1. Introduction

The outer layer of the earth’s atmosphere receives 174 petawatts (PW) of solar radiation. Around 30% of this radiation is bounced back to space, and the remaining 122 PW is absorbed by clouds, oceans, and land masses. The amount of solar energy reaching land surfaces exceeds world’s energy demand. However, due to intermittent availability of sunshine as well as low energy conversion efficiencies of solar energy conversion systems, a large quantity of this free energy remains untapped. Most population on earth reside in regions with annual sunlight radiation rates of between 3.5 and 7.0 kWh/m2 or 150 to 300 W/m2. With this tremendous amount of solar energy reaching the surface of the earth, there should be more efforts to benefit from the most abundant free energy available. Solar energy can be harnessed by various technologies, mainly categorized into photovoltaic and solar thermal, that would reduce the dependance to non-renewable energy resources.

Most of solar irradiation reaching the earth's ground has a wavelength within 300–2500 nm, which covers the UV light (<380 nm), visible light (380–780 nm, and near infrared (NIR) light (>780 nm). The thermal band of solar irradiance, depicted in

Figure 1, can be converted to thermal energy in liquid and gaseous heat transfer fluids such as water, air and nanofluids [

1]. One of the simplest technique is direct water heating that is widely used in residential and commercial sectors. A Solar Water Heating (SWH) system typically comprises of solar collectors, storage tank, heat exchangers and pumps. SWH system can achieve thermal conversion efficiency of 70% as compared to around 17% for photovoltaic system, with the main contributor to its thermal efficiency improvement being the high convective heat transfer coefficient [

2]. In 2010, around 70 million houses worldwide benefited from SWH system, which are not only environmentally friendly but also require minimal maintenance and operation cost compared to other solar energy applications, along with an attractive payback period of 2–4 years [

2]. There are four major classifications of SWH by its thermal absorbing mechanism. These are: 1. flat plate collectors [

3], 2. hybrid photovoltaic/Thermal collectors producing both electricity and heat energy [

4], 3. evacuated tube collectors and 4. compound parabolic collectors [

5]. Flat plate solar collectors in particular, are generally designed for working temperatures between 40 and 60°C, making them ideal for domestic hot water applications [

6]. The global market for solar water heaters was valued at 4.7 billion dollars in 2019 and is anticipated to increase at a rate of 6.1% from 2020 to 2027 to reach 6.7 billion dollars [

7].

In Malaysia, SWH is becoming more popular in its residential area due to its ability to reduce household electricity cost. As most of the SWH systems are equipped with pump, there would still be some extent of electricity costing to power the pump which aids water circulation, but the electricity cost to operate SWH system is much lower than to operate electric water heater. However, the SWH system has a high initial cost. The range of prices for a SWH system in Malaysia would come around MYR4,000.00 to MYR10,000 depending on the capacity of the tank in the system. Most of the SWH available to Malysia’s market are passive flat plate type equipped with metal heat absorber. Metal tubes such as copper or aluminum are used as heat absorbers due to their high thermal conductivity. Unfortunately, the downsides of metal heat absorbers is that they are more susceptible to internal tube scaling which eventually lead to early failure [

8]. During extended operation duration, as the solubility range of the heat transfer fluid in metal tubes exceeded certain limits, ions will leave the solution and adhere to the metal pipe walls. Over time, these ions accumulate to form what appear to be scales all over the inside of the pipe. Scaling build-up in the long term can constrict water flow as it decreases the effective pipe diameter. Besides, scaling build-up in the metal pipe of a heat absorber will also affect the thermal conductivity of the pipe, hence, decreasing the heat absorbers efficiency.

One way to overcome the high initial cost and maintenance challenge is to use alternative material for thermal absorber tubes. Among others, polymer tube, which is widely available and reasonably priced, is a very practical option. Polymers tubes are cheaper, non-corrosive, and easy to fabricate into thermal collector. By optimizing the geometry, layout, fluid flow rate and other related factors, comparable performance can be achieved. Many polymer and plastic materials have been tested for the SWH systems. Sopian et.al used thermoplastic natural rubber (TPNR) in a thermosyphon type SWH, produced 65

oC hot water with photo-thermal conversion efficiency of 72% [

8]. The used of ethylene propylene diene monomer (EPDM), a petroleum-based product has also been explored [

9]. Other polymer materials explored include polyethylene (PE) and polypropylene (PP) in a thermosyphon SWH system, with over 90% maximum photo-thermal conversion efficiency, producing 60

oC hot water operating under a 22 MJ/m

2day solar irradiance [

10]. Polyethylene tubes can replace aluminum tubes with up to 95% thermal efficiency with four times cheaper to manufacture [

11].

Another factor affecting the performance of SWH is the tube geometry and layout that optimized heat transfer fluid residence time in the SWH thermal collector. In addition, the heat transfer rate is increased by elevating turbulence. Collector tubes improvements can be achieved by a number of techniques such as twisted tape inserts, perforated twisted tape inserts, wire coil inserts, wire mesh etc. in the flow passage [

5]. For example, inserting steel wire coil in the collector tube increased the heat transfer rate by 200% for mass flow rates in the range 0.011–0.047 kg/s, producing 14–31% increase in average thermal efficiency [

12,

13]. Inserting helical twisted tape with different twist ratios inside the copper tubes resulted in increased turbulence, thus reduced the collector area requirement by 8–24% for a given efficiency [

14]. In terms of tube layout, the most common design is straight riser tube and serpentine.

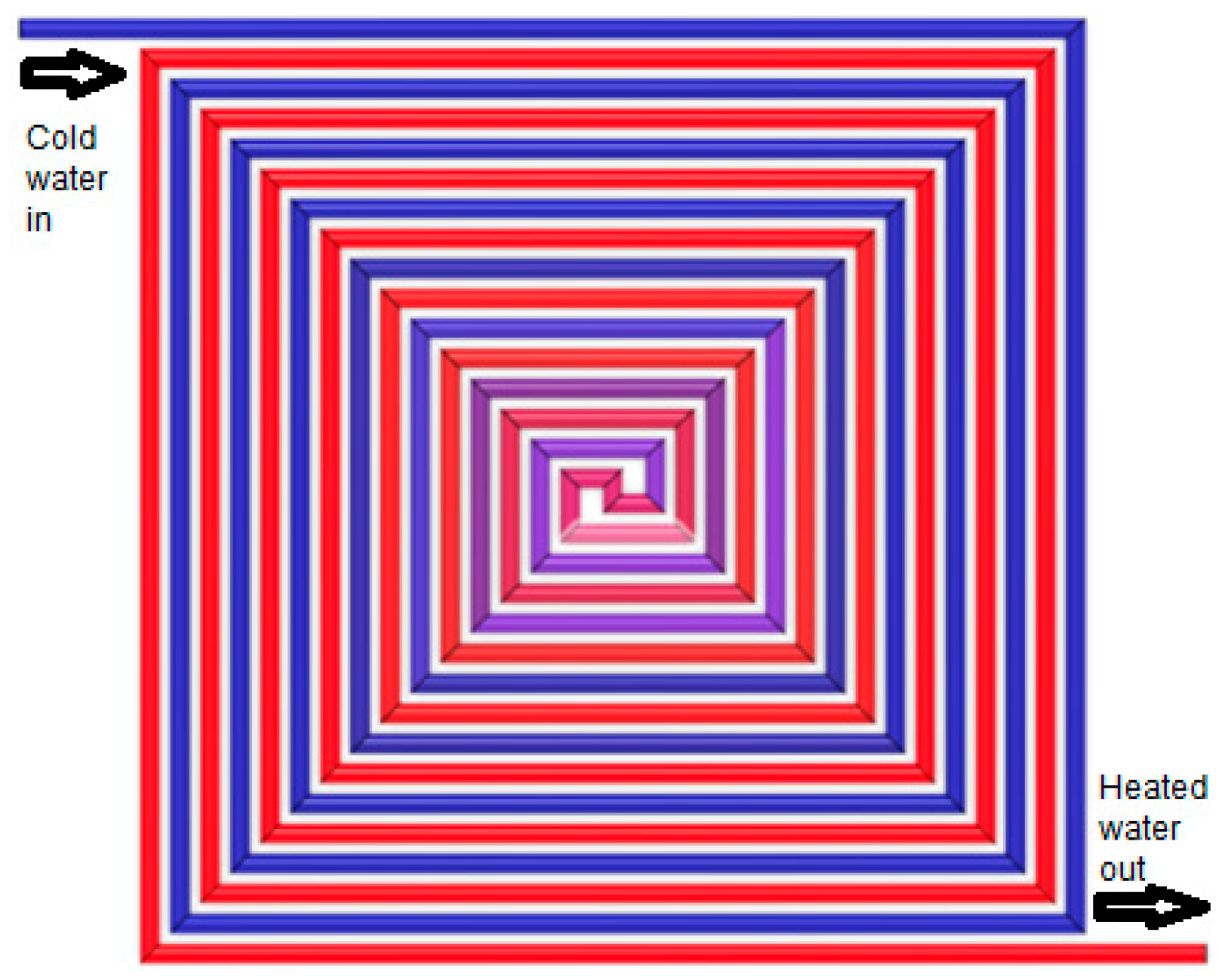

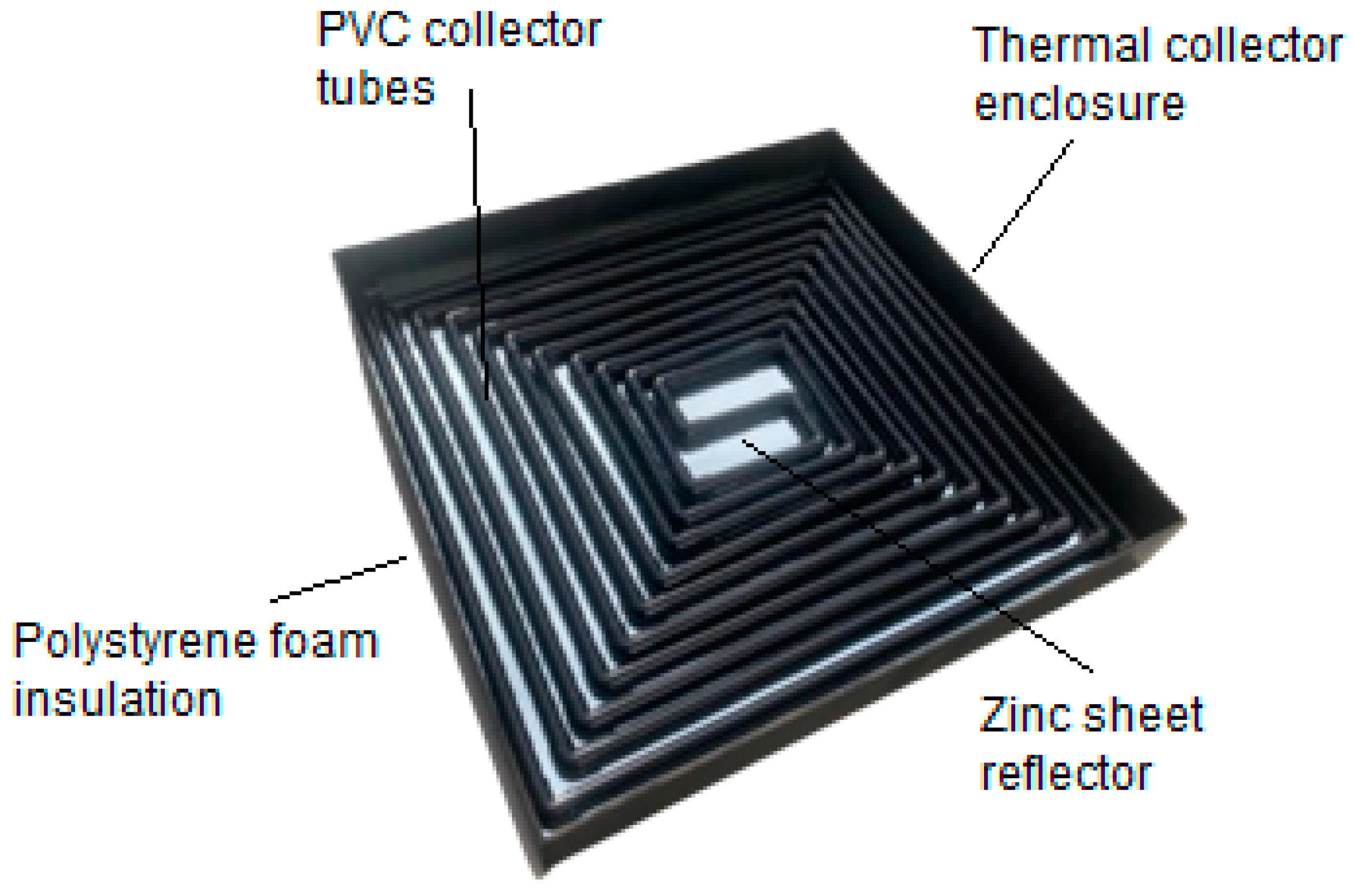

In this work, a novel tube layout coined as RSioaf (rectangular spiral inward-outward alternating-flow) was developed and tested. It combined the benefit of using polymer material and increasing water residence time in the thermal collector while more uniformly absorbing solar radiation over the surface of the thermal collector. PVC is selected as the tube material. PVC possesses a good maximum temperature range of 75-100

oC and excellent hydrolysis stability. However its poor UV radiation resistance can pose a challenge in the long run [

15].

3. Results and Discussion

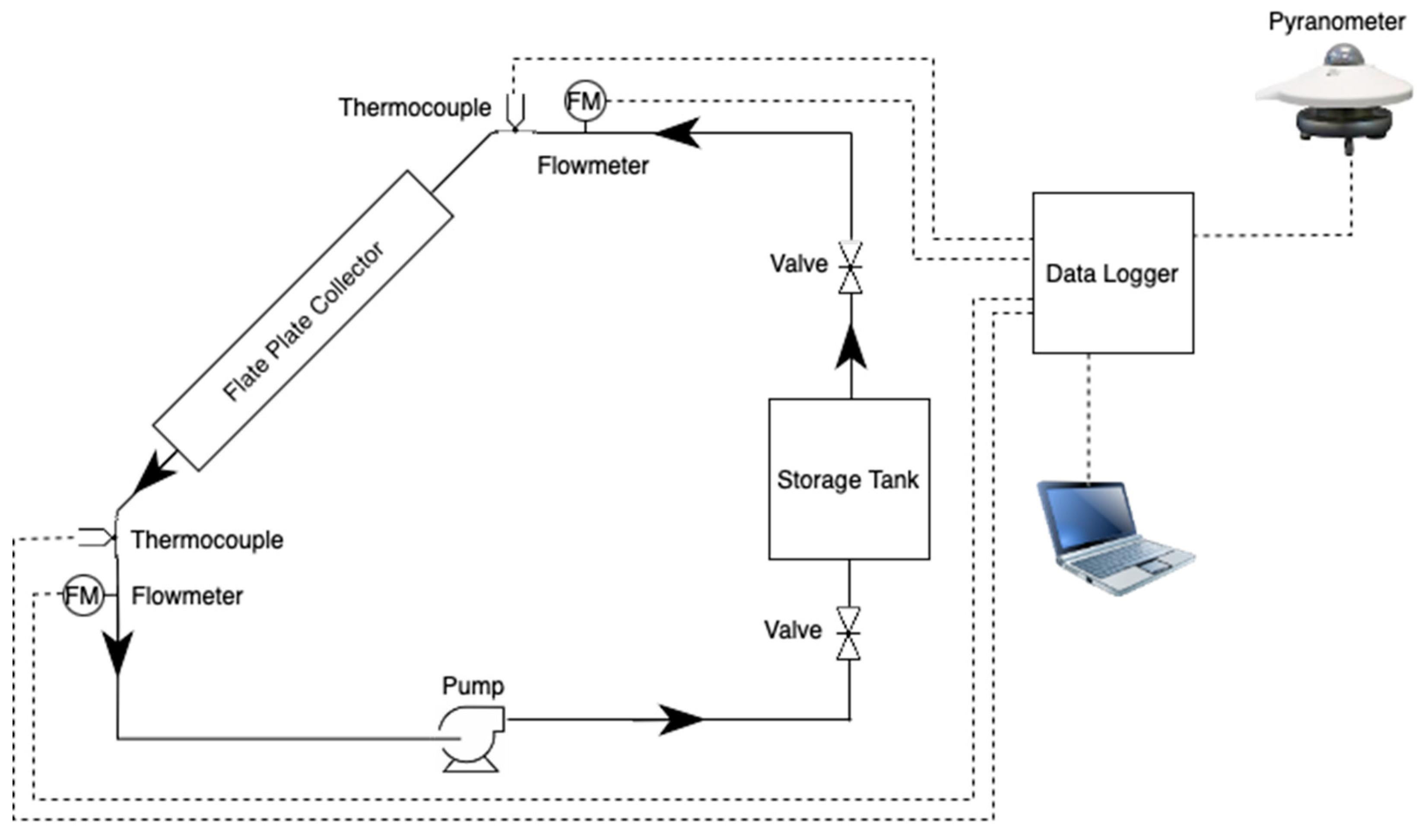

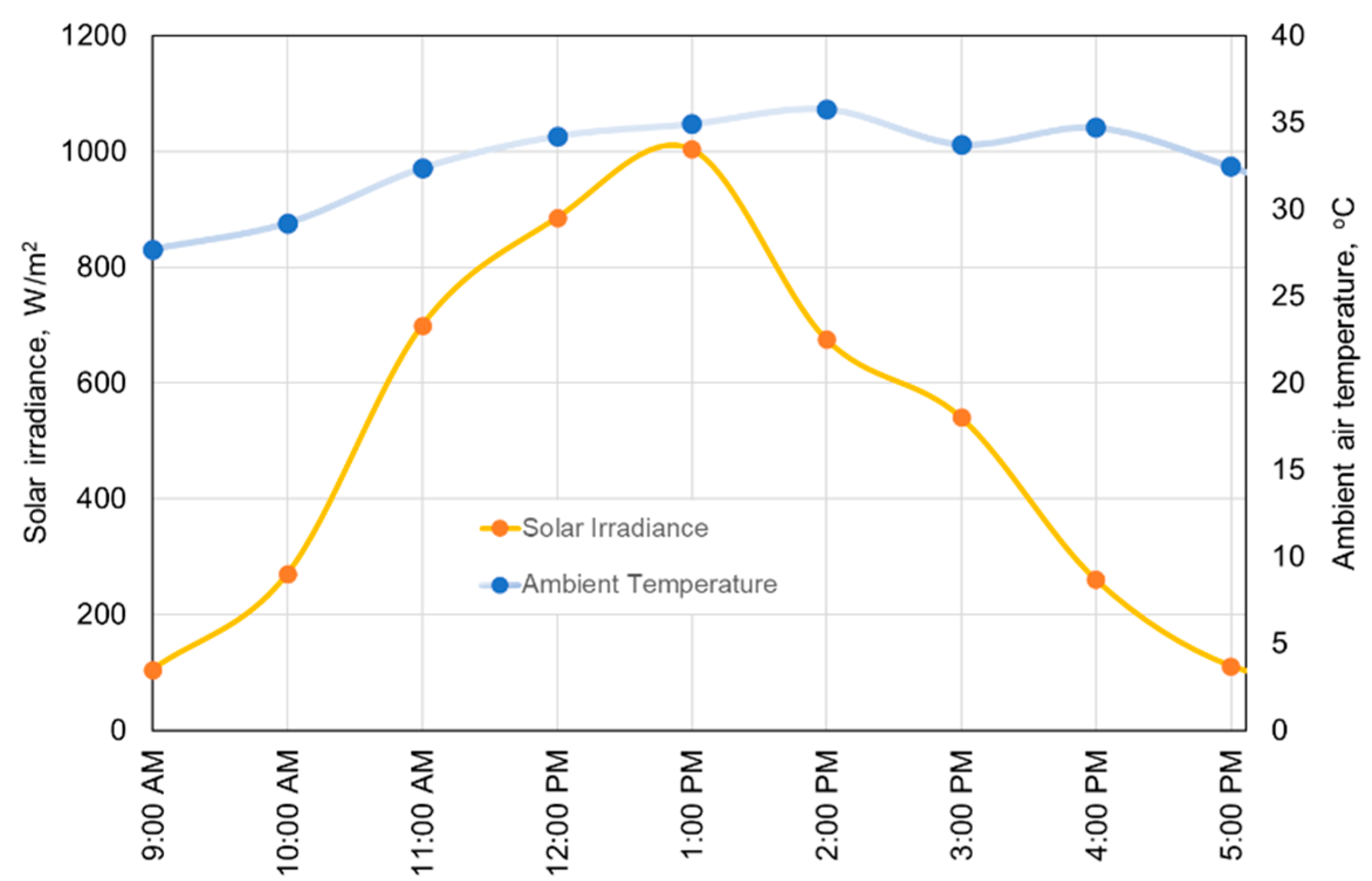

The solar water heating (SWH) system, a polymer tube with RSioaf collector design, underwent testing in the local climate of Seri Iskandar, situated on the central west side of Peninsular Malaysia. The test was conducted over a single day, from 9 a.m. to 5 p.m., in April 2023, with data collected and presented on an hourly basis. The solar irradiance and ambient temperature values, detailed in

Figure 6, showcase the day's conditions. The initial value observed for solar irradiance was approximately 100 W/m

2 at 9:00 a.m., gradually reaching a peak value of 1004 W/m

2 by 1:00 p.m. Afterwards, it dropped slowly to a minimum value of 110 W/m

2 at 5:00 p.m. The sky was partially cloudy throughout the day of the test, particularly after 1:00 p.m., leading to a notable decrease in irradiance from 1004 W/m

2 to approximately 640 W/m

2 at 2:00 p.m. The ambient temperature was recorded at 27°C at the start of the day, gradually rising to a maximum of 36°C at around 2:00 p.m. Due to cloudy sky, the temperature only dropped to 32

oC by 5.00 pm.

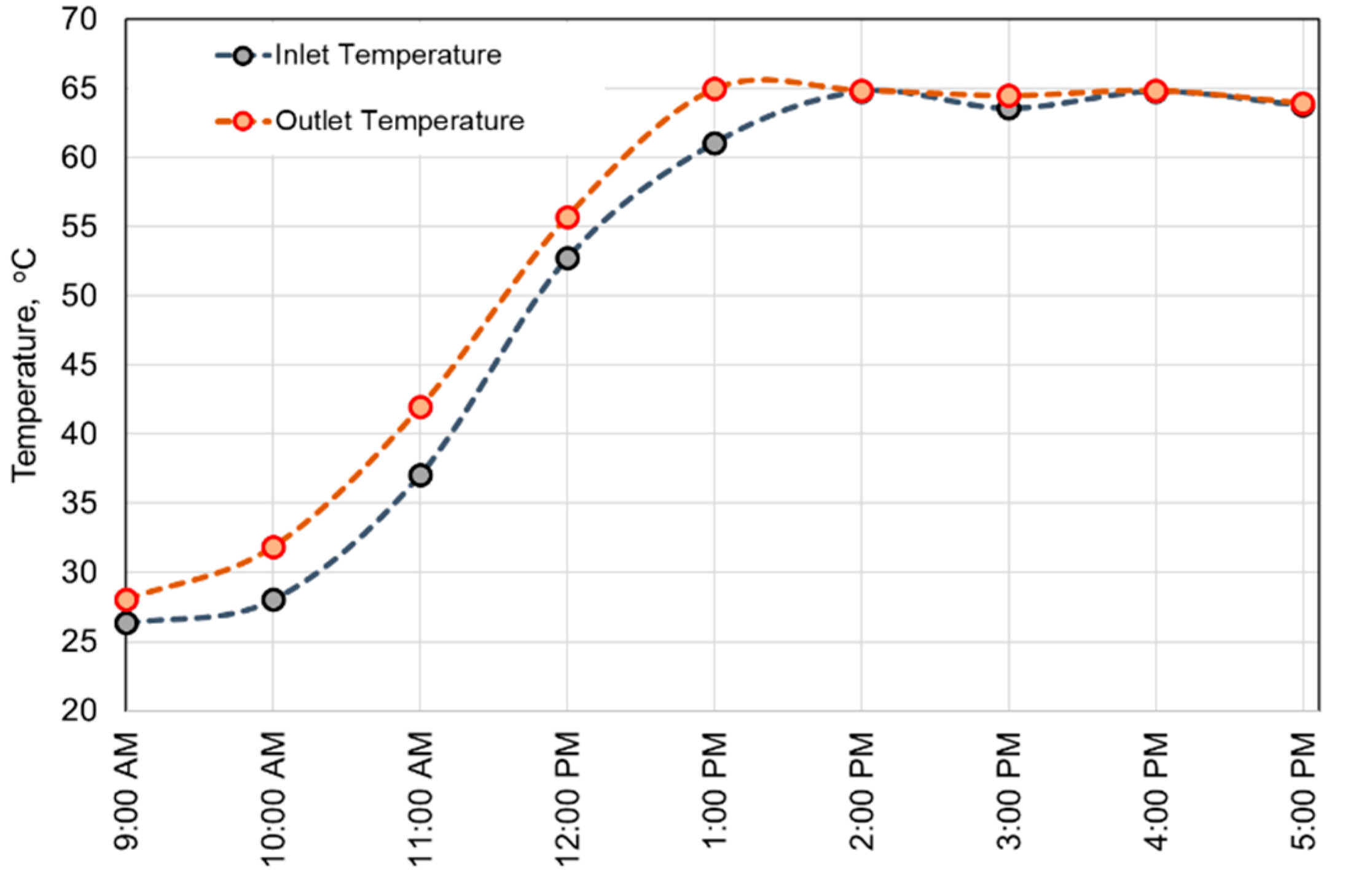

The hourly recorded water temperatures at the collector inlet and outlet, as illustrated in

Figure 7, provide insight into the system's thermal behavior. Starting from 26.4°C at the inlet and 28.1°C at the outlet, the temperatures steadily rose, reaching peak values of 61.1°C and 65°C, respectively, at 1:00 p.m. Subsequently, both temperatures remained relatively constant at around 65°C for the duration of the test, indicating a thermal equilibrium where heat gain and loss were balanced. The narrowing temperature difference between the inlet and outlet temperatures is a result of the closed-loop water circulation nature of the system, demonstrating its ability to maintain stability in operation.

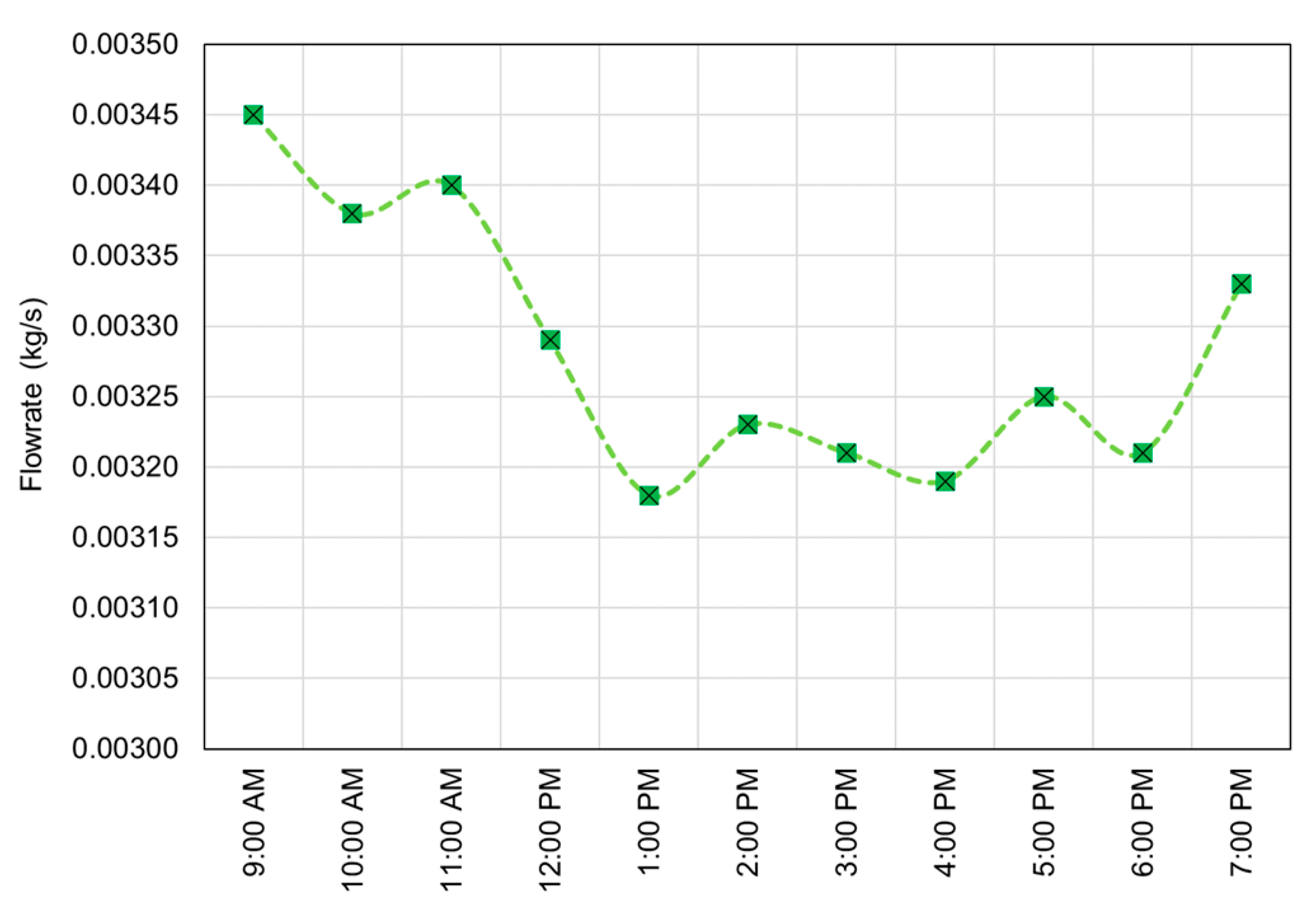

Figure 8 depicts the mass flow rate of water at the thermal collector inlet throughout the test period. Ranging from 3.18 g/s to 3.45 g/s, the flow rate is inversely related to water temperature. As temperatures increased, the mass flow rate decreased due to water expansion within the system. This phenomenon reduces both the amount and rate of heat absorption, contributing to a drop in efficiency at higher water circulation temperatures. Careful adjustment of the flow rate can lead to higher photo-thermal conversion efficiency. The control strategy is not developed for this experiment.

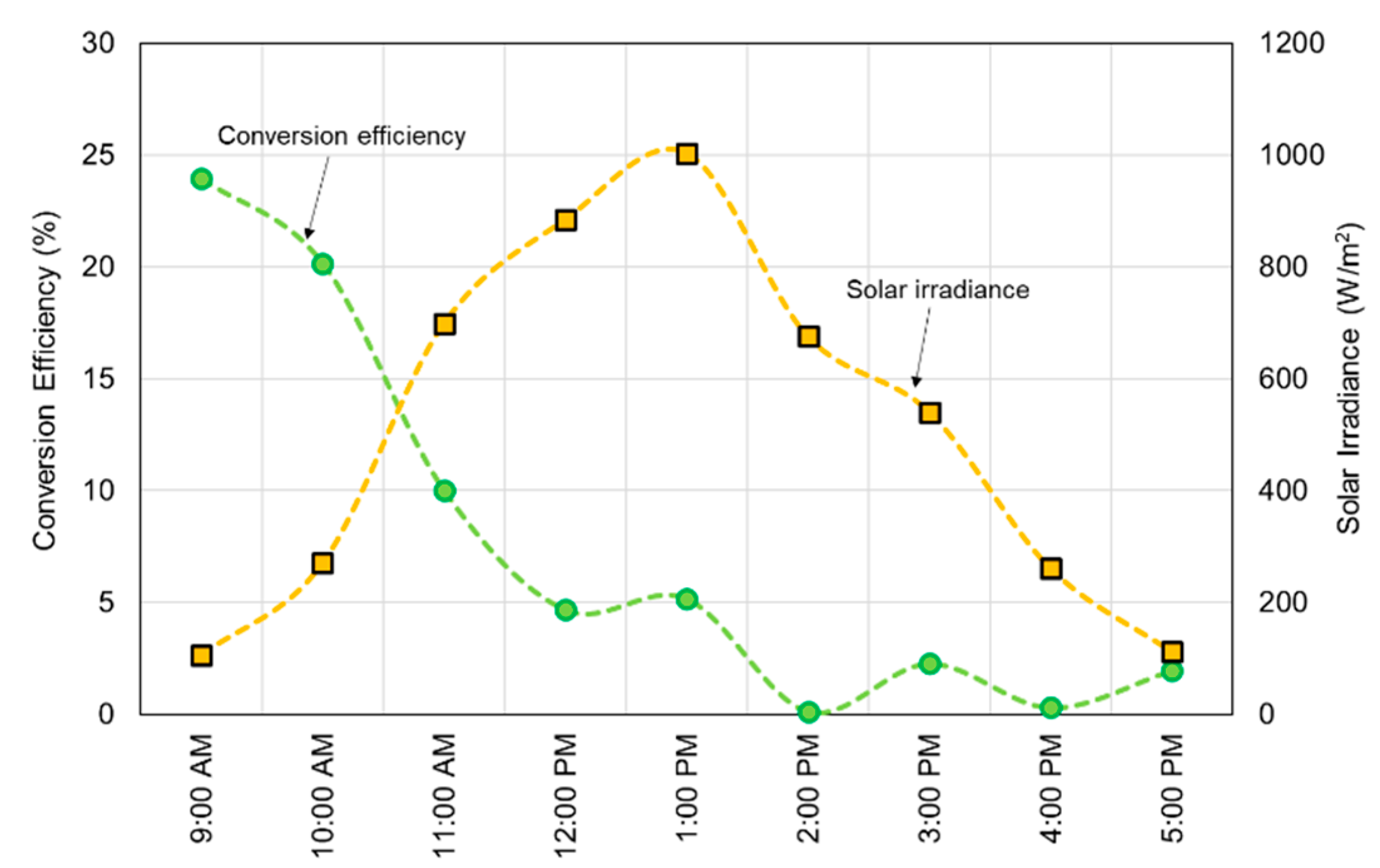

The photo-thermal conversion efficiency, shown in

Figure 9, was calculated based on a closed-loop water circulation system, allowing for gradual heating of the water over the course of the day. The efficiency peaked at 24% in the first hour, gradually declining as the day progressed. This decline can be attributed to the narrowing temperature difference between the inlet and outlet temperatures over time, coupled with increasing solar irradiance towards midday. Post-1:00 p.m., the efficiency gradually declined and nearly reached zero by 2:00 p.m. This decrease was largely due to minimal temperature differences between the inlet and outlet, as shown in

Figure 7. When the temperature difference approaches zero, the energy absorbed by the collector (

Qa) also approaches zero, leading to an efficiency of zero according to equation (2). Although using metal tube may reach a similar maximum temperature more quickly due to its absorptivity and thermal conductivity, achieving the same efficiency with a polymer tube is feasible with appropriate mass flow rate adjustments. Increasing the residence time of water in the collector tube could lead to a higher maximum temperature achieved at a faster rate. Additionally, the absence of transparent cover called “glazing”, limits the system's performance. With glazing, more heat could be retained in the collector, enhancing heat transfer from the enclosed air to the collector tubes.

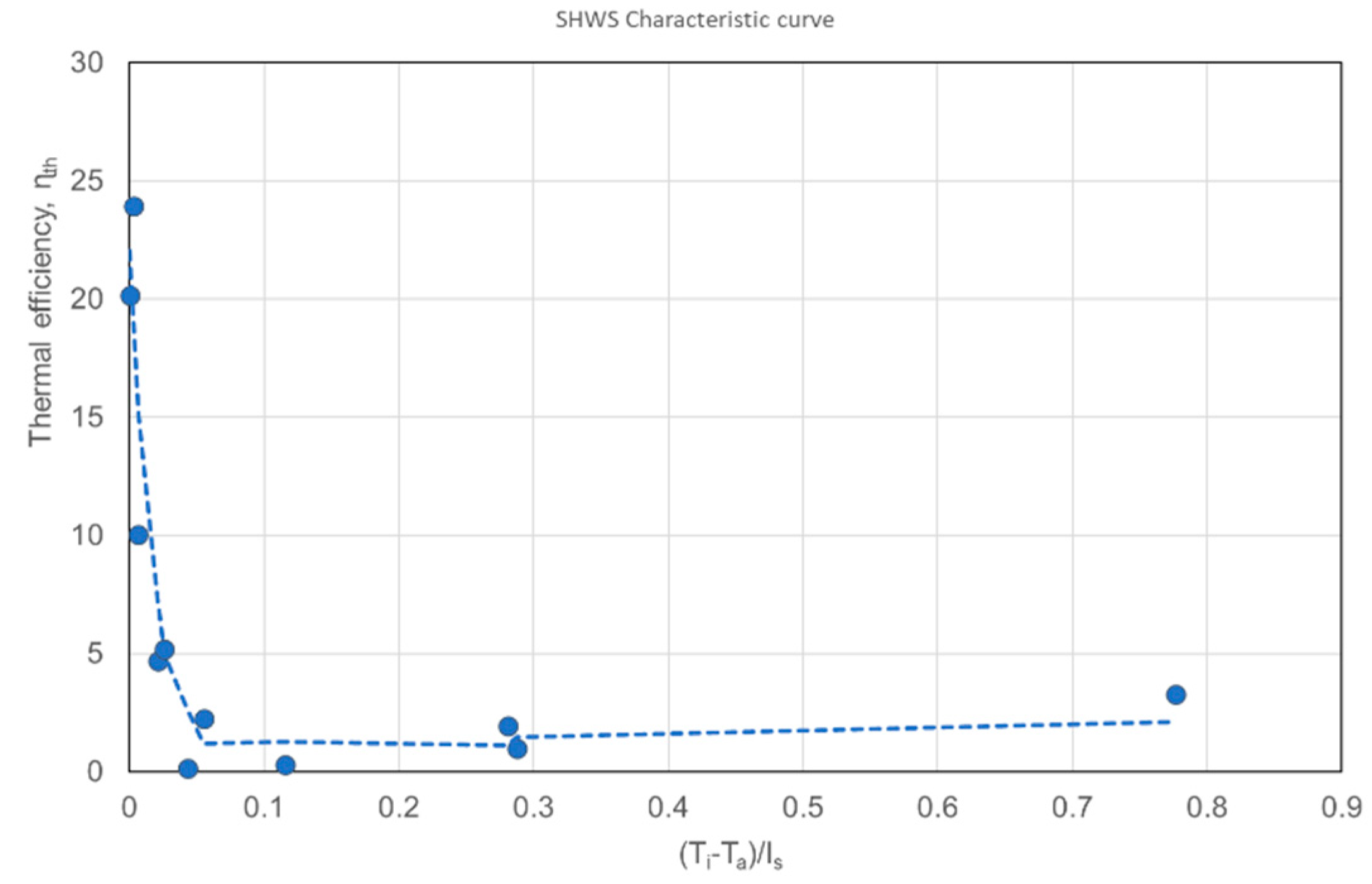

The collector efficiency

ηth plotted against

(Ti − Ta)/Is as shown in

Figure 10. The slope of this curve,

-FRUL, explained in equation (2), represents the rate of heat loss from the collector. Since this collector is unglazed, steeper slopes can be seen especially at the small temperature difference between inlet water and ambient. The maximum collector efficiency,

FRτα, significantly relies on the optical properties of the collector. The moderately selective black paint applied on the thermal absorbers improved the overall thermal efficiency due to increased radiation absorption.

Overall, the performance of this polymer tube solar water heater has demonstrated a comparable outcome with the ones using metal tubes. Even though the thermal conductivity of PVC is 0.05% of that in copper, it can still produce hot water at a temperature of between 60oC and 70oC, which is a typical temperature setting for household applications. Increasing water residence time in the thermal collector through spiraling and the alternating cold and hot water flow can be considered to be the design advantage of RSioaf in producing the observed results. The photo-thermal conversion efficiency can be further expanded and improved with an open loop water circulation, where inlet water is kept constant around ambient temperatures. This will lead to a more comprehensive characterization of this renewable energy system. Further parametric and geometric refinement includes optimization of tube size, inclusion of glazing and regulating water flow.