Submitted:

07 May 2024

Posted:

10 May 2024

You are already at the latest version

Abstract

Keywords:

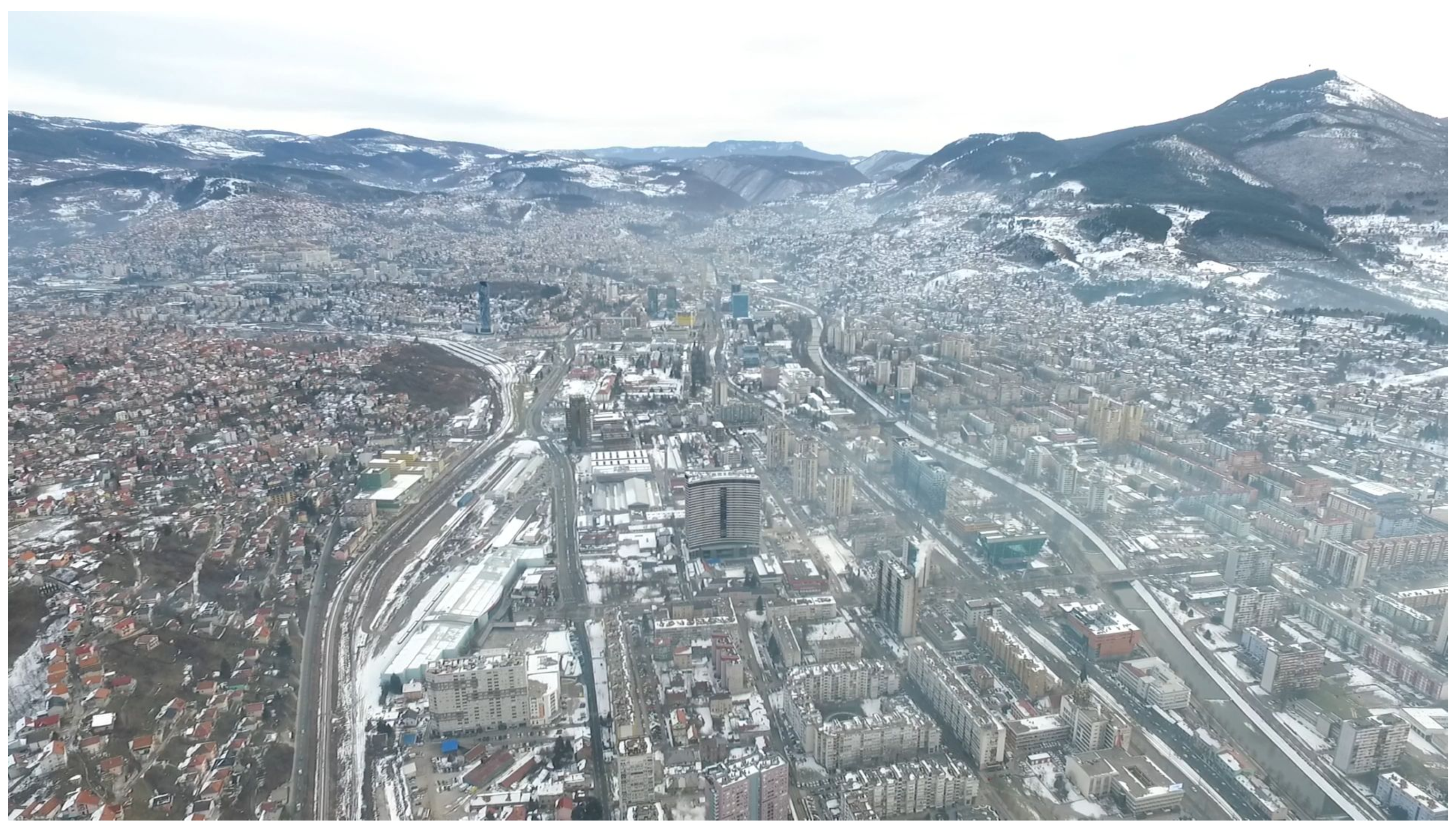

1. Introduction

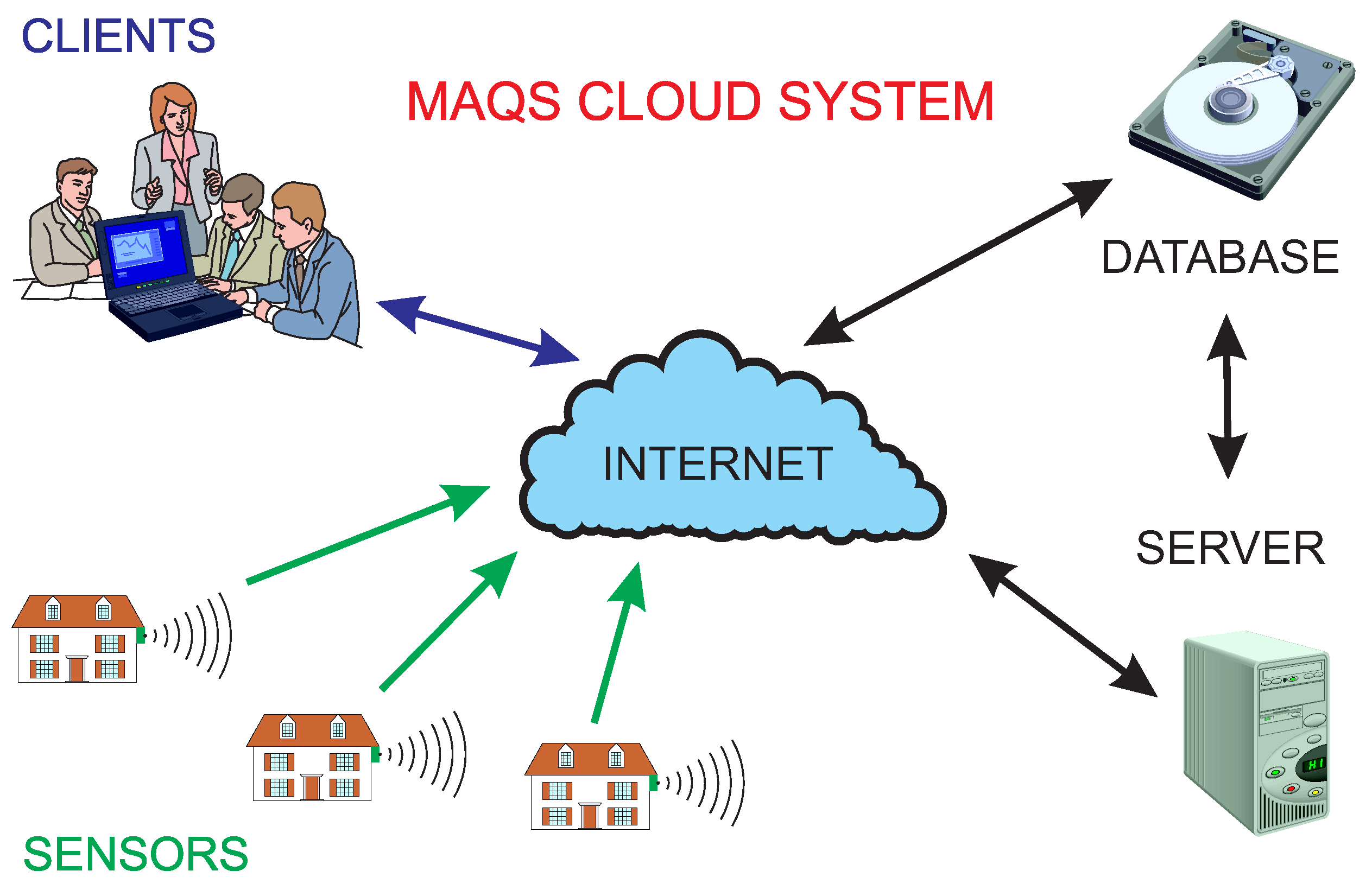

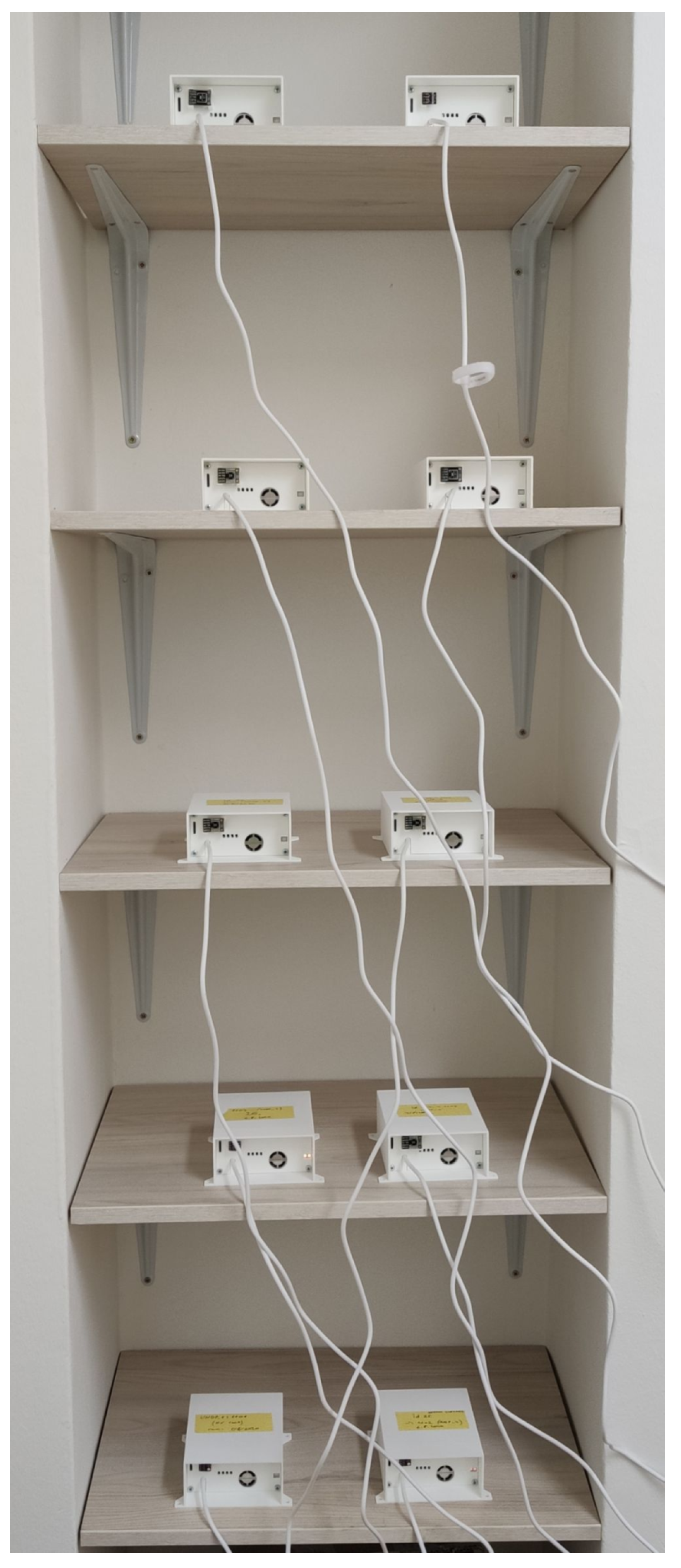

2. About MAQS

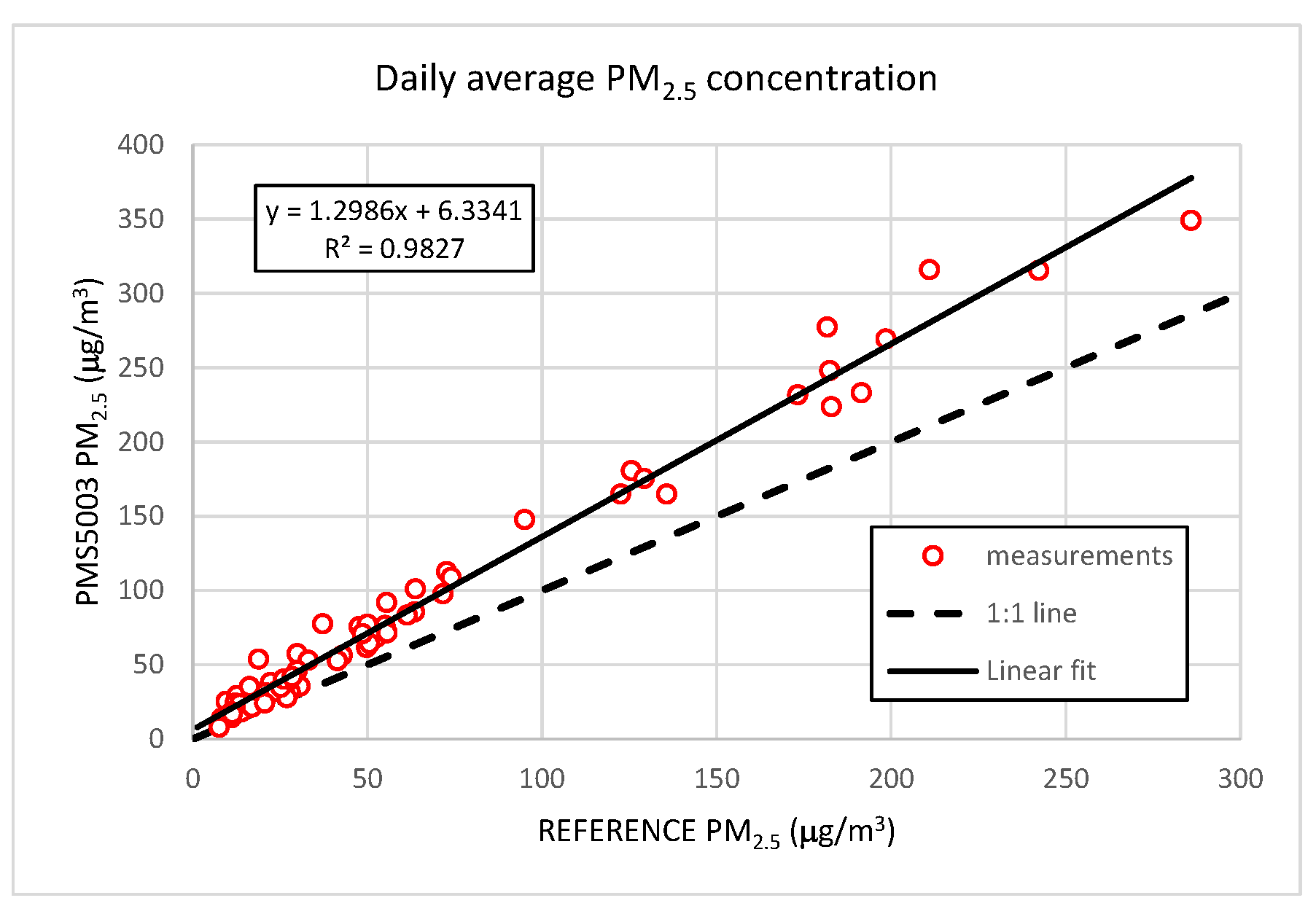

2.1. Particulate Matter Sensor

- it can’t detect properly coarse particles (especially those larger than 2.5 m) because most particles miss the focal point of laser beam. When this happens for large particle, it is incorrectly sized,

- strong wind can obstruct sensor’s aspiration, depending on the wind direction relative to the sensor inlet.

3. Results and Discussion

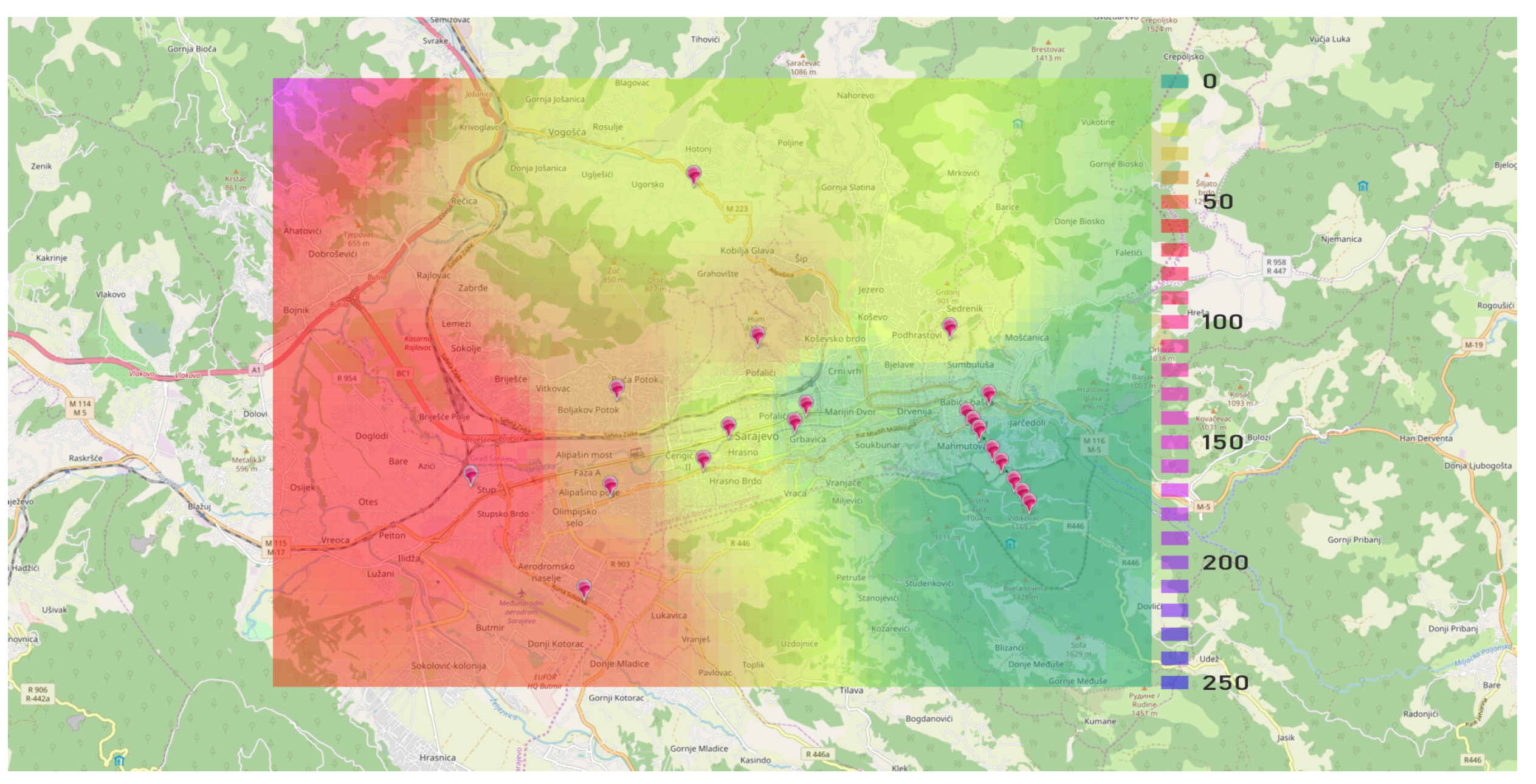

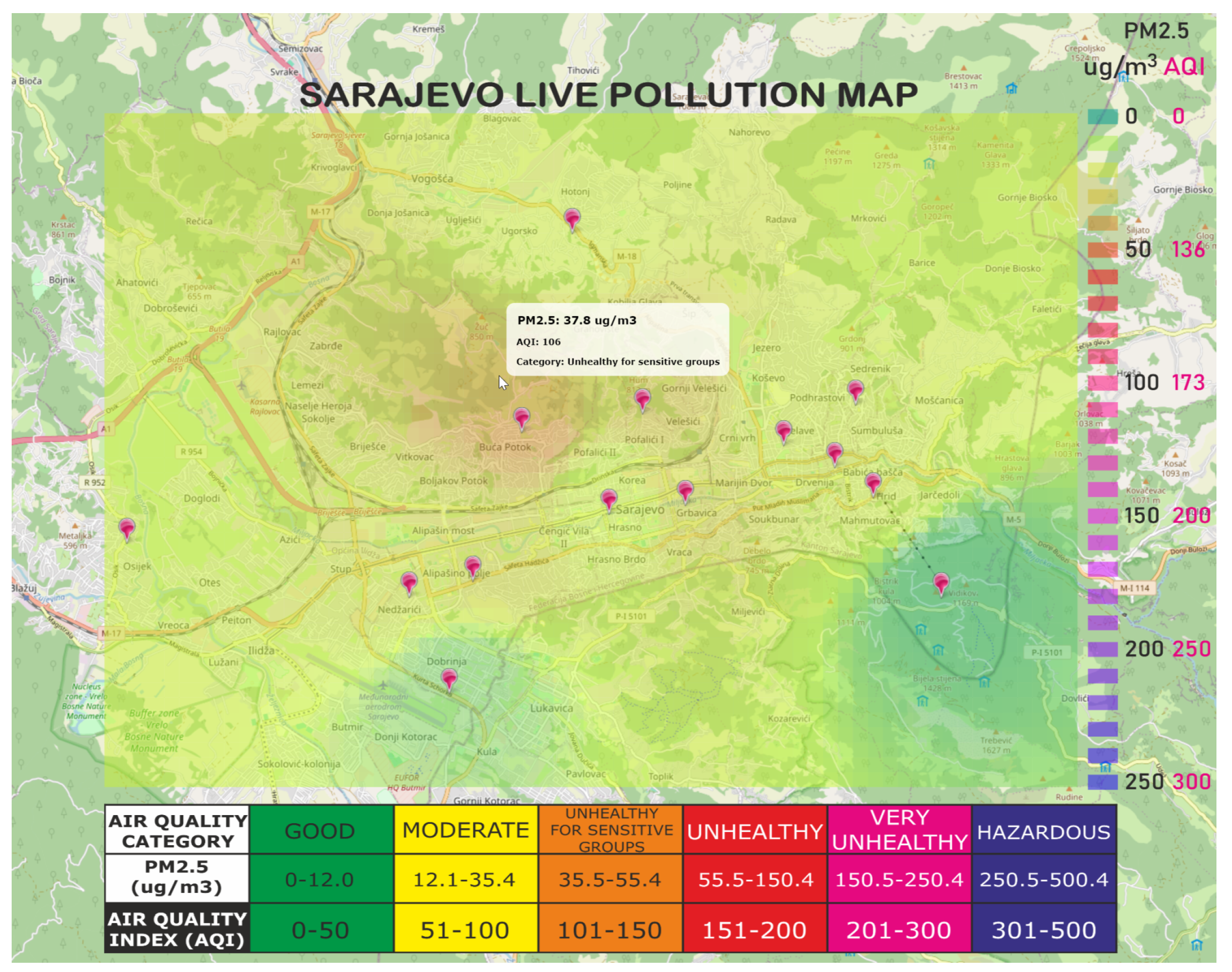

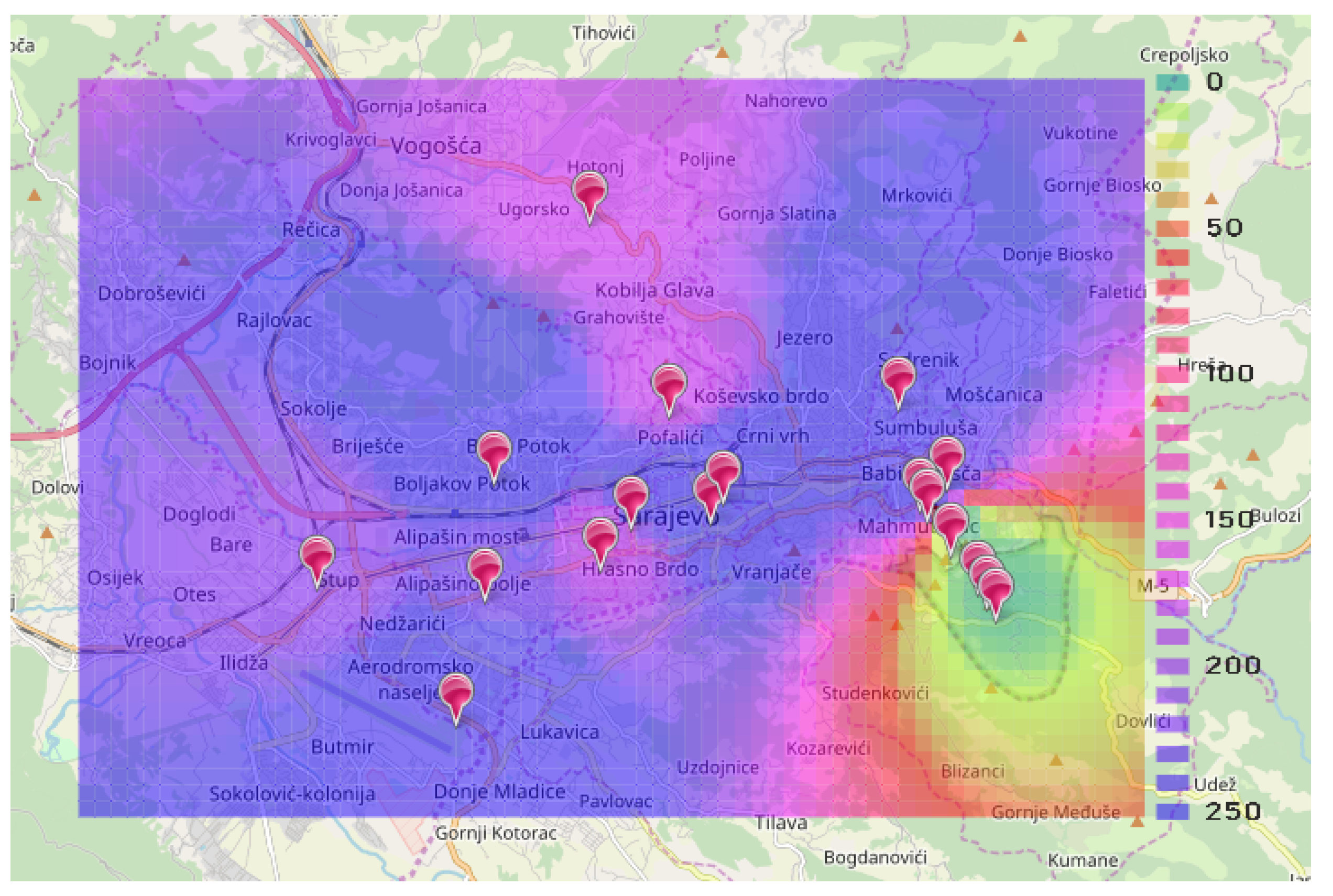

3.1. Pollution Map

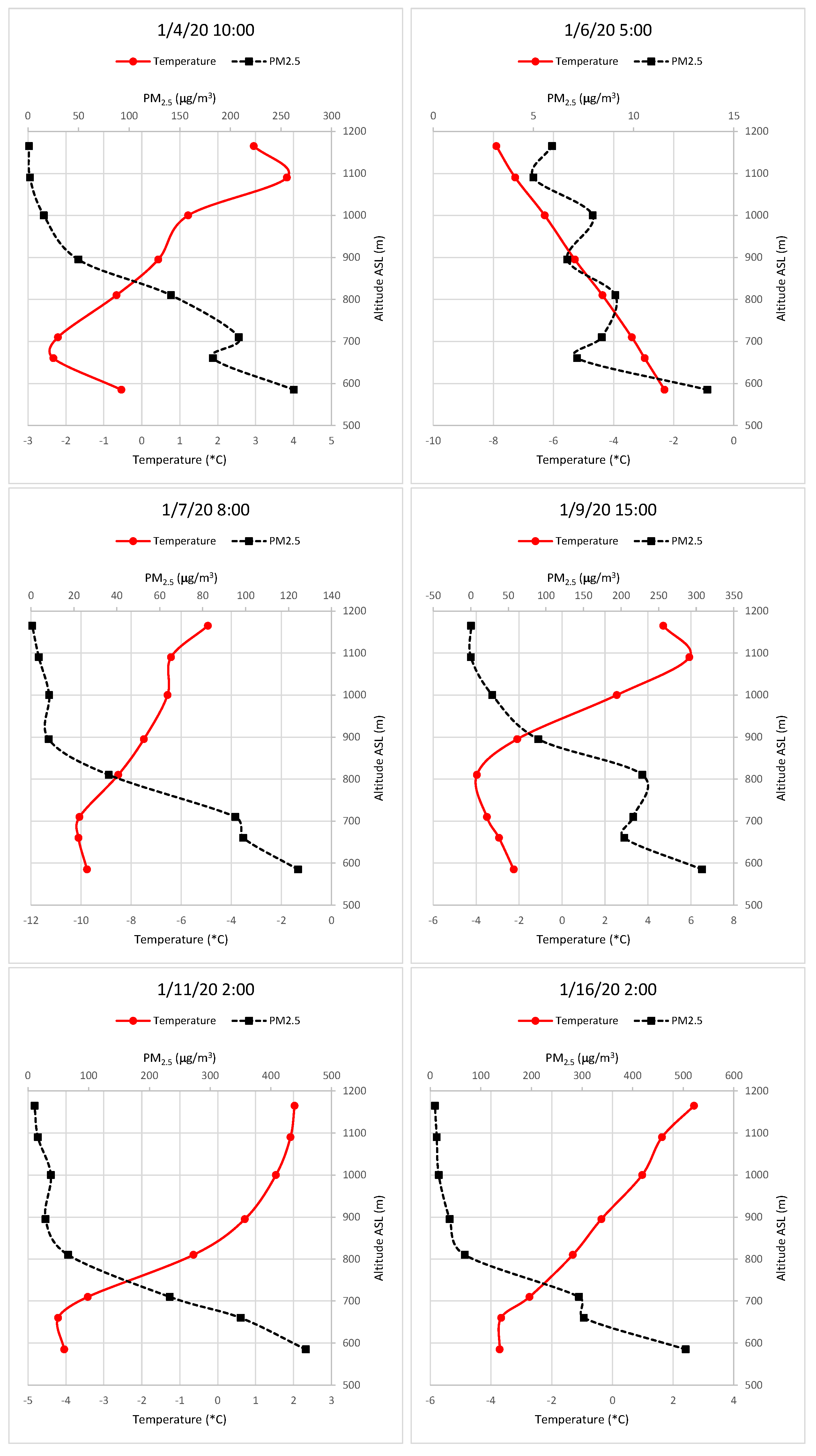

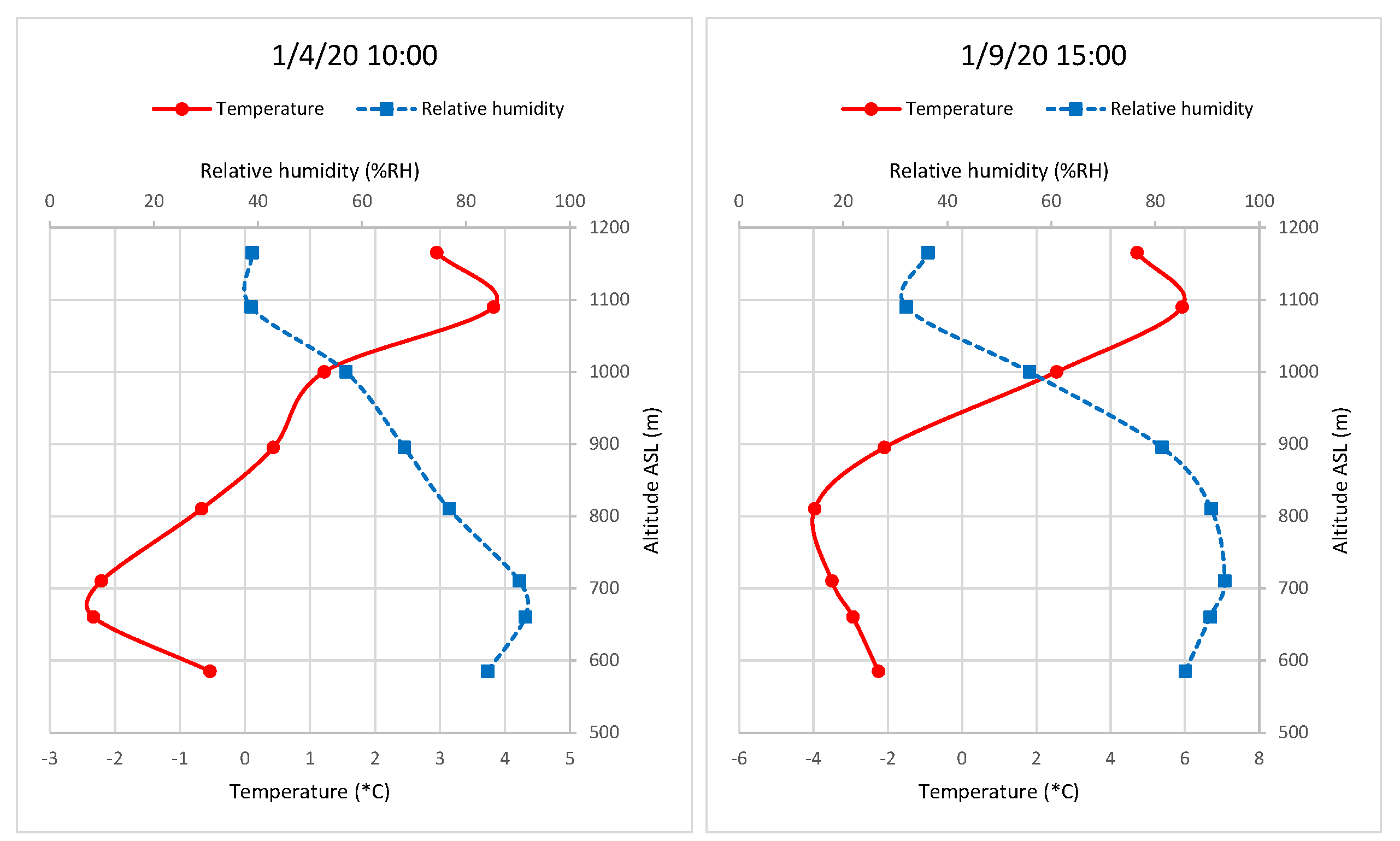

3.2. Vertical Profiles and Temperature Inversion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AQI | Air Quality Index |

| AGL | Above Ground Level |

| ASL | Above Sea Level |

| GNSS | Global Navigation Satellite System |

| IDW | Inverse Distance Weighting |

| MAQS | Mobile Air Quality System |

| PM | Particulate Matter |

| SQL | Structured Query Language |

| TCP/IP | Transmission Control Protocol/Internet Protocol |

References

- Trako, N.; Masic, F.; Ajanovic, F.; Merdan, S.; Huremovic, J.; Zero, S.; Masic, A.; Gojak-Salimovic, S. Health risk assessment of heavy metals in PM2.5 and PM10 in Sarajevo air, Bosnia and Herzegovina. Journal of Environmental Science and Health, Part A. 2024. [Google Scholar] [CrossRef]

- Awe, Y.A.; Murisic, M.; Kreso Beslagic, E.; Rinnerberger, N.; Oguz Kuntasal, O.; Brody, M.S.; Golub, E.S.; Enriquez, S.; Paranos, D.; Colovic-Daul, M.; Air Quality Management in Bosnia and Herzegovina (English). Washington, D.C. : World Bank Group. Available online: https://documents.worldbank.org/curated/en/117281576515111584/Air-Quality-Management-in-Bosnia-and-Herzegovina (accessed on 04/30/2024).

- Masic, A.; Bibic, Dz.; Pikula, B.; Dzaferovic-Masic, E.; Musemic, R. Experimental study of temperature inversions above urban area using unmanned aerial vehicle. Thermal Science. 2019, 23, 3327–3338. [Google Scholar] [CrossRef]

- Air Quality Index (AQI) Basics. Available online: https://www.airnow.gov/aqi/aqi-basics/ (accessed on 04/30/2024).

- Boost C++ libraries. Available online: https://www.boost.org/ (accessed on 04/30/2024).

- PostgreSQL: The World’s Most Advanced Open Source Relational Database. Available online: https://www.postgresql.org/ (accessed on 04/30/2024).

- Arduino. Available online: https://www.arduino.cc/ (accessed on 04/30/2024).

- ESP-IDF. Available online: https://idf.espressif.com/ (accessed on 04/30/2024).

- Masic, A.; Bibic, Dz.; Pikula, B.; Blazevic, A.; Huremovic, J.; Zero, S. Evaluation of optical particulate matter sensors under realistic conditions of strong and mild urban pollution. Atmos. Meas. Tech. 2020, 13, 6427–6443. [Google Scholar] [CrossRef]

- Tryner, J.; L’Orange, C.; Mehaffy, J.; Miller-Lionberg, D.; Hofstetter, J.C.; Wilson, A.; Volckens, J. Laboratory evaluation of low-cost PurpleAir PM monitors and in-field correction using collocated portable filter samplers. Atmos. Environ. 2020, 220. [Google Scholar] [CrossRef]

- Magi, B.I.; Cupini, C.; Francis, J.; Green, M.; Hauser, C. Evaluation of PM2.5 measured in an urban setting using a low-cost optical particle counter and a Federal Equivalent Method Beta Attenuation Monitor. Aerosol Sci. Tech. 2020, 54, 147–159. [Google Scholar] [CrossRef]

- Kosmopoulos, G.; Salamalikis, V.; Pandis, S.N.; Yannopoulos, P.; Bloutsos, A.A.; Kazantzidis, A. Low-cost sensors for measuring airborne particulate matter: Field evaluation and calibration at a South-Eastern European site. Sci. Total Environ. 2020, 748. [Google Scholar] [CrossRef]

- Mie, G. Beitrage zur Optik truber Medien, speziell kolloidaler Metallosungen (contributions to the optics of diffuse media,especially colloid metal solutions. Ann. Phys. 1908, 25, 377–445. [Google Scholar] [CrossRef]

- Kuula, J.; Makela, T.; Aurela, M.; Teinila, K.; Varjonen, S.; Gonzalez, O.; Timonen, H. Laboratory evaluation of particle-size selectivity of optical low-cost particulate matter sensors. Atmos. Meas. Tech. 2020, 13, 2413–2423. [Google Scholar] [CrossRef]

- Ouimette, J.; Arnott, W.P.; Laven, P.; Whitwell, R.; Radhakrishnan, N.; Dhaniyala, S.; Sandink, M.; Tryner, J. Fundamentals of low-cost aerosol sensor design and operation. Aerosol Sci. Technol. 2024, 58, 1–15. [Google Scholar] [CrossRef]

- Barkjohn, K.K.; Gantt, B.; Clements, A.L. Development and application of a United States-wide correction for PM2.5 data collected with the PurpleAir sensor. Atmos. Meas. Tech. 2021, 14, 4617–4637. [Google Scholar] [CrossRef]

- Chacon-Mateos, M.; Laquai, B.; Vogt, U.; Stubenrauch, C. Evaluation of a low-cost dryer for a low-cost optical particle counter. Atmos. Meas. Tech. 2022, 15, 7395–7410. [Google Scholar] [CrossRef]

- Nothhelfer, M.; Sperber, O.; Todea, A.M.; Schunke, B.; Romazanowa, O.; Schumacher, S.; Bathen, D.; Asbach, C. Effect of an Aerosol Dryer on Ambient PM Measurements with SDS011 Low Cost Sensors during a Two-year Period in Duisburg, Germany. Aerosol Air Qual. Res. 2023, 23. [Google Scholar] [CrossRef]

- Couzo, E.; Valencia, A.; Gittis, P. Evaluation and Correction of PurpleAir Temperature and Relative Humidity Measurements. Atmosphere 2024, 15, 415. [Google Scholar] [CrossRef]

- OpenLayers library. Available online: https://openlayers.org/ (accessed on 04/30/2024).

| Year | PM (g/m) |

|---|---|

| 2019 | 33.9 |

| 2020 | 46.1 |

| 2021 | 29.3 |

| 2022 | 35.1 |

| 2023 | 35.6 |

| Physical quantity | Supported sensors |

|---|---|

| Position and time | All U-blox GNSS receivers |

| Barometric pressure | Bosch BME and BMP series |

| Wind speed | in-house developed cup anemometer |

| Carbon dioxide concentration | Amphenol Telaire 6703, Plantower DS-CO2-20 |

| Temperature | Sensirion SHT 30 and 40 series |

| Relative humidity | Sensirion SHT 30 and 40 series |

| Pillar | Sensor altitude ASL (m) |

|---|---|

| S2 | 585 |

| S3 | 660 |

| S4 | 710 |

| S5 | 810 |

| S6 | 895 |

| S7 | 1000 |

| S8 | 1090 |

| S9 | 1165 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).