Submitted:

08 May 2024

Posted:

09 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

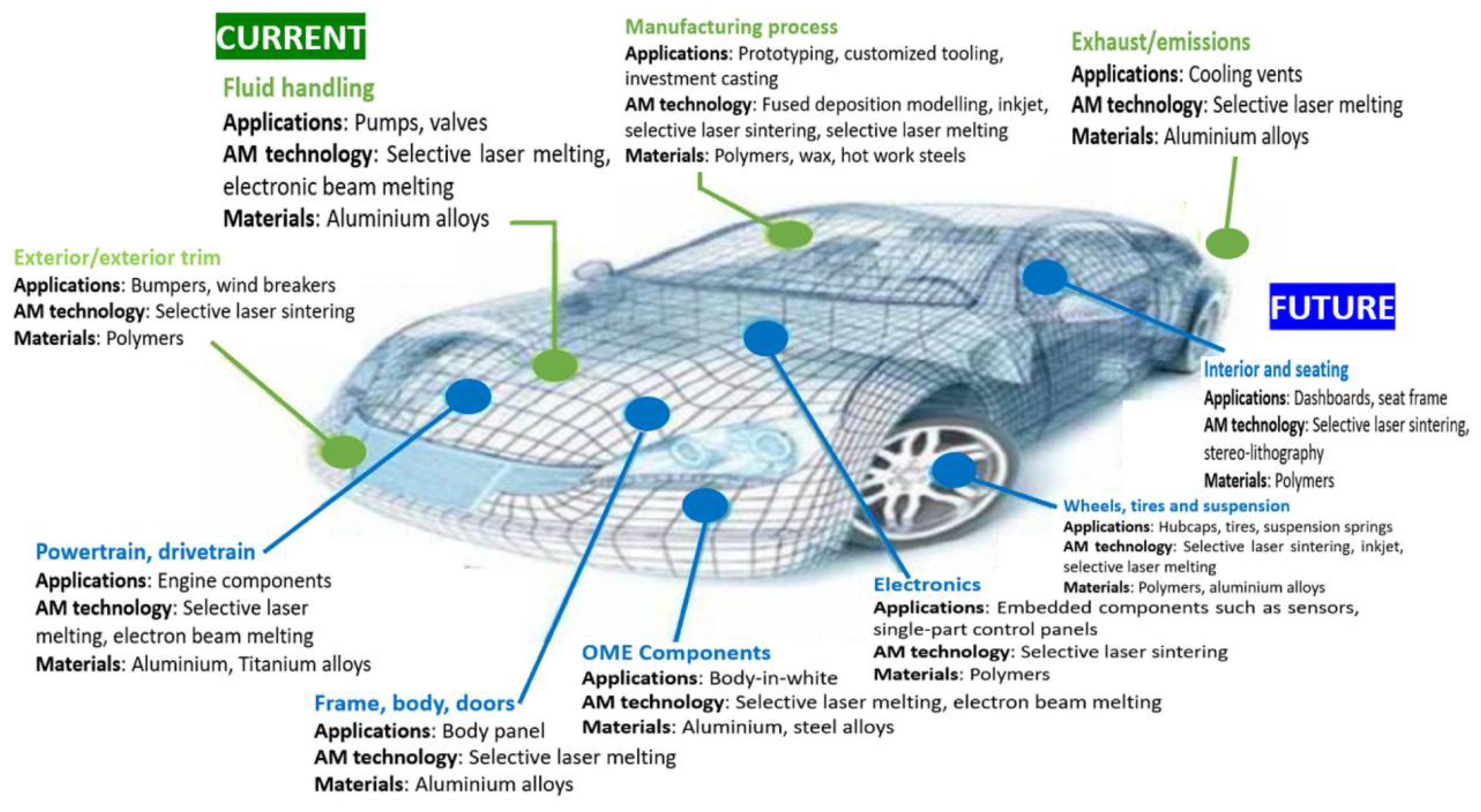

2. Additive Manufacturing Techniques Used in Automobile Industry

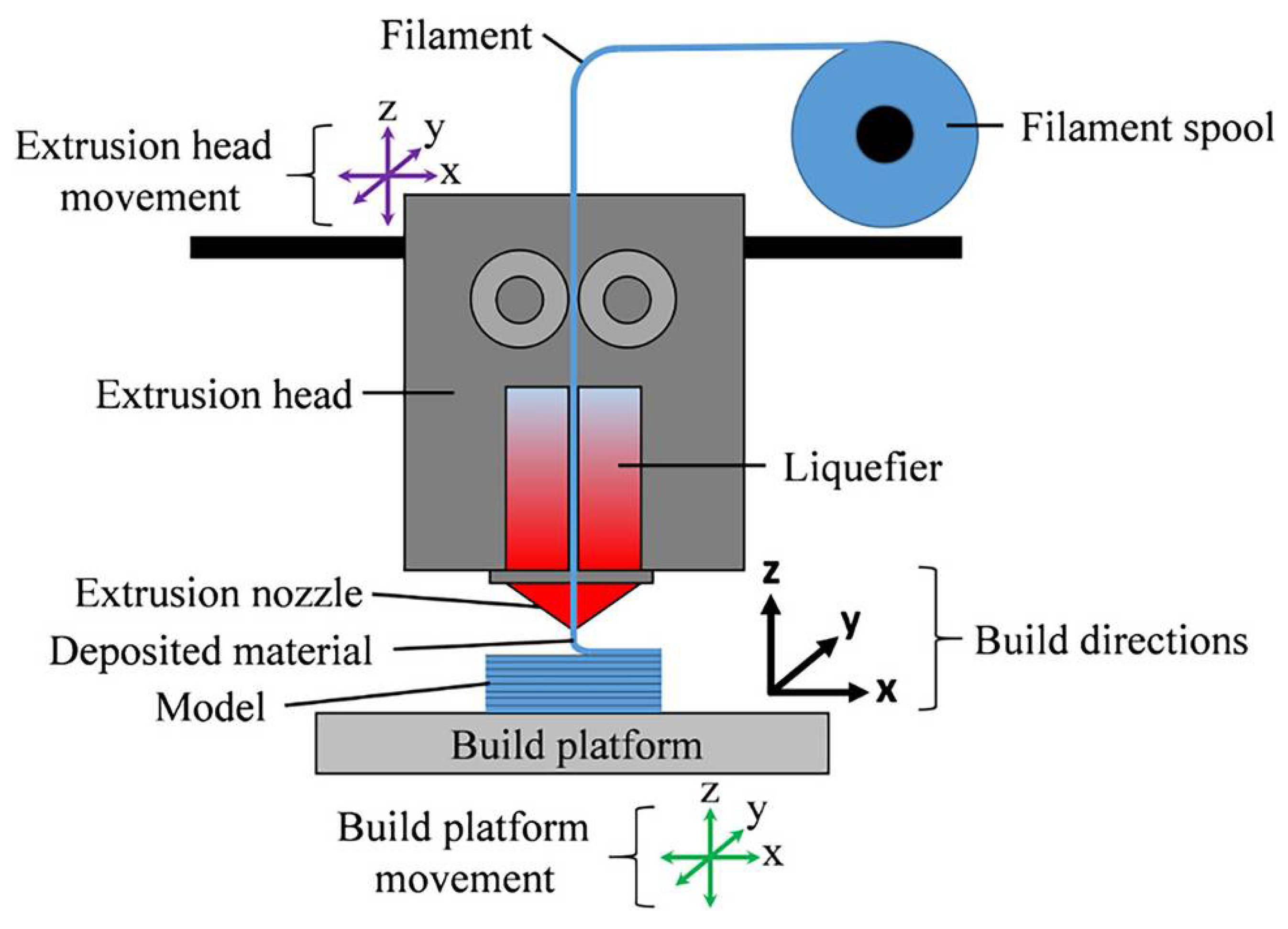

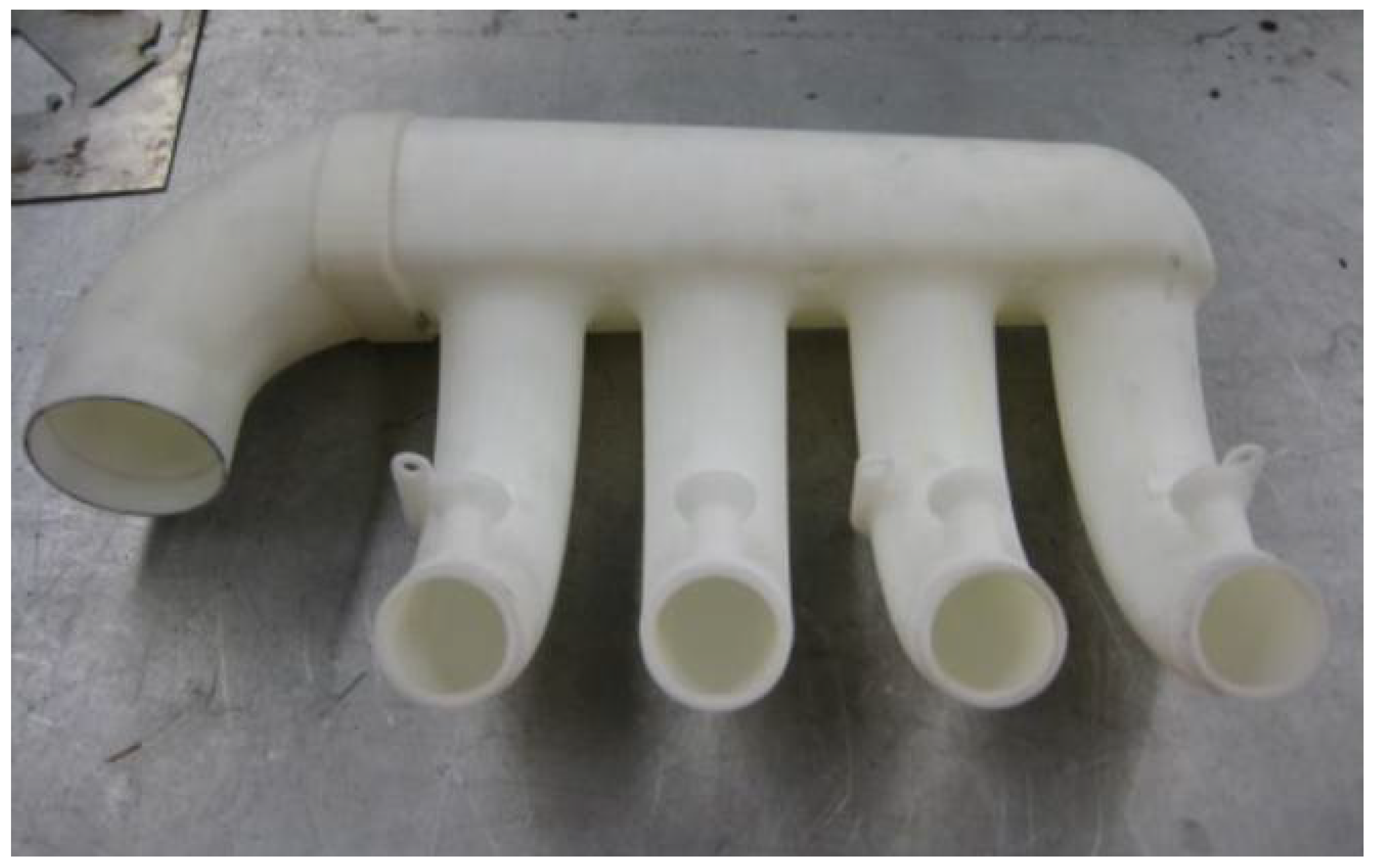

2.1. Material Extrusion

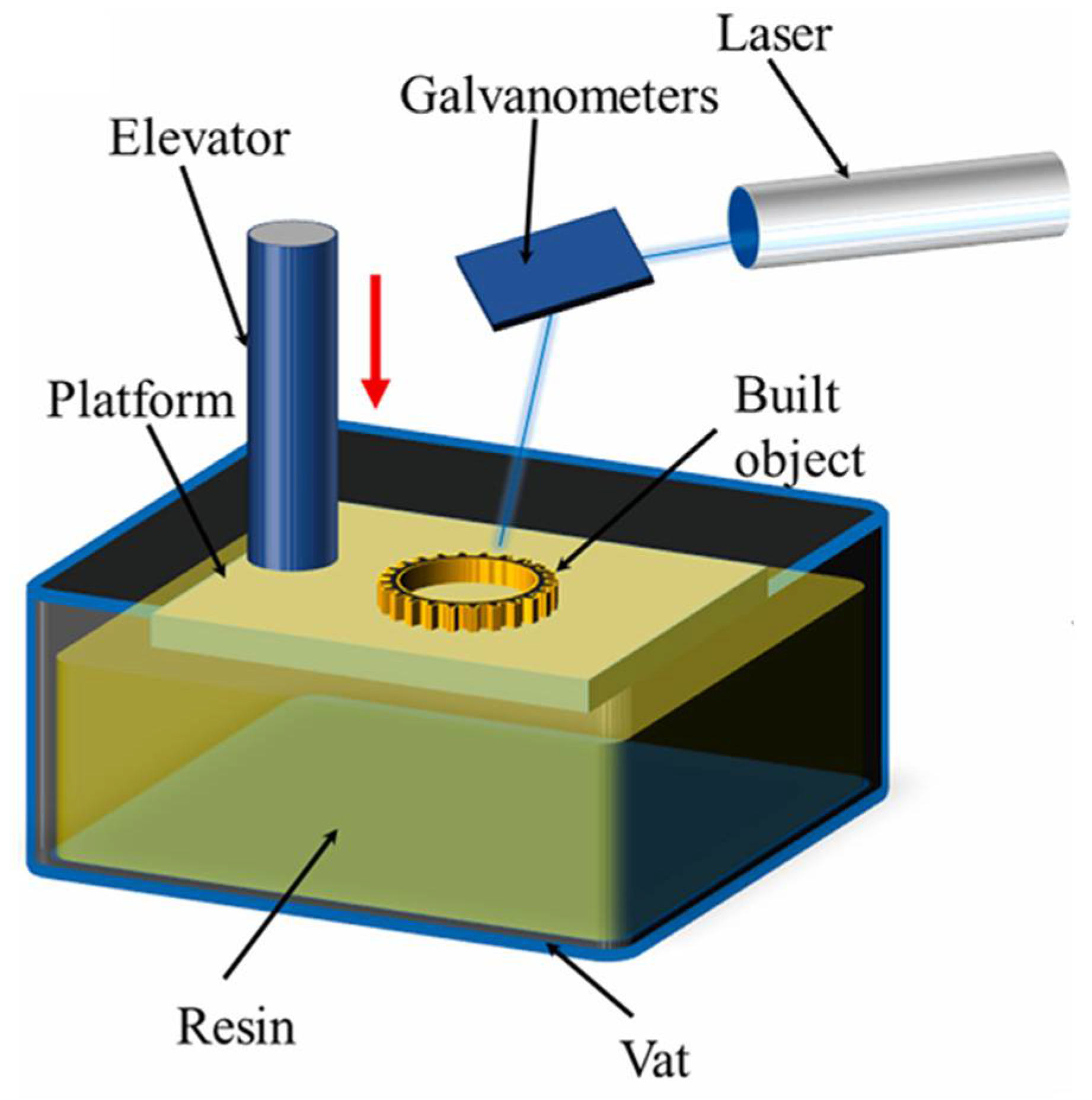

2.2. Vat Photopolymerization

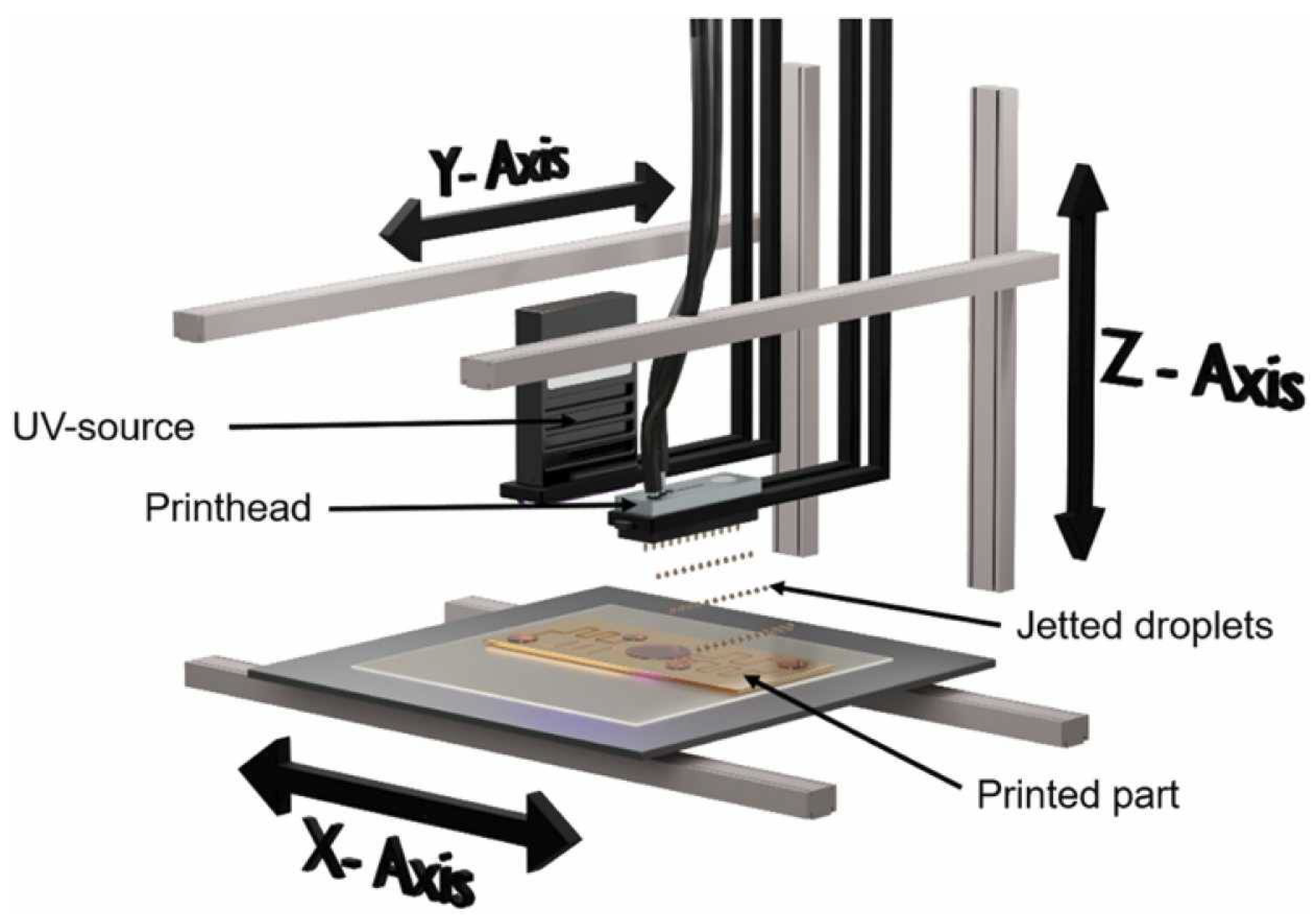

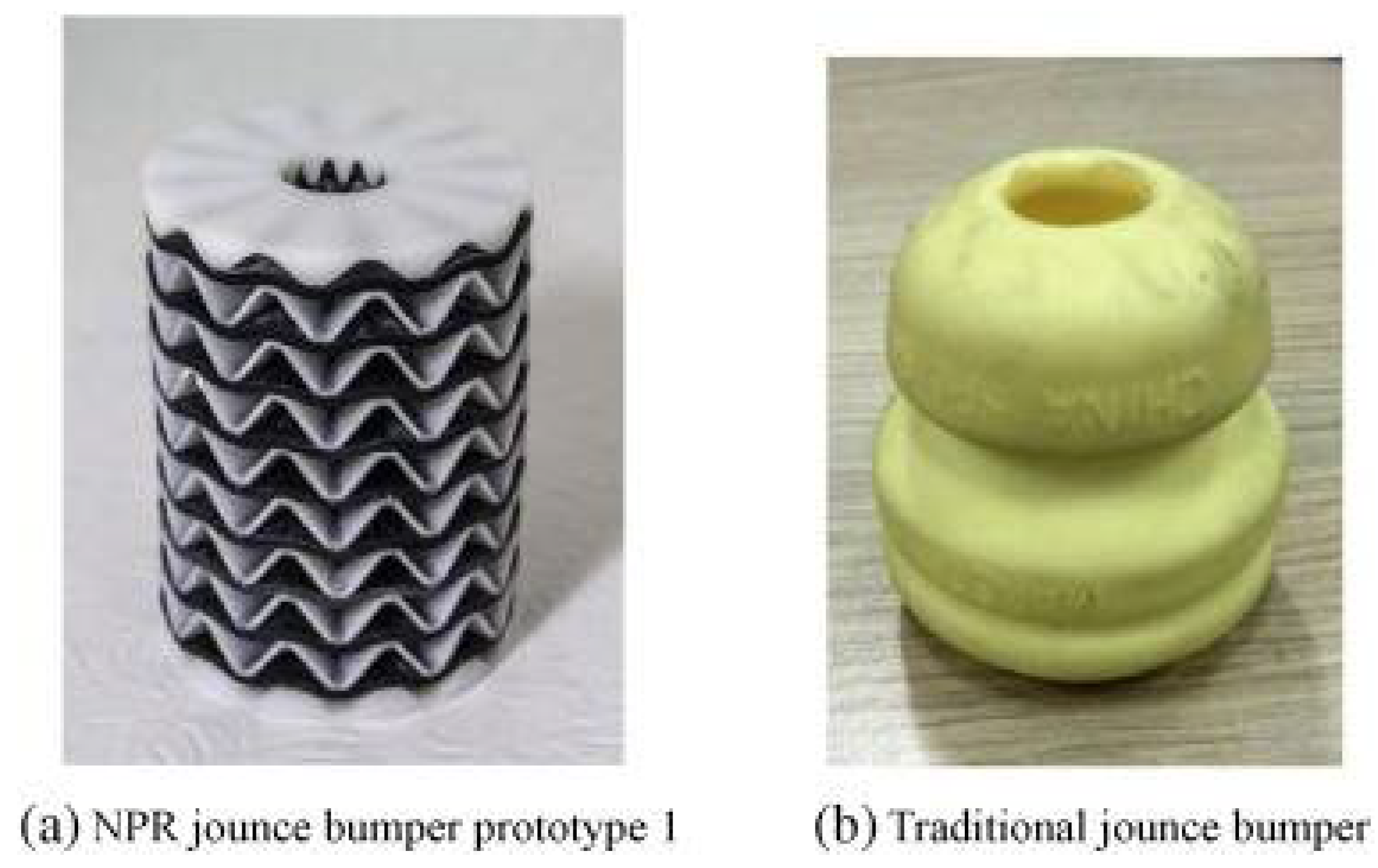

2.3. Material Jetting

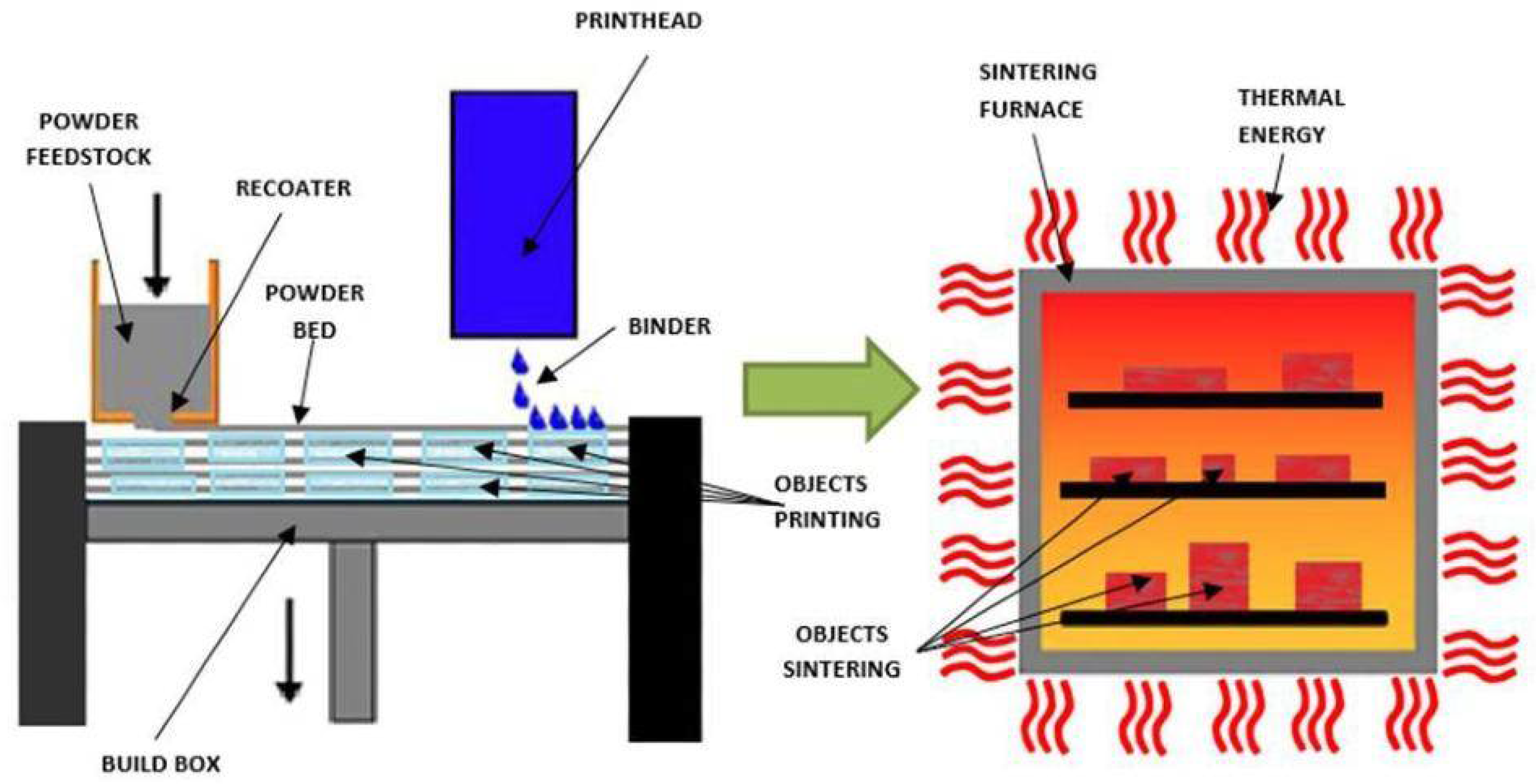

2.4. Binder Jetting

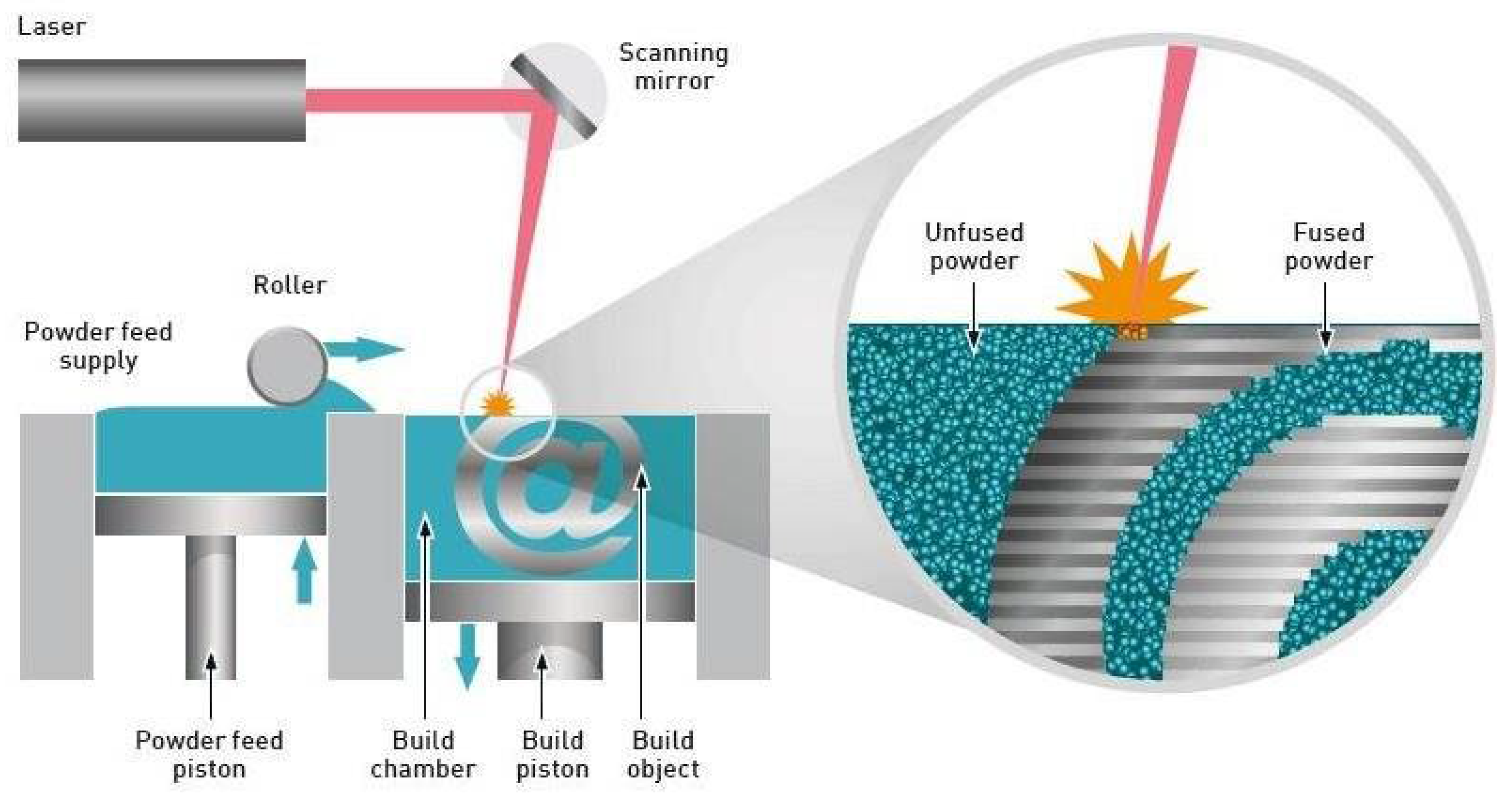

2.5. Powder Bed Fusion

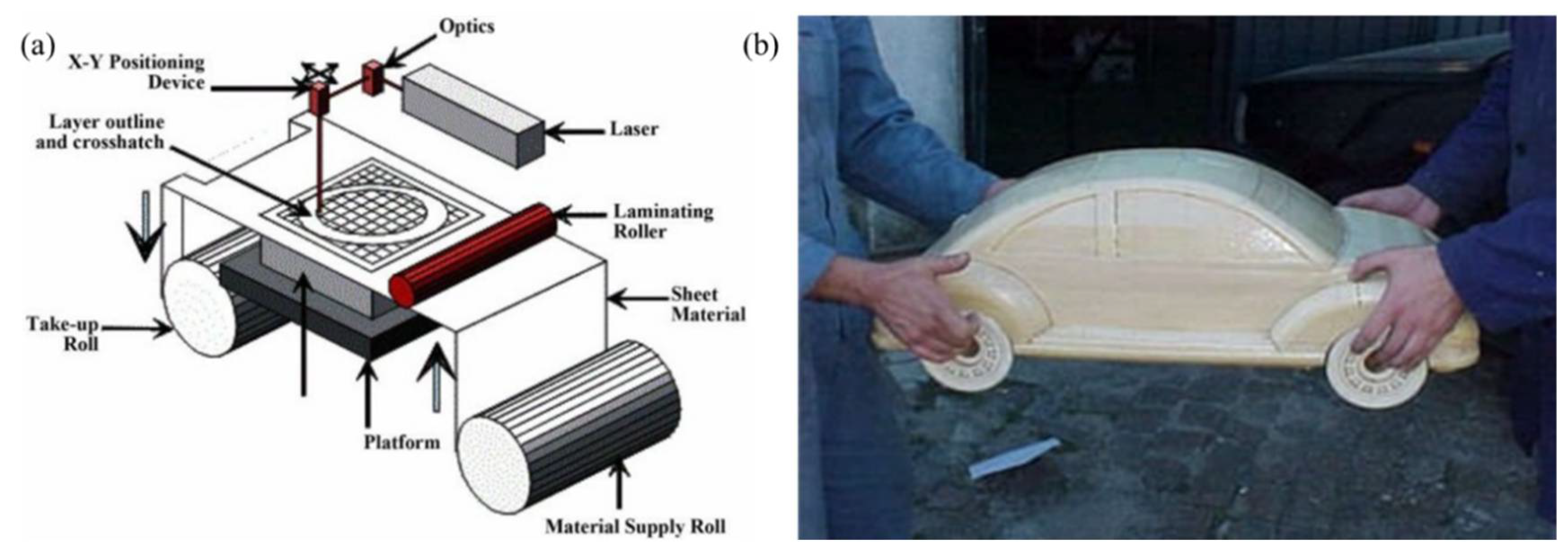

2.6. Sheet Lamination

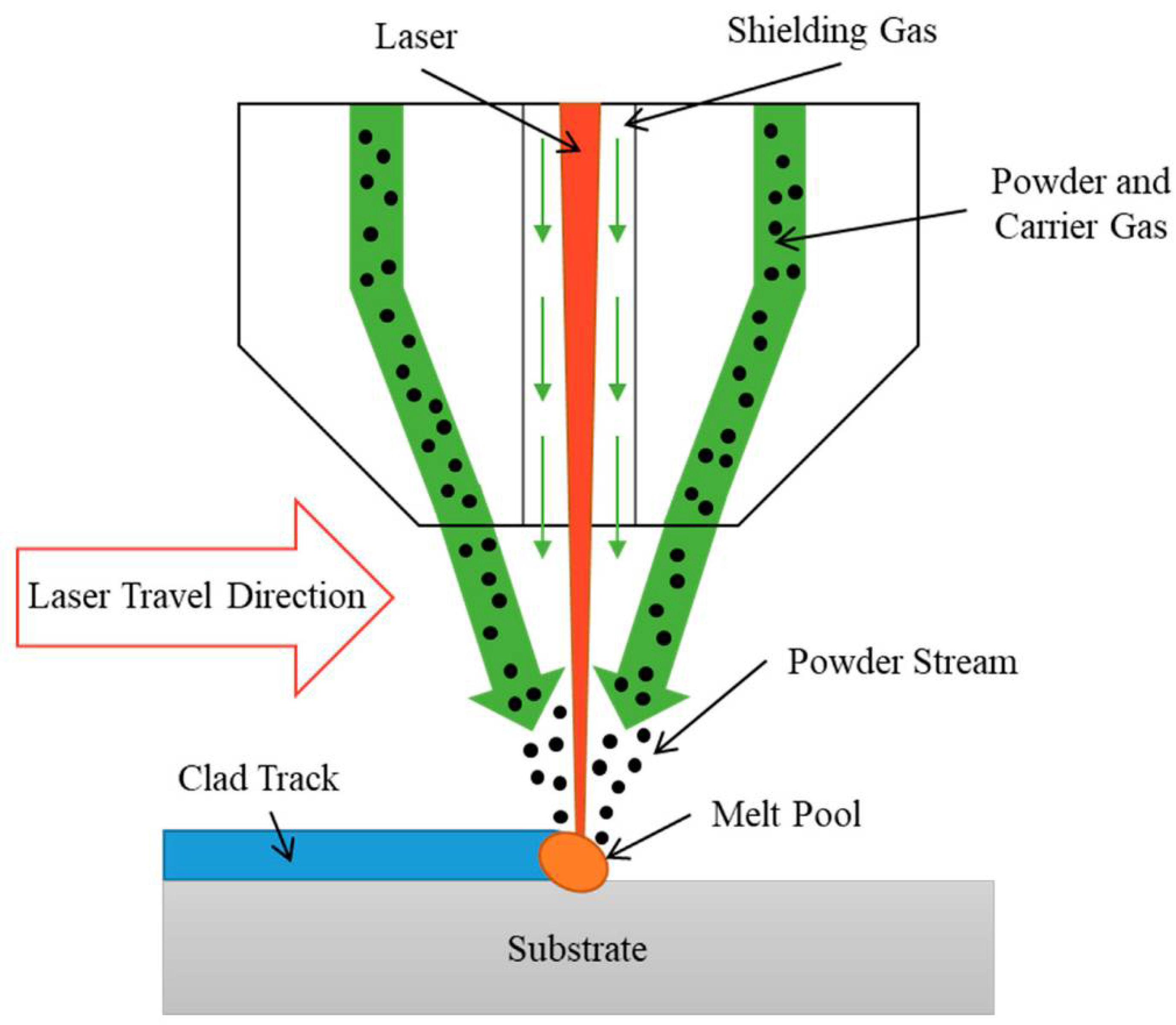

2.7. Directed Energy Deposition

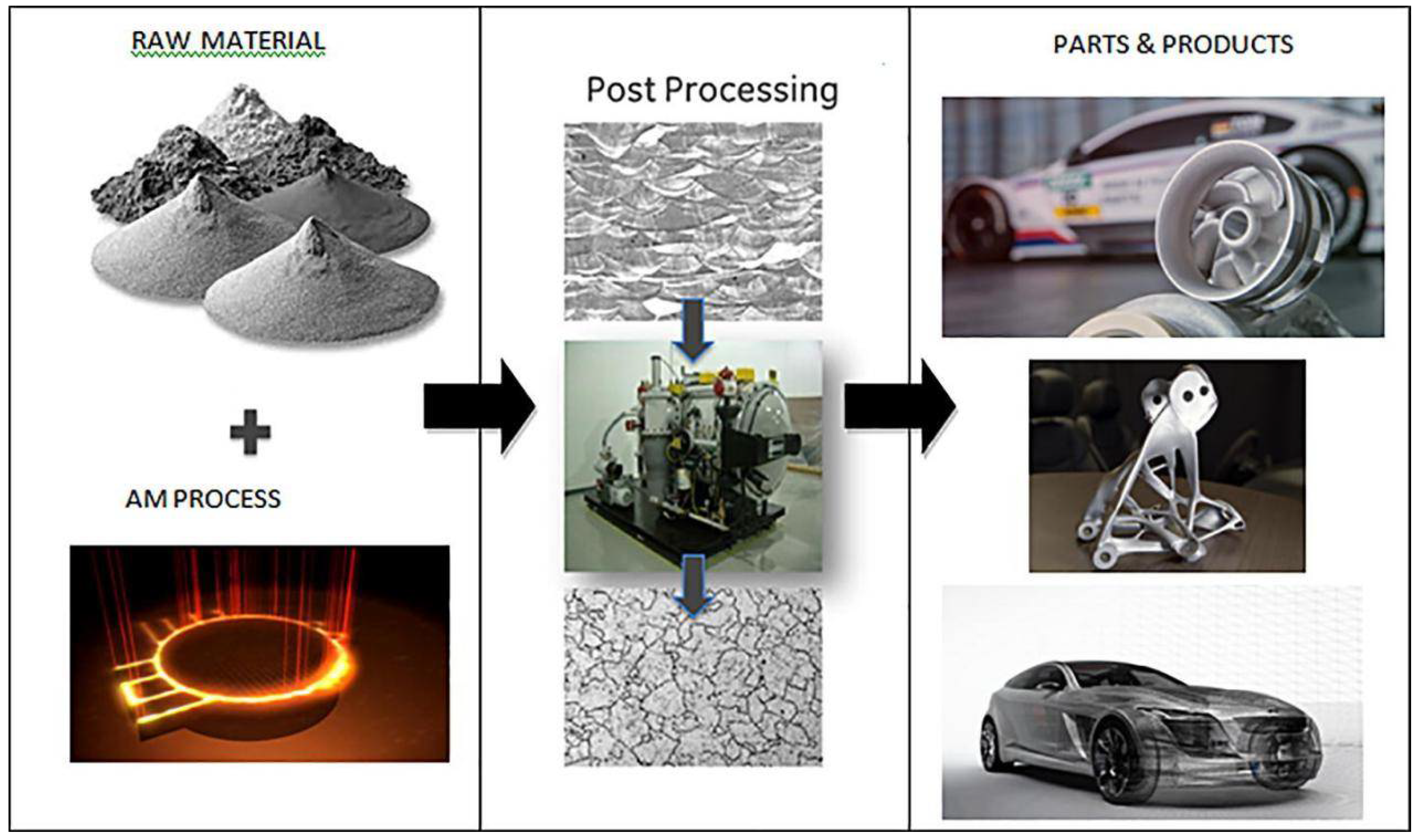

3. Printable Materials for Automobile AM Applications

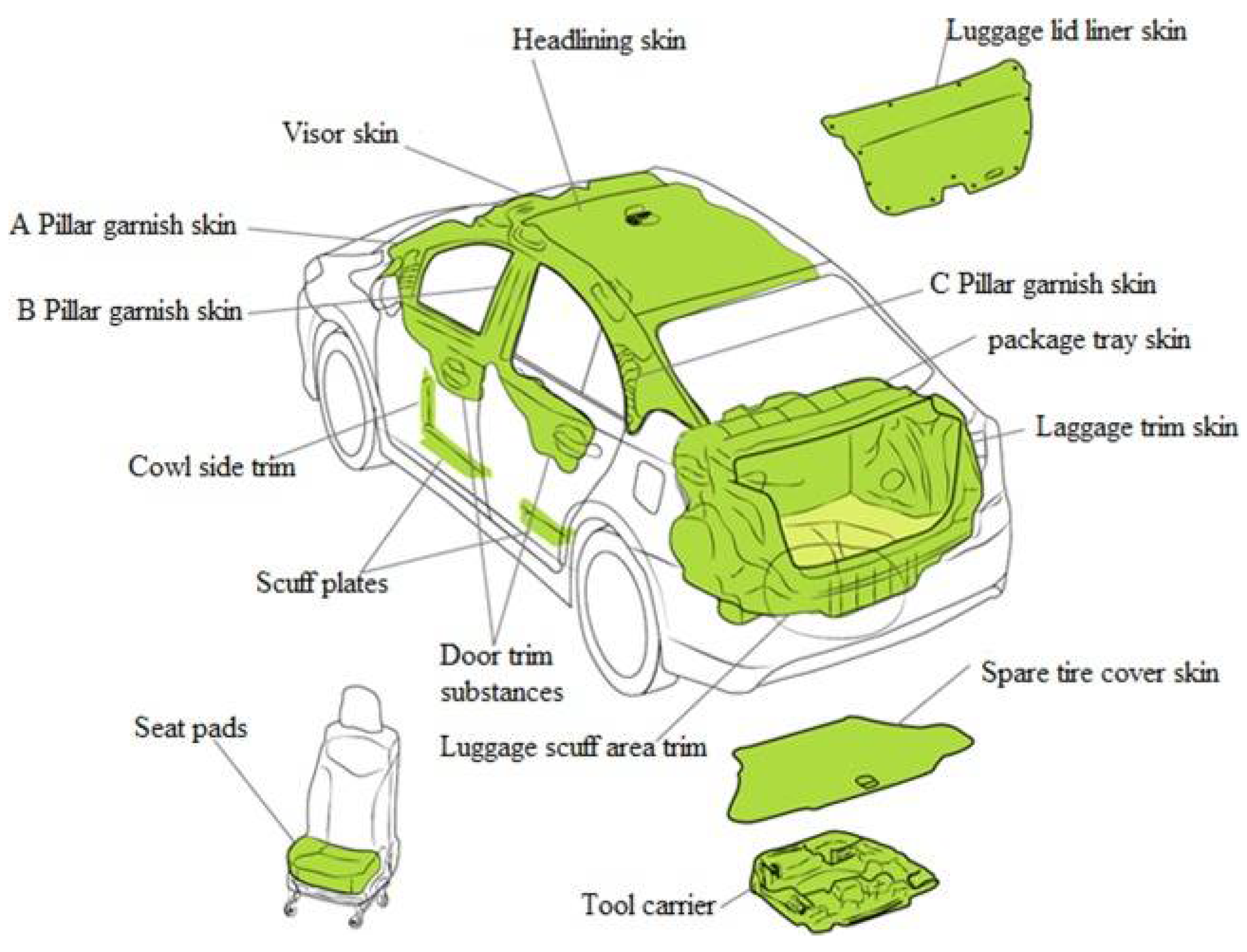

3.1. Polymer Additive Manufacturing

3.2. Metal Additive Manufacturing

3.3. Ceramic Additive Manufacturing

4. Challenges and the Future Opportunities

5. Conclusions

Data Availability Statement

Acknowledgements

Conflicts of Interest

References

- Business Research Insight. Automotive Market Size & Growth [2023-2030] Report. https://www.linkedin.com/pulse/automotive-market-size-growth-2023-2030-report/.

- H. M. V. Montemayor, R. H. Chanda. Automotive industry's circularity applications and industry 4.0. Environmental Challenges 2023, 12, 100725.

- Sarfraz, M.S.; Hong, H.; Kim, S.S. Recent developments in the manufacturing technologies of composite components and their cost-effectiveness in the automotive industry: A review study. Compos. Struct. 2021, 266. [Google Scholar] [CrossRef]

- Gastrow, M. A review of trends in the global automotive manufacturing industry and implications for developing countries. Afr. J. Bus. Manag. 2012, 6. [Google Scholar] [CrossRef]

- Nayeem, A.M.; Hossain, M.M.N. USAGE OF ADDITIVE MANUFACTURING IN THE AUTOMOTIVE INDUSTRY: A REVIEW. Int. J. Account. Finance Rev. 2023, 8, 9–20. [Google Scholar] [CrossRef]

- Li, K.; Yang, T.; Gong, N.; Wu, J.; Wu, X.; Zhang, D.Z.; Murr, L.E. Additive manufacturing of ultra-high strength steels: A review. J. Alloy. Compd. 2023, 965. [Google Scholar] [CrossRef]

- Cheng, H.; Luo, X.; Wu, X. Recent research progress on additive manufacturing of high-strength low-alloy steels: Focusing on the processing parameters, microstructures and properties. Mater. Today Commun. 2023, 36. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, H.; Wu, X. Nanomaterials Reinforced Polymer Filament for Fused Deposition Modeling: A State-of-the-Art Review. Polymers 2023, 15, 2980. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yang, R.; Luo, X.; Cheng, H.; Wu, X. Facile Fabrication of Carbon Nanocolloid-Silver Composite Ink for the Application of All Inkjet-Printed Wearable Electronics. Adv. Sens. Res. 2023, 2. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, R.; Wu, X. Recent progress in the development of conductive hydrogels and the application in 3D printed wearable sensors. RSC Appl. Polym. 2023, 1, 132–157. [Google Scholar] [CrossRef]

- Chen, X.; Yang, R.; Wu, X. Printing of MXene-based materials and the applications: a state-of-the-art review. 2D Mater. 2022, 9, 042002. [Google Scholar] [CrossRef]

- Yang, R.; Chen, X.; Zheng, Y.; Chen, K.; Zeng, W.; Wu, X. Recent advances in the 3D printing of electrically conductive hydrogels for flexible electronics. J. Mater. Chem. C 2022, 10, 5380–5399. [Google Scholar] [CrossRef]

- Yang, R.; Tu, Z.; Chen, X.; Wu, X. Highly stretchable, robust, sensitive and wearable strain sensors based on mesh-structured conductive hydrogels. Chem. Eng. J. 2024, 480. [Google Scholar] [CrossRef]

- V. Verboeket, H. V. Verboeket, H. Krikke. AM is recognized as a game-changer for the production process by replacing traditional manufacturing. Logistics 2019, 3(2), 13.

- J. C. Vasco. Additive manufacturing for the automotive industry. In: Additive manufacturing. Elsevier. 2021, 505-530.

- S. N. Yewale. Additive manufacturing in automobile industry. Int J Res Aeronaut Mech Eng 2019, 7(4), 1–10.

- Delic, M.; Eyers, D.R. The effect of additive manufacturing adoption on supply chain flexibility and performance: An empirical analysis from the automotive industry. Int. J. Prod. Econ. 2020, 228, 107689. [Google Scholar] [CrossRef]

- S. Akre. 3D Printing in Automotive Market Size, Share Analysis Report 2030. 2023. https://www.marketresearchfuture.com/reports/3d-printing-automotive-market-4207.

- Zhao, N.; Parthasarathy, M.; Patil, S.; Coates, D.; Myers, K.; Zhu, H.; Li, W. Direct additive manufacturing of metal parts for automotive applications. J. Manuf. Syst. 2023, 68, 368–375. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. Perspective of additive manufacturing for metamaterials development. Smart Mater. Struct. 2019, 28, 093001. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; Shi, J. Additive manufacturing of zirconia ceramics: a state-of-the-art review. J. Mater. Res. Technol. 2020, 9, 9029–9048. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. In-plane impact resistance enhancement with a graded cell-wall angle design for auxetic metamaterials. Compos. Struct. 2020, 247, 112451. [Google Scholar] [CrossRef]

- Wu, X.; Mu, F.; Lin, Z. Three-dimensional printing of graphene-based materials and the application in energy storage. Mater. Today Adv. 2021, 11, 100157. [Google Scholar] [CrossRef]

- D. Herzog, V. Seyda, E. Wycisk, C. Emmelmann. Additive manufacturing of metals. Acta Materialia 2016, 117, 371–392.

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

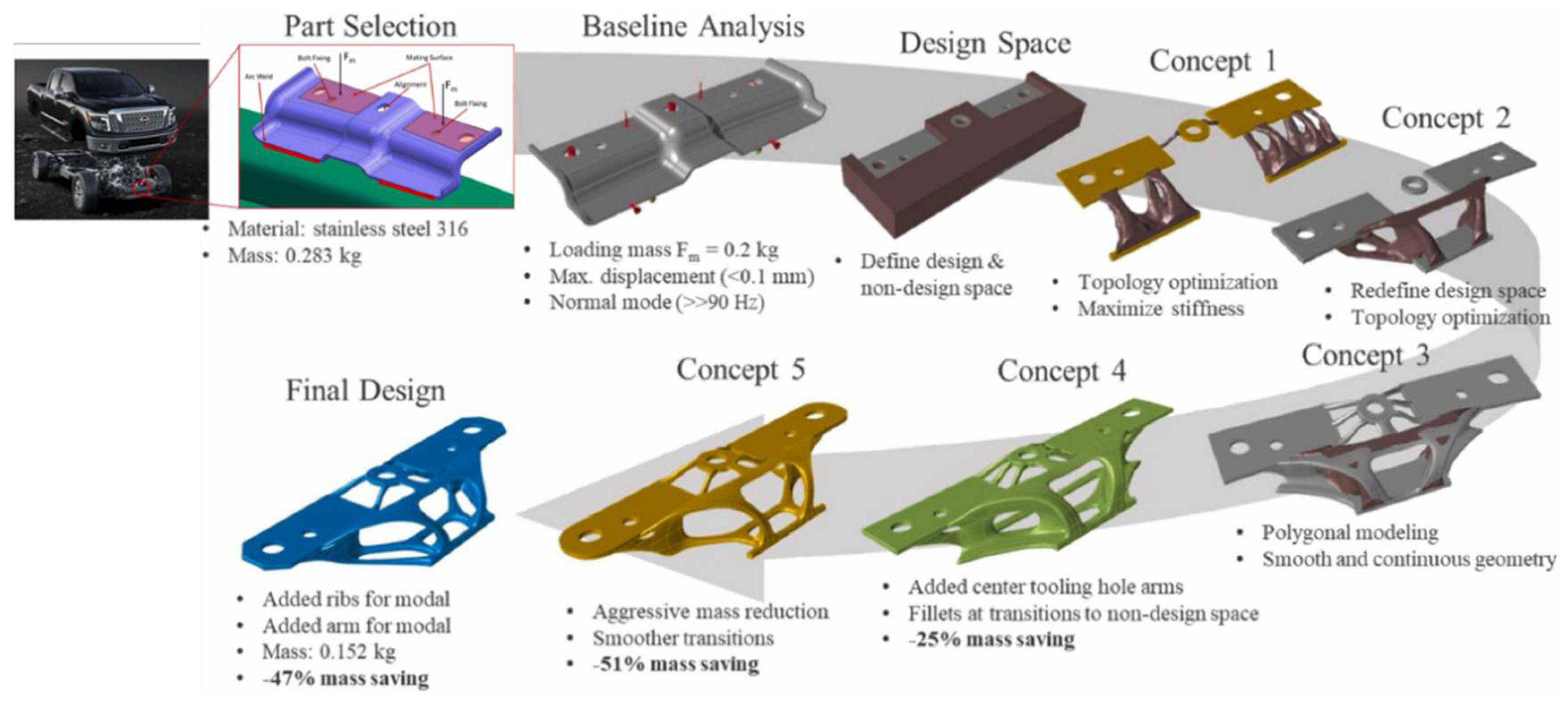

- T. Boissonneault. Honda uses AM and generative design to optimize crankshaft. 2020. https://www.voxelmatters.com/honda-am-generative-design-crankshaft/.

- M. Alderton. Driving a lighter, more efficient future of automotive part design at GM. 2018. https://www.autodesk.com/design-make/articles/automotive-design.

- V. Carlota. The Role of AM in the Automotive Industry. 2021. https://www.3dnatives.com/en/the-role-of-am-in-the-automotive-industry/.

- Salifu, S.; Desai, D.; Ogunbiyi, O.; Mwale, K. Recent development in the additive manufacturing of polymer-based composites for automotive structures—a review. Int. J. Adv. Manuf. Technol. 2022, 119, 6877–6891. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- S. Trzcielinski, B. S. Trzcielinski, B. Mrugalska, W. Karwowski, E. Rossi, M. D. Nicolantonio. Advances in Manufacturing, Production Management and Process Control. Proceedings of the AHFE 2021 Virtual Conferences on Human Aspects of Advanced Manufacturing, Advanced Production Management and Process Control, and Additive Manufacturing, Modeling Systems and 3D Prototyping, -29, 2021, USA. 25 July.

- Yi, L.; Gläßner, C.; Aurich, J.C. How to integrate additive manufacturing technologies into manufacturing systems successfully: A perspective from the commercial vehicle industry. J. Manuf. Syst. 2019, 53, 195–211. [Google Scholar] [CrossRef]

- M. A. Fentahun, M. A. Savas. Materials Used in Automotive Manufacture and Material Selection Using Ashby Charts. International Journal of Materials Engineering 2018, 8, 40–54.

- J. P. Davim, K. J. P. Davim, K. Gupta. Handbooks in Advanced Manufacturing: Additive manufacturing. Elsevier 2021.

- K. Rajan, M. Samykano, K. Kadirgama, W. S. W. Harun, M. M. Rahman. Fused deposition modeling: process, materials, parameters, properties, and applications. The International Journal of Advanced Manufacturing Technology 2022, 120, 1531–1570.

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B: Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Mishra, A.; Srivastava, V.; Gupta, N.K. Additive manufacturing for fused deposition modeling of carbon fiber–polylactic acid composites: the effects of process parameters on tensile and flexural properties. Funct. Compos. Struct. 2021, 3, 045007. [Google Scholar] [CrossRef]

- Ilardo, R.; Williams, C.B. Design and manufacture of a Formula SAE intake system using fused deposition modeling and fiber-reinforced composite materials. Rapid Prototyp. J. 2010, 16, 174–179. [Google Scholar] [CrossRef]

- M. R. Sakthivel, S. Vinodh. Parametric optimization of fused deposition modelling process using Grey based Taguchi and TOPSIS methods for an automotive component. Rapid Prototyping Journal 2021, 27, 155–175.

- Yadav, D.K.; Srivastava, R.; Dev, S. Design & fabrication of ABS part by FDM for automobile application. Mater. Today: Proc. 2020, 26, 2089–2093. [Google Scholar] [CrossRef]

- Lyu, M.-Y.; Choi, T.G. Research trends in polymer materials for use in lightweight vehicles. Int. J. Precis. Eng. Manuf. 2015, 16, 213–220. [Google Scholar] [CrossRef]

- H. Klippstein, A. Sanchez, H. Hassanin, Y. Zweiri, L. Seneviratne. Fused Deposition Modeling for Unmanned Aerial Vehicles (UAVs): A Review. Advanced Engineering Materials 2018, 20, 1700552.

- Medellin, A.; Du, W.; Miao, G.; Zou, J.; Pei, Z.; Ma, C. Vat Photopolymerization3D Printing of Nanocomposites: A Literature Review. J. Micro Nano-Manufacturing 2019, 7. [Google Scholar] [CrossRef]

- Chartrain, N.A.; Williams, C.B.; Whittington, A.R. A review on fabricating tissue scaffolds using vat photopolymerization. Acta Biomater. 2018, 74, 90–111. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhu, L.; Li, Z.; Wang, S.; Shi, J.; Tang, W.; Li, N.; Yang, J. The recent development of vat photopolymerization: A review. Addit. Manuf. 2021, 48, 102423. [Google Scholar] [CrossRef]

- SLA 3D Printing in the Automotive Industry. https://www.3dprotofab.com/sla-3d-printing-in-the-automotive-industry.html.

- How Can 3D DLP Printing Boost the Automotive Industry? https://www.uniontech3d.com/how-can-3d-dlp-printing-boost-the-automotive-industry.html.

- Wiese, M.; Kwauka, A.; Thiede, S.; Herrmann, C. Economic assessment for additive manufacturing of automotive end-use parts through digital light processing (DLP). CIRP J. Manuf. Sci. Technol. 2021, 35, 268–280. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Elkaseer, A.; Chen, K.J.; Janhsen, J.C.; Refle, O.; Hagenmeyer, V.; Scholz, S.G. Material jetting for advanced applications: A state-of-the-art review, gaps and future directions. Addit. Manuf. 2022, 60. [Google Scholar] [CrossRef]

- Maurya, N.K.; Rastogi, V.; Singh, P. Comparative Study and Measurement of Form Errors for the Component Printed by FDM and PolyJet Process. 2019, 18, 353–359. [CrossRef]

- Wang, Y.; Wang, L.; Ma, Z.-D.; Wang, T. A negative Poisson's ratio suspension jounce bumper. Mater. Des. 2016, 103, 90–99. [Google Scholar] [CrossRef]

- Y. Wang, Z. -D. Ma, L. Wang. A finite element stratification method for a polyurethane jounce bumper. Proc IMechE Part D: J Automobile Engineering. 2016, 230, 983–992.

- A. Mostafaei, A. M. Elliott, J. E. Barnes, F. Li, W. Tan, C. L. Cramer, P. Nandwana, M. Chmielus. Binder jet 3D printing-Process parameters, materials, properties, modeling, and challenges. Progress in Materials Science 2021, 119, 100707.

- Gibson, D. Rosen, B. Stucker, M. Khorasani. Binder Jetting Additive Manufacturing Technologies Springer, Cham, 2020, 237-252.

- Hanson. Binder-jet 3D printer use is on the rise. https://www.thefabricator.com/additivereport/article/additive/binder-jet-3d-printer-use-is-on-the-rise.

- M. Urban. Decision Support System for a Metal Additive Manufacturing Process Chain Design for the Automotive Industry. Industrializing Additive Manufacturing. AMPA 2020. Springer, Cham.

- A. Elliott, J. A. Elliott, J. Wing. Binder Jet Tooling for Automotive Lighting Industry. CRADA Final Report. Oak Ridge National Laboratory. 2019. [Google Scholar]

- ExOne qualifies aluminum binder jet 3D printing with Ford. https://www.exone.com/en-US/Ford-and-ExOne-Achieve-Scientific-Breakthrough.

- Im, S.; Ghasri-Khouzani, M.; Muhammad, W.; Batmaz, R.; Esmati, K.; Chakraborty, A.; Natarajan, A.; Martin. Evaluation of Different Sintering Agents for Binder Jetting of Aluminum Alloy. J. Mater. Eng. Perform. 2023, 32, 9550–9560. [Google Scholar] [CrossRef]

- Zhao, N.; Parthasarathy, M.; Patil, S.; Coates, D.; Myers, K.; Zhu, H.; Li, W. Direct additive manufacturing of metal parts for automotive applications. J. Manuf. Syst. 2023, 68, 368–375. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: a state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Vock, S.; Kloeden, B.; Kirchner, A.; Weissgaerber, T.; Kieback, B. Powders for powder bed fusion: a review. Prog. Addit. Manuf. 2019, 4, 383–397. [Google Scholar] [CrossRef]

- Ninpetch, P.; Kowitwarangkul, P.; Mahathanabodee, S.; Chalermkarnnon, P.; Ratanadecho, P. A review of computer simulations of metal 3D printing. THE SECOND MATERIALS RESEARCH SOCIETY OF THAILAND INTERNATIONAL CONFERENCE. LOCATION OF CONFERENCE, ThailandDATE OF CONFERENCE; p. 050002.

- M. Narvan. Laser Powder Bed Fusion of AISI H13 Tool Steel for Tooling Applications in Automotive Industry. Doctor Thesis, McMaster University, 2021.

- A. V. Lacy. Powder Bed Fusion for Electromechanical Plastic Components in High Voltage Electric Vehicle Applications. Master’s Thesis, Aalto University, 2020.

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder bed fusion process in additive manufacturing: An overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Park, J.; Tari, M.J.; Hahn, H.T. Characterization of the laminated object manufacturing (LOM) process. Rapid Prototyp. J. 2000, 6, 36–50. [Google Scholar] [CrossRef]

- R. Gupta, M. R. Gupta, M. Dalakoti, A. Narasimhulu. A Critical Review of Process Parameters in Laminated Object Manufacturing Process. Advances in Materials Engineering and Manufacturing Processes. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore, 2020.

- Weisensel, L.; Travitzky, N.; Sieber, H.; Greil, P. Laminated Object Manufacturing (LOM) of SiSiC Composites. Adv. Eng. Mater. 2004, 6, 899–903. [Google Scholar] [CrossRef]

- Laminated object manufacturing. https://www.slideshare. 6165.

- Kumar, S.; Singh, I.; Koloor, S.S.R.; Kumar, D.; Yahya, M.Y. On Laminated Object Manufactured FDM-Printed ABS/TPU Multimaterial Specimens: An Insight into Mechanical and Morphological Characteristics. Polymers 2022, 14, 4066. [Google Scholar] [CrossRef] [PubMed]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22. [Google Scholar] [CrossRef]

- G. Suresh, K. L. Narayana, M. K. Mallik. A review on development of medical implants by rapid prototyping technology. International Journal of Pure and Applied Mathematics 2017, 117, 257–276.

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Zapata, A.; Bernauer, C.; Celba, M.; Zaeh, M.F. Studies on the Use of Laser Directed Energy Deposition for the Additive Manufacturing of Lightweight Parts. Lasers Manuf. Mater. Process. 2023, 1–16. [Google Scholar] [CrossRef]

- Li, Z.; Sui, S.; Ma, X.; Tan, H.; Zhong, C.; Bi, G.; Clare, A.T.; Gasser, A.; Chen, J. High deposition rate powder- and wire-based laser directed energy deposition of metallic materials: A review. Int. J. Mach. Tools Manuf. 2022, 181. [Google Scholar] [CrossRef]

- Aprilia, A.; Wu, N.; Zhou, W. Repair and restoration of engineering components by laser directed energy deposition. Mater. Today: Proc. 2022, 70, 206–211. [Google Scholar] [CrossRef]

- Singh, D.D.; Arjula, S.; Reddy, A.R. Functionally Graded Materials Manufactured by Direct Energy Deposition: A review. Mater. Today: Proc. 2021, 47, 2450–2456. [Google Scholar] [CrossRef]

- Cho, K.T.; Nunez, L.; Shelton, J.; Sciammarella, F. Investigation of Effect of Processing Parameters for Direct Energy Deposition Additive Manufacturing Technologies. J. Manuf. Mater. Process. 2023, 7, 105. [Google Scholar] [CrossRef]

- Bennett, J.; Garcia, D.; Kendrick, M.; Hartman, T.; Hyatt, G.; Ehmann, K.; You, F.; Cao, J. Repairing Automotive Dies With Directed Energy Deposition: Industrial Application and Life Cycle Analysis. J. Manuf. Sci. Eng. 2019, 141. [Google Scholar] [CrossRef]

- Repair and Remanufacturing of HEMM spares with Directed Energy Deposition. https://amchronicle.com/insights/repair-and-remanufacturing-of-hemm-spares-with-directed-energy-deposition/.

- Elkotb, H.H.; Mostafa, R.; Samad, A.A.A.; Enab, T.A. Manufacturing and Characterization of Functionally Graded Material Automotive Piston Using Centrifugal Casting Technique. Solid State Phenom. 2021, 318, 13–24. [Google Scholar] [CrossRef]

- Chioibasu, D.; Mihai, S.; Cotrut, C.M.; Voiculescu, I.; Popescu, A.C. Tribology and corrosion behavior of gray cast iron brake discs coated with Inconel 718 by direct energy deposition. Int. J. Adv. Manuf. Technol. 2022, 121, 5091–5107. [Google Scholar] [CrossRef]

- Nayeem, A.M.; Hossain, M.M.N. USAGE OF ADDITIVE MANUFACTURING IN THE AUTOMOTIVE INDUSTRY: A REVIEW. Int. J. Account. Finance Rev. 2023, 8, 9–20. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14. [Google Scholar] [CrossRef]

- S. Curran, et al. Big area additive manufacturing and hardwarein-the-loop for rapid vehicle powertrain prototyping: a case study on the development of a 3-D-printed Shelby Cobra. SAE Tech Pap 2016, 0148-7191.

- Picard, M.; Mohanty, A.K.; Misra, M. Recent advances in additive manufacturing of engineering thermoplastics: challenges and opportunities. RSC Adv. 2020, 10, 36058–36089. [Google Scholar] [CrossRef] [PubMed]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2016, 38, 2553–2569. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2019, 2, e97. [Google Scholar] [CrossRef]

- Rocha, C.R.; Perez, A.R.T.; Roberson, D.A.; Shemelya, C.M.; MacDonald, E.; Wicker, R.B. Novel ABS-based binary and ternary polymer blends for material extrusion 3D printing. J. Mater. Res. 2014, 29, 1859–1866. [Google Scholar] [CrossRef]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the Fused Deposition (FDM) Printing Process on Polylactic Acid (PLA) Chemistry and Structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef]

- Matijašić, G.; Gretić, M.; Vinčić, J.; Poropat, A.; Cuculić, L.; Rahelić, T. Design and 3D printing of multi-compartmental PVA capsules for drug delivery. J. Drug Deliv. Sci. Technol. 2019, 52, 677–686. [Google Scholar] [CrossRef]

- Kim, J. Park, J. Suh, M. Kim, Y. Jeong, I. Park. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sensors and Actuators A: Physical 2017, 263, 493–500. [Google Scholar]

- V. R. Sastri. Engineering thermoplastics: acrylics, polycarbonates, polyurethanes, polyacetals, polyesters, and polyamides. Plastics in medical devices 2010, 121-173.

- Bahar, A.; Belhabib, S.; Guessasma, S.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R. Mechanical and Thermal Properties of 3D Printed Polycarbonate. Energies 2022, 15, 3686. [Google Scholar] [CrossRef]

- MacCurdy, R.; Katzschmann, R.; Kim, Y.; Rus, D. Printable hydraulics: A method for fabricating robots by 3D co-printing solids and liquids. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 3878–3885. [Google Scholar]

- S. N. Yewale. Additive manufacturing in automobile industry. Int J Res Aeronaut Mech Eng 2019, 7(4), 1–10.

- W. E. Frazier. Metal Additive Manufacturing: A Review. Journal of Materials Engineering and Performance 2014, 23, 1917–1928.

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal additive manufacturing: Technology, metallurgy and modelling. J. Manuf. Process. 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- D. Bourell, J. P. Kruth, M. Leu, G. Levy, D. Rosen, A. M. Beese, A. Clare. Materials for additive manufacturing. CIRP Annals 2017, 66, 659–681.

- T. Gechev. A short review of 3D printing methods used in the automotive industry. Conference: Youth Science Conference MACHINES, INNOVATIONS, TECHNOLOGIES, 2022.

- Mehdiyev, Z.; Felho, C. Metal Additive Manufacturing in Automotive Industry: A Review of Applications, Advantages, and Limitations. Mater. Sci. Forum 2023, 1103, 49–62. [Google Scholar] [CrossRef]

- W. Jensen. Automotive: Formula Student Germany-EOS Supports Racing Team by Producing a Topology-Optimized Steering Stub Axle. http://additivemanufacturing.global/index.php/en/print-en/automotive/3480-formula-student-germany-eos-supports-racing-team-by-producing-a-topology-optimized-steering-stub-axle.

- J. Bakewell. Customising Production. https://www.automotivemanufacturingsolutions.com/customisingproduction/31218.article.

- Tyrrell. Use of 3D Printed Components at BMW Jumps 42% Annually. https://www.pesmedia.com/3d-printing-components-bmw-group/.

- V. Anusci. BMW’s New S58 Engine Features Cylinder Head Made with 3D Printing. https://www.voxelmatters.com/bmw-s58-engine-3d-printed-cylinder/.

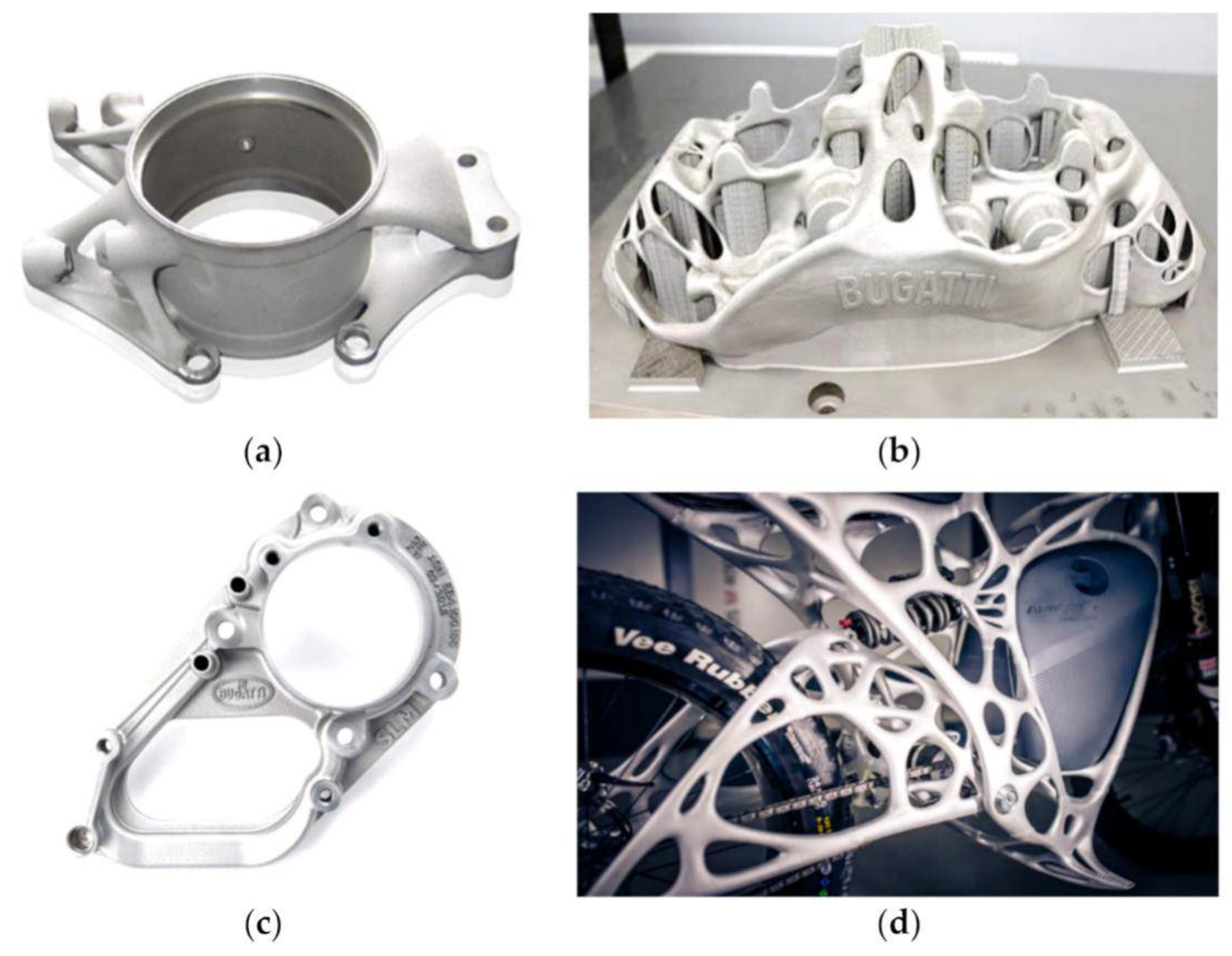

- T. M. Wischeropp, H. T. M. Wischeropp, H. Hoch, F. Beckmann, C. Emmelmann. Opportunities for Braking Technology Due to Additive Manufacturing Through the Example of a Bugatti Brake Caliper. In Proceedings of the XXXVII Internationales µ-Symposium 2018 BremsenFachtagung, Bad Neuenahr, Germany, 2018, 181-193.

- W. Jensen. Automotive: Formula Student Germany-EOS Supports Racing Team by Producing a Topology-Optimized Steering Stub Axle. https://www.eos.info/press/customer_case_studies/rennteam_uni_stuttgart.

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- J. Deckers. Additive manufacturing of ceramics: A review. Journal of Ceramic Science and Technology 2014, 245-260.

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [PubMed]

- Z. Chen, Z. Li, J. Li, C. Liu, C. Lao, Y. Fu, C. Liu, Y. Li, P. Wang, Y. He. 3D printing of ceramics: A review. Journal of the European Ceramic Society 2019, 39, 661–687.

- Pinargote, N.W.S.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- A. G. Steinbach. Ceramics in 3D-printing for the automobile industry. https://www.steinbach-ag.de/en/technical-ceramics/areas-of-application/automobile-industry.

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221. [Google Scholar] [CrossRef]

- Sivanur, K.; Umananda, K.V.; Pai, D. Advanced materials used in automotive industry-a review. PROCEEDINGS OF THE 14TH ASIA-PACIFIC PHYSICS CONFERENCE. LOCATION OF CONFERENCE, MalaysiaDATE OF CONFERENCE; p. 020032.

- Mostafaei, A.; Zhao, C.; He, Y.; Ghiaasiaan, S.R.; Shi, B.; Shao, S.; Shamsaei, N.; Wu, Z.; Kouraytem, N.; Sun, T.; et al. Defects and anomalies in powder bed fusion metal additive manufacturing. Curr. Opin. Solid State Mater. Sci. 2022, 26, 100974. [Google Scholar] [CrossRef]

- C. Brennan, J. S. Keist, T. A. Palmer. Defects in Metal Additive Manufacturing Processes. Journal of Materials Engineering and Performance 2021, 30, 4808–4818.

- Wu, X. On residual stress analysis and microstructural evolution for stainless steel type 304 spent nuclear fuel canisters weld joint: Numerical and experimental studies. J. Nucl. Mater. 2020, 534, 152131. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; Fuh, J.Y.H.; Wang, H. A Review of Post-Processing Technologies in Additive Manufacturing. J. Manuf. Mater. Process. 2021, 5, 38. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2020, 37, 101619. [Google Scholar] [CrossRef]

- Laureijs, R.E.; Roca, J.B.; Narra, S.P.; Montgomery, C.; Beuth, J.L.; Fuchs, E.R.H. Metal Additive Manufacturing: Cost Competitive Beyond Low Volumes. J. Manuf. Sci. Eng. 2017, 139. [Google Scholar] [CrossRef]

- Kawalkar, R.; Dubey, H.K.; Lokhande, S.P. A review for advancements in standardization for additive manufacturing. Mater. Today: Proc. 2021, 50, 1983–1990. [Google Scholar] [CrossRef]

- C. Scott. Challenges and Future Trends in Additive Manufacturing. https://wohlersassociates.com/uncategorized/challenges-and-future-trends-in-additive-manufacturing/.

- A. Charles, A. A. Charles, A. Hofer, A. Elkaseer. S. G. Scholz. Additive Manufacturing in the Automotive Industry and the Potential for Driving the Green and Electric Transition. In book: Sustainable Design and Manufacturing. 2021. [Google Scholar]

- Abo-Khalil, A.G.; Abdelkareem, M.A.; Sayed, E.T.; Maghrabie, H.M.; Radwan, A.; Rezk, H.; Olabi, A. Electric vehicle impact on energy industry, policy, technical barriers, and power systems. Int. J. Thermofluids 2022, 13, 100134. [Google Scholar] [CrossRef]

| Categories | Technologies | Power Source | Materials | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Material extrusion | Fused deposition modeling | Thermal energy | Thermoplastics (ABS, PLA, PC, nylon) | Inexpensive, multimaterial, easy to operate | Poor resolution and surface finish, poor bonding |

| Vat photopolymerization | Stereolithography,刘digital light processing,continuous liquid interfaceproduction,刘daylight polymer printing | Ultraviolet light | Photosensitive resin, ceramics | High accuracy, good resolution, fully automation | Overcuring lengthy post-processing, single composition, high cost of materials |

| Binder jetting | Binder jetting | Binder/thermal energy | Polymer/ceramic/metal powder | Wide material selection, relatively fast printing | Lengthy postprocessing, porosities within parts |

| Material jetting | Drop on demand, PolyJet,刘nanoparticle jetting | Thermal energy | Photopolymer resins, metals, ceramics | High accuracy, smooth surface finish, multimaterial | Low mechanical strength |

| Powder bed fusion | Direct metal laser sintering,刘electron beam melting, selective laser melting, selective laser sintering | Laser, electron beam | Polymer/ ceramic/metal powder | High accuracy, high resolution, fully dense parts, high strength | Powder recycling, support structures, single material, residual stress |

| Sheet lamination | Laminated object manufacturing | Laser | Plastic/metal/ceramic foil | High surface finish | Material limitation |

| Directed energy deposition | Laser engineered net shaping, direct metal deposition, laser metal deposition, laser cladding, laser consolidation | Laser | Metal/ceramic/powder | Repair of worn components, multimaterial (functionally graded materials) | Low accuracy, low surface finish, residual stress, require postmachining |

| Company | AM processes |

|---|---|

| BMW | Fused Deposition Modeling (FDM) (Davies, 2023)Selective Laser Sintering (SLS) (Ricoh 3D, 2020)Multi Jet Fusion (BMW Group, 2020)刘Laser Beam Melting (BMW Group, 2020) |

| Audi | Selective Laser Melting (SLM) (Petch, 2018)Stereolithography (SLA) (Krassenstein, 2015)刘Fused Deposition Modeling (FDM) (Krassenstein, 2015)刘Multi Jet Fusion (MJF) (Krassenstein, 2015) |

| Toyota | Selective Laser Sintering (SLS) (SAE International, 2021)Fused Deposition Modeling (FDM) (SAE International, 2021)Stereolithography (SLA) (SAE International, 2021)刘Multi Jet Modeling (MJM) (SAE International, 2021)刘Digital Light Processing (DLP) (SAE International, 2021) |

| Honda | Liquid Deposition Modeling (LDM) (Everett, 2021) |

| Ford | Selective Laser Sintering (SLS) (Ford Motor Company, n.d.)Stereolithography (SLA) (Ford Motor Company, n.d.)Fused Deposition Modeling (FDM) (Cune, 2018)刘Metal Binder Jet Printing (Molitch-Hou, 2021) |

| Volvo | Selective Laser Sintering (SLS) (Volvo Group, 2019) 刘Fused Deposition Modeling (FDM) (Pearson, 2020) |

| Rolls-Royce | Electron Beam Melting (EBM) (Molitch-Hou, 2015) 刘Selective Laser Melting (SLM) (Tyrrell, 2022) 刘Direct Energy Deposition (DED) (Kingsbury, 2019) |

| Chevrolet | Selective Lase Sintering (SLS) (General Motors, 2020) 刘Selective Laser Melting (SLM) (General Motors, 2020) 刘Fused Deposition Modeling (FDM) (General Motors, 2020) |

| Nissan | Selective Lase Sintering (SLS) (General Motors, 2020)刘Selective Laser Melting (SLM) (General Motors, 2020)刘Fused Deposition Modeling (FDM) (General Motors, 2020) |

| Tesla | Sand Binder Jetting (Madeleine P., 2023)刘Fused Deposition Modeling (FDM) (3D printing.com, 2020) |

| Mercedes-Benz | Selective Laser Melting (SLM)(Additive News, 2017; Moore,2020)刘Fused Deposition Modeling (FDM)(Moore, 2020)Stereolithography (SLA)(Moore, 2020)刘Selective Laser Melting (SLM) (Moore, 2020) |

| Volkswagen | Binder Jetting (Volkswagen AG, 2021)刘Fused Deposition Modeling (FDM) (Jackson, 2017) |

|

| Materials | Automobile application | Advantages | Disadvantages |

|---|---|---|---|

| Polymers | - Rapid tooling and fixture production刘- Functional prototypes and刘testing parts刘- Customized automotive刘Parts刘- Composite materials with刘polymers | - Low cost and ease of processing刘- Lightweight, suitable for interior components刘- Excellent design flexibility and complexity刘- Good impact resistance and vibration damping | - Limited mechanical strength and load-bearing刘capacity刘- Limited thermal stability and chemical刘resistance刘- Limited dimensional accuracy and potential for刘warping or distortion during printing刘- Limited recyclability and environmental刘concerns |

| Metals | - Engine parts and刘components刘- Transmission components and gears刘- Suspension systems and chassis components刘- Exhaust systems and刘engine components刘- Braking components and systems | - High strength-to-weight ratio刘- Excellent mechanical properties刘- High thermal conductivity刘- Good wear resistance and fatigue resistance刘- High resistance to extreme temperatures and harsh environments | - High material and processing costs刘- Limited design complexity and intricate features刘- Limited availability of AM-grade materials for刘high-performance applications刘- Potential for microstructural defects in printed parts刘- Post-processing may be required to achieve desired mechanical properties |

| Ceramics | - High-performance brake components刘- Engine components and exhaust systems刘- Bearings and wear resistant components刘- Spark plugs and ignition systems刘- Electrical insulators and components刘- Sensors and electronic components | - High-temperature resistance andthermal stability刘- Excellent mechanical properties刘- Low density, lightweight刘- Good chemical inertness and resistance to corrosion | - Limited design complexity刘- High processing temperatures required for sintering刘- Cost and availability of specialized ceramic powders刘- Challenging to achieve dense and void-free prints due to high processing temperatures |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).