1. Introduction

The economic development and growth of a nation depends on major factors such as technology because it allows for more efficient production and better goods and services. Energy is a major driver of technology and its availability determines sustainable and rapid development of a nation’s technological and industrial growth [

1]. However, the prevalent use of fossil fuel for energy generation has raised major concerns globally because they result in the release of greenhouse gases that trap heat in the atmosphere and cause global warming. As a result, several alternatives have been exploited for energy generation. One of the alternative sources is biomass energy which has proven to be viable, renewable and sustainable.

Biomass exists naturally and abundantly and hence can serve as an ideal alternative energy resource [

2,

3,

4]. Biomass can be harnessed to produce a lot of power and one of its major applications is found locally in cooking and warming of households. There are studies that have pointed to the potential of generating power regionally and globally from biomass [

2,

5,

6,

7,

8] where it has been noted that there are several methods to harness biomass energy. Biochemical methods of harnessing biomass for various applications have included anaerobic digestion [

9], fermentation [

10]. Thermochemical methods include gasification [

11,

12], pyrolysis [

13], torrefaction [

14] and carbonization [

8]. Mechanical methods include size reduction [

15,

16] and densification [

17].

Biomass in its free form is often not usable directly in combustion grates or in some gasification processes because of its low bulk density, low energy output and size. To circumvent these problems, loose biomass can be pressed into solid fuels in form of pellets or briquettes with improved properties. A briquette is compressed block of biomass material [

18,

19] which is produced in any convenient shape and can burn like wood. Briquetting is a densification technology that converts loose low-density biomass to briquettes under applied pressure, thereby improving its physical properties [

19,

20,

21]. During biomass densification, process variables must be taken into consideration and they include hold-time, pressure and temperature. Other material variables that must be considered are moisture content, particle size, biomass type, or biochemical composition. These variables potentially determine the physico-mechanical and combustion characteristics of manufactured briquettes [

8,

22,

23].

Obi [

24] considered the influence of temperature on the biomass briquette properties and showed that temperature significantly affected the physical and combustion behaviour of briquettes. Lela et al. [

25] also investigated the physico-mechanical and combustion properties of sawdust briquettes for energy generation. The study reported that pressure did not have much significance on the calorific value but temperature was observed to significantly affect the briquette properties. Orisaleye et al. [

26] studied the influence of densification variables on the density of briquettes noting the importance of such study for the design of efficient densification equipment. The briquette density was dependent on the applied pressure, die temperature and particle size of the corncobs. Orisaleye et al. [

27] discovered that higher die temperature and hold time improved water resistance of corncob briquettes. Kpalo et al. [

28] evaluated the properties of briquettes of paper pulp with

Mesua ferrea leaves. The shatter index ranged between 79.18 and 99.9% with density reaching up to 370 kg/m

3.

Shuma and Magyira [

29] reported the effect of various production variables utilized in production of briquettes from loose biomass using cactus and cow dung as binders. Oriabure [

30] investigated briquette properties using

Terminalia metalis and

Daniela oliveri and found that the biomass material determined the shatter index of the briquettes. Orisaleye et al. [

31] utilized a hydraulic briquetting press to produce poplar briquettes and found that the temperature was significant to the density, water resistance and durability of the briquettes. Jekayinfa et al. [

32] developed empirical models from multiple regression analysis for corncob briquettes which relates densification variables to physical properties of briquettes. Zepeda-Cepeda et al. [

33] considered how particle sizes of sawdust influenced briquettes from

Pinus durangensis. The best mixture of particle sizes for optimum compressive strength and shatter index were determined using RSM.

Ladla et al. [

34] investigated properties of briquettes produced in a low-pressure briquetting machine and found that the shatter index and water resistance were within the range of 80 to 95% with compressive strength reaching up to 19.52 MPa. Jekayinfa et al. [

35] showed that the quality of densified rice bran pellets was affected by binder utilization, and die configuration and design. Ossei-Bremang et al. [

36] utilized bentonite clay and cardboard pulp as binders for palm kernel and decanter cake briquettes and optimum shatter index of briquettes was determined using Response Surface Methodology (RSM). Orisaleye et al. [

37] also conducted investigations on physical properties of briquettes from Abura sawdust using RSM. Statistical significant variables identified to influence density were hold time, temperature and pressure. For water resistance, only the die temperature was significant. Afrifah et al. [

38] found that by varying the composition of materials and pressure, briquettes with desired quality can be produced with low pressure from sugarcane peels, empty fruit bunch and sawdust.

Previous studies have noted that each biomass has its set of characteristics which determine the quality of briquettes produced. This creates a need to investigate and optimize the characteristics of briquettes produced from different biomass sources. There are very few studies on the utilization of sawdust from Abura wood despite its availability and extensive utilization as timber in West Africa. Jekayinfa et al. [

2] and Ojolo et al. [

7] noted that a large quantity of residues is produced during logging. The forestry residues can be utilized effectively after densification into briquettes or pellets. This study investigates effects of process variables on mechanical characteristics of briquettes made from Abura sawdust without the utilization binders and to develop empirical models to predict and optimize the properties of briquettes.

2. Materials and Methods

2.1. Acquisition and Properties of Sawdust

Abura (

Mitragyna ciliata) is a tropical hardwood species which is largely available in West Africa with lignin ranging between 19.0 to 21.5% [

39]. Sawdust from processing Abura wood was acquired from an industrial sawmill in Lagos State, South-West Nigeria. After acquisition, drying of the sawdust was carried out under ambient conditions in the laboratory to reduce the moisture content. Thereafter, sieving was carried out to remove lumps, stones and other large materials from the sawdust before they were stored in polyethylene bags.

2.2. Experimental Briquetting Press

An experimental-scale uniaxial briquetting press was utilized for the manufacture of the briquettes. The press compacts biomass materials within a heated cylindrical mould using a hydraulic jack. The temperature of the mould was regulated using a thermocouple with a temperature regulator. The pressure used in compaction was determined from a pressure gauge attached to the hydraulic jack. During operation, the mould was closed on one end and pressed from the other end. After the briquetting operation, the closed end is opened and the hydraulic jack used to push the compacted briquette out of the mould. Thereafter, the briquette is cooled and the properties of the briquette tested.

2.3. Design of Experiment

The investigation of the properties of the briquettes was carried out using RSM. A Box-Behnken design of experiment (DOE) with 3 factors and 3 levels was utilized. The process variables, or factors, that were investigated are compaction pressure, hold time and temperature. The temperatures used were 100, 125 and 150 °C; hold times were 15.0, 22.5 and 30.0 min; and compaction pressures utilized were 9, 12 and 15 MPa. The Box-Behnken DOE and the variables that were studied are presented in

Table 1.

2.4. Determination of Mechanical Properties of Briquettes

2.4.1. Compressive Strength

The lateral compressive strength of briquettes was determined rather than the longitudinal compressive strength since it is a more consistent measure of briquette strength [

40]. A laboratory compression strength tester was used to carry out the compressive strength tests. The load at which the briquette fractured was taken from the compression tester and the area of the cross-section of the geometry of the fracture plane was estimated. The radial, or lateral, compressive strength (CS) was determined from Equation 1 [

40].

2.4.2. Shatter Index

The shatter index tests were carried out on sawdust briquettes to determine the durability of the compacted biomass produced under different conditions. The test requires the briquette samples to be dropped onto a solid base from a height of 2 m. The number of drops and the number of pieces the briquettes break into were noted. The shatter index (SI) was obtained from Equation 2 [

40].

2.5. Statistical Analysis

The responses from the experimental design were analysed utilizing Design Expert version 13. Response surface models were developed using multiple regression analysis, and the models relate the independent variables to the responses. Analysis of Variance (ANOVA) was carried out to identify variables which influence the mechanical properties of the briquettes. The ANOVA was also used to determine if the model was appropriate. Contour plots were utilized to determine the combined influence of the variables.

3. Results and Discussions

In

Table 1, alongside the Box-Behnken experimental design, results for the compressive strength and shatter index of sawdust briquettes are shown. From

Table 1, the shatter index ranged between 50 and 600. The compressive strength of sawdust briquettes ranged from 2.06 to 5.15 MPa. The range of compressive strength for both sawdust briquettes is lower than briquettes produced by Thliza

et al. [

41] and Borowski and Hycnar [

42] which used binders.

3.1 Compressive Strength Analysis

The results of the compressive strength of sawdust briquettes were analysed using ANOVA.

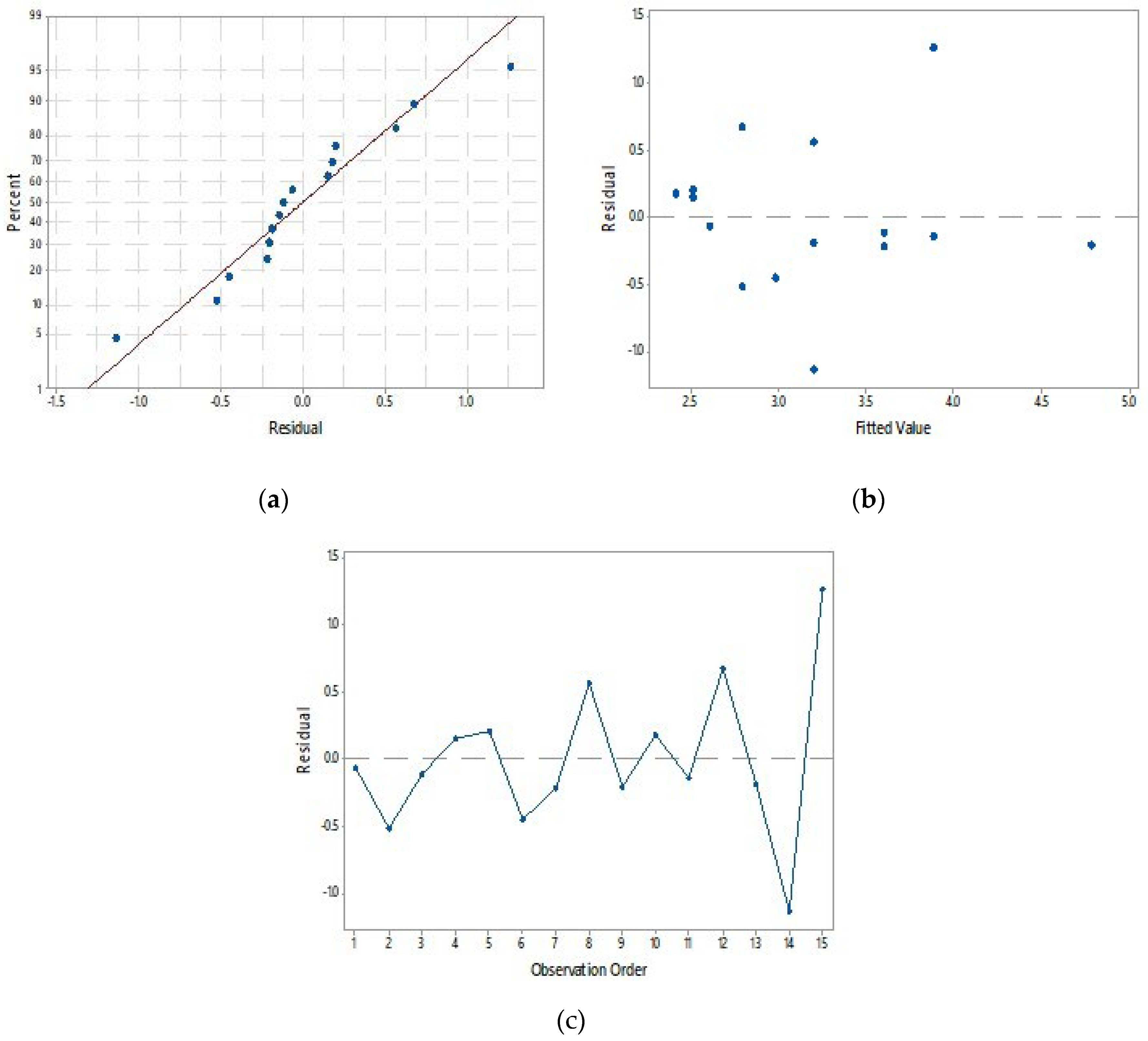

Figure 1 shows that the assumptions of ANOVA were not violated for the analysis of compressive strength of sawdust briquettes. As is required, the normal distribution plot can be fitted with a linear plot and the points are not distant from the linear plot. Similarly, the residual versus fits plot is well distributed across the entire plot area and the residual versus order plots are random and do not follow any distinct pattern. The ANOVA for compressive strength of sawdust briquettes is shown in

Table 2 where backward elimination has been used in the elimination of the least influential terms from the response surface model. It is observed that none of the terms in the model is significant at a level of significance of 5%. However, at a level of significance of 10%, the pressure significantly affects the compressive strength of the briquettes. The model is, however, observed to be significant (P<0.05) but lack of fit of the model is not significant (p>0.05) implying the model could be useful in investigation of the influence of the variables on the strength of briquettes. Comparable to the observation in this study, Gao et al. [

43] found that briquetting load was a very influential factor to the production of briquettes from sewage sludge. This also aligns with the finding of Helwani et al. [

44] which showed that the pressure was significantly influential on the compressive strength of briquettes produced from palm oil stems using byproducts of biodiesel as adhesive.

The response surface model derived from the regression modelling, with backward elimination, is presented in Equation 3. The values of

and

are 57.97% and 46.50%, respectively.

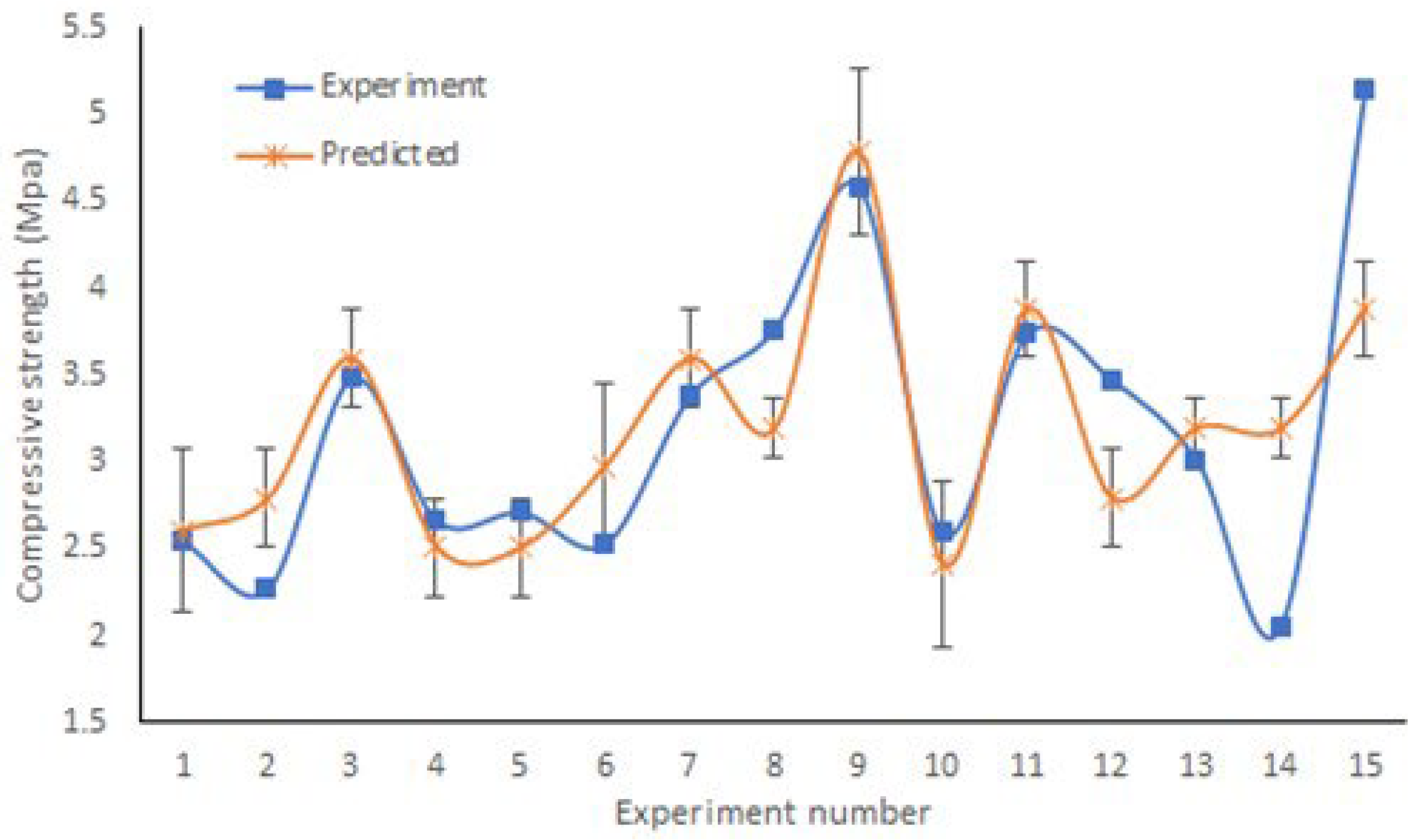

The comparison between the estimated values for the compressive strength of sawdust briquettes and experimental values are presented in

Figure 2. The figure shows that the model is quite useful in the prediction of the compressive strength of briquettes made from sawdust. The contour plots of the compressive strength of sawdust briquettes with the pressure and temperature is presented in

Figure 3. From the plots, it is seen that the maximum compressive strength of briquettes is obtained at the highest value of pressure (15 MPa) and temperature (150 °C). This is likely because at high temperatures considered, the natural components such as lignin are more readily available for binding of the biomass particles. With the availability of the binder, a high pressure forces the biomass particles into close proximity which makes them more compact. The combination of high pressure and temperature ensures that the particles are well bonded and compact to resist external forces.

3.2. Shatter Index Analysis of Briquettes

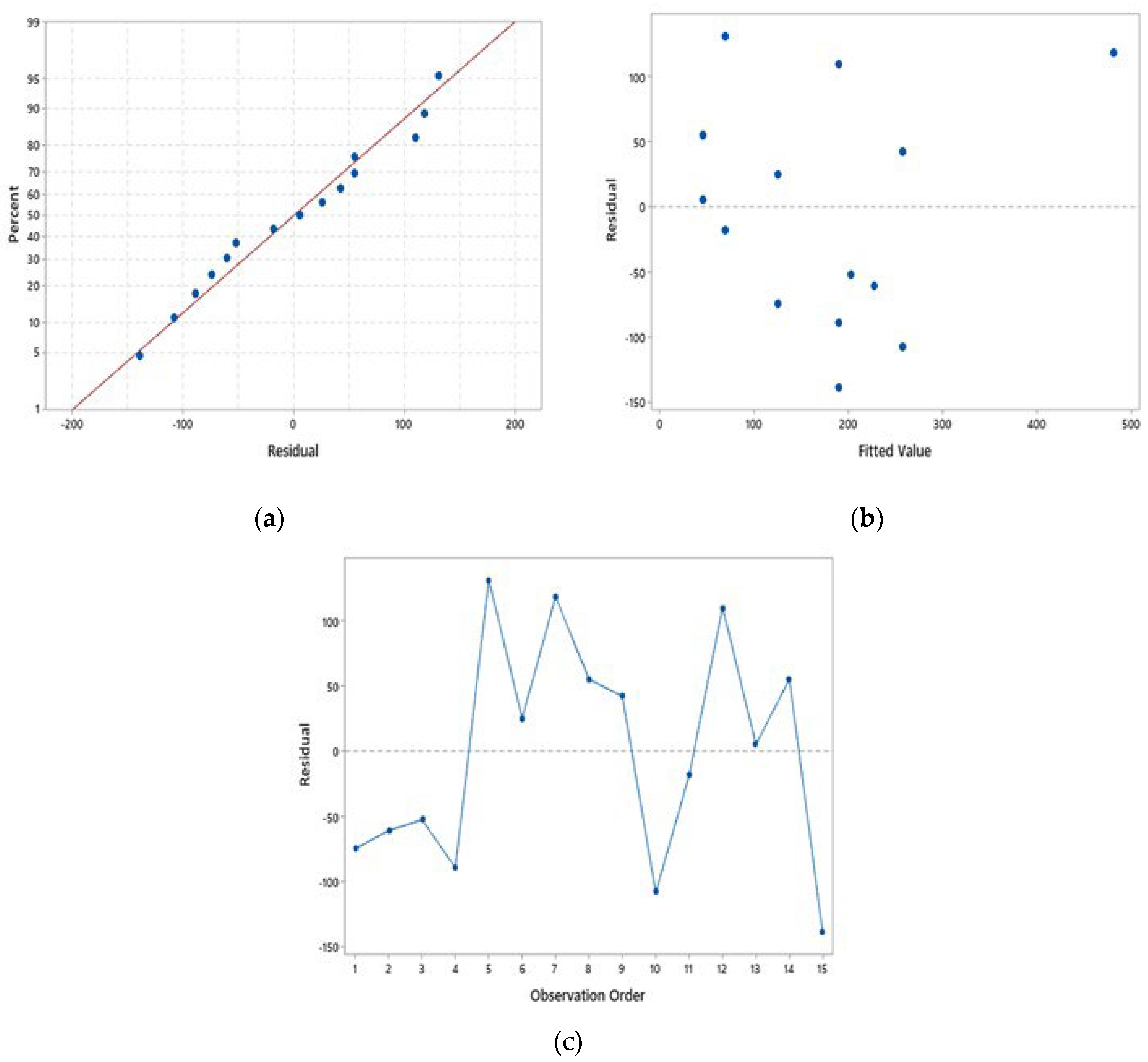

The responses for the shatter index obtained for sawdust briquettes were checked to verify that the assumptions of ANOVA were not violated.

Figure 4 shows that the assumptions of ANOVA including normality, variance, and independence were not violated.

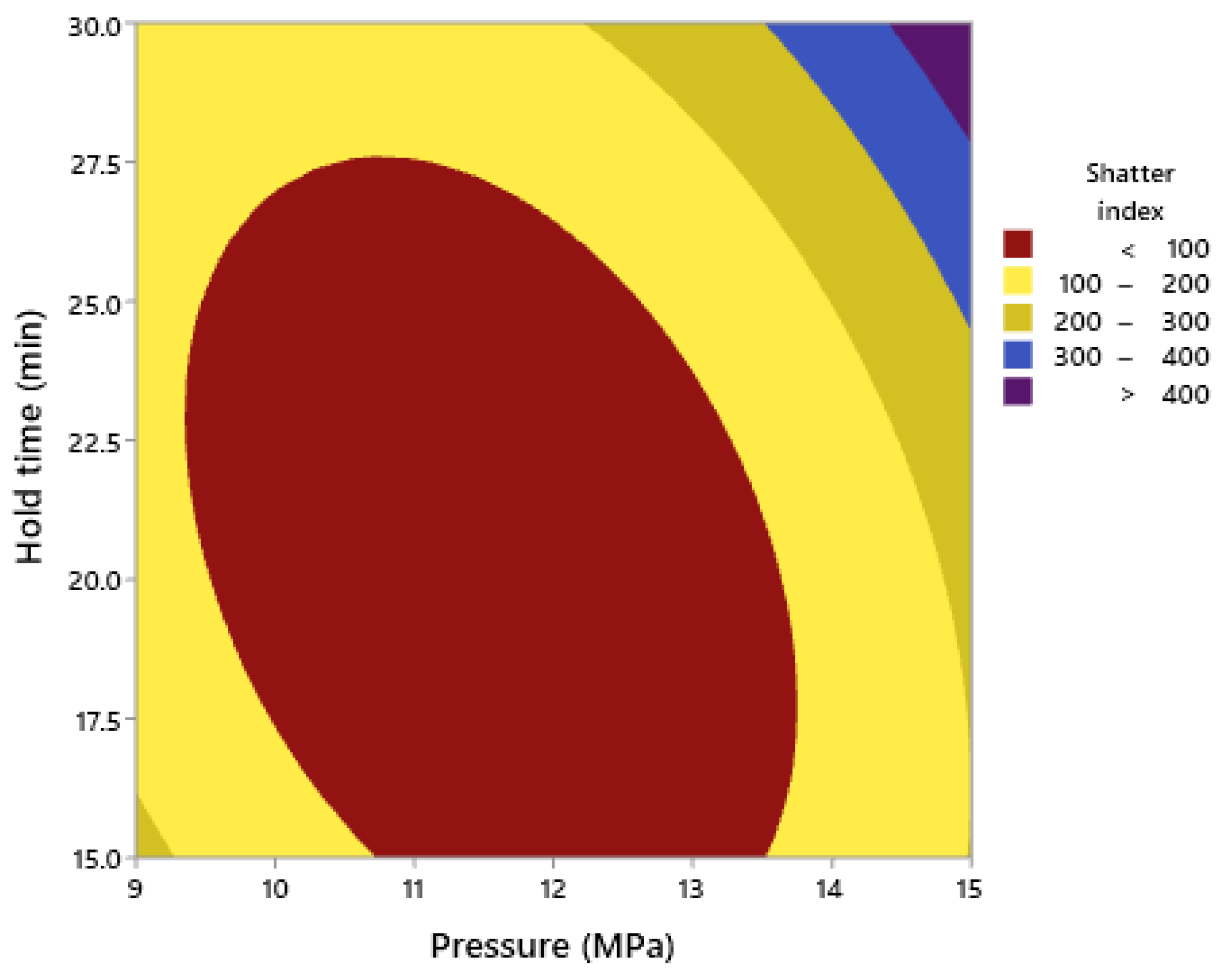

Table 3 presents the ANOVA using backward elimination to check for the significant variables to the shatter index of briquettes. From

Table 3, the significant terms influencing shatter index of briquettes are pressure and the square term of pressure (p < 0.05). Ossei-Bremang et al. (2024) also discovered that pressure was influential in determining shatter index of decanter cake and charred palm kernel shell briquettes using cardboard pulp as binder.

Based on the terms considered in the ANOVA, the model developed is stated in Equation 4. The model has

and

values of 64.73% and 45.14%, respectively.

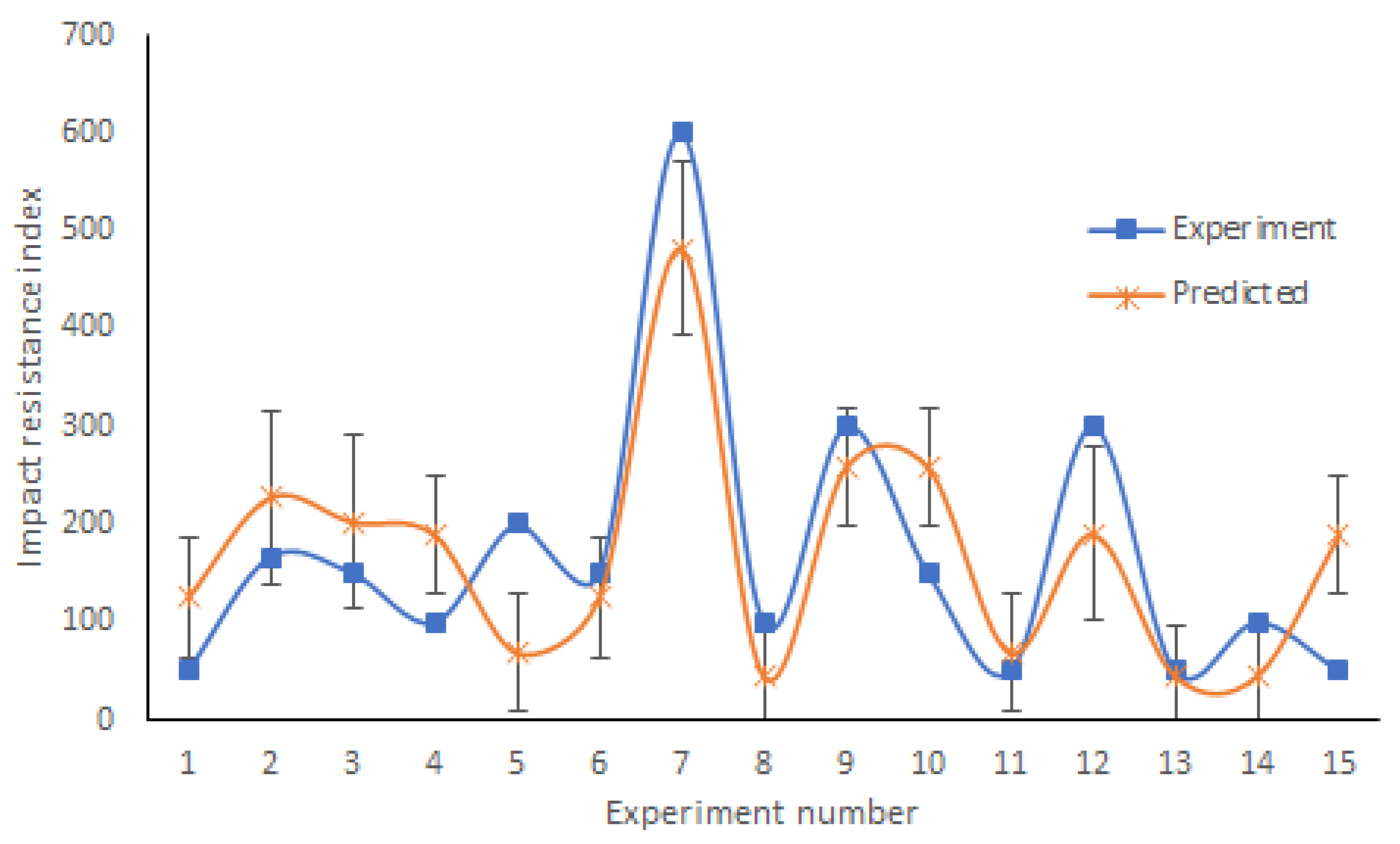

Figure 5 shows plots comparing the predicted values with actual data obtained from the experimental data. The plots are seen to have similar trend which shows the applicability of the model for prediction.

Figure 6 shows the contour plot of the combined effects of the pressure and hold time on shatter index of sawdust briquettes. The figure reveals that the maximum value of shatter index of briquettes is obtained when the pressure and hold time are at the highest setting. The findings on the relationship of shatter index with pressure is similar to observations from the studies of Adu-Poku et al. [

45] and Ossei-Bremang et al. [

36]. The studies observed that the shatter index of the briquettes produced increased with increase in the compaction pressure.

4. Conclusion

The effects of process variables on the strength and durability of briquettes produced from Abura sawdust were investigated in this study. The lateral compressive strength of Abura sawdust briquettes was between 2.06 and 5.15 MPa. The shatter index of the sawdust briquettes was between 50 and 600. From the statistical analysis, the pressure was found to be significant to the determination of the compressive strength (p < 0.1) and the shatter index (p < 0.05). The empirical models developed from the RSM were good predictors for the lateral compressive strength and shatter index of the briquettes but had low values for coefficients of determination. The optimum compressive strength was obtained at the maximum pressure of 15 MPa and temperature of 150 °C. The highest shatter index was obtained at the maximum pressure and hold time of 30 min. With proper selection of densification variables, strong and durable briquettes can be produced.

Author Contributions

Conceptualization, J.I.O., S.O.J. and A.A.O.; methodology, J.I.O., S.O.J., A.A.O., and O.O.A.; software, J.I.O., M.R.S., O.O.A. and K.O.O.; validation, J.I.O., S.O.J., A.A.O., O.O.A. and K.O.O.; formal analysis, J.I.O., M.R.S., A.A.O., O.O.A. and K.O.O.; investigation, J.I.O., M.R.S., A.A.O., O.O.A. and K.O.O.; resources, J.I.O., M.R.S., O.O.A. and K.O.O.; writing—original draft preparation, J.I.O., O.O.A. and A.A.O.; writing—review and editing, S.O.J., M.R.S. and K.O.O.; visualization, J.I.O., A.A.O. and M.R.S.; supervision, J.I.O. and S.O.J.; project administration, J.I.O. and S.O.J.; funding acquisition, J.I.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data used in this study are contained within this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Aremu, J.O. Epileptic Electric Power Generation and Supply in Nigeria: Causes, Impact and Solution. Journal of Contemporary Research in Social Sciences 2019, 1, 73–81. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Orisaleye, J.I.; Pecenka, R. An assessment of potential resources for biomass energy in Nigeria. Resources 2020, 9, 92. [Google Scholar] [CrossRef]

- Obi, O.F.; Okongwu, K.C. Characterization of fuel briquettes made from a blend of rice husk and palm oil mill sludge. Biomass Conversion and Biorefinery 2016, 6, 449–456. [Google Scholar] [CrossRef]

- Roy, R.; Ray, S. Effect of various pretreatments on energy recovery from waste biomass. Energy Sources, Part A: Recovery, Utilization and Environmental Effects 2023, 45, 1–13. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Scholz, V. Potential availability of energetically usable crop residues in Nigeria. Energy Sources, Part A: Recovery, Utilization and Environmental Effects 2009, 31, 687–697. [Google Scholar] [CrossRef]

- Ndukwu, M.C.; Onwude, D.I.; Bennamoun, L.; Abam, F.I.; Simo-Tagne, M.; Horsfall, I.T.; Briggs, T.A. Nigeria’s energy deficit: The challenges and eco- friendly approach in reducing the energy gap. International Journal of Sustainable Engineering 2021, 14, 442–459. [Google Scholar] [CrossRef]

- Ojolo, S.J.; Orisaleye, J.I.; Ismail, S.O.; Abolarin, S.M. Technical potential of biomass energy in Nigeria. Ife Journal of Technology 2012, 21, 60–65. [Google Scholar]

- Zubairu, A.; Gana, S.A. Production and characterization of briquette charcoal by carbonization of agro-waste. Energy Power 2014, 4, 41–47. [Google Scholar]

- Jekayinfa, S.O.; Adebayo, A.O.; Oniya, O.O.; Olatunji, K.O. Comparative analysis of biogas and methane yields from different sizes of groundnut shell in a batch reactor at mesophilic temperature. J Energy Res Rev 2020, 5, 34–44. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Olorunmaiye, J.A.; Ogunsola, A.D.; Soji-Adekunle, A.R. Evaluation of petrol and ethanol mixture as a fuel for gasoline engines. Adeleke University Journal of Engineering and Technology 2018, 1, 139–148. [Google Scholar]

- Ojolo, S. J.; Orisaleye, J. I. Design of a laboratory scale biomass gasifier. In Building a Non-Oil Export Based Economy for Nigeria: The Potential of Value-Added Products from Agricultural Residues; Jekayinfa, S.O., Ed.; Cuvillier Verlag: Göttingen, Germany, 2012; pp. 61–68. [Google Scholar]

- Ojolo, S. J.; Orisaleye, J. I. Design and development of a laboratory scale biomass gasifier. Journal of Energy and Power Engineering 2010, 4, 33. [Google Scholar]

- Ogunsina, B.S.; Ojolo, S.J.; Ohunakin, O.S.; Oyedeji, O.A.; Matanmni, K.A.; Bamgboye, I.A. Potentials for generating alternative fuels from empty palm bunches by pyrolysis. JOMAR 2014, 8, 50–60. [Google Scholar]

- Orisaleye, J.I.; Jekayinfa, S.O.; Pecenka, R.; Ogundare, A.A.; Akinseloyin, M.O.; Fadipe, O.L. Investigation of the effects of torrefaction temperature and residence time on the fuel quality of corncobs in a fixed-bed reactor. Energies 2022, 15, 5284. [Google Scholar] [CrossRef]

- Pecenka, R.; Lenz, H.; Jekayinfa, S.O.; Hoffmann, T. Influence of tree species, harvesting method and storage on energy demand and wood chip quality when chipping poplar, willow and black locust. Agriculture 2020, 10, 116. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Ogundare, A.A.; Adefuye, O.A.; Bamido, E. Effect of screen size on particle size distribution and performance of a small-scale design for a combined chopping and milling machine. Cleaner Engineering and Technology 2022, 7, 100426. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Ojolo, S. J.; Ajiboye, J.S. Mathematical modelling of die pressure of a screw briquetting machine. Journal of King Saud University-Engineering Sciences 2020, 32, 555–560. [Google Scholar] [CrossRef]

- Aina, O.M.; Adetogun, A.C.; Iyiola, K.A. Heat energy from value-added sawdust briquettes of Albizia zygia. Ethiopian Journal of Environmental Studies and Management 2009, 2, 42–49. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Xiong, Y.; Tan, H.; Niu, Y. Study of briquetted biomass co-firing mode in power plants. Applied Thermal Engineering 2014, 63, 266–271. [Google Scholar] [CrossRef]

- Tembe, E.; Otache, P.; Ekhuemelo, D. Density, shatter index, and combustion properties of briquettes produced from groundnut shells, rice husks and saw dust of Daniellia oliveri. Journal of Applied Biosciences 2014, 82, 7372. [Google Scholar] [CrossRef]

- Obi, O.F.; Olugbade, T.O.; Orisaleye, J.I.; Pecenka, R. Solid Biofuel Production from Biomass: Technologies, Challenges, and Opportunities for Its Commercial Production in Nigeria. Energies 2023, 16, 7966. [Google Scholar] [CrossRef]

- Jha, P.; Yadav, P. Briquetting of saw dust. Applied Mechanics and Materials 2012, 110–116, 1758–1761. [Google Scholar] [CrossRef]

- Setter, C.; Silva, F.T.M.; Assis, M.R.; Ataíde, C.H.; Trugilho, P.F.; Oliveira, T.J.P. Slow pyrolysis of coffee husk briquettes: Characterization of the solid and liquid fractions. Fuel 2020, 261. [Google Scholar] [CrossRef]

- Obi, O.F. Effect of briquetting temperature on the properties of biomass briquettes. African Journal of Science, Technology, Innovation and Development 2015, 7, 386–394. [Google Scholar] [CrossRef]

- Lela, B.; Barasic, M.; Nizetic, S. Cardboard/sawdust briquettes as biomass fuel: Physical-mechanical and thermal characteristics. Waste Management 2016, 47, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Orisaleye, J.I.; Jekayinfa, S.O.; Adebayo, A.O.; Ahmed, N.A.; Pecenka, R. Effect of densification variables on density of corn cob briquettes produced using a uniaxial compaction biomass briquetting press. Energy Sources, Part A: Recovery, Utilization and Environmental Effects 2018, 40, 3019–3028. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Pecenka, R.; Onifade, T.B. Effect of densification variables on water resistance of corn cob briquettes. Agronomy Research 2019, 17, 1722–1734. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Halim, H.A.; Ahmad, A.F.; Abbas, Z. Physical characterization of briquettes produced from paper pulp and Mesua ferrea mixtures. Biofuels 2022, 13, 333–340. [Google Scholar] [CrossRef]

- Shuma, R.; Madyira, D.M. Production of loose biomass briquettes from agricultural and forestry residues. Procedia Manufacturing 2017, 7, 98–105. [Google Scholar] [CrossRef]

- Oriabure, E.D.; Terzungwue, T.E.; Emoh, O.F. Density, shatter index and heating value of briquettes produced from the leaves of Terminalia mentalis and sawdust of Daniela oliveri. International Journal of Pure Agricultural Advances 2017, 1, 38–44. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Dittrich, C.; Obi, O.F.; Pecenka, R. Effects of feeding speed and temperature on properties of briquettes from poplar wood using a hydraulic briquetting press. Resources 2023, 12, 12. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Pecenka, R.; Orisaleye, J. I. Empirical model for prediction of density and water resistance of corn cob briquettes. International Journal of Renewable Energy Technology 2019, 10, 212–228. [Google Scholar] [CrossRef]

- Zepeda-Cepeda, C.O.; Goche-Télles, J.R.; Palacios-Mendoza, C.; Moreno-Anguiano, O.; Núñez-Retana, V.D.; Heya, M.N.; Carrillo-Parra, A. Effect of sawdust particle size on physical, mechanical, and energetic properties of pinus durangensis briquettes. Applied sciences 2021, 11, 3805. [Google Scholar] [CrossRef]

- Ladla, P.; Dussadee, N.; Homdoung, N.; Thararux, C.; Ramaraj, R.; Tantikul, S. Influence of types and preheating agricultural waste on physical properties briquette fuel. The 26th Tri-U Joint Seminar and Symposium, Jiangu University, China, October 20-24, 2019; pp. 333–336. [Google Scholar]

- Jekayinfa, S.O.; Abdulsalam, I.A.; Ola, F.A.; Akande, F.B.; Orisaleye, J.I. Effects of binders and die geometry on quality of densified rice bran using a screw-type laboratory scale pelleting machine. Energy Nexus 2024, 13, 100275. [Google Scholar] [CrossRef]

- Ossei-Bremang, R.N.; Adjei, E.A.; Kemausuor, F.; Mockenhaupt, T.; Bar-Nosber, T. Effects of compression pressure, biomass ratio and binder proportion on the calorific value and mechanical integrity of waste-based briquettes. Bioresource Technology Reports 2024, 25, 101724. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Braimoh, O.M.; Edhere, V.O. Empirical models for physical properties of abura (Mitragyna ciliata) sawdust briquettes using response surface methodology. Cleaner Engineering and Technology 2022, 7, 100447. [Google Scholar] [CrossRef]

- Afrifah, K.A.; Asiedu-Agyei, E.O.A.; Mitchual, S.J. Statistical optimization of the physical and mechanical properties of briquettes of Ceiba pentandra sawdust and agricultural residue. Pro Ligno 2020, 16, 46–60. [Google Scholar]

- Ndukwe, N.A.; Okiei, W.O.; Alo, B.I. Correlates of the yield of chemical pulp, lignin and the extractive materials of tropical hardwoods. African Journal of Agricultural Research 2012, 7, 5518–5524. [Google Scholar]

- Adeleke, A.; Odusote, J.; Ikubanni, P.; Lasode, O.; Malathi, M.; Pasawan, D. Physical and mechanical characteristics of composite briquette from coal and pretreated wood fines. International Journal of Coal Science & Technology 2021, 8, 1088–1098. [Google Scholar]

- Thliza, B.A.; Abdulrahman, F.I.; Akan, J.C.; Chellube, Z.M.; Kime, B. Determination of compressive strength and combustibility potential of agricultural waste briquette. Chem. Sci. Int. J 2020, 29, 30–46. [Google Scholar] [CrossRef]

- Borowski, G.; Hycnar, J.J. Utilization of fine coal waste as a fuel briquettes. International Journal of Coal Preparation and Utilization, 33, 194–204.

- Gao, P.; Bai, Z.; Zhang, T.; Jia, Y.; Hou, Y.; Li, W.; Chen, J.; Guo, Z.; Kong, L.; Bai, J.; Li, W. Optimization of briquetting conditions and influencing factors of high-strength sludge briquette. Journal of Cleaner Production 2023, 432, 139749. [Google Scholar] [CrossRef]

- Helwani, Z.; Ramli, M.; Rusyana, A.; Marlina, M.; Fatra, W.; Idroes, G. M.; Suhendra, R.; Ashwie, V.; Mahlia, T.M.I.; Idroes, R. Alternative briquette material made from palm stem biomass mediated by glycerol crude of biodiesel byproducts as a natural adhesive. Processes 2020, 8, 777. [Google Scholar] [CrossRef]

- Adu-Poku, K.A.; Appiah, D.; Asosega, K.A.; Derkyi, N.S.A.; Uba, F.; Kumi, E.N.; Akowuah, E.; Akolgo, G.A.; Gyamfi, D. Characterization of fuel and mechanical properties of charred agricultural wastes: experimental and statistical studies. Energy Reports 2022, 8, 4319–4331. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).