1. Introduction

Aflatoxins are highly toxic secondary metabolites produced primarily by certain species of fungi, particularly Aspergillus flavus and Aspergillus parasiticus. These fungi commonly contaminate agricultural commodities such as maize, peanuts, cottonseed, and tree nuts, especially under conditions of high temperature and humidity. Aflatoxins alone contaminateone-fourth of the world’s food grain (Chatterjee et al., 2023). There are several types of aflatoxins, with aflatoxin B1 being the most potent carcinogen. Consumption of aflatoxin-contaminated food and feed poses significant health risks, including hepatotoxicity, carcinogenicity, immunosuppression, and growth impairment in humans and animals (Bennett and Klich, 2003) due to this, aflatoxin contamination is a significant concern in global trade. In agricultural settings, aflatoxin contamination can lead to economic losses due to rejected crops, reduced market value, and trade restrictions. Therefore, research efforts in molecular biology and plant biotechnology often focus on understanding the mechanisms of aflatoxin biosynthesis, developing strategies for aflatoxin management, and enhancing crop resistance to fungal contamination through breeding or biotechnological approaches.

The Food and Agriculture Organization (FAO) of the United Nations has reported that approximately 25% of crops worldwide are impacted by mycotoxins (FAO, 2017). Aflatoxins, produced by the food-borne fungi Aspergillus flavus and A. parasiticus, primarily contaminate food crops like maize, peanuts, and tree nuts in tropical and subtropical regions across the globe (Bandyopadhyay et al., 2007). These crops often face unfavourable storage conditions, leading to the accumulation of aflatoxins (Strosnider et al., 2006; Williams et al., 2004). Exposure to dietary aflatoxins is a concern for over 5 billion people worldwide (Strosnider et al., 2006). These naturally occurring mixes of aflatoxins, including aflatoxins B1, B2, G1, and G2, are known to be highly potent liver carcinogens. The International Agency for Research on Cancer has classified them as a Group 1 human carcinogen (IARC, 2002).In individuals exposed to chronic hepatitis B virus (HBV) infection and aflatoxin, the risk of developing liver cancer is significantly higher than in those exposed to either risk factor alone (Groopmanet al., 2008). The risk can be up to 30 times greater in individuals exposed to both factors and it also shows a multiplicative relationship between aflatoxin and HBV in the induction of liver cancer. As per the report of Food and Agriculture Organization (FAO, 2004) of the United Nations, more than 120 countries worldwide have established regulations regarding aflatoxins in food. This represents a 30% increase from 1995 (FAO, 1997) in terms of the number of countries with aflatoxin maximum levels (MLs). These regulations aim to safeguard human health by reducing dietary exposure to aflatoxin (FAO, 2004; Wu and Guclu, 2012). While these measures are crucial for protecting human and animal health, they can also significantly influence global food trade activities (Wu, 2004).

Mycotoxins in general or aflatoxins specifically offerdetrimental effects in two different ways. The first one iseconomic losses by virtue of production of contaminated food products while the other in the form of health implications upon consuming such contaminated foods. Such implications may arise during the course of ingestion of infected foods like food grains, milk, meat etc. The toxicity principle behind such health issues lies not only due to the parent toxin molecule i.e. aflatoxin but mainly due to its toxic metabolites such as its epoxides or diols, damaging the liver in majority of the cases but often damagingthe kidney or adrenal too. Further, such chronic exposure may lead to liver cancer, convulsions and death in severe cases (Leeson et al., 1995; Eaton and Groopman, 1994; Heathcote and Hibbert, 1978; Goldbatt, 1969).

Aflatoxins (AF) along with other mycotoxins are commonly suspected to play a crucial role in the development of oedema in malnourished people as well as in the pathogenesis of kwashiorkor in malnourished kids (Coulter et al., 1986). More than this, AF contamination negatively affects crop and animal production leading not only to natural resource waste but also decreased market value that may cause significant economic losses. Due to these impacts, several countries and some international organizations have established strict rules and regulations to manage AF contamination in food and feeds and also to prohibit the trade of contaminated products (Juan et al., 2012). The regulations on “acceptable health risk” usually depend on a country’s economic level and development, the amount of consumption of high-risk crops, and the susceptibility to contamination of crops that have to be regulated (Kendra and Dyer, 2007). The established safe limit of AFs for human consumption ranges from 4 to 30µg/kg (Mahato et al., 2019). The EU has set very strict standards, which establish that any product for direct human consumption cannot be marketed with a concentration of AF-B1 and total AFs greater than 2 µg/kg and 4 µg/kg, respectively. Likewise, US regulations have also specified the maximum acceptable limit for AFs at 20 µg/kg (Wu, 2006).

However, if the EU aflatoxin standard is adopted worldwide, developing countries of Asia and Sub-Saharan Africa will face both economic losses and additional costs related to meeting those standards. This situation requires alternative technologies at pre- and post-harvest levels that will help to minimize contamination of commercial foods and feeds, at least to ensure that AF levels remain below safe limits (Prietto et al., 2015). Implementation of innovative technologies is invaluable to address the challenges related to AFs and their effects. Reduction of AF contamination through knowledge of pre- and post-harvest management is one of the first and most important steps toward an appropriate strategy to improve agricultural production and productivity in a sustainable way. This has a direct positive effect on improving the quality and nutritional value of foods, conserving natural resources, as well as improving local and international trade by increasing competitiveness. It is important to identify and document available technologies that can effectively control and minimize aflatoxin contamination to sustain healthy living and socioeconomic development. There exists ample literature on tools for AF control and their benefits. Therefore, this review compiles data on innovative pre- and post-harvest technologies developed that can manage AF contamination in foods. The benefits of these technologies are also discussed in terms of food security, human health, and economic value. Most importantly, implications for research and management policies addressing AF issues are emphasized.

2. Global Trade Hindered by Aflatoxin

To address this issue, international organizations like the Codex Alimentarius Commission, jointly established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), develop standards and guidelines for food safety. These standards include maximum allowable limits for aflatoxin levels in various foods and feed products, ensuring that they are safe for consumption. Additionally, the World Trade Organization (WTO) oversees trade agreements and regulations among its member countries. Aflatoxin regulations may be included in trade agreements or enforced through sanitary and phytosanitary measures to protect human, animal, or plant health. Overall, global trade regulations regarding aflatoxin aim to safeguard public health while facilitating the movement of safe agricultural products across borders (

Table 1).

- a.

Regulation and global trade

Mycotoxins are a significant category of food contaminants that are closely monitored in international trade. Aflatoxins, which have been identified as carcinogenic and immunosuppressive (Dash et al., 2007; Wild and Hall, 1999; Williams et al., 2004), are a prominent example of mycotoxins. The detrimental health effects associated with mycotoxins are the main driving force behind the increasing concerns regarding food safety among researchers and policymakers. To address the health risks posed by aflatoxins, the World Trade Organization's (WTO) Sanitary and Phytosanitary Standards (SPS) agreement empowers member countries to establish their own food standards for the protection of consumers (Yue et al., 2006). The precautionary principle, also known as the SPS policy, is the term used by the WTO to describe this approach. Over the years, food standards in developed countries have undergone changes. For instance, the European Commission has recently introduced new regulations regarding aflatoxin in imported food items (Otsuki et al., 2001a; Otsuki et al., 2001b). In the United States, the US Food and Drug Administration (US FDA) has issued a Compliance Policy Guide for Aflatoxins in Peanuts and Peanut Products, Sec. 570.375 (FDA, 1980). Similarly, in Canada, the Canadian Food Inspection Agency (CFIA) has established regulations concerning aflatoxin levels in food and feeds (CFIA, 2017). In Australia and New Zealand, the regulation of maximum levels (MLs) for aflatoxins in peanuts falls under the jurisdiction of Food Standards Australia New Zealand (FSANZ) through Schedule 19: Maximum levels of contaminants and natural toxicants (FSANZ, 2017). On the other hand, the Food Safety and Standards Authority of India (FSSAI) introduced the Food Safety and Standards (Contaminants, toxins and Residues) Regulations (F. No. 3/15015/30/2011) in 2011, which specifies MLs for aflatoxins in all foods (FSSAI, 2011).The National Health and Family Planning Commission (NHFPC) and the China Food and Drug Administration (CFDA) in China have released the National Food Safety Standard of Maximum Levels of Mycotoxin in Foods, outlining a specific limit for AFB1 in peanuts and their derivatives (USDA, 2018). Meanwhile, Japan's Food and Agricultural Materials Inspection Centre (FAMIC) has set regulatory thresholds for AFB1 in all food categories (FAMIC, 2011). Furthermore, MERCOSUR, a trade agreement comprising Argentina, Brazil, Paraguay, Uruguay, and Venezuela, has adopted uniform maximum levels for aflatoxins in peanuts and peanut products (FAO/WHO 2004).

Numerous countries have responded by implementing stringent legal limits on Aflatoxin in various food products. In 2006, the European Commission established the maximum allowable level of Aflatoxin B1 (AFB1) at 2.0 mg/kg for grain and grain products, and at 0.1 mg/kg for processed cereal-based baby foods (European Commission, 2006). Conversely, the Food and Drug Administration (FDA) in the United States of America (USA) tolerates higher levels of AFB1, allowing up to 20 mg/kg. Additionally, the FDA has set the maximum level of Aflatoxin M1 (AFM1) in milk at 0.5 mg/kg (FDA, 2000). The implementation of strict regulations on trading practices, food monitoring, and storage methods in industrialized nations has proven successful in reducing the health risks associated with Aflatoxin (Brown et al., 1999).

- b.

Legislation in feed and feed ingredients

Mycotoxins are estimated to affect approximately 25% of the world's food crops (Kumar et al., 2008). Aflatoxin, a major contaminant, has been found in maize, wheat, rice, barley, and oilseeds such as peanut, sunflower, soybeans, mustard, cottonseed, and their products in many countries across Asia, Latin America, and sub-Saharan Africa (Filazi and Sireli, 2013; Lee et al., 2015). The impact of this contamination can result in significant economic losses for developing nations, particularly due to the lack of drying equipment and high humidity conditions. Aflatoxin B1, among various types of aflatoxins, is considered the most dangerous toxin, with the upper safe limit regulated by BIS at a narrow margin of 20 ppb in most animal feedstuffs (BIS, 2021). Aflatoxin-M1, a type of aflatoxin, can be transmitted from the feed consumed by ruminant animals to their milk, posing a significant risk to human health (FSSAI, 2020). The presence of aflatoxin is not limited to milk alone; it has also been found in other dairy products, eggs, and edible animal products. This has led to the development of regulations aimed at minimizing aflatoxin exposure in food animals. Surprisingly, aflatoxin has even been detected in pasteurized ultra-high temperature milk, broiler chicken meat, eggs, and sausage (Siddappa et al., 2012; Shaltout et al., 2014). Although the financial impact of aflatoxin contamination in animal feeds is not specifically determined in India, the U.S. corn industry in the southern region experiences considerable annual losses estimated at US$ 1.68 billion due to climatic conditions (Mitchell et al., 2016). The presence of aflatoxin and ochratoxin, natural contaminants commonly found in animal feeds, can have a significant negative impact on animal production, leading to substantial economic losses (Battacone et al., 2010). Among these contaminants, aflatoxin poses the greatest risk to human health when it enters the food or feed chain. The exposure to mycotoxins can vary significantly depending on various factors, including the source of contamination, the type of food, storage conditions, and climatic factors (Sanders et al., 1984). It is crucial to carefully evaluate the consumption of maize, cereals, peanuts, and milk through the feed-food carryover, as these commodities are widely consumed globally and contribute to elevated levels of aflatoxin exposure in humans (Wild & Gong, 2010).A significant concern has arisen in Africa's dairy sector regarding the contamination of milk with Aflatoxin M1 (AFM1) through animal feeds that are contaminated with Aflatoxin B1 (Abebe et al., 2020; Mulunda et al., 2013; Voth-Gaeddert et al., 2019). AFM1 is a metabolite of Aflatoxin B1 (AFB1), which is a potent hepatocarcinogen produced by Aspergillus fungi found in certain dairy animal feed ingredients. While the consumption of high-quality dairy products could potentially address Africa's malnutrition problems, the presence of contaminated milk may undermine these benefits and even have more severe consequences on child morbidity or mortality (Grace et al., 2020; SahaTurna et al., 2023; SahaTurna and Wu, 2022).

The U.S. Food and Drug Administration (FDA, 2019) has established the acceptable threshold for aflatoxin M1 (AFM1) in milk and other dairy products at 0.50 μg/L. Additionally, the maximum level of total aflatoxins (AFB1+AFB2+AFG1+AFG2) in feed ingredients provided to dairy animals and foods intended for human consumption is set at 20 μg/kg (FDA, 2019). On the other hand, the European Commission has implemented strict regulations, setting an action level of 0.05 μg/L for AFM1 in liquid milk. Furthermore, the limits for AFB1 are 20 μg/kg in all feedstuffs, 10 μg/kg in complete feeds, and 5 μg/kg in complete feeds for dairy animals (European Commission, 2006). In India, the Bureau of Indian Standards (BIS) has established a maximum permissible level of 20 μg/kg or 20 ppb for aflatoxin B1 in all animal feeds. However, the Food Safety and Standards Authority of India (FSSAI, 2020) recommends a maximum permissible limit of 10 μg/kg for aflatoxin B1 in ready-to-eat oilseeds and oils and 0.5 μg/kg for aflatoxin M1 in milk intended for human consumption.

Iran and the United States dominate the global pistachio market, with a combined contribution of over 70% to the world's pistachio exports. According to FAOSTAT (2011), Iran accounts for 47% of the exports, while the US contributes 25%. However, pistachios also pose a significant risk in terms of dietary aflatoxin exposure. They are responsible for 7-45% of the total aflatoxin exposure from all sources for humans, as stated by JECFA (2007). This has led to several instances of aflatoxin contamination in pistachios, causing trade disruptions. In 1997, the European Union imposed a ban on pistachio imports from Iran due to high aflatoxin levels ranging from 11-400 ng/g in consignments intended for European import. The United Kingdom also called for a reinstatement of the ban in 2002, as over 10% of sampled consignments were found to be contaminated. More recently, in 2010, the US implemented a ban on all Iranian pistachios, as reported by JECFA (2007).

Aflatoxin, known for its hepatotoxic and immunosuppressive properties, is classified as a group-1 carcinogen, leading to strict regulations on both agricultural goods and animal products. The levels of aflatoxin M1 in dairy items and aflatoxin B1 in eggs and meat are influenced by the contamination levels in animal feed. Aflatoxin M1 has been found in human breast milk and animals exposed to contaminated feed. The transfer rate of aflatoxin M1 ranges from 0.8-6.5% based on species, milk production, and lactation stage (Churchill, 2017). High levels of aflatoxins have also been detected in sausages and various meat products worldwide (Aziz and Youssef, 1991; Shaltout et al., 2014).

- c.

Regulation and control

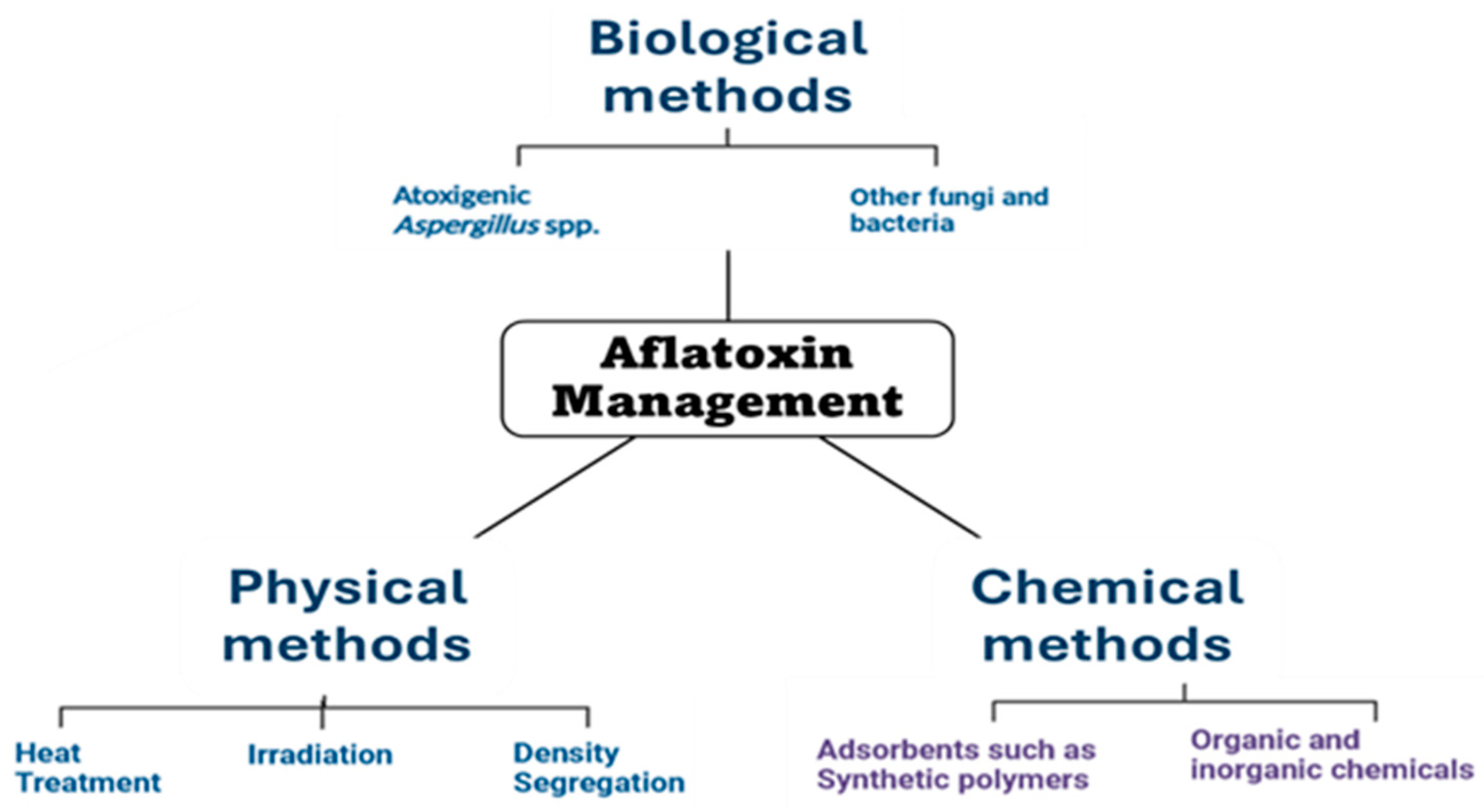

Governments and international organizations establish regulations and guidelines to safeguard public health by limiting the levels of aflatoxin in food and feed. These regulations often include maximum allowable limits (MRLs) for different aflatoxins in various foods and feed commodities. For example, the European Union has established strict MRLs for aflatoxins in foods such as nuts, dried fruits, and cereals. Prevention is a key aspect of aflatoxin control. Agricultural practices such as crop rotation, proper storage facilities, timely harvesting, and use of resistant crop varieties can help reduce fungal contamination and aflatoxin production in the field. Regular monitoring and surveillance programs are conducted to assess the levels of aflatoxin contamination in food and feed. Sampling and analysis are carried out using validated methods to ensure accurate detection and quantification of aflatoxin. If aflatoxin contamination is detected above regulatory limits, various control measures may be implemented. These can include sorting and cleaning of contaminated grains, use of chemical and biological agents to inhibit fungal growth, and application of physical methods such as irradiation or thermal treatments to reduce aflatoxin levels. Educating farmers, food producers, and consumers about the risks associated with aflatoxin contamination is crucial for effective control. Training programs, informational campaigns, and dissemination of best practices can help stakeholders understand how to prevent, detect, and manage contamination throughout the food supply chain.

- d.

Risk assessment

Understanding the framework used for aflatoxin risk assessment is equally important, which involves hazard identification, exposure assessment, dose-response assessment, and risk characterization. Recognizing the various pathways through which humans and animals are exposed to aflatoxin, including ingestion of contaminated food and feed, inhalation of fungal spores, and dermal exposure are the keys to assessing the risk. Gaining insights into the adverse health effects associated with aflatoxin exposure, including acute toxicity, carcinogenicity, immunosuppression, reproductive disorders, and developmental abnormalities may give an idea of the potentiality of the risk emanating from consumption of the aflatoxin. Vulnerability of different population groups to aflatoxin exposure, such as infants, children, pregnant women, immunocompromised individuals, and livestock species may also be taken into consideration. Learning about the international regulatory standards and guidelines established by organizations such as the Codex Alimentarius Commission, the World Health Organization (WHO), and the Food and Agriculture Organization (FAO) to ensure food safety and protect public health is necessary. One has to understand the sources of uncertainty and variability in aflatoxin risk assessment, including variability in toxin levels, exposure patterns, susceptibility factors, and data limitations. Risk management options available for mitigating aflatoxin contamination in food and feed, including good agricultural practices (GAPs), hazard analysis and critical control points (HACCP), maximum allowable limits (MRLs), and post-harvest interventions may be explored. Developing a comprehensive understanding of aflatoxin risk assessment and its role in setting international regulatory standards to safeguard food safety and public health is, therefore, crucial.

- e.

Legislative framework

The legislative framework for food safety has evolved over centuries, with scientific advancements leading to formal regulations aimed at protecting consumers from chemical and microbiological hazards. Natural toxins, especially mycotoxins like aflatoxins, are among the most regulated contaminants globally. Initially, only a few developed countries had such regulations, but by 2003, around 100 countries had adopted specific guidelines, covering about 85% of the world's population (Van Egmond and Jonker, 2004). The international trade in food and feed has driven the need for consistent global standards to ensure consumer safety and fair trade, with the food industry valued at approximately 2000 billion dollars annually.

The Codex Alimentarius Commission (CAC), a joint effort of the FAO and WHO, develops international food standards, including for contaminants in food and feed (Eskola et al., 2020). The Codex Committee for Contaminants in Foods (CCCF) manages risk by setting maximum permitted levels (MLs), prioritizing risk assessments, and creating sampling and analysis methods. The Joint FAO/WHO Expert Committee on Food Additives (JECFA) conducts scientific evaluations to inform these decisions. The Codex General Standard for Contaminants and Toxins in Food and Feed outlines principles for setting MLs to protect consumers without creating trade barriers. These standards are integrated into the WTO’s Agreement on Sanitary and Phytosanitary Measures, aiding in trade dispute resolution. Specific limits for aflatoxins in various commodities, including peanuts, are provided, along with sampling plans.

In the European Union, the legislation for food safety, including contaminant limits, follows principles defined in Council Regulation (EEC) No 315/93. The European Commission (EC) sets maximum limits for contaminants and specifies detection and sampling methods. Risk management is handled by the Directorate-General for Health and Food Safety (DG SANTE). The European Food Safety Authority (EFSA) now conducts risk assessments, a role previously held by the Scientific Committee on Food. EFSA's various panels, like the CONTAM Panel, evaluate toxicological data and methods for contaminants in food and feed. Initial regulations, such as Commission Regulation (EC) No 1525/98, were updated by Regulation (EC) No 466/2001 and later by Regulation (EC) No 1881/2006 to align with new developments and Codex guidelines (Eskola et al., 2018).

- f.

Global health impact, economic risks and vulnerable regions

Governments and international organizations establish regulatory standards and quality control measures to limit aflatoxin contamination in food and feed. Maximum allowable limits (MRLs) are set for aflatoxin levels in agricultural commodities, and food safety regulations are enforced to ensure compliance throughout the supply chain. These regulatory interventions aim to safeguard public health and maintain consumer confidence in food safety. Aflatoxin exposure poses significant health risks to both humans and animals. Acute toxicity can lead to symptoms such as vomiting, abdominal pain, and liver damage, while chronic exposure is associated with serious health conditions like liver cancer, immune suppression, and stunted growth in children. Recognizing these health impacts underscores the importance of stringent food safety regulations and public health interventions. Researchers employ various methodologies to quantify the social costs associated with fungi and aflatoxins in maize and peanuts. This involves estimating both direct costs, such as losses incurred from contaminated crops and medical expenses related to aflatoxin poisoning, and indirect costs, which encompass broader economic impacts like reduced agricultural productivity and trade disruptions due to contaminated exports.

Aflatoxins are widely recognized as the most crucial mycotoxins in terms of safeguarding human and animal health (Marshall et al., 2020). Discovered in the 1960s, aflatoxin was the first mycotoxin to be identified and remains the most extensively researched (Bennett and Klich, 2003; Richard, 2008). These toxins are known to be carcinogenic, immunogenic, and teratogenic to both humans and animals (Marshall et al., 2020), with potential impacts on immunity, fertility, and child growth (IARC, 2012a). The prevalence of chronic undernourishment affecting 821 million individuals globally (United Nations, 2019), coupled with reports linking aflatoxins to child stunting in Africa (IARC, 2015; Matacic, 2016), highlights the significant food and feed losses resulting from mycotoxin contamination, particularly in developing countries and Sub-Saharan Africa. Aflatoxins present a significant challenge when crops are stored in unfavourable conditions that promote the growth of moulds (Bennett and Klich, 2003; CAST, 2003). In farm animals, the consumption of Aflatoxin affects both growth and the immune system, leading to a strain on local meat production, the national economy, and the global food supply (Wild and Gong, 2010). The IARC (International Agency for Research on Cancer) has classified these fungal metabolites as class-1 agents due to their carcinogenic properties. Aflatoxins are known to cause cancer, especially when combined with a chronic Hepatitis B virus (HBV) infection. Although the causal relationship with Hepatitis C virus is likely, it lacks strong evidence (Wild and Montesano, 2009). Aflatoxins are statistically associated with a significant risk of developing Hepatocellular Carcinoma (HCC) (Qian et al., 1994; Ross et al., 1992). The WHO's 2017 report revealed 788,000 global deaths from HCC in 2015, making it the second leading cause of cancer-related deaths worldwide after lung cancer. In developing nations, HBV and Aflatoxin e are common risk factors for HCC (Liu and Wu, 2010). Dietary exposure to aflatoxins has a significant human health consequence, leading to hepatocellular carcinoma (HCC). This disease causes the death of about 250,000 people annually in Sub-Saharan Africa, with the high intake of aflatoxins in food and the presence of the Hepatitis B virus (HBV) being identified as key factors (Ladeira et al. 2017).A massive outbreak of hepatitis with an estimated 106 deaths of tribal people due to consumption of aflatoxin-contaminated maize was reported in 1974 in the Indian states (Gujarat and Rajasthan) (Krishnamachari et al., 1975). Most recently, aflatoxicosis outbreaks occurred in Kenya in 2004 and 2005, following the consumption of mouldy maize that had been harvested early and stored improperly (Strosnider et al., 2006). In the 2004 outbreak, the largest ever recorded, 317 people became ill and 125 died (Azziz-Baumgartner et al., 2005). Two additional human diseases have also been associated with the ingestion of food contaminated with aflatoxin. These include Kwashiorkor, a form of malnutrition commonly seen in children, and Reye's syndrome, which is characterized by encephalopathy and fatty degeneration of the organs in children. The exact cause of Reye's syndrome remains unknown (CAST 2003; et and Klich 2003).

Various symptoms of chronic aflatoxicoses have been documented in livestock, including decreased rate of weight gain in cattle, pigs, and poultry, as well as reduced feed intake and conversion in pigs and poultry. Additionally, cows may experience reduced milk yields, while poultry may suffer from immunosuppression and decreased egg production (CAST 2003; Diaz 2005; EC 1994). On the other hand, acute exposure to aflatoxins can result in liver necrosis and eventual fatality (EC 1994; CAST 2003). Nevertheless, it is the long-term exposure to these toxins in animals that poses the most significant economic impact, surpassing the consequences of acute animal mortality (CAST 2003).

Aflatoxin contamination in agricultural products has far-reaching consequences that extend beyond public health concerns. It also impacts trade and economic aspects for both developed and developing nations. For instance, maize farmers in the United States face a yearly loss of $160 million due to aflatoxin issues (Wu, 2015). In developing countries, particularly in sub-Saharan Africa, the losses are even more significant, totalling $450 million, which accounts for 38% of global agricultural losses caused by aflatoxin (Gbashi et al., 2018). Moreover, aflatoxins play a crucial role in causing a significant drop in agricultural trade between developed and developing countries (Wu, 2015). The direct economic consequences of aflatoxin pollution in crops primarily stem from a decline in marketable products due to rejection in the global market, as well as losses incurred from livestock diseases, resulting in morbidity and mortality, leading to reduced volume and value in national markets, ultimately causing substantial economic harm (Wagacha and Muthomi, 2008).

The socio-economic consequences of aflatoxin contamination extend beyond individual health impacts to affect entire communities and livelihoods, particularly in regions where maize and peanuts are staple crops. Smallholder farmers, in particular, face reduced income and food insecurity when their crops are contaminated, while trade disruptions limit market access and economic opportunities. Fungal contamination and aflatoxin presence in maize and peanuts are influenced by a range of factors including environmental conditions (such as temperature and humidity), agricultural practices (such as crop rotation and pesticide usage), and post-harvest handling and storage techniques. Understanding the dynamics of contamination is crucial for implementing effective control measures. Effective risk management strategies encompass both pre-harvest and post-harvest interventions.

3. Factors Influencing Toxicity for Aflatoxin Affecting Health

Aflatoxins are the mycotoxins that pose the most threat to food safety because of their high toxicity and widespread presence in foods and feeds. Geographically, aflatoxins are most prevalent in tropical and subtropical areas. They are contaminants of food and feed like peanuts, maize, and their derivatives Aflatoxin-related health issues have been linked since its discovery; it significantly increases the risk of certain chronic diseases that can be fatal, including aflatoxicosis outbreaks.It is now widely documented that aflatoxins induce a variety of different acute and chronic disorders, most of which are severe, even though they have been primarily linked to cancer-related illnesses. Aflatoxin carcinogenicity has long been linked to the liver, where the metabolization process releases reactive intermediate metabolites (Benkerroum, 2020). Nevertheless, later animal and epidemiological research showed that they could cause cancer in organs other than the liver, such as the kidney, pancreas, bladder, bone, viscera, central nervous system, etc.

- a.

Chemistry of aflatoxin toxicity and degradation mechanism

Aflatoxin is a group of 20 fungal metabolites, viz., B1, B2, G1, G2, M1 and M2 etc. Of them, Aflatoxin B1 (AFB1) and aflatoxin B2 (AFB2) are produced by both A. flavus and A. parasiticus; AFB1 is believed to be the most potent and common food contaminants among all aflatoxins.Aflatoxin G1 (AFG1) and aflatoxin G2 (AFG2) are also produced by A. parasiticus, found in the foodstuff (Vankayalapati, 2018). Whereas, Aflatoxin M1 (AFM1) is produced in the fermentation broth ofA. parasiticus; AFM1 and AFM2 also metabolized from AFB1 and AFB2 in the infected liver cell (OwuorLalah et al., 2020) and are found in human and animal milk (Kamkar et al., 2014).

Aflatoxins are crystalline, colourless to pale yellow compounds that are easily soluble in solvents that are somewhat polar, such as methanol, chloroform, and dimethyl sulfoxide, and they have a water solubility of 10–20 μg/mL (Sarmento Amoras and Pena Costa, 2020). Aflatoxin molecules become unstable when exposed to certain conditions, such as oxygen-rich ultraviolet light, extreme pH values (pH < 3 or > 10), oxidizing agents, and high temperatures that cause ammonization (Dhakal et al., 2023). This irreversible reaction leads to the opening of the lactone ring and the decarboxylation of the aflatoxin molecule. These poisons belong to a special class of naturally occurring heterocyclic chemicals that are highly oxygenated.

The most studied aflatoxin, AFB1-exo 8,9-epoxide, is produced by the microsomal cytochrome enzyme (CYP450) at the beginning of AFB1 metabolism (Guengerich et al., 1998). In the instance of aflatoxin B1, it has been established that this aflatoxin is ultimately responsible for genotoxicity (Benkerroum, 2020). There is mounting evidence that the oxidative stress caused by AFB1 is equally, if not more, responsible for the genotoxicity of aflatoxin (Ma et al., 2021). The mechanisms underlying aflatoxin immunotoxicity, which is likely the second most well-studied toxicological impact, are becoming understood. Other aflatoxin-induced acute and chronic health issues, such as malnutrition diseases, delayed physical and mental maturity, reproduction, nervous system diseases, etc., have been demonstrated in humans or animals in addition to these major toxicological effects (Peles et al., 2019); however, more clarification is needed regarding their mechanisms of action. Although reports of its immunostimulatory effects have also been produced, aflatoxin is most recognized for its immunosuppressive characteristics.

- b.

Toxicity and health implications of aflatoxin exposure

Numerous toxicological effects of aflatoxin processes are produced, many of which are yet not well known. Numerous investigations have been carried out to investigate the mechanisms behind the toxicity of aflatoxins, providing a scientific basis for the creation of control and prevention measures. Food safety authorities can also utilize their expertise as a scientific tool to create regulations. The mutagenesis effects of aflatoxin AFB1 have been extensively studied since its discovery, and these effects have primarily been linked to the intermediate metabolite AFB1-exo-8,9 epoxide (AFBO) (Bedard and Massey, 2006). When AFBO combines with cellular macromolecules including proteins, phospholipids, and nucleic acids (Zhuang et al., 2016), it can alter genetic, metabolic, signalling, and cell structural aspects of the cell because of its severe instability. However, an increasing amount of evidence is being gathered that demonstrates how AFB1 causes oxidative stress (OS), which has effects on cell integrity and function that are at least as substantial if not more so (Kövesi et al., 2021). AFB1's several toxicity pathways produce genotoxicity, immunotoxicity, and acute poisoning when they interact with genomic DNA, other functional macromolecules, and immunocompetent cells (Dabuo et al., 2022). OS and AFBO are involved in these mechanisms. The refractory nature of AFB1-FAPy lesions to NER repair may not be the only explanation for their enhanced mutagenicity, since these lesions can also be repaired through the less sensitive to helix distortion mechanism of base excision repair (BER) (McCullough and Lloyd, 2019). Glycosylases in BER identify the damaged bases on a site-specific basis, allowing them to be eliminated and replaced with the correct base (Dianov and Hübscher, 2013). However, it is now well established that exposure to aflatoxins alters repair genes in a variety of ways, including through epigenetic alterations that stop the BER pathway.

For example, it has recently been shown that transcriptional inhibition of the gene caused by hypermethylation of the promoter of the NEIL1 (Nei Like 1) gene, which codes for a DNA glycosylase (NEIL1) crucial for BER, lowers the excision efficacy in AFB1-FAPy adducts (Hildrestrand et al., 2021). The prevalent polymorphisms that result in catalytically inactive NEIL1 enzyme may also make it more difficult for people's AFB1-FAPy lesions to repair (Zuckerman et al., 2023). Aflatoxin-induced HCC in high-exposure scenarios has also been demonstrated to be associated with polymorphism in multiple human DNA repair genes, such as XPC, XPD, XRCC1, XRCC3, XRCC4, XPD, and XRCC7 (Long et al., 2013).

This risk is exacerbated with concurrent polymorphism of repair genes and phase II-enzyme detoxification genes, as was demonstrated for the combined polymorphisms of XRCC1 (involved in BER repair) with GSTM1 and HYL1*2 (coding for GST and microsomal epoxide hydrolase, respectively) (Tiemersma et al., 2001). However, the effect of the AFB1-detoxifying gene polymorphism alone on the increased risk of HCC remains a matter of continuous controversy.

- c.

Aflatoxicosis outbreaks

Aflatoxicosis is a global mycotoxicosis that produces strong hepatotoxins on animal feed during hot weather (drought) and in storage. It frequently happens at the same time as agricultural pest damage. Usually invading peanuts, almonds, corn (maize), and cottonseed, Aspergillus flavus and A. parasiticus can swiftly produce significant amounts of aflatoxins, with aflatoxin B being the most dangerous (Kumar et al., 2017). In the liver, aflatoxins are broken down into an epoxide that attaches to macromolecules, such as nucleic acids. Mutagenesis, cancer, teratogenesis, immunosuppression, and liver damage with decreased protein synthesis are a few examples of the harmful effects. Patients may exhibit poor growth, bleeding, icterus, sadness, unthriftiness, and inappetence to food. Aspergillus flavus and A.parasiticus infestation of corn (maize), peanuts, almonds, rice, cottonseed, and other crops can lead to aflatoxicosis, a global health concern (Sarma et al., 2017).

Aflatoxin severely affects fish, humans, animals, birds, dogs, cats, and rodents; the young are especially vulnerable. Aflatoxin targets the liver, kidney, spleen, brain, gut, skin, testis, and cardiac tissue and is mutagenic, carcinogenic, teratogenic, and immunosuppressive (Dai et al., 2022). Adverse consequences can result in low production, food residues, and even death. They are associated with liver damage. Aflatoxin contamination in feed should be avoided by nursing animals due to aflatoxin M1 residual in milk, and most countries have regulatory limitations on the amount of aflatoxin in animal feeds, human food, and milk (Akbar et al., 2020). The feed should be chemically evaluated before use. The hydrated sodium calcium aluminosilicates can function as aflatoxin binders in feed and minimize harmful effects and milk aflatoxin M1 residue. The treatment is supportive.

Around the world, aflatoxicosis affects growing fowl, particularly ducklings and turkey poults, as well as young pigs, pregnant sows, calves, and canines (Dalvi et al., 1986). Though they are susceptible if toxic diets are fed for extended periods, adult cattle, sheep, and goats are rather resistant to the acute phase of the disease. All examined animal species have demonstrated some degree of vulnerability in experiments (Allah Ditta et al., 2019). Aflatoxin dietary quantities that are often tolerated in animals include dogs, cats, cattle, and weaner pigs, 100 ppb in calves, < 50 ppb in dogs, < 100 ppb in calves, and < 300 ppb in cattle (Jallow et al., 2021).

Clinical illness, including some mortality, is anticipated to occur at about double the specified acceptable levels. Aflatoxin M1 and M2, two detectable metabolites, are excreted in the milk of nursing animals at dietary levels as low as 10–20 ppb (Zentai et al., 2023); dairy cows, goats, or sheep should not be fed feedstuffs containing aflatoxin. Different nations have varying acceptable legal limits for milk, which can range from 0.05 ppb to 0.5 ppb (Aslam et al., 2015). When contamination happens, state or federal regulatory organizations should be consulted. In the liver, aflatoxins are broken down into an epoxide that attaches itself to macromolecules, particularly nucleic acids and nucleoproteins. Their harmful consequences include immunosuppression, decreased protein synthesis, teratogenesis, carcinogenesis, and mutagenesis brought on by the alkylation of nuclear DNA (Bou Zerdan et al., 2021). Decreased synthesis of proteins leads to a decrease in vital metabolic enzymes and growth-promoting structural proteins. The primary organ impacted is the liver. Aflatoxin dosages that are too high cause hepatic necrosis, while doses that are too low over time cause immunosuppression, decreased growth rate, and enlarged liver.

- d.

Aspergillosis and cancer

Species of Aspergillus, a fungus or mould, can lead to the development of aspergillosis in individuals. The symptoms and severity of aspergillosis-related infections can vary widely, but they generally affect the respiratory system. Aspergillus, can grow both indoors and outdoors. While the majority of these mould strains are harmless to breathe in, a small number can pose a significant risk to individuals with compromised immune systems, underlying lung conditions, or asthma (Vanfleteren et al., 2018). The symptoms and signs of aspergillosis differ based on the type of infection. Some individuals with cystic fibrosis or asthma may have allergic reactions to Aspergillus mould. This condition, also known as allergic bronchopulmonary aspergillosis, is characterized by fever, a cough that may produce mucus plugs or blood, as well as exacerbation of chronic lung diseases such as severe sarcoidosis, emphysema, and tuberculosis (Chen et al., 2022). In individuals with aspergillus infections, fungus fibres may enter lung cavities and form tangled masses (fungus balls) known as aspergillomas. Initially, aspergillomas may cause a mild cough or no symptoms at all (Dib et al., 2019). However, over time and without treatment, aspergillomas have the potential to worsen underlying chronic lung conditions and lead to a cough that frequently produces blood (hemoptysis), as well as symptoms such as sighing, breathing difficulty, and unintentional weight loss.

4. Aflatoxin Contamination Contributors

Mycotoxins, which are fungal toxins naturally present, pose a threat to food staples during their production and storage, resulting in health concerns for humans and animals alike (Diao et al., 2014; Villers, 2014). The contamination of food items by mycotoxins occurs throughout the pre-harvest and postharvest stages, particularly when they are exposed to moisture or stored under conditions of high temperature or humidity (Villers,2014). Aflatoxins (AFs) are particularly noteworthy among mycotoxins due to their prevalence, toxicity, and economic consequences. Aflatoxin B1 (AFB1) is the most commonly found AF in contaminated agricultural products, alongside approximately 20 other identified AFs. These toxins, including AFB2, AFG1, and AFG2, are primarily produced by toxigenic strains of Aspergillus fungi, notably Aspergillus flavus, Aspergillus parasiticus, and Aspergillus nomius. Additionally, aflatoxin M1 (AFM1), a metabolite of AFB1, holds significance within the AFs group, particularly for its occurrence in human and animal milk when contaminated food or feed contains AFB1.For decades, aflatoxin contamination in peanuts has remained a persistent global concern, garnering widespread attention since the 1960s. These fungal byproducts pose substantial health risks to both humans and animals, thereby imposing significant economic burdens on stakeholders across the production, handling, processing, and distribution chains of contaminated peanuts. The inevitability of aflatoxin contamination is rooted in the diverse array of factors influencing peanuts at various stages, from pre-harvest conditions to harvesting and postharvest practices (Diao et al., 2014).

- g.

Environmental factors

As climatic conditions undergo significant shifts, ecosystems experience alterations in temperature, precipitation, and humidity, all of which create conducive environments for fungal proliferation and subsequent mycotoxin synthesis (Achaglinkame et al., 2017; Nleya et al., 2020). Fungi inhabit numerous crops and exhibit adaptability to diverse environmental conditions, occupying distinct ecological niches that may overlap (Perrone et al., 2020). The proliferation of fungi and the production of aflatoxins in cereals are contingent upon factors such as temperature, moisture levels, soil composition, and storage conditions (Achaglinkame et al., 2017). Various abiotic factors (temperature, water activity, pH levels, carbon availability, and nitrogen content) significantly impact the pathway of aflatoxin biosynthesis (Liu et al., 2017). However, aflatoxin contamination is particularly influenced by temperature and water activity. These factors not only stimulate the growth of aflatoxin-producing fungi, primarily A. flavus, but also significantly impact the activation of the gene cluster responsible for aflatoxin production (Abdel-Hadi et al., 2011; Bernáldez et al., 2017; Tejero et al., 2021). Increased water activity promotes enhanced fungal growth and the synthesis of toxins (Bhatnagar et al., 2006). It's been determined that a water activity of approximately 0.99 aw and temperatures ranging from 29 to 30°C are conducive to aflatoxin production (Tejero et al., 2021). These two factors, namely temperature and water activity (aw), are pivotal in regulating the transcription of two significant genes (aflR and aflS) in the pathway of aflatoxin biosynthesis (Liu et al., 2017). Medina et al. (2014) explored how key environmental factors affect the molecular ecology, growth, and aflatoxin production by Aspergillus flavus, both in vitro and in maize grains. Recent studies on water activity × temperature interactions and aflatoxin biosynthesis are examined, revealing a direct correlation between gene expression levels and aflatoxin B1 production. A model integrating the expression of 10 biosynthetic genes, growth, and AFB1 production was validated under elevated temperature and water stress conditions. The impact of water activity × temperature × elevated CO2 levels is detailed for the first time, showing significant effects on aflatoxin biosynthetic gene expression (including structural aflD and regulatory aflR genes) and AFB1 production. Baazeem et al. (2021) demonstrated that A. flavus strains isolated from pistachio nuts exhibited optimal growth at approximately 35 °C on both pistachio nut-based media and raw pistachio nuts. AFB1 production, however, peaked at around 30 °C. Under climate change conditions with elevated temperatures (35 vs. 37 °C) and CO2 levels (400 vs. 1000 ppm), growth of A. flavus strains showed minimal variation, regardless of water availability. Notably, AFB1 production was stimulated under these conditions both in vitro and on raw pistachio nuts (Baazeem et al.,2021), accompanied by changes in the expression of the structural and regulatory genes (aflD and aflR) involved in toxin biosynthesis, with some strain variability observed. This integrative approach provides crucial insights into the effects of climate change on mycotoxigenicity. Temperatures outside the range of 25 to 37°Care unsuitable for the growth and synthesis of aflatoxins, while moisture levels below 0.85 aw hinder growth and toxin production, ceasing completely at 0.70–0.75 aw (Bhatnagar et al.,2006). Elevated temperatures, higher levels of carbon dioxide (CO2), drought, and rainfall directly influence maize crops, altering the prevalence of Aspergillus flavus. These environmental factors stimulate fungal growth, conidiation, and spore dispersal, while also hindering the growth and maturation of maize (Ojiamboet al., 2018; Nleya et al., 2018). Extended periods of frequent droughts stimulate mycotoxin production both before and after harvest (Ojiambo et al., 2018; Nleya et al., 2018; Kachapulula et al., 2017; Medina et al., 2017; Dövényi-Nagy et al., 2020). The impact of climate change on maize production is multifaceted, with factors such as rainfall distribution, prevalence of pests and diseases, and temperature fluctuations playing significant roles (Mapfumo et al.,2020). According to research by Zuma-Netshiukhwi et al. (2021), even a modest temperature rise of 1°C to 2°C can lead to a substantial decrease in grain yield, estimated at around 20–25%. Other studies suggest even higher reductions in yield, possibly up to 50%, contingent upon the plant's reproductive stage (Adisa et al., 2019; Jain et al., 2019).

As projected, a reduction of approximately 15% in rainfall is anticipated by the close of the 21st century (Jury et al., 2013). Boko et al. (2007) envisage a 5% to 8% augmentation in aridity and semi-aridity throughout Africa, positing potential implications such as heightened drought occurrences and ensuing crop stress. These circumstances may contribute to an elevation in mycotoxin contamination levels (Kachapulula et al., 2017; Hajnal et al., 2017). Climate projections suggest that atmospheric CO2 levels are expected to increase two to threefold (from 350-400 ppm to 800-1200 ppm) over the next 25 to 50 years. This escalation in CO2, along with rising temperatures and frequent drought episodes, is likely to have significant impacts on pest dynamics, disease prevalence, and crop yields across various regions. Climate projections indicate that atmospheric CO2 levels are anticipated to rise two to threefold (from 350-400 ppm to 800-1200 ppm) within the next 25 to 50 years. This increase, coupled with higher temperatures and more frequent droughts, is expected to significantly affect pest dynamics, disease incidence, and crop yields in various regions. Baazeem et al. (2021) found that acclimatizing A. flavus for five generations in elevated CO2 on raw pistachio nuts caused different strains to exhibit varied growth and AFB1 production. Both the original and acclimatized AB3 and B10 strains showed similar colonization under different climate-related conditions of temperature, CO2, and water availability. The effect of these abiotic factors on AFB1 production varied by strain. For AB3, the acclimatized strain produced more AFB1 than the original at 37°C, 1000 ppm CO2, and 0.98 aw. For AB10, AFB1 production increased at 0.93 aw after 5 and 10 days at 37°C and 1000 ppm CO2.Storage conditions of ≥0.90 aw, especially at temperatures ≥25-30 °C, significantly increase the risk of AFB1 contamination to levels that could lead to product rejection, even after just 10-20 days of storage. This underscores the need for optimal storage conditions to minimize aflatoxin contamination in chillies (Al-Jaza et al.,2022). Aflatoxin-producing moulds can grow in a pH range of 1.7 to 9.3, with an optimal range of 3 to 7 (Yoshinari et al. 2010). Lower pH levels (1 to 3) reduce fungal growth, while a slightly higher pH (3 to 6) promotes both fungal growth and aflatoxin production (Eshelli et al. 2015). An initial pH of 5 enhances AFB production, while a pH of 7 favours AFG production. The media composition also affects the pH (Dalié et al. 2010).

- h.

Nutritional factors

Aflatoxin production is significantly influenced by the substrate and various nutritional factors, including carbon, amino acids, nitrogen, lipids, and trace elements. Carbohydrate-rich substrates enhance aflatoxin production more than oil-rich substrates because carbohydrates readily supply the carbon necessary for optimal fungal growth (Ma et al.,2014). According to Liu et al. (2016), glucose, ribose, sucrose, xylose, and glycerol are effective substrates for aflatoxin production. In contrast, peptone, lactose, and sorbose do not promote aflatoxin production. Most previous research has focused on controlling AFB1 production in crops, with few studies examining the factors responsible for different levels of AFB1 contamination in various grains. While some studies have suggested a connection between lipids and AFB1 production in crops, the complex composition of grains means that AFB1 production is also influenced by other nutrients, including starch, proteins, saccharides, and trace elements (Liu et al.,2016). Nitrogen, when provided as nitrite and nitrate, significantly enhances aflatoxin production by A. flavus through various mechanisms (Wang et al.,2017). Lipids play a significant role in the production of aflatoxins. The biosynthesis of aflatoxins in toxigenic fungi is initiated by lipophilic epoxy fatty acids and fungal growth, as well as aflatoxin production, is triggered by ergosterol oxidation (Reverberi et al., 2014). Consequently, lipids serve both as a substrate for obtaining an acyl-CoA starter and as a signalling molecule. Aflatoxin production and accumulation are higher in full-fat substrates compared to low-fat ones. Adding corn oil to defatted wheat infected with A. flavus promotes more aflatoxin production than in media without corn oil (Liu et al., 2016). Vitamins, amino acids, and metal ions collectively enhance aflatoxin production. Amino acids such as glycine, glutamate, and alanine, along with bivalent metals like zinc and magnesium, are known to promote aflatoxin production (Bolu et al., 2014). Liu et al. (2016, 2016a) worked on maize and other grains and reported aflatoxin production increased by 4, 5, and 19 times with zinc concentrations of 20, 50, and 100 mg/L, respectively (Liu et al., 2016). Amino acids like tyrosine promote aflatoxin production, whereas tryptophan inhibits it (Chang et al., 2015). AFB1 production is supported by arginine, glycine, glutamic acid, and aspartic acid at a concentration of 0.5%.

- i.

Biological factors

Biological factors such as fungal species, weeds, and insect damage affect aflatoxin production. Weeds compete with crops and cause stress, increasing aflatoxin levels. The amount of aflatoxin produced depends largely on the fungal species involved. Insect wounds create stress and entry points for aflatoxigenic fungi, leading to contamination (Kinyungu et al., 2019). Aflatoxin production varies by strain, with A. flavus producing fewer aflatoxins than A. parasiticus (Manjunatha et al., 2018). Despite various factors, A. flavus is the primary species responsible for aflatoxin contamination due to its abundance in soil and its ability to thrive on diverse organic substrates such as compost, plant debris, cotton, dead insects, stored grains, field crops, animal corpses, and fodder (Kakde, 2012). Pre-harvest contamination of crops is common due to presence of A. flavus in soil, while post-harvest contamination occurs during storage as it spoils food grains. A. flavus lacks host specificity, contaminating both monocot and dicot seeds (St. Leger et al. 2000).

- j.

Agricultural practices

Conventional methods are ineffective in preventing mycotoxin formation during the pre-harvest stages of crop production; however, several non-conventional techniques and good agricultural practices have demonstrated efficacy. These pre-harvest strategies encompass crop rotation, intercropping, residue management, optimal sowing times, early harvesting, and the judicious use of fertilizers, insecticides, and herbicides. By disrupting the infectious cycle, crop rotation and intercropping significantly reduce mycotoxin contamination. Therefore, identifying appropriate crop combinations is essential for effective mycotoxin management. For instance, rotating legume crops such as cowpea and soybean with maize can disrupt pest and disease cycles and enhance soil fertility (Logrieco et al., 2021; Abbas et al., 2012). Mutiga et al. (2014) observed that intercropping cowpea, beans, and maize lowers aflatoxin levels in maize compared to growing maize as a sole crop, owing to enhanced soil nitrogen content. Moreover, residues or debris from prior harvests can carry fungal spores that remain dormant in the soil between crop cycles. Therefore, effective management of residues from previous harvests, either by removal or burial, can significantly reduce fungal infections in the field (Blandino et al., 2008). Additionally, adjusting sowing times or selecting cultivars suited to lower temperatures and reduced water stress can help mitigate mycotoxin contamination. This strategy also helps to avoid wet periods during early flowering. Early harvesting is also strongly recommended in high-risk areas as it reduces the time fungal pathogens have to develop and produce aflatoxins (Dövényi-Nagy et al., 2020; Mondaet al., 2020).

5. Aflatoxin: Impact on Human and Animal Health

Effects on Human Health

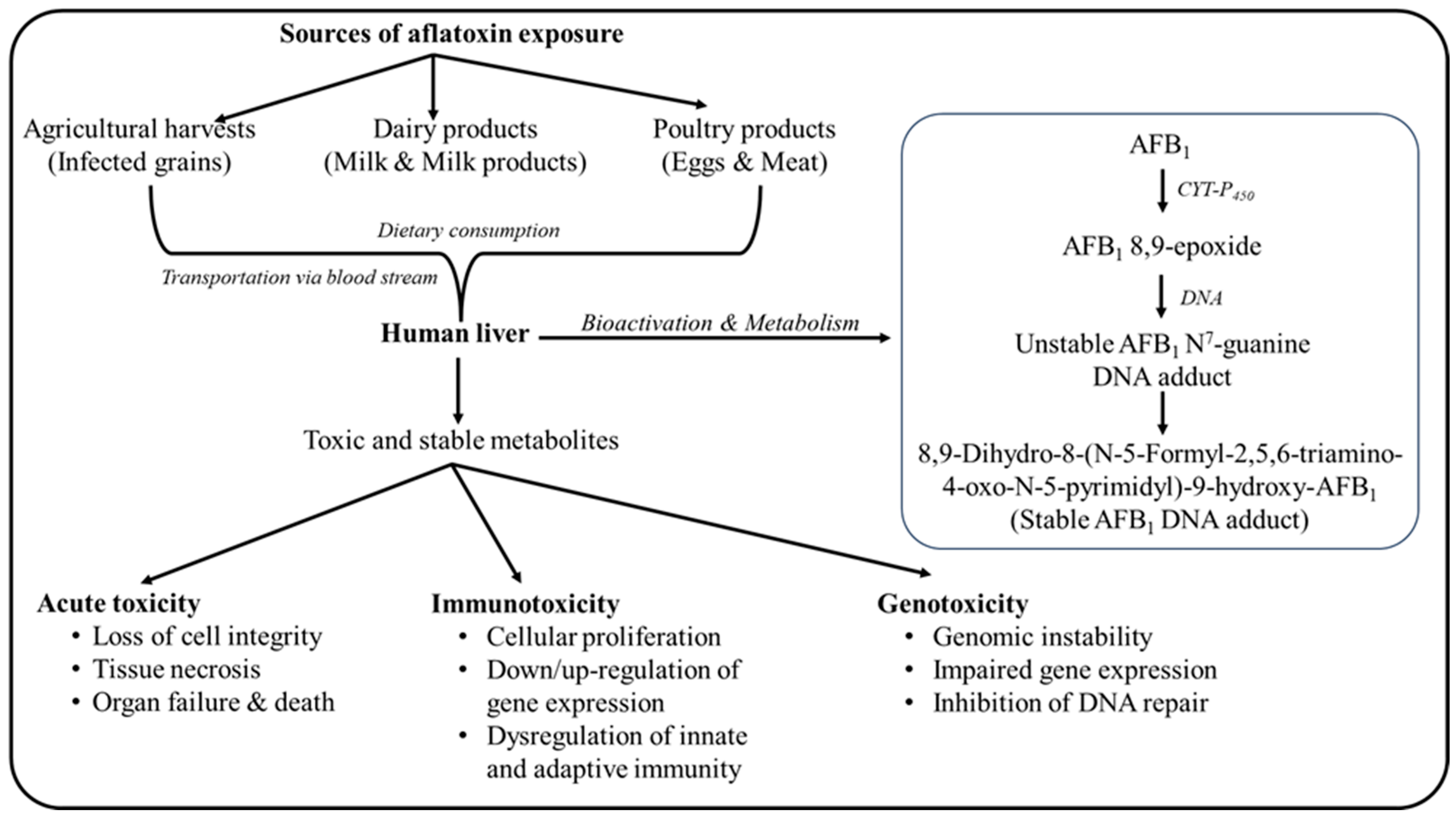

The major source of aflatoxin exposure in the human body is through ingestion of aflatoxin-contaminated food products such as meat, eggs, milk, milk products contaminated grains etc. (Tchana et al., 2010). Agricultural harvests including cotton seeds, coffee and spices along with major food crops such as rice and wheat are the major sources of aflatoxin contamination in the human body (Refai, 1988). These crops can be infected prior to harvesting or post-harvesting during storage. Warm and humid environments in the storage area result in enhanced concentrations of aflatoxins in food grains (Awuchi et al., 2020; Jajic et al., 2018).

Post consumption human body particularly the liver metabolizes the aflatoxin present in bloodstream manifolds. Cytochrome P-450 enzyme present in the human liver bioactivates the aflatoxin and metabolizes into its toxic, unstable and reactive epoxides, responsible for its toxicity principle (Usha

et al., 2017). Post activation and metabolism the resulting aflatoxin epoxides form adduct with the DNA, RNA and proteins resulting in its inhibition leading to acute toxicity, genotoxicity and immunotoxicity (Smith

et al., 2018; Smela et al., 2001; Gouas et al., 2009). The generalized toxicity mechanism of aflatoxin in the human body has been depicted in

Figure 1. Often high exposure of aflatoxin in human body leads to acute aflatoxicosis which ultimately leads to liver cirrhosis or liver cancer. Frequent and chronic exposure leads to increased concentrations of its epoxide moieties resulting in DNA intercalation causing p53 gene mutation, a vital enzyme responsible for cell cycle progression. Such metabolism often leads to signalling apoptosis resulting in programmed cell death (Bedard and Massey, 2006). Although dietary consumption of aflatoxin-contaminated foods results in severe liver cancer but other organs such as the pancreas, bladder, gastrointestinal tract and kidney have also been reported to develop such tumours upon prolonged exposure (Fouad

et al., 2019; Williams

et al., 2004). In fact, there are several reports claiming symptoms of teratogenicity, immunosuppression, cytotoxicity and mutagenicity in humans due to chronic exposure to aflatoxin. The mechanism behind every form of aflatoxin toxicity in human body lies in the chemistry of aflatoxin metabolites. Covalent bonding of aflatoxin epoxide to DNA leads to alkylation at N

7 of guanine residues to form 8,9-dihydro-8-(N7-guanyl)- 9-hydroxy-AFB1 (a stereoselective alkylated aflatoxin adduct (Perri et al., 2016; Coskun et al., 2019). The adduct developed is highly unstable and during stabilization releases itself leaving behind an apurinic DNA molecule. Further imidazole ring opening of the toxic metabolite in the alkaline medium of liver cells results in the development of AFB1-formamidopyrimidine in the body responsible for every proliferation mechanism in any cell of the human body (Chawanthayatham et al., 2017; Croy and Wogan, 1981).

Table 2 enlists the toxic metabolites and symptoms of aflatoxin toxicity in the human body.

Effects on Animal Health

Animals are fed with crops that are usually unfit for human consumption due to the presence of some insects, moulds or rotten feeds etc. The feed that is usually served to animals in developing nations are cotton seeds, groundnuts, maize and copra. Such crop leftovers or feeds are a major source of aflatoxin contamination in animals (FAO, 2008). There are several reports which establish the fact that most of the feed materials meant for animals are usually contaminated with high concentrations of aflatoxin, even more than 52% of the feed materials used in Europe, the Mediterranean region and African nations were reported to be contaminated with aflatoxin (Binder et al., 2007; Rodrigues and Naehrer, 2012). Such contaminations have been reported to possess several health implications for animal health. Susceptibility doses of aflatoxin have been reported to vary as per the difference in animal body weight. Rabbits, ducks, and cats have been reported to be highly susceptible to aflatoxin exposure having LC50 values as low as less than 1 mg/kg body weight while some animals such are dogs, horses, pigs and sheep are moderately susceptible with relatively high concentrations of aflatoxin such as 1-2 mg/kg body weight (Grace, 2013; Hamilton, 1986).

Many experimental studies suggest possible health implications in poultry animals. Some report suggests broiler chicken to be more susceptible than that of layer chicken. Chicken health has been reported to be severely deteriorated upon aflatoxin exposure up to 1000 ppb. Several symptoms have been diagnosed post-aflatoxin exposure such as reduced egg weight, frequency of egg laying, egg shell thinning, yolk weight and color etc. Sometimes impaired immune responses have been diagnosed upon heavy exposure to aflatoxin through contaminated feed with more than 200 ppb concentration (Dersjant-Li et al., 2003; Gabal and Azzam, 1998; Otim et al., 2005). Sheep and goats, moderately susceptible animals have been reported to show symptoms like decreased body weight, liver and nasal tumours and often mortality upon exposure at concentration levels up to 1750 ppb for a period of up to 3.5 years (Lewis et al., 1967; Ewuola et al., 2013). Susceptibility towards aflatoxin in fishes varies from species to species. In the majority of the cases, most usual symptoms involve weight loss, anorexia, liver malfunction, hepatic injury etc. Susceptible species like rainbow trout develop such symptoms at a very low concentration of 0.4 ppb while most resistant fish species like catfish are deprived of such symptoms at very high concentrations of 10,000 ppb. Chances of liver damage and tumour development are most common in the case of susceptible ones while mere weight reduction was observed in the case of resistant species (Jantrarotai and Lovell, 1990; Tuan et al., 2002).

Overall Impact of Aflatoxin on Human and Animal Health

Aspergillus flavus and Aspergillus parasiticus can contaminate crops like maize, peanuts, cottonseed and various spices. The toxins produced are strong carcinogens that endanger both human as well as animal health (Shabeer et al., 2022). Aspergillosis is a fungal infection caused by the genus Aspergillus, namely A. fumigatus, A. flavus, and A. niger (Garbino, 2004). Aspergillosis is one of the top four diseases that lead to death in immune-compromised persons worldwide (Winters et al., 2012). This illness frequently affects the respiratory system, particularly in people with impaired immune systems or underlying lung disorders such as asthma or cystic fibrosis. Aspergillosis affects rabbits, chickens, turkeys, and geese also. In addition, A. flavus produces stone brood sickness in honeybees (Shabeer et al., 2022). Inhaling Aspergillus spores can cause a wide range of clinical symptoms, from moderate allergic reactions to severe invasive illness. The second leading cause of infection is the spread of spores through infected wounds and the smoking of contaminated tobacco or marijuana plants. Aspergillosis manifests clinically in a variety of ways, including extrinsic asthma, allergic bronchopulmonary aspergillosis, extrinsic allergic alveolitis, saprophytic pulmonary and extra-pulmonary colonization (Amaike and Keller, 2011). Allergic bronchopulmonary aspergillosis (ABPA) and allergic fungal sinusitis (AFS) are two of the less severe Aspergillosis, affecting 1- 15% of the world's population and characterized by respiratory symptoms such as coughing, wheezing and nasal congestion. In contrast, invasive aspergillosis is a serious hazard to immunocompromised people, causing pneumonia with symptoms such as fever, chest pain, and difficulty breathing, and it can spread to other organs if not treated.

Aflatoxicosis is another serious health condition resulting from the ingestion of the toxic metabolites produced by

Aspergillus flavus and

Aspergillus parasiticus. The occurrence of various Aflatoxins is common in wide varieties of food and feed (

Table 3). Aflatoxicoses can manifest in both acute and chronic forms, with symptoms ranging from mild gastrointestinal disturbances to severe liver damage and even death. A few studies suggest that 1000 µg/kg of aflatoxin in food can cause toxicity in humans (WHO, 2018), while the acceptable level for animals is 50-300 µg/kg (Grace et al., 2015). Acute aflatoxicosis typically occurs after consuming high levels of aflatoxin-contaminated food, leading to symptoms such as nausea, vomiting, abdominal pain, and liver failure. Chronic exposure to lower levels of aflatoxins can result in long-term health effects, including an increased risk of liver cancer, immune system suppression, growth impairment, and developmental delays (Dhanasekaran et al., 2011). Prevention strategies focus on minimizing aflatoxin contamination in food and feed through proper storage, handling, and agricultural practices, alongside regulatory measures and routine monitoring to ensure food safety and protect public health.

6. Detection of Aflatoxin

Aflatoxin contamination is the primary problem with food safety in both developed and developing countries. Accurate and effective detection is essential to reducing the risk of mycotoxin contamination in food and feed before it affects human and animal health. Although the discovery of aflatoxins dates back to the early 1960s (Pickova et al., 2021), concomitant technological advancements increased the efficiency and precision of aflatoxin detection. While culture-based approaches were employed in the past, many developing nations now frequently employ assays based on high-performance liquid chromatography (HPLC) and enzyme-linked immunosorbent assay (ELISA). A range of technologies have been developed to date for the detection of aflatoxins, such as fluorescence spectroscopy (FS) (Bertania et al. 2020; Wu and Xu 2020), immunology-based enzyme-linked immunosorbent assay (Nardo et al., 2020), lateral flow immunoassay (Di Nardo et al., 2019), etc. These technologies can be grouped into different forms of aflatoxin detection strategies.

- k.

Culture-based techniques

Traditionally, different culture-dependent techniques have been used to detect aflatoxins in foods and feeds. This approach includes (1) fluorescence test and (2) ammonium hydroxide vapour test to detect aflatoxigenic isolates of Aspergillus spp. In the fluorescence test, the detection of blue fluorescence of aflatoxin B1 is done under UV light (365 nm) particularly when the culture medium is supplemented with β-cyclodextrin (Ordaz, 2003). The presence of a blue fluorescent zone around the growing fungal colony visualized on the reverse side indicates the aflatoxin-producing ability of the fungal isolates. Further, yellow pigment (anthraquinones) production on the reverse side of colonies is used for the rapid identification of aflatoxigenic strains of A. flavus, as the yellow pigment was associated with the aflatoxin biosynthetic pathway (Shier et al., 2005). The ammonium hydroxide vapour test can also be employed to detect the aflatoxin-producing ability of A. flavus isolates based on the intensity of colour changing from yellow to red (Saito and Machida, 1999). These culture-based processes can be easily performed as these are visualization-based detection approaches, but very labour-intensive, time-consuming, and less accurate; sometimes yield false-positive or false-negative results.

- l.

Molecular techniques

Different molecular approaches, viz., Polymerase chain reaction (PCR), loop-mediated isothermal amplification (LAMP), and other DNA-based techniques can be used to detect genes involved in aflatoxin production in mould samples. These methods can provide rapid screening for aflatoxin-producing moulds in food and feed samples. For the conventional PCR and multiplex PCR-based detection, different housekeeping genes coding for ribosomal RNA and or genes, viz., aflM, aflP, aflR, and aflOinvolved in the aflatoxins biosynthesis (Adetunji et al., 2019) can be amplified to detect the contamination of Aspergillus flavus in food grains (Reddy et al., 2009; Mangal et al., 2016); whereas for the quantitative estimation using real-time PCR (qPCR) the Aspergillus norsolorinic acid reductase gene (NOR1) can be selected (Sardiñas et al., 2011; Kumsiri and Kanchanaphum, 2020). Similarly, LAMP-based strategy was developed to amplify the Norsolorinic Acid gene (nor1) to distinguish aflatoxigenic and non-aflatoxigenic fungal strains in rice grain (Douksouna et al., 2020). Further, a nor1 gene-specific single LAMP assay was developed for rapid and sensitive detection of several aflatoxin-producing species within Aspergillus section Flavi in food raw materials, spices, and dried fruit (Niessen et al., 2018). For the rapid evaluation of mycotoxin synthesis by fungi, PCR-based methods are generally used because of their simplicity, speed, cost-effectiveness, and reliability.

- m.

Chromatography and spectroscopy

Spectrophotometry and chromatography are two efficient techniques that are widely used for aflatoxin detection in food and agricultural items because of their sensitivity and accuracy. Chromatography uses features like size, charge, and polarity to distinguish aflatoxin molecules from other chemicals in a sample (Abbas, 2022), while spectroscopy uses electromagnetic spectra to identify individual atoms and molecules (Dadi and Yasir, 2022).

Chromatography techniques

Thin-Layer Chromatography (TLC): A chromatographic technique called TLC can be used to identify, isolate, and assess the purity of aflatoxin (Wacoo et al., 2014). The components are then separated based on how effectively they bind to the stationary phase after the sample is spotted onto a thin film of adsorbent material. Mycotoxins were easily separated by TLC using a range of solvents (Odhav and Naicker, 2002), such as acetic acid, acetone, acetonitrile, chloroform, ether peroxide free, ethyl alcohol, hexane, isopropanol, toluene, etc.

High-Performance Liquid Chromatography(HPLC): Aflatoxin can be precisely quantified using HPLC, a technology that is frequently used (Yazdanpanah et al., 2013). In HPLC methods, you can alter the elution mixes and gradients, detectors, and column types (normal or reverse phase, different packing, particle size, etc.) (Kizis et al., 2021). Most HPLC processes use an acidic mobile phase, such as C18 columns, acetonitrile, methanol, water, or mixtures of these that have been acidified with phosphoric or acetic acid, and are performed in reversed-phase (Afsah-Hejri et al., 2011). When components of a sample are arranged based on their affinities for a stationary phase and a mobile phase, aflatoxin separation takes place.

Gas Chromatography (GC): GC distinguishes volatile compounds because their retention times vary. Mycotoxin detection in food products can also be achieved through mycotoxin conversion into volatile compounds. GC is not frequently employed for mycotoxin analysis since most mycotoxin components are extremely polar and non-volatile. Detectors for electron capture (ECD), flame ionization (FID), or mass spectrometry (MS) are frequently used with gas chromatography (GC) to identify volatile mycotoxins, including patulin and trichothecenes (Yang et al., 2020). Aflatoxin analysis can also be done using GC-MS, or gas chromatography coupled with mass spectrometry (Janik et al., 2021) and MS locates and categorizes the chemicals based on their mass-to-charge ratios.

Spectroscopy Techniques

Spectroscopy is a useful tool for studying the interaction between matter and electromagnetic radiation. Its basic concepts are derived from the properties of matter and light. Spectroscopy studies a wide range of electromagnetic spectrum wavelengths, from radio waves to gamma rays. Different parts of this spectrum are the focus of different spectroscopic techniques. When matter interacts with electromagnetic radiation, it can either emit or absorb photons. Absorption spectroscopy measures the light that a sample absorbs, as opposed to emission spectroscopy, which measures the light that a material emits. This technique quantifies aflatoxins, which are toxic metabolites produced by certain moulds, primarily A. flavus and A. parasiticus.

Mass spectrometry: Mass spectrometry (MS) techniques, offer high sensitivity and selectivity for aflatoxin detection. These methods can identify and quantify aflatoxins in complex samples with high accuracy (Ahuja et al., 2023). The process typically involves several steps:

(1) Sample preparation through solvent extraction, solid-phase extraction (SPE), and QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) can be used depending on the sample type and the desired sensitivity.

(2) Chromatographic separation of aflatoxins from other components present in the sample using High-performance liquid chromatography (HPLC), ultra-high-performance liquid chromatography (UHPLC) or liquid chromatography-mass spectrometry (LC-MS).

(3) Ionization of aflatoxins to generate charged species via electrospray ionization (ESI) and atmospheric pressure chemical ionization (APCI).

(4) Mass analysis of the ionized aflatoxin molecules in the mass spectrometer, where they are separated based on their mass-to-charge ratio (m/z). The mass spectrometer detects these ions and generates mass spectra, which provide information about the molecular weight and fragmentation pattern of the aflatoxins.

(5) Analysis of acquired mass spectra using specialized software to compare the observed mass spectra with reference spectra of known aflatoxin standards and identify and quantify the aflatoxins present in the sample.

Mass spectrometry offers several advantages for aflatoxin detection, including high sensitivity, selectivity, and the ability to analyze multiple aflatoxin types simultaneously (Liu et al., 2024). Additionally, mass spectrometry can be coupled with various chromatographic techniques to enhance separation and detection capabilities, making it a versatile tool for food safety testing and regulatory compliance.

Nuclear magnetic resonance (NMR) spectroscopy: Nuclear Magnetic Resonance (NMR) spectroscopy is another analytical technique used in the detection and characterization of aflatoxins, complementing mass spectrometry approaches (Kluczkovski et al., 2022). While mass spectrometry relies on the mass-to-charge ratio of ions, NMR spectroscopy exploits the magnetic properties of certain atomic nuclei, such as hydrogen (^1H) and carbon-13 (^13C), to provide information about the molecular structure of compounds. NMR spectroscopy can be used to detect aflatoxins based on their characteristic chemical shifts in the NMR spectrum. This method provides structural information about aflatoxin molecules, aiding in their identification. In aflatoxin analysis, NMR spectroscopy can be employed in several ways:

Structural Identification: NMR spectroscopy can provide detailed structural information about aflatoxins, including the connectivity of atoms within the molecule, the types of functional groups present, and the configuration of stereocenters (Xu et al., 2023). By comparing the NMR spectra of unknown samples with reference spectra of known aflatoxins, analysts can confirm the presence of aflatoxins and determine their chemical structure.

Metabolite Profiling: NMR spectroscopy is valuable for studying the metabolic fate of aflatoxins in biological systems. By analyzing the NMR spectra of biological samples, researchers can identify and quantify aflatoxin metabolites formed during detoxification or biotransformation processes in organisms (Ogunade et al., 2018).

Quality Control: NMR spectroscopy can be used for quality control purposes in food safety testing and regulatory compliance. By establishing NMR-based methods for aflatoxin analysis, laboratories can ensure the accuracy, reliability, and reproducibility of their analytical results (Sobolev et al., 2022).

NMR spectroscopy offers several advantages for aflatoxin analysis, including non-destructive analysis, high structural specificity, and the ability to analyze complex mixtures without the need for extensive sample preparation. However, NMR spectroscopy generally has lower sensitivity compared to mass spectrometry, which may limit its utility for trace-level detection of aflatoxins in highly contaminated samples. Nonetheless, when combined with other analytical techniques, such as mass spectrometry and chromatography, NMR spectroscopy can provide comprehensive information about aflatoxin contamination in food and feed samples.

Fluorescence Spectroscopy: Aflatoxins exhibit natural fluorescence under certain conditions. Fluorescence spectroscopy can exploit this property for detection. Aflatoxins can be excited by a specific wavelength of light, and the emitted fluorescence can be measured to quantify their presence (Bartolić et al., 2022).

The process typically involves several steps:

1. Sample preparation for the extraction of aflatoxins from the sample matrix and purifying the extract to remove any interfering substances that could affect the fluorescence signal.

2. Excitation of aflatoxin at the specific wavelength of light to excite the molecules in the sample and to move to higher energy states.

3. Emission of light (fluorescence signal) from the aflatoxin at a longer wavelength.

4. Detection of the emitted fluorescence signal and its intensity and wavelength.

5. Quantitative measurement of the concentration of aflatoxins in the sample based on the intensity of the fluorescence signal using calibration curves.

Fluorescence spectroscopy is rapid, highly sensitive and specific, allowing for the detection of aflatoxins even at very low concentrations (Chen et al., 2021). Additionally, it can distinguish between different types of aflatoxins, providing valuable information for food safety and quality control.