1. Introduction

Composite materials have attracted considerable interest in various fields of application over the last decades. Thanks to their high stiffness-to-weight ratio, these materials gained great importance in those contexts where light structures with good mechanical properties are needed: this is the case of aerospace, automotive and construction industries. Despite this, a prevailing belief is that the optimal use of laminate structures can still be improved, in order to fully unlock the potential of fibres properties. For instance, when utilizing composites with straight fibers and a constant thickness, it becomes challenging to fully profit from the directional properties of this kind of materials. This limitation becomes especially problematic for complex geometries featuring geometrical discontinuities such as cut-outs. VAT plates are distinguished by the variation of fiber angles within the structure plane, which significantly enhances the design possibilities for a specific structure. Originally, VATs were produced using automated tape placement and automated fiber placement techniques [

1]. Modern production techniques, such as Additive Manufacturing (AM) technologies, enable the overcoming of limitations related to automated processes, such as the existence of defects like overlaps. AM entails the incremental deposition of materials layer by layer to fabricate a three-dimensional object. In the context of VAT composites, AM processes are employed to deposit and cure layers of composite materials with varying fiber orientations, as explained by Zhuo et al. [

2]. A key challenge in employing VATs lies in the complexity of the analysis. In such scenarios, it becomes essential to account for a higher number of variables, and during the optimization process, it is possible to end up with unfeasible fiber patterns.

The following is a concise summary of typical techniques employed in the analysis of the mechanical behavior of VATs, with particular emphasis on buckling investigations. One of the early methods made the assumption of constant fiber angle within each element in a Finite Element (FE) framework. This approach approximates the continuous variation of fiber direction discretely in a stepwise manner. Hyer and Lee in [

3] used this technique to maximize the buckling load of a composite plate through a sensitivity analysis. The fibers angle corresponding to the maximum buckling load was identified for each element. Through a gradient-search technique, the influence of orientation changes on the buckling load was assessed. The buckling load was then optimized through recursive modifications of elements orientations, also considering the interactions between elements. However, a key limitation of these approaches arises from their reliance on an element-wise representation of the fiber paths. With this approach, the optimized solutions might exhibit fragmented fiber paths, making them impractical for manufacturing and necessitating a computationally expensive post-processing phase for adjustment [

4]. A discrepancy between the structural responses computed based on the optimized fibers path and those computed after the optimized solution has undergone post-processing (recovery) has been often observed.

Gürdal et al. [

5] utilized the classical lamination theory to analyze the mechanical response of VAT plates. They used the Rayleigh-Ritz method to conduct buckling analyses. The same method was applied by Oliveri and Milazzo [

6] for analyzing the postbuckling behavior of VAT stiffened panels through the first-order shear deformation theory. The structures were modeled through the domain discretisation into plate-like subdomains by imposing boundary conditions for each component. Hao et al. [

7] used the Mindlin plate theory within an isogeometric analysis to perform a linear buckling study of variable-stiffness panels, ensuring the continuity of fiber angle on the whole structure plane. Hao et al. [

8] introduced a flow field function for the representation of fibers paths through a reduced numbers of variables. The buckling optimization of variable-stiffness composite panels with multiple cut-outs was performed through a bi-level optimization framework. In the first level, straight fiber paths with optimized orientation angles were first established to achieve a quasi-optimal design for maximizing buckling load and, in the second level, the flow field function was utilized to represent the fiber path. Raju et al. [

9] used the Airy’s stress function to accurately predict the prebuckling behavior of VAT plates. They used the differential quadrature method and the classical laminated plate theory to analyze the buckling response of VATs modelled. Sciascia et al. [

10] studied VAT shells considering buckling, free vibrations and prestressed vibrations. The eigenvalue problem was solved through the Ritz formulation, while the shell kinematics was described with the first-order shear deformation theory. Chen et al. [

11] presented an analytical model to predict the global, mixed and local buckling response of VAT plates with delaminations. The Rayleigh-Ritz approach was used to solve the prebuckling and buckling problems. Wu et al. [

12] introduced a two-level optimization framework for the buckling of VAT plates. VATs were defined through lamination parameters represented by B-spline entities.

The Multi-Scale Two-Level (MS2L) approach leverages a dual-scale analysis of composite structures. It considers both micro and macro levels, enabling a detailed examination of material properties at the microscopic level while accounting for the overall structural behavior. This method allows to split the optimization problem into two levels. In the first step, the composite is considered as an equivalent homogeneous anisotropic plate, aiming to determine the optimal distribution of geometric and mechanical design variables governing VAT structure behavior at this scale. Among various macroscopic anisotropy representations, the most efficient one utilizes polar parameters (see Montemurro [

13,

14]). In the second step, the focus shifts to the mesoscopic scale and the objective is to identify at least one stack that aligns with the optimized arrangement of the polar parameters obtained from the initial optimization phase. The MS2L technique was applied by Montemurro and Catapano [

15] with the aim of maximizing the buckling load of VAT plates. In the initial step, B-spline surfaces are used to represent the distribution of the polar parameters across the structure, while in the subsequent step, manufacturing constraints are taken into consideration. The initial framework for the gradient-based optimization of VAT structures was introduced by Montemurro and Catapano in [

16,

17]. Its application to eigenvalue buckling problems was done by Fiordilino et al. [

18], who introduced the analytical expression of the gradient of objective and constraint functions in buckling problems.

Carrera’s Unified Formulation (CUF) has shown accurate results in the analysis of VATs. Considering plate geometries, CUF allows to choose a-priori the approximation functions along the thickness (Carrera [

19,

20]). Early works concerning CUF, presented the development of a Navier closed-form solution, which has been applied by Carrera et al. [

21] and Carrera and Giunta [

22] to perform, respectively, the static and failure analysis of isotropic plates under various loading conditions. Giunta et al. [

23] used a Navier-type solution in order to perform the indentation failure analysis of composite sandwich plates. Giunta et al. [

24] used CUF in order to study the linear buckling of thin-walled beams. Hui et al. [

25] conducted a multiscale nonlinear analysis of composite beam structures using a series of one-dimensional (1D) CUF models. The asymptotic numerical method was employed to study the impact of microscopic imperfections on the macroscale response. Specifically, the influence of fiber defects was investigated by introducing sinusoidal geometries. By considering these imperfections, this work aimed to understand how they affect the overall behavior of the composite beam structures at a larger scale. A data-driven computational mechanics approach has been also employed with CUF models. In this context, Hui et al. [

26] used 1D CUF models for static analysis of beam structures and found that the accuracy is dependent on the number of layers in the database. This demonstrates the potential for CUF models to be integrated with modern computing techniques. Viglietti et al. [

27] and Fallahi et al. [

28] employed a 1D CUF model to conduct free-vibration and buckling analyses of VAT structures, respectively. Fallahi et al. [

29] further investigated buckling optimization in VATs using a genetic algorithm, applied to a one-dimensional CUF model. Sánchez-Majano et al. [

30] studied the effects of manufacturing defects, such as varying fibre volume and fibre misalignments, on the buckling response of VAT plates. The Monte Carlo method was applied to perform stochastic buckling analyses. Pagani and Sánchez-Majano [

31] incorporated Monte Carlo simulations and layer-wise CUF models in order to explore the impact of meso-scale fiber misalignments as defects in VAT laminates. The extension of CUF allows for the use of different expansions for each component of the displacement vector. This approach was demonstrated by Demasi et al. [

32] for the study of VAT plates using triangular elements. Vescovini and Dozio [

33] used Ritz’s method within CUF for vibrational and buckling analyses of VATs. CUF offers an additional advantage through its compatibility with various variational formulations. Reissner’s Mixed Variational Theorem, an alternative to the traditional Principle of Virtual Displacements, considers both displacements and out-of-plane transverse stresses as unknowns, demonstrating the flexibility of CUF in its applications. RMVT was widely used within CUF for the study of straight fibers composite structures. Carrera and Demasi [

34] showed how to apply RMVT to CUF from a theoretical point of view, whereas in the second part of the article [

35] static analyses were performed on straight fibers plates.

Inspired from the above works, the goal of this paper is to extend the previous works by Giunta et al. [

36] and Iannotta et al. [

37] on an RMVT-based family of plate finite elements within the CUF framework for dynamic and static analyses of VAT plates, respectively, to accurately predict buckling loads when curvilinear fibers are present.

The structure of the paper is as follows.

Section 2 introduces the CUF approach and demonstrates its application to the two variational statements mentioned earlier.

Section 3 considers three benchmark problems and performs linear buckling analyses with various loading conditions to discuss the differences between PVD and RMVT models and the reference solutions obtained in Abaqus using three-dimensional (3D) elements. Finally,

Section 4 draws the conclusive remarks.

2. Carrera’s Unified Formulation

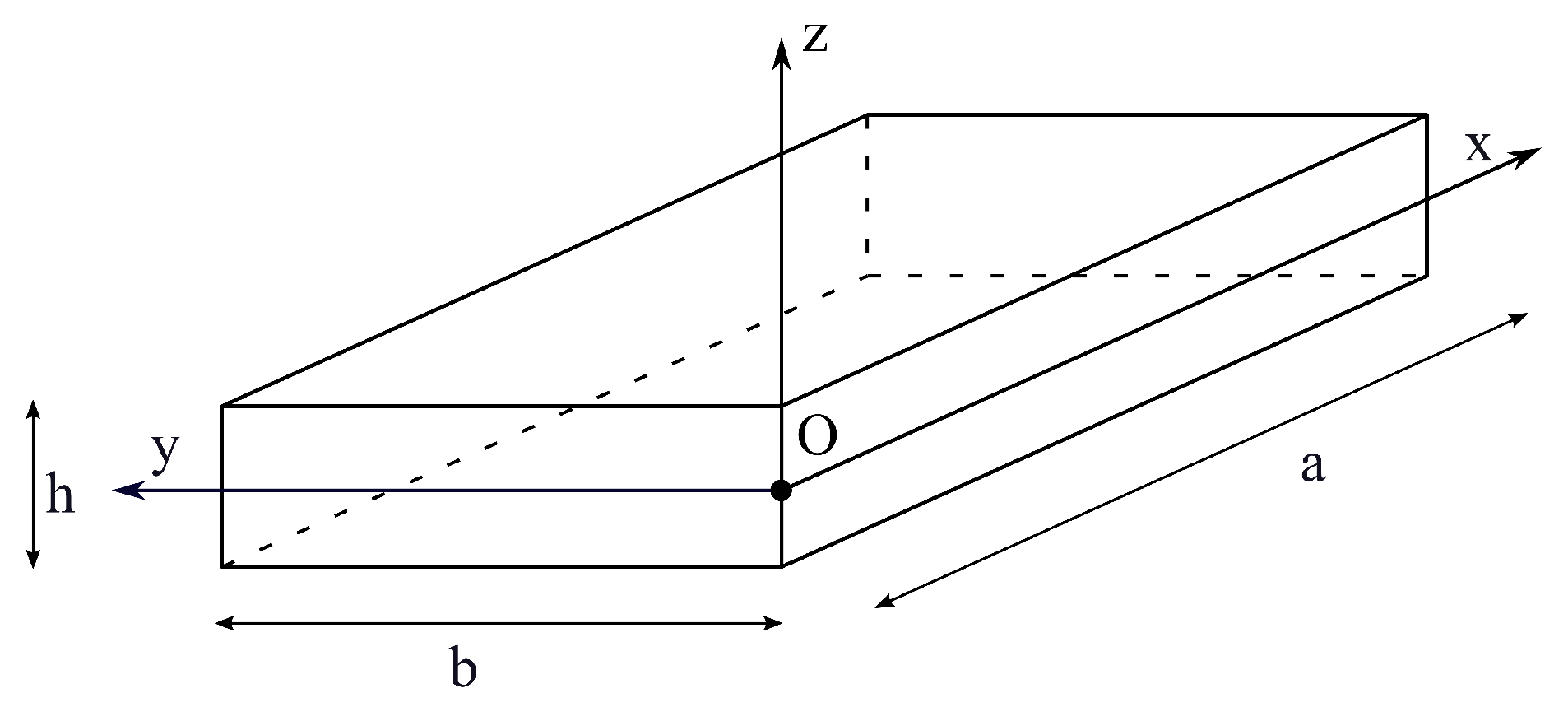

A plate is a flat and thin structural element having in-plane dimensions significantly greater than its thickness. A global Cartesian reference system is considered to describe displacements, strains and stresses. The

x-axis and

y-axis are aligned with the in-plane sides of the plate, whose dimensions are indicated as

a and

b, respectively. The

z-axis is oriented perpendicular to the plane of the plate, in the same direction of the thickness

h, which is negligible in comparison with

a and

b. The problem geometry and global reference system are illustrated in

Figure 1.

The displacement field is expressed as:

The strain vector can be represented through Voigt’s notation and, then, divided in its in-plane and out-of-plane components:

The assumption of small displacements permits the utilization of a linear relationship:

where

and

are the following differential operators:

The non-linear part of the strains can be introduced in a Green-Lagrange sense (see [

38]):

The complete Cartesian components of strain can be obtained by summing the linear and non-linear terms. The in-plane and out-of-plane stress components can be written as:

Hooke’s law reads:

where the terms

,

,

and

are the components of the material stiffness matrix.

2.1. Variable-Angle Tow Composite Plates

VAT laminates are characterized by a point-wise variation of the material stiffness matrix components along the in-plane directions. Because of the laminate stacking sequence, the material stiffness matrix is also subjected to a layer-wise variation along the thickness of the plate. The equation enabling the rotation of the material stiffness matrix

by a designated angle

around the

z-axis is expressed as follows:

Here,

denotes the material stiffness matrix in the material reference system, whereas

represents the matrix after a rotation. The rotation matrix

is a function of the angle

. For conciseness, the specific components of

and

are omitted in this context (refer to Reddy [

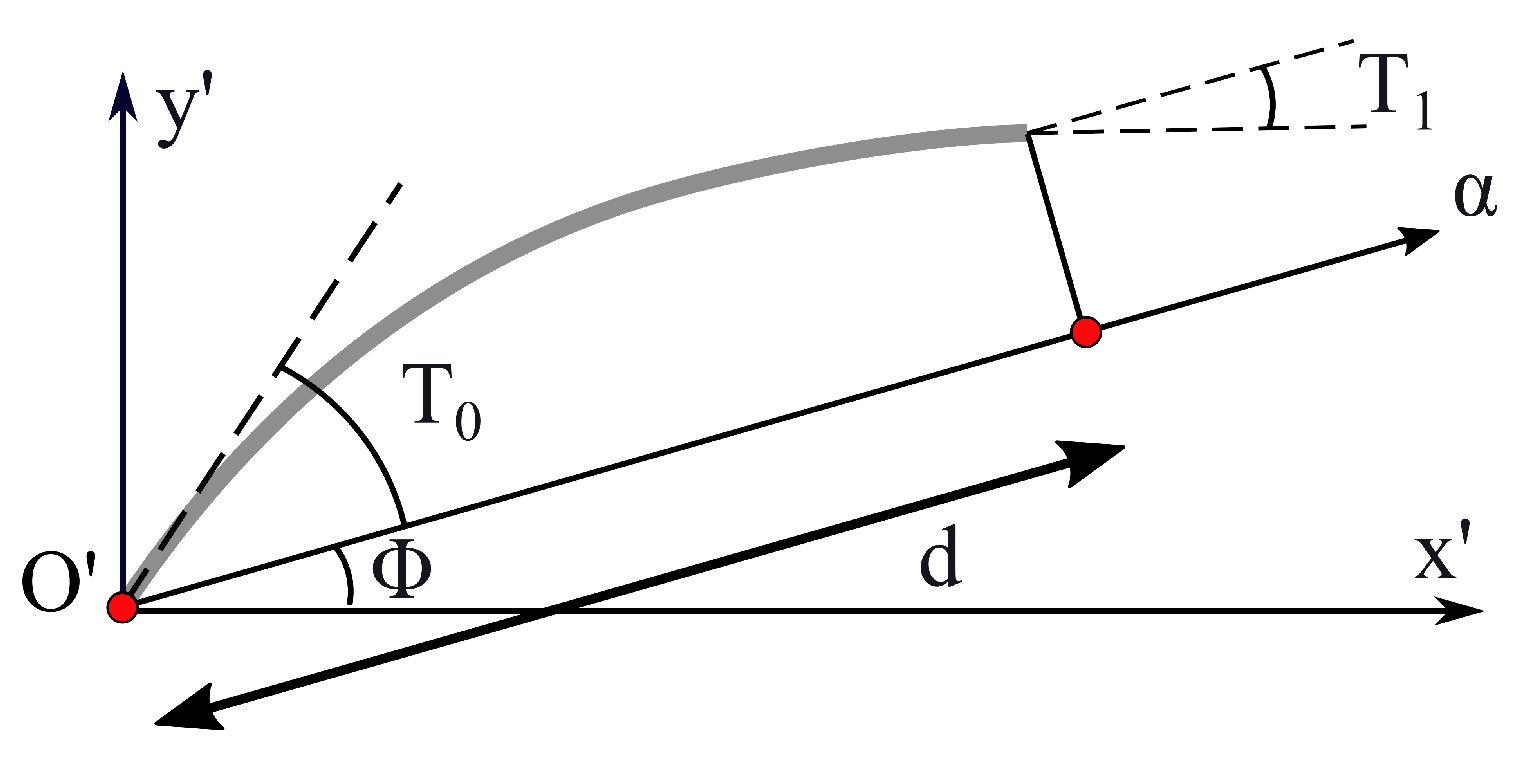

38] for detailed information). A linear variation law can be formulated as:

The angle

represents the initial direction of variation for

,

is a spatial variable given as:

where

and

denote the axes of the angle reference system.

indicates the initial fiber angle when

, and

represents the fiber angle when

as shown in

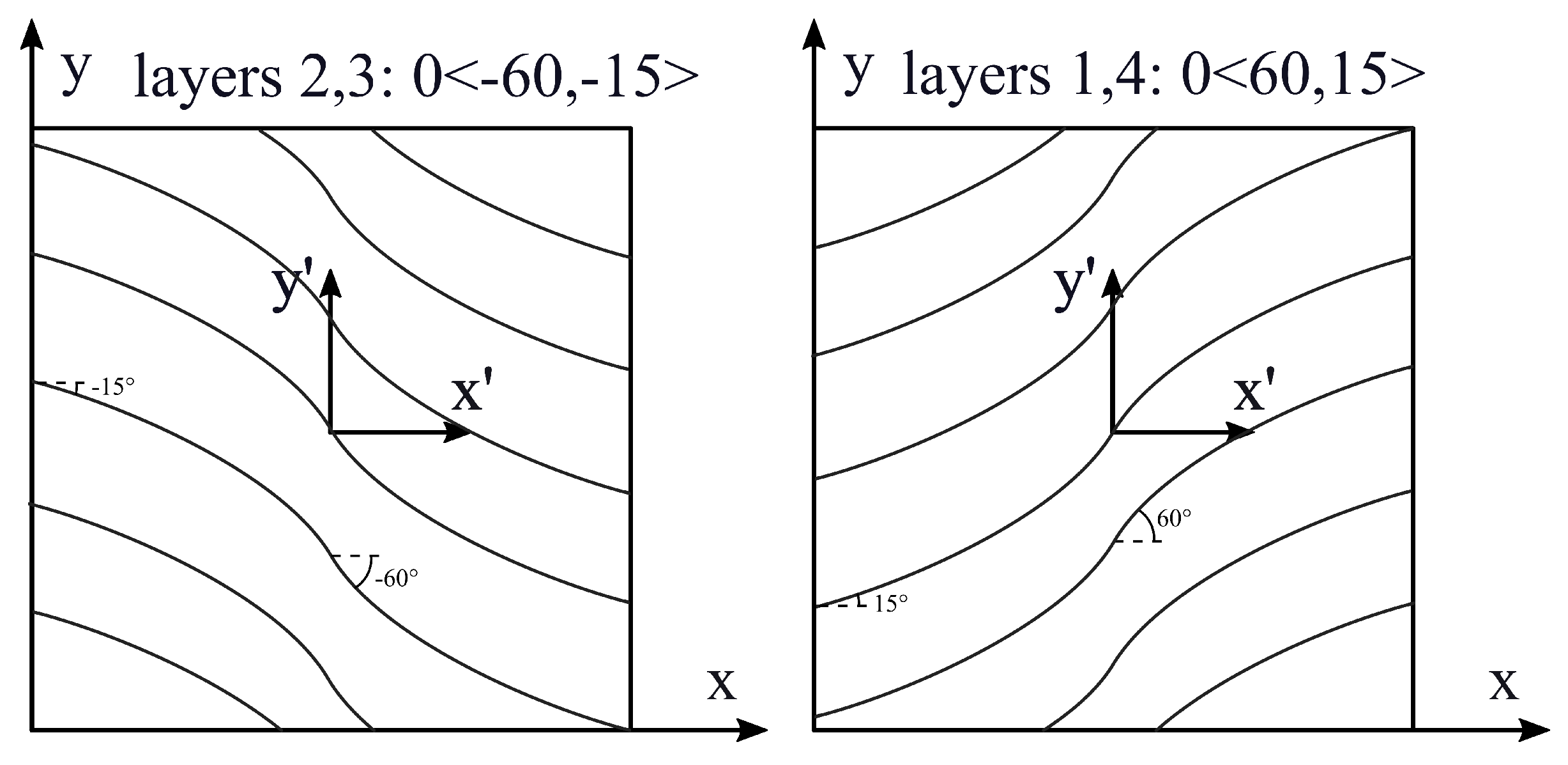

Figure 2.

Within this paper (and without loss of generality), the fibers angle is measured with respect to the

axis. The direction of variation of

can be along

,

or a combination of theirs, depending on the specific case. The notation

is used to describe the in-plane path of the fibers, which is based on the parameters introduced earlier. More details about the variation law of the local fiber orientation can be found in Gürdal et al. [

5].

2.2. Variational Formulation

The governing equations are here derived through the consideration of PVD and RMVT variational statements. The key distinction lies in PVD focusing solely on displacements as unknowns, whereas RMVT incorporates both displacements and transverse stresses, denoted as

, as primary unknowns. To effectively address the buckling problem, a prebuckling analysis is essential for determining the non-uniform stress distribution resulting from an external load. For the PVD case, the virtual internal work can be expressed as:

The subscript ‘

G’ refers to components derived from geometrical relations outlined in Eqs. (

3), whereas the subscript ‘

H’ corresponds to components obtained through Hooke’s law as specified in Eqs. (

7). The term

represents the mid surface of the plate in the in-plane directions and the subscript ‘

T’ stands for the transpose of a vector/matrix. The virtual internal work for the RMVT case is

where the ‘

M’ subscript refers to the transverse stress components considered as primary unknowns in the mixed formulation. In the RMVT formulation, Hooke’s law is expressed as follows:

where

,

,

and

are obtained by the following relations (see Carrera and Demasi [

34]):

2.2.1. Prebuckling Problem

In the context of a prebuckling analysis, the following balance equation applies:

where the virtual work associated with external loads reads:

where

is a surface load applied on the surface

at

z coordinate

.

2.2.2. Linear Buckling Problem

The stress field obtained through the prebuckling analysis can be integrated for the computation of the pre-stresses virtual work

which reads:

where

are the pre-stresses energetically conjugate to the non-linear strains

, with

. The linear buckling problem can be written for both PVD and RMVT cases as:

2.3. Kinematic Assumption and Finite Element Approximation

CUF allows to introduce an axiomatic approximation in order to mathematically represent the primary unknowns along the direction parallel to the thickness (see Carrera [

20]). Considering

as a generic unknown component, the following expansion can be introduced:

In this context, f can represent solely a displacement component within a formulation derived by the PVD or a displacement or an out-of-plane stress component in the case of a RMVT formulation. serves as an approximation function along the thickness, while represents an unknown two-dimensional function that approximates the in-plane variation. The used Einstein’s notation assumes that a twice repeated index implies a sum over that index range. This notation simplifies mathematical expressions and calculations. N represents the approximation order, which can be chosen a-priori. Similarly, can also be imposed beforehand. The flexibility of the CUF enables the formulation of multiple theories within the same framework, making it a versatile tool for VATs analysis. Equivalent Single Layer (ESL) and Layer-Wise (LW) theories can be obtained through the adequate choice of and a coherent implementation of the layers stiffness matrices assembly.

2.3.1. Equivalent Single-Layer Theories

In the ESL framework, 1D polynomials of the type

are used as

in order to obtain Taylor’s expansion for the representation of primary variables:

In this case, the number of layers does not affect the total number of unknowns. The components of the stiffness matrix are computed by summing the integrals of the thickness functions for each layer, each multiplied by its corresponding stiffness coefficient. Even if ESL models are characterized by a diminished computational complexity/cost and show a good prediction of thin laminates behavior, they lack in accuracy when thick plates are considered. Due to their reliance on

approximation functions, ESL approaches are unable to accurately capture the zigzag displacements effect. However, it might be feasible to incorporate this feature by introducing Murakami’s function, as detailed in Carrera [

39].

2.3.2. Layer-Wise Theories

Lagrange or Legendre polynomials can be used to approximate the unknown fields independently for each layer resulting, in this way, in a LW model for which it is possible to write the following approximation along the

z-axis:

The superscript ‘

k’ denotes a generic layer within the structure, with

k ranging from one to

, where

represents the total number of layers. Subscripts ‘

t’ and ‘

b’ correspond to the top and bottom faces of the generic layer, respectively. In the case of Legendre polynomials, the approximating functions along

z-axis are:

where

represents the ith-order Legendre polynomial defined within the domain of the kth layer with the dimensionless through-the-thickness local coordinate

bounded within

and

. LW models can accurately predict the zig-zag through-the-thickness behavior of the displacement field. However, they come with a higher computational cost, as the number of unknowns depends on the number of layers.

2.3.3. Finite Element Formulation

When a FE approximation is applied, it is necessary to incorporate the shape functions into the formulation. In the case of a 2D model, Eq (

19) becomes:

where

denotes the shape functions of the element and

corresponds to the number of nodes utilized for the domain discretisation. Classical Lagrange shape functions are used. They are not explicitly detailed here for the sake of brevity and interested readers can refer to [

40] for further information.

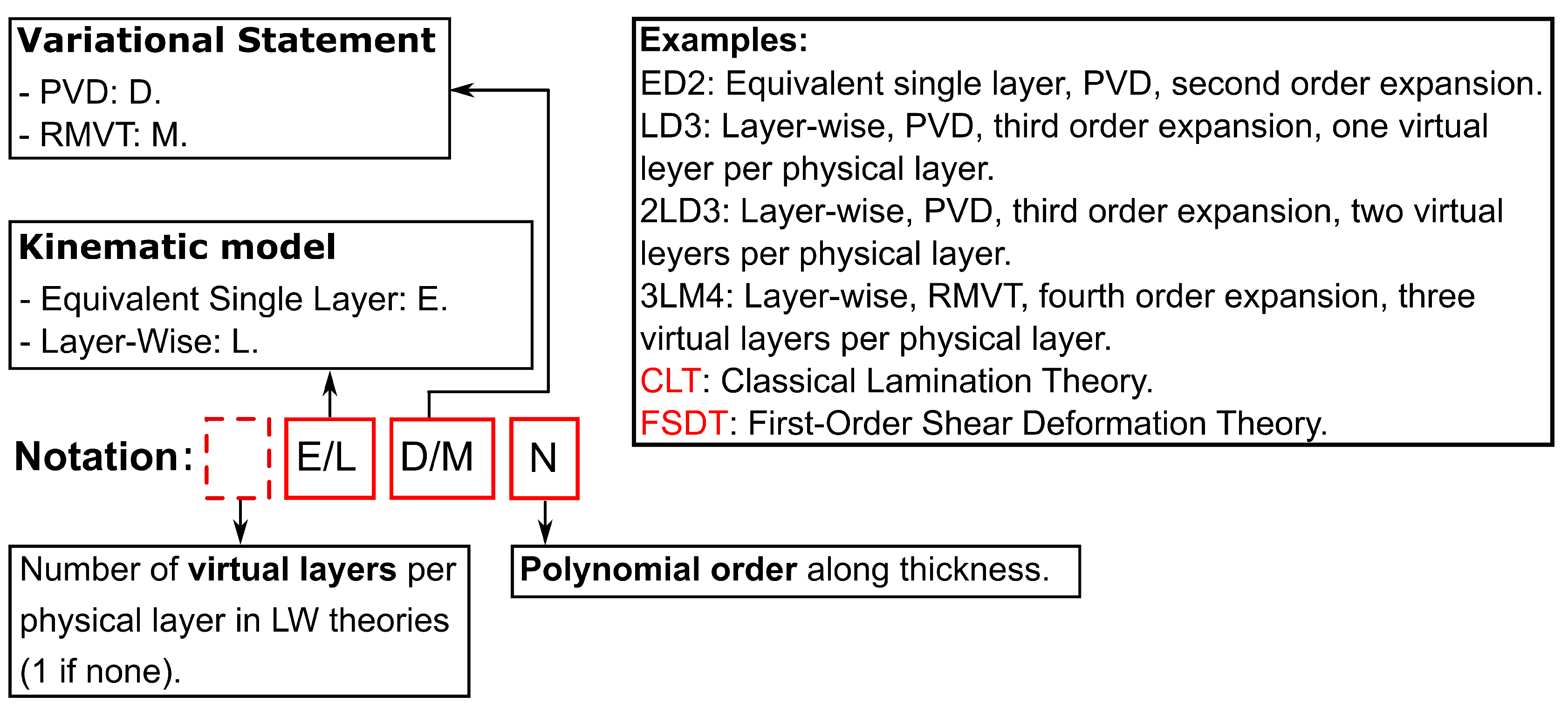

2.4. Acronym System

A comprehensive acronym system is implemented to identify the derived theories. The first letter designates the employed approximation level: ‘E’ corresponds to ESL models, while ‘L’ corresponds to LW models. The second letter denotes the variational statement: ‘D’ or ‘M’ signifies PVD or RMVT, respectively. The final number indicates the expansion order utilized along the plate thickness. If the first number is present, it signifies the number of virtual layers employed for the LW model to represent each physical layer. If the acronym begins without a numerical value, it is implicitly understood that only one virtual layer has been used for each physical layer. This system is shown in

Figure 3.

For instance, the displacement field in EDN models corresponds to the following vectorial form:

where

and

. Classical theories arise as specific cases of the ED1 solution: Classical Lamination Theory (CLT) and First-order Shear Deformation Theory (FSDT) are denoted as CLT and FSDT, respectively. FSDT is derived by penalizing the

term in a first-order through-the-thickness approximation, whereas CLT requires penalization of the therms coming from the work of the transverse shear stresses. The material stiffness matrix is reduced to account for a plane stress state in both CLT and FSDT and avoid thickness locking.

For LDN solutions, only displacements are considered as unknowns:

For LMN solutions, also transverse stresses are included among the unknowns:

In both cases, N refers to the approximation order employed in each layer. Noticeably, ESL theories can be viewed as specific instances of LW theories. In ESL, integration along the thickness is carried out to represent composite properties through an equivalent single layer. In contrast, in LW theories, integration is computed layer by layer. This allows for the individual representation of the kinematics of each layer in LW models. Unless otherwise specified, LDN solutions are derived using Lagrange polynomials with equally spaced nodes, while LMN solutions utilize Legendre polynomials.

2.5. Stiffness Matrices Expression

Considering PVD, the displacement field groups the primary unknowns. In a PVD context, displacements from Eq (

23) can be written as follows:

Through the substitution of Eqs. (

3), (

7), (

27) and (

11) into Eqs. (

18), the PVD governing equations are obtained:

where:

Index ‘

z’ when preceded by a comma refers to the derivative along

z-axis. In a compact vectorial form, Eq (

28) reads:

where

is a

Fundamental Nucleus (FN). The loops on the indices

,

s,

i and

j allow to build the stiffness matrix of the whole plate element expanding over the kinematic approximation and the finite element approximation, respectively.

In the RMVT case, also transverse stresses constitute an unknown field:

Through the substitution of Eqs. (

3), (

13), (

27), (

32) and (

12) into Eqs. (

18), the governing equations of the RMVT can be written as follows:

where:

In this case, four fundamental nuclei are obtained. Gauss quadrature has been used to compute the in-plane integrals. Due to the varying stiffness coefficients of the materials, the number of Gauss points must be adjusted for a given analytical formula describing the local fibers orientation to ensure converged integration. A reduced integration is used to correct the shear locking phenomenon. A

grid of Gauss points is used for the fully integrated terms, while a

grid is used for the reduced ones. Through the substitution of Eqs. (

5) and (

27) into Eqs. (

17), it is possible to obtain the pre-stresses virtual work:

In a compact form it reads:

where

is the fundamental nuclues of the geometric stiffness matrix.

4. Conclusions

In this study, linear buckling analyses of VAT plates have been performed by developing two-dimensional CUF finite elements within Reissner’s Mixed Variational Theorem. Thanks to its adaptability to a wide range of structural problems and the possibility to choose the approximation theory a-priori, CUF shows a good prediction of buckling loads with an acceptable computational cost. Even though only linear laws have been considered in the numerical simulations for the variation of fibres angle, the implemented numerical framework allows to address a generic variation law. Three numerical examples of plates containing curvilinear fibres have been analyzed and results are compared to Abaqus 3D and literature reference solutions. The comparison among the various results allows to distinguish the developed models according to their accuracy and numerical complexity. Even though CLT and FSDT show a reduced amount of degrees of freadom, allowing to correctly predict buckling loads for the considered benchmark structures 2 and 3, they show a higher loss of accuracy when plates which are not symmetric and balanced are considered, as observed in the first benchmark case. Increasing the through-the-thickness polynomial order, general ESL displacements theories are obtained, which allow to improve the results accuracy. A further improvement in the prediction of buckling loads is obtained through the development of LW displacements models. ESL and LW theories can correctly predict Abaqus 3D results with a limited number of DOF, but being derived from a PVD variational statement show a lack in accuracy for the out-of-plane stresses, which strongly influence the evaluation of the geometric stiffness matrix needed for the linear buckling analysis. Hence, the derivation of LW models to RMVT allows to overcome this problem, enhancing the solution accuracy, specially in the case of the first critical load. Even if LM models allow to improve the prediction of the through-the-thickness behavior, they are characterized by the maximum computational cost among the two-dimensional theories developed in this study, and yet their application is still advantageous mainly when plates characterized by complex stacking sequences are considered especially when compared to the cumberson three-dimensional simulations. In summary, the utilization of RMVT in the context of CUF has demonstrated the potential to enhance the precision and efficiency of modeling VAT plates for buckling analyses. Nevertheless, the scope of this approach extends beyond plate analysis, as there are promising prospects for employing, as a future perspective, this framework in the examination of more challenging VAT structures such as shells.

Figure 1.

Plate geometry and reference system.

Figure 1.

Plate geometry and reference system.

Figure 2.

Example of in-plane fibers path.

Figure 2.

Example of in-plane fibers path.

Figure 3.

Acronym system.

Figure 3.

Acronym system.

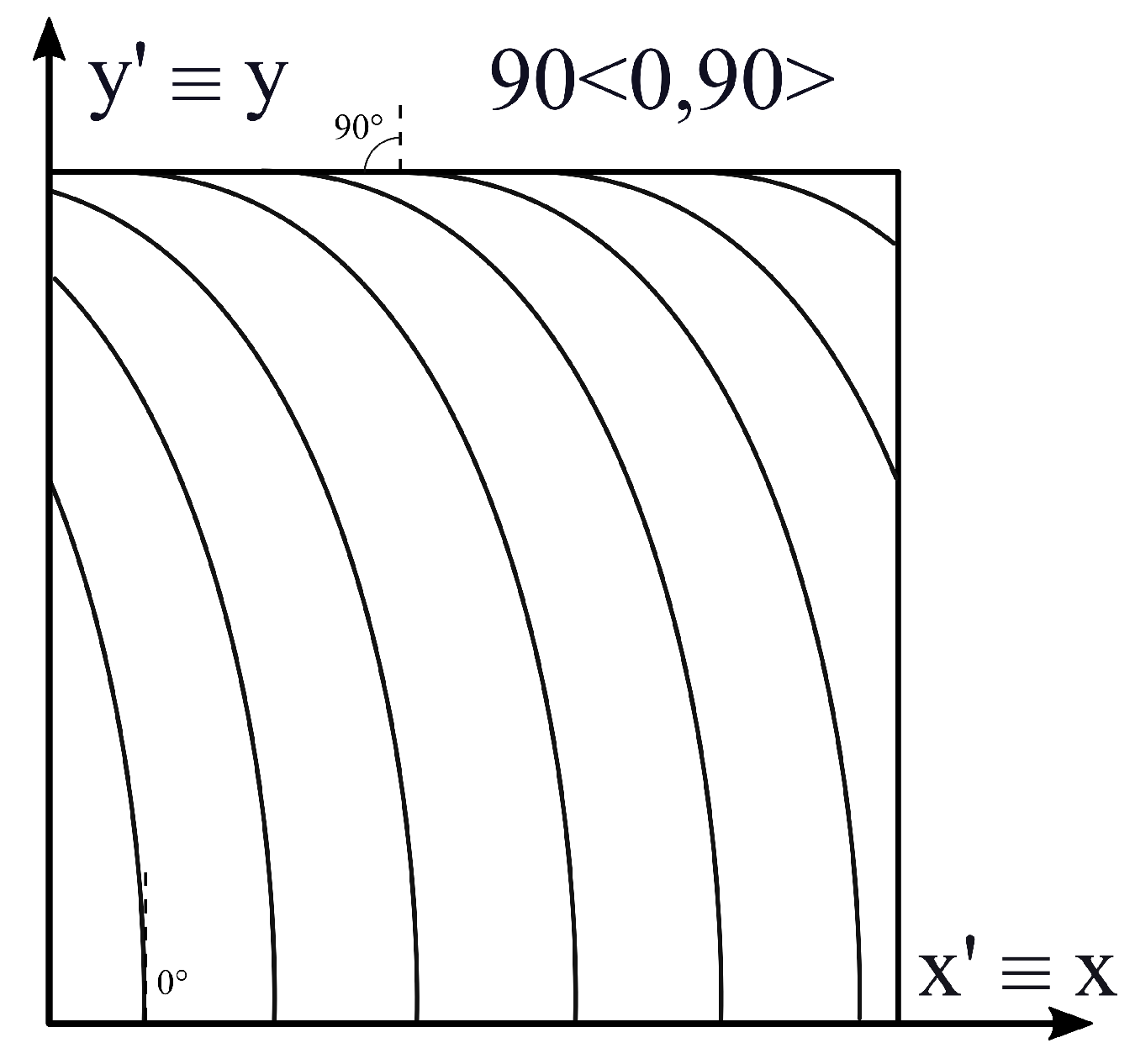

Figure 4.

In-plane fibers variation path, case 1.

Figure 4.

In-plane fibers variation path, case 1.

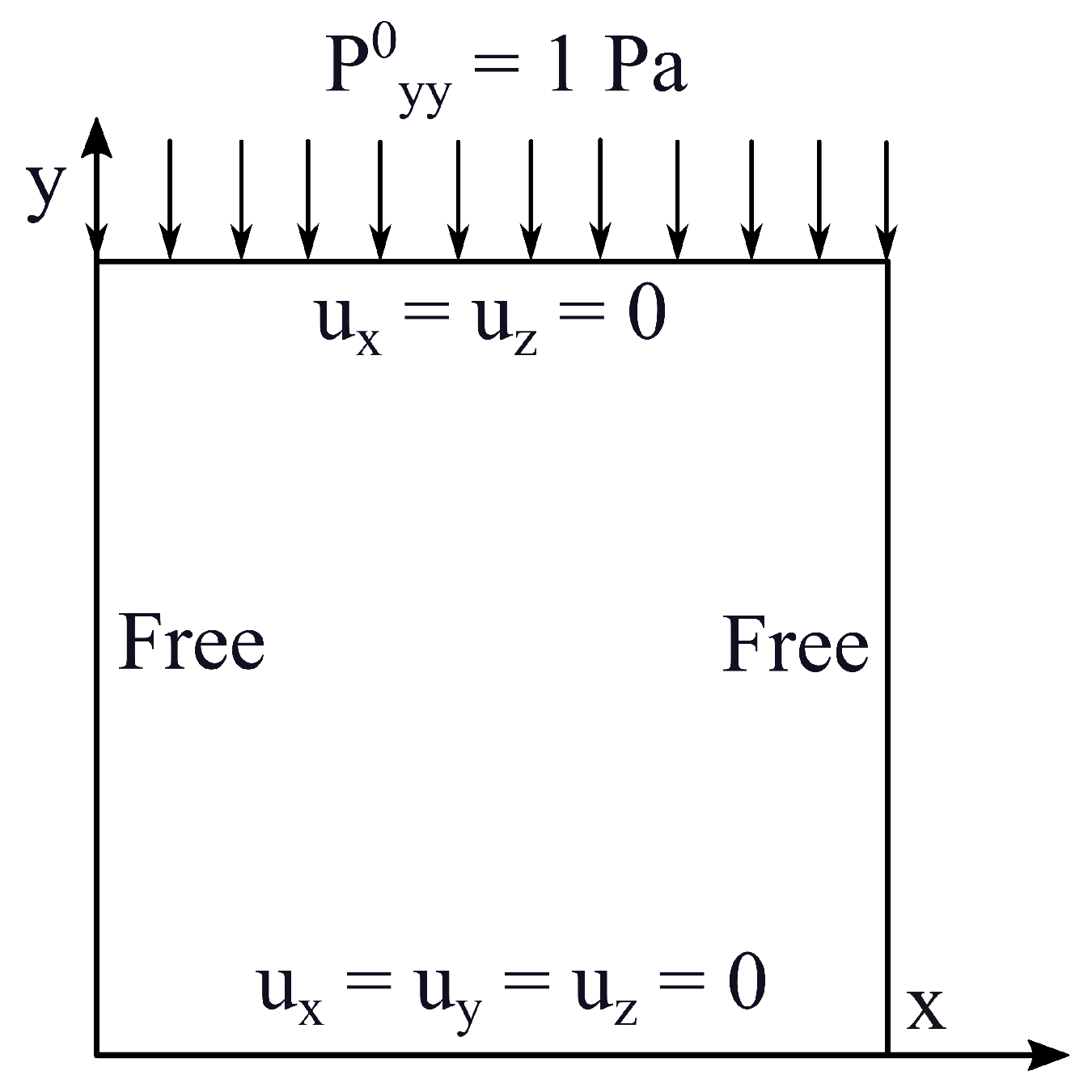

Figure 5.

Boundary and loading conditions, case 1.

Figure 5.

Boundary and loading conditions, case 1.

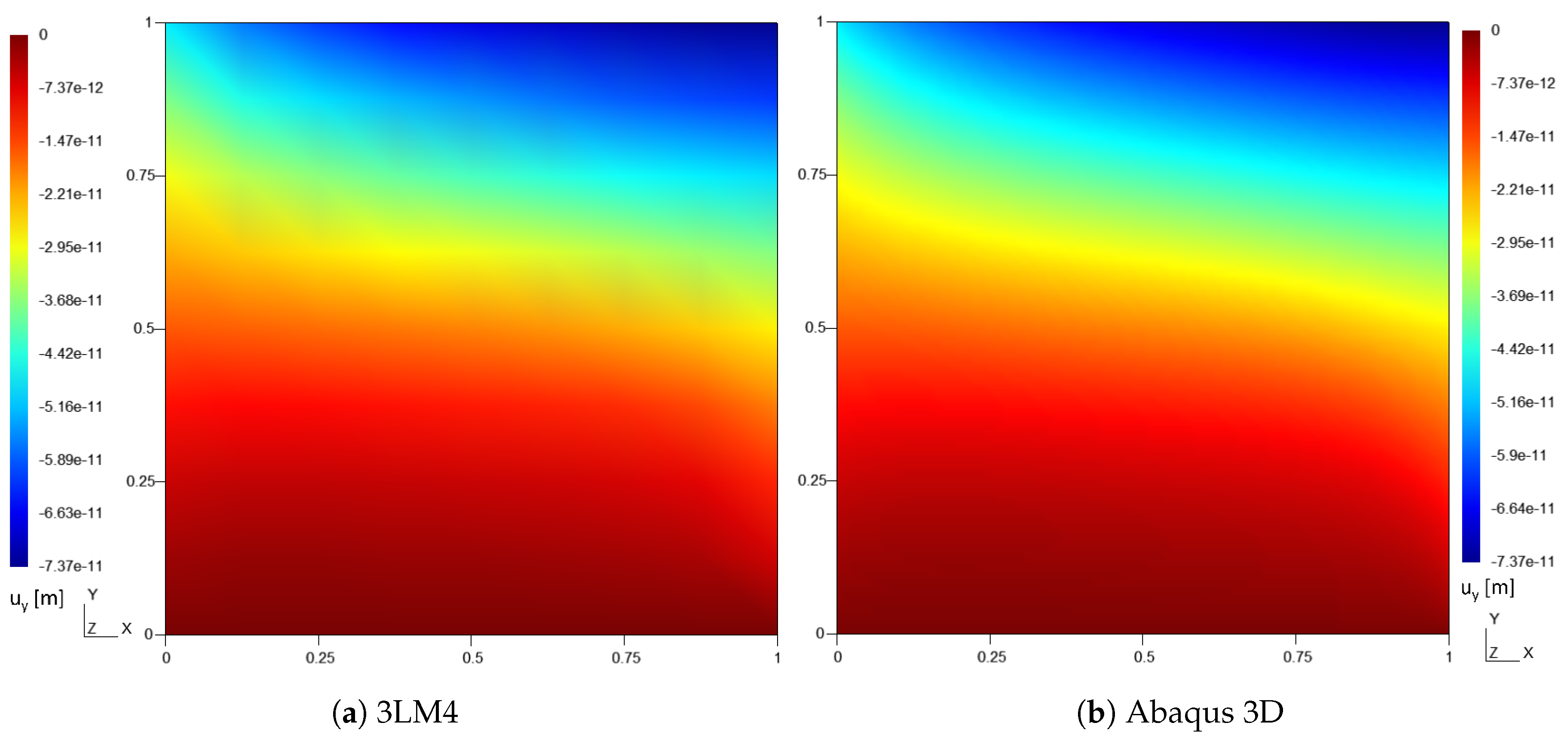

Figure 6.

Contour plots of the displacement along y axis [m], case 1.

Figure 6.

Contour plots of the displacement along y axis [m], case 1.

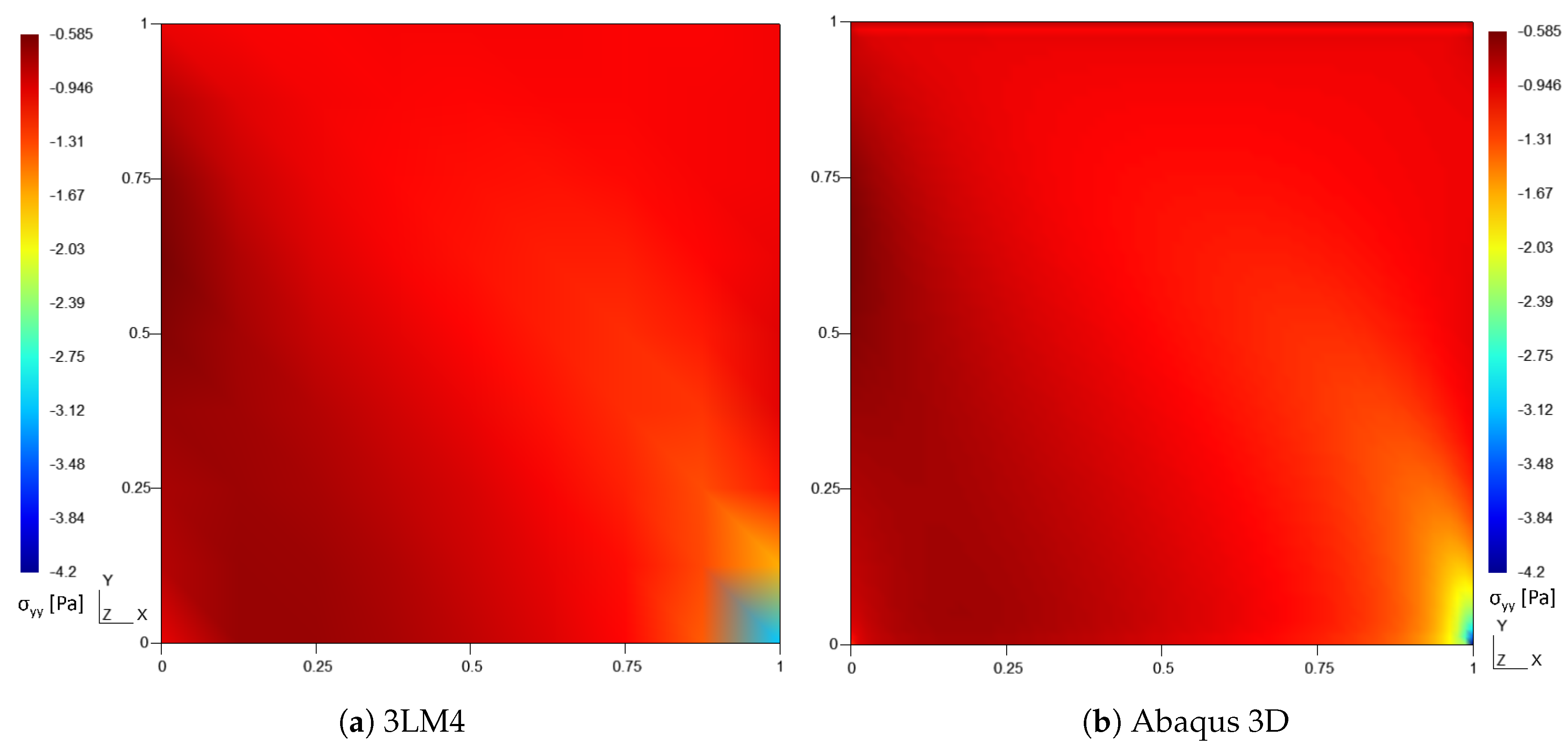

Figure 7.

Contour plots of the in-plane normal stress [Pa], case 1.

Figure 7.

Contour plots of the in-plane normal stress [Pa], case 1.

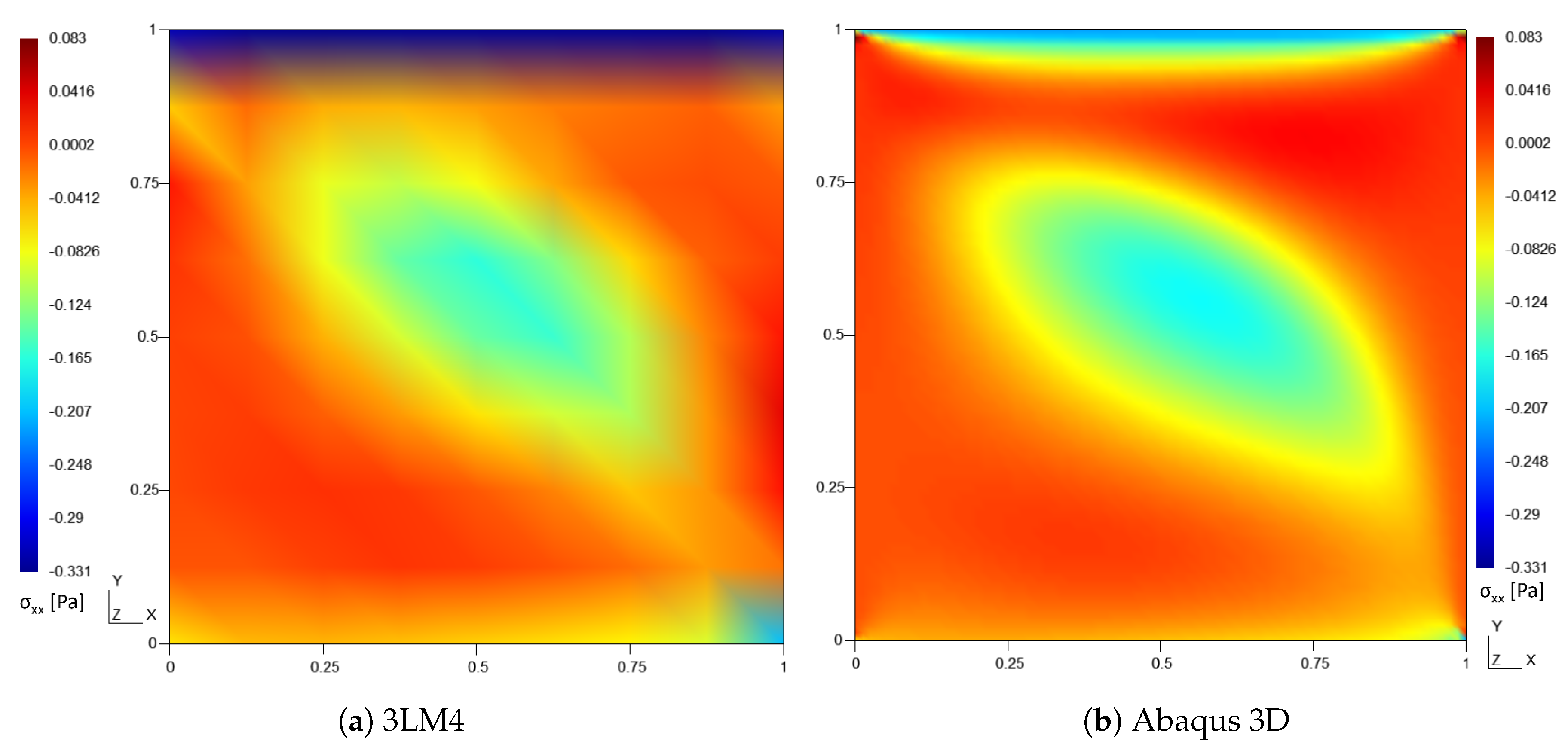

Figure 8.

Contour plots of the in-plane normal stress [Pa], case 1.

Figure 8.

Contour plots of the in-plane normal stress [Pa], case 1.

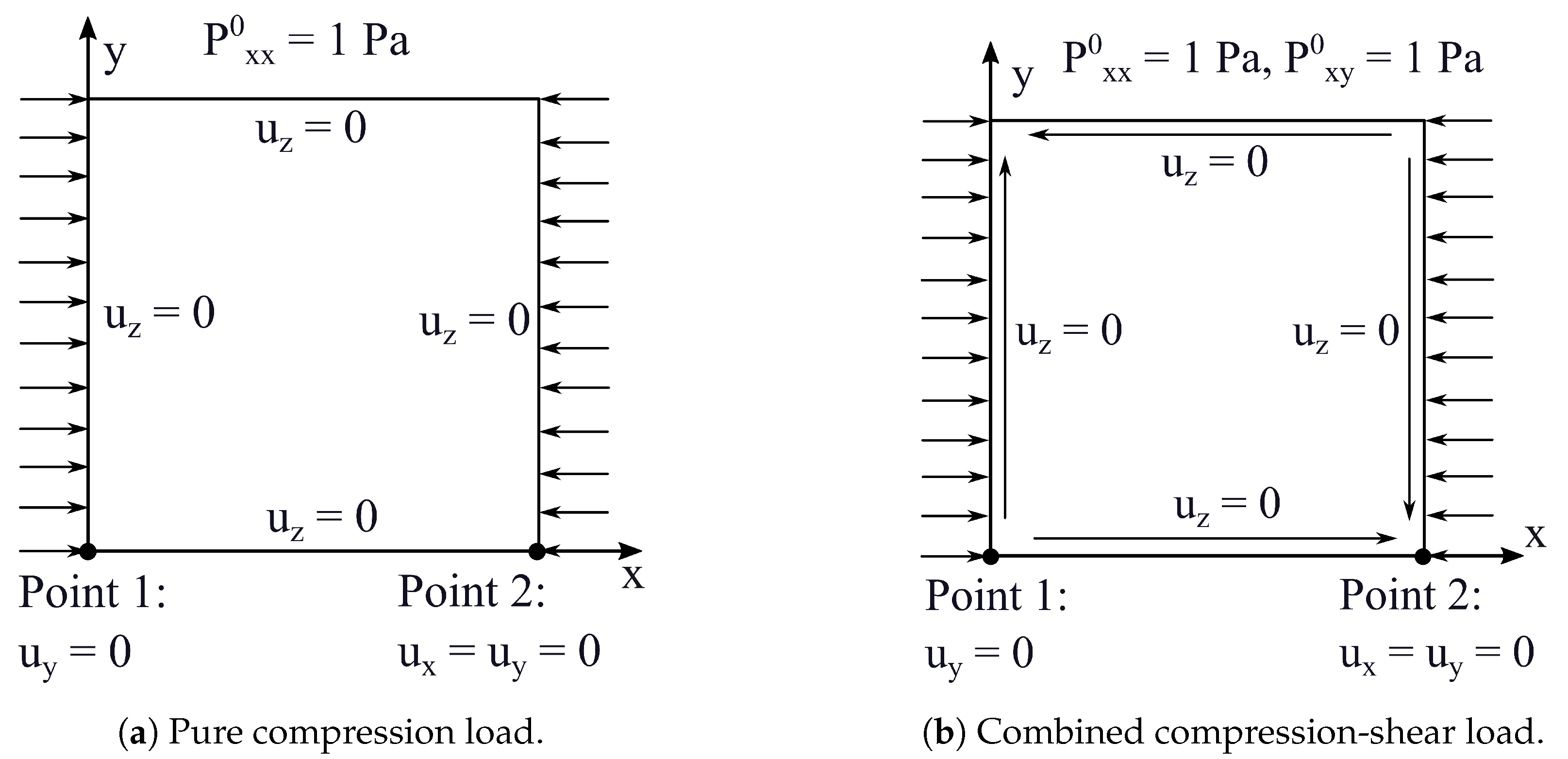

Figure 9.

In-plane fibers path and stacking sequence, case 2.

Figure 9.

In-plane fibers path and stacking sequence, case 2.

Figure 10.

Boundary and loading conditions, case 2.

Figure 10.

Boundary and loading conditions, case 2.

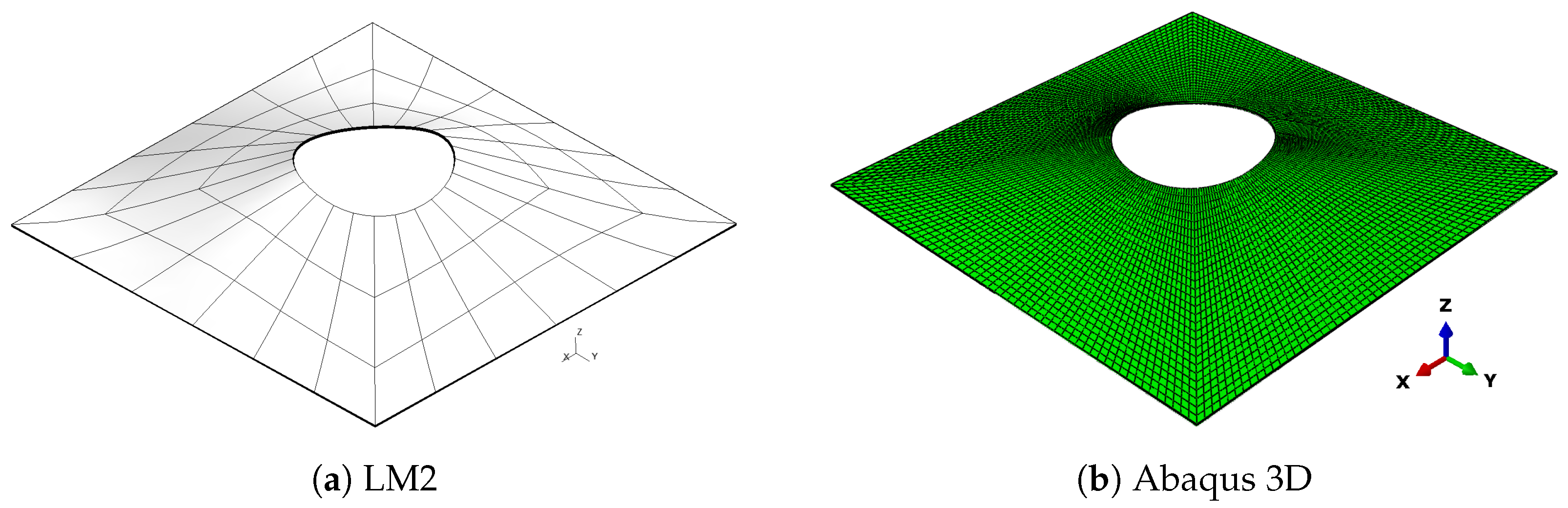

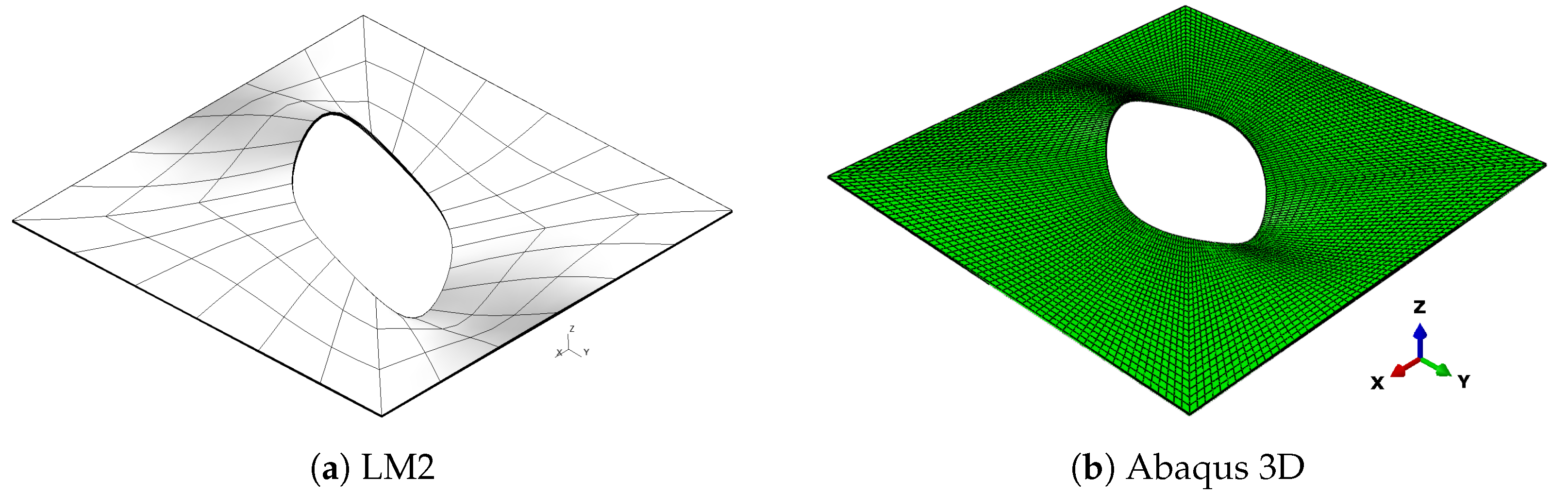

Figure 11.

First buckling mode, compression-shear load Pa, case 3.

Figure 11.

First buckling mode, compression-shear load Pa, case 3.

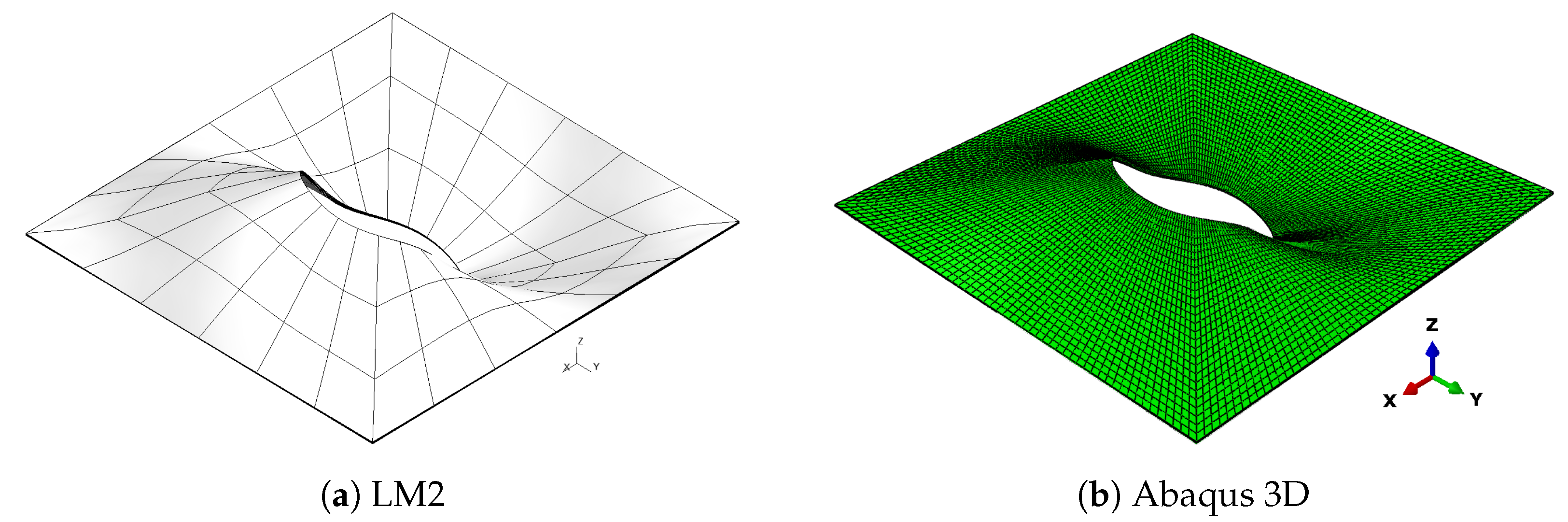

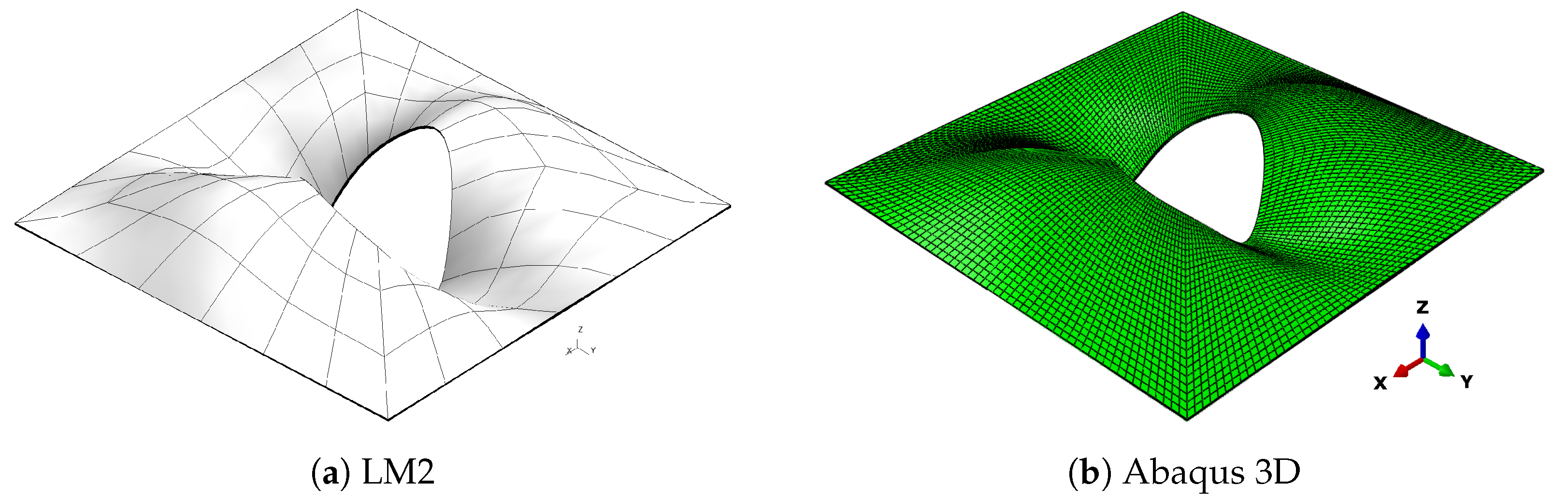

Figure 12.

Second buckling mode, compression-shear load Pa, case 3.

Figure 12.

Second buckling mode, compression-shear load Pa, case 3.

Figure 13.

Third buckling mode, compression-shear load Pa, case 3.

Figure 13.

Third buckling mode, compression-shear load Pa, case 3.

Figure 14.

Fourth buckling mode, compression-shear load Pa, case 3.

Figure 14.

Fourth buckling mode, compression-shear load Pa, case 3.

Table 1.

Material properties.

Table 1.

Material properties.

| Case |

[GPa] |

[GPa] |

[GPa] |

[GPa] |

,

|

| 1 |

50 |

10 |

5 |

5 |

|

| 2, 3 |

181 |

|

|

|

|

Table 2.

Comparison of DOF and critical loads [N] between Abaqus 3D and ED2 mesh, case 1.

Table 2.

Comparison of DOF and critical loads [N] between Abaqus 3D and ED2 mesh, case 1.

| |

DOF |

|

|

|

|

| Abaqus 3D |

1,310,499 |

28.926 |

57.366 |

85.585 |

122.498 |

|

225 |

29.901 |

57.475 |

136.926 |

170.607 |

|

729 |

28.126 |

55.545 |

88.768 |

125.994 |

|

1521 |

28.333 |

56.023 |

85.550 |

122.138 |

|

2601 |

28.473 |

56.323 |

85.196 |

121.744 |

|

3969 |

28.565 |

56.524 |

85.160 |

121.739 |

Table 3.

Number of degrees of freedom, case 1.

Table 3.

Number of degrees of freedom, case 1.

| Model |

DOF |

| Abaqus 3D |

1,310,499 |

| 3LM4 |

22,542 |

| 3LM2 |

12,138 |

| 3LD4 |

11,271 |

| 3LD2 |

6069 |

| ED4 |

4335 |

| ED2 |

2601 |

| FSDT |

1734 |

| CLT |

1734 |

Table 4.

Critical loads [N], case 1.

Table 4.

Critical loads [N], case 1.

| |

|

|

|

|

| Abaqus 3D |

28.926 |

57.366 |

85.585 |

122.498 |

| 3LM4 |

28.962 |

57.319 |

85.796 |

122.756 |

| 3LM2 |

28.958 |

57.309 |

85.788 |

122.743 |

| 3LD4 |

28.979 |

57.478 |

85.891 |

122.928 |

| 3LD2 |

28.979 |

57.479 |

85.892 |

122.929 |

| ED4 |

28.468 |

56.296 |

85.154 |

121.683 |

| ED2 |

28.473 |

56.323 |

85.196 |

121.744 |

| FSDT |

30.461 |

59.571 |

90.594 |

128.661 |

Table 5.

Critical loads [N], pure compression load Pa, case 2.

Table 5.

Critical loads [N], pure compression load Pa, case 2.

| |

|

|

|

|

| Abaqus 3D |

13.63 |

21.57 |

35.42 |

54.46 |

| Ref. [7] |

13.63 |

21.64 |

35.41 |

54.56 |

| Ref. [28] |

13.67 |

21.68 |

35.69 |

54.60 |

| LM4 |

13.63 |

21.57 |

35.62 |

54.47 |

| LM2 |

13.63 |

21.57 |

35.62 |

54.47 |

| LD4 |

13.63 |

21.57 |

35.62 |

54.47 |

| LD2 |

13.63 |

21.57 |

35.62 |

54.47 |

| ED4 |

13.64 |

21.71 |

35.80 |

54.60 |

| ED2 |

13.67 |

21.74 |

35.85 |

54.81 |

| FSDT |

13.84 |

22.03 |

36.46 |

55.47 |

| CLT |

14.00 |

22.35 |

36.97 |

56.83 |

Table 6.

Critical loads [N], compression-shear load Pa, case 2.

Table 6.

Critical loads [N], compression-shear load Pa, case 2.

| |

|

|

|

|

| Abaqus 3D |

12.04 |

18.46 |

30.86 |

41.87 |

| Ref. [7] |

12.04 |

18.49 |

30.83 |

41.84 |

| LM4 |

12.05 |

18.51 |

31.03 |

42.39 |

| LM2 |

12.05 |

18.51 |

31.03 |

42.39 |

| LD4 |

12.05 |

18.51 |

31.03 |

42.39 |

| LD2 |

12.05 |

18.51 |

31.03 |

42.39 |

| ED4 |

12.07 |

18.55 |

31.14 |

42.56 |

| ED2 |

12.08 |

18.58 |

31.20 |

42.75 |

| FSDT |

12.49 |

19.31 |

32.50 |

44.12 |

| CLT |

12.65 |

19.55 |

32.98 |

45.08 |

Table 7.

Critical loads [N], compression load Pa, case 3.

Table 7.

Critical loads [N], compression load Pa, case 3.

| |

|

|

|

|

| Abaqus 3D |

13.322 |

22.522 |

31.974 |

36.974 |

| LM4 |

13.294 |

22.386 |

31.352 |

37.071 |

| LM2 |

13.298 |

22.390 |

31.360 |

37.077 |

| LD4 |

13.378 |

22.534 |

31.661 |

37.280 |

| LD2 |

13.383 |

22.539 |

31.672 |

37.288 |

| ED4 |

13.369 |

22.554 |

31.763 |

37.301 |

| ED2 |

13.420 |

22.633 |

31.916 |

37.432 |

| FSDT |

13.562 |

22.937 |

32.317 |

38.092 |

| CLT |

13.637 |

23.144 |

32.757 |

38.402 |

Table 8.

Critical loads [N], compression-shear load Pa, case 3.

Table 8.

Critical loads [N], compression-shear load Pa, case 3.

| |

|

|

|

|

| Abaqus 3D |

11.152 |

19.396 |

23.956 |

32.302 |

| LM4 |

11.146 |

19.322 |

23.491 |

32.337 |

| LM2 |

11.149 |

19.326 |

23.496 |

32.343 |

| LD4 |

11.204 |

19.436 |

23.638 |

32.519 |

| LD2 |

11.207 |

19.440 |

23.646 |

32.526 |

| ED4 |

11.228 |

19.490 |

23.730 |

32.611 |

| ED2 |

11.253 |

19.536 |

23.808 |

32.709 |

| FSDT |

11.355 |

19.761 |

24.078 |

33.190 |

| CLT |

11.416 |

19.943 |

24.372 |

33.519 |