1. Introduction

Total hip arthroplasty (THA) replacement surgeries have been very successful for decades. Kurtz et al. reported that the number of patients in the USA who need a THA and consequent revision is increasing because of an aging population [

1].

The fixation of the metal and later ceramic head to the titanium alloy stem is achieved by a Morse taper, which consists of a stem taper (male taper) and a taper in the femoral head (female taper) [

2,

3,

4]. Each stem taper has characteristic properties such as taper angle, diameter, base dimension, straightness, roundness, and surface properties, as shown in

Figure 1. Every modular connection of metal alloys in contact with body fluids and exposed to micromotion is subject to corrosion [

5,

6,

7]. The taper’s interface is influenced by several factors, such as (i) design and material, (ii) assembly (surgical factors), and (iii) loading (patient factors) [

3,

6]. Urish et al. explained in detail the basic principles of corrosion types that can occur in an orthopedic implant surface including pitting, crevice, fretting, and mechanically assisted crevice corrosion [

6].

Cales et al. reported that each implant company applies its specifications for manufacturing and discussed the advantages and disadvantages of standardization of tapers in hip endoprostheses [

8]. However, until today, no uniform taper regarding dimensions, metallurgy, manufacturing tolerances, or surface finish has been achieved by the International Organization for Standardization (ISO) and ASTM International [

8]. The general standard is 12/14 (it was pioneered in the orthopedic industry by the Italian firm Cremascoli, formerly known as Adler Ortho), indicating a 12 mm diameter at the apex of the cone and 14 mm at its base. However, the exact length of the taper is not rigorously defined, thus the angle may exhibit slight variations. It is recommended, particularly for partial dentures, that both components originate from the same manufacturer. However, this recommendation becomes less imperative during revisions, where strict adherence is not maintained. The specific shape of the taper, including notches and surface finish, remains undefined.

Approximately 60 different types of cementless stem components [

17] of hip prostheses are currently available on the market and knowledge of the behavior of the individual prosthesis in certain clinical conditions is very important [

6,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19].

The Zweymüller cementless hip endoprosthesis with SL-PLUS

® femoral stem has been used for the last 30 years with no change in design. It is made of forged titanium Ti6Al7Nb alloy, or in the USA and non-EU countries Ti6Al4V alloy, with a double-taper straight stem of rectangular cross-section. Its grit-blasted 2-5 µm surface roughness enhances bone ingrowth. Roškar et al., report that till now, there has been no report on more than 2000 Zweymüller endoprostheses from a single center with over 20 years of follow-up [

20,

21].

Aseptic loosening and periprosthetic joint infection are the main causes of the premature failure of joint arthroplasty [

12,

15]. Aseptic loosening can be induced by different causes, such as the micromotion of the implant in the bone during loading, corundum wear particles from grit-blasted surfaces, including taper, wear-particle generation, causing inflammation and bone resorption, and consequently the formation of a poor functional interface (osteointegration) between the implant and the patient’s bone [

22,

23,

24,

25,

26,

27].

The aim of the present study is the investigation of cementless Zweymüller stems, the femoral component, of hip endoprostheses. We were interested in the micro-threaded stem taper and its influence on premature failure, aseptic loosening, and infection. We have focused on the characterization of surface properties, micromorphology, microstructure, phase structure, and surface properties of two new (Alloclasic of Ti6Al7Nb and Lima Corporate of Ti6Al4V alloy) and three retrieved taper stems.

We examined retrievals in which the only source of modularity with a metallic component was the head-stem interface between the Ti6Al7Nb alloy taper stem and the ceramic head.

Stockhausen et al. reported that the degradation at the modular head-neck interface in THA is predominately expressed in the form of corrosion and fretting, potentially causing peri-prosthetic failure by adverse reactions to metal debris [

2]. Their retrieval study aimed to quantify variations in stem taper surface topographies and to assess the influence on the formation of corrosion and/or fretting in titanium alloy stem tapers combined with ceramic heads. They found high variability in surface characteristics between threaded stem tapers: Alloclassic and CLS tapers feature deeply threaded trapezoid-shaped profiles with thread heights over 65 μm; low thread heights below 14 μm characterize the sawtooth-shaped Bicontact and triangular SL-Plus taper. Significantly lower corrosion and fretting scores were observed in lightly threaded, compared to deeply threaded, tapers in ceramic head combinations. They concluded that the relationship between stem taper surface topography and the formation of clinical results of corrosion and fretting could help improve the performance of modern THAs and lead to longer-lasting clinical results [

2,

3,

28,

29].

The aim of this study is the characterization of microstructure, surface properties, and microtopography of new and retrieved 12/14 stem tapers of different manufacturers where the retrievals examined were those in which the sole source of modularity with a metallic component was the head-stem taper interface between the Ti alloy taper stem and the ceramic head.

2. Materials and Methods

2.1. Materials

All the retrieved Ti6Al7Nb stems of the cementless Zweimüller (ZM) type hip endoprostheses were collected within the frame of the register of the explanted orthopaedic endoprostheses (UMC-Ljubljana, Slovenia) during the revision surgeries. For comparison, we investigated two out of five new stems (after their expiry date) of Smith & Nephew, Alloclasic Varial, Alloclasic Zimmer, and Lima Corporate manufacturers. The investigation included 45 stems of cementless hip endoprostheses that prematurely failed due to (i) aseptic loosening (15 implants), (ii) infection (15 implants), and (iii) low-grade infection (15 implants). The interval between the primary hip replacement and the revision surgery was 36 months to 259 months for aseptic loosening, 3 months to 40 months for infection, and 12 months to 198 months for low-grade infection [

3,

13,

14].

The retrieved stems were SL-Plus, Smith & Nephew (London UK), and Endoplus (London, UK) manufacturers. The retrieved implants were sent after the revision surgery for sonication and microbiological analyses in Ringer’s solution and afterward for cleaning and sterilization [

3,

4,

5,

6].

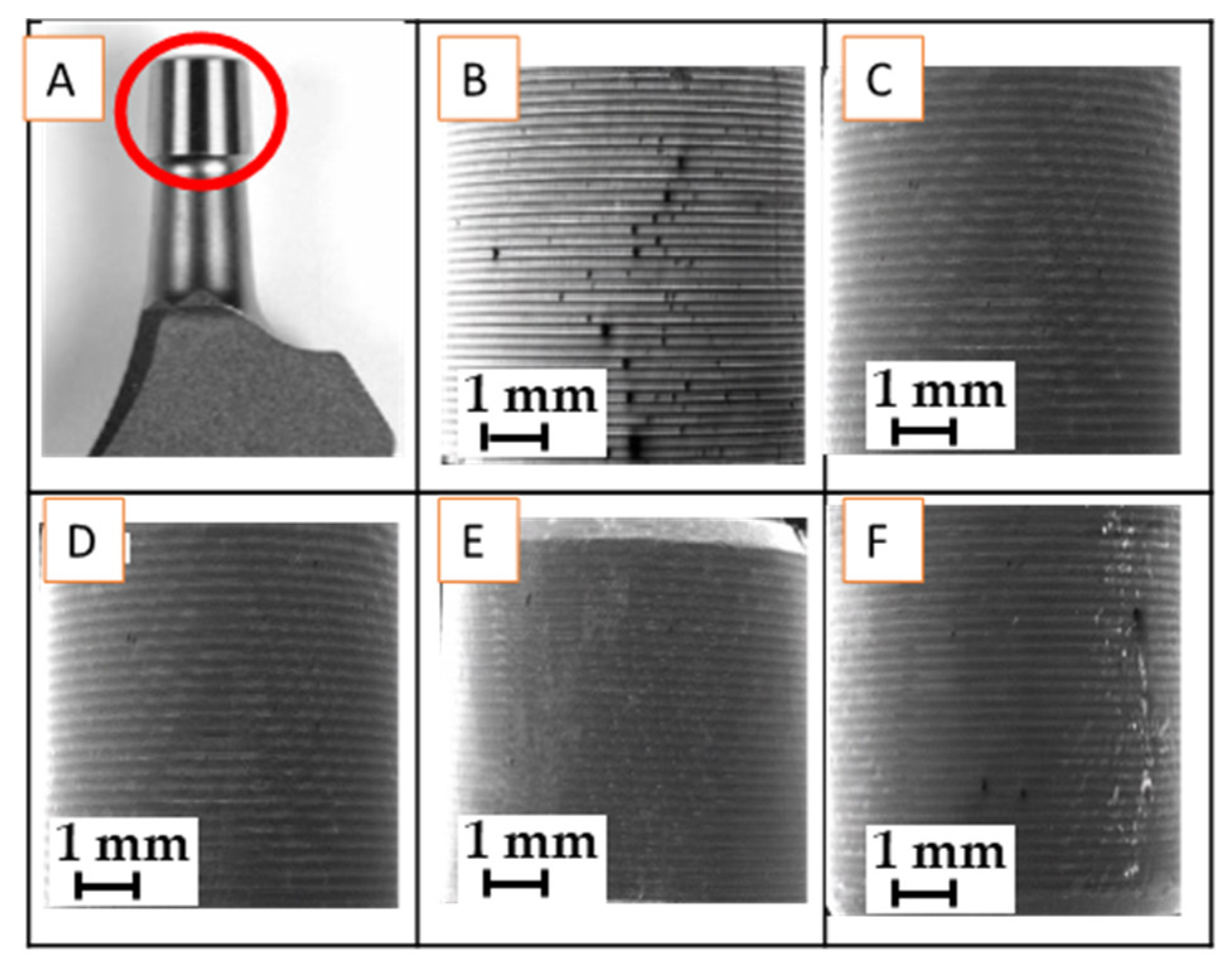

The samples: tapers, described in

Table 1, and in

Figure 2, were cut from the stems, and cleaned by standard procedures. The micro-threaded taper surface of 5 selected samples: (i) A-283-239 month -aseptic loosening, (ii) I-212-32 month- infection, (iii) I -129-32 low-grade infection, (iv) Alloclassic Varial -new and (v) Lima Corporate-new (Ti6Al4V), were examined.

2.2. Methods

The morphology, microstructure, surface chemistry, and phase analysis of the samples of both Ti6Al7Nb and Ti6Al4V alloys, were investigated in the field-emission scanning electron microscope (ZEISS crossbeam 550 FIB-SEM Carl Zeiss AG, Oberkochen, Germany).

The instrument is equipped with secondary-electron (SE), backscattered-electron (BE) imaging modes for analyses of the morphology of the samples and energy-dispersive X-ray spectroscopy, EDS, (EDAX, Octane Elite, Draper, Cambridge, MA, USA) for the surface chemistry (to a depth of about 3 µm). For the SE and BE imaging an acceleration of 15 kV at a current of approximately 1.5 nA was used at a vacuum below 10−6 mbar.

For phase analysis and grain orientation, the instrument is equipped with an electron back-scattered diffraction analyzer, EBSD, with Hikari Super Plus camera with ApeX (Edax) software, and data analyzed in OIM (Edax).

The micro-threaded surface roughness of stem tapers was measured using the optical profilometer made by Alicona Infinite Focus G4 (Raaba-Grambach, Austria). Standard roughness parameters Ra - average surface roughness and Rz - mean peak to valley height of roughness profile were used for this investigation. Profile depth and peak spacing for different samples were also investigated. For all samples, the evaluation length was 2.67mm.

For corrosion rate measurement, an electrochemical study was performed in a simulated physiological Hank’s solution at 37 °C and pH = 7.8 using a BioLogic Modular Research Grade Potentiostat/Galvanostat/FRA Model SP-300 (BioLogic Science Instruments, Seyssinet-Pariset, France) with EC-Lab Software (EC-Lab V11.27). The experiments were carried out in a three-electrode cell where tested specimens were employed as the working electrode (WE), a saturated calomel electrode (SCE, 0.242 V vs. SHE) as the reference electrode (RE), and a platinum net as the counter electrode (CE). The samples were stabilized at the open-circuit potential (OCP) for 1 h before the electrochemical measurements were made. The potentiodynamic curves were measured with a scan rate of 1 mV s

-1 from -250 mV vs. SCE according to the OCP [

30].

All the measurements were repeated three times.

3. Results

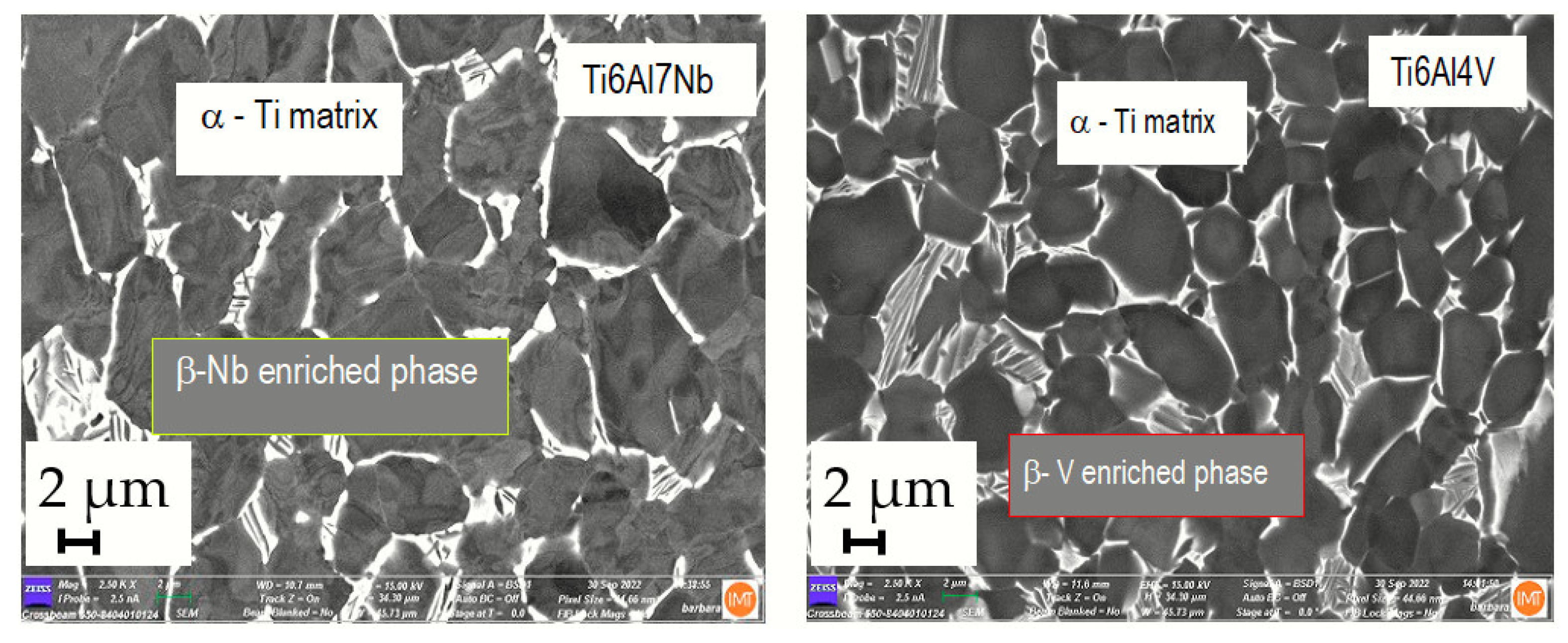

3.1. Microstructure of Ti6Al7Nb and Ti6Al4V Stem Tapers

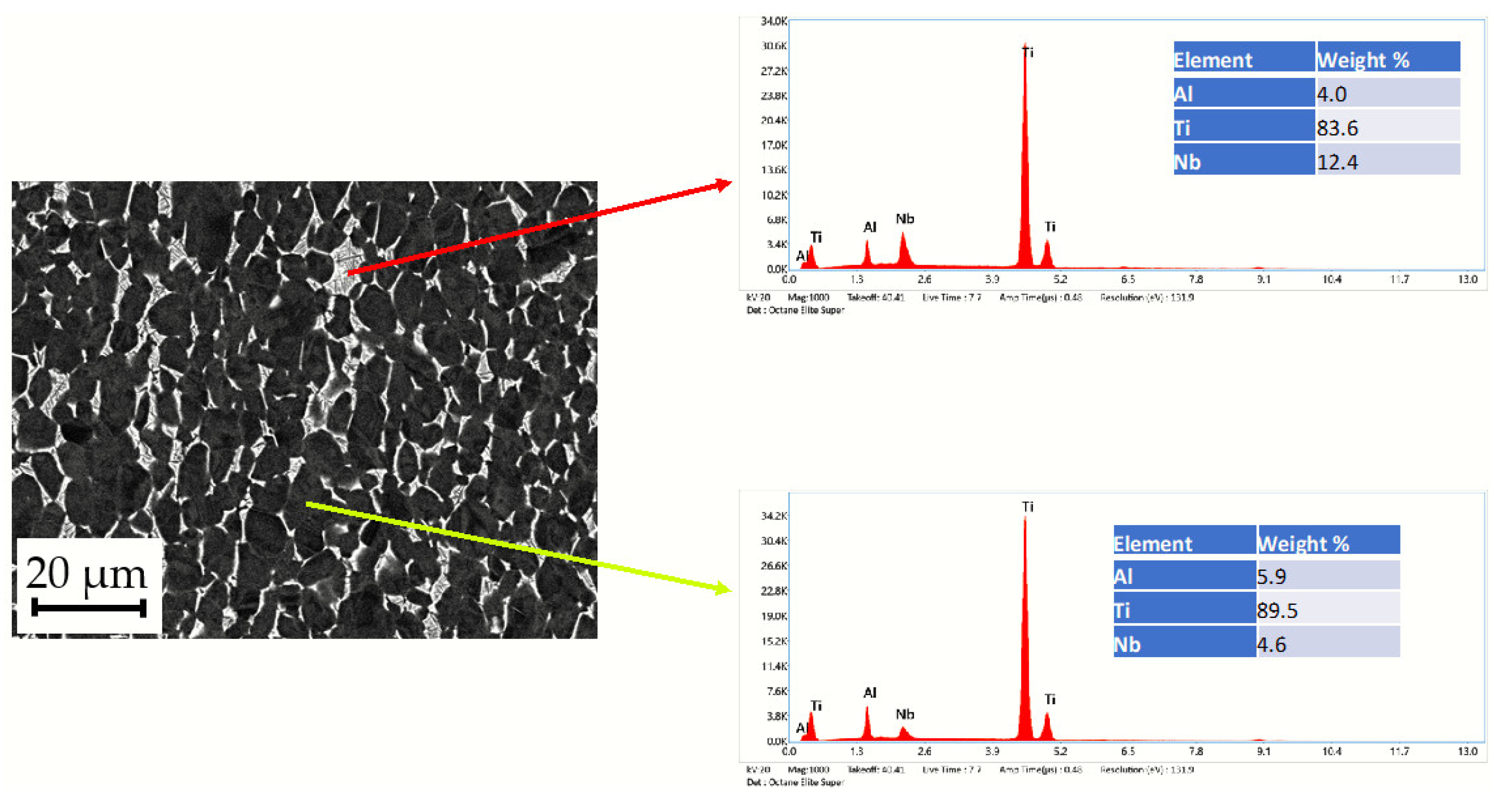

The microstructure of the stem taper of the implants manufactured from Ti alloys (Ti6Al7Nb and Ti6Al4V) is shown in

Figure 3. A dual-phase microstructure is observed in the matrix, Ti phase is α -Ti (dark grey) and the Nb-rich or V-rich phase (light grey) is β-Ti (

Figure 4). The dual-phase structure is confirmed using the EBSD method (

Figure 5).

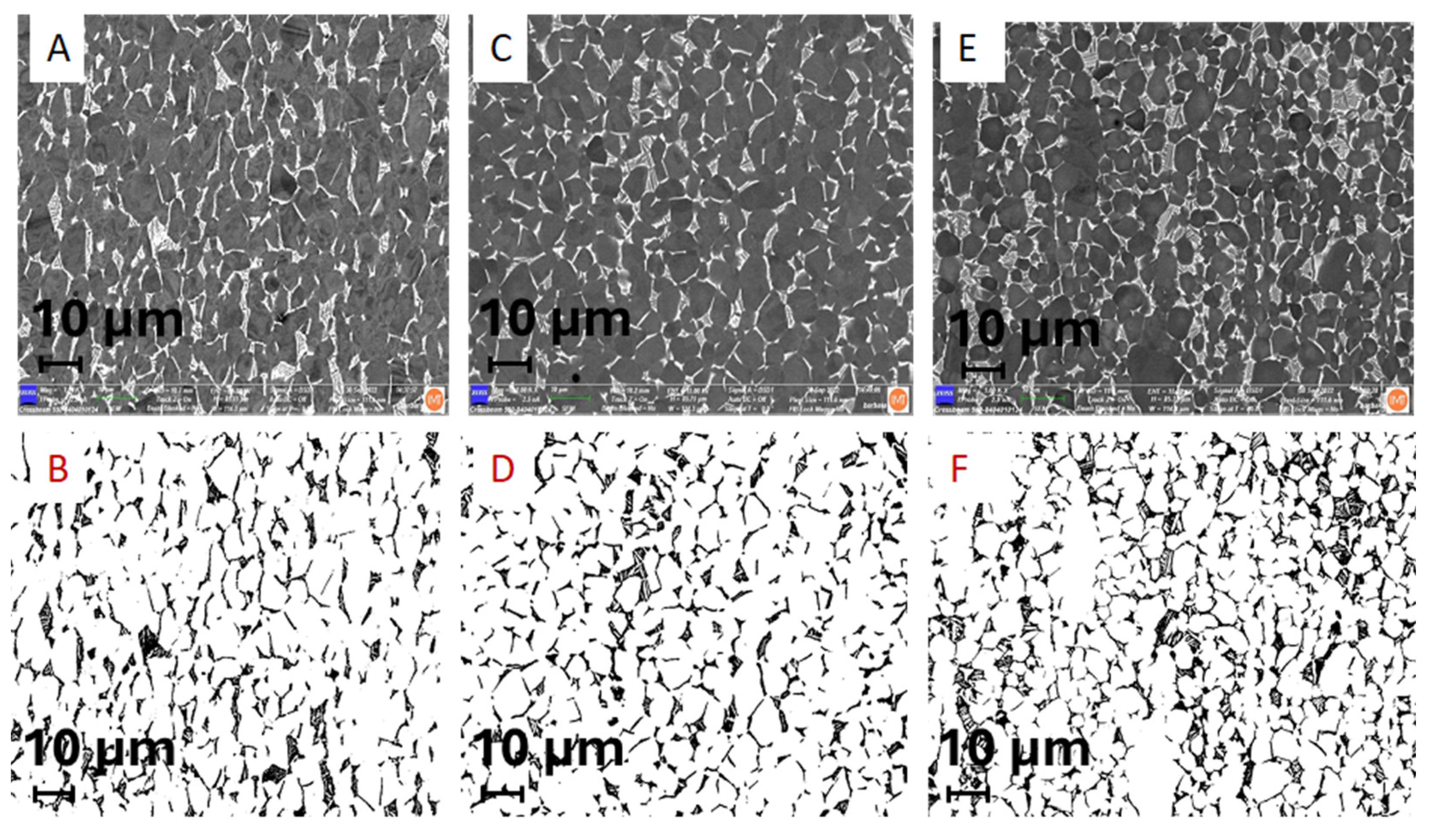

3.2. The Estimation of Microstructure- Alpha and Beta Phase Contents in Ti6Al7Nb and Ti6Al4V Alloys

Ti implant alloys have a dual-phase microstructure (α + β). Their distribution was estimated using a field emission scanning electron microscope by SE (secondary electron image) and BE (backscattered electron image. Results are shown in

Figure 4 and

Table 2.

The results of the microstructure analysis of selected retrieved and two new samples for comparison (

Table 2) showed that according to the standards [

32,

33] (ASTM F-1295 Ti6Al7Nb; and ASTM F-136 Ti6Al4V), the dominant phase, α phase (matrix), with 85 to 92 % and 8 to 15% β Nb enriched phase of retrieved samples and 79 to 89 α phase and 11 to 21% of β phase of new samples of the same alloy Ti6Al7Nb. We compared microstructure analysis with Ti6Al4V alloy where we found 84% α phase, matrix, and V-enriched β phase 16%. Of all the investigated samples, only the I-212 stem taper that prematurely failed after 3 months due to infection hip endoprostheses differs slightly in microstructure with the lowest Nb enriched β phase. Besides the material properties, such as microstructure, the survivorship, of cementless is very complex and depends on several factors such as the impact on surgeons, the patient, materials, contamination, etc.

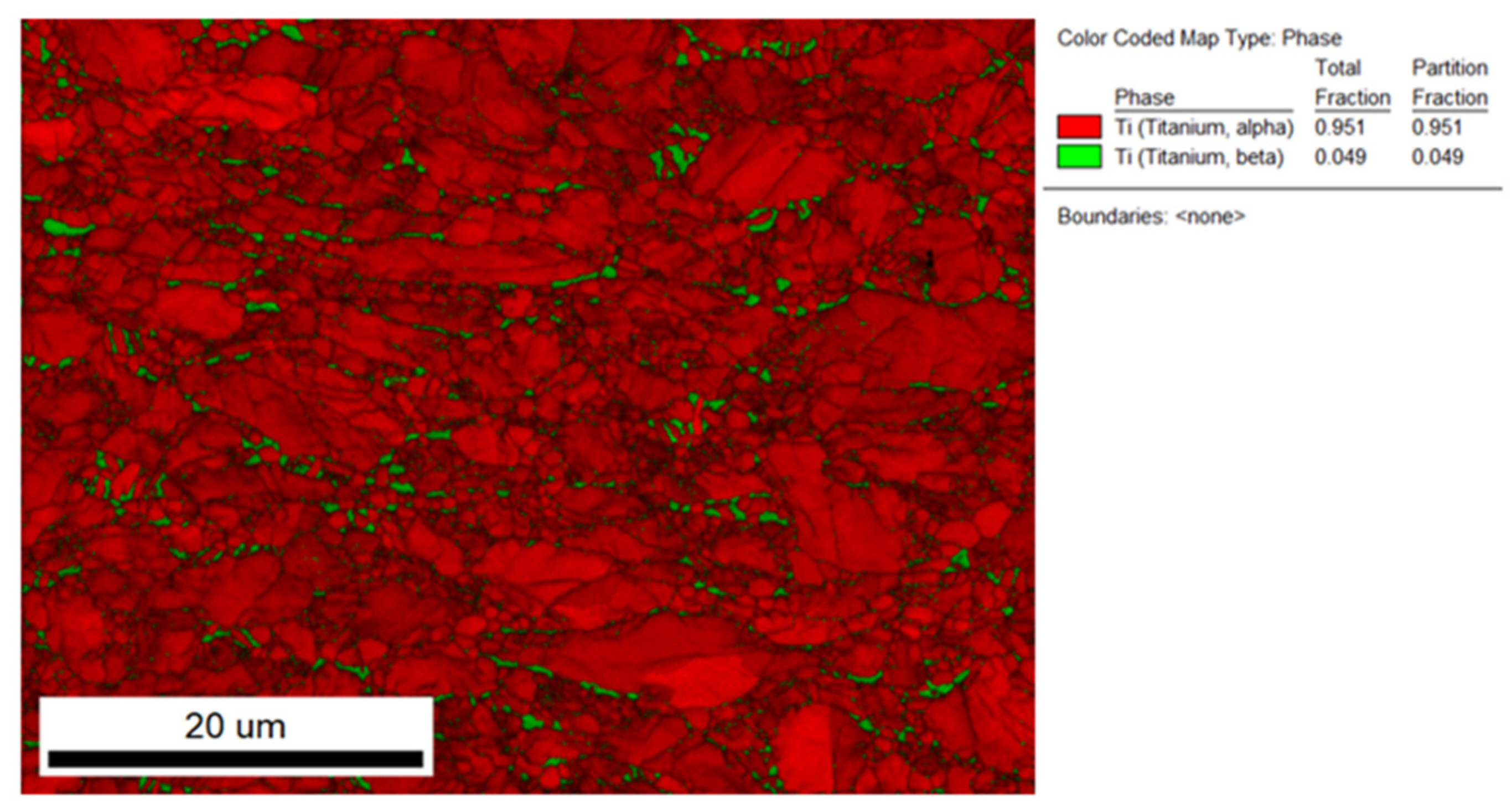

3.3. SEM/EBSD Characterization of Stem Taper Phase Microstructure

The quantitative determination of phase distributions in the new sample Ti6Al7Nb alloy is possible by using the electron-backscattered diffraction integrated technique on the field emission scanning electron microscope, EBSD, where the stem-taper microstructure is (α+β),

Figure 5. The EBSD method is compatible with the XRD method, but on a smaller scale and for that reason is mounted on the FE-SEM. The EBSD method is very precise, the limitation of EBSD besides being a very accurate, precise method, is that it is very time consuming, and for that reason is suitable for basic research and development of new biomaterial alloys.

The microstructures of all the investigated stem tapers manufactured from Ti6Al7Nb alloy are similar. We compared the stem-tapers microstructure of Ti6Al4V and found that the latter is more small-grained which is already known from several investigations [

17].

3.4. SEM / EDS Characterization of Stem-Taper New Implants Microstructure

Two new tapers were investigated for comparison with the retrieved, premature failed implants. The results were similar, so we represent one sample, with the longest survivorship A283 in

Figure 7.

The SEM/EDS images of the surface chemistry are shown in

Figure 7. The selected stem taper with a survivorship of 239 months, prematurely failed due to aseptic loosening. The typical (α + β) dual-phase Ti6Al7Nb alloy is shown in

Figure 7 a.

Figure 7 b shows the distribution of Ti in the sample, (c) EDS mapping shows the distribution of Al in the microstructure and (d) SEM/EDS mapping shows the distribution of Nb. We may conclude that the major dark grey phase is the Ti matrix, α-phase, and the light grey phase, enriched with Nb is the β-phase.

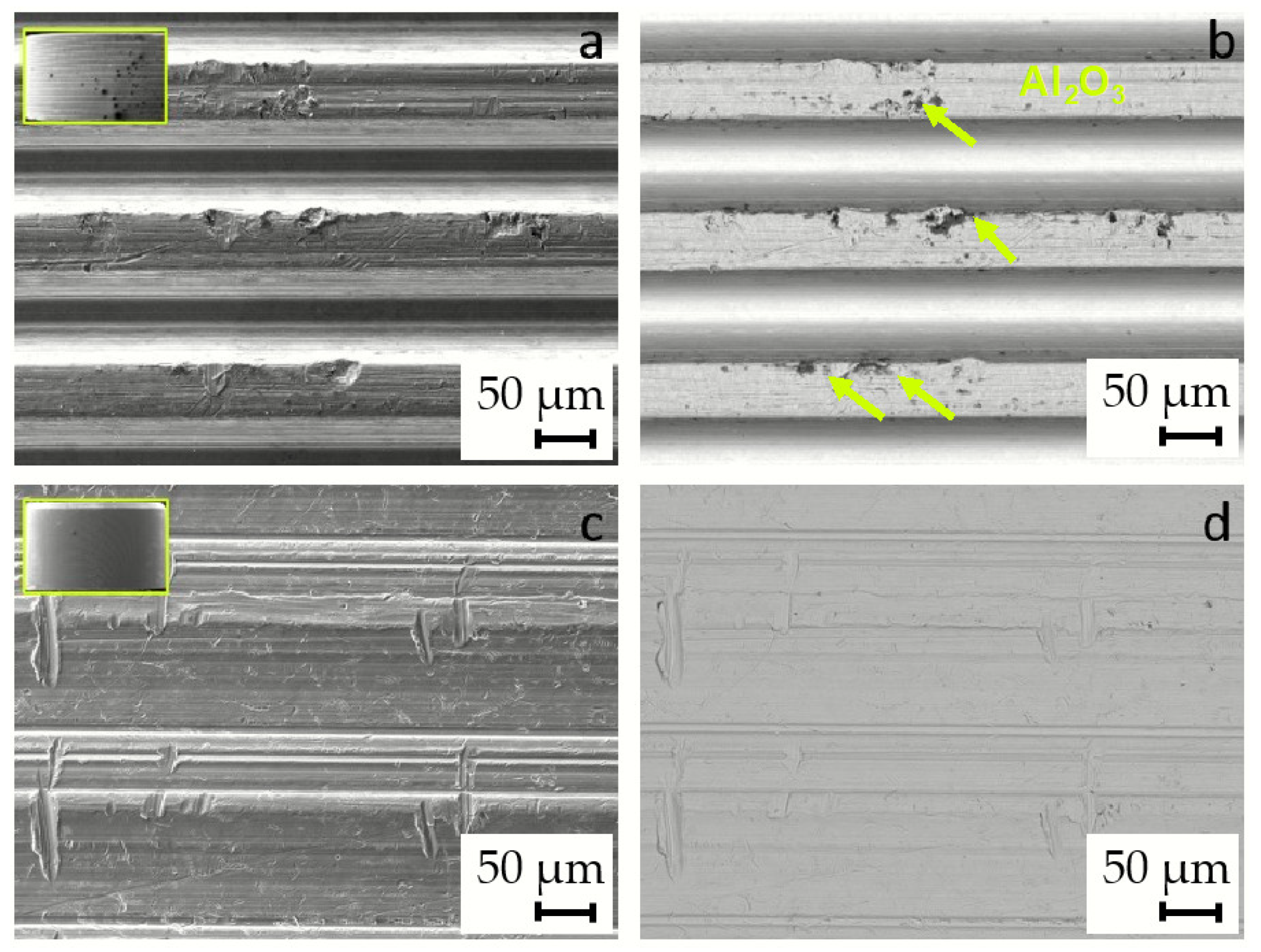

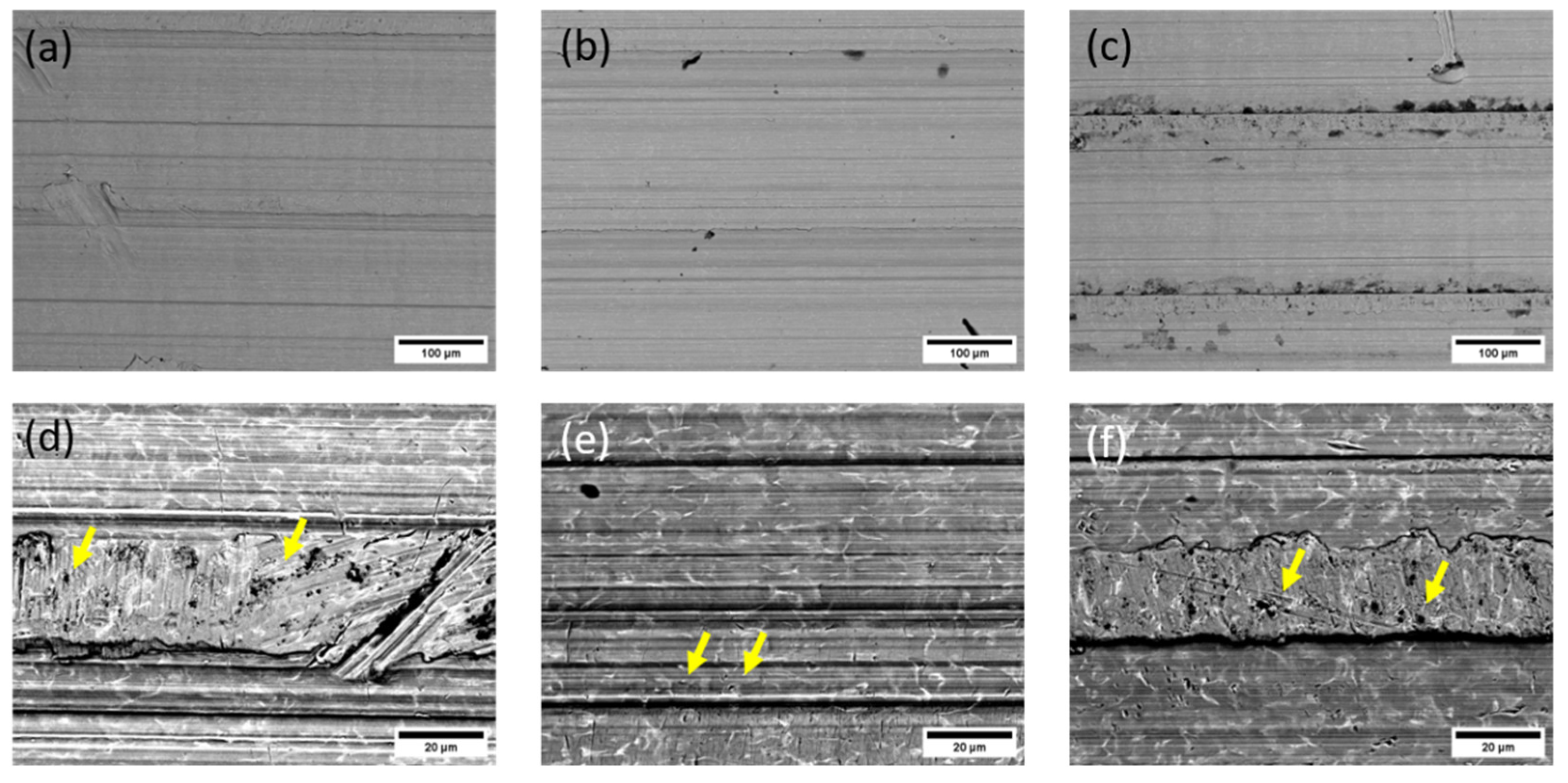

The images of the new, unused implants show some signs of abrasive damage and wear, which is attributed to the manufacturing process as seen in

Figure 8. Some dark particles are visible in the backscattered electron images (BE), in the case of the Alloclassic implant (

Figure 8(b)), while in the case of Lima Corporate implant taper, the surface seems rough, but no particles are visible in the (sub)surface area.

To identify the dark particles in the BE image of the Alloclassic taper part of the implant, we performed SEM/EDS mapping of a selected area. As is evident from the image in

Figure 9(b), the black particles are remnants of corundum (Al2O3) sandblasting that was performed as a finishing step in the taper manufacturing process. Additionally, the dual microstructure of the titanium alloy can be seen.

On the other hand, the new implant Lima Corporate, does not show larger dark particles that are visible in the backscattered electron image. The surface of the new implant nonetheless shows signs of abrasive wear, as is evident from

Figure 10.

The new, unused tapers of the implants do not have a smooth surface, in both cases, and there is evidence of deposited material (Al2O3) from sandblasting, and mechanical wear damage is visible in both cases. It has been shown that corundum Al2O3 sandblasting remains from the process and affects the corrosion properties and can lead to an increased number of infections [

11,

12].

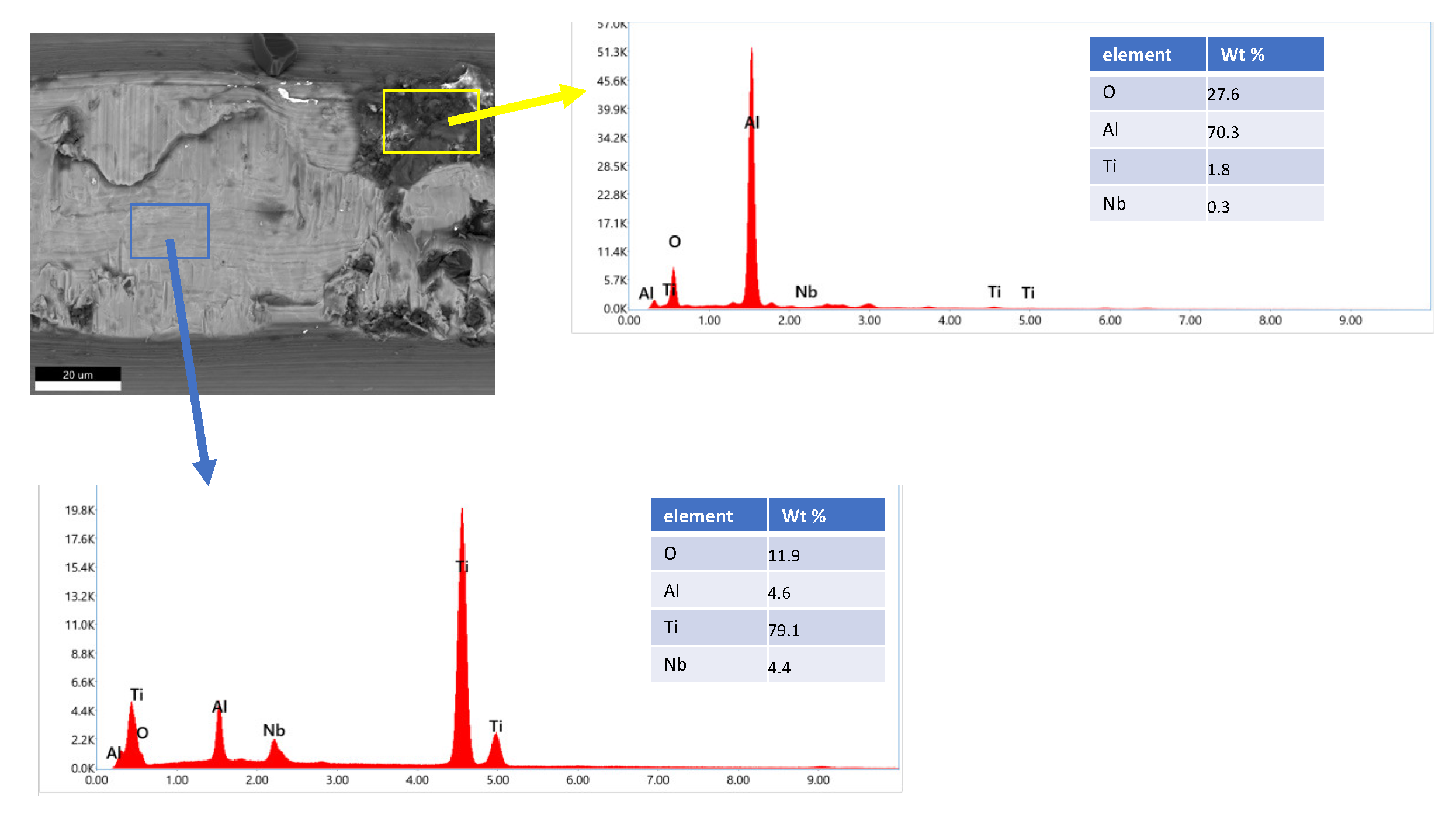

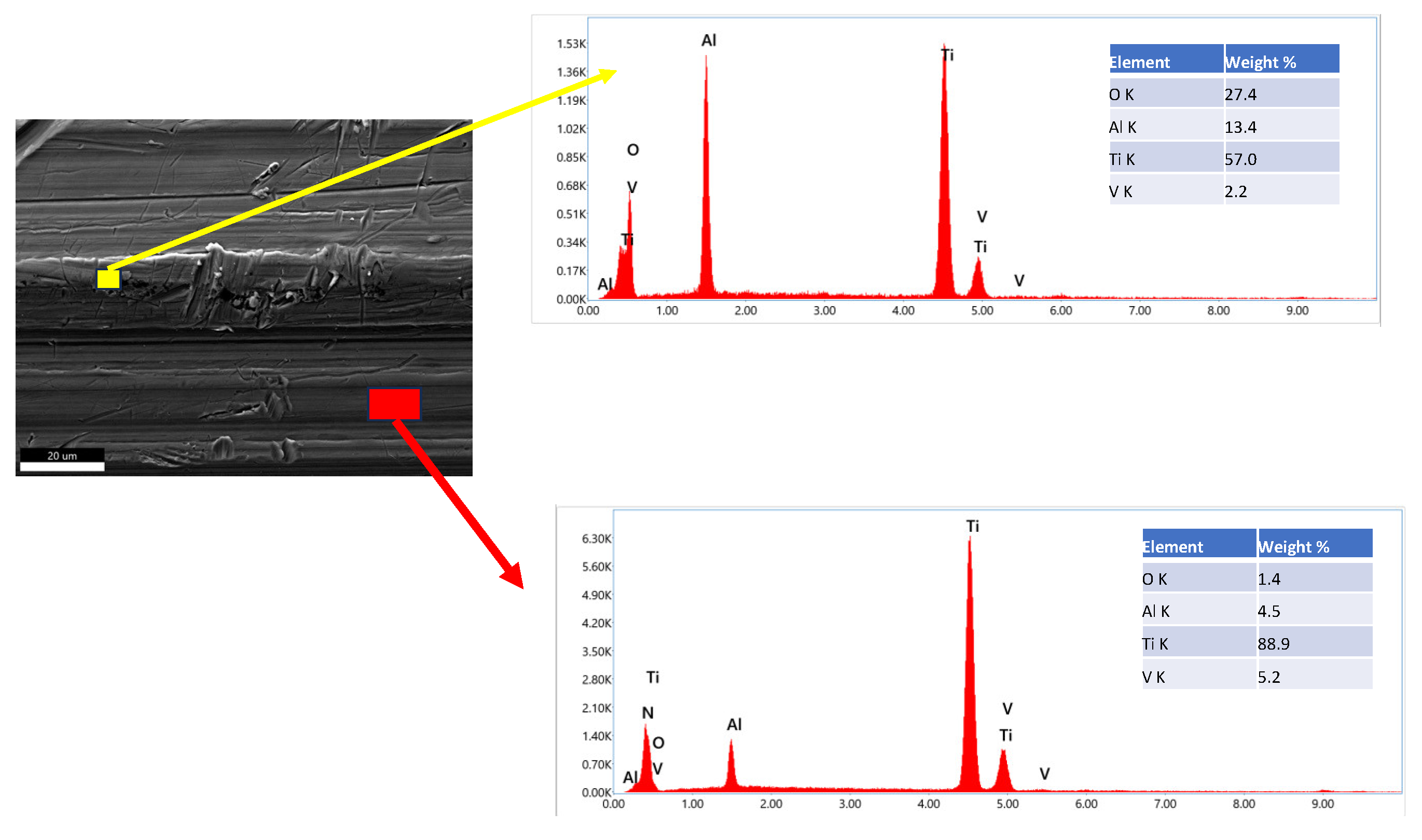

3.5. SEM /EDS Characterization of Prematurely Failed Implants

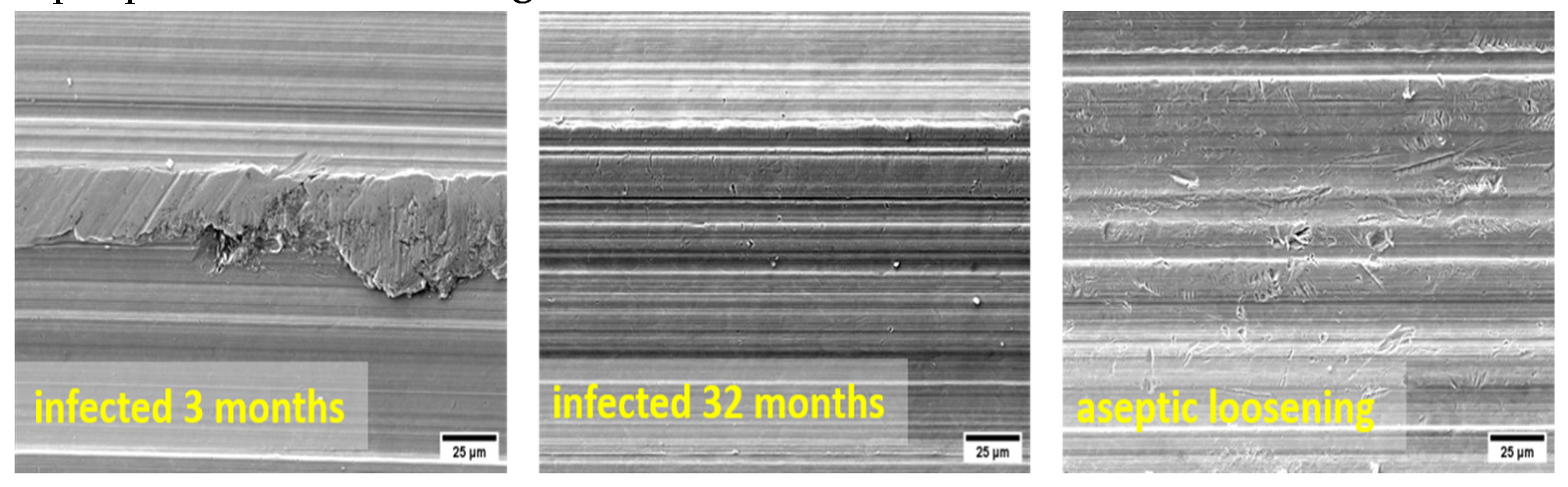

Three failed implants were chosen for examination with SEM/EDS. Two implants prematurely failed due to infection, the first one after 32 months and the second after 129 months, while the third implant failed because of aseptic loosening after 239 months. The images of the surfaces of the implant taper parts are shown in

Figure 11.

The surfaces of prematurely failed implants show signs of abrasive wear, like the new, unused implants, mainly due to machining and further sandblasting, as seen in

Figure 12 and

Figure 13. No cracks or oxidation products are visible on the implant surfaces. Additional abrasive wear (most prominent in the case of the implant that failed due to aseptic loosening) could also be attributed to the revision surgery.

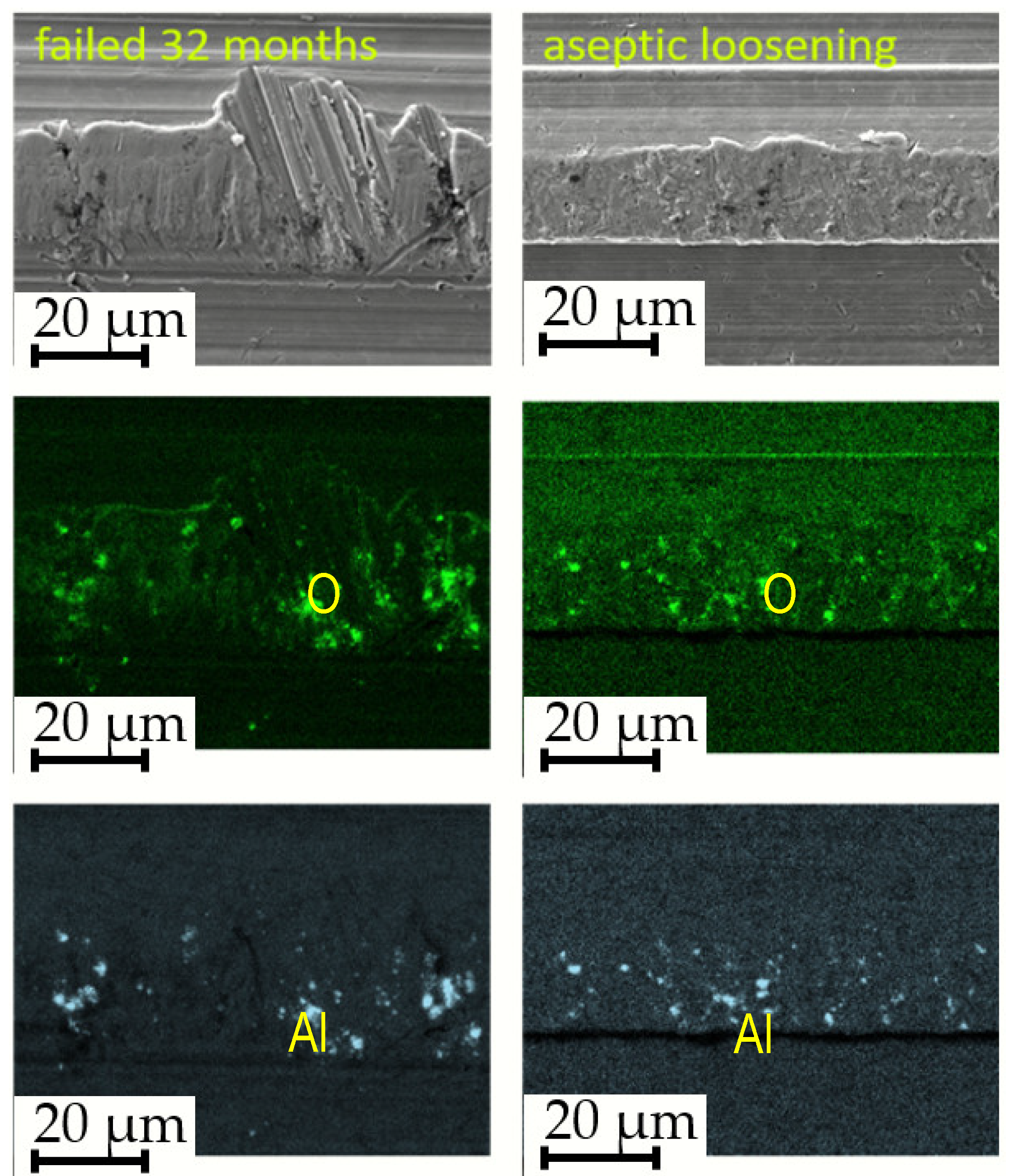

EDS mapping showed that there are some remnants of corundum in the subsurface layers of the failed implants, as is seen in

Figure 12. The corundum remains are clustered, and the particle sizes are up to approximately 10 µm in diameter, with a similar distribution compared to the new Lima implants. No large particles (such as in the case of a new Alloclassic implant) were found on the examined surfaces of the failed implants. This is most evident from large-scale backscattered electron images, shown in

Figure 13, upper panel. Only at higher magnification (lower panel of

Figure 13, it is possible to distinguish individual clusters of small embedded corundum particles. In all implants, no signs of corrosion or cracks due to fretting were observed.

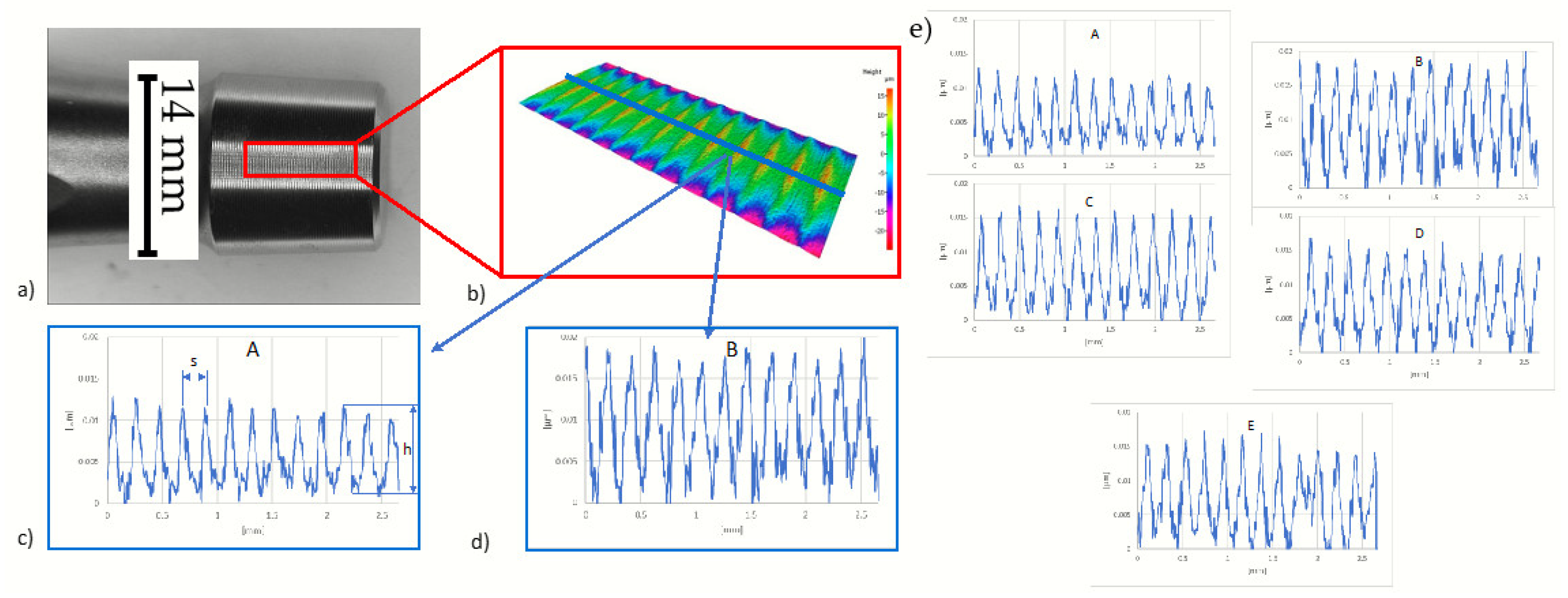

3.6. Stem Taper Morphology, Surface Roughness

Five samples were investigated, in

Table 3, samples 1 to 5, two new (Alloclasic Varial -AV, and Lima corporate), and three retrieved (A-283, I-212, and I-031) with different survivorships from 3 to 239 months. Roughness profiles of stem tapers were obtained from the surface of the taper as seen in

Figure 2. Peak spacing - s and profile depth – h (

Figure 2c) also measured for comparison. As can be seen from

Table 3, there is no significant difference in roughness associated with a longer time of use. New samples AV and Lima have the lowest and highest values of Ra and Rz values. Samples AV and Lima also have different profile depths of the peaks (

Figure 2 c and 2d). Sample AV has an average depth of 9.3 and sample Lima 14.4 μm. (

Table 3). This can be attributed to different manufacturers and thus different manufacturing methods. Retrieved samples on the other hand result in slightly lower values of surface roughness and profile depth which can contribute to the deformation of the peaks. Results of surface roughness indicate that the three retrieved samples (A-238, I-212, and I-031) were manufactured using the same or similar method as sample Lima.

3.7. Corrosion Properties of Investigated New and Retrieved Stem Taper Samples.

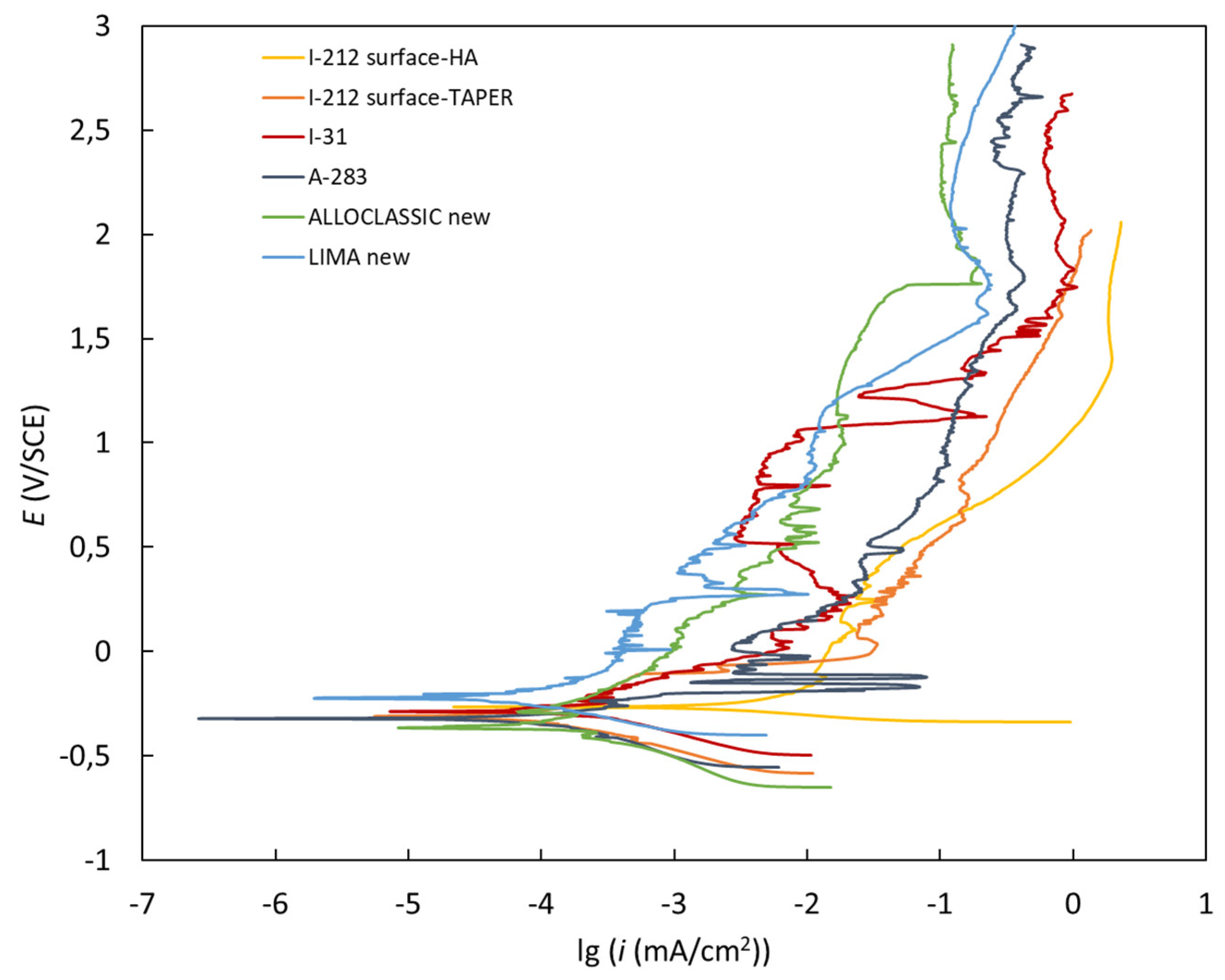

The potentiodynamic behaviour of the investigated materials in Hank’s solution is shown in

Figure 15. All the investigated materials exhibited a broad range of passivation after the Tafel region due to the formation of a compact outer passive film, which inhibits the diffusion of aggressive species and therefore improves the corrosion properties of the material [

30,

32,

33]. The corrosion potentials (

Ecorr), corrosion current densities (

icorr) and corrosion rates (

vcorr) are listed in

Table 4. The results show that the corrosion rates for both the new samples and the one with the longest exposure to real-body conditions were lower compared to the other three with shorter exposure times. The implants with shorter exposure times to real-body conditions were all subjected to infection, which is probably related to the formation of conditions that are detrimental to corrosion. In contrast, new implants with an intact surface as well as the implant with the longest survival in real-body conditions showed an increased corrosion resistance.

4. Discussion

This study investigated the damage that occurred in vivo on Ti-alloy micro-threaded 12/14 tapers. The in vivo damage in secondary implants with ceramic heads was compared with the new implants. Qualitative and quantitative evaluations were carried out on 45 retrievals.

Every modular connection of metal alloys in contact with body fluids and exposed to micromotion is subject to corrosion. The taper’s interface is influenced by several factors, such as (i) design and material, (ii) assembly (surgical factors), and (iii) loading (patient factors).

Mueller et al. demonstrated that stem taper characteristics largely differ between manufacturers [

4].

The assembly condition plays an important role in the strength of the taper’s connection. Minimal invasive surgery with small incisions might indirectly be associated with the frequency of the taper’s corrosion due to the challenges in cleaning the taper and applying appropriate assembly forces in the taper’s direction.

We investigated retrievals provided by the Department for Orthopaedic Surgery of UMC Ljubljana, Slovenia in which the only source of modularity with a metallic component was the ceramic head stem-taper interface.

We investigated the corrosion resistance using electrochemical studies and there was no corrosion of the retrieved tapers that prematurely failed due to aseptic loosening after 239 months, infection after 3 months, and low-grade infection after 32 months. Further, three retrieved tapers and, for comparison, two new tapers were exposed to potentiodynamic measurements in Hank’s solution. The results show very low corrosion rates for both new samples (Zimmer, Lima Corporate) and the retrieved sample that prematurely failed due to aseptic loosening after 239 months. The corrosion rates of the infected and low-grade infected tapers were higher. We observed small differences in the microstructure within the limits of the standards [

17]. The microstructure is very important for minimizing corrosion and bio-tribo-corrosion, taper corrosion, etc., which can lead to aseptic loosening or joint infection, the main causes of failure with joint arthroplasty.

This study has some limitations. The ceramic femoral heads were not investigated in this study and no statement can be made about the material transfer from taper to ceramic head that can occur. However, Stockhausen reported that both fretting and corrosion scores in the head and the neck are correlated, making neck scores a good indicator of degradation in the head [

2,

3].

In our investigation we didn’t observe taper corrosion, fretting, and crevice corrosion due to the use of ceramic heads with a dominant head size of 32 mm, which agrees with the published results [

3,

4,

10] and the fact that the Slovenian hospital protocol requires carefully cleaned, rinsed, and dried taper stems before assembly.

Furthermore, corrosion of metal alloys always occurs in the human body due to the aggressive environment, but it does not necessarily become a clinical problem if the amount of corrosion is small. [

4,

34,

35,

36,

37,

38,

39,

40,

41].

5. Conclusion

This study demonstrated that the 12/14 investigated tapers are not uniform, and the stem and head tapers are manufactured specifically in terms of geometry as well as topography at different manufacturers as well as from the same manufacturer.

In our study of different stems from prematurely failed cementless hip endoprostheses regarding the geometry, high variations in taper length were observed whereas the taper angle and opening taper diameter vary only to a small degree.

In our study we didn’t observe taper corrosion, fretting, and crevice corrosion due to the use of ceramic heads with a dominant head size of 32 mm, which agrees with the published results and the fact that the hospital protocol requires carefully cleaned, rinsed, and dried taper stems before assembly.

Moreover, within the human body, metal alloys inevitably undergo corrosion owing to the hostile physiological environment. However, the clinical significance of this corrosion is not inevitable, contingent upon the extent of its occurrence.

Ultimately, the results from this study provide relevant taper design characteristics of new components, which can also serve as a reference for retrieval studies describing the initial state for experimental studies of taper corrosion.

It is obvious that further investigations of the influence of stem tapers of ZM cementless hip endoprostheses on the biological response are needed and the dimensions of the stem taper as well as materials are not standardized and vary between manufacturers. Therefore careful and precise assembly of the femoral component and ceramic acetabular heads is required/ very important.

Author Contributions

Conceptualization, M.J.; D.D., M.G.; B.K.; M.D.; B.S-B.; methodology, M.J.; D.D.; M.G.; A.K.; B.S-B.;.JTG, formal analysis, B.S-B; A.K.; investigation, M.G.; resources, M.J.; M.G., writing—original draft preparation, M.J.; M.D., writing—review and editing, M.D.; D.D.; M.G.; B.K., JTG supervision, D.D.; project administration, M.J., M.G. funding acquisition, M.J.and D.D., M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Slovenian Research Agency, ARIS, L3-2621, and the Department for Orthopedic Surgery UMC, Ljubljana, Slovenia, Tertiary projects: TP No. 20220103 and TP No. 20230194.

Conflicts of Interest

Declare conflicts of interest or state “The authors declare no conflict of interest.”

References

- Kurtz, S.; Ong, K.; Lau, E.; Mowat, F.; Halpern, M. Projections of primary and revision hip and knee arthroplasty in the United States from 2005 to 2030. J. Bone Joint Surg. Am. 2007, Volume 89, pp.780–785. [CrossRef]

- Stockhausen, K.E.; Riedel., C.; Belinski, A.V.; Rothe, D.; Gehrke, T.; Klebig, F.; Gebauer, M.; Amling, M.; Citak, M.; Bussel, B. Variability in stem taper surface topography affects the degree of corrosion and fretting in total hip arthroplasty, Scientific Reports | (2021) 11:9348 | . [CrossRef]

- Morlock, M.M.; Hube, R.; Wassilew, G.; Prange, F.; Huber, G.; Perka,C.; Taper corrosion: a complication of total hip arthroplasty, EOR, 2020, Volume 5, pp. 776-784. [CrossRef]

- Mueller, U.; Braun, S.; Schroeder, S.; Sonntag,R.; J. Philippe Kretzer, J.P. Same Same but Different? 12/14 Stem and Head Tapers in Total Hip Arthroplasty, The Journal of Arthroplasty 2017, 32, 3191-3199. [CrossRef]

- Cales,B.; Stefani, Y. Risks and advantages in standardization of bores and cones for heads in modular hip prostheses, Journal of Biomedical Materials Research, First Published: 31 July 2002. [CrossRef]

- Martelli, A.; Erani, P.; Pazzagli, N.; Cannillo, V.; Baleani, M. Surface Analysis of Ti-Alloy. Micro-Grooved 12/14 Tapers Assembled to Non-Sleeved and Sleeved Ceramic Heads. A Comparative Study of Retrieved Hip Prostheses. Materials 2023, 16, 1067. [CrossRef]

- Merola, M., Affatato, S., Review Materials for Hip Prostheses. A Review of Wear and Loading Considerations. Materials 2019, Volume 12, pp. 495. [CrossRef]

- Cör, A., Histological Picture of the Wear Particles, and the Biological Response in Periprosthetic Tissue, MTAEC9, 53(1)77(2019). [CrossRef]

- Kocjančič B.; Avsec, K.; Šetina Batič, B.; Feizpour, D.; Godec, M.; Kralj-Iglič, V.; Podlipec, R.; Cör, A.; Debeljak, M.; Grant, J.T.; et al. The Impact of Al2O3 Particles from Grit-Blasted Ti6Al7Nb (Alloy) Implant Surfaces on Biocompatibility,Aseptic Loosening, and Infection. Materials 2023, 16, 6867. [CrossRef]

- Jan, Z., Hočevar, M., Kononenko, V., Michelini, S., Repar, N., Caf, M., Kocjančič, B., Dolinar, D., Kralj, S., Makovec, D., Iglič, A., Drobne, D., Jenko, M., Kralj-Iglič, V. Inflammatory, oxidative stress and small cellular particle response in HUVEC induced by debris from endoprosthesis processing. Materials. 2023, vol. 16, iss. 9, str. 1-17, ilustr. ISSN 1996-1944. . [CrossRef]

- Dolinar, D.; Gorenšek, M.; Jenko, M.; Godec, M.; Šetina, B.; Donik, Č.; Kocijan, A.,; Debeljak, M.; Kocjančič, B.; Biomaterials in endoprosthetics. Materiali in tehnologije, 2018, Volume 52, 1, pp. 89-9. [CrossRef]

- Savin, L.; Pinteala, T.; Mihai, D.N.; Mihailescu, D.; Miu, S.S.; Sirbu, M.T.; Veliceasa, B.; Popescu, D.C.; Sirbu, P.D.; Forna, N. Updates on Biomaterials Used in Total Hip Arthroplasty (THA). Polymers 2023, 15,3278. [CrossRef]

- Jenko,M.; Gorenšek, M.; Godec,M.; Hodnik,M.; Setina Batic, B.; Donik, C.; Grant,J.T.; Dolinar, D. Surface chemistry and microstructure of metallic biomaterials for hip and knee endoprostheses. Applied Surface Science 2018, Volume 427A, pp. 584-593. doi.org/10.1016/j.apsusc.2017.08.007.

- Avsec, K.; Jenko, M.; Conradi,M.; Kocijan, A.; Vesel,A.; Kovač, J.; Godec, M.; Belič, I.; Šetina; B.; Donik, C.; Gorenšek, M.;, Kocjančič, B.; Dolinar,D. Surface properties of retrieved cementless femoral hip endoprostheses produced from a Ti6Al7Nb alloy. Coatings. 2019, Volume 9, 12, pp. 1-15. [CrossRef]

- Urish,K.L, Giori,N.J., Lemons, J.E., Mihalko, W.M., Hallab,N. Trunnion corrosion in Total Hip Arthroplasty, Basics concepts, Orthop. Clin North Am. 2019 July 50(3):281-288. [CrossRef]

- Avsec, K.; Conradi, M.; Jenko, M.; Kocjančič, B.; Debeljak, M.; Gorenšek, M.; Dolinar, D. Effect of sterilization on the surface properties of Ti6Al7Nb alloy femoral stems Materiali in tehnologije 2021, Volume 55, 1, pp. 59-64. [CrossRef]

- Roškar, S.; Antolič, V.; Mavčič, B. Surgeon-stratified cohort analysis of 1976 cementless Zweymüller total hip arthroplasties from a single hospital with 23,255 component years of follow-up. Archives of orthopaedic and trauma surgery, 2020, Volume 140, pp. 1275-1283. [CrossRef]

- Soliman, M.M.; Chowdhury, M.E.H.; Islam, M.T.; Musharavati, F.; Mahmud, S.; Hafizh, M.; Ayari, M.A.; Khandakar, A.; Alam, M.K.; Nezhad, E.Z. Design and Performance Evaluation of a Novel Spiral Head-Stem Trunnion for Hip Implants Using Finite Element Analysis. Materials 2023, 16, 1466. [CrossRef]

- Urish,K.L, Giori,N.J., Lemons, J.E., Mihalko, W.M., Hallab,N. Trunnion corrosion in Total Hip Arthroplasty, Basics concepts, Orthop. Clin North Am. 2019 July 50(3):281-288. [CrossRef]

- Cooper,J.; Della Valle, C. J. ; Berger R. A.; et al. Corrosion at the head-neck taper as a cause for adverse local tissue reactions after total hip arthroplasty. Journal of Bone and Joint Surgery— American Volume, 2012, Volume 94, 18, pp.1655–1661. [CrossRef]

- Godoy, M., Sipek, K., Gustafson, J.A.; Yuh, C.; Levine, B.R.; Pourzal,R.; Hannah J. Lundberg, H. J. Effect of Femoral Head Material, Surgeon Experience, and Assembly Technique on Simulated Head-Neck Total Hip Arthroplasty Impaction Forces, The Journal of Arthroplasty 2024, 39, 507-513 . [CrossRef]

- Bitar, D.; Parvizi, J.; Biological response to prosthetic debris, World J. Orthop 6, 2015, Volume 2, pp. 172-189. [CrossRef]

- Porter DA, Urban RM, Jacobs JJ, Gilbert JL, Rodriguez JA, Cooper HJ. Modern trunnions are more flexible: mechanical analysis of THA taper designs. Clin Orthop Relat Res 2014; Volume 472, pp. 3963–3970. [CrossRef]

- C. Sittig,C.; Textor, M.; Spencer, N.D.; Wieland, M.; Vallotton P.H. Surface characterization of implant materials cp Ti, Ti-6Al-7Nb and Ti-6Al-4 V with different pretreatments. J. Mater. Sci. Med., 10 (1999), pp. 35-46. [CrossRef]

- Raphel,J.; Holodniy, M.; Goodman, S.B. ; Heilshor, S.C. Multifunctional coatings to simultaneously promote osseointegration and prevent infection of orthopaedic implants. Biomaterials 2016, Volume 84 pp. 301-314.

- 26. doi: 10.1016/j.biomaterials.2016.01.016. [CrossRef]

- ASTM G102 – 89 (2015) Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements. Available online: https://www.astm.org/Standards/G102 (accessed on 10 February 2024).

- Jauch SY, Coles LG, Ng LV, Miles AW, Gill HS. Low torque levels can initiate a removal of the passivation layer and cause fretting in modular hip stems. Med Eng Phys 2014; 36:1140–1146. [CrossRef]

- 1295; 29. ASTM F- 1295 Standard Ti6Al7Nb Standard Specification for Wrought Titanium-6Aluminum-7Niobium Alloy for Surgical Implant Applications (UNS R56700).

- 2021; 30. ASTM F-136 -13 (2021) Standard Ti6Al4V Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401).

- Lutzner J, Gunther KP, Postler A, Morlock M. Metal ion release after hip and knee arthroplasty - causes, biological effects, and diagnostics. Z Orthop Unfall 2020 Aug;158:369 382 . [CrossRef]

- Del Balso C, Teeter MG, Tan SC, Howard JL, Lanting BA. Trunnionosis: does head size affect fretting and corrosion in total hip arthroplasty? J Arthroplasty 2016;31: 2332–2336. [CrossRef]

- Osman K, Panagiotidou AP, Khan M, Blunn G, Haddad FS. Corrosion at the head-neck interface of current designs of modular femoral components: essential questions and answers relating to corrosion in modular head-neck junctions. Bone Joint J 2016;98– B:579–584. [CrossRef]

- Kurtz, S. M. et al. Do ceramic femoral heads reduce taper fretting corrosion in hip arthroplasty? A retrieval study. Clin. Orthop. Relat. Res. 471, 3270–3282 (2013). [CrossRef]

- Kocagoz, S.B.; Underwood, R.J., MacDonald, D.W., Gilbert, J.L., , S.M. Ceramic Heads Decrease Metal Release Caused by Head-taper Fretting and Corrosion. Clin Orthop Relat Res. 2016 Apr; 474(4): 985–994. [CrossRef]

- Pezzotti, G. Affatato ,S.; Rondinella,A., Yorifuji M, Marin, E.; Zhu, W.; McEntire,B.; Bal, S.B.; Yamamoto,K., et al. In vitro versus in vivo phase instability of zirconia-toughened alumina femoral heads: a critical comparative assessment. Materials (Basel). 10, (2017). [CrossRef]

- Hallab, N.J. Fretting Corrosion of Orthopedic Implants. Comprehensive Biomaterials II, 2017 Volume 7, pp. 106-117.

- Hothi, H.S.; Panagitopoulos A.C.; Whittaker, R.K.; Bills, P.J., McMillan, R.; Skinner,J.A.; Hart, A.J.; Damage patterns at the head-stem taper junction helps understand the mechanisms of material loss, The Journal of Arthroplasty 2017, Volume 32,291e295292. [CrossRef]

- Dyrkacz, R. M. R., Brandt, J.-M., Ojo, O. A., Turgeon, T. R. & Wyss, U. P. The influence of head size on corrosion and fretting behaviour at the head-neck interface of artificial hip joints. J. Arthroplasty 28, 1036–1040 (2013). [CrossRef]

- Bechstedt, M. et al. Contact conditions for total hip head-neck modular taper junctions with micro-grooved stem tapers. J. Biomech. 109689 (2020).

- Rehmer, A., Bishop, N. E. & Morlock, M. M. Influence of assembly procedure and material combination on the strength of the taper connection at the head-neck junction of modular hip endoprostheses. Clin. Biomech. (Bristol, Avon) 27, 77–83 (2012).

Figure 1.

The measured taper characteristics are proximal female and distal male diameters, contact length, and total length, as shown for a stem taper at the left. The investigated cementless hip stems from different manufacturers. 1-SL-Plus, Smith & Nephew, 2-Alloclassic Varial Zimmer, 3-Alloclassic Zweymüller Zimmer, 4-Adler Ortho Modula, and 5- Lima corporate ZM C2.

Figure 1.

The measured taper characteristics are proximal female and distal male diameters, contact length, and total length, as shown for a stem taper at the left. The investigated cementless hip stems from different manufacturers. 1-SL-Plus, Smith & Nephew, 2-Alloclassic Varial Zimmer, 3-Alloclassic Zweymüller Zimmer, 4-Adler Ortho Modula, and 5- Lima corporate ZM C2.

Figure 2.

(A) micro threaded 12/14 stem taper, new Smith & Nephew, (B-F): 11x magnification SEM/SE images of different ZM 12/14 tapers and different manufacturers: (B) Alloclasic Varial new, (C) Lima new, (D) retrieved I-212-32-month, Smith & Nephew, (E) retrieved I-31-129-month, Smith & Nephew, and (F) retrieved A383-239 month, Endoplus.

Figure 2.

(A) micro threaded 12/14 stem taper, new Smith & Nephew, (B-F): 11x magnification SEM/SE images of different ZM 12/14 tapers and different manufacturers: (B) Alloclasic Varial new, (C) Lima new, (D) retrieved I-212-32-month, Smith & Nephew, (E) retrieved I-31-129-month, Smith & Nephew, and (F) retrieved A383-239 month, Endoplus.

Figure 3.

SEM/BE image of Ti6Al7Nb alloy microstructure (A283). It consists of two phases (α+ β). α -phase (dark) represents the matrix which has a close-packed hexagonal crystal structure (hcp), and the β -Nb-enriched β phase (white) in the body-centered cubic structure. (b) SEM/BE image of Ti6Al4V alloy microstructure of new Lima stem. α -phase (dark) represents the matrix, β phase V-enriched phase (white) at M2500.

Figure 3.

SEM/BE image of Ti6Al7Nb alloy microstructure (A283). It consists of two phases (α+ β). α -phase (dark) represents the matrix which has a close-packed hexagonal crystal structure (hcp), and the β -Nb-enriched β phase (white) in the body-centered cubic structure. (b) SEM/BE image of Ti6Al4V alloy microstructure of new Lima stem. α -phase (dark) represents the matrix, β phase V-enriched phase (white) at M2500.

Figure 4.

(A-B) BE/SE image of dual phase microstructure (α + β) and their distribution of a stem taper retrieved after 239 months (ENDOPLUS, London, UK) prematurely failed due to aseptic loosening Ti6Al7Nb alloy A-283, M1000; (C-D) SEM/BE image of dual phase microstructure (α + β) and phase distribution in stem taper prematurely failed after 3 months due to infection, I-31 Smith & Nephew (London, UK), M1000, (E-F) SEM/BE image of dual phase microstructure α + β and their distribution of new stem taper Lima, made of Ti6Al4V alloy, M1000 β-phase in the row below(b, d, e) is black. The amount of α (Ti, Al, O, N, matrix) and β (Nb or V enriched phase) is represented in

Table 2.

Figure 4.

(A-B) BE/SE image of dual phase microstructure (α + β) and their distribution of a stem taper retrieved after 239 months (ENDOPLUS, London, UK) prematurely failed due to aseptic loosening Ti6Al7Nb alloy A-283, M1000; (C-D) SEM/BE image of dual phase microstructure (α + β) and phase distribution in stem taper prematurely failed after 3 months due to infection, I-31 Smith & Nephew (London, UK), M1000, (E-F) SEM/BE image of dual phase microstructure α + β and their distribution of new stem taper Lima, made of Ti6Al4V alloy, M1000 β-phase in the row below(b, d, e) is black. The amount of α (Ti, Al, O, N, matrix) and β (Nb or V enriched phase) is represented in

Table 2.

Figure 5.

EBSD image of Ti6Al7Nb new sample. α phase is Ti matrix in hcp structure, red, and with Nb enriched β phase, bcc structure green.

Figure 5.

EBSD image of Ti6Al7Nb new sample. α phase is Ti matrix in hcp structure, red, and with Nb enriched β phase, bcc structure green.

Figure 7.

(a) SEM/BE image of A-283, Ti6Al7Nb alloy, stem-taper of the hip endoprosthesis, survivorship 239 months, aseptic loosening, microstructure dual phase is observed (b) Ti X-ray signal intensity, (c) Al X-ray signal intensity, (d) Nb X-ray signal intensity.

Figure 7.

(a) SEM/BE image of A-283, Ti6Al7Nb alloy, stem-taper of the hip endoprosthesis, survivorship 239 months, aseptic loosening, microstructure dual phase is observed (b) Ti X-ray signal intensity, (c) Al X-ray signal intensity, (d) Nb X-ray signal intensity.

Figure 8.

Images of the surface of the new, unused tapers. (a): SE image of Alloclassic new, (b) BE image of Alloclassic new; the remains of grit blasting are observed, dark particles, marked with yellow arrows, (c) SE image of Lima Corporate new, and (d) BE image of Lima Corporate new.

Figure 8.

Images of the surface of the new, unused tapers. (a): SE image of Alloclassic new, (b) BE image of Alloclassic new; the remains of grit blasting are observed, dark particles, marked with yellow arrows, (c) SE image of Lima Corporate new, and (d) BE image of Lima Corporate new.

Figure 9.

EDS analysis of a selected area of new Alloclassic taper (a) BE image of the area, yellow box indicates the remnants of Al2O3(corundum) of micro threaded blaster finishing, blue box shows the matrix Ti6Al7Nb alloy.

Figure 9.

EDS analysis of a selected area of new Alloclassic taper (a) BE image of the area, yellow box indicates the remnants of Al2O3(corundum) of micro threaded blaster finishing, blue box shows the matrix Ti6Al7Nb alloy.

Figure 10.

Surface damage (abrasive wear) of a new, unused Lima Corporate taper part of the implant. EDS mapping shows evidence of corundum Al2O3 particles implanted in the material due to the manufacturing process of the implant.

Figure 10.

Surface damage (abrasive wear) of a new, unused Lima Corporate taper part of the implant. EDS mapping shows evidence of corundum Al2O3 particles implanted in the material due to the manufacturing process of the implant.

Figure 11.

SE images of the surface of the three failed implants. The surface area shown in the figures is 230 µm x 170 µm.

Figure 11.

SE images of the surface of the three failed implants. The surface area shown in the figures is 230 µm x 170 µm.

Figure 12.

Evidence of corundum remains in an infected implant that failed after 32 months and an aseptically loosened implant after 239 months.

Figure 12.

Evidence of corundum remains in an infected implant that failed after 32 months and an aseptically loosened implant after 239 months.

Figure 13.

SEM/Backscattered electron images (BE) of the failed implant surfaces; (a) and (d) infected implant, failure time 3 months; (b) and (e) infected implant, failure -32 months; and (c) and (f) failure due to aseptic loosening after 239 months—the arrows in the lower panel point to locations of embedded corundum particle clusters.

Figure 13.

SEM/Backscattered electron images (BE) of the failed implant surfaces; (a) and (d) infected implant, failure time 3 months; (b) and (e) infected implant, failure -32 months; and (c) and (f) failure due to aseptic loosening after 239 months—the arrows in the lower panel point to locations of embedded corundum particle clusters.

Figure 14.

a) Image of male steam taper, b) 3D pseudo profile picture c) 2D roughness profile of stem A and d) 2D roughness profile of stem B, e) roughness of all five investigated stem tapers collected in

Table 3.

Figure 14.

a) Image of male steam taper, b) 3D pseudo profile picture c) 2D roughness profile of stem A and d) 2D roughness profile of stem B, e) roughness of all five investigated stem tapers collected in

Table 3.

Figure 15.

Potentiodynamic curves for the investigated new and retrieved samples were measured in simulated physiological Hank´s solution at pH=7.8 and 37 °C.

Figure 15.

Potentiodynamic curves for the investigated new and retrieved samples were measured in simulated physiological Hank´s solution at pH=7.8 and 37 °C.

Table 1.

Investigated samples of new and retrieved stem tapers.

Table 1.

Investigated samples of new and retrieved stem tapers.

| Number |

Sample |

Lifetime

month |

Cause of premature failure |

Material |

Tapers |

| 1 |

Allocassic Varial |

new |

|

Ti6Al7Nb - ZM stem |

12/14 |

| 2 |

Lima Corporate |

new |

|

Ti6Al4V - ZM stem |

12/14 |

| 3 |

I-212 |

032 |

Infection |

Ti6Al7Nb/ceramics BD- diameter 36** |

12/14 |

| 4 |

I-031 |

129 |

Low-grade infection |

Ti6Al7Nb/ceramics BD -diameter 32** |

12/14 |

| 5 |

A-283 |

239 |

Aseptic loosening |

Ti6Al7Nb/ceramics BF -diameter 32* |

12/14 |

Table 2.

Microstructure analysis: the estimation of investigated stem tapers proportion of α and β phase.

Table 2.

Microstructure analysis: the estimation of investigated stem tapers proportion of α and β phase.

SAMPLE No/

STEM TAPER ALLOY |

Survivorship of THA /months |

Magnif-ication |

Analyzed area (μm2) |

Content

α-phase (%) |

Content

β -phase (%) |

| A 283 02/Ti6Al7Nb |

239 |

250 |

143.05 |

85,32 |

14,68 |

| A 283 04/Ti6Al7Nb |

239 |

500 |

38.59 |

87,06 |

12,94 |

| A 283 06/Ti6Al7Nb |

239 |

1000 |

9.69 |

87,51 |

12,49 |

| I 212 02/Ti6Al7Nb |

3 |

250 |

143.05 |

92,21 |

7,79 |

| I 212 04/Ti6Al7Nb |

3 |

500 |

38.59 |

92,49 |

7,51 |

| I 212 06/Ti6Al7Nb |

3 |

1000 |

9.69 |

92,64 |

7,36 |

| I31 02/Ti6Al7Nb |

129 |

250 |

143.05 |

86,73 |

13,27 |

| I31 04/Ti6Al7Nb |

129 |

500 |

38.59 |

87,60 |

12,40 |

| I31 06/Ti6Al7Nb |

120 |

1000 |

9.69 |

87,62 |

12,38 |

| Alloclassic 02/ Ti6Al7Nb |

new |

250 |

143.05 |

80,41 |

19,59 |

| Alloclassic 04/Ti6Al7Nb |

new |

500 |

38.59 |

78,19 |

21,81 |

| Alloclassic 06/Ti6Al7Nb |

new |

1000 |

9.69 |

89,47 |

10,53 |

| Lima 02/Ti6Al4V |

new |

250 |

38.59 |

81,86 |

18,14 |

| Lima 04/Ti6Al4V |

new |

500 |

9.69 |

83,93 |

16,07 |

| Lima 06/Ti4Al4V |

new |

1000 |

1.55 |

82,62 |

17,38 |

Table 3.

Roughness parameters Ra and Rz and profile depth and peak spacing for investigated new and retrieved samples.

Table 3.

Roughness parameters Ra and Rz and profile depth and peak spacing for investigated new and retrieved samples.

| |

Ra [μm] |

Rz [μm] |

Profile depth[μm] |

Peak spac. [μm] |

| A – new |

1.98 |

9.64 |

206.3 |

9.3 |

| B – new |

2.92 |

14.90 |

209.7 |

14.4 |

| C – 3 months |

2.60 |

12.36 |

205.1 |

13.8 |

| D – 13 months |

2.27 |

13.22 |

199.9 |

14.1 |

| E – 91 months |

2.52 |

12.52 |

206.8 |

15.3 |

Table 4.

Electrochemical parameters determined from the potentiodynamic curves.

Table 4.

Electrochemical parameters determined from the potentiodynamic curves.

| Material |

Ecorr (V) |

icorr (uA cm-2) |

vcorr (um year-1) |

| I-212 surface-taper 32 months |

-326,6 |

0,14 |

1,21 |

| I-31 3 months |

-250,7 |

0,14 |

1,20 |

| A-283 239 months |

-284,6 |

0,08 |

0,70 |

| ALLOCLASSIC new |

-286,3 |

0,09 |

0,81 |

| LIMA Corporate new |

-221,5 |

0,05 |

0,40 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).