Submitted:

23 May 2024

Posted:

24 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results

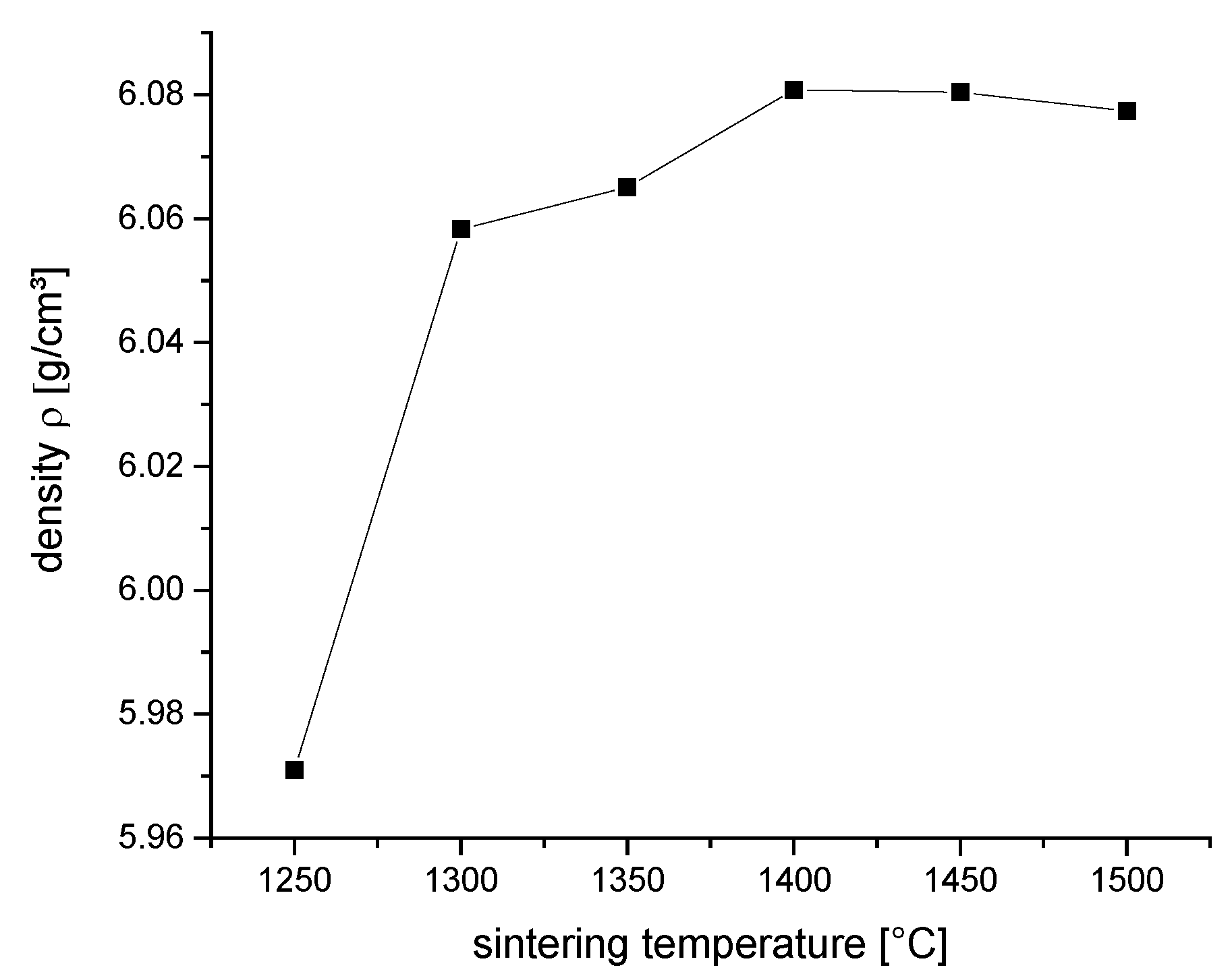

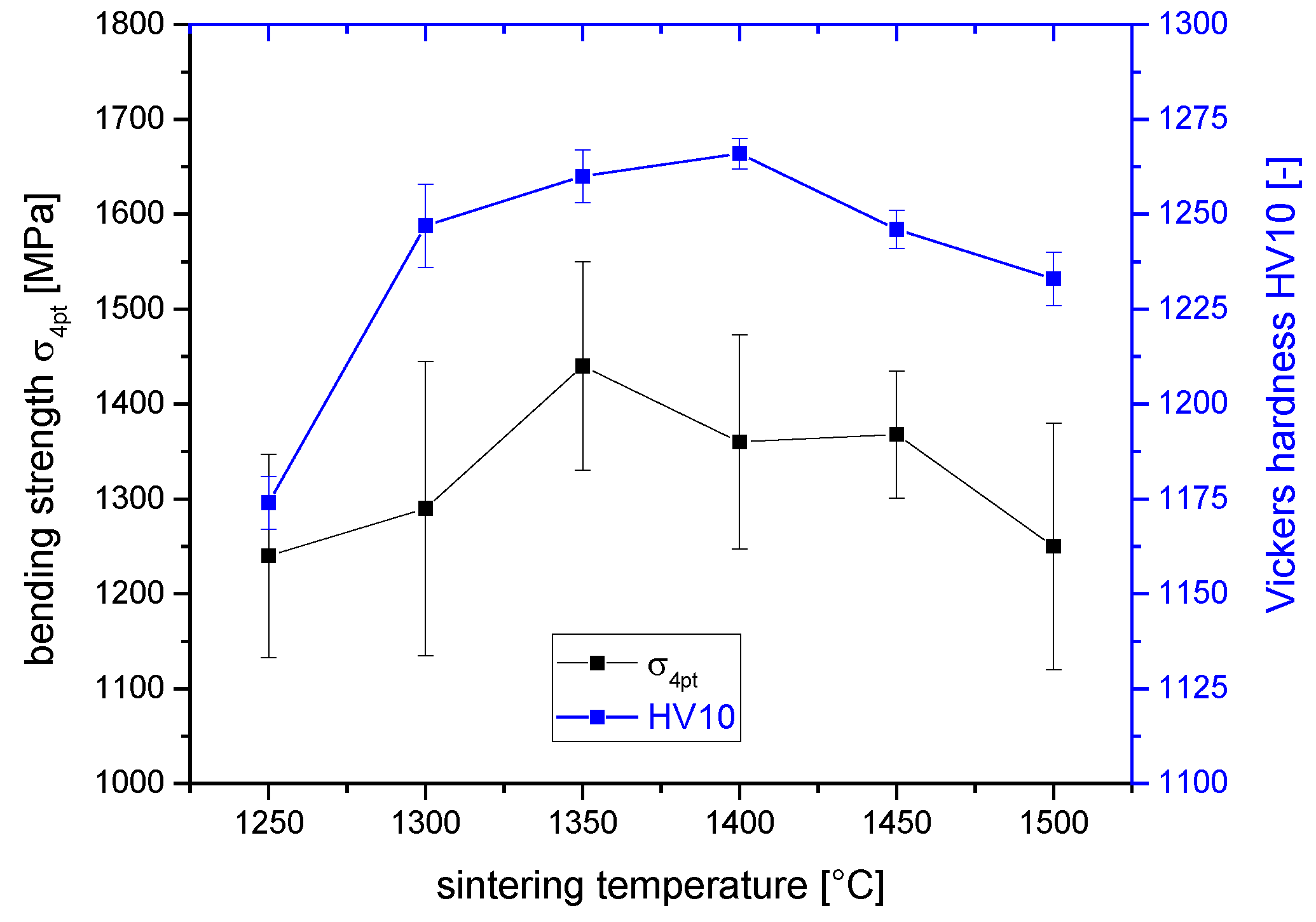

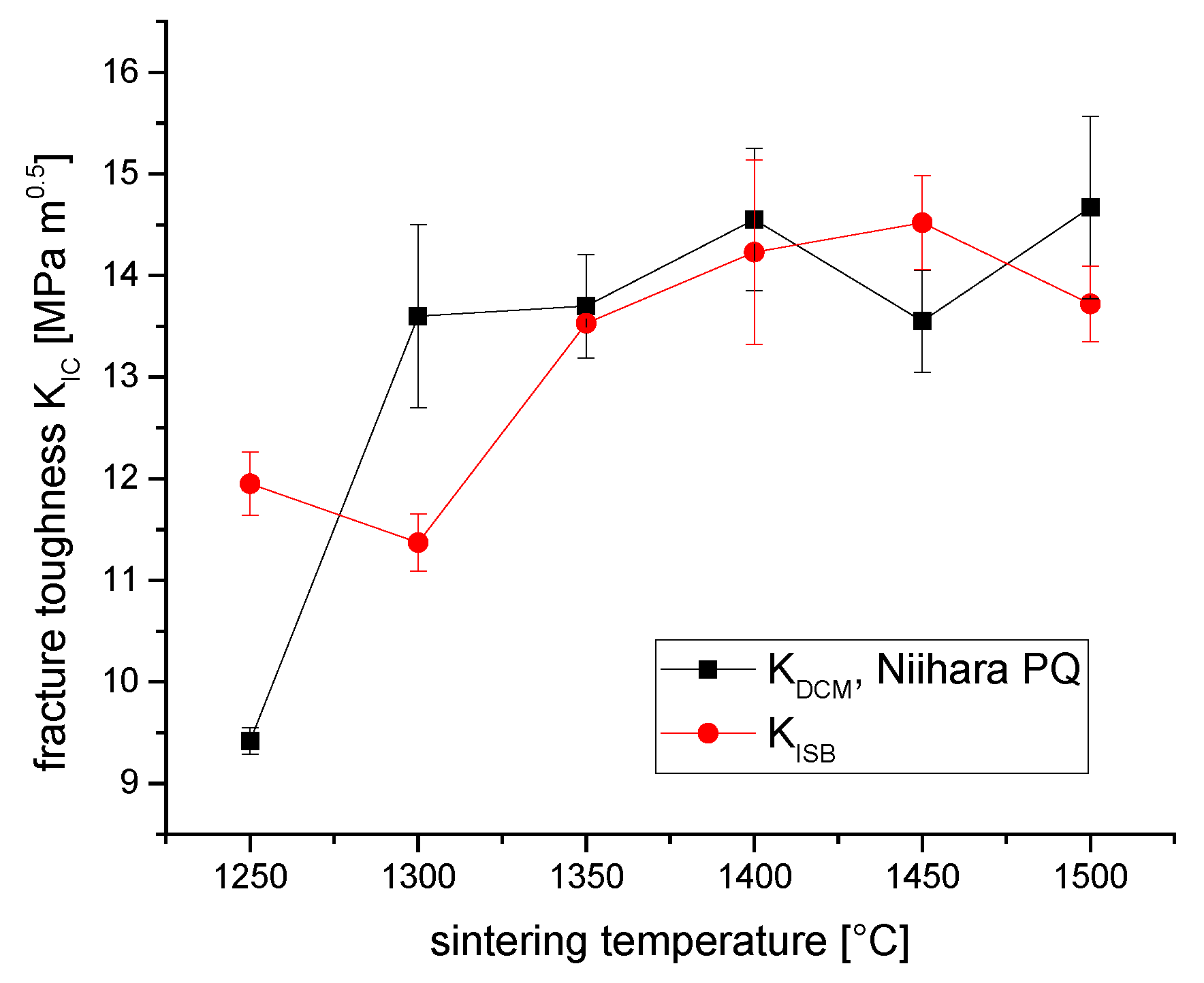

3.1. Density and Mechanical Properties

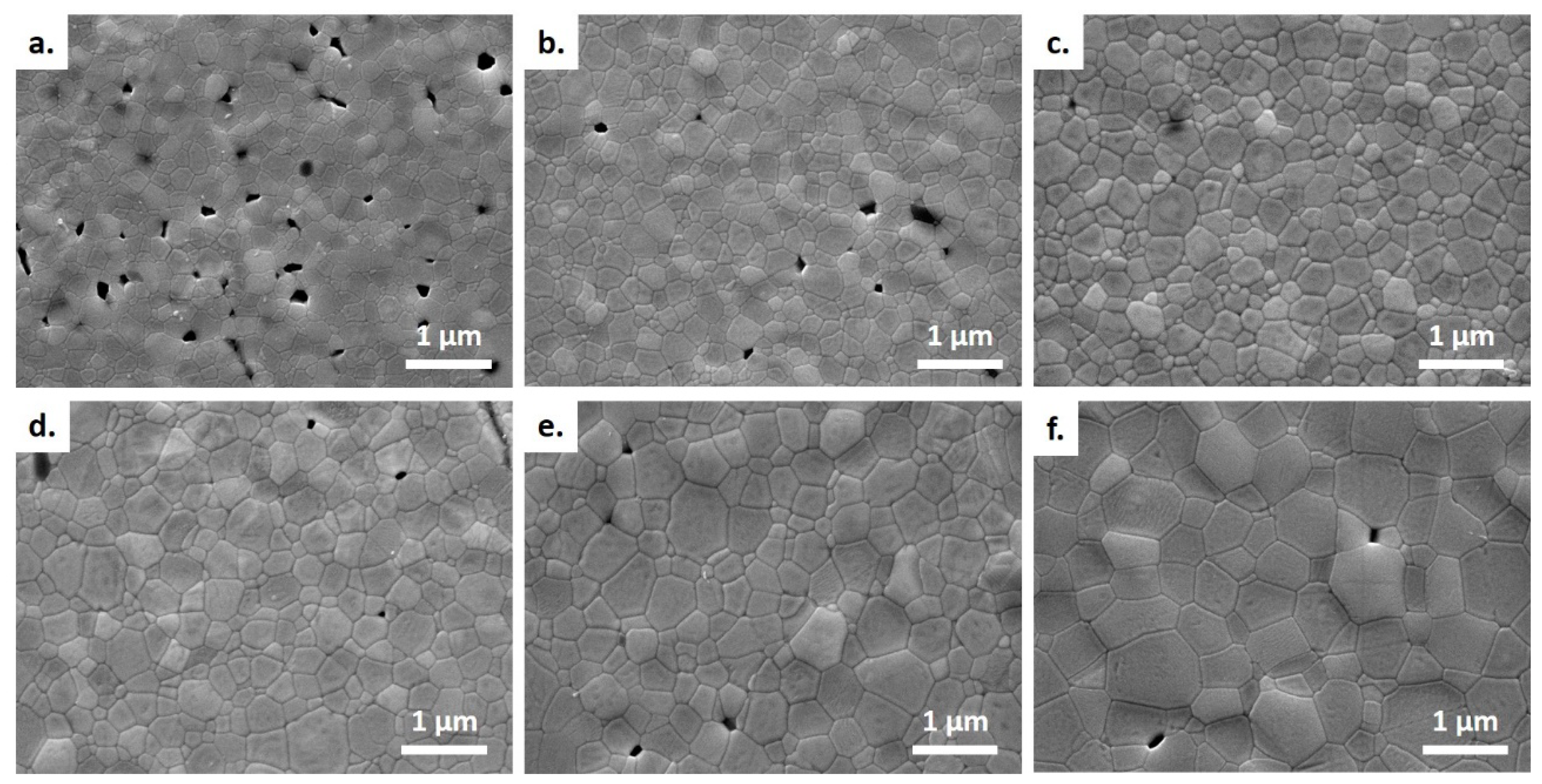

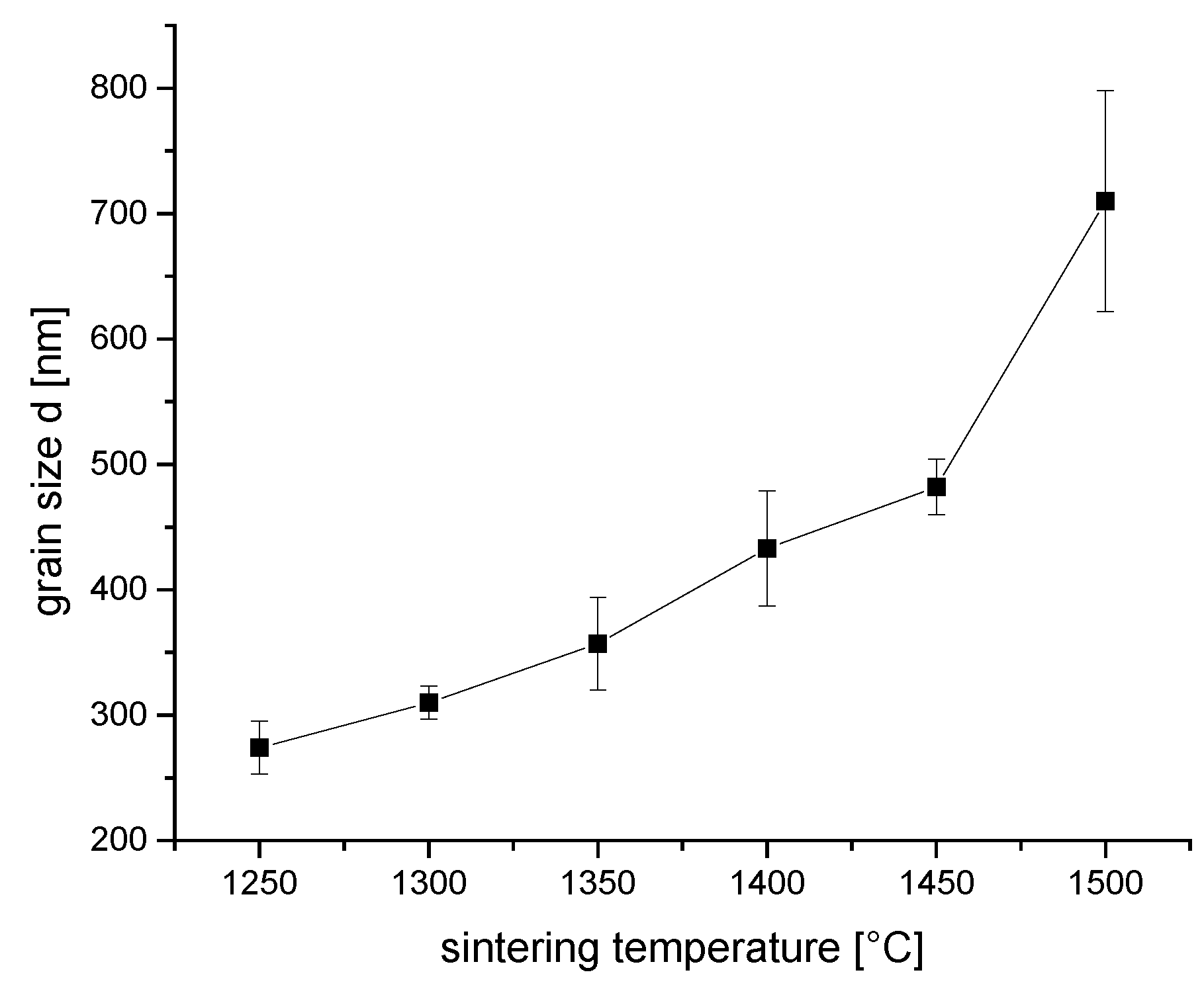

3.2. Microstructure

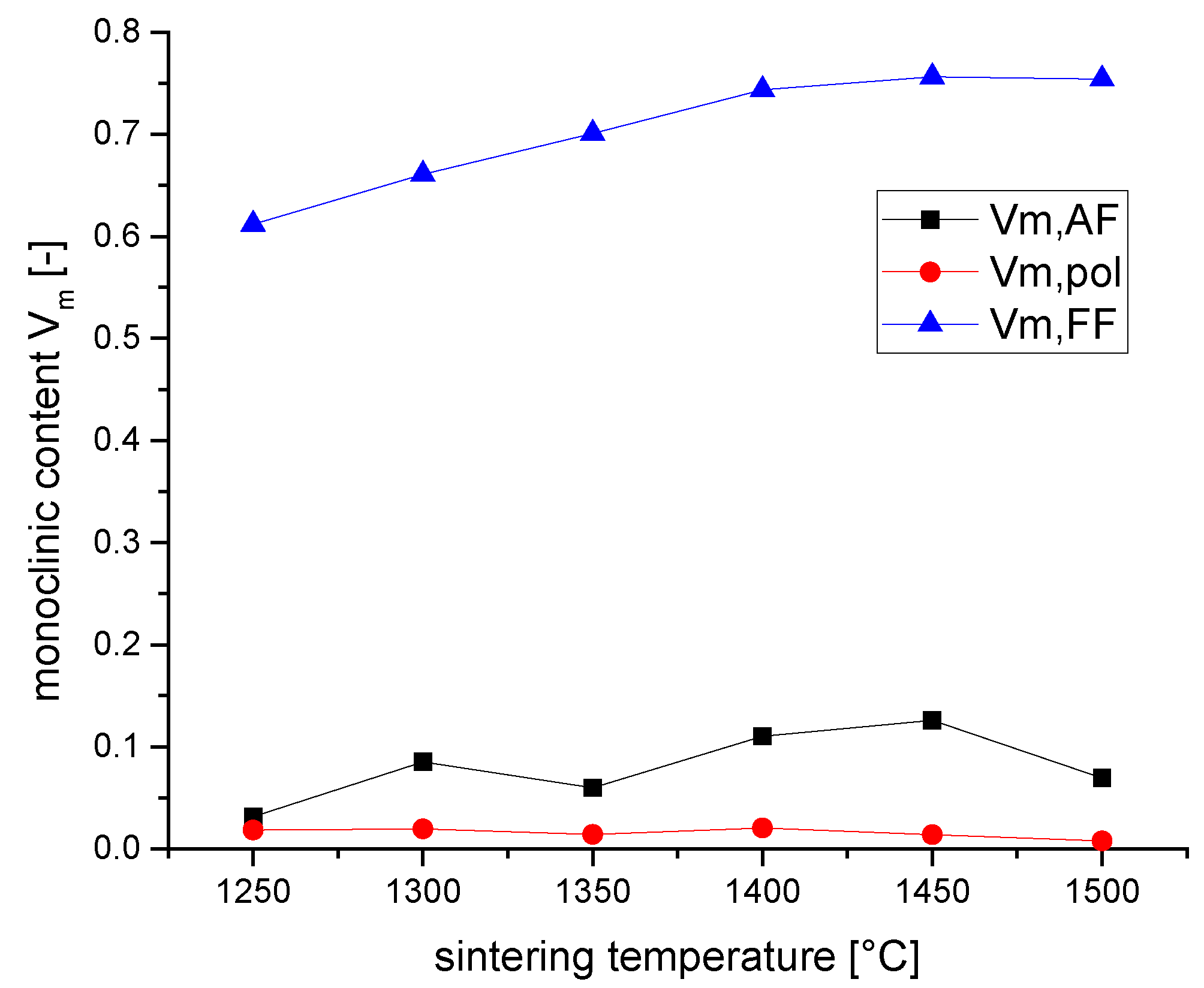

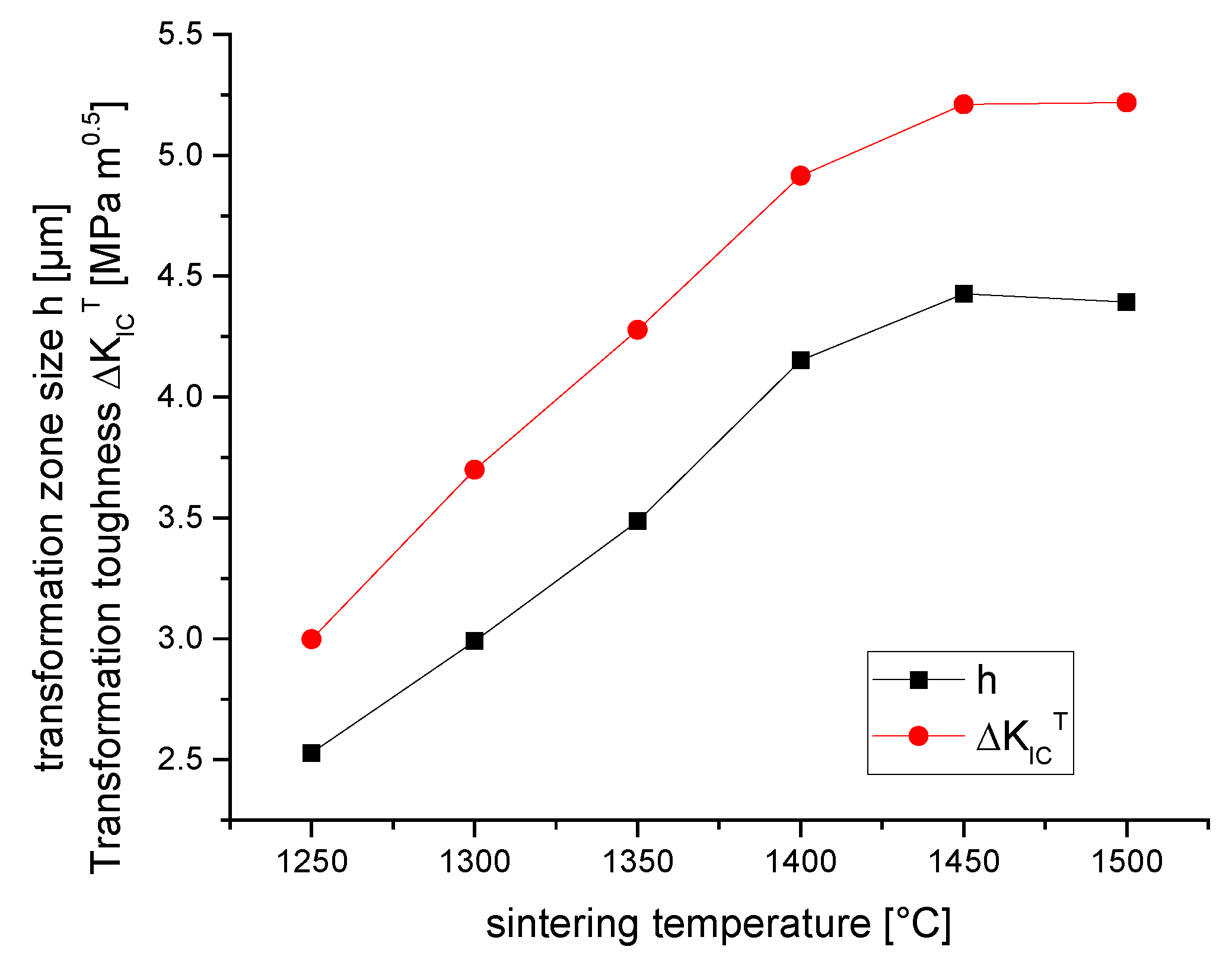

3.3. Phase Composition and Transformation toughening Effect

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation Toughening in Zirconia-Containing Ceramics. Journal of the American Ceramic Society 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Kelly, P.M.; Rose, L.R.F. The martensitic transformation in ceramics — its role in transformation toughening. Progress in Materials Science 2002, 47, 463–557. [Google Scholar] [CrossRef]

- Rose, L.R.F. The mechanics of transformation toughening. Proc. R. Soc. Lond. A 1987, 412, 169–197. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J.E. Effect of Dopants on Zirconia Stabilization - An X-ray Absorption Study: I, Trivalent Dopants. Journal of the American Ceramic Society 1994, 77, 118–128. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J.E. Effect of Dopants on Zirconia Stabilization - An X-ray Absorption Study: II, Tetravalent Dopants. Journal of the American Ceramic Society 1994, 77, 1281–1288. [Google Scholar] [CrossRef]

- Chen, M.; Hallstedt, B.; Gauckler, L.J. Thermodynamic modeling of the ZrO2–YO1.5 system. Solid State Ionics 2004, 170, 255–274. [Google Scholar] [CrossRef]

- Kelly, J.R.; Denry, I. Stabilized zirconia as a structural ceramic: An overview. Dent. Mater. 2008, 24, 289–298. [Google Scholar] [CrossRef]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Phase-transformation and grain-growth kinetics in yttria-stabilized tetragonal zirconia polycrystal doped with a small amount of alumina. Journal of the European Ceramic Society 2010, 30, 1679–1690. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The Tetragonal-Monoclinic Transformation in Zirconia: Lessons Learned and Future Trends. Journal of the American Ceramic Society 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Ruiz, L.; Readey, M.J. Effect of Heat Treatment on Grain Size, Phase Assemblage, and Mechanical Properties of 3 mol% Y-TZP. J Am Ceram Soc 1996, 79, 2331–2340. [Google Scholar] [CrossRef]

- Binner, J.; Vaidhyanathan, B.; Paul, A.; Annaporani, K.; Raghupathy, B. Compositional Effects in Nanostructured Yttria Partially Stabilized Zirconia. International Journal of Applied Ceramic Technology 2011, 8, 766–782. [Google Scholar] [CrossRef]

- Chevalier, J.; Cales, B.; Drouin, M. Low-Temperature Aging of Y-TZP Ceramics. Journal of the American Ceramic Society 1999, 82, 2150–2154. [Google Scholar] [CrossRef]

- Lange, F.F. Transformation toughening: Part 3 Experimental observations in the ZrO2- Y203 system. Journal of Materials Science 1982, 17, 240–246. [Google Scholar] [CrossRef]

- Tsukuma, K. Thermal and Mechanical Properties of Y2O3-Stabilized Tetragonal Zirconia Polycrystals, Science and Technology of Zirconia II. Advances in Ceramics 1984, 12, 382–390. [Google Scholar]

- Kern, F.; Reveron, H.; Chevalier, J.; Gadow, R. Mechanical behaviour of extremely tough TZP bioceramics. J. Mech. Behav. Biomed. Mater. 2019, 90, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Matsui, K.; Hosoi, K.; Feng, B.; Yoshida, H.; Ikuhara, Y. Ultrahigh toughness zirconia ceramics. Proc. Natl. Acad. Sci. U. S. A. 2023, 120, e2304498120. [Google Scholar] [CrossRef] [PubMed]

- Imariouane, M.; Saâdaoui, M.; Denis, G.; Reveron, H.; Chevalier, J. Low-yttria doped zirconia: Bridging the gap between strong and tough ceramics. Journal of the European Ceramic Society 2023, 43, 4906–4915. [Google Scholar] [CrossRef]

- Imariouane, M.; Saâdaoui, M.; Cardinal, S.; Reveron, H.; Chevalier, J. Aging behavior of a 1.5 mol% yttria doped zirconia exhibiting optimized toughness and strength. Journal of the European Ceramic Society 2024, 44, 1053–1060. [Google Scholar] [CrossRef]

- Niihara, K. A fracture mechanics analysis of indentation-induced Palmqvist crack in ceramics. Journal of Materials Science Letters 1983, 2, 221–223. [Google Scholar] [CrossRef]

- Chantikul, P.; Anstis, G.R.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: II, Strength Method. Journal of the American Ceramic Society 1981, 64, 539–543. [Google Scholar] [CrossRef]

- Cook, R.F.; Braun, L.M.; Cannon, W.R. Trapped cracks at indentations: Part I: Experiments on yttria-tetragonal zirconia polycrystals. Journal of Materials Science 1994, 29, 2133–2142. [Google Scholar] [CrossRef]

- Dransmann, G.W.; Steinbrech, R.W.; Pajares, A.; Guiberteau, F.; Dominguez-Rodriguez, A.; Heuer, A.H. Indentation Studies on Y2O3-Stabilized ZrO2: II, Toughness Determination from Stable Growth of Indentation-Induced Cracks. J American Ceramic Society 1994, 77, 1194–1201. [Google Scholar] [CrossRef]

- Benzaid, R.; Chevalier, J.; Saadaoui, M.; Fantozzi, G.; Nawa, M.; Diaz, L.A.; Torrecillas, R. Fracture toughness, strength and slow crack growth in a ceria stabilized zirconia-alumina nanocomposite for medical applications. Biomaterials 2008, 29, 3636–3641. [Google Scholar] [CrossRef] [PubMed]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration Curve for Quantitative Analysis of the Monoclinic-Tetragonal ZrO2 System by X-Ray Diffraction. Journal of the American Ceramic Society 1984, 67, C119–C121. [Google Scholar] [CrossRef]

- Kosmać, T.; Wagner, R.; Claussen, N. X-Ray Determination of Transformation Depths in Ceramics Containing Tetragonal ZrO2. Journal of the American Ceramic Society 1981, 64, C–72. [Google Scholar] [CrossRef]

- McMeeking, R.M.; Evans, A.G. Mechanics of Transformation-Toughening in Brittle Materials. J Am Ceram Soc 1982, 65, 242–246. [Google Scholar] [CrossRef]

- Mendelson, M.I. Average Grain Size in Polycrystalline Ceramics. Journal of the American Ceramic Society 1969, 52, 443–446. [Google Scholar] [CrossRef]

- Liens, A.; Swain, M.; Reveron, H.; Cavoret, J.; Sainsot, P.; Courtois, N.; Fabrègue, D.; Chevalier, J. Development of transformation bands in ceria-stabilized-zirconia based composites during bending at room temperature. Journal of the European Ceramic Society 2021, 41, 691–705. [Google Scholar] [CrossRef]

- Billovits, T.; Demel-Eckhart, S. Exploring the boundaries of strength and toughness: AuerTec® 2Y- 40A, extended abstract ECERS XVIII, Lyon, France. Available online: https://www.ecers2023.org/data/onglet34/module0/modalPreview.php?langue=fr¶mProjet=89 (accessed on 15 May 2024).

- Swain, M.V.; Rose, L.R.F. Strength Limitations of Transformation-Toughened Zirconia Alloys. Journal of the American Ceramic Society 1986, 69, 511–518. [Google Scholar] [CrossRef]

- Mamivand, M.; Asle Zaeem, M.; El Kadiri, H. Phase field modeling of stress-induced tetragonal-to-monoclinic transformation in zirconia and its effect on transformation toughening. Acta Materialia 2014, 64, 208–219. [Google Scholar] [CrossRef]

- Evans, A.G. Perspective on the Development of High-Toughness Ceramics. J Am Ceram Soc 1990, 73, 187–206. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).