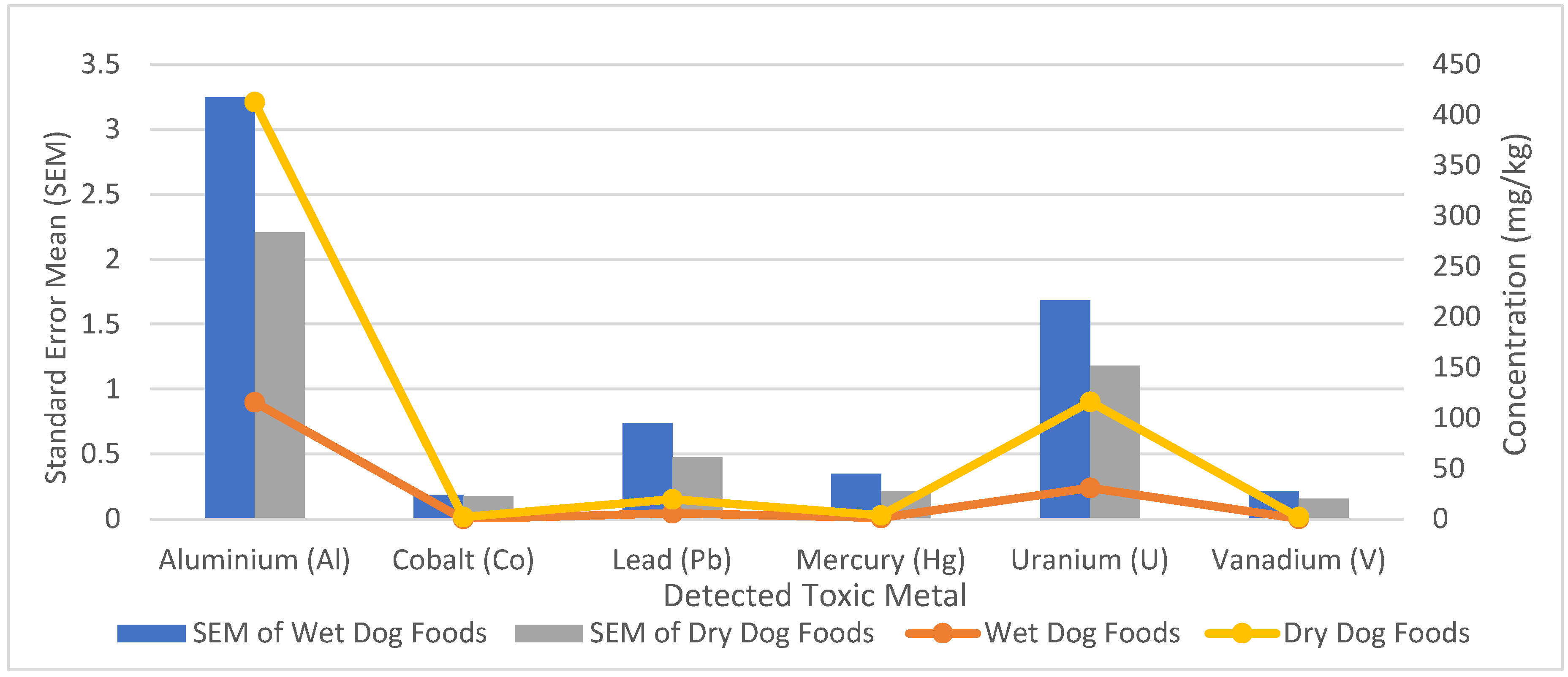

Heavy metals are toxic substances that can harm dogs if they are consumed or exposed over a maximum tolerated dose. Exposure to toxic metals can occur in dogs through various means such as contaminated water, soil, food, or specific household objects. Several studies showed that high concentrations of toxic metals exist in different commercial pet food products while some of them such as lead (Pb), mercury (Hg), aluminum (Al), and uranium (U) are even out of the maximum tolerated level (MTL). In all samples of dog food, certain elements like antimony (Sb), barium (Ba), chromium (Cr), tin (Sn), iron (Fe), and Hg were found. The substances arsenic (As), boron (B), beryllium (Be), and selenium (Se) were found to be too low for detection in all the samples of both dog and cat foods, with a limit of 0.05mg/kg. However, some elements like Al, Pb, Cobalt (Co), Hg, U, and vanadium (V) had values higher than the limits which are shown in

Table 6 [

36].

In the literature data and as shown from

Figure 4, Al is found in large quantities in commercial dog foods, reaching levels as high as 11,900 mg/kg of food. This is 59.1 times more than the highest allowed limit. For Hg, the detect value is much higher than the maximum tolerated level. Between the effects of excessive dosage of Hg intake, it is observed that it will lead to motor incoordination, ataxia and loss of balance while the histopathological findings demonstrated neurological injuries as well [

36]. It is also crucial that they found concentrations of lead that were higher than what is considered safe for dogs and cats. The results are concerning because consuming excessive lead has been linked to signs of stomach and intestine problems, disorders in the brain and nerves, and bone marrow system, and even injuries to the kidneys [

36].

In another study, from 2009 to 2019, the amount of several heavy metal detected from dog food were increased experientially (see

Table 7). In 2009, 44% of the dog food samples was tested with arsenic, however, in 2019, 70% of the samples with greater amount of arsenic which is considered unsafe for a dog weighing 50 lbs., according to the World Health Organization. The amount of nickel exposure that went over the allowed limits increased from 22% in 2009 to almost 46% in 2019.

The type and severity of symptoms in dogs exposed to heavy metals can differ depending on both the metal and extent of their exposure. Various types of heavy metals can have negative impacts on different parts of dog’s body, which can result in a variety of symptoms. For instance, different heavy metals will exhibit gastrointestinal issues and neurological abnormalities which includes weakness, seizures, paralysis and tremors. Also, it will also damage their renal and hepatic function. Furthermore, some heavy metals like mercury and lead can harm the kidney and liver. The toxicity of heavy metal can impact the function or production of red blood cells which resulted in anemia. Thus, it is important to know that the symptoms can be different for each specific heavy metals, the intake dose and sensitivity of independent dog.

3.2.1.2. Sodium and Phosphorus

Excessive intake of sodium and phosphorus can have negative impacts on dogs. This is notably the case with their diet includes a significant proportion of these elements. Although sodium and phosphorus are essential mineral to dogs and play an important role in maintaining the electrolyte balance and cellular function, excessive sodium and phosphorus content can result in health issue.

According to The European Pet Food Industry Federation (FEDIAF) guidelines, all 13 wet dog foods sample contain more phosphorus than recommended for their energy intake. These energy intake levels, measured in calories per kilogram of body weight, are commonly used to calculate the daily energy needs of dogs. Out of all the foods looked at, 10 of them had too much phosphorus, which is more than double the recommended amount. Three of the diets for adult dogs had phosphorus levels higher than 4 grams per 1,000 calories, which is the maximum amount recommended for healthy adult dogs by FEDIAF (2018) [

38].

From

Table 8, three dog product samples contained too much phosphorus based on the upper limit set by FEDIAF, which is harmful because it can cause a condition named struvite uroliths. These uroliths can be difficult to dissolve when there is too much phosphorus in the diet [

38]. It is necessary to differentiate the form of phosphorus that present when measuring its amount in foods since organic and inorganic forms have different effects on the body. The organic form of phosphorus sticks to proteins, which makes it harder for animals to absorb. On the other hand, the inorganic form of phosphorus is easier to absorb, so if there is too much of it, it can be more harmful to animals [

39]. Dog will increase blood pressure, thirst and urination if they consume excessive sodium and phosphorus content. In addition, prolonged high intake will put extra stress on their heart and kidneys. Hence, dogs with kidney disease need to pay special attention that consuming less phosphorus in their diet to help slowing down the disease and make it easier for their kidney to work.

3.2.2. Biological

3.2.2.1. Bacteria

The components of raw pet food include uncooked meat, animal remains, and raw vegetables. It can be made at home or bought fresh, frozen, or freeze-dried from stores [

40,

41]. In recent years, many people have started to feed their dogs food that has raw meat in it. They think this is a better choice because it is more natural that without any preservatives or additives compared to regular commercial pet food [

41,

42]. However, raw pet food potentially consist of Salmonella, a type of bacteria that can lead to gastrointestinal illness in dogs, which can be present in dog’s food at various stages of its production, such as during ingredient sourcing or packaging and handling. Uncooked meat, eggs, or chicken used in dog food are easily contaminated with Salmonella. When dogs consume food that consist of Salmonella bacteria, the bacteria can spread in their stomach and make them sick. The severity of health effect based on the dog’s age, health condition, and the variety of Salmonella.

The most common problem caused by Salmonella infection in dogs is gastrointestinal suffering including signs like diarrhea, loss of appetite, vomiting and abdominal pain, as well as indication of restlessness and discomfort. Due to the discomfort in gastrointestinal, it will lead to dehydration to them. Dehydration leads to thirsty, dry gums, lethargy and less skin elasticity. Furthermore, when dogs are infected with Salmonella, they may get a fever that higher body temperature than normal which is usually around 38.3°C to 39.2°C may be observed as their immune system is fighting against the infection.

3.2.2.2. Mycotoxins

Mycotoxins are harmful substances that can be found in many pet foods. The major type of mycotoxins are aflatoxins, ochratoxins, and Fusarium mycotoxins. They have particular toxicity that cause adverse health effect to animal and are present in different amounts in different places. They get into the food making processes through dirty ingredients and they can slowly harm the health of animals [

43]. Mycotoxins usually occur in mold or fungus and they are commonly found in crops such as corn and peanuts that have been stored in warm and humid conditions. The regional prevalence and sources in feed of mycotoxins are shown on

Table 9.

Chronic adverse health effects will be occur on dogs for high dosage consumption of aflatoxin. Flavus is a type of fungus that has four different strains and they are B1, B2, G1 and G2. The most harmful substance among them is aflatoxin B1 which causes cancer and negatively affect the liver and immune system. Meanwhile, anorexia and depression are common signs of aflatoxicosis in dogs and are easily noticeable. Dogs with this condition may also experience sudden death. They usually come into contact with aflatoxins when contaminated corn is unintentionally added to their food during the process of feed production [

43].

Table 10.

Examples of ingredients known to be potentially contaminated with Aflatoxins [

43].

Table 10.

Examples of ingredients known to be potentially contaminated with Aflatoxins [

43].

| Examples |

|---|

| Cereals |

Wheat, maize (corn), corn gluten feed and meal, rice, sorghum, millet, dried dostoller’s grains |

| Spices |

Chili peppers, coriander, black pepper, ginger, tapioca, turmeric |

| Nuts |

Brazil nuts, peanuts, sunflower, soybean, walnut, almond, pistachio, cotton seed |

Dogs may exhibit various symptoms when they consume mycotoxins, which depend on the type of mycotoxin and the extent of exposure. The mycotoxin substance will affect their gastrointestinal and symptoms like diarrhea, loss of appetite, vomiting, and abdominal pain, as well as neurological signs such as disorientation, weakness, tremors, and seizures will be demonstrated. It will damage their liver like pale gums and jaundice in the worst case. Dogs may feel difficult to breathe since mycotoxin may harm their respiratory system including symptoms of coughing and sneezing.

3.2.3. Physical

Dog food contains any foreign things or chemicals that are consumed by dogs might endanger their health and well-being by posing physical hazards. These dangers might unintentionally enter dog food during the processes of production, processing, packaging or transportation. Some metal or plastic fragments originate from manufacturing related tools or machines might loose and contaminate the food by falling into or mixing with the products [

44]. Moreover, if glass containers or fragments are broken during manufacturing or packaging, or if they are handled carelessly, glass particles may unintentionally contaminate dog food. If appropriate sorting and cleaning procedures are not employed, some stones, rocks or pebbles might be found in raw meat or vegetable items used in dog food. Also, if there are problems with the procurement and processing of materials, wood particles or bark may accidentally end up in dog food. Rodent droppings, insect pieces and hair can also contaminate dog food as a result of rodent or insect infestation in storage facilities. Thus, packaging materials like plastic wrap, seals or labels might wind up in the dog food and provide a health risk if they are separated or broken. When a dog is choking, they may exhibit a difficult or labor on breathing. Breathing difficulties can result from partial or total blockage of the airway caused by choking [

45]. In an effort to remove the impediment, dogs may paw at their mouth or face. Choking result in anxiety and panic that show signs of agitation or anxious demeanor.

3.3. Testing Methods

Contaminant testing is sight to find out if there are any dangerous substances in food, like heavy metals, mycotoxins, fungi or other harmful chemicals. Different methods like chromatography and mass spectrometry are used to find measure and quantify harmful substances in pet food samples. Inductively coupled plasma-optical emission spectrometer (ICP-OES) is one of the testing method for detecting heavy metals. Researchers used a PerkinElmer instrument called an inductively coupled plasma-optical emission spectrometer (ICP-OES) to analyze the primary samples. We used a machine to find out what elements are in the food. They looked for standards that would help us account for any other substances in the food that might affect our results. ICP-OES measures elements like aluminum, calcium, copper, iron, magnesium, manganese, phosphorus, potassium, selenium, silicon, sodium, sulfur, and zinc [

37].

The ways to detect D-xylitol are through gas chromatography (GC), high performance liquid chromatography (HPLC), and capillary electrophoresis. Bio-technology methods that have been developed recently can analyze mixtures of substances without separating them beforehand. This is possible because biomolecules can specifically recognize D-xylitol through non-covalent interactions between molecules [

30]. Gas chromatography-mass spectrometry (GC-MS) is a scientific method that separates and identifies different parts of a mixture. Gas chromatography separates the parts, and mass spectrometry describes each part. The combination of GC and MS has made this analytical method much better. GC-MS is a method that can be relied on to consistently produce similar results, it can identify substances with great detail, and it is not affected much by other substances present in the sample [

46]. HPLC is a method to separate different substances, identifying, and measure how much of each is in a mixture. There is no need for altering the compounds to achieve easy evaporation during HPLC. As far back as the 1980s, there were studies on how to measure D-xylitol using HPLC [

47,

48].

Microbiological testing is aim to find out and measure microorganisms such as bacteria, mold and yeast in pet food. It can detect different pathogens like E.coli, Salmonella and Listeria. The process of microbiological testing involves examining dog food for the presence of microorganisms. Samples of the food are taken and examined using various techniques such as Polymerase Chain Reaction (PCR), Enzyme-Linked Immunosorbent Assay (ELISA) and culture-based methods.

Polymerase Chain Reaction and Enzyme-Linked Immunosorbent Assay are two common methods used in laboratory to detect if there is Salmonella in dog food. PCR is a scientific method that amplify lots of copies of certain parts of DNA. In Salmonella detection, PCR can find and amplify parts of the Salmonella genes and identify it. Two methods for detecting minuscule quantities of Salmonella in dry pet food have been developed and tested by scientists. They used a highly sensitive method called real-time PCR. These fast ways are better than the current ways of confirming cultures [

49]. Therefore, PCR can be effective tools to monitor the microbial safety of dry pet food. ELISA assay facilitates the detection of specific proteins within the bodies. These proteins can be antigens or antibodies. In the case of detecting Salmonella, ELISA can be used to find specific parts of Salmonella in a sample of dog food. The general outline of ELISA process is Sample preparation, Antigen capture, Washing and Detection. Both PCR and ELISA are accurate tests for detecting Salmonella. PCR can detect Salmonella DNA, while ELISA can detect certain parts of Salmonella. These methods help to quickly and correctly find Salmonella in dog food samples, guaranteeing that pet food product is safe.

4. Existing Regulation on Dog Food Production

4.1. Dog Food Problems

In United Stated and Europe, dog food product will be recalled when there is a concern about the safety or quality as same as human food products. Problems such as quality control issues, misbranding, adulteration, additives that poses potential health risk to the dogs are the reasons that leads to product recall. However, several regulations and food safety management systems (FSMS) can restrict and oversee the production process and safety of dog food. Standards and regulations in different countries and FSMS are going to be discussed in the following sessions.

4.2. Standards, Regulations & Certification Schemes

Several certification schemes and labels have been developed to guide people in identifying dog foods that are of good quality. These certifications usually give guarantees about the ingredients, production process and the quality of the food. Certification programs can vary across different regions (See

Table 11).

In Asia, China is based on GB/T 31216 standard and China Feed Industry Association to regulate the pet food safety. For Japan, there are three regulations and authorities to inspect pet food that are Law o. 83 of 2008, Ministry of Agriculture, Forestry and Fisheries and Japan Pet Food Association. Singapore and Taiwan also have their own laws and authorities to regulate the pet food safety.

In Australia, the AS 5812 and 4841 are the standards in pet food manufacturing and the hygienic production of pet meat.

FEDIAF from Europe is an organization that represents the European pet food industry. They give instructions for the Europe pet food manufactures about the ingredients, nutritional adequacy, labelling and recommendation. At the same time, The European Commission sets regulations for pet food including different aspects of ingredient specifications, labelling and hygiene standards etc.

In The United States (USA), the Food and Drug Administration (FDA) ensures that pet food is safe and has clear labels. The FDA sets rules about the ingredients in pet food like colorants and additives. They also monitor for anything that pose health risks to dogs. Association of American Feed Control officials (AAFCO) is a group in the United States that makes rules for pet food. A common indication on dog food packaging, reaffirming adherence to AFFCO’s guidelines, is usually found on products specially formulated to meet dog nutritional requirement based on their life stages. Moreover, The United States Department of Agriculture (USDA) certification verifies that the ingredients utilized in the production of dog food are cultivated and managed in compliance with organic principles. Products need to have a certain amount of organic ingredients and follow strict rules about using man-made chemicals, fertilizers and genetically modified organisms (GMOs) in order to obtain this certificate. Another certification scheme, named Global Animal Partnership (GAP), which verifies that the animals utilized in dog food production receive proper care and follow specific guidelines concerning their well-being. This certification includes numerous types of animals that are used for meat, poultry and fish.

4.3. Adoption of HACCP and GMP Practice in Dog Food Manufacturing

There is a strong consensus among people and organizations that Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practices (GMP) should be utilized in the production of dog food. These are important rules and practices that help ensure the production of safe and high-quality dog food in order to comply with the aforementioned regulations from their own countries.

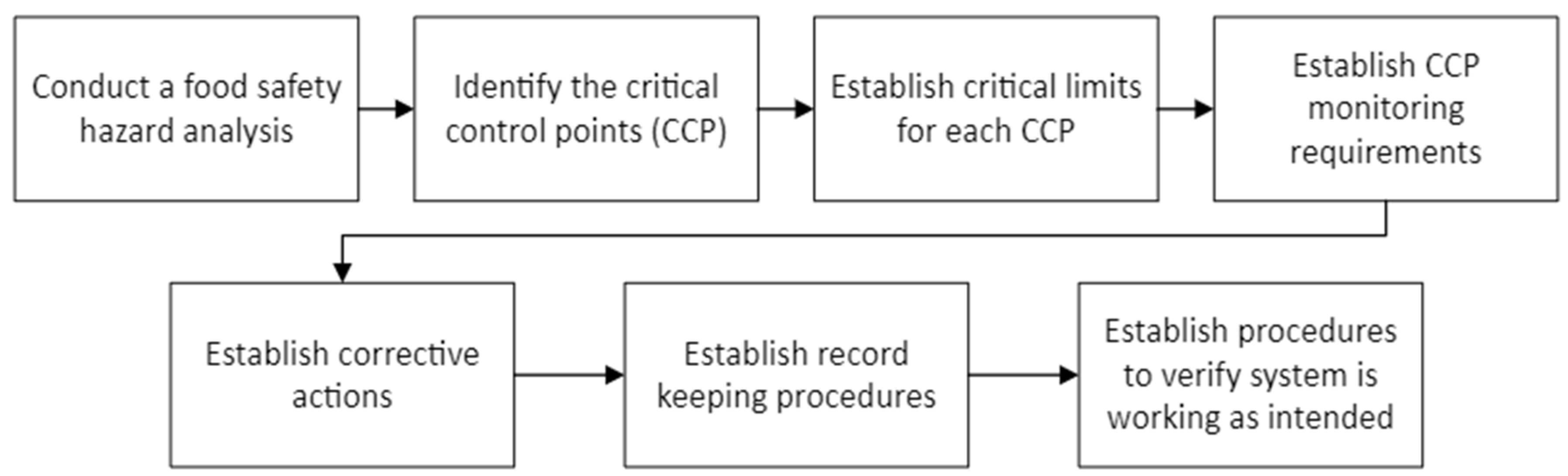

Dog food manufactures frequently use HACCP as a method to find and manage possible dangers in their production methods. They carefully analyze to find out any potential dangers related to the step of ingredients sourcing, packaging, storage and processing etc. By pinpointing critical control that necessitate control, they create boundaries guarantee efficient management of possible threats. Monitoring, verification procedures and corrective actions are implemented to make sure they follow the control measures [

62].

Figure 5.

HACCP control steps.

Figure 5.

HACCP control steps.

Dog food manufacturers implement GMP to ensure the safe production and high quality of their products as GMP guidelines cover a wide range of topics including ingredient sourcing, product manufacturing, quality assurance, facility design, record keeping and cleanliness maintenance. Manufacturers follow these practices to keep their production area clean and hygienic, ensuring the good quality of ingredients, implement proper production procedures, conduct regular quality checks and comprehensive records [

63].

Dog food manufacturers usually follow certain standards and guidelines, like HACCP and GMP, to meet government regulations. Pet food manufacturers must adhere to specific practices mandated by regulatory authorities in various countries to ensure the safety and quality of their products. It is important for them to follow these guidelines so they can comply with the regulations and show their commitment to produce safe dog foods.

In the Pet Food Hazard Assessment (see

Table 12), the team of HACCP should evaluate each hazard based on severity likelihood matrix, which is alike the hazard assessment for human food and is beneficial to classify the significant of hazards. In the evaluation of hazard severity, critical means death and high means there is a substantial harm. Also, if there is a mild illness or no harm, it will count as medium and low severity. For the evaluation of hazard likelihood, it will classify as high, medium and low chance of occurrence [

44].

4.4. Additional Quality Management Systems

There are some additional quality management systems that helps to address ingredient quality and supplier control in the production of dog foods.

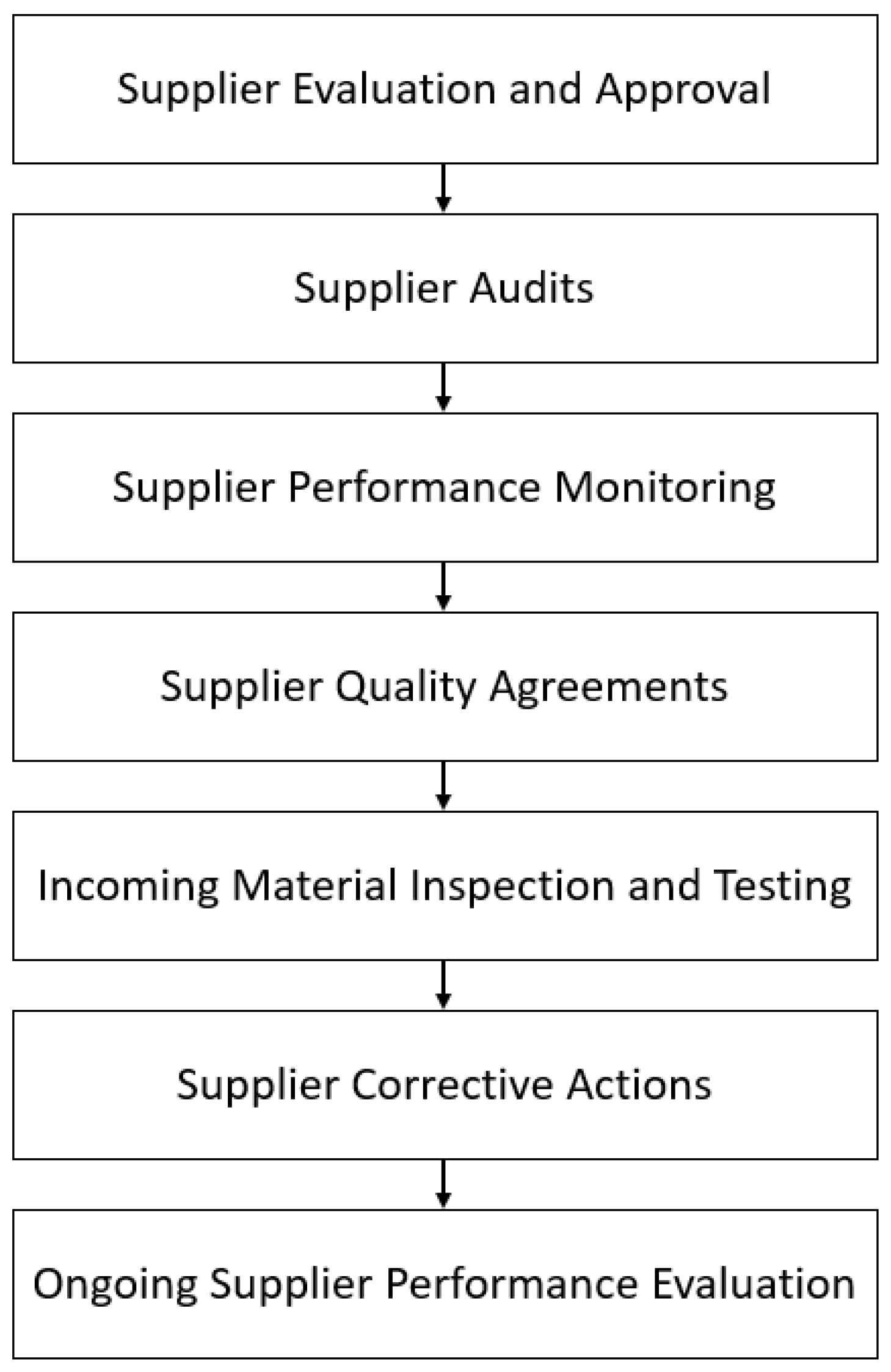

By establishing a Supplier Quality Assurance Program involves implementing guidelines and procedures for evaluating and endorsing ingredient suppliers. It involves conducting regular checks on suppliers’ performance or even do site visit inspections, adherence to ingredient specifications and quality management. Manufacturers guarantee the ingredients in dog food are safe and in good quality by setting standards for their suppliers and applying appropriate testing methods to test the raw material. It involves establishing regulations for each component, specifying their required nutrients, water content, permissible bacteria levels and the presence of potentially harmful substances. Regular testing of raw materials when they arrive the factory contributes on finding any non-conformities that the manufacturer do not expected. It helps them determining whether to inform the supplier or discard any substandard ingredients. Furthermore, conducting ingredient risk assessments helps finding out possible dangers connected to certain ingredients. This includes confirming the ingredient’s origin, inspecting for harmful substances, identifying potential allergens and addressing any known safety risks. Manufacturers have the ability to enhance their ingredient selection process, modify their production methods and handle potential risks via thorough risk assessments.

Figure 6.

Steps of implementing a Supplier Quality Assurance Program.

Figure 6.

Steps of implementing a Supplier Quality Assurance Program.

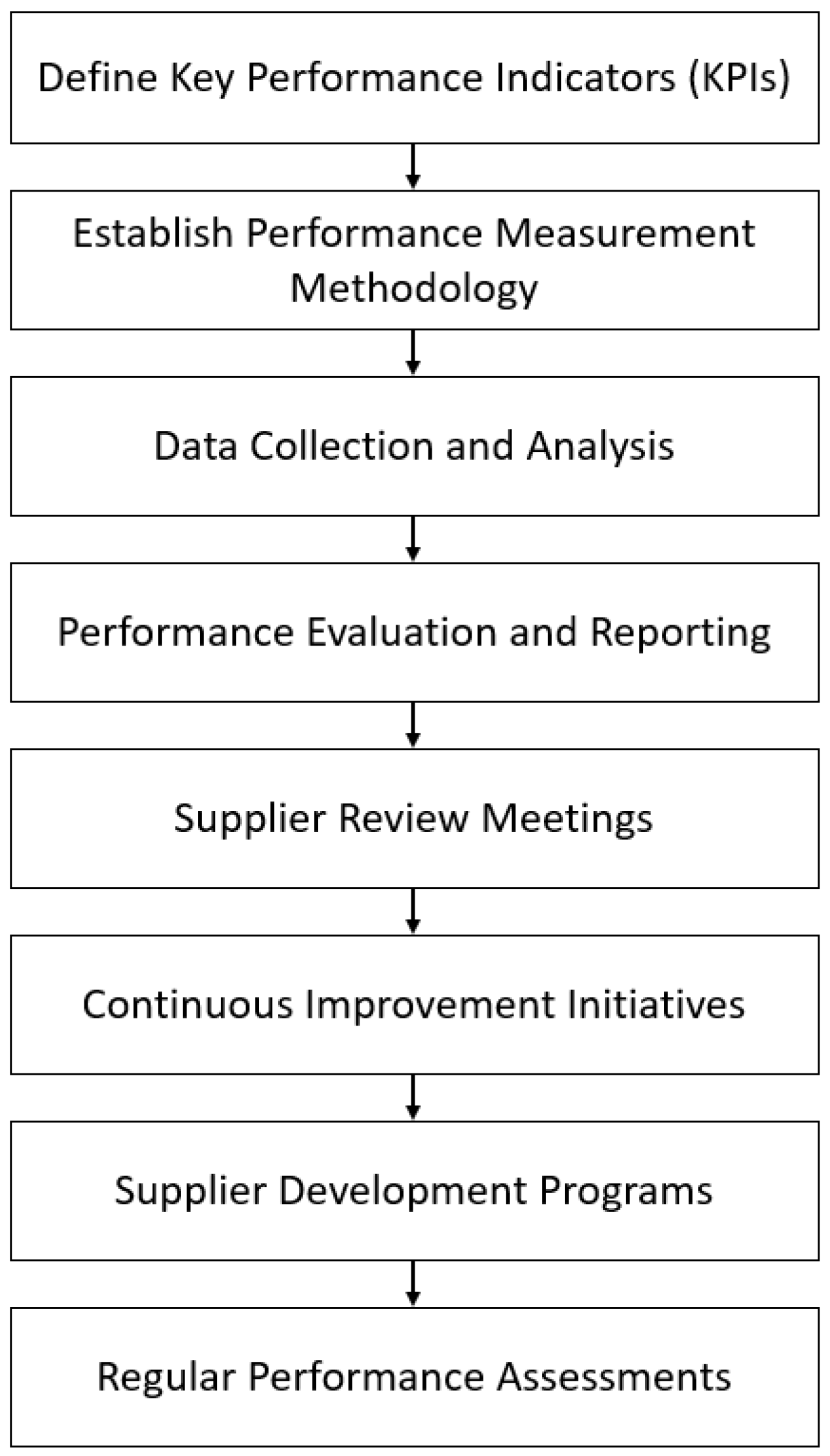

Figure 7.

Steps of implementing continous supplier performance monitoring in the production of dog foods.

Figure 7.

Steps of implementing continous supplier performance monitoring in the production of dog foods.

4.5. Suggestion & Prevention

Apart from the aforementioned countries that have implemented comprehensive regulations and have various authorities to govern the pet food safety, there are still several developed countries in Asia do not have pet food regulations as Hong Kong, such as Thailand and Korea [

64,

65]. In Thailand and Korea, 7 dogs in total died from renal failure due to consumption of pet food that contaminated with Ochratoxin A (OTA) [

65,

66]. Regulations or monitoring program is necessary for overseeing and regulating the pet food production process to reduce these cases and ensure the health of the companion dogs.

Moreover, as recent news indicated that some dog food products do not meet the recommendation by the international Pet Food Organization. The news pointed out that the Consumer Council of Hong Kong tested 20 canned or boxed wet foods for dogs on the market and found that more than 80% of the samples contained minerals whilst two other staple food cans with insufficient vitamin D content. The remaining 16 samples had 1 to 8 mineral contents that were too high or too low, which might pose health risk to dogs and even damage their bones distortion [

67]. For example, the reputable pet food manufacturer Hill’s had recalled more than 20 canned dog foods in USA because those batch of canned food consist excessive vitamin D. Hill’s Hong Kong official said that two cans in Hong Kong were also implicated. As most of pet food that sell in Hong Kong are imported from other countries such as USA, Europe and Australia etc., therefore, it is urgent to have a regulation and policy on the pet food products inspection before importing Hong Kong and distributing between retails. Pet food regulation can ensure that the pet food industry adheres to legal standards and undergoes inspections. Regulation are put in place to ensure the production of pet food that is both safe and of high quality. They also verify that companies comply with these regulations. Therefore, a pet food regulation is essential in Hong Kong which guarantee the pet food safety and benefit Hong Kong pets and pet owners.

In the light of the above news and references from other countries, there are some suggestion and preventive action for Hong Kong government to control dog food safety. It is necessary for the government to establish guidelines to guarantee the safety of dog food. There should be standards and protocols in place for the production, labeling and distribution of dog food. It is important to continuously inspect the facilities where dog food is produced, stored and shipped to ensure the safety of the products for dogs. Safety checks can be conducted either according to a scheduled time to guarantee the manufacturers consistently comply with safety regulations. Aside from verifying and examining, it is crucial to ensure the products quality at every stage of the production. This implies rigorous monitoring the sources of ingredients, the production process, packaging methods and label content. In house quality control testing should be done on the components and the final dog food to detect any harmful elements like bacteria, heavy metals and toxins for canine consumption before distribution. Moreover, the above news of Hill’s pet company showed that a robust recall and reporting system is also important. Manufacturers should be required to report any potential risks or incidents associate with the products. It is important to efficiently and quickly remove products from market and protect the health of pets. Collaborating with industry groups and companies is also beneficial for ensuring the safety of dog food. Engaging in conversation and exchanging information can enable to identify potential hazards and address preventively. The government should work together with the industry to make sure they understand and follow safety rules.

Apart from establishing a pet food regulation, government also need to ensure the inspectors consistently follow the established safety standards. Since having an effective inspection is one of the key prevention and government can implement different measures. For instance, by providing complete training and certification courses for inspectors and implementing inspection guidelines that align with safety standards. Government can also monitor inspection quality through assessments and internal audits to ensure the adherence. These actions can help government ensure that safety regulations are more strictly followed by inspectors. Meanwhile, inspectors need to adhere to safety guidelines and carry out their tasks with proficiency which requires a collective effort from everyone involved.

Furthermore, due to the major supply of pet food in Hong Kong are importation, government should set up authority to conduct regular inspection and checking for the imported dog food products as well. In order to prevent large-scale outbreak of sickness due to problematic dog food, the authority should be able to strictly control the imported dog food and screen out the products that does not comply with the regulations and may cause adverse health effect to dogs.

5. Conclusion

In conclusion, this study on the control of dog food safety sheds light on the importance of ensuring the well-being and health of our canine companions. This paper highlights the crucial role of maintaining highly stringent quality control measures at every stages of the supply chain, spanning from ingredient procurement to product manufacturing. This emphasizes the importance of regularly testing and checking raw materials to minimize possible dangers. As a matter of fact, there are no regulation in monitoring the pet food safety in Hong Kong. Therefore, the pets and pet owners do not have any legal protection. It is important that Hong Kong government should formulate a pet food safety policy and take reference from other countries. By following strict quality control measures, the manufacturers can reduce the chances of health problems and ensure the products are safe. In order to ensure the safety and well-being of dogs, we should ensure that the food they consume adheres to strict quality standards and complies with safety regulations. Dogs will benefit from a healthier and safer environment with this initiative.

Author Contributions

Conceptualization, S.L.M.,K.M.M. and T.H.C; methodology, S.L.M.,K.M.M. and T.H.C; validation, S.L.M.,K.M.M. and T.H.C; formal analysis, S.L.M.,K.M.M. and T.H.C; investigation, S.L.M.,K.M.M. and T.H.C; resources, W.F.T. and C.H.L.; data curation, S.L.M.,K.M.M. and T.H.C; writing—original draft preparation, S.L.M.,K.M.M. and T.H.C; writing—review and editing, S.L.M.,K.M.M., W.Y.C. and T.H.C; visualization, S.L.M.,K.M.M. and T.H.C; supervision, S.L.M. and C.C.L.; project administration, S.L.M. and W.F.T.; funding acquisition, S.L.M. and W.F.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded the RGC Research Matching Grant Scheme (Project No. 2020/3010)

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are included within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, S. Low Fertility and Policy Responses in Korea.; 2009.

- Dog Population in Europe 2022. Available online: https://www.statista.com/statistics/515579/dog-population-europe/ (accessed on 6 September 2023).

- Statistics | Eurostat. Available online: https://ec.europa.eu/eurostat/databrowser/view/tps00204/default/table?lang=en (accessed on 4 September 2023).

- Number of Pet Owning Households in the United States 2023. Available online: https://www.statista.com/statistics/198095/pets-in-the-united-states-by-type-in-2008/ (accessed on 12 December 2023).

- National Vital Statistics Reports Volume 72, Number 1 January 31, 2023.

- Thematic Household Survey Report, No. 66.

- Annual-Report-2022-2.Pdf.

- Di Cerbo, A.; Morales-Medina, J.C.; Palmieri, B.; Pezzuto, F.; Cocco, R.; Flores, G.; Iannitti, T. Functional Foods in Pet Nutrition: Focus on Dogs and Cats. Research in Veterinary Science 2017, 112, 161–166. [Google Scholar] [CrossRef]

- McConnell, A.R.; Paige Lloyd, E.; Humphrey, B.T. We Are Family: Viewing Pets as Family Members Improves Wellbeing. Anthrozoös 2019, 32, 459–470. [Google Scholar] [CrossRef]

- Rauktis, M.E.; Rose, L.; Chen, Q.; Martone, R.; Martello, A. “Their Pets Are Loved Members of Their Family”: Animal Ownership, Food Insecurity, and the Value of Having Pet Food Available in Food Banks. Anthrozoös 2017, 30, 581–593. [Google Scholar] [CrossRef]

- Legislative Council of the Hong Kong Special Administrative Region - Regulation of Pet Food. Available online: https://www.legco.gov.hk/research-publications/english/essentials-1516ise14-regulation-of-pet-food.htm (accessed on 5 October 2023).

- Nutrilab, Inc. v. Schweiker, 713 F.2d 335 (1983): Case Brief Summary. Available online: https://www.quimbee.com/cases/nutrilab-inc-v-schweiker (accessed on 11 May 2023).

- Thompson, A. Ingredients: Where Pet Food Starts. Topics in Companion Animal Medicine 2008, 23, 127–132. [Google Scholar] [CrossRef]

- Carrión, P.; Thompson, L. Pet Food. Food Safety Management: A Practical Guide for the Food Industry, 2013; 379–396. [Google Scholar] [CrossRef]

- Girginov, D. EVALUATION AND USE OF DOG FOODS. Trakia Journal of Sciences 2007, 5. [Google Scholar]

- Kępińska-Pacelik, J.; Biel, W. Microbiological Hazards in Dry Dog Chews and Feeds. Animals 2021, 11, 631. [Google Scholar] [CrossRef]

- FEDIAF | Nutritional Guidelines. Available online: https://europeanpetfood.org/self-regulation/nutritional-guidelines/ (accessed on 27 September 2023).

- Alegría-Morán, R.A.; Guzmán-Pino, S.A.; Egaña, J.I.; Muñoz, C.; Figueroa, J. Food Preferences in Dogs: Effect of Dietary Composition and Intrinsic Variables on Diet Selection. Animals 2019, 9, 219. [Google Scholar] [CrossRef]

- Samant, S.S.; Crandall, P.G.; Jarma Arroyo, S.E.; Seo, H.-S. Dry Pet Food Flavor Enhancers and Their Impact on Palatability: A Review. Foods 2021, 10, 2599. [Google Scholar] [CrossRef]

- FEDIAF_How_wet_pet_food_is_made.Pdf.

- Riaz, M.N.; Rokey, G.J. Extrusion Problems Solved: Food, Pet Food and Feed; Elsevier, 2011; ISBN 978-0-85709-520-6.

- Siregar, J.A.; Arkoudilos, J. Semi-Moist Dog Food Preparation 1983.

- Manual for the Manufacturing of Safe Pet Foods 2014.

- FEDIAF_How_dry_pet_food_is_made.Pdf.

- FEDIAF | The Safety of Pet Food. Available online: https://europeanpetfood.org/pet-food-facts/fact-sheets/quality-and-safety/the-safety-of-pet-food/ (accessed on 25 September 2023).

- Chen, C.; Zhang, J.; Delaurentis, T. Quality Control in Food Supply Chain Management: An Analytical Model and Case Study of the Adulterated Milk Incident in China. International Journal of Production Economics 2014, 152, 188–199. [Google Scholar] [CrossRef]

- Chocolate Poisoning In A Dog. International Journal of Veterinary Health Science & Research (IJVHSR) 2013, 1, 16–17.

- Gwaltney-Brant, S. Chocolate Intoxication. Veterinary Medicine 2001, 96. [Google Scholar]

- Xia, Z.; He, Y.; Yu, J. Experimental Acute Toxicity of Xylitol in Dogs. Journal of Veterinary Pharmacology and Therapeutics 2009, 32, 465–469. [Google Scholar] [CrossRef]

- Jiang, Z.; Amartey, S.; Jiang, Z.-H.; Qin, W. D-Xylitol. In; 2012; pp. 245–263 ISBN 978-3-642-31886-3.

- Raisin and Grape Toxicosis in Dogs - Toxicology. Available online: https://www.msdvetmanual.com/toxicology/food-hazards/raisin-and-grape-toxicosis-in-dogs (accessed on 6 December 2023).

- Paul Pion, D.V.M.; Spadafori, G. Veterinary Partner. VIN.com 2017. [Google Scholar]

- Onion Toxicity In Dogs: How To Spot The Symptoms | Kingsdale Animal Hospital. Available online: https://www.kingsdale.com/onion-toxicity-in-dogs-how-to-spot-the-symptoms (accessed on 6 December 2023).

- Mak, S.L.; Au, S.L.; Tang, W.F.; Li, C.H.; Chiu, W.H.; Lee, C.C.; Wu, M.Y.T. A Critical Review on Safety of Pet Food Products. In Proceedings of the 2022 IEEE International Symposium on Product Compliance Engineering - Asia (ISPCE-ASIA); January 2022; pp. 1–5. [Google Scholar]

- Feng, T.; Keller, L.R.; Wang, L.; Wang, Y. Product Quality Risk Perceptions and Decisions: Contaminated Pet Food and Lead-Painted Toys. Risk Analysis 2010, 30, 1572–1589. [Google Scholar] [CrossRef]

- Zafalon, R.V.A.; Pedreira, R.S.; Vendramini, T.H.A.; Rentas, M.F.; Pedrinelli, V.; Rodrigues, R.B.A.; Risolia, L.W.; Perini, M.P.; Amaral, A.R.; de Carvalho Balieiro, J.C.; et al. Toxic Element Levels in Ingredients and Commercial Pet Foods. Scientific Reports 2021, 11, 21007. [Google Scholar] [CrossRef]

- Atkins, P.; Restivo, T.; Lockerman, B. Heavy Metals in Pet Food: Changes in Heavy Metal Contamination in Pet Food Over the Past Decade. Spectroscopy 2021, 36, 13–23. [Google Scholar]

- Brunetto, M.A.; Zafalon, R.V.A.; Teixeira, F.A.; Vendramini, T.H.A.; Rentas, M.F.; Pedrinelli, V.; Risolia, L.W.; Macedo, H.T. Phosphorus and Sodium Contents in Commercial Wet Foods for Dogs and Cats. Vet Med Sci 2019, 5, 494–499. [Google Scholar] [CrossRef]

- Coltherd, J.C.; Staunton, R.; Colyer, A.; Thomas, G.; Gilham, M.; Logan, D.W.; Butterwick, R.; Watson, P. Not All Forms of Dietary Phosphorus Are Equal: An Evaluation of Postprandial Phosphorus Concentrations in the Plasma of the Cat. British Journal of Nutrition 2019, 121, 270–284. [Google Scholar] [CrossRef]

- Freeman, L.M.; Chandler, M.L.; Hamper, B.A.; Weeth, L.P. Current Knowledge about the Risks and Benefits of Raw Meat-Based Diets for Dogs and Cats. Journal of the American Veterinary Medical Association 2013, 243, 1549–1558. [Google Scholar] [CrossRef]

- Davies, R.H.; Lawes, J.R.; Wales, A.D. Raw Diets for Dogs and Cats: A Review, with Particular Reference to Microbiological Hazards. Journal of Small Animal Practice 2019, 60, 329–339. [Google Scholar] [CrossRef]

- Hellgren, J.; Hästö, L.S.; Wikström, C.; Fernström, L.-L.; Hansson, I. Occurrence of Salmonella, Campylobacter, Clostridium and Enterobacteriaceae in Raw Meat-Based Diets for Dogs. Veterinary Record 2019, 184, 442–442. [Google Scholar] [CrossRef]

- Mycotoxins in Pet Food: A Review on Worldwide Prevalence and Preventative Strategies. Available online: https://pubs.acs.org/doi/epdf/10.1021/jf062363%2B (accessed on 25 September 2023).

- Medicine, C. for V. CVM GFI #245 Hazard Analysis and Risk-Based Preventive Controls for Food for Animals. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/cvm-gfi-245-hazard-analysis-and-risk-based-preventive-controls-food-animals (accessed on 6 December 2023).

- Zahn, S. General First Aid for Dogs; J & J Enterprises, 1984; ISBN 978-0-912183-02-2.

- Kopka, J. Current Challenges and Developments in GC–MS Based Metabolite Profiling Technology. Journal of Biotechnology 2006, 124, 312–322. [Google Scholar] [CrossRef]

- Anumula, K.R. Rapid Quantitative Determination of Sialic Acids in Glycoproteins by High-Performance Liquid Chromatography with a Sensitive Fluorescence Detection. Analytical Biochemistry 1995, 230, 24–30. [Google Scholar] [CrossRef]

- Lohmander, L.S. Analysis by High-Performance Liquid Chromatography of Radioactively Labeled Carbohydrate Components of Proteoglycans. Analytical Biochemistry 1986, 154, 75–84. [Google Scholar] [CrossRef]

- Balachandran, P.; Friberg, M.; Vanlandingham, V.; Kozak, K.; Manolis, A.; Brevnov, M.; Crowley, E.; Bird, P.; Goins, D.; Furtado, M.R.; et al. Rapid Detection of Salmonella in Pet Food: Design and Evaluation of Integrated Methods Based on Real-Time PCR Detection. Journal of Food Protection 2012, 75, 347–352. [Google Scholar] [CrossRef]

- Pet Food Standards | The Pet Food Industry Association of Australia.

- PISC Technical Report 88.Pdf.

- 国家标准|GB/T 31216-2014. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=A8758F9C4633B2CCBEE9C82CC3F4A4D1 (accessed on 24 October 2023).

- 中国饲料工业协会宠物. Available online: http://www.chinafeed.org.cn/xwdt_10092/xhxw/202205/t20220516_403234.htm (accessed on 24 October 2023).

- European Pet Food Industry Federation (FEDIAF). Available online: https://www.eesc.europa.eu/en/policies/policy-areas/enterprise/database-self-and-co-regulation-initiatives/132 (accessed on 25 October 2023).

- 10_GAPFA_Factsheet_How_pet_food_is_regulated.Pdf.

- Sugiura, K.; Fujii, T.; Onodera, T. Introduction of a Pet Food Safety Law in Japan. Veterinaria italiana 2009, 45, 297–303. [Google Scholar]

- Safety of Feeds and Pet Foods : MAFF. Available online: https://www.maff.go.jp/e/policies/ap_health/petfood/ (accessed on 26 October 2023).

- 一般社団法人ペットフード協会. Available online: https://petfood.or.jp/index.html (accessed on 26 October 2023).

- Animal Protection Act (2017). | FAOLEX. Available online: https://www.fao.org/faolex/results/details/en/c/LEX-FAOC040369 (accessed on 25 October 2023).

- R.O.C.(Taiwan), M. of A., Executive Yuan Ministry of Agriculture, Executive Yuan, R.O.C.(Taiwan). Available online: https://eng.moa.gov.tw/ws.php?id=2505344 (accessed on 26 October 2023).

- The Association of American Feed Control Officials. Available online: https://www.aafco.org/ (accessed on 24 October 2023).

- Saskatoon-Based Raw Pet Food Manufacturer, Spring Meadows Natural Pet Food, Receives HACCP Canada Certification. NASDAQ OMX’s News Release Distribution Channel, 2018.

- Institute of Food Science and Technology; Louise Manning Food and Drink - Good Manufacturing Practice : A Guide to Its Responsible Management; Wiley-Blackwell: Chichester, West Sussex, UK, 2013; Vol. 6th ed; ISBN 978-1-118-31820-1.

- Lee, J.M.; Jang, M.A. The Current Status of the Companion Animal products and Pet Cosmetics industry. The Journal of the Convergence on Culture Technology 2021, 7, 833–844. [Google Scholar] [CrossRef]

- Tansakul, N.; Trongvanichnam, K.; Udomkusonsri, P.; Limsuwan, S. A Survey of Aflatoxins and Ochratoxin A Contamination in Pet Food in Thailand. Journal of Mahanakorn Veterinary Medicine 2014, 9, 1–9. [Google Scholar]

- Jeong, W.-I.; Do, S.-H.; Jeong, D.; Chung, J.; Yang, H.; Yuan, D.; Hong, I.; Park, J.-K.; Goo, M.; Jeong, K.-S. Canine Renal Failure Syndrome in Three Dogs. Journal of veterinary science 2006, 7, 299–301. [Google Scholar] [CrossRef]

- 80% of Complete Canned Dog Food Failed to Meet Internationally Recommended Levels for Micronutrients and Amino Acids Negligence of Labelling and Misfeeding May Cause Health Risks | Consumer Council. Available online: https://www.consumer.org.hk/en/press-release/534-canned-pouched-pet-food-for-dogs (accessed on 12 December 2023).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).