1. Introduction

Life Cycle Assessment (LCA) is a powerful tool used to assess the environmental impact of processes and products. It involves analyzing the material and energy flows throughout the entire life cycle of a product, such as from cradle to grave or cradle to gate, enabling the quantification of the impacts and identification of bottlenecks and improvement opportunities of the environmental performance. It quantifies the environmental impact of a set of elementary processes throughout the life cycle of a product. The ISO 14040 provides general guidelines for conducting LCA, which defines LCA as the "compilation and evaluation of the inputs, outputs, and potential environmental impacts of a product system throughout its life cycle." The life cycle includes the utilization of natural resources for the production of inputs and products, transportation stages, product use, and final disposal.

In transition to a low-carbon economy, LCA of a productive process becomes of fundamental importance. LCA enables the identification of bottlenecks and improvement opportunities in terms of environmental aspects throughout the life cycle of a production process. It can assist the design of an industrial process comparing the environmental impact caused by different technological routes. This tool can help in a decision-making process or even to be used for marketing purposes, showing the process is really green.

Despite the availability of various LCA tools like OpenLCA®, SimaPro®, and Gabi®, these software platforms lack integration with modeling, simulation, and process optimization environments. Previous studies integrating LCA with process simulation have not employed a structured approach that allows for direct integration of an LCA software with a process simulator [1-3].

Kalakul et al. [

4] developed an LCA calculator (LCSoft) integrated with process simulation tool, but it did not represent an integration of LCA software that includes a comprehensive database and LCA methodologies. Thus, there were some discrepancies between the results from SimaPro and LCSoft. Furthermore, the calculated values were not widely integrated within the simulation environment.

The structured integration of life cycle assessment calculations into modeling, simulation, and process optimization environments creates a powerful tool for the development of cleaner processes. A structured integration allows consistency of the LCA through a proper query of the inventory databases with assessment methodologies. This consistency is fundamental to guarantee that the LCA is properly evaluated according to each methodology of impact factors. This type of tool not only provides a way for monitoring emissions throughout the product life cycle but also offers valuable metrics for determining the most sustainable process design.

The Life Cycle Inventory (LCI) involves data collection and calculations to quantify the inputs and outputs of the defined product system. The ISO 14040 also states that all mass and energy flows should be considered, including different raw materials, and energy sources used, as well as the efficiency of energy conversion.

In Life Cycle Impact Assessment (LCIA), various methodologies have been developed. Among the existing methodologies, two main approaches are used to classify and characterize environmental impacts: the problem-oriented approach (midpoint) and the damage-oriented approach (endpoint). Among the methodologies include the CML-IA [

5] and ReCiPe [

6] approaches.

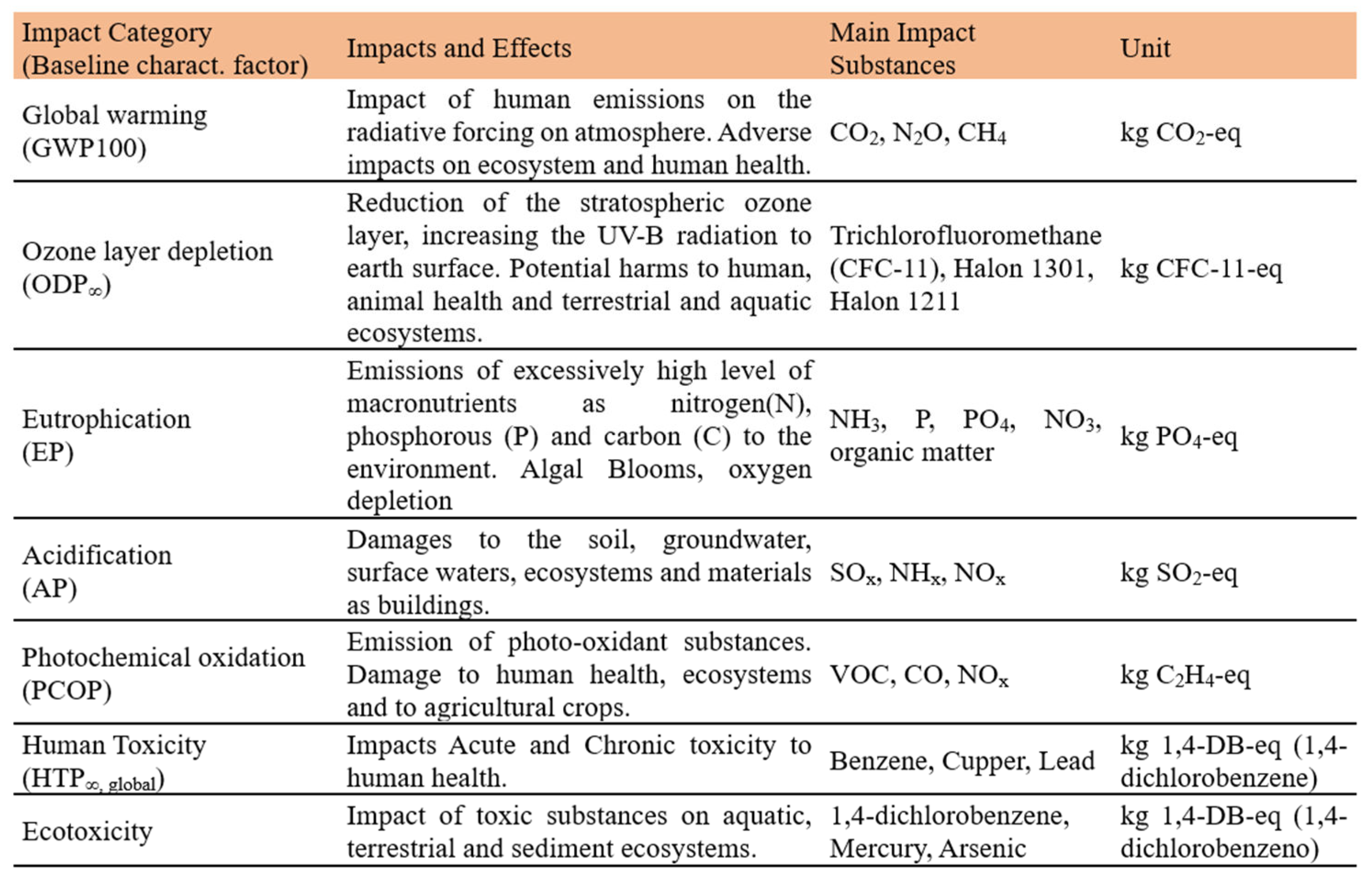

Table 1 presents some impacts categories and its respective baseline characterization factors from CML-IA baseline, impacts and effects, main impact substances and unit of measurement.

Several software tools, such as OpenLCA®, SimaPro®, and Gabi®, have incorporated Life Cycle Inventory (LCI) databases and impact assessment methodologies. OpenLCA® is free software for LCA; however, the acquisition of specific database licenses is required. The impact assessment methodologies available in OpenLCA® include CML-IA 2001 [

5], ReCiPe 2016 [

6], and 99 other methodologies, totaling 1,479 impact categories.

This study aims to bridge this gap by proposing the integration of the OpenLCA software's database with the process modeling, simulation, and optimization tool EMSO® [

7]. A dedicated tool for integrating these two software platforms has been developed.

EMSO® is an open environment for process modeling, simulation, and optimization with equation-oriented approach and object-oriented modeling language [

7]. EMSO® offers seamless integration with OPC®, Python, Matlab®, Scilab®, Excel®, LibreOffice®, and provides easy integration with real-time industrial systems.

The proposed tool, EMSO_OLCA, enables several valuable functionalities, including real-time emissions monitoring, optimal process design considering environmental parameters, techno-economic environmental analysis of processes, and optimization and control of processes guided by environmental metrics. The main advantage is that the tool is totally integrated to the EMSO’s environment, allowing the LCA results be solved simultaneously to the process simulations, design, optimization, sensitivity analysis, and parameter estimation.

2. Methodology

The EMSO_OLCA tool was developed in C++ and follows the structure defined by the ISO 14040 [

8] Life Cycle Assessment - Principles and Framework, and ISO 14044 [

9] Environmental management — Life cycle assessment — Requirements and guidelines. This tool integrates EMSO with the LCA methodologies available in the OpenLCA, and the calculation of inputs is obtained from the LCIA database of process inputs. It leverages the comprehensive database provided by OpenLCA. Additionally, since the impact assessment databases are provided by OpenLCA, they are automatically updated by OpenLCA, thus, this eliminates the need for separate database updates.

The requirements for using the EMSO_OLCA tool are as follows:

Obtain the LCIA methods from the OpenLCA Nexus website. These files are proprietary to OpenLCA but are available free of charge.

Select and export the impacts of process inputs in OpenLCA to a .csv file using the provided export functionality.

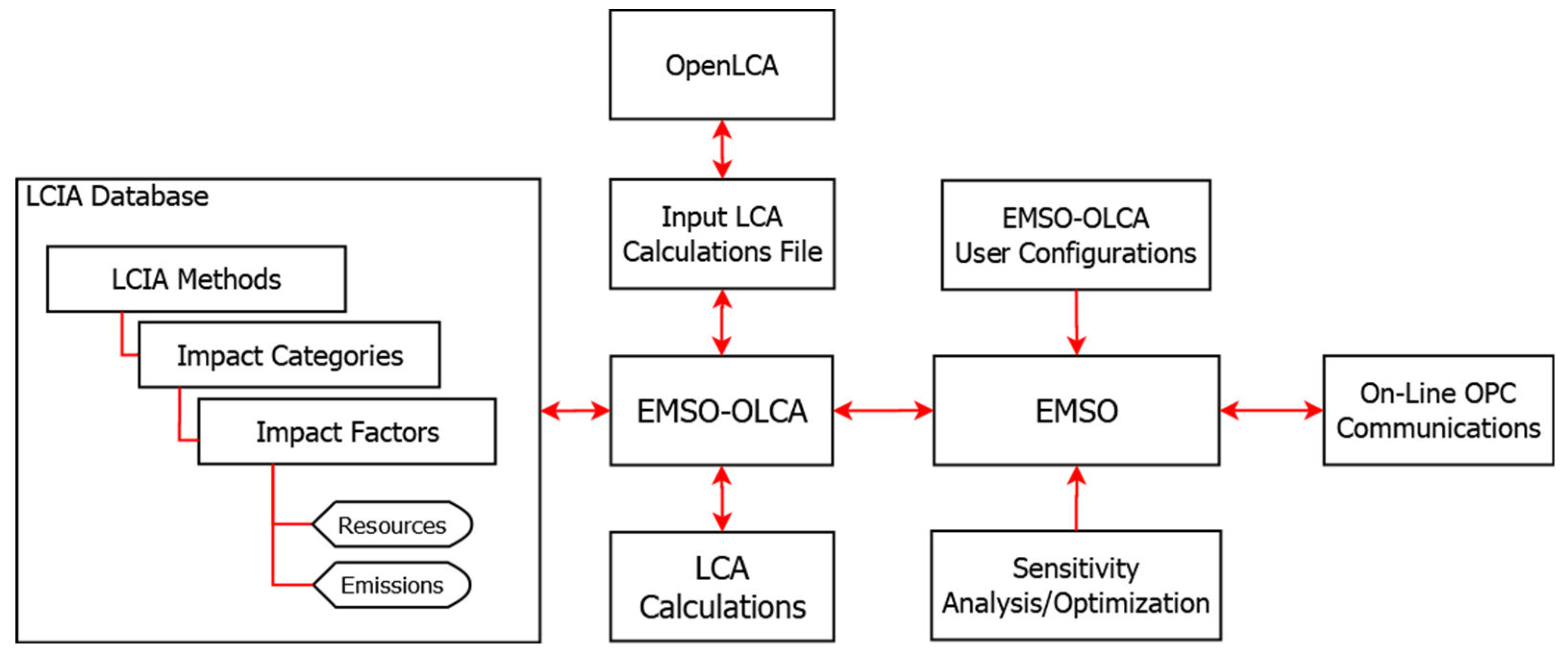

The information flow in the EMSO_OLCA tool is bidirectional between EMSO and EMSO_OLCA. User sets the EMSO-OLCA User Configurations that informs the LCA inventory, the methodology and the characterization factors in EMSO, which are passed down to EMSO_OLCA. EMSO_OLCA then queries the LCIA database and retrieves the impact factors based on the characterization factors defined by the user. EMSO_OLCA also searches for the file containing the pre-calculated impact assessment of inputs, which is generated by a Python application in OpenLCA, as illustrated in

Figure 1.

As in

Figure 1, EMSO-OLCA performs the LCA calculations, which are directly available within the EMSO environment. This integration enables extensive utilization of sensitivity analysis and internal optimization tools provided by the simulator. Moreover, EMSO allows communication obtained LCA values through industrial protocols such as OPC and Python.

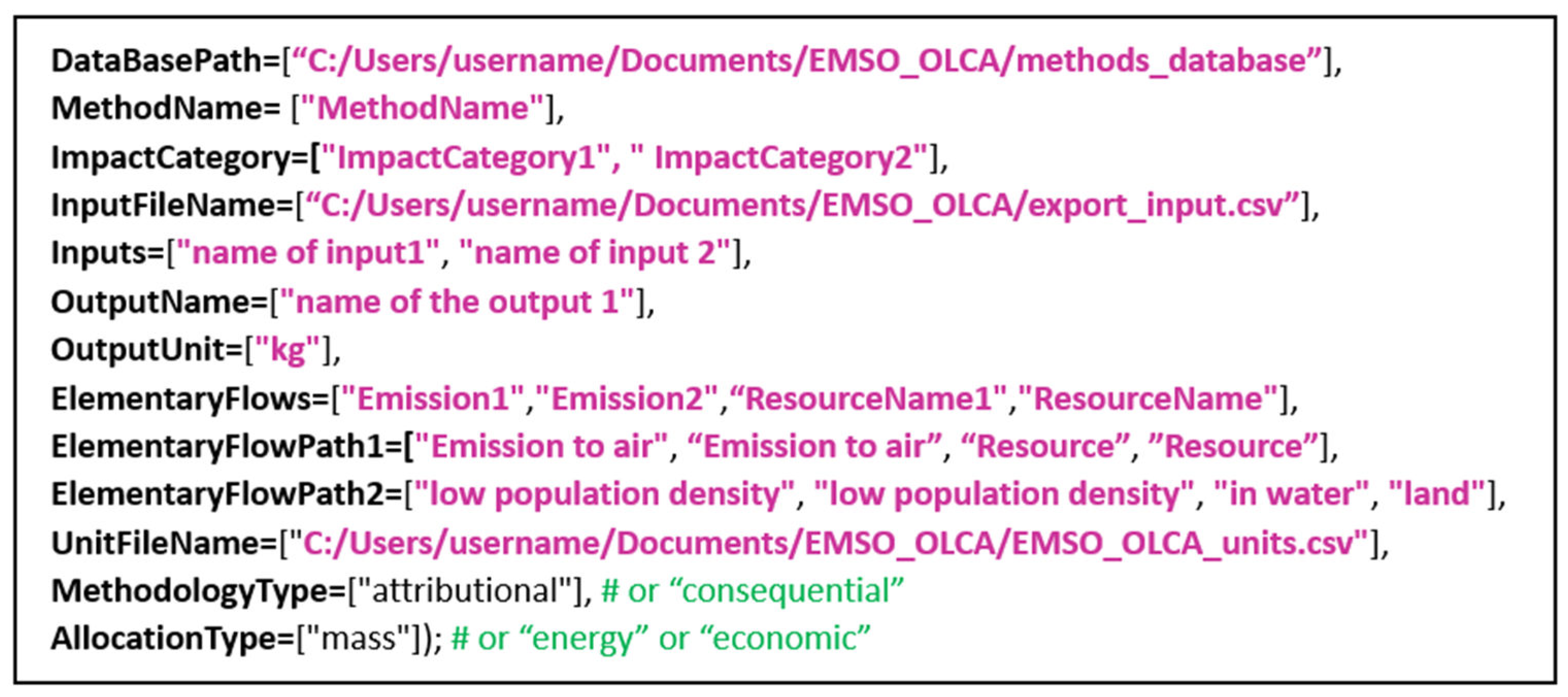

In the user settings, it is required to fulfill the information related to the LCA scope and inventory: the functional unit is defined; as well as the impact methods and impact categories, and the LCIA database path. The user settings also include: the type of methodology (attributional or consequential) and the type of allocation and the path of the file containing the pre-calculated inputs. The user configuration syntax is presented in

Table 2.

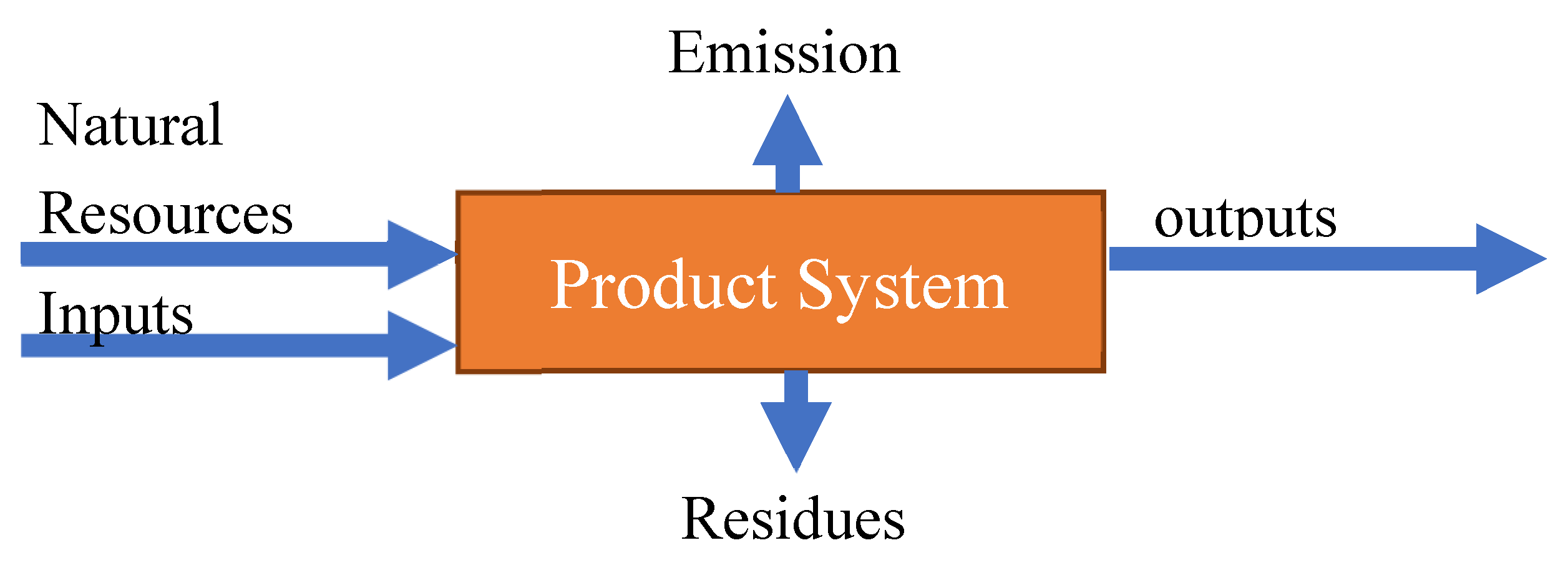

The inventory of a product system is defined by the user, which englobes inputs of energy, inputs of raw materials, outputs as products and co-products, and elementary flows. The elementary flows include emissions to atmosphere, water and soil, waste, and use of natural resources, as depicted in

Figure 2. All the names of the inputs, outputs and elementary flows are defined in the user settings as well as the inventory quantities, which can be associated with the simulation variables, ensuring mass and energy balances.

For calculation purposes, each impact assessment methodology has associated impact categories. Category "

c" defines a specific impact factor for each component "

i" (

). The total impact value of category "

c" (

) is obtained by multiplying the Impact Factor

of component "

i" for category "

c" with the quantity of component "

i" emitted (

), as shown in Equation 1 [

10].

The impact factor values for the inputs are obtained through the OpenLCA software and exported as a .csv file. The OpenLCA links the elementary flows emitted during the life cycle of the inputs production and exports the results to the .csv file. For emissions and residues emitted during the process, the impact factor is directly obtained from the impact factor database for each impact.

There is an allocation option for multi-product systems, using attributional approach. In this case, the total impact value of category "

c" is multiplied by the allocation factor

. The calculation of the allocation factor is given by Equation 2 [

5]:

where the quantity is given by (

) and

is the allocation parameter for each product of the product system analyzed. The denominator is the sum of the product of the units multiplied for the allocation parameter. For mass allocation, the allocation parameter (

) is set to 1 for all products. This means that the impact of the category is evenly distributed among the different products based on their mass. For energy allocation, the allocation parameter (

) is set to the energy content of each product (in MJ/kg). This means that the impact of the category is allocated to the products based on their energy content. For economic allocation, the allocation parameter (

) is set to the price of each product (in

$/kg). This means that the impact of the category is allocated to the products based on their economic value or price.

2.1. Validation of EMSO_OLCA compared to OpenLCA

A validation test was conducted to examine the calculation error of the EMSO_OLCA tool in comparison to the values obtained from OpenLCA. In the implementation test of the EMSO_OLCA tool, the EcoInvent 3.8 [

11] database inventory was used for a case study of ethanol production for autonomous units as a reference. The results obtained from OpenLCA and EMSO_OLCA were compared. In this test, the CML-IA baseline methodology was used with all the characterization factors associated with this method. Furthermore, a simulation with LCA case study was also conducted on the production of steam and energy from sugarcane bagasse and straw.

2.2. Combined Heat and Power (CHP) Study Case

A case study was also conducted on the LCA of a bioenergy and steam cogeneration unit. Scenarios for bioenergy and steam production from sugarcane bagasse and straw were compared. The composition of sugarcane bagasse was 42.19% cellulose, 27.60% hemicellulose, 21.56% lignin, 5.63% impurities, and 2.84% ash [

12]. The composition of straw was 46.05% cellulose, 27.20% hemicellulose, 24.67% lignin, and 2.08% ash [

13]. Oliveira et al. [

14] estimated the availability of sugarcane bagasse at 153 kg per ton of sugarcane with 10% moisture content, and 94 kg of straw per ton of sugarcane with 10% moisture content.

The parameters adopted in the boiler simulation were: boiler efficiency based on the lower heating value of 87.2%; gas outlet temperature of 160°C; produced steam pressure and temperature of 65 bar and 485°C; excess air of 30% [

15,

16]. The combustion reactions of cellulose, hemicellulose, and lignin were considered, with reaction values of -2804.2, -2170.9, and -5243 kJ/mol, respectively [

15]. A turbine efficiency of 85% and generator efficiency of 98% were assumed [

16]. The steam demand for a first-generation ethanol plant (1G) is 370.5 kg of 2.5-bar steam per ton of processed sugarcane [

17]. The plant operates 80% of the time during 210 days in a year for a horizon of 25 years [

17].

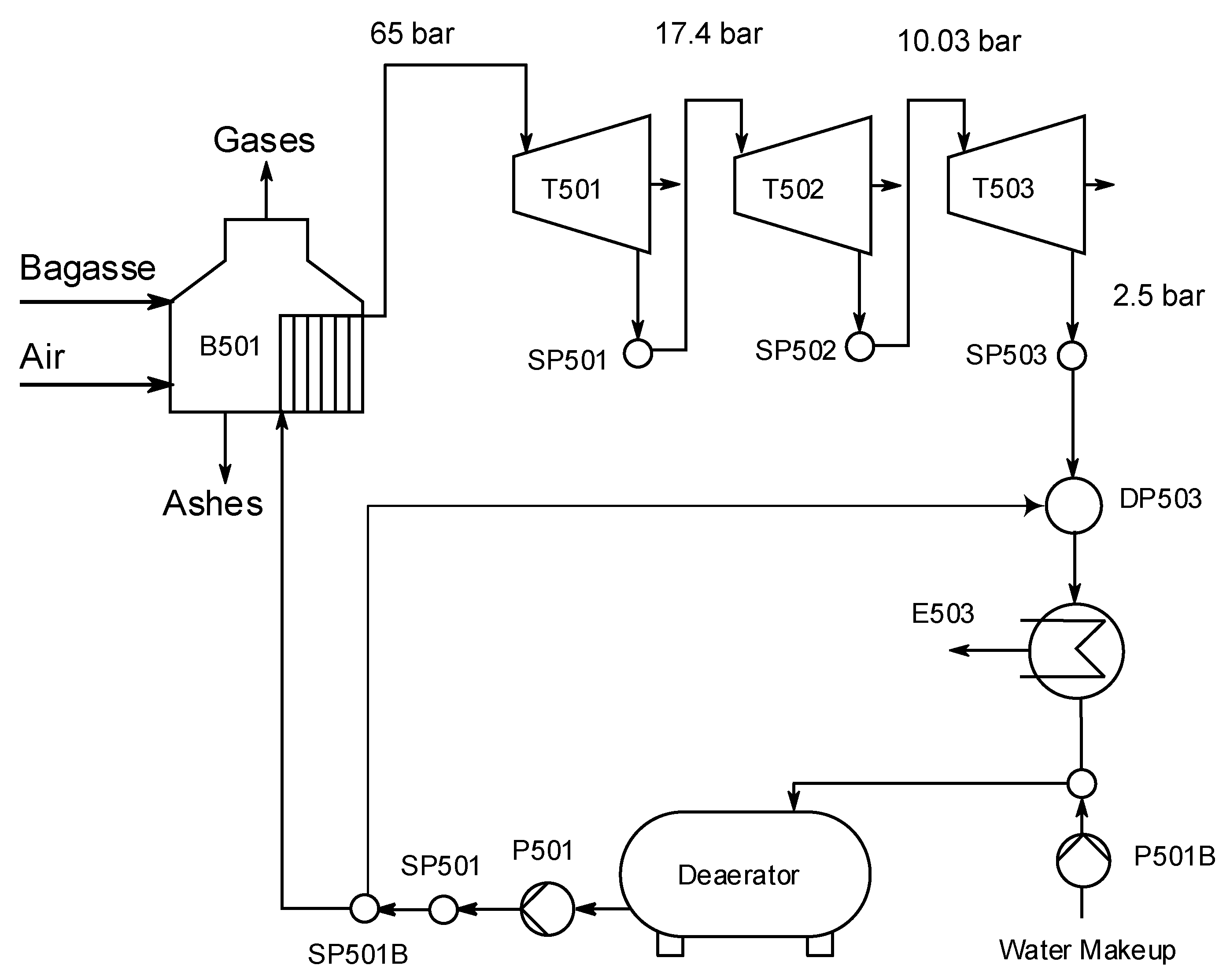

Two scenarios were considered for this steam demand. In the first scenario, the quantity of bagasse and straw was designed to meet the steam demand, using a 65-bar boiler. In the boiler, biomass is burned with excess air to produce superheated steam at 65 bar. The steam is directed to a three-stage turbine, producing bioelectricity. After reaching a pressure of 2.5 bar, liquid water is added to obtain saturated steam. The steam is then directed to the process, releasing its latent heat and returning as saturated liquid. This liquid is added to the water makeup, which is directed to a deaerator receiving a small amount of steam at 2.45 bar, resulting in saturated liquid, which is compressed and returned to the boiler. A simplified diagram is presented in

Figure 3.

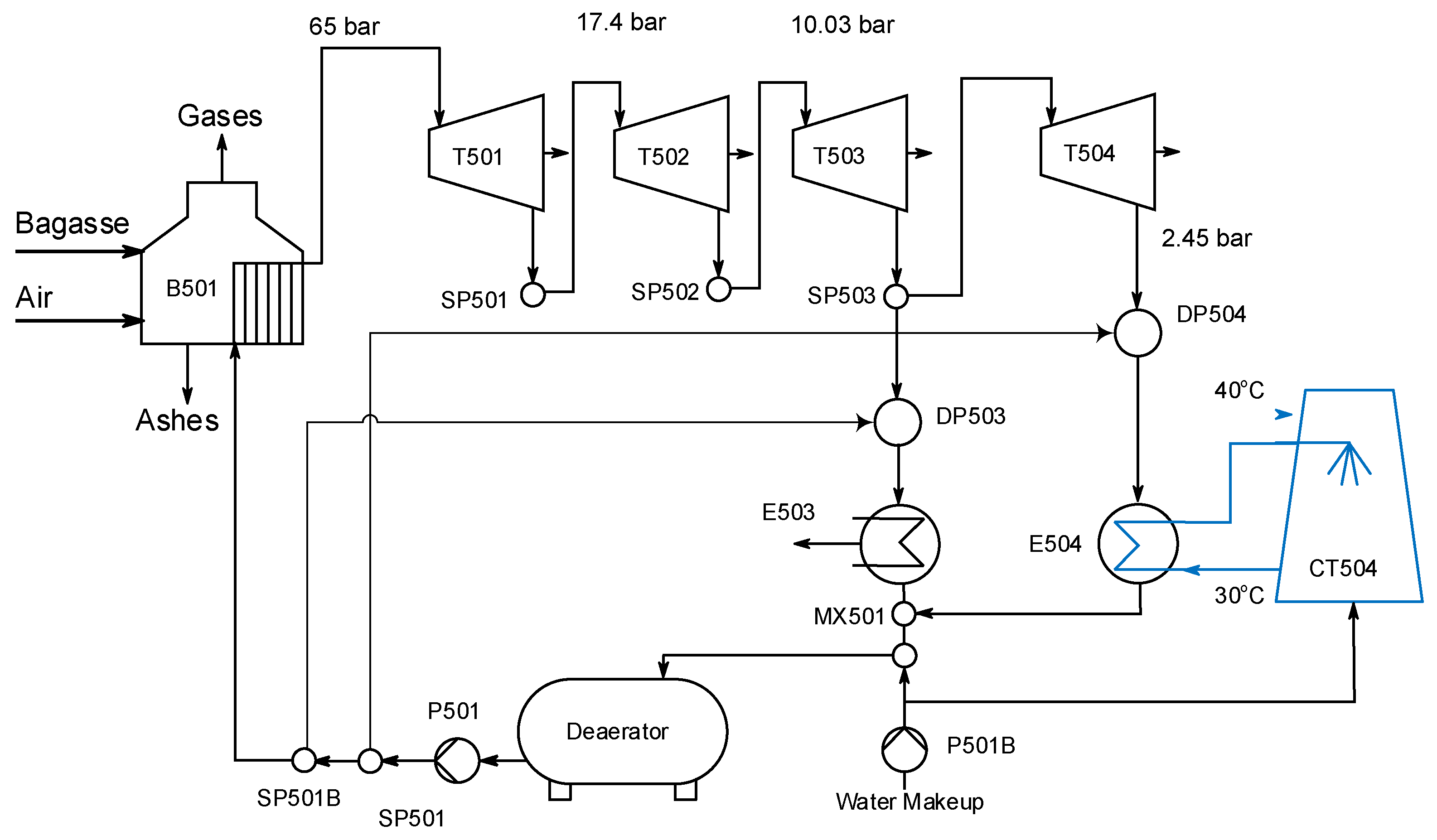

In the second scenario, an additional condensing turbine was added to the three-stage turbines, utilizing all available sugarcane bagasse and straw for power generation. As there is also steam generation in the condensing cycle, the heat produced in the condensing turbine is directed to a cooling tower. The diagram for this scenario is presented in

Figure 4.

In the case of cogeneration without a condensing turbine, Scenario 1, the objective of the Combined Heat and Power Unit is to meet the ethanol heat demand requirement. On the other hand, in the case of cogeneration with a condensing turbine, the objective of the plant is to increase the production of surplus electricity burning the bagasse and straw available. Considering the cogeneration process without a condensing turbine, the generated steam is sent to three back-pressure turbines, where the steam produced in one of the turbines is directed to the process units. In Scenario 2, there is no utilization of the steam from the condensing turbines, thus the heat is compensated by a cooling tower unit.

The simulation of the case studies was implemented in EMSO, and the environmental impact was assessed simultaneously in EMSO and OpenLCA using the EMSO_OLCA tool. For the LCA analysis, the methodology used was also the CML-IA baseline, incorporating all corresponding characterization factors in the attributional approach. The inputs considered were sugarcane bagasse and water. The outputs considered were the heat of the 2.5 bar steam in MJ and net bioelectricity production, taking into account the energy consumption of pumps and the water-cooling tower (if applicable).

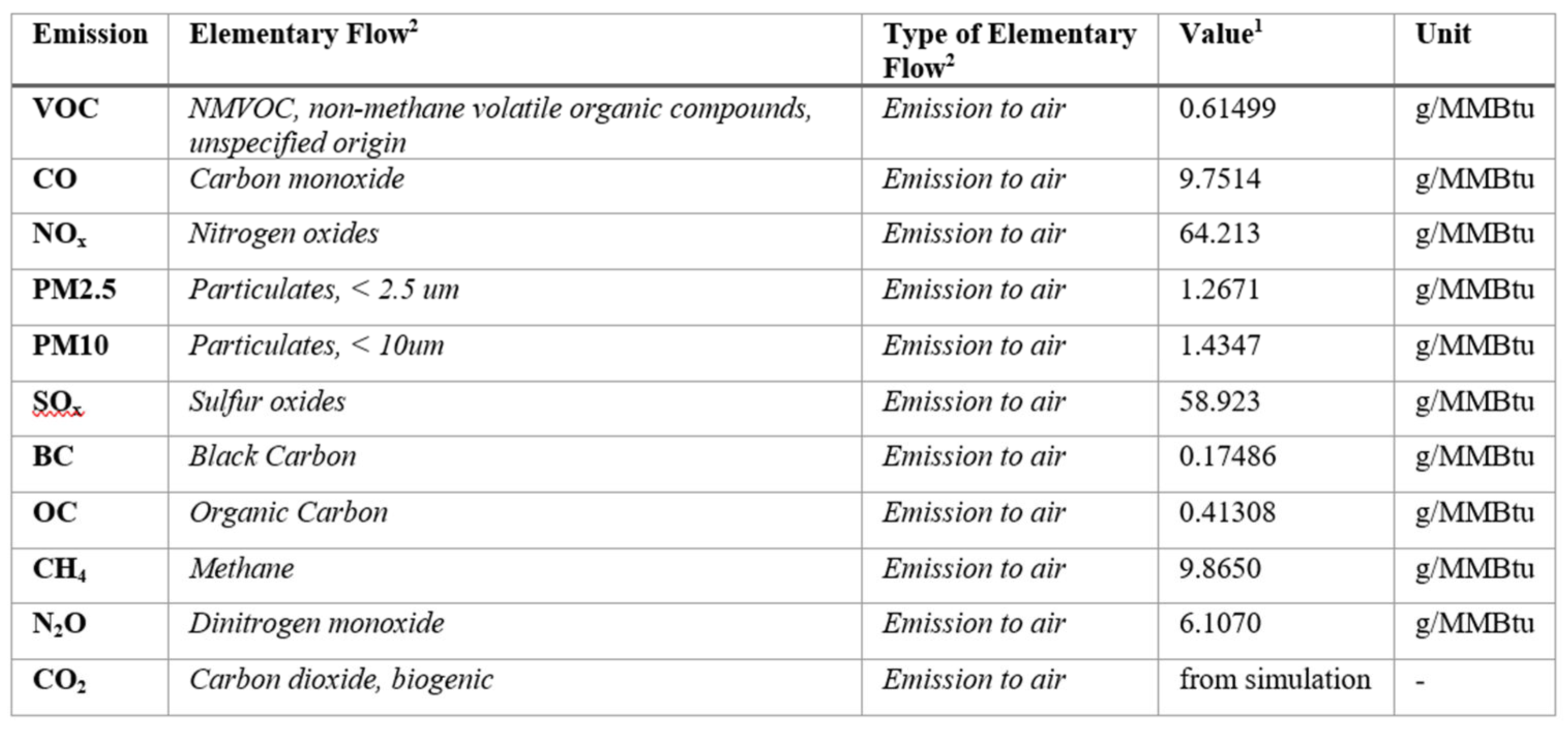

The emissions resulting from the combustion of bagasse and straw were referenced based on Greet [

18], and the combustion of biogenic CO

2 was obtained from the simulation. The reference for each emission considered is also presented in

Table 3.

From the simulation and estimation of emissions, the life cycle inventory of each simulated scenario was obtained. The scope of the LCA was cradle to gate. The categories and methodology applied were all categories of CML-IA Baseline methodology. The database EcoInvent 3.8 database was employed to assess the impacts from the inputs. The allocation was energy based. It was also identified the percentage each input and emission contributed to the LCA obtained result.

A simplified economic analysis was also performed to estimate the net revenue of steam production system. This analysis considered the process revenues, raw material costs per GJ of steam produced, as shown in Equation 3.

For the prices of bagasse, water, and energy, the average value in US dollars over the past 5 years was used for the Brazilian market, as shown in

Table 4.

A sensitivity analysis was conducted by comparing the results obtained from the life cycle assessment (GWP100a) and the net revenue varying the steam consumption. This sensitivity analysis was combined in two bagasse prices range: US$ 14.58 per ton for low bagasse prices and US$ 158.75 per ton for high bagasse prices.

3. Results and Discussion

3.1. Validation of EMSO_OLCA compared to OpenLCA

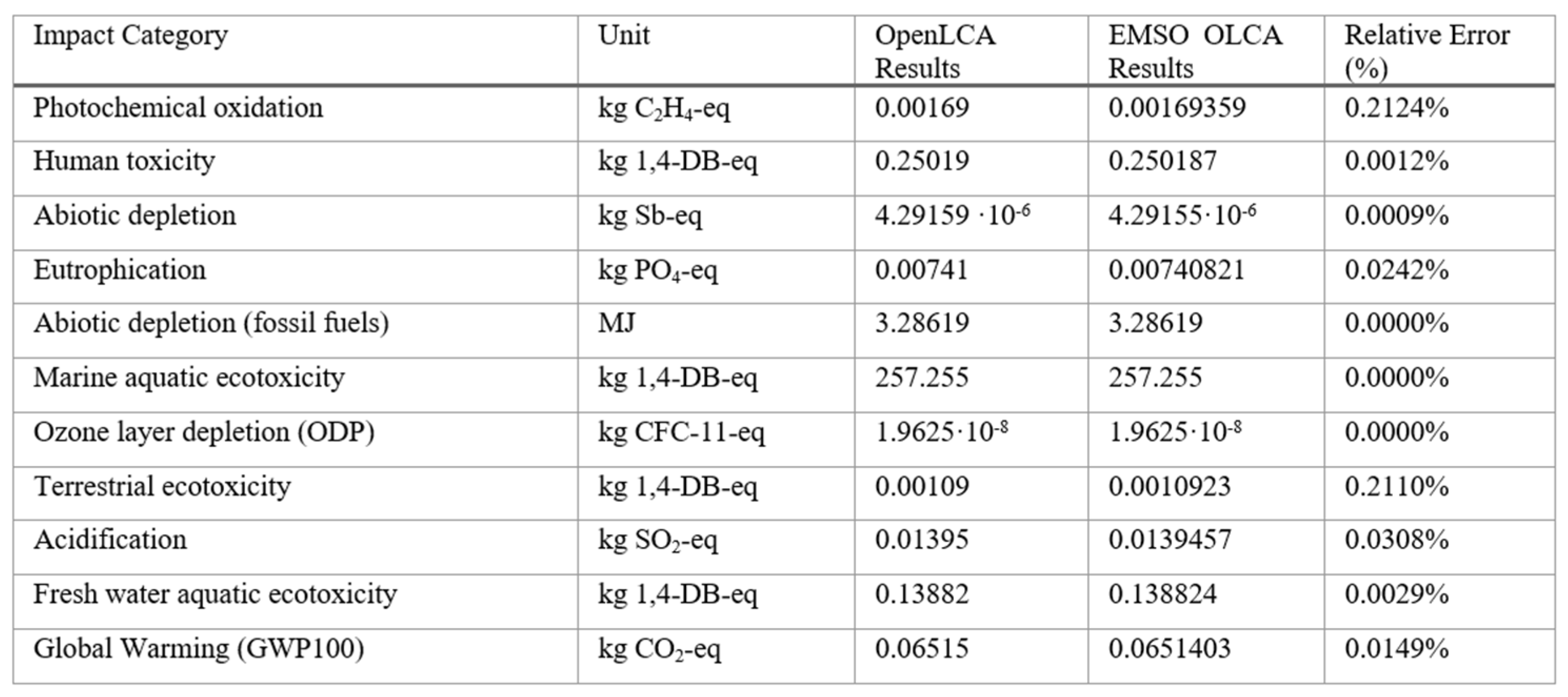

The results obtained of the comparison between the LCA from the inventory of sugarcane production in autonomous units in Brazil in OpenLCA and the results obtained from the same inventory in EMSO_OLCA applying CML-IA baseline methodology are presented in

Table 5.

Table 5 shows that EMSO_OLCA is capable of reproducing calculations from OpenLCA with high accuracy for all categories assessed. The average relative error is 0.045% for the evaluated categories. It is important to note that the computational time required for the calculations was 0.3 seconds, with a 12th Gen Intel® Core™ i7-12700 processer and 32 GB RAM memory. This time is significantly lower than the available LCA software, as a substantial portion of computational time is spent on the preliminary calculation of input impacts evaluation of OpenLCA. This high computational speed of 0.3 seconds is a valuable characteristic for real-time applications in process simulators as EMSO.

3.2. Combined Heat and Power (CHP) Study Case

In order to process a flow rate of 500 t/h of sugarcane, a total availability of 123.5 t/h of sugarcane bagasse and straw is observed. In general, 5% of the available sugarcane bagasse is reserved for unforeseen operational issues and for the start-up of the next harvest season. Thus, the total availability of bagasse and straw is 117.325 t/h. The steam consumption of a 1G ethanol plant is 370.5 kg of steam at 2.5 bar per ton of processed sugarcane [

17], thus, 185 tons of steam per hour are required, resulting in a demand of 113.35 MW of 2.5 bar steam.

As mentioned in the methodology, two scenarios of combined heat and power are studied: the first scenario, considered the production of steam in a 65 bar boiler and bioelectricity in a 3 stage turbine and 113.35 MW of 2.5 bar steam. The second scenario included the 65 bar boiler steam production in a 3 stage turbine to produce 113.35 MW of 2.5 bar steam, plus a condensing turbine in order to produce the maximum of electricity as possible. The heat produced in the condensing turbine is compensated by a cooling water tower.

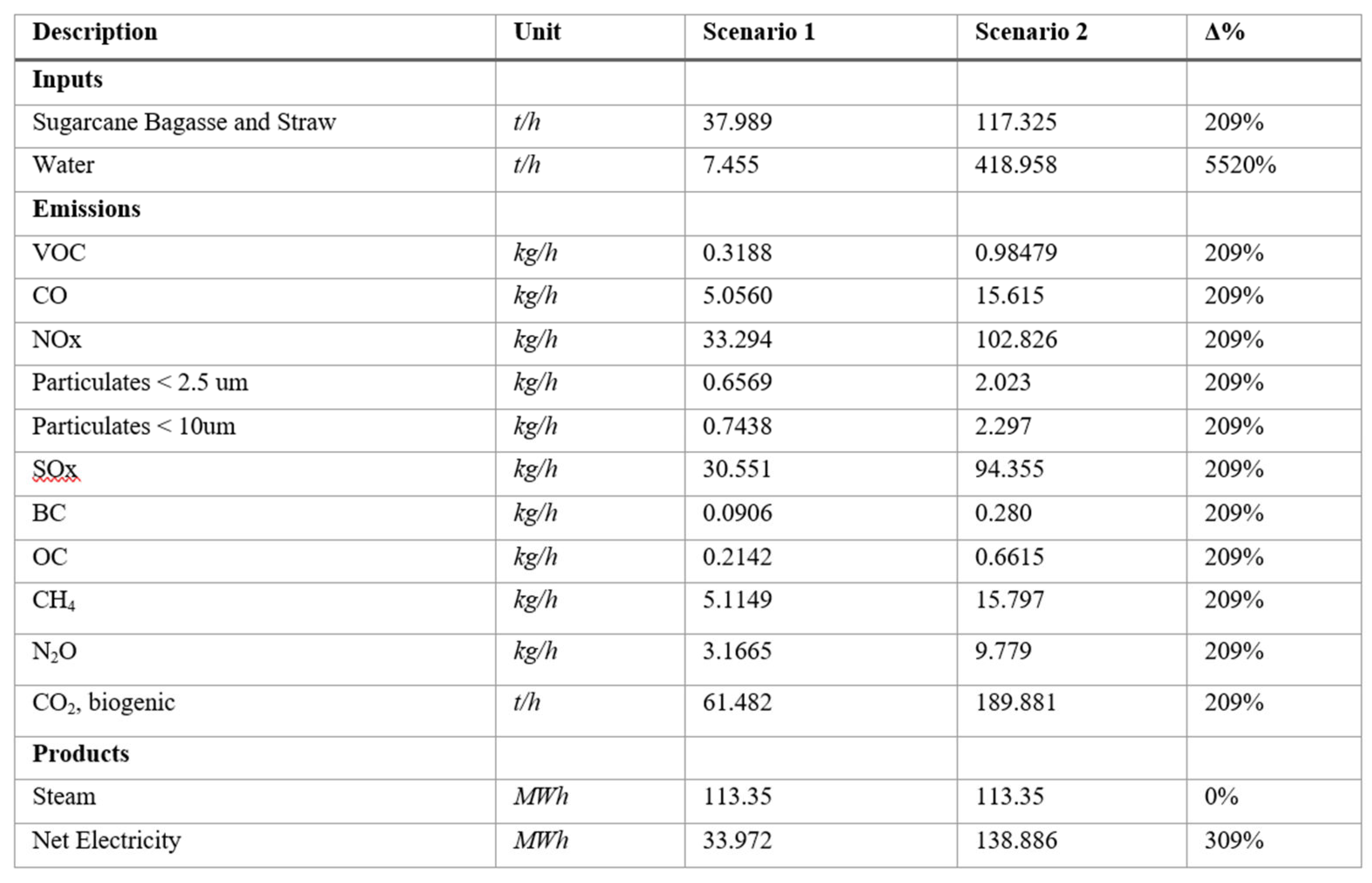

The life cycle inventories obtained supply 113.35 MW of 2.5 bar steam for both studied scenarios are presented in

Table 6.

As shown in

Table 6, the second scenario allows for the combustion of all available straw and bagasse. Therefore, there is a 209% increase in emissions resulting from biomass combustion in the boiler. However, it produces more net electricity totaling 138.87 MWh of surplus of electricity production. This can be explained because the condensing turbine enables the production of a greater amount of electricity, by burning all the available fuel. Moreover, as the steam generated (in condensing turbine) is not utilized in the process, it results in additional quantity of water usage and electricity consumption in the cooling tower. Therefore, this second alternative exhibits higher water, electricity and fuel consumption, thus, it is not efficient as the scenario without the condensing turbine.

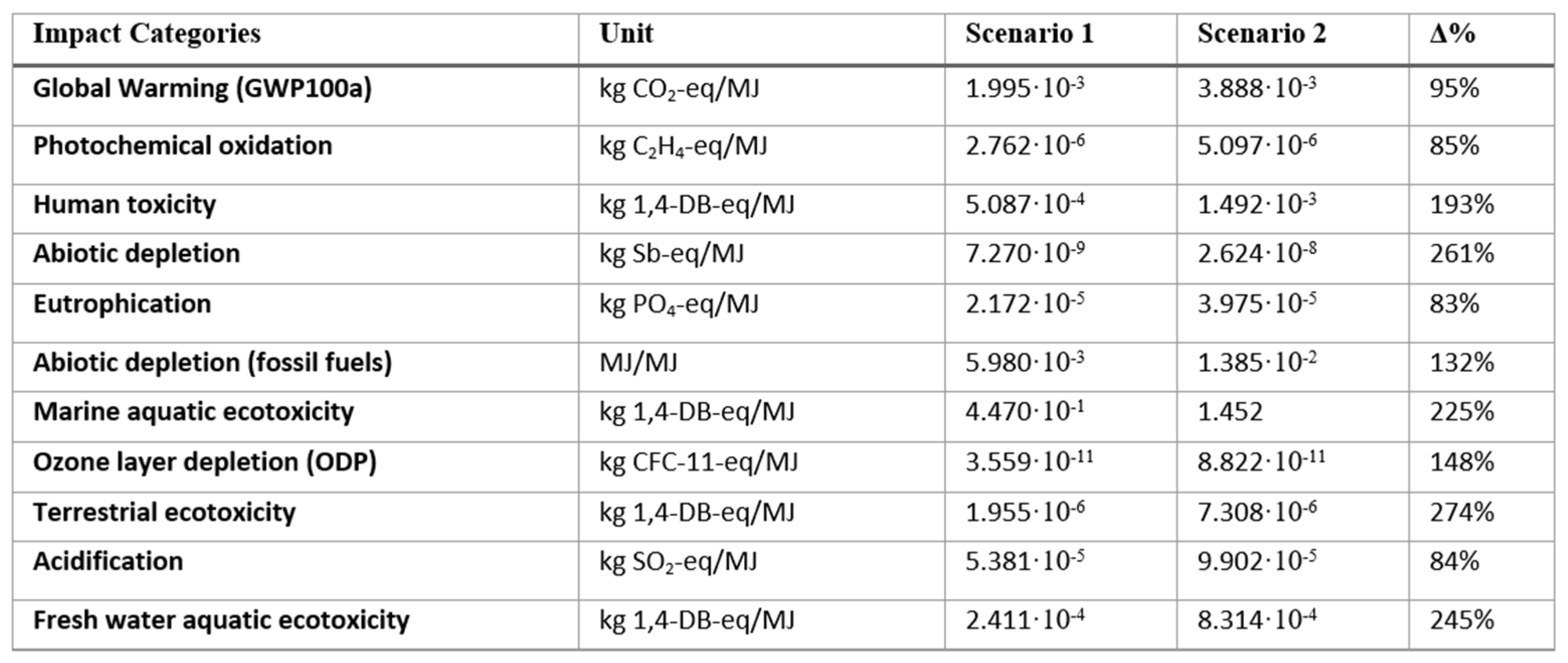

The life cycle assessment results for each studied scenario, using CML-IA methodology, are presented in

Table 7.

According to

Table 7, there is an increase in all impact categories per MJ of steam and net electricity when it is used the condensing turbine. This indicates that the intensity of the use of natural resources is increased with the condensing turbines. This occurs because there is a significant increase of bagasse burning and the heat of this extra stream production is totally wasted. Therefore, by incorporating the condensing turbine, the energy efficiency of 89.6% in Scenario 1 is reduced to 49.7% in Scenario 2. Thus, the use of cogeneration systems with condensing turbines leads to higher natural resource use intensity with lower efficiency.

The carbon intensity found for the first and second scenarios are equivalent to 7.18 kg of CO2-eq per MWh and 13.97 kg of CO2-eq per MWh, respectively. This value is equivalent to a reduction of 96% and 93% of the impact of the Brazilian electricity mix that are, according to EcoInvent 3.8, 201.01 kg of CO2-eq per MWh. As the results showed, the first scenario has lower carbon intensity as burns the amount of bagasse needed for the required steam production, and the second scenario burns all available bagasse to produce the maximum of electricity.

In relation to the economic aspect, the net revenue obtained for the first scenario is US$ 2.69 per GJ of steam and surplus electricity, and US$ 5.79 per GJ of steam and electricity for the second scenario without any carbon credit. The net revenue was also greater in the second scenario also due the higher quantity of electricity sold to the grid; thus, this type of designing could be interesting economically.

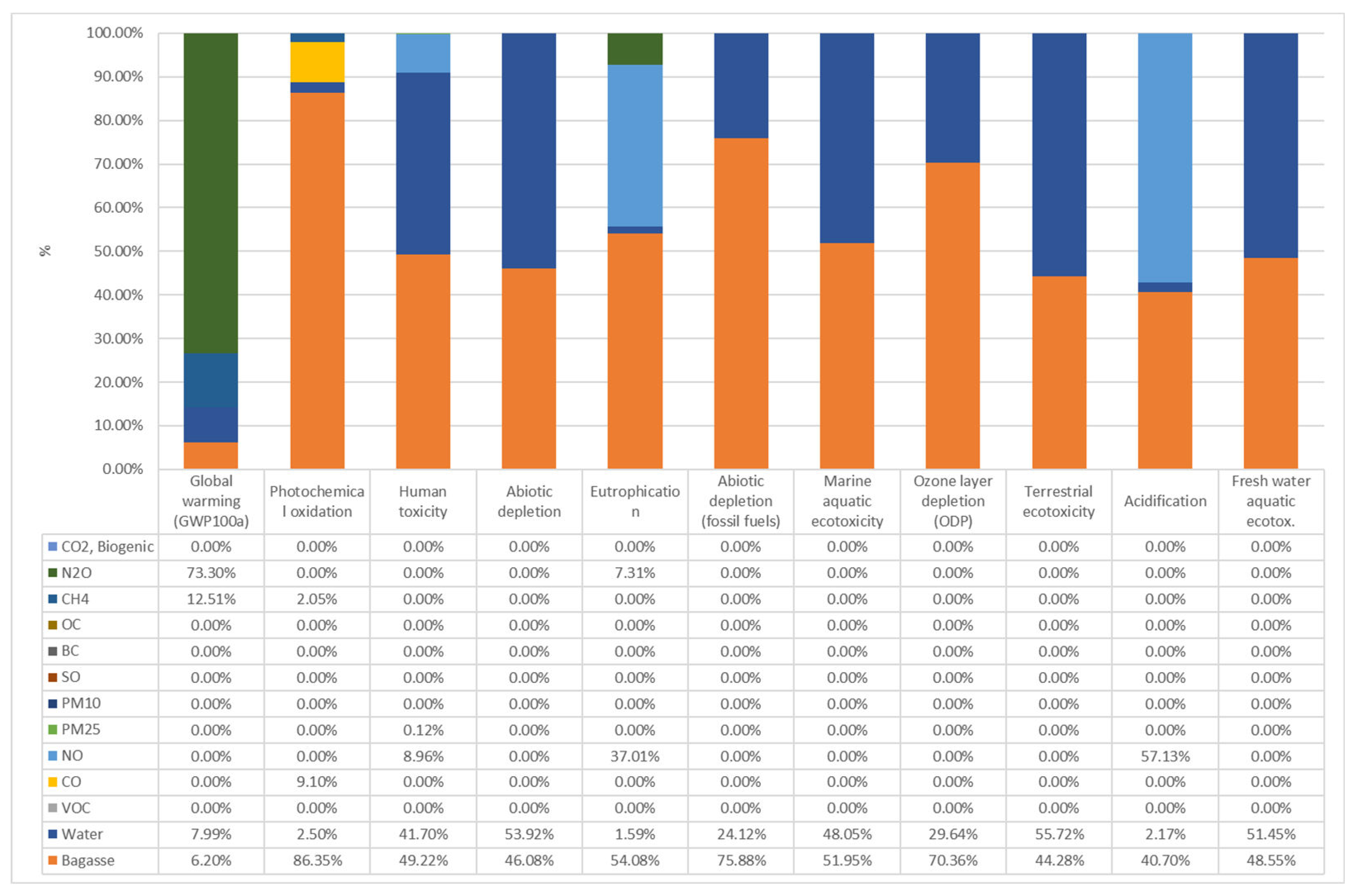

The EMSO_OLCA tool also allows the user to visualize the contributions of the inputs and the emissions on the LCA category results.

Figure 5 illustrates the contribution of inputs and emissions for the LCA of Scenario 1.

Figure 5 shows that the bagasse production impact is responsible for most of the impact of the assessed categories except acidification, eutrophication and global warming. In acidification, the NO produced in the bagasse burning is responsible for 58.3% of the impact. In eutrophication, the NO also is responsible by 37.6% of the impact and in global warming, dioxide of nitrogen also produced in bagasse burning is responsible by 79.3% of the impact of the Global Warming under a horizon of 100-years (GWP100).

Figure 6 illustrates the contribution of inputs and emissions for the LCA of Scenario 2.

As shown in

Figure 6, the impact of the water increases remarkably in comparison to

Figure 5. In this case, the extra steam produced goes to the condensing turbine and needs to be condensated by a cooling tower, thus, the water consumption is increased for the cooling tower water makeup. In relation to eutrophication and acidification categories, they are still impacted by nitrogen oxides emissions; and the global warming by the dioxide of nitrogen, that are produced in the sugarcane bagasse burning.

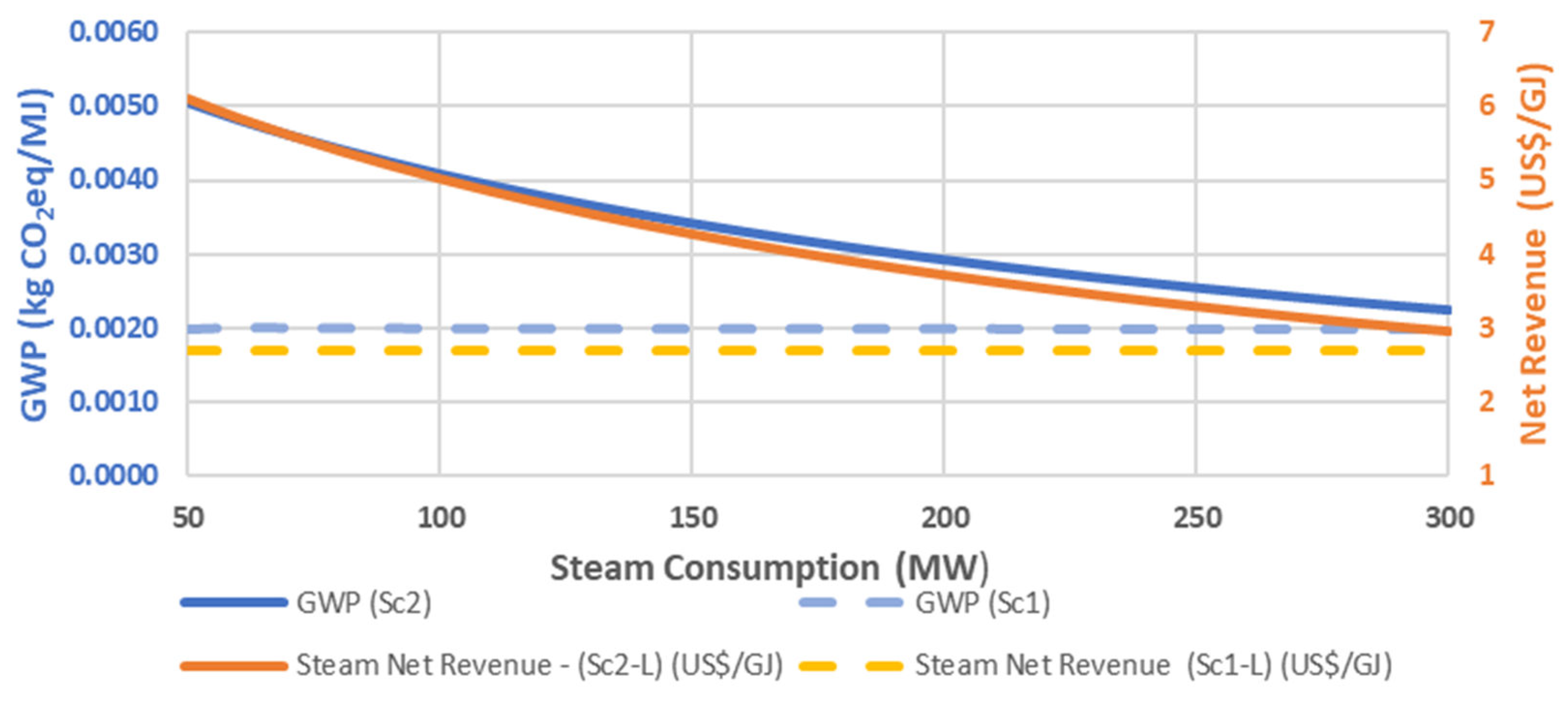

As mentioned, a sensitivity analysis can be performed internally in EMSO, showing the variation of LCA results in relation to process inputs. In order to illustrate that, it is shown a sensitivity analysis of the variation of the 2.5 bar steam consumption in relation to the GWP and the net revenue. This sensitivity analysis was combined in two bagasse prices range: US

$ 14.58 per ton for low bagasse prices and US

$ 158.75 per ton for high bagasse prices.

Figure 7 shows the behavior of GWP 100 and net revenue in low bagasse price (US

$ 14.58) scenario according to the steam consumption.

In

Figure 7, it is evident that in the first scenario, where the condensing turbine is not present, the carbon intensity remains constant throughout the lifecycle, regardless of steam consumption. Similarly, the net revenue also remains constant. This observation can be attributed to the adjustment of bagasse and straw burning to meet steam consumption requirements, resulting in a constant carbon intensity and net revenue per GJ of steam and electricity.

The second scenario is intriguing as it involves burning all available bagasse and straw to maximize electricity production. The inclusion of a condensing turbine enables higher electricity generation. However, in the studied case, the steam from the condensing turbine is not utilized in the process and is instead lost in a cooling tower. Consequently, as electricity production increases, steam consumption in the condenser decreases, leading to process inefficiency, higher carbon intensity, and increased process net revenue. The net revenue per GJ also rises as more electricity is generated using the same amount of bagasse and straw. This second scenario exemplifies a situation that the economic objectives conflict with environmental objectives. Such problems can be further explored in the context of multi-objective optimization.

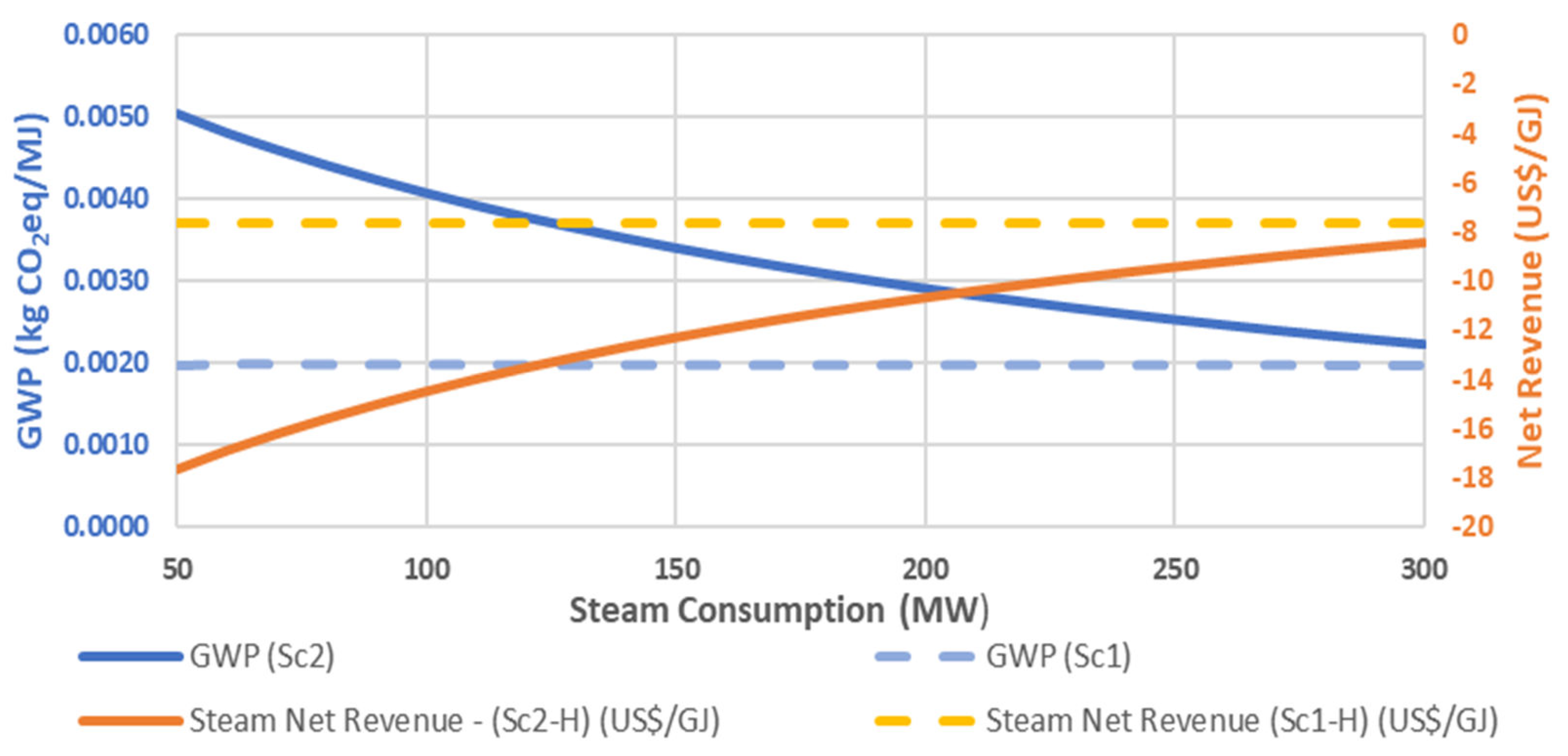

The same type of sensitivity analysis is also presented to a higher bagasse price (US

$ 158.75) per ton bagasse price) as illustrated in

Figure 8.

According to

Figure 8, in Scenario 1, it can be observed that the carbon intensity measured by the GWP remains constant regardless of the steam requirement change. This occurs because as the steam demand increases in this scenario, there is an increase in the combustion of bagasse and straw. This is also reflected in the ratio of carbon credits per ton of burned bagasse, which remains constant.

In Scenario 2, with the condensing turbine, the economic results improve as the consumption of steam increases. This case reflects the fact that the price of the electricity does not pay the fuel. For this case the carbon intensity of the steam and electricity production is reduced when the steam consumption is increased (only for use of cooling towers in condensing turbine). In this case, both economic and environmental objectives vary in the same direction.

4. Conclusions

This work has developed a platform named EMSO_OLCA for integrating the open-source software OpenLCA with the open Environment for Modeling, Simulation, and Process Optimization (EMSO) in order to fill the gap between process simulation environments and Life Cycle Assessment software.

The EMSO_OLCA allows the user to maintain the LCA methodology consistency as designed in the OpenLCA; annually updated of LCA Assessment databases given by the OpenLCA; computational speed as required in simulation software as inputs calculations are accomplished previously. Other advantage is the integrated tools of EMSO as simulation, optimization, sensitivity analysis, and communication to Python, Matlab® and OPC® communication. The tests showed accuracy of EMSO_OLCA with mean relative error of 0.045%.

A cogeneration heat power system with sugarcane bagasse and straw as fuel was studied as a process simulation application. The results for this case study were obtained in just 2.0 seconds through the integration of EMSO_OLCA. The first scenario presented lower carbon intensity and lower economic results in relation to the second scenario for the bagasse price of US$14.58. The second scenario in lower bagasse prices (US$14.58) presented conflicting economic and environmental objectives and with higher bagasse price (US$ 158.75) presented environmental and economic objectives in the same direction as varying steam requirements. Thus, the price of the raw materials could influence if the economic and environmental objectives are conflicting or not.

The studied sugarcane bagasse heat and power units allow a significant reduction in the carbon footprint in Brazilian electricity grid, representing 96% and 93% for the first scenario and the second scenario, respectively. The first and second scenarios achieved a GWP of 7.18 and 13.97 kg of CO2-eq per MWh, in contrast of Brazilian mix of 201.01 kg of CO2-eq per MWh. Thus, biomass-based cogeneration units should be promoted by governmental policies and financing agencies.

The EMSO_OLCA showed to be a powerful tool to enhance the decision-making process allied to process simulation when evaluating different chemical pathways, facilitates comprehensive techno-economic and environmental assessments, and empowers the optimization and control of processes based on environmental performance indicators.

Author Contributions

Simone C. Miyoshi: conceptualization, methodology, software, formal analysis, validation, investigation, writing – original draft, writing – review & editing, visualization. Argimiro R. Secchi: conceptualization, methodology, validation, resources, writing – review & editing, supervision, project administration. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are thankful to the financial support of the Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP) and FINEP for sponsoring the Program of Human Resources 4.1 Digital Technologies in the O&G Sector. The authors also thanks to Brazilian National Council for Scientific and Technological Development (CNPq), grant number 303587/2020-2.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Potrich, E.; Miyoshi, S.C.; Machado, P.F.S.; Furlan, F.F.; Ribeiro, M.P.A.; Tardioli, P.W.; Giordano, R.L.C.; Cruz, A.J.G.; Giordano, R.C. Replacing hexane by ethanol for soybean oil extraction: Modeling, simulation, and techno-economic-environmental analysis. Journal of Cleaner Production, 2020, v. 244, p. 118660. [CrossRef]

- Carpio, R.R.; Miyoshi, S.C.; Elias, A.M.; Furlan, F.F.; Giordano, R.C.; Secchi, A.R. Multi-objective optimization of a 1G-2G biorefinery: A tool towards economic and environmental viability. J. Clean. Prod., 2021, v. 284. [CrossRef]

- Ferdous, J.; Bensebaa, F.; Pelletier, N. Integration of LCA, TEA, Process Simulation and Optimization: A systematic review of current practices and scope to propose a framework for pulse processing pathways. J. Clean. Prod., 2023, p. 136804. [CrossRef]

- Kalakul, S.; Pomthong, M.; Kitipat, S.; Rafiqul, G. Integration of life cycle assessment software with tools for economic and sustainability analyses and process simulation for sustainable process design. Journal of cleaner production, 2014, v. 71, pp. 98-109. [CrossRef]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A. de; Oers, L. van; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; Bruijn, H. de; Duin, R. van; Huijbregts, M.A.J. Handbook on life cycle assessment. Operational guide to the ISO standards. I: LCA in perspective. IIa: Guide. IIb: Operational annex. III: Scientific background. Kluwer Academic Publishers, ISBN 1-4020-0228-9, Dordrecht, 2002, 692 p. [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Zelm, R.V. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess, 2017, v. 22, pp. 138–147. [CrossRef]

- Soares, R.P.; Secchi, A.R. EMSO: A New Environment for Modelling, Simulation and Optimisation. Computer Aided Chemical Engineering, 2003, v. 14, pp. 947-952. [CrossRef]

- ISO 14040, 2006. Environmental management – life cycle assessment – principles and framework. International Standard Organization (ISO 14040:2006). https://www.iso.org/standard/37456.html (accessed 01 Jan 2022).

- ISO 14044, 2006. Environmental management – life cycle assessment – Requirements and guidelines. International Standard Organization (ISO 14044:2006). https://www.iso.org/standard/38498.html (accessed 01 Jan 2022).

- Jolliet, O.; Saadé, M.; Crettaz, P. Analyse du cycle de vie: comprendre et réaliser un écobilan, 2010, v. 23, PPUR Presses Polytechniques.

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): overview and methodology. Int J Life Cycle Assess, 2016, v. 21, pp. 1218–1230. [CrossRef]

- Rocha, G.J.M.; Nascimento, V.M.; Goncalves, A.R.; Silva, V.F.N.; Martín, C. Influence of mixed sugarcane bagasse samples evaluated by elemental and physical–chemical composition. Industrial Crops and Products, 2015, v. 64, pp. 52-58. [CrossRef]

- Bonomi, A.; Mariano, A.P.; Jesus, C.D.F.; Franco, H.C.J.; Cunha, M.P.; Dias, M.O.S.; Chagas, M.F.; Cavalett, O.; Mantelatto, P.E.; Maciel Filho, R.; Junqueira, T.L; Cardoso, T.F. The Virtual Sugarcane Biorefinery (VSB). Brazilian Bioethanol Science and Technology Laboratory (CTBE), Technological Assessment Program (PAT), Internal Report, Campinas, São Paulo, 2012.

- Oliveira, R.A.; Barros, R.R.O.; Ferreira-Leitão, V.S.; Freitas, S.P.; Bon, E.P.S. Energy supply design for the integrated production of 1G + 2G ethanol from sugarcane. Renewable Energy Focus, 2020, v. 35, pp. 171-177. [CrossRef]

- Dias, M.O.S. Development and optimization of first and second generation ethanol and electricity production processes from sugar cane (in Portuguese). PhD Thesis – Chemical Engineering Faculty, Universidade Estadual de Campinas. Campinas, Brazil, 2011.

- Dias, M.O.; Junqueira, T.L.; Cavalett, O.; Cunha, M.P.; Jesus, C.D.; Mantelatto, P.E.; Rossel, C.E.V.; Maciel Filho, R.; Bonomi, A. Cogeneration in integrated first and second generation ethanol from sugarcane. Chemical Engineering Research and Design, 2013, v. 91, n. 8, pp. 1411-1417. [CrossRef]

- Furlan, F.F.; Filho, R.T.; Pinto, F.H.; Costa, C.B.; Cruz, A.J.; Giordano, R.L.; Giordano, R.C. Bioelectricity versus bioethanol from sugarcane bagasse: is it worth being flexible? Biotechnology for Biofuels, 2013, v. 6, pp. 1-12. [CrossRef]

- Wang, M.; Elgowainy, A.; Lee, U.; Baek, K.H.; Bafana, A.; Benavides, P.T.; Burnham, A.; Cai, H.; Cappello, V.; Chen, P.; Gan, Y.; Gracida-Alvarez, U.R.; Hawkins, T.R.; Iyer, R.K.; Kelly, J.C.; Kim, T.; Kumar, S.; Kwon, H.; Lee, K.; Liu, X.; Lu, Z.; Masum, F.H.; Ng, C.; Ou, L.; Reddi, K.; Siddique, N.; Sun, P.; Vyawahare, P.; Xu, H.; Zaimes, G. Summary of Expansions and Updates in GREET® 2022. United States, 2022. [CrossRef]

- CEDAE, 2022. Tariff Structure (in Portuguese). https://cedae.com.br/estruturatarifaria. (accessed 15 May 2024).

- Águas do Rio, 2023. Legislation and Tariffs (in Portuguese). https://aguasdorio.com.br/legislacao-e-tarifas/. (accessed 15 May 2024).

- ANEEL, 2023. National Electric Energy Agency (in Portuguese). https://www.gov.br/aneel/pt-br. (accessed 15 May 2024).

- MDIC, 2023. Ministry of Development, Industry, Commerce and Services COMEXSTAT. http://comexstat.mdic.gov.br/pt/home. (accessed 01 Jan 2023).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).