1. Introduction

The world's seas and oceans have long been a source of sustenance, providing a vital lifeline for communities that rely on fisheries for their economic livelihoods and nutritional needs. However, the sustainable management of marine resources has become an increasingly urgent global concern, with fisheries discards emerging as a prominent issue at the forefront of discussions. The introduction of the landing obligation (LO) in the European Union, a pivotal policy shift in the EU fisheries management [

1], has brought renewed attention to the complex challenges surrounding discards, and has spurred a global conversation on their avoidance and potential valorization [

2,

3,

4]. The LO, also known as the discard ban, was introduced as part of the European Union's Common Fisheries Policy (CFP) reforms to address the issue of unwanted catches being discarded at sea. The primary objective of the LO is to promote sustainable fisheries management by requiring fishermen to land and account for all catches, including previously discarded species.

Historically, discards, or the practice of returning unwanted or non-targeted catch back to the sea [

5], have posed a threat to marine ecosystems and fish stocks. This wasteful practice not only undermines the principles of sustainable fisheries but also hampers efforts to achieve long-term environmental balance. The LO, implemented in various regions worldwide, mandates that all catches, including discards, must be landed and accounted for. This policy shift aims to promote responsible fishing practices, reduce overfishing, and encourage the industry to adopt more selective and environmentally friendly methods [

6].

As the fishing industry grapples with the implications of the LO, the need to explore effective strategies for discard avoidance has become paramount [

7]. Fishers, policymakers, and scientists are collaborating to develop innovative technologies, gear modifications, and management approaches that minimize bycatch and discards without compromising the economic viability of fishing operations [

8]. Moreover, the valorization of discards—transforming them into valuable products, such as fish meal, nutraceuticals, or other bio-based materials, presents an opportunity to turn a historically wasteful practice into a sustainable and economically viable solution [

9,

10]. In this context, a discussion delves into the multifaceted aspects of fisheries discards, exploring the challenges and opportunities associated with their avoidance and valorization [

6]. Taking into account the latest research, policy developments, and industry initiatives, scientists aim to shed light on the dynamic landscape of fisheries management in the era of the LO [

11]. The journey towards more sustainable and responsible fishing practices requires a collaborative effort, engaging stakeholders from all sectors to navigate the seas of change successfully [

12].

The impact of the LO on discards in European fisheries has been a subject of ongoing research and assessment[

13,

14]. Several studies and reports have assessed the effectiveness of the LO in reducing discards, and the results have varied across different fisheries and regions. The implementation of the LO has led to changes in fishing practices, gear modifications, and increased selectivity to minimize unwanted catches [

15]. However, the extent to which discards have been reduced depends on various factors, including the specific fisheries, the type of gear used, and the adaptability of the fishing industry [

14]. The effectiveness of the LO may vary depending on the species and the complexity of the fisheries. There have been instances where compliance with the LO has been difficult, especially in mixed fisheries where several species are caught simultaneously. In some cases, fishermen have expressed concerns about the economic viability of their operations and the potential for increased unwanted catches. Overall, the impact of the LO on discards in European fisheries is a nuanced and evolving issue. While positive strides have been made in some fisheries, challenges remain, and ongoing efforts are needed to refine and adapt fisheries management strategies to achieve the overarching goals of sustainability and reduced discards. Continuous research, stakeholder engagement, and adaptive management approaches are crucial to address the complexities of discards in the context of the LO.

The EU Scientific Technical and Economic Committee for Fisheries (STECF) reports that even though the LO has been in force for nearly ten years, and STECF has been assessing Joint Recommendations submitted since 2014, it is apparent that there is little obvious change in fishing practices to avoid unwanted catches [

14]. Exemptions are used principally to maintain the fisheries status quo rather than as a last resort to cover small, residual unwanted catches. The majority of exemptions are still justified as being to avoid choke situations, yet there is little evidence of such situations occurring. STECF concludes that despite several research projects (e.g., DISCARDLESS, MINOUW, MedBLand, etc.) showing otherwise, there is no expectation from the sector that improved practices and selectivity increase will lead to positive economic returns. Improving size and species selectivity would require considerably larger meshes, which may significantly reduce profitability [

11,

14]. The urgent need to reduce the biological impacts of bottom trawling in the Mediterranean should be addressed by promoting the adoption of more ecologically sustainable fishing gears through the introduction of more selective meshes or gear modifications[

16].

Moreover, waste from the fisheries processing industry and retail markets is produced in huge quantities and their valorization can be an emerging biotechnology field, even in an oligotrophic sea like the Mediterranean, where its biological productivity decreases from north to south and west to east [

17,

18]. Waste management is a socially relevant issue that has an impact on society and as seafood waste accounts for nearly two thirds of the entire amount caught, raising serious environmental and economic issues, it is now imperative to address the question of how to dispose of and recycle these pollutants [

19].

To solve environmental issues and fully utilize fish side streams, which have significant commercial value, better fish waste management is therefore imperative. In recent years, there has been a rise in interest in finding alternate applications for fish byproducts, which has aided in sustainable development and economic expansion. The scope of this paper is to estimate in a systematic way the volume of fish by-products and fisheries discards (FBPD) in Greece, as well as their potential for the production of high-added value biomolecules (HAVB), such as fish meal, fish-oil, various forms of collagen, fatty acids, and minerals-trace elements in order to design/initiate a national Master Plan for their exploitation.

2. Results

2.1. The HAVB That Can Potentially Be Produced from FBPD

A series of potential products that can be obtained from FBPD have been investigated, aiming to add value to every kilogram of unavoidably caught and discarded biomass, taking also into account category 3 fish by-products (for definition see [

20]) from the processing of fish, and to develop and assess practices that have been applied in several European countries, after adaptation to the Greek conditions. These products can be directed either to human use and consumption and therefore can result in a higher price or be used as feed ingredients depending on the preservation methodology and separation procedures.

Of course, there are many more products (HAVB) that can be produced, but for the purposes of this study we have focused on the products presented in

Table 1, depending on the source of fish to be exploited and the way in which it is preserved.

2.2. Estimation of Potential Sources of Raw Material for Production of HAVB from FBPD

Three potential sources of raw material for production of HAVB using FBPD have been identified:

2.2.1. Catches That Are Not Ultimately Sold at the 11 Official Greek Fish Auctions (Hereafter Referred as Landing Sites)

The estimate is that on an annual basis they amount to approximately 722 tonnes, of which 87% is concentrated in 3 fish landing sites of the Central Markets and Fishery Organization (CMFO): in Thessaloniki 273 tonnes, in Kavala 114 tonnes and in Piraeus 245 tonnes (

Table 2).

2.2.2. Discards

The term discards refers to the percentage of unwanted catches that, after being brought on board, are then discarded at sea due to their unmarketable value. Significant quantities of discards are produced by the artisanal fleet (about 14,500 vessels) which, however, operates throughout the Greek territory and is difficult to integrate them into a central planning since the landing points are scattered throughout the Greek territory. The Greek designated ports for landing of Reg. (EC) No. 1967/2006 and swordfish (SWO) and blue fin tuna (BFT) landing/transshipment are 252. Thus, emphasis should be placed mainly on trawlers (236 vessels in 2022 – 5,850 tonnes of annual average discards) and secondarily on purse seiner vessels (224 vessels in 2022 – 1,803.3 annual average tonnes of discards). The data show that the mean annual discard estimates summed across all areas and combined for trawlers and purse seiners is 7,653.3 tonnes (see

Table 3). The discarded catch from artisanal fisheries is estimated at 3,417 tonnes for the whole country of Greece (see supplementary material), however, although not negligible, as it is scattered throughout the Greek Territory, these quantities cannot currently be included in a central planning of their exploitation as the logistics for their collection and concentration into a processing unit would be quite expensive. These quantities could be considered at a later stage.

2.2.3. Category 3 Fish By-Products (FBP-3) from the Processing of Fish in the Commercial and Processing Chain

Our analysis showed that there is a potential biomass in the order of 10,504 tonnes (average value for the years 2017-2021) for the production of HAVB from Category 3 fish by-products and the processing of fishery and aquaculture products in the commercial and processing chain. Supermarkets already apply a system of collection and removal of FBP in contrast to fishmongers and street markets; however, they are directed towards compost and biogas production and not towards production of HAVB. From the estimated quantities of FBP, an amount of 3.821 tonnes is in the Attica region and 2,056 in the Thessaloniki region (see

Table 4).

2.2.4. Total Biomass Available for Valorization

If the above sources are classified by geographical area, it follows that the total potential biomass of raw material for the production of HAVB from FBPD is of the order of 18,879 tonnes on an annual basis. The largest amount is recorded in the region of Attica where 4,524 tonnes per year could be collected and utilized (23.96% of the total), followed by the region of Eastern Macedonia - Thrace (Kavala and Alexandroupolis) where 3,747 tonnes can be collected annually (19.85% of the total) and the region of Central Macedonia with 3,320 tonnes per year (17.59% of the total), although 255 tonnes of FBP produced in the retail outlets of the Western Macedonia region have also been taken into account. These three areas gather 61% of the potential raw material for the production of HAVB from FBPD (see

Table 5). The highest quantities are available during October (2,066.71 tonnes), November (1,897.30 tonnes) and March (1,717.70 tonnes) and the lowest in July (1,075.65 tonnes) and August (1,178.33 tonnes).

2.3. Assumptions

Taking into account the total potential fishery biomass sources in Greece (

Table 5), it is clear that for the creation of the biomolecules of high added value (

Table 6), there are many combinations in terms of the available raw material of fishery by-products and discarded fish to be exploited. Some assumptions must therefore be made in order for the solution(s) to be given and become more structured.

1

st Assumption. In principle we start with the assumption that we take into account the quantities listed in

Table 3.

2

nd Assumption. All quantities of discarded catches from trawlers and purse seiners will be channeled into the category of potential products of the category "1. HAVB from fresh or frozen FBPD " of

Table 1. All quantities of the catch that are not finally sold at the fish landing sites as well as those of category 3 fish by-products (FBP-3) from the processing of fish in the commercial and processing chain (including supermarkets), will be channeled to category "2. HAVB from ensilaged FBPD " of

Table 1

2.4. Yields Per Production Line and Master Plan Scenarios

The monthly quantities of FBPD in Greece are not negligible and can support the development of a dynamic blue bio-refinery valorizing the quantities of discarded catches from the three main sources identified, i.e. i) fish catch that is not sold at the Greek fish landing sites (722,13 tonnes per year), ii) discarded catches from trawlers and purse seines (7,653.3 tonnes per year) and iii) fish by-products from the fish processing in the commercial and retail processing chain (7,749.3 tonnes per year).

Therefore, the following four indicative scenarios have been analyzed:

Scenario A: Valorize the quantities that will be landed at the fish landing sites of Kavala, Alexandroupoli, Thessaloniki (Nea Michaniona), Piraeus, Chios, Patras. This is equal to 5,656.6 tonnes on an annual basis, which is equivalent to 73.91% of the annual quantity of 7,653.3 tonnes.

Scenario B: Valorize the quantities that will be landed at the fish landing sites of Scenario A, plus the fish landing sites of Chalkida and Volos. This is equal to 6,270.6 tonnes on an annual basis, which is equivalent to 81.93% of the annual quantity of 7,653.3 tonnes.

Scenario C: Valorize the quantities that will be landed at the fish landing sites of Scenario A, plus the fish landing sites of Scenario B and Cyclades. This is equal to 7,016.4 tonnes on an annual basis, which is equivalent to 91.68% of the annual quantity of 7,653.3 tonnes.

Scenario D: Valorize the quantities collected from unsold catches in the fish landing sites of Piraeus, Thessaloniki, Kavala, Alexandroupolis, Patras, Chalkida and Volos, as well as those from FBP-3 from the processing of fish in the commercial and processing chain (including super markets), which is equivalent to 79.71% of the annual capacity which amount to 8,947.9 tonnes.

As mentioned in the assumptions, the quantities of the catch that are not finally sold at the fish landing sites, as well as those of FBP-3 from the processing of fish in the commercial and processing chain (except the ones that are traded in the super markets and are obliged to follow Reg (EC) 1069/2009 and Reg (EC) 142/2009), will be channeled to category "2. HAVB from ensilaged FBPD" of

Table 1.

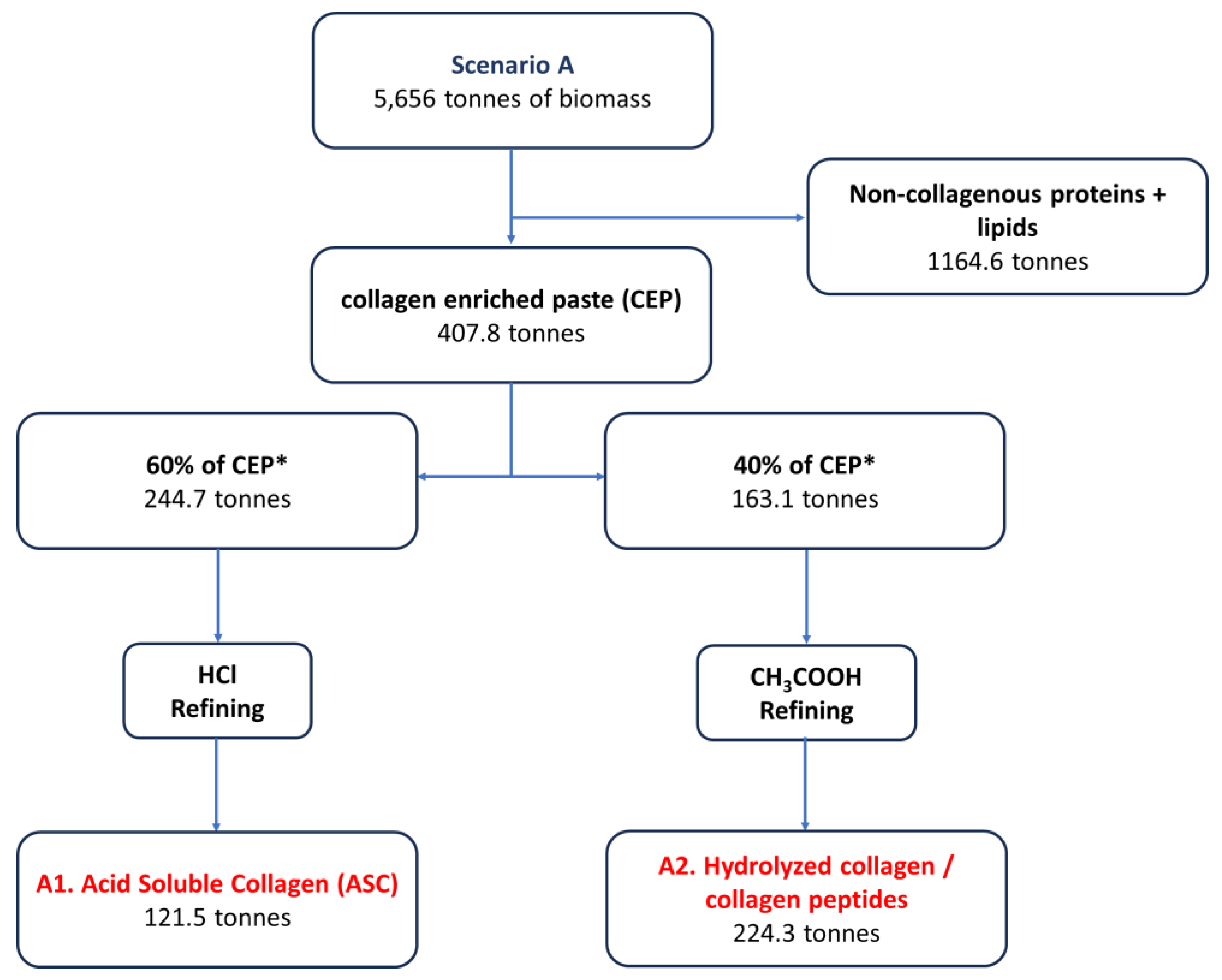

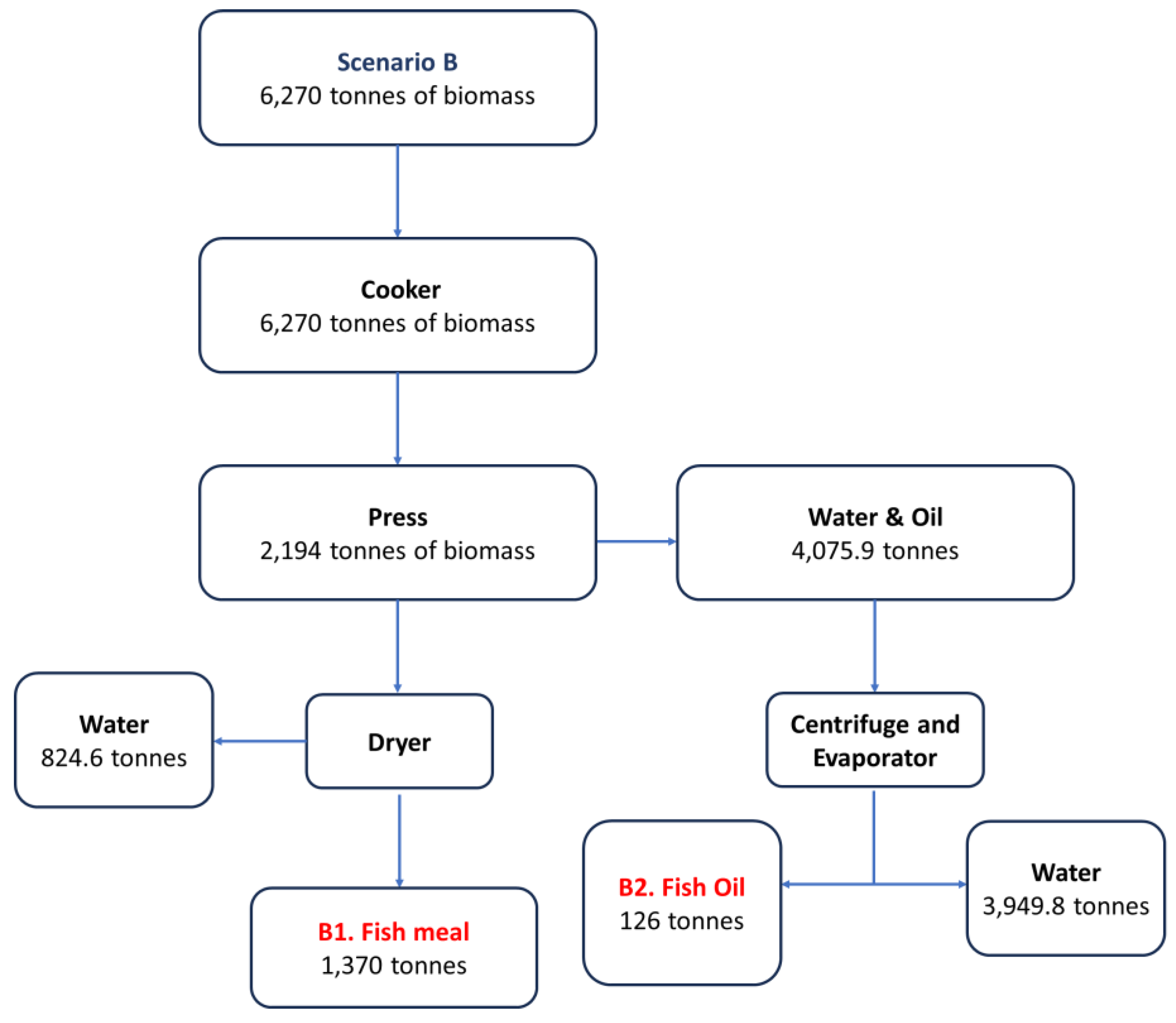

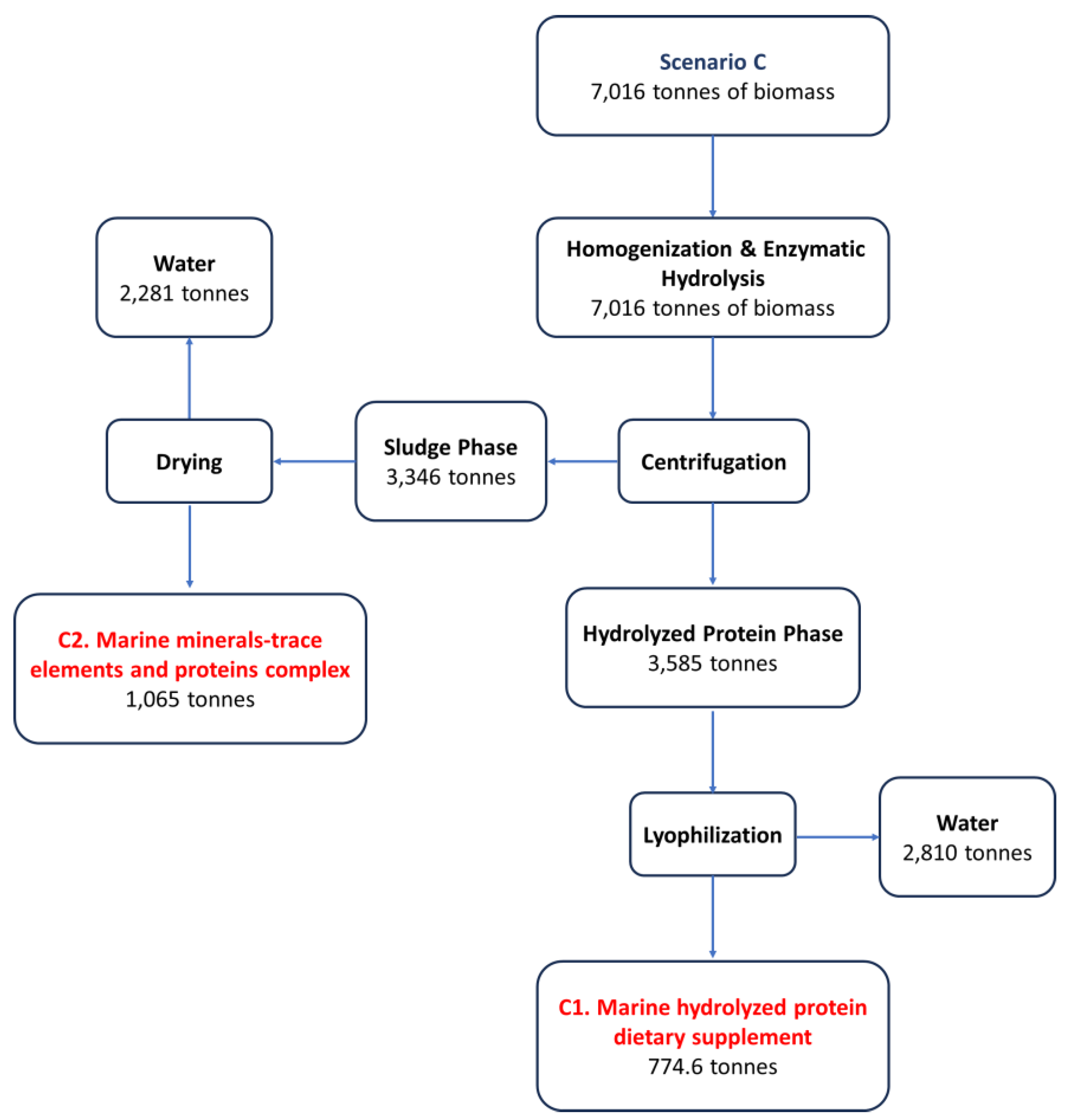

Figure 1,

Figure 2 and

Figure 3 analyze indicative scenarios from the utilization of fresh or frozen discarded catches for the production of HAVB. In total, six (6) different products can be produced from four (4) production lines.

In Scenario A (73.91% of the annual capacity), the average monthly biomass is 471.39 tonnes, while the maximum amount is 683.2 tonnes (October) and the smallest are observed in the months of July (239.1 tonnes) and September (243.3 tonnes). In Scenario A, the utilization of the available biomass will be mainly directed for the production of high value bio active compounds. Initially, all the available fish biomass will be used to produce Collagen enriched paste (CEP) as it is the first step of the refining process for both production lines, the biomass will be dried resulting in 4,084 tonnes of moisture and the refining will produce approximately 407,8 tonnes of CEP. Afterwards, 60% (244.7 tonnes) will be directed to produce 224.34 tonnes of A1. Hydrolyzed collagen / collagen peptides and 40% (163.1 tonnes) for 121.5 tonnes of A2. Acid Soluble Collagen (ASC). The total utilization of dry biomass is calculated to reach about 20.4% (

Figure 1).

In Scenario B (81, 93% of annual capacity), the average monthly biomass is 522.56 tonnes, while the maximum amount is 765.1 tonnes (October) and the smallest are observed in the months of July (256.3 tonnes) and September (256.0 tonnes). Scenario B will emphasize in the production of animal feedstuff, to harness all of the unutilized fish biomass (6,270.6 tonnes) resulting in 1,370 tonnes of fish meal and 126 tonnes of fish oil. The valorization of total dry biomass in this scenario rises to 80%.

In Scenario C (91.68% of the annual capacity), the average monthly biomass is 584.71 tonnes, while the maximum amount is 891.5 tonnes (October) and the smallest are observed in the months of July (265.5 tonnes) and September (274.0 tonnes). In Scenario C, predominantly fish will be valorized using enzymatic hydrolysis to produce 774.6 tonnes of

C1 (Marine hydrolyzed protein dietary supplement) and 1,065 tonnes of

C2 (Marine minerals-trace elements and proteins complex) using a single production line for a total DM utilization percentage of 87.4% (

Figure 3).

Figure 4 presents an additional indicative scenario for the utilization of unsold catches, as well as those from FBP-3 from the processing of fish in the commercial and processing chain (including super markets) per fish farm area as a potential source of raw material for the production of HAVB. Three different products result from the separation of the silage fractions and one more from drying the silage without further processing.

Specifically, in Scenario D, the quantities collected from the fish landing sites of Piraeus, Thessaloniki, Kavala, Alexandroupolis, Patras, Chalkida and Volos are used, which amount to 8,947.9 tonnes on an annual basis, which is equivalent to 79.71% of the annual capacity. The average monthly biomass is 566.12 tonnes, while the maximum amount is 638.5 tonnes (April) and the smallest are observed in the months of August (417 tonnes) and February (469 tonnes).

In Scenario D, 60% of the annual quantity equivalent to 5,368 tonnes is directed to production line D which concerns the separation of the three phases of silage resulting in 121.3 tonnes of Ω-3 fatty acid supplement, 592.7 tonnes of Marine hydrolyzed protein and 815 tonnes of complex marine metal-trace elements and protein. The remaining 40% of the annual quantity equivalent to 3,579 tonnes is directed to the silage production line and after drying 741.6 tonnes of protein concentrate are produced for a DM biomass utilization of 84.6% (

Figure 4).

3. Discussion

The analysis of the data obtained highlights the significant valorization potential in Greece for the production of HAVB derived from FBPD. The data categorize the raw material by geographical areas, shedding light on the distribution of available resources and emphasizing the possibility of creating a national exploitation Master Plan. Currently, the available fish discards and by-products biomass is practically unexploited in Greece, in the sense that no HAVB are currently produced.

The data reveal that geographical distribution and concentration of the FBPD biomass is primarily located in the regions of Attica, Eastern Macedonia - Thrace and Central Macedonia, collectively constituting 61% of the total biomass. This concentration suggests that these regions could play a pivotal role in any strategic planning for HAVB production. The abundance of raw material in certain regions, particularly in Central Macedonia and Eastern Macedonia - Thrace, presents a valuable opportunity for sustainable resource utilization and economic development.

The incorporation of fishery by-products from retail outlets in the Western Macedonia region underscores the importance of considering the entire supply chain in the analysis. This integration brings forth a more comprehensive perspective on the potential biomass available for HAVB production. Evaluating the dynamics of by-product generation in retail outlets can offer insights into consumer behavior, waste management practices, and opportunities for collaboration between different sectors.

The temporal dynamics of biomass availability throughout the year are crucial for planning and operational considerations. The higher quantities in October and November are related to specific fishing seasons, migration patterns, or other ecological factors. Understanding these patterns can aid in the development of adaptive strategies to maximize resource utilization during peak periods.

This study emphasizes the role of utilizing fishery discards and by-products in the context of environmental sustainability and circular economy. The production of HAVB from these resources aligns with the principles of minimizing waste and creating value from otherwise discarded materials. Strategies for sustainable harvesting, processing and utilization must be explored to ensure the long-term viability of such initiatives.

In addition to being safer and more socially acceptable than the collagen isolated from terrestrial sources, several reports indicate that the presence of marine collagen in biomaterials could promote cell adhesion, differentiation and growth, as well as wound healing [

21]. Thus, marine collagen and its denatured and hydrolyzed forms could find applications not only in the food sector but also in health-related sectors, namely in cosmetics, the pharmaceutical industry and in medical care [

18].

The targeted value chains present significant economic interest as the marine collagen market is expected to exceed 980 million USD by 2025, due to the constantly increasing usage of collagen in the cosmetic, food and beverage industry [

22], with fish waste presenting a vast and unutilized source of collagen for the industry[

23]. Moreover, the average market value for hydrolyzed collagen could reach a minimum of 16 euro per kilogram as stated by Araujo et al. (2021) [

24], depending on the production process and product quality.

As for the fish hydrolysates, the market size was estimated at 420 million USD globally in 2019 and it is expected to increase by 4.5% CAGR (compound annual growth rate) in the time between 2020 and 2026 [

25]. Marine organisms are an excellent source of bioactive peptides [

26], and the isolation of hydrolysates and purified peptides from various fish species by means of enzymatic hydrolysis, acid-alkaline hydrolysis and fermentation has been excessively studied [

27,

28].

Regarding food and pharmaceutical applications, enzymatic hydrolysis presents the most suitable method as it produces high quality peptides without any residual organic solvents and chemicals [

29]. Hydrolysates and purified peptides have been reported to serve for the prevention of various human pathologies with antimicrobial, antihypertensive, antioxidant and neuroprotective activities being commonly referred as health-related functions [

30].

Considering the experimental yields and the available literature, protein hydrolysate could potentially be a profitable valorization method since the average market value could reach 22 euro per kilogram for human consumption, as reported by Araujo et al. (2021) [

24]. For animal feed and pet food purposes the global fish protein hydrolysate industry in 2018 produced 39,127 tonnes of fish protein hydrolysate in powder and 5,411 tonnes in liquid form for approximately 167.94 and 12.35 million USD, respectively. The main processing method for the industrial production of fish protein hydrolysate is exogenous enzymatic hydrolysis which claimed 83% of the global market in 2018, followed by 12% of acidic and 5% of autolytic hydrolysis [

31].

Along with the annual increase of the global aquaculture production, there is a simultaneous need for sustainable aquafeeds that have relied largely on fish meal and fish oil [

32] as the main protein and lipid sources, respectively, particularly for carnivorous fish species. The rising gap between supply and demand has prompted the search for sustainable alternatives, such as discarded fish species and fish processing by-products that have been reported to have high nutritional value by Saleh et al. (2022) [

33] and Khiari et al. (2022) [

34]. From a nutritional stand point, fish meal produced from discards and processing by-products have been evaluated for the diets of coho salmon (

Oncorhynchus kisutch) [

35], rainbow trout (

Oncorhynchus mykiss) [

36] red drum (

Sciaenops ocellatus) [

37,

38], olive flounder (

Paralichthys olivaceus) [

39] and European seabass (

Dicentrarchus labrax) [

40] with promising results for partial and total industrial fish meal substitution. Data from the proximate composition analysis of Mediterranean fish species with relatively low economic value suggest that the nutritional profile is comparable to industrially produced fish meal, therefore, the concept of a fish meal processing chain could present a viable solution for the valorization of discards and fish by-products.

As for the fish oil, the global market size is projected to reach 2,800 USD million by 2027 [

41], with Europe producing approximately 120,000 tonnes of fish oil each year, driven by the increasing demand of the aquaculture industry, which is utilizing 90% of the global fish oil supplies [

42]. To satisfy the demand, the global production of oil from fish by-products accounted for 26% of total fish oil production in 2016, and it is expected to increase in volume [

43]. For both fishing and aquaculture industries, oils are a significant fraction of processing waste that depends on the fish parts, age, sex, nutritional status, and time of the year [

44]. Fish biomass typically contains 2-30% oils and about 50% of the body ends up as by-product from processing operations [

45]. In particular, fish oil could be generated from visceral mass, flesh, heads, tails in varying quantities [

46] to satisfy the needs in long chain polyunsaturated fatty acids (PUFAs), including eicosapentaenoic acid (EPA, C20:5, n-3) and docosahexaenoic acid (DHA, C22:6, n-3) that are essential for human health and since they cannot be biosynthesized, they need to be supplemented through diet [

47]. Long chain fatty acids from industrial fish processing operations can be valorized in multiple markets such as food/feed and pharmaceutical industries [

48]. Taking into account the current average market value of fish oil, which ranges from 5.2 USD per kilogram for animal feed usage up to 12 USD per kilogram for fish oil with high levels of EPA & DHA (28%) [

49], and the projected increase in the future, such a processing line could produce a valuable raw material which promotes circular economy and mitigates environmental issues.

To successfully implement a national exploitation Master Plan, collaboration among various stakeholders, including government bodies, fishing industries, environmental agencies, and research institutions, is essential. Policymakers need to consider the economic, social, and environmental implications and engage with local communities to ensure a balanced and inclusive approach to resource utilization. In Greece the basic European and Greek national legislative framework that governs the management of animal (including fish) by-products are included in the supplementary material.

In conclusion, the presented data offer a promising foundation for the development of a comprehensive plan for the exploitation of fishery discards and by-products in Greece. Strategic planning, sustainable practices and stakeholder collaboration are crucial for realizing the full potential of these resources while safeguarding the marine ecosystem and promoting economic development.

4. Materials and Methods

4.1. Discards Data

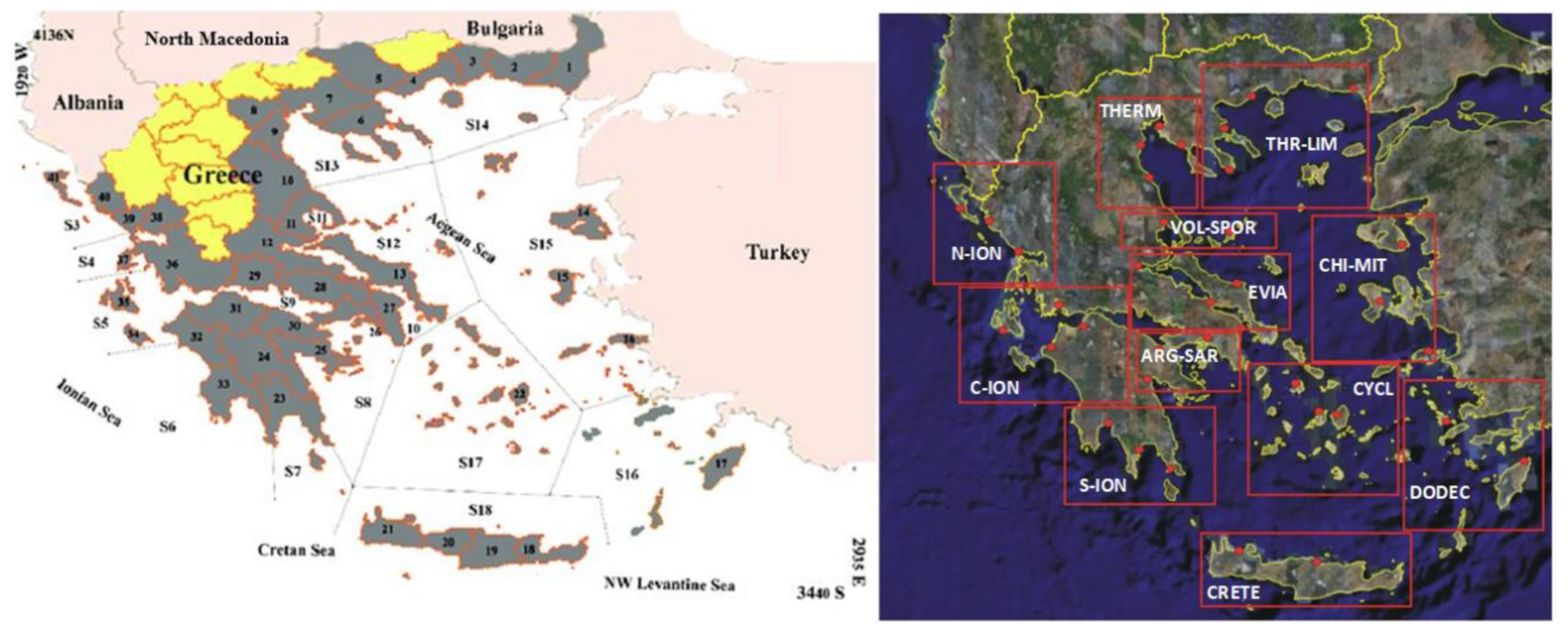

National Fisheries Data Collection Framework Program (DCF-EPSAD) data were obtained from sampling on commercial vessels (seine and trawlers) in twelve regions of Greece (

Figure 4) in the period 2013-2018. Specifically, this action of the National DCF includes recording the composition of commercial and discarded catches by observers on commercial vessels. Observers do not interact with the crew during fishing or stripping and record the number of individuals, total weight, and lengthwise composition by species after the process is over. Based on these measurements, discard ratios/fractions (discarded to commercial catch) are calculated, both for each species and overall, for a fishing gear and/or an area.

4.2. Landings Data

Estimates from the DCF-EPSAD regarding fishing productions (landings) for purse seiners and trawlers for the Greek seas (divided into twelve regions) were obtained in the year 2014. These estimates are based on a collection of information on (a) catches per vessel and (b) the fishing effort per vessel.

Data from catches that are not eventually sold at the 11 official Greek landing sites (see

Table 2) were obtained from the official Central Markets and Fishery Organization (CMFO) records.

Data from the Integrated Fisheries Information System (OSPA,

http://www.alieia.minagric.gr/ospa) regarding fishing productions (landings) for grayling and trawlers in twelve areas were obtained in the years 2015-2017.

ELSTAT's monthly landing data regarding the coastal fishing fleet (nets, longlines, traps). Data after 2015 (specifically 2016 and 2017 where available) were used to estimate coastal fisheries landings and discards. The reason was because until the reference year 2015, ELSTAT's Marine Fisheries Survey sampled motorized professional fishing vessels with a horsepower of 20 horsepower and above. From the reference year 2016 onwards, the survey covers a sample of all motorized professional fishing vessels, regardless of horsepower. However, it was not possible to carry out a spatial analysis as this information was not available from ELSTAT.

Hellenic Statistical Authority ELSTAT's[

50] monthly landing data regarding the coastal fishing fleet (nets, longlines, traps). Data after 2015 (specifically 2016 and 2017 where available) were used to estimate artisanal fisheries landings and discards. The reason was because until the reference year 2015, ELSTAT's Marine Fisheries Survey sampled motorized professional fishing vessels with a horsepower of 20 horsepower and above. From the reference year 2016 onwards, the survey covers a sample of all motorized professional fishing vessels, regardless of horsepower. However, it was not possible to carry out a spatial analysis as this information was not available from ELSTAT.

The matching of the CMFO fish landing sites to the DCF-EPSAD areas and their distribution in the three geographical subareas of the General Fisheries Commission for the Mediterranean GFCM (GSAs) is shown in

Table 9 and

Figure 5. The division of the Hellenic marine fisheries into 12 areas followed by the DCF-EPSAD largely corresponds to the division followed by the Hellenic Statistical Authority (ELSTAT). Specifically, ELSTAT divides the fishing activity in Greece into 16 regions (plus two overseas), i.e. four additional regions compared to DCF) (

Figure 5). The differences are found mainly in the Ionian Sea where each region of the DCF-EPSAD corresponds to two areas of ELSTAT, while also South Evia is a separate region in ELSTAT. The remaining areas correspond fully between EPSAD and ELSTAT.

To estimate the quantities of trawl and purse seine discards, the monthly landings of each of the 12 areas were multiplied by the ratio (R, discard ratio) of discards (D) to commercial (M) catches:

Although in most cases data were available to calculate a discard ratio per month and per region, more than one estimate was made, applying different ratios (see below) in order to a) account for the fact that in some regions/seasons the uncertainty was large due to small sampling effort and b) to perform an uncertainty analysis In the cases (regions/seasons) where there were information gaps regarding the discard ratio, a general discard ratio was used, calculated either over the whole year for each region, or at the level of the Aegean or Ionian seas for trawlers or purse seines. Listed below are the different approaches followed, of which the first three do not take into account the species caught but only aggregated data per fishing gear, while the last one assesses at the species level and presents the aggregated results:

1. Estimates based on universal discard ratios for each GSA (GSA 20 Ionian, GSA 22 Aegean and GSA 23 Crete). A single discard ratio per gear was applied using all data collected per GSA for the entire time period, regardless of species.

2. Estimates based on monthly discard ratios per GSA for the entire catch. For each gear, a different discard ratio was applied for each month based on data collected in a GSA that month, regardless of species.

3. Estimates based on monthly discard ratios for the entire catch by DCF-EPSAD region. For each fishing gear, a different discard ratio was applied for each month and each DCF-EPSAD, area based on the data collected in that area and that month, regardless of species.

4. Estimates based on discard ratios by species for each GSA. For each species a separate discard ratio was applied and estimated using all data for that species, by GSA and by fishing gear. The final estimate is obtained by summing up the discards of each species. In this particular analysis, however, to avoid details, the intermediate calculation steps are not listed.

Regarding the discards of artisanal fisheries, a single discard ratio was applied to ELSTAT's landing data based on the study by Tzanatos et al. (2007)[

51] where it was estimated at 10% of total captures (i.e. R = D/M = 0.11).

The third potential source of fisheries biomass for the production of high-value-added biomolecules (HVAB) is from category 3 fish by-products (FBPs) from the processing of fishery and aquaculture products in the commercial and manufacturing chain. Many of the fishery and aquaculture products traded in supermarkets, street markets, neighborhood fishmongers as well as central markets where fish are sold, are returned to customers after being processed, i.e. the common "cleaning". "Cleaning", depending on the species of fish, may include gutting, scaling, cutting, skinning, filleting, removing gills, removing the head, etc. After this treatment, about 15-25% (entrails, scales, backbones and heads).

The estimation of this quantity is difficult to evaluate precisely. In Greece, the apparent consumption of fishery and aquaculture products (fish, mollusks and crustaceans in fresh, frozen or processed form) presented in

Table 10, takes into account all forms, even canned or smoked products, etc. To determine the FABs from the processing of fishery and aquaculture products in the commercial and processing chain, the following calculations have been made which are summarized in the following Table:

The data in

Table 10 have been derived from ELSTAT (fisheries and aquaculture) & FAO (FIGIS - Fisheries Global Information System) (imports and exports) and the following assumptions:

From fisheries production only fish was considered, cephalopods, bivalves and crustaceans have been removed as no raw material for HAVP considered in this study (ELSTAT data).

In the production of aquaculture, bivalves (mussels and oysters) and crustaceans have been removed as no raw material to be used have been considered in this study (ELSTAT data).

As the vast majority of imports concern frozen products, canned goods and other processed products, only the ISSCAAP Division of diadromous fishes, freshwater fishes and marine fishes were taken into account (data from FishstatJ of the FAO Global Fishery and Aquaculture Production Statistics).

From exports, only the ISSCAAP Division of diadromous fishes, freshwater fishes and marine fishes were taken into account (data from FishstatJ of the FAO Global Fishery and Aquaculture Production Statistics)[

52].

After these assumptions, an average apparent consumption of 70,026.71 tonnes (years 2017-2021) and a per capita consumption of 6.68 kg per inhabitant per year results. If we also make the assumption that the same percentages of fishery and aquaculture products are consumed throughout the Greek Territory, then based on the apparent consumption the following Table is obtained if we assume that a conservative percentage of the order of 15% is removed during the "cleaning" at the retail points.

4.2. Collagen-Enriched Paste

The first step for the preparation of hydrolyzed collagen and acid soluble collagen value chains was the production of collagen enriched paste (CEP), which begins with the addition of 20% NaCl in the homogenized fish biomass, and the mechanical stirring of the mixture for 24 h to remove non-collagenous proteins. Filtration and removal of the filtrate followed, and the process was repeated three times until the aqueous phase was nearly colorless. The filtrate was removed using a 540-mesh permeable filter and the residue was rinsed twice with deionized water. Subsequently, dispersion of the residue took place in a solution of 0.5 M EDTA, pH 7.4 at a ratio of 1:5 (w/w) and mechanical stirring for 24 h to remove Ca2+ ions. Filtration and removal of the filtrate followed, and the process was repeated two more times. The filtrate was removed using a 540-mesh permeable filter and the residue was rinsed twice with deionized water. Finally, for the removal of lipid substances, the residue was dispersed in a solution of 10% iso-BuOH at a ratio of 1:10 (w/v) and subjected to mechanical stirring for 24 h. Filtration and removal of the filtrate followed, and the process was repeated two more times. The filtrate was removed using a 540-mesh permeable filter and the residue was rinsed twice with deionized water. All steps were performed at 8°C. After the completion of the procedure, CEP was obtained.

4.3. Hydrolyzed Collagen / Collagen Peptides

For the isolation of hydrolyzed collagen, CEP was suspended in a solution of 10 mM HCl in a ratio of 1:10 (w/v). The mixture was heated for 48 h at 60°C. The hydrolyzed collagen was separated after removing insoluble components by filtration using a 210-mesh permeable filter and then lyophilized.

4.4. Acid Soluble Collagen (ASC)

CEP was suspended in a solution of 0.5 M acetic acid in a ratio of 1:10 (w/v). The mixture was then mechanically stirred for 24 h at 8°C. After filtration and removal of the filtrate, the process was repeated two more times. After centrifugation at 6,000 x g for 30 min, the supernatant was collected and NaCl was added to a final concentration of 0.9 M to precipitate the acid-soluble collagen (ACS). The solution was left at rest at 4°C overnight. The ASC was collected as a pellet after centrifugation at 10,000 x g for 1 h. The pellet was redissolved in an appropriate volume of 0.5 M acetic acid and subjected to dialysis initially against 0.1 M acetic acid and then against deionized water. After lyophilization, high-purity ACS was obtained.

4.5. Fish Meal – Fish Oil Potential Yield Estimation

The industrial mass balance for a prospective manufacturer consists of three major fractions of the raw material, solids (fat-free dry matter), oil and water. The actual composition of the raw material will vary, particularly that of the oil content, therefore the estimates were calculated based on analytical results along with a literature review of industrial best practices, and thus, are sufficient to illustrate the general trend.

To assess the nutritional value and the potential yields of Mediterranean fish species, samples of bogue (Boops boops), European pilchard (Sardina pilchardus), European anchovy (Engraulis encrasicolus), mackerel (Scomber scombrus), common pandora (Pagellus erythrinus), large-eye dentex (Dentex macrophthalmus), common scad (Trachurus trachurus), white seabream (Diplodus sargus) and blotched picarel (Spicara maena) were homogenized, lyophilized and analyzed for dry matter and ash according to AOAC (2005). Moisture content was measured after drying the samples at 105°C for 24 h, ash was determined after ignition at 500°C for 12 h, crude protein content was analyzed by using the Kjeldahl method (N × 6.25) (Kjeltec 8100, FOSS, Denmark) and total fat was estimated gravimetrically by using SoxtecTM (FOSS, 2050 automated analyzer, Denmark) and petroleum ether extraction. Additionally to receive accurate data for the yield estimations of the discarded Mediterranean fish species, small-spotted catshark (Scyliorhinus canicular), shortnose greeneye (Chlorophthalmus agassizi), velvet belly lanternshark (Etmopterus spinax), blackmouth catshark (Galeus melastomus), four-spot megrim (Lepidorhombus bosccii), hollowsnout grenadier (Coelorhynchus coelorhynchus), greater fork-beard (Phycis blennoides), silver scabbardfish (Lepidopus caudatus), agrentine (Argentina sphyraena), boarfish (Capros aper), blackbelly rosefish (Helicolemus dactylopterus), silvery pout (Gadiculus argenteus), African armoured searobin (Peristedion cataphractum), Phaeton dragonet (Synchiropus phaeton), blackbellied angler (Lophius budegassa), and silver roughy (Hoplostethus mediterraneus) proximate compositions were analyzed.

4.6. Fish Silage Separation Yields

To accurately assess the potential of ensilaging as a valorization method, the experimental ensilaging protocol was applied to samples of bogue (Boops boops), European pilchard (Sardina pilchardus), European anchovy (Engraulis encrasicolus) and a mixture of the three in equal parts. Three samplings (15, 30 and 80 days) followed to examine the stability of the silage as well as the effects of long-term storage to the nutritional profile. Afterwards, to investigate an indicative scenario in commercial conditions, according to the received quantities, a mixture was formed containing 40.2% bogue (Boops boops), 10% mackerel (Scomber scombrus), 10.1 % common pandora (Pagellus erythrinus), 8.9% large-eye dentex (Dentex macrophthalmus), 10% common scad (Trachurus trachurus), 10.7% white seabream (Diplodus sargus) and 10.1% blotched picarel (Spicara maena).

For the preparation of the fish silages, 1.5kg of homogenized fish pulp was carefully weighted in glass vessels with 2-liter volume. Afterwards, formic acid 99% (Analytical reagent grade, Carlo Erba) was added with simultaneous mixing, while the pH was constantly monitored with a Seven excellence Multiparameter pH meter (Melter Toledo) until the pH value reached the aim of 3.5 to 4 to prevent bacterial growth. Approximately, 20ml of formic acid for 1kg of fish pulp are necessary to achieve the appropriate conditions for liquefaction. The fish silage could be either utilized in its crude liquid form or be subjugated to freeze drying to produce a protein concentrate.

4.7. Marine Minerals-Trace Elements and Proteins Complex

Samples from the experimental fish silages were removed and placed in 50ml falcon tubes, which were then weighed to estimate the yields gravimetrically. The tubes were then centrifuged at 3000rpm with a temperature of 10°C for 10 minutes in a refrigerated centrifuge. Afterwards, the sample was separated in three phases, lipid, hydrolyzed protein and sludge. The upper layers were then removed, and lipid extraction was performed in the remaining phase to isolate the marine-trace elements and proteins complex using petroleum ether. Each extraction cycle consisted of the addition of 20ml of petroleum ether in the falcon tubes, vigorous mixing in the vortex, centrifugation at 3000 rpm for 10mins and isolation of the upper phase (organic solvent). The cycles were repeated until the solvent appears colorless. The tubes were then placed in a freezer -20°C overnight and were lyophilized to remove the remaining moisture from the final product, which was analyzed for proximate composition, phosphorus (P) calcium (Ca), magnesium (Mg), manganese (Mn), iron (Fe) and zinc (Zn) using Microwave Plasma – Atomic Emission Spectroscopy (MP-AES).

4.8. Marine Hydrolyzed Protein Dietary Supplements

The two phases from the previous procedure (lipid and hydrolyzed protein layers) were placed in falcon tubes and an extraction protocol using petroleum ether was performed to separate the phases, each extraction cycle consisting of the addition of 20ml of petroleum ether in the falcon tubes, vigorous mixing in the vortex, centrifugation at 3000 rpm for 10mins and isolation of the upper phase (organic solvent). The cycles were repeated until the solvent appears colorless. The tubes were then placed in a freezer -20°C overnight and lyophilized to remove the remaining moisture from the final product which was analyzed for proximate composition and amino acid profile after acid hydrolysis (6N HCl, 110°C, 24 h) and derivatization by AccQ-Tag™ Ultra according to Kotzamanis et al. (2020)[

53]. DL- Norvaline (Sigma) 2.5 mM was used as an internal standard. UPLC was performed on an Acquity system (Waters Corporation, Milford, MA, U.S.A.) equipped with PDA detector and the detection wavelength was set at 260 nm. The column used was BEH C18 column (100mm × 2.1 mm i.d., 1.7μm) from Waters. The flow rate was 0.7 ml/min and the column temperature was kept at 55°C. Peak identification and integration was performed by the software Empower v.2.0 (Waters Corporation, Milford, MA, U.S.A.) using Amino Acid Standard H (Thermo Scientific Pierce) as an external standard.

4.9. Omega-3 Fatty Acid Supplements

The isolated lipid phase was placed in pre-weighed evaporation vessels, to calculate the yield gravimetrically. The vessels were then placed on a rotary evaporator using a water bath that was set at 40°C. The vessels were carefully dried, placed on a desiccator to remove excess moisture and weighed on 4-digit analytical balance to assess the lipid content. Additionally, fatty acid methyl-esters (FAMEs-) were analyzed using an Agilent GC-7890 B gas chromatograph (Agilent Technologies, Santa Clara, CA, USA), equipped with a flame-ionization detector (GC-FID) and a DB-23 capillary column (60 m x 0.25 mm i.d. x 0.15 µm film thickness) (Agilent, Santa Clara, CA, USA). Helium was used as carrier gas at 2 ml/min constant flow; the split ratio was 1:50 and the injected volume 1.0 μL. The thermal gradient was 50°C for 1 min, 50°C to 175°C at 25°C/min, 175°C to 230°C at 4°C/min and held at 230°C for 15 min. The injector and detector temperature were maintained at 250 and 280°C, respectively. Fatty acids were identified by comparison with known standard mixture (Supelco 37 Component FAMΕ Mix).

Author Contributions

Conceptualization, G.T. and Y.K.; methodology, E.R., G.T., V.I., K.T., A.M., L.A.T., V.R., E.I., and Y.K.; validation, E.R., G.T., V.I., K.T., A.M., L.A.T., V.R., E.I. and Y.K.; formal analysis, E.R., G.T., V.I., K.T., A.M., L.A.T., V.R., E.I. and Y.K.; investigation, E.R. and L.A.T.; resources, E.I. and Y.K.; writing—original draft preparation, E.R., G.T., L.A.T. and Y.K.; writing—review and editing, E.R., G.T., V.I., K.T., A.M., L.A.T., V.R., E.I. and Y.K.; visualization, E.R., G.T., V.I., K.T., A.M., L.A.T., V.R., E.I. and Y.K. supervision, G.T., V.R., E.I. and Y.K.; project administration, G.T., V.I., V.R., E.I. and Y.K.; funding acquisition, G.T., E.I. and Y.K. All authors have read and agreed to the published version of the manuscript.