1. Introduction

A promising direction of construction material science is the improvement of technology and study of operational properties of self-compacting concrete (SCC) - a type of concrete, which is increasingly actively used in the construction industry of the Republic of Kazakhstan [

1].

The undoubted advantages of SCC are high mobility, ability to compact under the action of gravity, to be placed in densely reinforced structures and the possibility to eliminate the process of vibration paving of concrete, which improves the quality of concrete structures and provides certain advantages for the construction process. Recently, more attention has been paid in the construction industry to the development of SCCs with improved physical-technical, performance and durability properties [

2]. The composition of SCC differs from that of conventional heavy concrete. In the composition of SCC there is an increased content of sand and binder (cement and fillers), as well as properly selected in quantitative composition superplasticisers based on polycarboxylates [

3]. SCC with properly selected composition is more homogeneous and its performance is more similar than that of conventional heavy concrete [

4]. At the same time, the requirements for SCCs for the manufacture of building products and structures are different from those for conventional concrete [

5]. Such special requirements are primarily due to the specifics of the production, transport and laying of the SCC. In the process of operation the structures from SCC in the southern and central regions of Kazakhstan experience a constant impact of a whole complex of aggressive factors: the impact of groundwater, cavitations effect of water flows (on hydromeliorative structures) and frequent temperature fluctuations of ambient air passing through 0 °C zone. The above-mentioned constantly acting aggressive influences reduce the reliability of structures and gradually destroy structures [

6].

Progressively increases the number of defects, occurrence of sinks and weakening of interstitial partitions and cement-filler contact zone, which in turn leads to significant loss of strength characteristics of the structure [

7]. The relevance of the study lies in the fact that there are very few studies devoted to the study of frost resistance and analysis of hydrophysical properties of self-compacting concretes, these works mainly consider the study of strength and deformative properties of SCC with the reflection of the solution of one or two specific problems, for example (solving the problem of crack resistance and shrinkage of concrete) [

8].

It is possible to increase the durability and improve the operational reliability of structures made of SCC by applying special protective cladding (monolithic and prefabricated), which reduces water filtration through the working surfaces. The use of protective cladding keeps filtration at 15-20%. However, the integrity of thin protective coatings (0.2 mm thick) is compromised by even minor mechanical impacts, which is a major problem in their use. Scientists are searching for effective materials, for example, polymer compositions capable of resisting both mechanical effects and aggressive environmental influences. Unfortunately, often proposed polymer compositions involve the use of expensive chemical components, which hinders their widespread use [

1]. It should be noted that important measures for further development and improvement of construction under the influence of aggressive environment are the improvement of work quality, optimisation of construction time, as well as rational use of properties of applied concretes and improvement of their quality [

9].

Concretes with portland cement clinker-based binders are still the basis of civil engineering. In modern construction, predominantly modified concretes are used, which make it possible to ensure a given level of quality [

10]. Even a small amount of modifying components can dramatically change the process of structure formation and produce durable concrete with improved physical and mechanical characteristics [

11]. Multi-component modifiers on the chemical-mineral basis, the use of which allows to obtain a dense durable structure, find practical application in construction [

12]. In order to obtain self-compacting concrete mixtures with optimal performance and to improve the operational properties of hardened concrete, the use of chemical and mineral modifiers is rational and promising [

4]. Thus, improving the quality of self-compacting concrete is a problematic issue and requires its development taking into account the proposed technological method, which provides for the use of cement in its composition together with a complex modifier (hyperplasticiser + polymer + microsilica). It is further proposed to consider separately each component of the system and its role in the creation of self-compacting concrete with specified properties of strength, water resistance and corrosion resistance [

11].

After analyzing the requirements of construction companies, we proposed the idea of combining the useful properties of two types of concrete: SCC and Fibre Concrete - a composite material consisting of a cement matrix with a uniform distribution of oriented or chaotically arranged discrete fibers (fibres) of different origin in order to obtain a matrix that is as dense and resistant to hydrophysical effects as possible. Fiber concretes have enhanced deformation properties, primarily flexural tensile strength, low shrinkage deformations, and high abrasion resistance [

8]. Having reviewed the scientific literature on hydrophysical indicators and corrosion resistance of concrete, having got acquainted with the works of scientists in the field of building materials science on investigation of the impact of various types of corrosion on the concrete matrix and focusing on the peculiarities of soils of southern and central Kazakhstan, we came to the conclusion that in this work it is necessary to investigate the indicators of corrosion resistance of modified SCC with the use of fiber reinforcement [

7,

13,

14].

The study of hydrophysical characteristics of concrete products and structures is a multifactorial scientific process consisting of the study of several physical and technical properties, since it is important not only to ensure the specified properties of concrete at the stage of manufacture, but also to maintain them during the entire period of operation of the structure. In order to conduct further experiments, a number of research objectives were formed:

- investigation of the influence of self-compacting concrete composition parameters and the amount of fiber reinforcement on the frost resistance of SCC, determination of quantitative dependencies reflecting this most important performance indicator of SCC from the point of view of practical application [

15];

- investigation of the influence of self-compacting concrete composition parameters and the amount of fiber reinforcement on water absorption, water resistance and porosity of SCC, determination of quantitative dependencies reflecting this most important performance indicator of SCC from the point of view of practical application [

16,

17];

- determination of corrosion resistance of SCC in conditions of aggressive impact of saline soils of southern regions of the Republic of Kazakhstan [

18].

The purpose of the work described in this article is to study the improvement of operational properties and reliability of building products from self-compacting concrete, operated under conditions of repeated freezing-thawing and aggressive environment of soils in southern and central Kazakhstan.

2. Materials and Methods

This work uses theoretical and applied research methods. The theoretical study was based on the fundamental laws of concrete science in order to study in detail and compare the corrosion resistance of self-compacting concretes of different compositions. The applied research was aimed at experimental confirmation of the theoretical hypothesis according to the current standards.

All components of self-compacting concrete are extracted and produced in the territory of the Republic of Kazakhstan. All studies and tests were carried out in accordance with the regulatory documentation in force in the territory of the Republic of Kazakhstan.

2.1. Characterisation of Concrete Mix Components

Cement CEM I 32.5H produced by "Standart Cement" LLP (Shymkent city, Kazakhstan) was accepted as a binder for the investigated concrete mixtures according to [

19]. To confirm the compliance of the selected binder with the standards and requirements [

20], a number of tests were carried out. The methods specified in these standards allow determining the following parameters of the binder:

Fineness of grind: Cement fineness is defined as the residue on the sieve with mesh No.008 as a percentage of the original weight of the sieved sample (to the nearest 0.1%). Cement is considered to meet the requirements of the normative documentation if at least 85% of the mass of the test sample has passed through the sieve [

21]. The tested binder showed a grinding fineness of 92.8%.

Normal density and setting time of cement batter: The tested binder showed a normal density of 26.7 % in the tests. The beginning of setting occurred after 2 h 4 min, the end of setting occurred after 4 h 13 min from the moment of mixing with water. These values are within the normalized range.

Compressive and flexural strength (at the age of 28 days): When determining the strength characteristics of the studied binder showed the result at the age of 28 days: bending - 5.3 MPa; compression - 41.1 MPa. These indicators are included in the normative area.

For the tests we used sand from the manufacturer "Giyada" LLP (Almaty region, Kazakhstan), which complies with the normative document [

22]. According to this standard, as fine aggregate for heavy concrete, under the definition of which will fall under the SCC, can be used sands with a maximum amount of dusty and clayey inclusions for the groups of increased coarseness, coarse and medium in the amount of 3%. However, in order to obtain satisfactory characteristics of the concrete mix of the SCC, it is necessary to use sand, the amount of dust-like inclusions in which does not exceed 1.5 per cent. The test for determining the amount of dusty and clayey inclusions of the considered sand was carried out by the method of scouring according to [

21]. According to the test results, the content of dusty and clayey inclusions in the tested sand was 1.07 %. The coarseness modulus of the tested sand was also determined, which was 2.6. These indicators are acceptable for the use of the investigated aggregate in SCC.

Crushed stone of fractions 5-10 mm and 10-20 mm produced by Novtehstroy LLP (Almaty region, Kazakhstan) with known physical and technical characteristics was used as a coarse aggregate [

23]. Grain composition of aggregate meets the requirements of the normative document [

24], which defines the basic requirements for crushed stone from dense rocks, used as aggregate for heavy concrete, including SCC.

Characteristics of granite crushed stone: density – 2850 kg/m3; water absorption – 0.1%; crushed stone strength grade – 12000 kg·f/cm2; frost resistance – F 400; porosity – 0.6 %; dusty and clayey particles content – up to 1%; content of lamellar grains – 11%; chemical composition: SiO2 – 49-64 %; Ai2O3 – 16-19%; CaO – 3-10%; MgO – 2.2-7.1%; Fe2O3 – 6.8-12.3%; SO3 –0.4-0.9%.

Chemical additive based on polycarboxylate esters of 2nd generation AR Premium, produced by "Ariranggroup" LLP (Astana, Kazakhstan) was used as hyperplasticiser [

25], with the following characteristics (

Table 1):

As a water-soluble polymer additive we used "Polyvinyl-pyrrolidone 40.0", a product of "Laborfarma" LLP (Almaty, Kazakhstan) with a molecular weight of 1200000 - 2500 000 g/mol and viscosity from 3000 to 6000 MPa s at 25 °C, meeting the requirements [

26].

By its nature, it is a synthetic polymer, not naturally occurring. Well miscible with alcohols, water-containing solutions, chloroform. Soluble in water and polar solutions. Almost incompatible with ethers. Molecular formula: C6H9NO; molar mass: 2.500 – 2.500.000 g/mol; density: 1200 kg/m³; melting point: 150-180 °C.

As a reactive pozzolanic additive was used micro-silica MKU-95, produced by Tau-Ken Temir LLP (Karaganda, Kazakhstan) corresponding [

28]. Microsilica is formed by the reduction of high-purity quartz with coal in arc furnaces during the manufacture of silicon and ferrosilicon and consists of very fine spherical particles containing amorphous or glassy silicon dioxide (SiO

2) in an amount of at least 85% of the additive weight. The composition and characteristics are summarized in

Table 2.

For volumetric reinforcement in the research chopped basalt fiber was used, manufactured in accordance with [

29], produced by LLP "Priority" Astana (Kazakhstan). The appearance and physical and mechanical characteristics of these fibers are given in

Table 3.

2.2. Investigated Compositions of Modified Self-Compacting Concrete with Regard to Consumption and Selection of Raw Materials

The task of increasing the strength and performance of the studied compositions of self-compacting concrete was solved by compacting its structure through the use of binder together with a complex modifier (Hyperplasticiser AR Premium +Polyvinylpyrrolidone 40.0 + Microsilica MKU-95). To improve corrosion resistance, an active mineral admixture in the form of reactive microsilica was added to the concrete mix, and basalt fiber was added to level the effect of bending moments.

In this test, the composition of self-compacting concrete of class C30/35 without the use of modifiers and fiber reinforcement [

4] was taken as a control.

Tests to determine the required amount of each of the modifiers were carried out stepwise, starting from the control composition, with each subsequent test hyperplasticiser AR Premium was introduced into the mixture at a rate of 1% of the binder per 1m3, adding at each subsequent test by 0.1% up to a rate of 2% per 1m

3, then the tests were repeated with the introduction of the polymer additive. Polyvinylpyrrolidone 40.0 at a rate from 0.1% of binder per 1m

3, adding at each subsequent test by 0.1% up to a rate of 1% per 1m

3, and further with the introduction of microsilica MKU-95 at a rate from 5% of binder per 1m

3, adding at each subsequent test by 1% up to a rate of 15% per 1m

3. The maximum amount of modifiers in the mixture was fixed based on previously published sources and on economic assumptions [

30]. The optimum content of the complex admixture (1.5%AR Premium + 0.3% Polyvinylpyrrolidone 40.0 + 15% MKU-95) was determined by strength testing of 100×100×100 mm cube specimens tested at the age of 28 days of normal curing for each concrete composition. The compositions presented in

Table 4 were used in further studies of physical-mechanical, hydrophysical characteristics and corrosion resistance.

2.3. Concrete Compressive Strength

The compressive strength of concrete determines the resistance of the material to an applied mechanical compressive load. To determine the compressive strength of the investigated concrete compositions, three cube specimens of each composition with the dimensions of the working Section 100x100x100 mm were prepared from the concrete mixture with the same water-cement ratio (W/C) and tested at the age of 28 days of normal curing according to the method [

33].

2.4. Determination of the Frost Resistance of Concrete

The method of repeated freezing and thawing in water-saturated state was used for these tests. The test methodology and processing of the results were carried out in accordance with [

15]. Water was used as the saturation medium. Air medium with freezing temperature of minus 18±2 °C, water with temperature of 20±2 °C as thawing medium. Determination of concrete frost resistance mark was carried out on specimens with ribs 100×100×100 mm at the age of 28 days, and the number of control specimens - 6 pcs and main specimens - 12 pcs for each composition was established. The main specimens were saturated with water by immersion for 24 h to 1/3 of the height of the cube specimens before freezing and the control specimens before strength testing. The next step required us to increase the level to 2/3 of the height and continue the soaking for 24 h, after which we increased the water level so that the distance from the top edge of the samples to the liquid level was more than 20 mm and continued the soaking for the next 48 h. For this study, the testing regime was strictly observed - the time of freezing the samples not less than 2.5 h and thawing for 2 ± 0.5 h, in case of chipping, cracking and flaking of ribs in the process of testing the sample - the study was stopped.

2.5. Determination of Water Resistance and Water Absorption of Concrete

The wet spot method was used to determine the water resistance. In accordance with the requirements of [

16], we prepared cylinder samples with a diameter of 150 mm and height of 150 mm, based on the fact that the largest grain size of the aggregate is 20 mm. For each investigated composition 6 specimens were prepared, which were stored in a chamber of normal hardening with a set temperature of 20±2 °C, relative humidity of 95±5% and preliminary curing for 1 day in the laboratory before testing. The process of testing, in the form of increasing water pressure, was carried out by loading in steps of 0.2 MPa for 1-5 min and the duration of loading in each step equal to 12 h. Water resistance of each cylinder specimen was assessed by fixing the maximum value of water pressure at which no water seepage through the specimen body in the form of wet spots or signs of water filtration in the form of drops was observed on the end surface of the specimen opposite to its surface through which water was pressurized. To determine the water tightness of a series of concrete specimens, the maximum water pressure at which no water filtration was observed on at least four specimens out of six was evaluated.

The water absorption study was carried out according to the requirements of [

17]. For this purpose, we used cube samples with dimensions 100×100×100 mm, based on the largest grain size of aggregate of 20 mm, 3 samples of each composition, which were placed in a container with water, temperature 20 ± 2 °C, so that the water level was higher by 50 mm above the top edge of the sample. Every 24 h of water absorption, samples were weighed until two consecutive weighing differed by no more than 0.1% The results were processed by determining the water absorption of a single concrete sample by weight (W

m) in per cent and an error of no more than 0.1% according to formula (1):

where: W

m –- water absorption of individual concrete specimen by mass, %; m

c – mass of dried sample, g; m

v - mass of water-saturated sample, g.

To determine the water absorption of a series of samples of each concrete composition, the arithmetic mean of the obtained results of an individual sample was calculated.

Determination of porosity of concrete cube specimens with rib size 70x70x70 mm series of two specimens for each composition was carried out by water absorption kinetics, discrete weighing method.

2.6. Determination of Corrosion Resistance of Concrete Specimens

The essence of the test method in accordance with [

18] is a comparative analysis of the obtained results of examination of test samples placed in a non-aggressive environment with the values of indicators of samples of the same composition placed in an aggressive environment. For each formulation, 3 control samples and 3 basic samples were prepared for each aggressive medium investigated. The dimensions are based on the largest aggregate size and are set as recommended with rib dimensions of 100×100×100 mm. Studies were carried out on cube specimens aged 28 days of normal curing in aqueous solutions of 5% sodium sulphate (Na

2SO

4), 3% sodium chloride (NaCl), distilled water and 0.01 M hydrochloric acid (HCl) solution. Bottled drinking water was used as a non-aggressive medium [

31]. The samples were dried and weighed before starting the studies. In the next step, three control specimens were tested for flexural tensile strength, and compressive strength. The prepared three specimen-prisms of each composition were placed in the above aggressive media, ensuring its uniform access to the specimen from all sides, with a study duration of 6 months.

Processing of test results was carried out by comparing the properties of specimens in aggressive environment and specimens cured in drinking water. Firstly, the mass loss of samples (Δm), % was estimated by formula (2):

where:

Δm – mass loss of samples, %;

m1 - mass of the specimen before the test, g;

m2 – mass of the specimen after the test, g.

At the next stage we needed to establish the change of tensile strength in bending (ΔR_tb,%), compressive strength (ΔR, %) by formulas (3) and (4):

where: ΔR – change in compressive strength, %; R

1 – compressive strength of control specimens (before testing), MPa; R

2 - compressive strength of the main specimens (at the end of the test), MPa.

where: ΔR

tb – change in tensile strength in bending, %; R

(1 tb) – tensile strength in bending of control specimens (before testing), MPa; R

(2 tb) - tensile strength in bending of the main specimens (at the end of the test), MPa.

3. Results

In the operation of products and structures made of self-compacting concrete, practical experience has shown that these structures are not durable and reliable enough. There are numerous cases of premature failure of some elements due to alternate freezing and thawing, corrosion of concrete, resulting in the need for costly repairs. It is necessary to take into account at once the factor of influence of aggressive environment, operating conditions of the structure, to choose the right raw materials [

32].

3.1. Compressive Strength

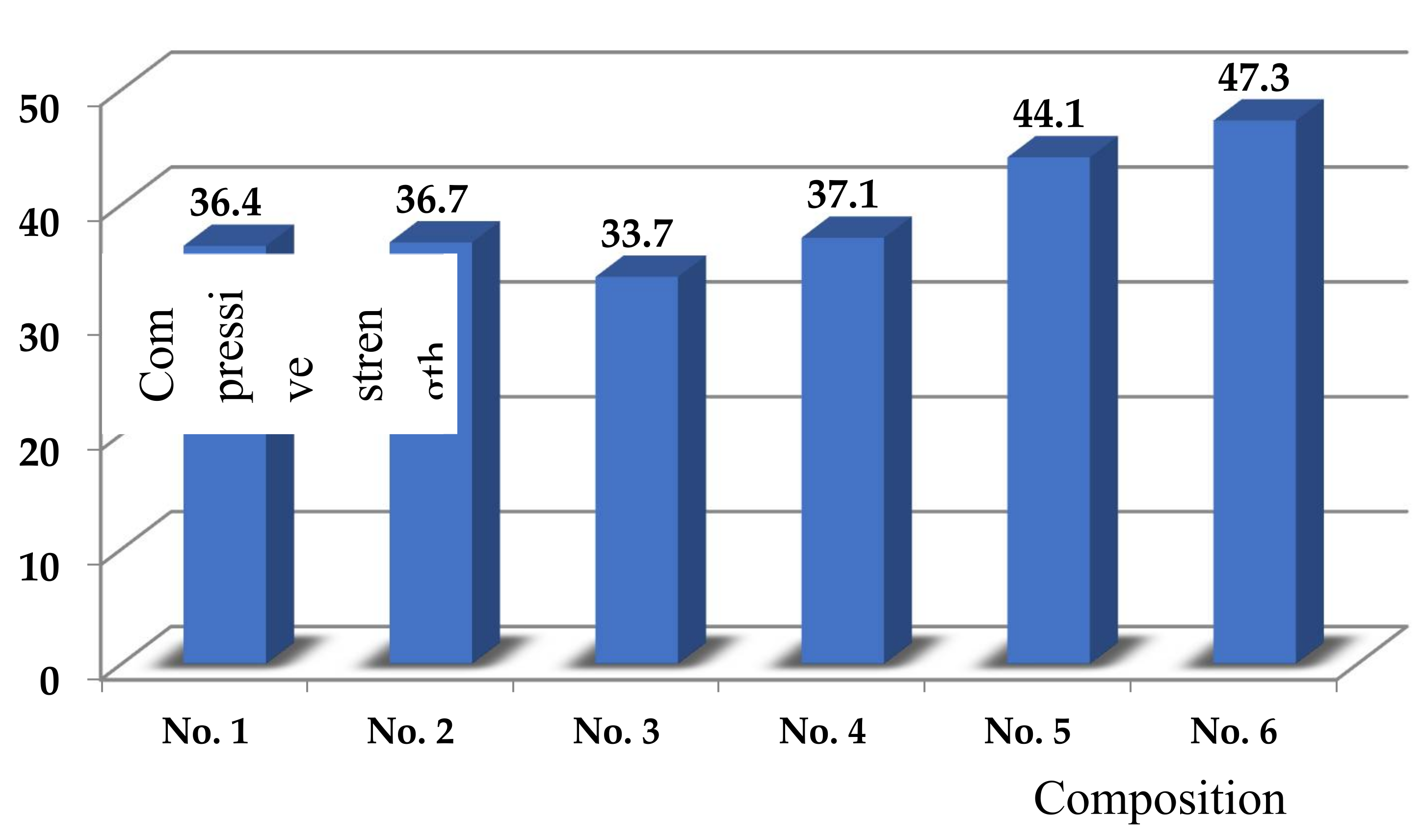

The compression test results of the modified self-compacting concrete specimens are presented in

Table 5 (

Figure 1).

The obtained data of the presented studies (

Table 5), allow us to establish the following scientific observations:

- an increase in the compressive strength of composition 5 (1.5% AR Premium + 0.3% Polyvinylpyrrolidone 40.0+15% MKU-95) by 21% relative to the control composition 1 and 20% relative to composition 2 (PC +1.5% AR Premium) was established, which is in absolute terms by 7.7 and 7.4 MPa, respectively. When a complex modifier (1.5% AR Premium + 0.3% Polyvinylpyrrolidone 40.0+15% MKU-95) is introduced into the concrete mixture, the processes of hydrolysis and hydration of cement particles are more intensive with the formation of additional crystallisation centres, which is confirmed by earlier microstructural analyses of cement stone [

34].

- found that by adding basalt micro-reinforcing fibre with fibre concentration of 0.7% of the binder weight to the proposed composition 6, a slight increase in strength by 7.2% in relation to the composition 5 (without fibre) is observed. It should also be noted that when the fibre content increases above 1% of the binder, clumping of fibres is observed, which negatively affects the strength of concrete. The obtained results are in agreement with the works [

30].

3.2. Determination of Frost Resistance of Modified Self-Compacting Concrete

In the next stage of research, frost resistance was determined, which depends on the structure and nature of pores in concrete. The relationship between porosity and frost resistance is a complex and interesting process, as evidenced by the use of air-entraining admixture in concrete by some researchers to create closed pores to increase its workability and frost resistance, but the amount of air-entraining admixture must be appropriate to maintain the strength of concrete. The presence of open pores available for water penetration has a bad effect on frost resistance and durability [

35].

The frost resistance of concrete is directly dependent on its structure, as it determines the volume and distribution of ice formed in the concrete body at sub-zero temperatures and, consequently, the value of the resulting stresses and the intensity of the increasing weakening process of the structure. Concrete micropores of ≈10

−5 cm usually contain bound water, which does not convert to ice even at very low temperatures (down to -70 °C). Therefore, micropores have no noticeable effect on the frost resistance of concrete and it depends on the volume of macropores in concrete [

36].

For frost resistance tests, the first basic method according to the requirements of [

15] was used for repeated freezing and thawing in water-saturated state. Determination of the frost resistance grade of concrete was carried out on specimens with 100×100×100 mm ribs at the age of 28 days. The results of tests at cyclic alternate freezing and thawing are shown in

Table 6.

The results of tests at cyclic alternate freezing and thawing of concrete cube samples of different composition, presented in

Table 6 showed:

- maximum weight loss up to 4.33% in the control composition 1 after 400 test cycles of alternate freezing and thawing, which exceeds the established indicators of the requirement [

15] (weight loss not more than 2%).

- The compositions containing complex modifier (1.5% AR Premium + 0.3% Polyvinylpyrrolidone 40.0+15% MKU-95) showed high frost resistance characteristics. After 600 cycles of tests the mass loss in compositions 5 and 6 was 1.9% and 1.6%, which confirms the sufficient frost resistance reserve of the proposed compositions of modified self-compacting concrete.

3.3. Determination of Water Resistance and Water Absorption of Concrete

When building structures from SCC in conditions of aggressive environment and contact with water, concrete should be dense and have good hydrophysical properties: low indicators of water absorption, capillary suction, water resistance and high indicators of frost and corrosion resistance. In works [

37,

38] improvement of hydrophysical properties of concrete with the use of modifiers, especially, which include ingredients of hydrophobic-plasticizing action by 20% and more is noted. We have carried out standard tests according to the methodology described in

Section 2.5 of the proposed modified self-compacting concrete compositions. The results of water absorption and water resistance tests are presented in

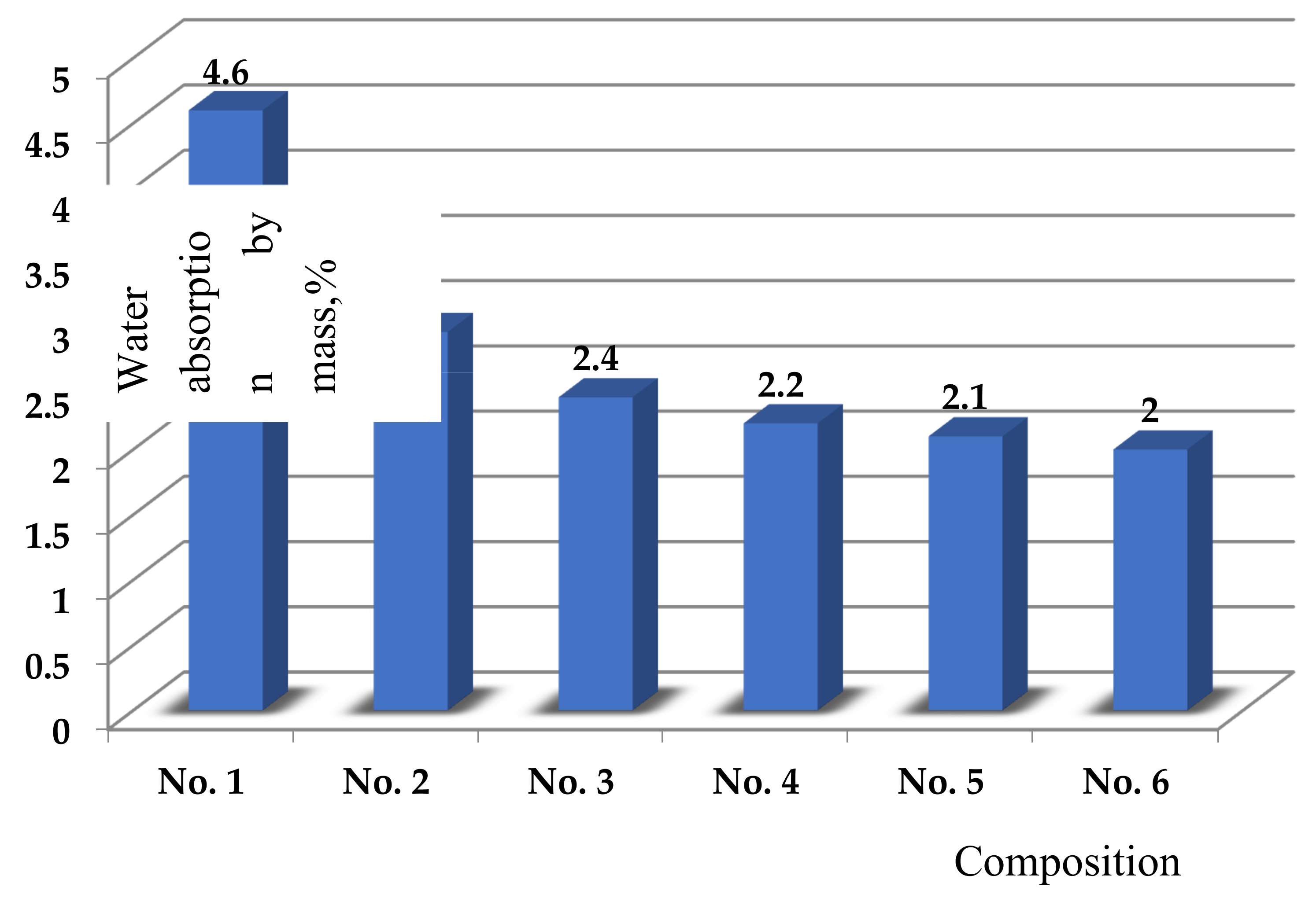

Table 7.

Analysis of the obtained data in

Table 7 (

Figure 2) shows that the concrete sample with complex modifier together with basalt fibre (Composition 6) reduced the water absorption index of concrete by - 56.5%; (Composition 2) by - 37%; (Composition 3) by - 47.8%; (Composition 4) by - 52.2%; (Composition 5) by - 54.3% compared to the control (Composition 1).

The water resistance of the modified SCC in (Composition 5) increased by 0.8 MPa or 4 grades (marks) in comparison with the control (composition 1). At the same time, the presence of basalt fibre in (Composition 6) did not affect its water resistance in comparison with (Composition 5).

3.4. Determination of Corrosion Resistance

Solutions of salts of low concentration are not aggressive to SCC at constant immersion of structures in them, but at alternate saturation and drying or at capillary absorption of such solution the concentration of solution in drying concrete and their crystallisation in concrete pores (salt form of concrete corrosion) are possible.

The saturation of SCC with salts containing chloridiones (NaCl chlorides) may cause corrosion of steel reinforcement of the structure, i.e., such salts are aggressive towards reinforced concrete. Based on the analysis of the causes of corrosion in concrete and the assessment of the degree of aggressiveness of media in relation to reinforced concrete structures, it follows that corrosion resistance depends both on the conditions of interaction between concrete and the external environment and on the composition of the influencing aggressive solution [

39].

In this work we studied the effect on self-compacting concrete of different liquid aggressive media simulating all three types of corrosion according to [

40]. The obtained test results are given in

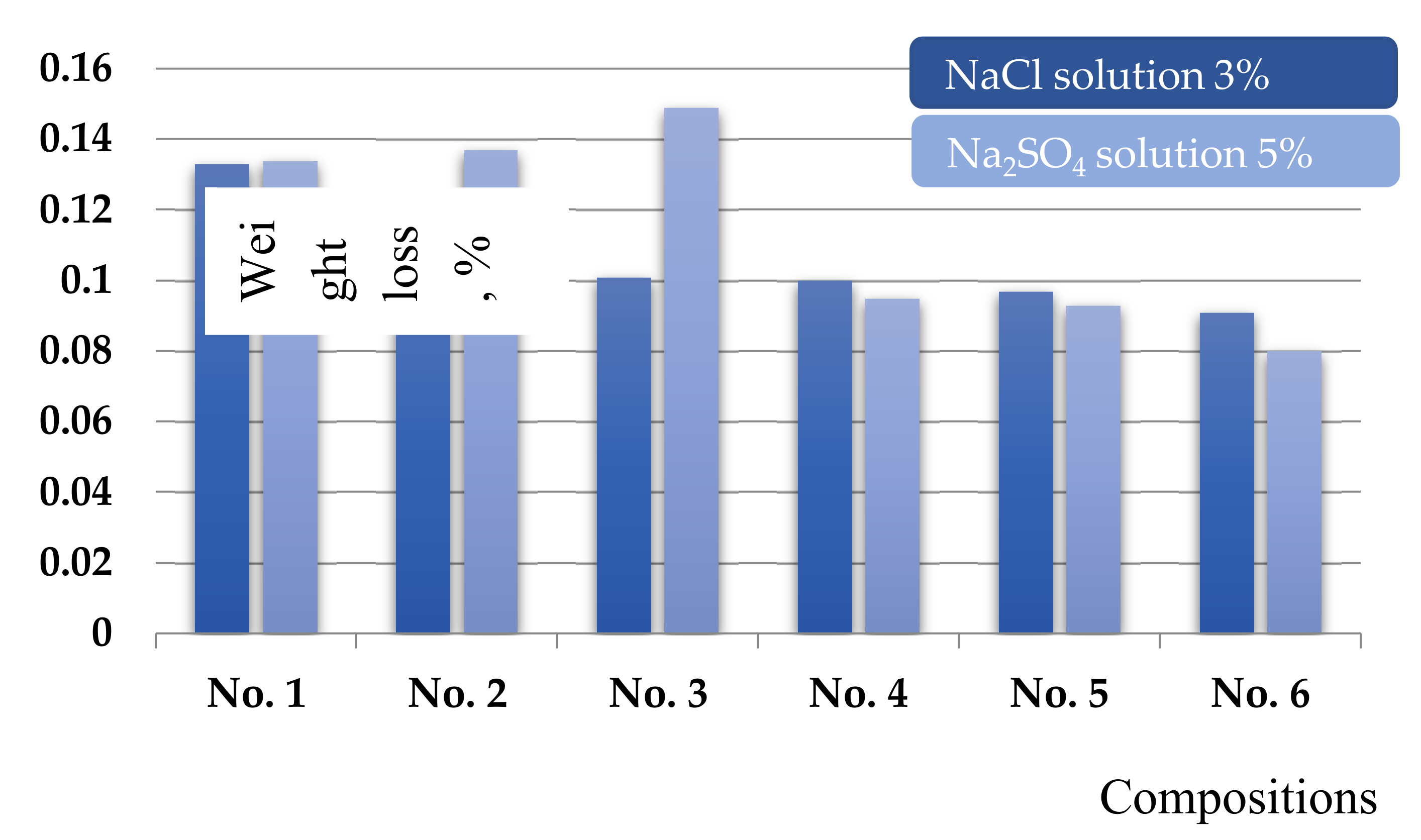

Table 8.

The results of the study of resistance to aggressive influences of SCC samples by changes in the average mass, tensile strength in bending and compression (

Table 8) showed that the proposed (Composition 6) has a high resistance to corrosion. When the specimens were kept in 3% NaCl solution, the mass loss Δmcr was 0.091%, compressive strength ΔR

av. - 0.144%, bending strength ΔR_tb - 0.131%, respectively.

During corrosion testing in 0.01 mol/L HCl hydrochloric acid solution, the following changes were observed in (Composition 6): decrease in the reduction of the average mass loss Δmav. - by 46.4%, compressive strength ΔRav. - by 56%; flexural tensile strength ΔR_tb - by 65.6%, compared to the control (Composition 1), respectively.

When tested by leaching corrosion in distilled water, the following changes were observed in (Composition 6): decrease in the reduction of average weight loss Δmav. - by 21.5%, compressive strength ΔRav. - by 48.8%; flexural tensile strength ΔR_tb - by 49.6%, compared to the control (Composition 1), respectively.

When tested (

Figure 3) for the aggressive effect of sulphate in 5% solution (Na

2SO

4), the increased performance was inversely shown by the specimens (Composition 6). Reductions in mass loss Δm

av. - by 40.3%, compressive strength ΔR

av. - by 38.4% and flexural tensile strength ΔR_tb - by 46.9% relative to the control (Composition 1) were observed, respectively. The obtained test results are in agreement with the results of [

32,

41].

4. Discussion

The results of compressive strength studies of SCC show a significant improvement in the strength properties in the modified formulations. For example, composition 5 containing 1.5% AR Premium, 0.3% polyvinylpyrrolidone 40.0 and 15% MKU-95 shows an increase in strength of 21% over control composition 1 and 20% over composition 2. This confirms the effectiveness of using these additives to improve the strength properties of concrete.

It is interesting to note that the basalt micro-reinforcing fibre in composition 6 has only a minor effect on increasing the compressive strength of concrete, increasing it up to 7% compared to composition 5 without fibre. This indicates that fiber only plays a positive role in improving concrete flexural strength and deformation under bending loads.

The use of a complex modifier including 1.5% AR Premium, 0.3% polyvinylpyrrolidone 40.0, 15% MKU-95 and 15% microsilica leads to a number of positive effects. This includes a reduction in the water-cement ratio, an increase in strength according to the basic law of concrete strength and an increase in density, which favors hydrophysical properties and corrosion resistance. Water-soluble polymer additive "Polyvinylpyrrolidone 40.0" modifies the pore space of cement stone, thereby increasing its impermeability, frost and corrosion resistance [

42]. Microsilica increases the density and strength of cement stone and concrete based on it; as well as resistance to Type I corrosion (leaching) due to the binding of portlandite Ca(OH)

2 into water-soluble low-base calcium hydrosilicates [

43]. Basalt fiber increases crack resistance by its micro-reinforcement, the result of which is the leveling and reduction of stress concentration in the concrete structure, particularly in the macro-defect zone [

44].

The conducted hydrophysical tests show a decrease in water absorption of the complex modifier-modified SCC and an increase in its water resistance.

The received positive results of tests confirm the fact of increase of pozzolanic activity to free Ca(OH)

2 of microsilica MKU-95 contained in (Composition 6) together with basalt fiber possessing chemical resistance, that speaks about conformity of results of research with theoretical assumptions about occurrence of additional centers of crystallization and decrease of pore space in a body of concrete by reactions of active pozzolanic additives (active microsilica SiO

2), there is a process of binding of Ca(OH)

2 by active mineral fiber – SiO

2 into a poorly soluble compound - calcium hydro silicate according to the equation: Ca(OH)

2 + SiO

2 + mH

2O = CaO·SiO

2·nH

2O [

45].

When studying the soils encountered in the south of Kazakhstan and their classifications, it is necessary to note those that have a high degree of aggressive impact on concrete structures. For example, saline soils of brown soils have pH 2.8-3.5, grey-brown soils of steppe zone are less aggressive and their pH is in the range of 4.5-5.5. Loamy soils are composed of sodium bicarbonate (NaHCO3) and sodium carbonate (Na2CO3) and are classified as alkaline soils with an elevated pH greater than 8.5. Corrosion processes associated with the leaching of calcium hydroxide Ca(OH)2 occurring in concrete under the action of soft water belong to the first group of corrosion. Corrosion of the second group includes corrosion processes associated with the process of interaction of cement stone and calcium hydroxide with an aggressive medium, resulting in the formation of easily leachable and easily soluble calcareous compounds or increase in volume, which is accompanied by a reaction: Ca(OH)2 + CO2 = CaCO3 + H2O. Calcium carbonate (CaCO3) is insoluble in water. Over time, it deposits in the pores of the cement stone, increasing the volume of the concrete and, as a result, further cracking and deterioration. However, calcium carbonate is able to further interact with the carbon dioxide in the water to form a soluble acidic salt, causing carbon dioxide corrosion of concrete CaCO3 + H2O + CO2 → Ca(HCO3)2.

Sulphate corrosion is one of the most common types of chemical deterioration of cement-based building materials. In contact with concrete, sulphates actively interact with calcium hydroxide and aluminates constituents of cement stone. As a result of the reaction of sulphates with calcium hydroxide, gypsum is formed, the accumulation and increase of which in the pore space of concrete leads to its destruction. At high concentration of sulphates in the liquid phase, an excess concentration of SO4−2 anions appears in the solution, which react with calcium cations: Ca2+ + SO4−2 → CaSO4 ∙ 2H2O, the resulting gypsum is saturated with water and increases in volume during crystallization, which leads to the destruction of the cement stone.

In order to obtain complete data on the corrosion resistance of modified self-compacting concrete, we conducted experiments to identify the resistance of concrete to three types of corrosion according to the classification of V.M. Moskvin [

46]. The corrosion resistance studies showed that the complex modifier-modified SCC formulations have a high degree of resistance in aggressive environments and leaching corrosion. The use of modifiers allowed to reduce mass loss of specimens during corrosion leaching up to 50%, loss of compressive strength ΔR

av. - up to 40% and flexural tensile strength ΔR_tb - up to 60% as compared to control specimens without modifiers.

5. Conclusions

Modified by complex modifier (Hyperplasticiser + Polymer + Microsilica + Basalt fibre), SCC compositions show high strength, frost resistance and resistance in aggressive environments. The introduction of a certain amount of complex modifier increases the durability of the current SCC compositions, increasing water resistance by 4 grades up to W16, frost resistance up to F=500, increasing the compressive strength by 20%, reducing the mass loss of samples during corrosion leaching up to 50%. This emphasizes the effectiveness of the proposed complex modifier in improving the properties of SCC, especially since the constituents of the complex modifier are inexpensive and readily available. Taking into account the results of the conducted work it should be noted that complex modifiers for concrete will be further recommended for practical application in Kazakhstan.

Author Contributions

Conceptualization, D.A.A. and M.M.B.; methodology, Z.O.Z., D.A.A. and D.K.S.; software, A.M.Z. and Y.V.P.; validation, D.K.S., Z.O.Z. and M.M.B.; formal analysis, A.M.Z. and Y.V.P.; investigation, D.A.A. and Z.O.Z.; resources, Z.O.Z.; data curation, A.M.Z.; writing—original draft preparation, A.M.Z. and D.A.A.; writing—review and editing, Z.O.Z.; visualization, D.K.S. and M.M.B.; supervision, Z.O.Z.; project administration, M.M.B.; funding acquisition, M.M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR21882292 – “Integrated development of sustainable construction industries: innovative technologies, optimization of production, effective use of resources and creation of technological park”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kalashnikov V.I. Evolution of compositions development and change of concrete strength. Concretes of the present and the future. Construction materials. 2016. No. 1-2. P. 96-103.

- Available online: https://journal-cm.ru/index.php/ru/zhurnaly/2016/vse-stati-za-2016/evolyutsiya-razvitiya-sostavov-i-izmenenie-prochnosti-betonov-betony-nastoyashchego-i-budushchego-chast-1-izmenenie-sostavov-i-prochnosti-betonov.

- Yahiaoui, W., Kenai, S., Menadi, B., and Kadri, E.H. (2017), “Durability of self compacted concrete containing slag in hot climate”, Advances in Concrete Construction, 5(3), 271-288. [CrossRef]

- Benyamina, S., Menadi, B., Bernard, S.K., & Kenai, S. (2019), “Performance of self-compacting concrete with manufactured crushed sand”, Advances in Concrete Construction, 7(2), 87-96. [CrossRef]

- Utepov, Y., Akhmetov, D., Akhmatshaeva, I. Effect of fine fillers from industrial waste and various chemical additives on the placeability of self-compacting concrete. Computers and Concrete. 2020. 25(1). pp. 59–65. [CrossRef]

- Specification and Guidelines for self-compacting concrete, EFNARC 2002, Norfolk, UK. Available online: https://wwwp.feb.unesp.br/pbastos/c.especiais/Efnarc.pdf.

- Bandurin M.A., Volosukhin V.A. Operational monitoring of flume canals of irrigation systems. Training manual. 2nd edition, revision. Krasnodar: Trubilin Kuban State Agrarian University, 2022. 49507107.

- Abd Elmoaty Mohamed Abd Elmoaty, Mechanical properties and corrosion resistance of concrete modified with granite dust, Construction and Building Materials 2013, Volume 47. [CrossRef]

- Akhmetov, D.A., Aniskin, A., Utepov, Y.B., Root, Y.N., Kozina, G. Determination of Optimal Fibre Reinforcement Parameters for Self-Compacting Concretes. Tehnicki vjesnik. 2020. 27(6). pp. 1982–1989. Available online: https://hrcak.srce.hr/248250. [CrossRef]

- Tkach E.V., Semenov V.S., Tkach S.A., Rozovskaya T.A. Highly effective water-repellent concrete with improved physical and technical properties. Procedia Engineering 2015. T. 111. [CrossRef]

- Bazhenov Y.M., Fomichev V.T., Erofeev V.T., Fedosov S.V., Matvievskiy A.A., Osipov A.K., Emelyanov. Ways of development of building material science: New concretes. Concrete Technology 2012. 22457451.

- Bazhenov Y.M., Demyanova V.S., Kalashnikov V.I. Modified high quality concretes. Moscow: ASV Publishing House, 2006. 368 p. Available online: https://rusneb.ru/catalog/000199_000009_003034382/.

- GOST 24211-2008 (GOST-Government standard). Additives for concrete and mortars. General technical conditions. - Moscow: Standardinform. 2010. 16p. European Committee for Standardization. EN 934-2:2001 Admixtures for concrete, mortar and grout - Part 2: Concrete admixtures - Definitions, requirements, conformity, marking and labeling. Brussels: CEN, 2001.

- Sh.M. Rakhimbaev, N.M. Tolypina. Increase of corrosion resistance of concrete by rational choice of binder and aggregates. Belgorod: Belgrade State Technical University. 2015. 26580490.

- Moskvin B.M., Ivanov F.M., Alekseev S.N., Guzeyev E.A.; Ed. by Moskvin V.M. Corrosion of concrete and reinforced concrete, Methods of their protection. Moscow: Stroyizdat 1980. 24898144.

- GOST 10060-2012. Concretes. Methods of determination of frost resistance. Moscow: Standardinform. 2018. 33 p. EN 12390-9:2006 - Testing hardened concrete - Part 9: Freeze-thaw resistance of specimens. European Committee for Standardization, Brussels.

- GOST 12730.5-2018. Concretes. Methods of determination of water resistance. Moscow: Standardinform. 2019. 19 p. EN 12390-8:2020 - Testing hardened concrete - Part 8: Depth of penetration of water under pressure. European Committee for Standardization, Brussels.

- GOST 12730.3-2020. Concretes. Method for determination of water absorption. Moscow: Standardinform. 2021. 3 p. EN 12390-6:2019 - Testing hardened concrete - Part 6: Tensile splitting strength of test specimens. European Committee for Standardization, Brussels.

- GOST 27677-88. Corrosion protection in construction. Concretes. General requirements for testing. - Moscow: Standards Publishing House. 1988. 6 p. EN ISO 9227:2017 - Corrosion tests in artificial atmospheres - Salt spray tests. International Organization for Standardization, Geneva.

- GOST 31108-2020. General construction cements. Technical conditions. Moscow: Standardinform. 2022. 14 p. EN 197-1:2011 - Cement - Part 1: Composition, specifications and conformity criteria for common cements. International Organization for Standardization, Geneva.

- EN 196-2:2013. Method of Testing Cement—Part 2: Chemical Analysis of Cement; SIST: Ljubljana, Slovenia, 2013; p. 73.

- GOST 8736-2014. Sand for construction works. Specifications. EN 12620:2013 - Aggregates for concrete. British Standards Institution, London. Available online: https://sciencealpha.com/gost-8736-2014-sand-for-construction-works-technical-specifications-with-amendment.

- GOST 8735-88. Sand for construction works. Test methods. Moscow: Standardinform. 2018. 25 p. EN 933-1:2012 - Tests for geometrical properties of aggregates - Part 1: Determination of particle size distribution - Sieving method. International Organization for Standardization, Geneva.

- GOST 8267-93. Crushed stone and gravel from dense rocks for construction works. Technical conditions. Moscow: Standard-Tinform. 2018. 11 p. EN 12620:2013 - Aggregates for concrete. British Standards Institution, London.

- EN 12620:2013. Aggregates for Concrete; SIST: Ljubljana, Slovenia, 2013; p. 54. Available online: https://ru.scribd.com/document/397483151/BS-en-12620-2013-Aggregates-for-Concrete.

- GOST 30459-2008. Admixtures for concretes and mortars. Determination and estimate of the efficiency. EN 934-2:2009 - Admixtures for concrete, mortar and grout - Part 2: Concrete admixtures - Definitions, requirements, conformity, marking and labelling. Available online: https://protect.gost.ru/document.aspx?control=7&id=175893.

- Technical conditions 9365-002-46270704-2001. Polyvinylpyrrolidone high molecular weight. Available online: https://e-ecolog.ru/crc/78.01.06.936.%D0%A2.003880.10.08?utm_referrer=https%3A%2F%2Fwww.google.com%2F.

- Akhmetov, D.A.; Pukharenko, Y.V.; Vatin, N.I.; Akhazhanov, S.B.; Akhmetov, A.R.; Jetpisbayeva, A.Z.; Utepov, Y.B. The Effect of Low-Modulus Plastic Fiber on the Physical and Technical Characteristics of Modified Heavy Concretes Based on Polycarboxylates and Microsilica. Materials 2022, 15, 2648. [Google Scholar] [CrossRef] [PubMed]

- EN 13263-1:2005+A1:2009. Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria; SIST: Ljubljana, Slovenia, 2009; p. 23. Available online: https://www.en-standard.eu/une-en-13263-1-2006-a1-2009-silica-fume-for-concrete-part-1-definitions-requirements-and-conformity-criteria/.

- Technical conditions 5952-002-13307094-08. CHOPPED BASALT FIBRE. Moscow region, Dubna. Limited Liability Company “Stone Age”. 2008. 21 p. Available online: https://e-ecolog.ru/crc/50.99.03.595.%D0%A2.004540.04.09?utm_referrer=https%3A%2F%2Fwww.google.com%2F.

- Akhmetov, D.; Akhazhanov, S.; Jetpisbayeva, A.; Pukharenko, Y.; Root, Y.; Utepov, Y.; Akhmetov, A. Effect of low-modulus polypropylene fiber on physical and mechanical properties of self-compacting concrete. Case Stud. Constr. Mater. 2022, 16, e00814. [Google Scholar] [CrossRef]

- GOST 23732-2011. Water for concrete and mortars. Technical conditions. Moscow: Standardinform. 2012. 11 p. EN 1008:2002 - Mixing water for concrete. British Standards Institution, London.

- Rakhimbaev Sh.M., Tolypina N.M. Increase of corrosion resistance of concrete by rational choice of binder and aggregates. - Belgorod: BSTU. 2015. 250 p. Available online: https://www.dissercat.com/content/povyshenie-korrozionnoi-stoikosti-betonov-putem-ratsionalnogo-vybora-vyazhushchego-i-zapolni.

- GOST 10180-2012. Concretes. Methods of determination of strength by control samples. Moscow: Standardinform. 2018. 31 p. EN 12390-3:2019 - Testing hardened concrete - Part 3: Compressive strength of test specimens. European Committee for Standardization, Brussels.

- Ilyas Abdraimov, Bakhadyr Kopzhassarov, Inna Kolesnikova, Daniyar Akbulatovich Akhmetov, Ilnura Madiyarova and Yelbek Utepov. Frost-Resistant Rapid Hardening Concretes. [CrossRef]

- Haimei Zhang. Building Materials in Civil Engineering. 2011. ISBN 9781845699567. Available online: https://www.researchgate.net/publication/296101365_Building_Materials_in_Civil_Engineering.

- Soloviev V.I., Tkach E.V., Serova R.F., Tkach S.A., Toimbayeva B.M., Seydinova G.A. Study of porosity of cement stone modified with complex organomineral modifiers. Fundamental researches 2014. No. 8-3. pp. 590-595. Available online: https://fundamental-research.ru/ru/article/view?id=34599.

- Zhao Y., Ding P., Ba C., Tang A., Song N., Liu Y., Shi L. Preparation of TIO2 coated silicate micro-spheres for enhancing the light diffusion property of polycarbonate composites. Displays. 2014. Vol. 35. No. 4. P. 220-226. [CrossRef]

- Yakovlev G.I., Pervushin G.N., Korzhenko A., Burianov A.F., Pudov I.A., Lushnikova A.A. Modification of cement concrete by multilayer carbon nanotubes. Stroitelnye materialy. 2011. No.2. P. 47-51. Available online: https://cyberleninka.ru/article/n/modifikatsiya-tsementnyh-betonov-mnogosloynymi-uglerodnymi-nanotrubkami.

- Grishina A.N., Korolev E.V., Mikheev A.V., Gladkikh V.A. Moisture deformations of concrete subjected to alkaline corrosion. Experimental results. Bulletin of Civil Engineers. 2020. No. 6 (83). P. 140-148. Available online: https://vestnik.spbgasu.ru/article/vlazhnostnye-deformacii-betona-podverzhennogo-shchelochnoy-korrozii-eksperimentalnye.

- Moskvin V.M., Ivanov F.M., Alekseev S.N., Guzeyev E.A. Corrosion of concrete and reinforced concrete, Methods of their protection. Edited by Moskvin V. M. Moskvin M. Moscow: Stroyizdat, 1980. 536p. Available online: https://books.totalarch.com/corrosion_of_reinforced_concrete_and_methods_protection.

- Rosenthal, N.K. Rosenthal N.K., Stepanova V.F., Chechniy G.V. Concretes of high corrosion resistance and rationing of their characteristics // Building materials, equipment, technologies of the XXI century. 2017. No. 3-4 (218-219). P. 14-19. Available online: http://stroymat21.ru/pdf/2017_03/14-19.pdf.

- Vipulanandan C. and Dharmarajan N. Analysis of Fracture Parameters of Polymer Concrete. ACI Materials Journal 1989. V. 86. No. 4. [CrossRef]

- Inozemtsev A.S., Korolev E.V., Zyong T.K. Rheological features of cement-mineral systems plasticized with polycarboxylate plasticizer. Regional architecture and construction 2019. No. 3(40). 41330285.

- Afroz M., Patnaikuni I., Venkatesan S. Chemical resistance and performance of modified basalt fiber in concrete environment. Construction and Building Materials, 2017. Vol. 154. [CrossRef]

- Tkach, E.V.; Sadchikova, Yu.S. Improvement of the operational properties of concrete for hydromeliorative construction. Construction Equipment Bulletin. Russia. 2019. No. 4 (1016). P.64-65. Available online: http://bstmag.ru/archive.

- Lukuttsova N.P., Pykin A.A., Ustinov A.G., Kondrik A.S. Corrosion resistance of concrete with the addition of carbon-silica nanomodifier. Construction and reconstruction. 2012. No.5 (43). P. 62-67.

- 18759251 chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://oreluniver.ru/public/file/archive/5-43.pdf.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).