Effective thermal management is crucial for maintaining optimal operating temperatures and ensuring the dependability of microelectronics. To increase heat transfer from electronic components into the surrounding ambient environment, heat sinks are ubiquitously employed. Through an enlarged surface area, they permit conduction, while their form enhances convection by facilitating airflow across the surface. J.Y. Ho et al. [

1] This model addresses the impact of airflow bypass and vortex effects, and its predictions exhibit outstanding consistency with experimental evidence. The findings of this work have great relevance for the design of electronic cooling, as they provide theoretical advice and prediction tools for adding aerodynamic wing-shaped fins to the cooling of integrated circuit boards. In summary, the article systematically investigates the heat transfer effects of fins with different profiles, explains the mechanisms by which aerodynamic wing-shaped fins enhance heat transfer, and establishes a corresponding predictive model, thus offering valuable resources for electronic cooling design. C-H Huang et al. [

2] A unique construction consisting of a distorted array of sinusoidal fins is proposed in order to enhance heat dissipation. By maintaining the fin volume constant, the parameters of the deformed sinusoidal wave are modified to reduce the average temperature of the fin array baseplate. Comparative analysis demonstrates that the optimized de-formed sinusoidal wave fin array outperforms both straight fins and regular sinusoidal wave fins, resulting in a reduction of the baseplate average temperature by 8.78% and 1.35%, respectively. The optimization approach takes into consideration the impact of air-flow bypass and enhances heat transmission through increased surface area and vortex effects. Experimental validation shows the efficiency of the numerical optimization since the numerical findings fit well with the temperature distribution recorded during experimentation. Xiaoling Yu et al. [

3] A unique composite heat sink has been produced by integrating cylin-drical fins into the flow channel, which is based on the flat plate heat sink. The numerical simulation data demonstrate that, when subjected to identical wind velocities, the thermal resistance of this composite radiator is lowered by 30% in contrast to the original flat radiator. The experimental measurements of the pressure drop in the composite radiator model coincide with the numerical simulation findings, therefore proving the efficacy of the numerical model. Under analogous input power levels, the composite radiator exhibits a cooling efficiency that is comparable to the optimized flat radiator. W. Yuan et al. [

4] Research was undertaken on the thermal fluid properties of a flat-plate-cylindrical fin composite heat sink (PPFHS). The research studied how different elements, such as air speed, fin size, arrangement of fins, and proximity to the center of adjoining fins in the direction of flow, influenced PPFHS's efficiency. The numerical model's efficacy was proven, exhibiting a good correlation between the numerical computations and the empirical data. Findings demonstrate that the speed of the air and the diameter of the fins play a substantial role in performance, whereas the layout of the fins and their central distance exert a minor impact. S.E. Razavi et al. [

5] Through numerical comparison, the characteristics of heat transfer and flow in a baffle-cylindrical fin heat sink were evaluated. Expanding on the basic structure of a cylindrical fin heat sink, a novel baffle-cylindrical fin heat sink (SPPFHS) was created, integrating a baffle located behind the cylindrical fins. Findings show that integrating a baffle, as opposed to a traditional cylindrical fin heat sink, can significantly lower both the pressure drop and the thermal resistance. By optimizing the movement around the cylindrical fins, the baffle decreases the reduction in pressure. Further, the larger surface area amplifies the effect of heat transport. Ambarish Maji et al. [

6] The heat transfer characteristics of various shaped perforated fin configurations were quantitatively examined using 3D computational fluid dynamics (CFD) simulations, including fins with circular, diamond, and elliptical perforation holes. The impacts of parameters comprising hole number, shape, and size, as well as fin arrangement, on heat transfer performance and pressure drop were examined. The investigation found that within a certain range of hole number and size, the perforated fins demonstrated better heat transmission capacities compared to solid fins and that staggered fin arrangements beat in-line designs. YueRong Xu [

7] A unique CPU cooler design featuring a U-shaped microchannel heat pipe array (U-MHPA) and rectangular fins was proposed. Its heat transfer and fluid flow resistance characteristics under varied air velocity and power input conditions were experimentally investigated using a wind tunnel system. The cooler structure might efficiently enhance heat dissipation. Experimental results indicated that under an ambient temperature of 20°C and a Reynolds number of about 1000, the cooler working temperature could be maintained at 75°C even when the power input reached 130 watts.Chirag R. Kharangate et al. [

8] The development of a unique 3D heat exchanger, having both longitudinal and transverse interwoven flow channels, was recommended as a substitute for the standard straight aluminum fin heat exchangers in air-cooled condensers. Findings revealed that this 3D interwoven flow path heat exchanger beats the traditional straight alu-minum fin heat exchangers in terms of COP performance under different heat flux scenarios. Anil Kumar Rao [

9] The author numerically examined the heat dissipation performance of fin plates with three different tilt degrees (1°, 2°, and 3°) against usually upright fin plates. It was determined that the fin plate slanted at 2° displayed the highest heat transfer performance, with a roughly 30% higher Nusselt number compared to the normally upright fin plate. The 2° inclined fin plate likewise demonstrated the lowest thermal resistance. Wadhah H. Aldoori [

10] The influence of fin height on forced convection heat transfer in rectangular fin arrays was examined. The temperature difference between the fin array surface and the airflow was evaluated under varied fin height settings and various heat input power levels. Results showed that as the Reynolds number climbed, the overall heat transfer coefficient of the airflow increased. As heat input increases, the temperature difference increases under all Reynolds number circumstances. Fin height and position impact heat transfer performance and demand additional study. The heat transfer performance was best at a fin height of 0.67m. Abdüssamed Kabakus et al. [

11] The cooling performance of electrospray cooling on smooth surface heat exchangers and finned heat exchangers was examined. The surface temperature, enhancement factor, and fin efficiency factor were studied between the smooth and finned heat exchangers. Although the two electrospray flow rates did not affect the spray modes, the 0.60 ml/min flow rate supplied more liquid to the heat exchanger surface, offering superior cooling enhancement 15–44% higher than 0.45 ml/min. Alhassan Salami Tijani et al. [

12] The study focused on the thermal performance of through-hole pin fin heat sinks under forced convection circumstances. It compared the heat transfer performance of heat sinks with diverse geometrical structures, including solid pin fins, through-hole pin fins, solid flat plates, and through-hole flat plates. The results showed that the through-hole pin fin heat sink had the maximum heat transfer coefficient. Furthermore, the pressure drop in the through-hole pin fin heat sink was smaller than that in the solid pin fins, which can reduce the power required for fluid transmission and enhance the efficiency of heat dissipation. W-X Chu et al. [

13] This study leverages deep reinforcement learning techniques to optimize and reduce the energy consumption of air-cooled server fans. We offer modified equations optimized to accurately estimate the thermal transfer and fluid dynamic behavior of plate-fin heat exchangers. The usefulness of these predictive models is emphasized by their precision, with the Nusselt number and pressure drop prediction errors maintained within a margin of 5% and 10%, respectively. Ammar A. Hussain et al. [

14] The study investigated the cooling efficiency of flat-plate fin heat sinks under varied flow conditions. Through numerical simulations, the accuracy of the data for flat-plate fin heat sinks without rounded corners under impinging flow conditions was validated. The study then examined the baseplate temperature and thermal resistance of flat-plate fin heat sinks with and without rounded corners under impeding flow conditions. The results indicated that a parallel flow design with rounded corners, compared to the standard impinging flow design without rounded corners, greatly reduces the temperature and thermal resistance of the heat sink's baseplate, hence enhancing cooling efficiency. C-H Huang et al. [

15] Numerical simulations and optimization methods were utilized to develop the ideal position, angle of attack, and perforation radius of vortex generators to decrease the average temperature of the heat sink's baseplate. The space between the vortex generator and the heat sink allows high-speed airflow to move along the edges of the heat sink, boosting cooling. The angle of attack determines the speed at which air enters the cooling channels, while perforations help minimize resistance. As the Reynolds number grows, the spacing between the vortex generator and the heat sink, the angle of attack, and the perforation radius must all be increased to ensure maximum cooling performance. Compared to a heat sink without vortex generators, the best-designed vortex generators can reduce the average temperature of the heat sink's baseplate by 11.2%. R. Bouchenafa et al. [

16] A unique wave fin heat sink was designed and compared with a flat plate fin heat sink. The study evaluated the effects of the number of wave fins and wave amplitude on flow field distribution, pressure drop, and heat transfer coefficient. The results showed that, compared to flat plate fins, wave fins greatly enhance heat transfer performance but also increase the pressure drop. As the number of waves and amplitude rise, the heat transmission effect is further improved. A wave fin heat sink with a wavelength of 5 waves and an amplitude of 4mm displayed the lowest thermal resistance. Khurram Altaf et al. [

17] This research studies the thermal transmission and fluid dynamics of heat sinks with different slot designs under conditions of forced convection. Employing a combination of numerical models and experimental approaches, we examined the efficacy of smooth heat sinks versus those with various slot layouts, characterized by changes in width, depth, and number. Findings reveal that the addition of slot patterns efficiently breaks the boundary layer flow on smooth heat sinks, thereby enhancing convective heat transfer. D-K Kim et al. [

18] Experiments with varying flow rates and channel widths were conducted to measure the pressure drop and thermal resistance of flat plate fin and pin fin heat sinks. Based on the experimental data, a model to predict pressure drop and heat resistance was presented using the volume averaging method. This model was used to calculate the thermal resistance of improved flat plate fin and pin fin heat sinks under fixed pump power settings. Conversely, when the dimensionless pump power is high and the dimensionless length of the heat sink is small, the optimized flat plate fin heat sink exhibits lower thermal resistance. C-H Huang et al. [

19] The goal is to design the op-timal pinhole width that minimizes the average temperature difference of the substrate and also minimizes the system pressure loss. Numerical simulation studies showed that the improved pinhole diameter arrays might reduce the average temperature of the substrate by 1.5–2.1%. The accuracy of the numerical findings was verified by experiments using an infrared thermometer, confirming the usefulness of the method in solving the optimal pinhole diameter design problem. Sakkarin Chingulpitak et al. [

20] The study studied the impact of varied sizes and numbers of through-cut notches on the thermal resistance ratio of heat sinks. Experimental tests suggested that the heat sink displayed the lowest thermal resistance at a notch length of 1.5 mm. Numerical results further revealed that, for the same input power, the thermal resistance ratio was at its lowest when the notch length ranged between 1.5 and 2.0 mm. Additionally, increasing the number of through-cut notches was found to reduce the heat resistance ratio. Je-Doo Ryu et al. [

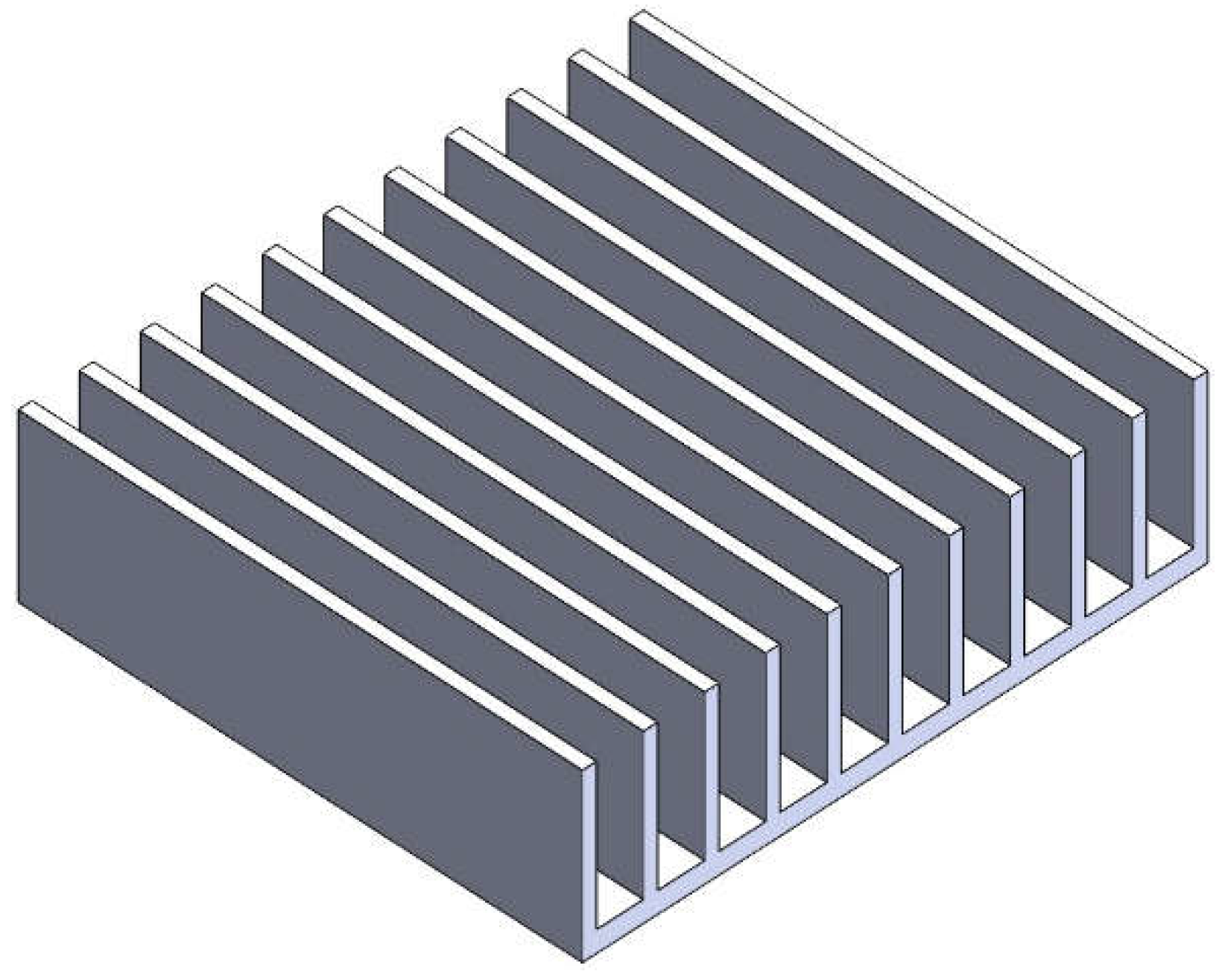

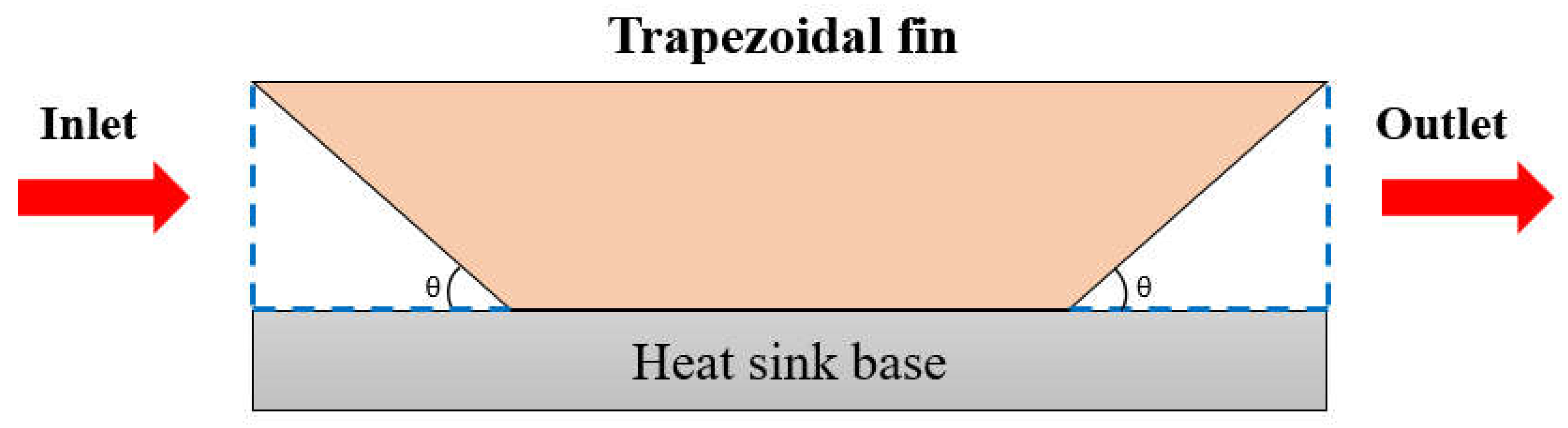

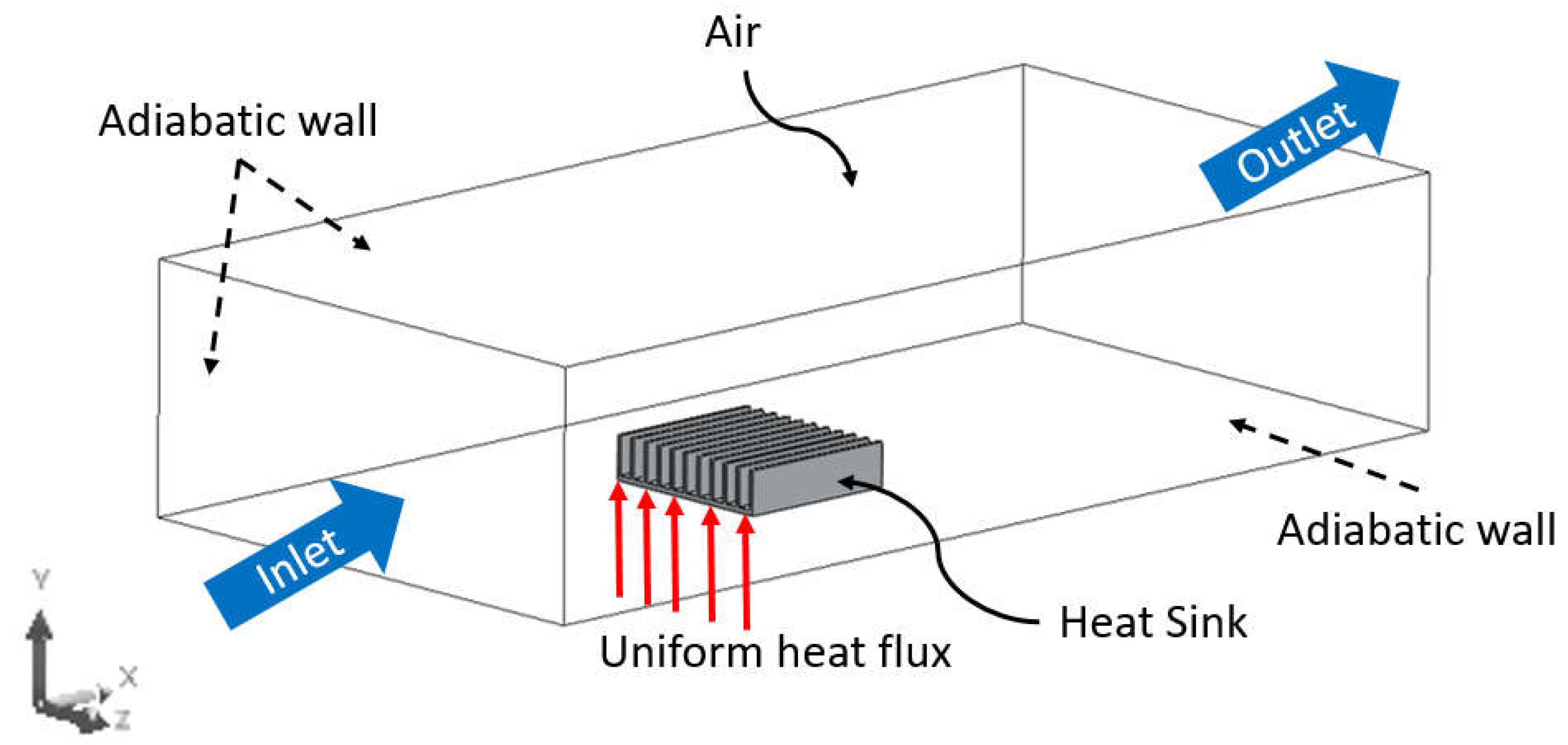

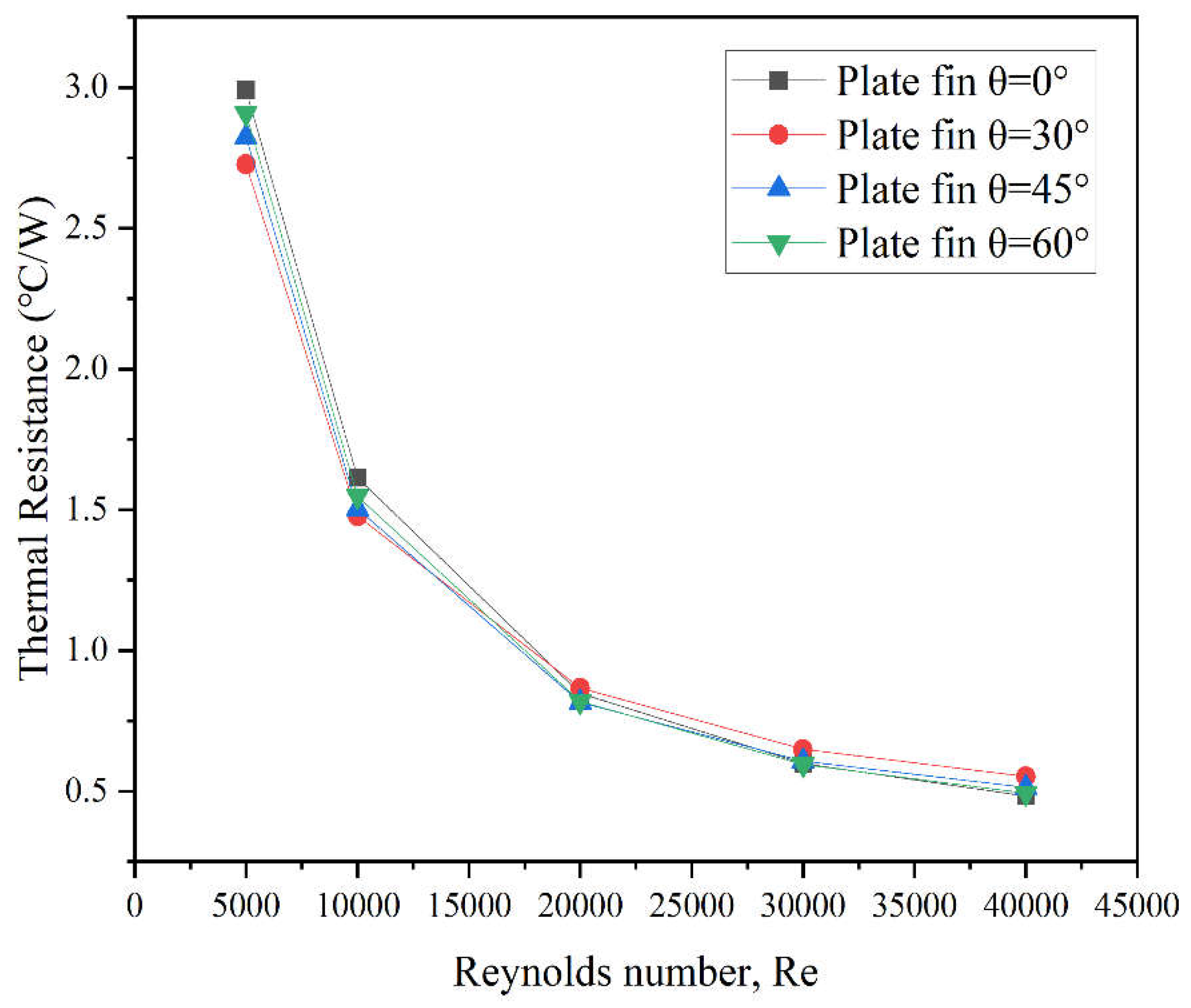

21]An investigation of jet flow fluid dynamics was conducted utilizing CFD numerical simulations and PIV experimental data. The numerical simulations were carried out using MIDAS NFX software, examining the velocity and pressure distributions under varied nozzle pressures. The PIV tests were conducted in a 22m x 3.5m x 3m water tank, utilizing a single-pulse laser and a high-speed camera to examine the jet flow field. The results suggest that while the velocity distribution patterns from both approaches showed comparable trends, there was a substantial variation in the maximum velocities. This shows that careful tuning of through-cut notch dimensions and numbers can greatly boost the thermal performance of heat sinks. The complete literature review demonstrates that various researchers have examined the thermal and dynamic features of plate-fin heat exchangers by applying approaches such as integrating plate and pin fins, introducing baffles, changing fin roughness, and implementing fin perforations. Contrasting these standard approaches, our numerical analysis presents an innovative design incorporating trapezoidal fins. This design intentionally employs angular modifications to increase cooling efficiency. When benchmarked against typical plate-fin heat exchangers, our trapezoidal fin design displays higher heat transfer efficacy, representing a significant improvement in heat exchanger technology.