1. Introduction

The majority of the existing structures in earthquake prone areas need to be strengthened either because they have been damaged in previous earthquakes or because they have been designed without or with old code provisions. The use of additional Reinforced Concrete (RC) layers or jackets has been proved to be an effective technique and there are various published studies in this field [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18]. These studies highlight the effectiveness of the use of additional RC elements and it has been found that two important parameters which affect the performance of this technique is the connection between the old and the new concrete and the shrinkage of the new concrete of the layer/jacket [

16,

17,

18]. In the last decades there has been an enormous development of novel high performance materials which have a great potential for applications in the field of repair and strengthening of existing structures. More specifically, there are extensive research studies on the development and applications of Ultra High Performance Fibre Reinforced Concrete (UHPFRC). UHPFRC is characterised by significantly enhanced compressive strength which exceeds 150 MPa, a tensile strength normally higher than 7-8 MPa and superior ductility and energy absorbance [

19,

20,

21]. Also, UHPFRC is characterised by significantly enhanced durability and low permeability, which are key factors for the protection of existing structures [

22]. Extensive research has been done in this field and it has been found that the mechanical characteristics of UHPFRC are significantly affected by the volume fraction of steel fibres in addition to the orientation and distribution of the fibres [

23,

24,

25].

UHPFRC has a great potential for the structural upgrade of existing structures, and the majority of the existing studies in this field are focused on the strengthening of RC beams [

26,

27,

28,

29,

30,

31,

32,

33]. It has been proved that UHPFRC can be effectively used for the structural strengthening of existing RC beams. UHPFRC layers reinforced with steel bars can offer superior structural performance. The connection between the UHPFRC and the existing concrete elements is significantly enhanced while the use of dowels can further improve the structural performance of the beams [

28]. UHPFRC has also been found to be quite effective for the prevention of bond failure in case of deficient lap splices in beams and bridge columns [

29]. The application of UHPFRC strips for shear strengthening has also been studied [

33]. The use of UHPFRC has also been successfully applied for the retrofitting of a bridge [

34] and for the strengthening of slabs enhancing the energy absorption and the post-cracking performance of the existing elements [

35].

The use of UHPFRC for the strengthening of existing RC columns is an area where further work is required as there are only very limited published studies [

36,

37,

38]. The axial load bearing capacity of jacketed columns with UHPFRC under eccentric loading has been studied [

36] showing that the stiffness, the strength, and the toughness of the strengthened columns are significantly enhanced. UHPFRC has also been used for the confinement of circular RC columns [

37]. However a systematic study on the effectiveness of the use of UHPFRC jackets (with and without the presence of steel rebars) on the lateral performance of RC columns is missing. This study aims to provide an in-depth evaluation of the lateral performance of columns strengthened with UHPFRC and to critically evaluate parameters such as the thickness of the jackets, the presence of additional steel bars, and the shrinkage strain of the jackets. Comparisons with the technique of conventional RC jackets have also been conducted to evaluate the performance of this strengthening method.

2. Numerical Modelling of Columns Strengthened with RC Jackets

The examined specimens are Reinforced Concrete (RC) columns strengthened with jackets. The geometry of the existing columns has been selected to be in agreement with a previous study [

17] which examined the strengthening of existing columns with conventional RC jackets.

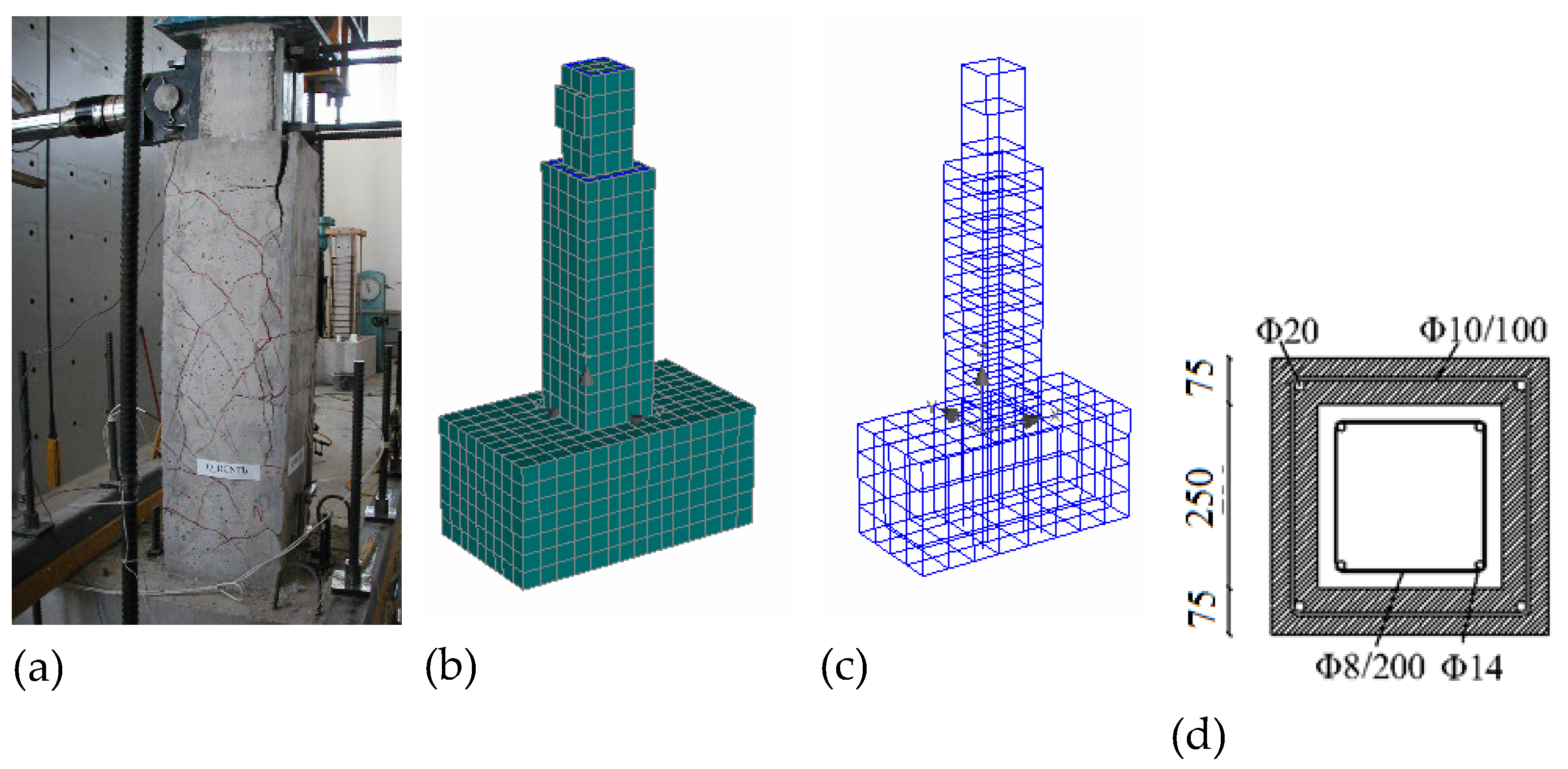

The initial column cross section dimensions were 250x250mm, and the height of the column was equal to 1800mm, representing half of a full-scale column with the appropriate boundary conditions. The initial column was reinforced with 4 longitudinal steel bars with 14 mm diameter and steel grade S220. Stirrups with 8 mm diameter and steel grade S220 were also placed along the heigh of the column at a spacing equal to 200 mm. A four-side RC jacket was used for the strengthening of the existing column with a thickness of 75 mm and a height equal to 1300 mm. RC jacket was reinforced with 4 bars of 20 mm diameter and 8 mm diameter stirrups spaced at 200 mm all of S500 steel grade. Regarding the concrete, the initial column concrete compressive strength (mean value) was found to be equal to 27 MPa while the respective strength of the jacket was 55.8 MPa. [

12,

13,

15,

17].

For the numerical modeling, ATENA FEA software has been used [

39]. Solid eight-node elements have been used for the modeling of concrete. Nonlinear behavior with softening in both tension and compression has been considered. In compression, the CEB-FIP Model Code 1990 [

40] model has been used, while in tension, a linear ascending model followed by an exponential softening branch based on fracture energy model has been adopted [

39].

Figure 1.

(

a) RC jacketed column tested in the lab [

12], (

b,

c) numerical models for the concrete and for the reinforcement, and (

d) cross section of the strengthened column [

17].

Figure 1.

(

a) RC jacketed column tested in the lab [

12], (

b,

c) numerical models for the concrete and for the reinforcement, and (

d) cross section of the strengthened column [

17].

Analysis was initially conducted assuming a perfect connection between the old and the new concrete (Specimen: Monolithic).

For the simulation of the old-to-new concrete interface, special two-dimensional contact elements have been used (Specimen: R

INT.). To consider the strength degradation of the interface due to the cycling loading, a reduction of the friction and cohesion characteristics with the loading cycles has been proposed which has been found to lead to equivalent results with the use of coefficients of friction and cohesion equal to 1.0 and 0.0 MPa and therefore these values have been used in this study [

17].

To consider the effect of jacket’s concrete shrinkage, a strain equal to 400 microstrains has also been applied to the elements of the jacket, value estimated for the age of the jacket using suitable analytical models [

17] (Specimen: R

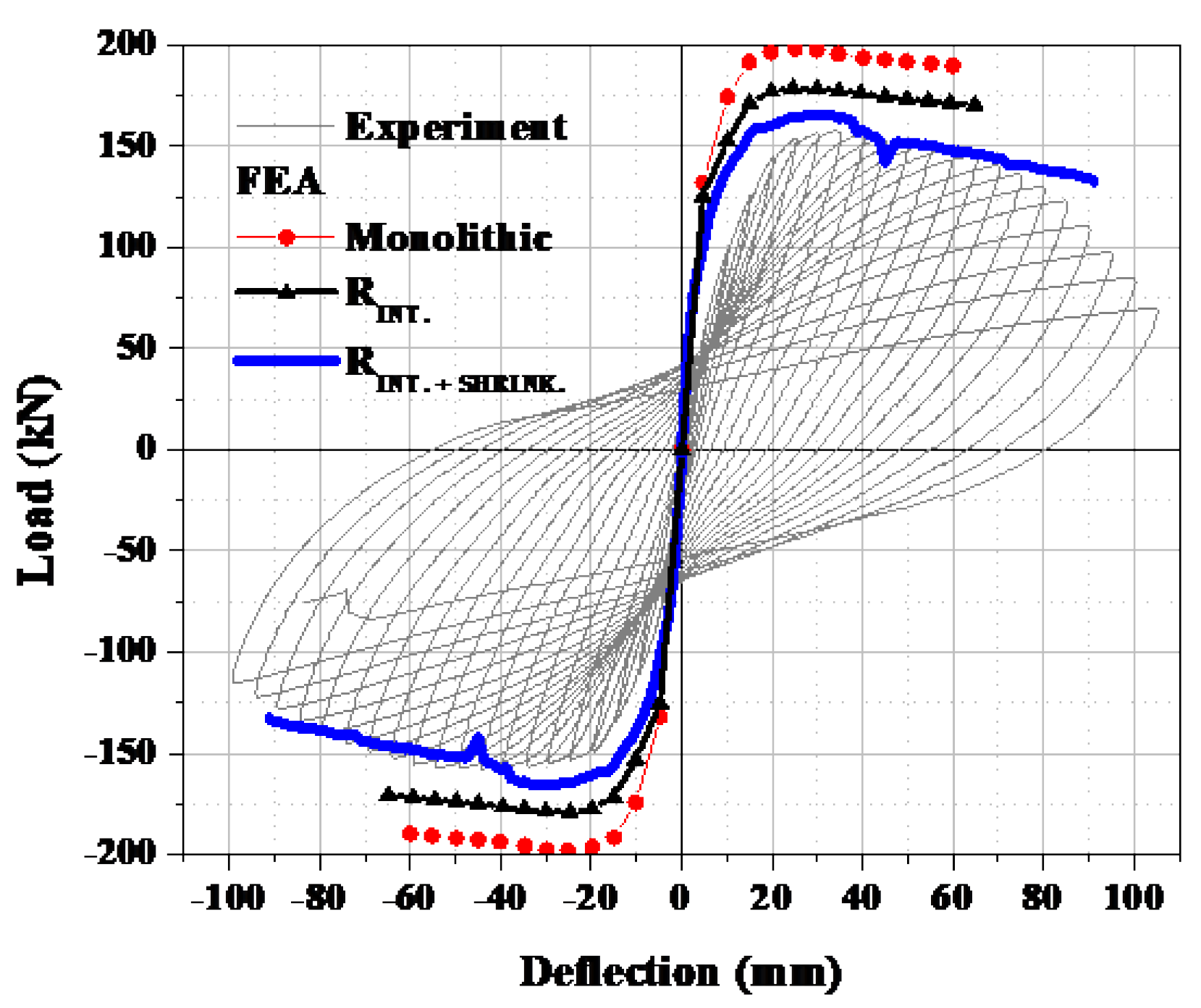

INT. + SHRINK.). The old-to-new concrete interface has been simulated with contact elements with friction and cohesion equal to 1.0 and 0.0 MPa. The numerical results of these three assumptions, together with the respective experimental results are presented in

Figure 2.

The results of

Figure 2 show that the assumption of perfect bond at the interface (Specimen: Monolithic) leads to a significant overestimation of the structural behaviour of the jacketed columns. In the case of specimen R

INT., where the old-new concrete interface is simulated without the presence of jacket’s concrete shrinkage, the load capacity is reduced but there is still an overestimation of the structural performance. The numerical simulations of the strengthened columns with the interface with reduced friction and cohesion (to take into consideration the strength degradation) and with the simulation of jacket’s concrete shrinkage (Specimen: R

INT. + SHRINK.) can accurately predict the response of the strengthened columns with RC jackets. The same assumptions have been used for the numerical simulations of the RC columns strengthened with UHPFRC jackets, and the results are presented in

Section 3.

3. Numerical Modeling Of Columns Strengthened with UHPFRC Jackets

The characteristics of the initial RC columns are the same as the ones presented in

Section 2. For the strengthening of the columns, UHPFRC jackets have been used with and without the presence of additional steel bars. The numerical assumption for the modeling of UHPFRC are presented in

Section 3.1.

3.1. Numerical Modelling of UHPFRC

Compressive and direct tensile test results have been used for the numerical simulation of UHPFRC. A typical UHPFRC mix design has been used in this study (

Table 1 [

22,

27]). Regarding the mixing process, the dry materials were mixed first for 3 minutes, followed by the addition of water and superplasticizer while the steel fibres were added at the end of the process. The specimens were heat cured at 90°C for 3 days and then they were stored at ambient temperature and humidity conditions for 14 days until the testing time.

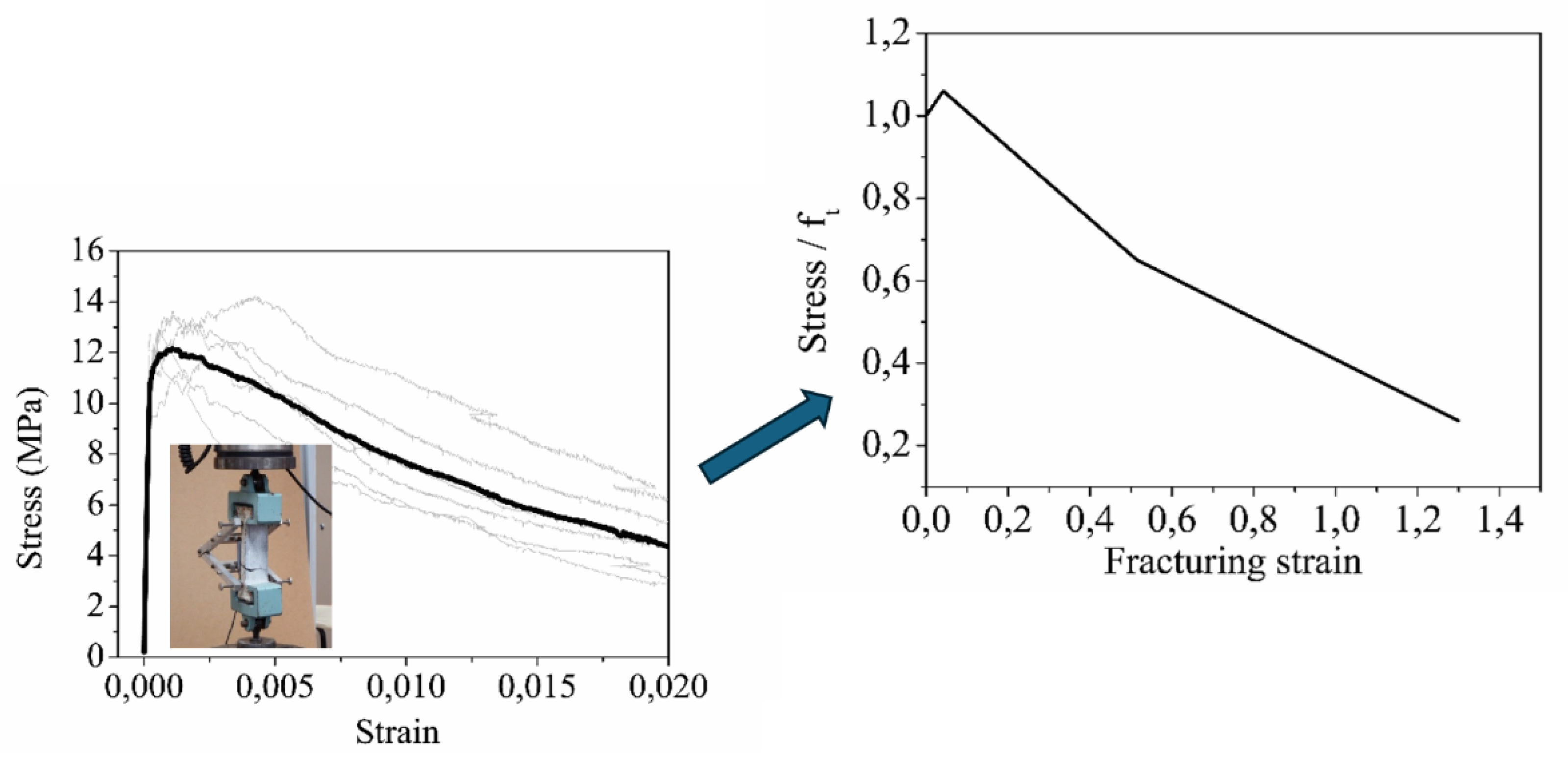

Standard 100mm side cubes were tested to evaluate the mean compressive strength of UHPFRC which was found to be equal to 164 MPa [

27]. Six dog-bone shaped specimens were also tested (

Figure 3) to evaluate UHPFRC tensile stress strain characteristics. UHPFRC is characterized by a significantly enhanced post cracking tensile stresses and superior energy performance which can be accurately captured with direct tensile tests.

These tests were performed under displacement control with a loading rate equal to 0.007 mm/sec, and for the strain measurements, a Linear Variable Differential Transformer (LVDT) was used for the measurement of the extension over a length of 105 mm [

27].

The stress-strain results for all the examined specimens, together with the average are illustrated in

Figure 3. ATENA Finite Element Analysis (FEA) software [

39] has been used for numerical simulations. The characteristics of the UHPFRC were determined from the compressive and tensile test results. The modulus of Elasticity has been taken equal to 57.5 GPa, and a compressive strength value of 164 MPa has been used. The constitutive model in tension has been derived from the direct tensile test results, and it consists of a linear part up to the tensile strength which was calculated to be equal to 11.5 MPa, followed by a tri-linear part as illustrated in

Figure 3. The fracturing strain values have been calculated considering characteristic element size equal to 2mm [

27].

This modeling approach has been thoroughly examined in a previous research study which presented a systematic study on the calibration and validation of the numerical model for the simulation of UHPFRC elements [

27]. The results of the numerical investigation of RC columns strengthened with UHPFRC jackets are presented in section 3.2.

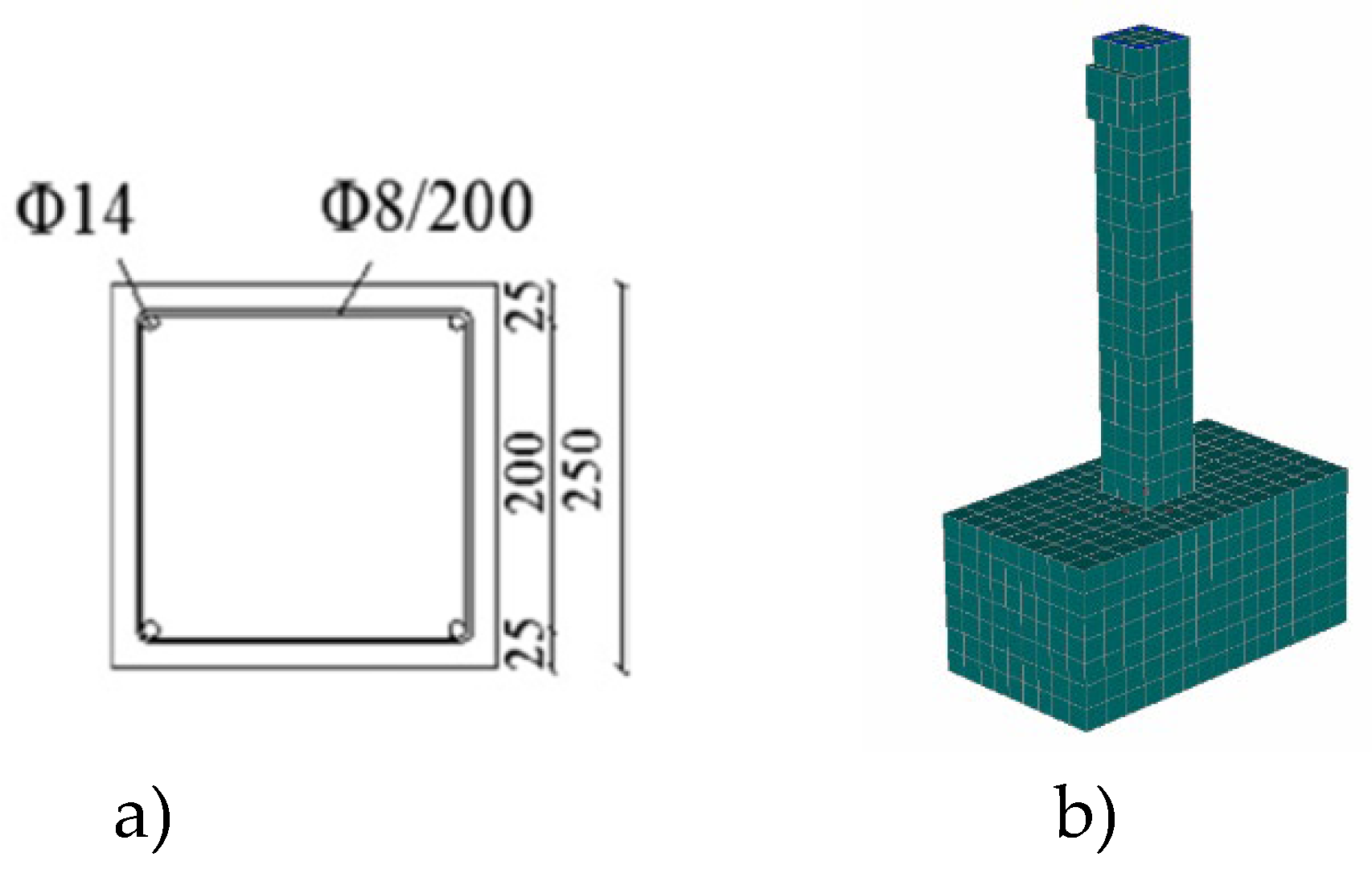

3.2. RC Column Prior to and after Strengthening with UHPFRC Jackets

The initial pre-strengthening RC columns have the same characteristics with the ones described in section 2 and the same modelling assumptions were used.

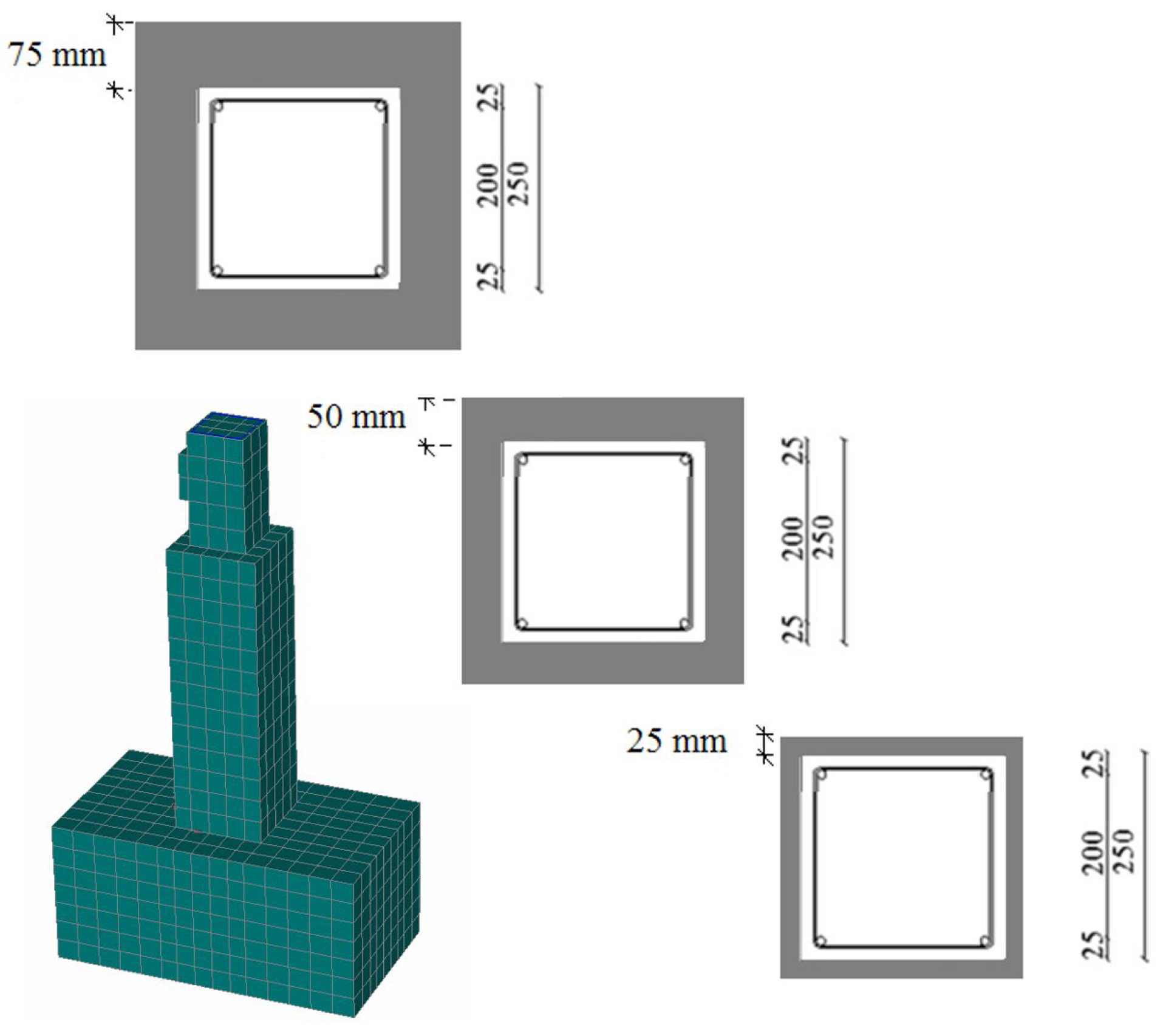

The numerical model and the cross section of the initial column are presented in

Figure 4.

Regarding the modelling of the strengthened RC columns with UHPFRC jackets, the numerical assumptions of section 2 have been used. The old-to-new concrete interface has been simulated with the same approach presented in section 2 (contact elements with coefficients of friction and cohesion equal to 1.0 and 0.0 MPa, respectively).

An extensive parametric study has been conducted to evaluate the effect of jacket’s thickness and shrinkage on the performance of the strengthened columns. The results are presented in the following sections.

3.2.1. Effect of UHPFRC Jacket Thickness

Three different thickness values have been examined; 25mm, 50mm and 75 mm (

Figure 5) [

38]. For the shrinkage of the jacket a value equal to 400 microstrains has been applied, which represents a 800 microstrains free shrinkage value reduced to half to consider concrete creep [

16].

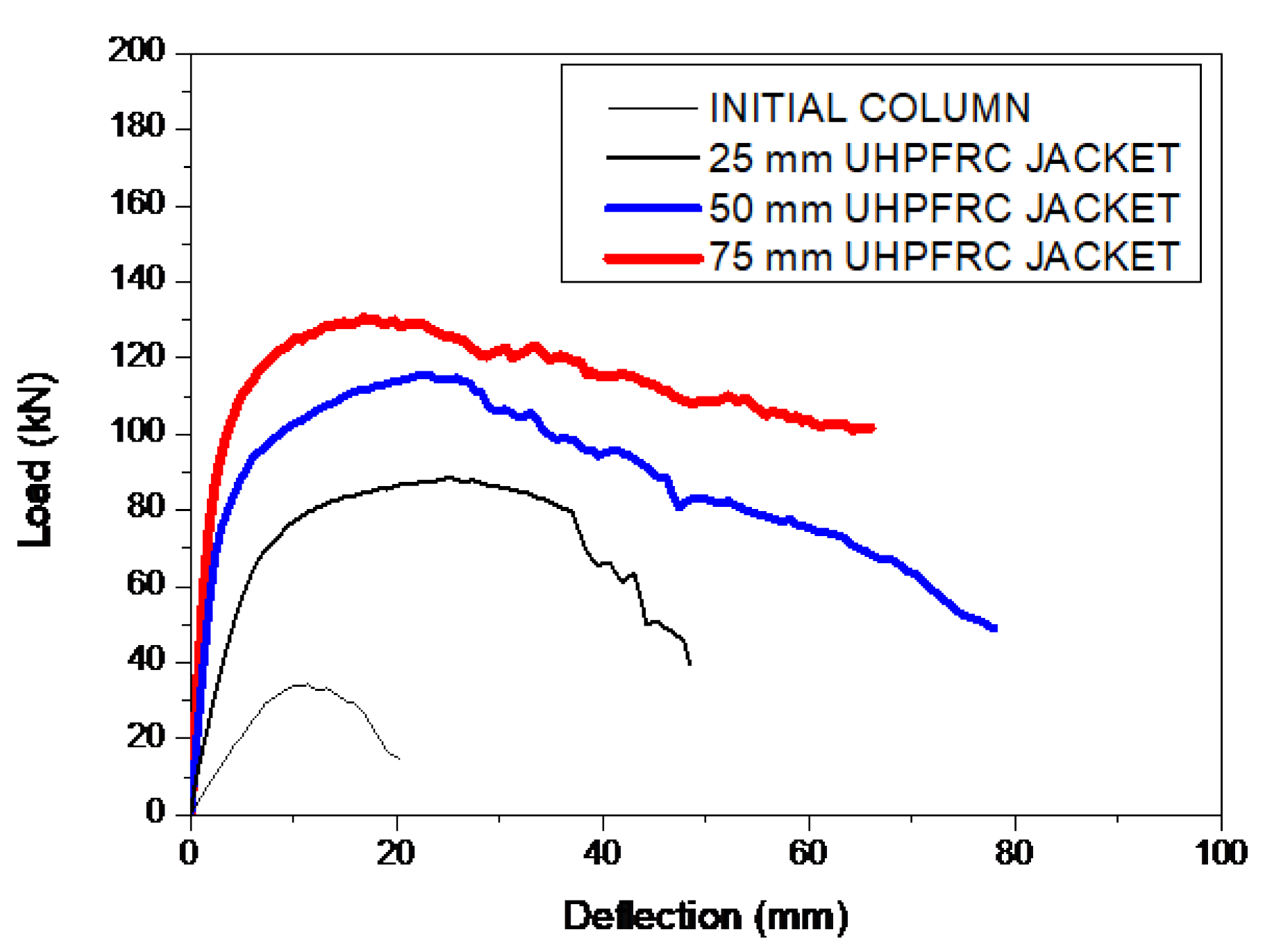

The results of the parametric study for the different values of the thickness of the UHPFRC jacket are illustrated in

Figure 6 [

38].

The results of

Figure 6 show that the thickness of the UHPFRC significantly affects the results, and as the thickness increases, the stiffness and the ultimate load capacity are increased as expected. The increment of the strength with the thickness of the UHPFRC jacket has been quantified using the F

u,S ratio which represents the ratio of the ultimate load of the strengthened columns over the respective results of the initial specimen (i.e.

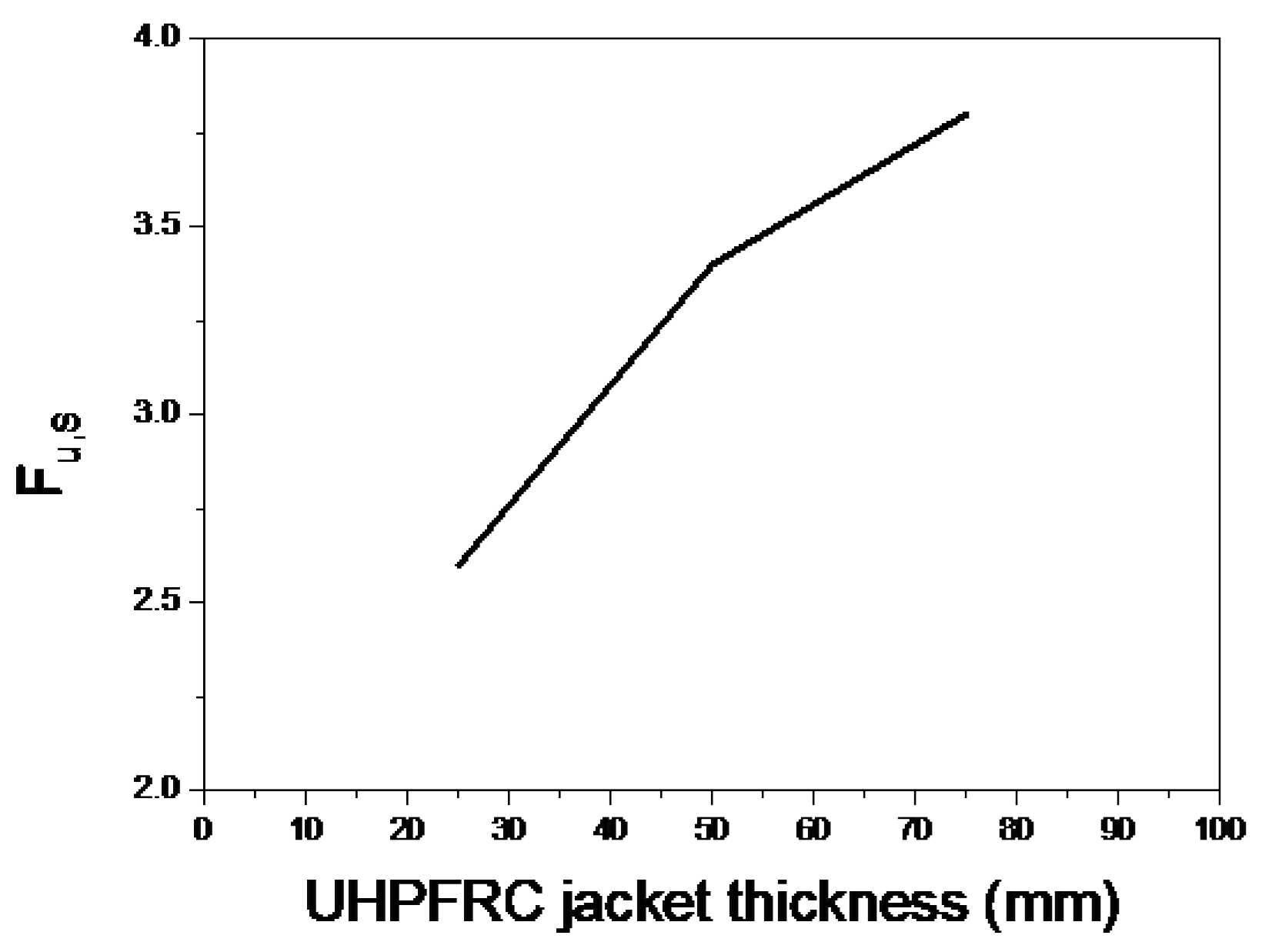

). The results of F

u,S for different values of the thickness of the UHPFRC jacket are presented in

Figure 7 [

38].

The results of

Figure 7 indicate that there is a significant effect of the thickness of the UHPFRC jacket on the strength enhancement of the initial RC column. An increment in the range of 2.6-3.8 times has been observed for UHPFRC thickness of 25mm-75mm.

3.2.2. Effect of the Addition of Steel Reinforcing Bars in UHPFRC Jackets

An additional investigation has been conducted for a 75mm thick UHPFRC jacket where steel bars have been used in addition to the fiber reinforcement. Longitudinal bars and shear links have been used with the same characteristics as the ones used in the conventional RC jacket (

Section 2,

Figure 1c).

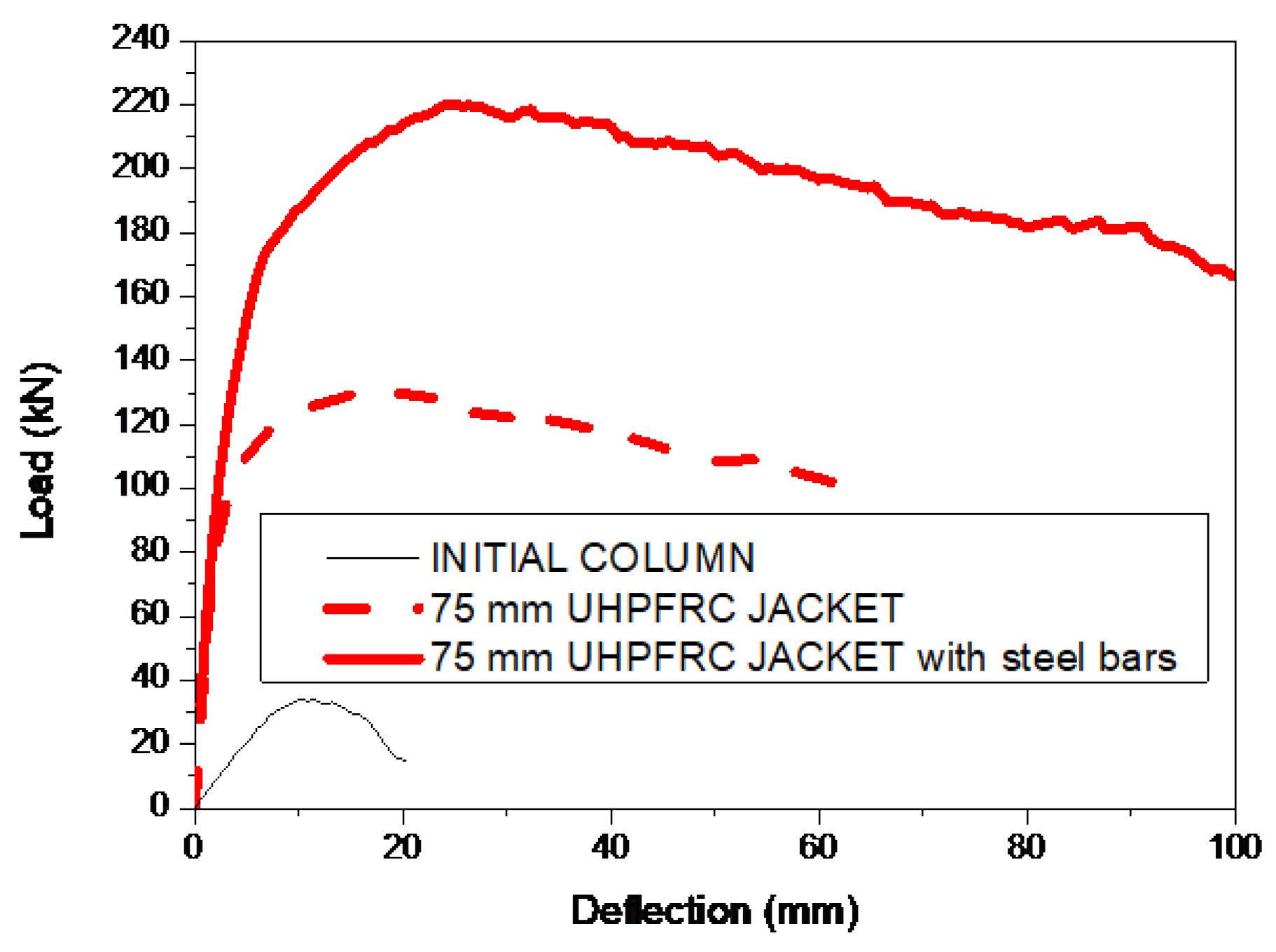

The results of the strengthened column with a 75mm UHPFRC jacket with and without additional steel bars are presented in

Figure 8.

The results of

Figure 8 show that the addition of steel bars reinforcement leads to a significantly higher load capacity. More specifically, the ultimate load of the strengthened column with 75mm UHPFRC jacket is 131 kN, while with the addition of steel bars this load is further increased by 68%, and the ultimate load is equal to 220 kN.

3.2.3. Effect of UHPFRC Jacket Shrinkage

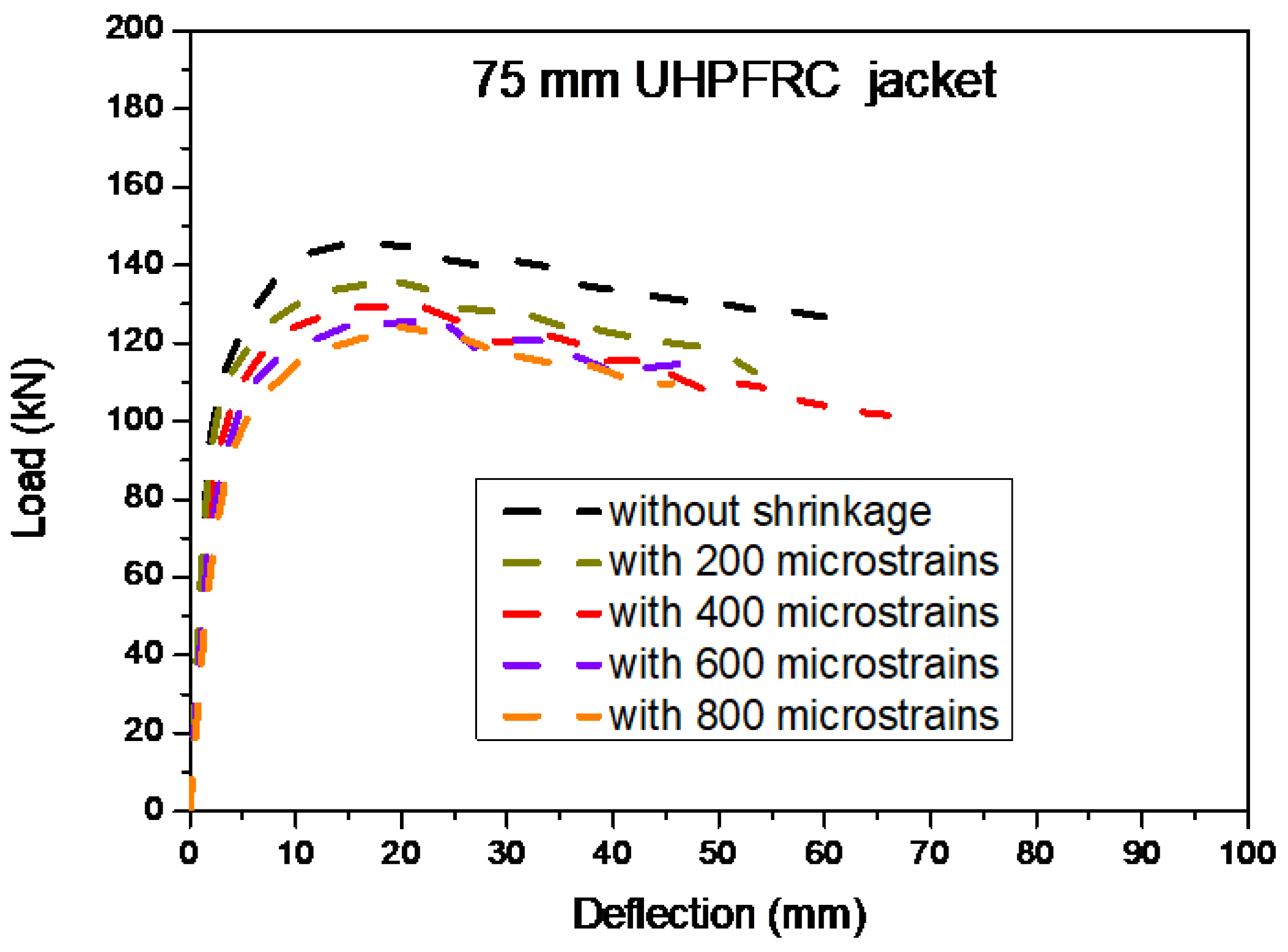

The effect of UHPFRC jackets’ shrinkage is presented in this section. A parametric study has been conducted for 75 mm thick UHPFC jackets with different values of concrete shrinkage. More specifically shrinkage strain values of 200, 400, 600, and 800 microstrains have been applied to the UHPFRC jacket and the numerical analysis results are presented in

Figure 9 [

38].

A parametric study on the variation of the UHPFRC shrinkage strain values has also been conducted for the case of a 75 mm UHPFRC thick jacket with additional steel bars, and the results are presented in

Figure 10.

The results of

Figure 9 and

Figure 10 show that there is a significant detrimental effect of the UHPFRC shrinkage strain on the ultimate load capacity of the strengthened columns. It can be observed that as the shrinkage strain values of the jacket are increased, there is a reduction of the maximum load capacity which is attributed to the induced tensile stresses due to the restrained concrete shrinkage of the jacket. This leads to a biaxial stress state which results in a reduction of the strength of the jacket and subsequent reduction of the ultimate load capacity of the examined elements [

17].

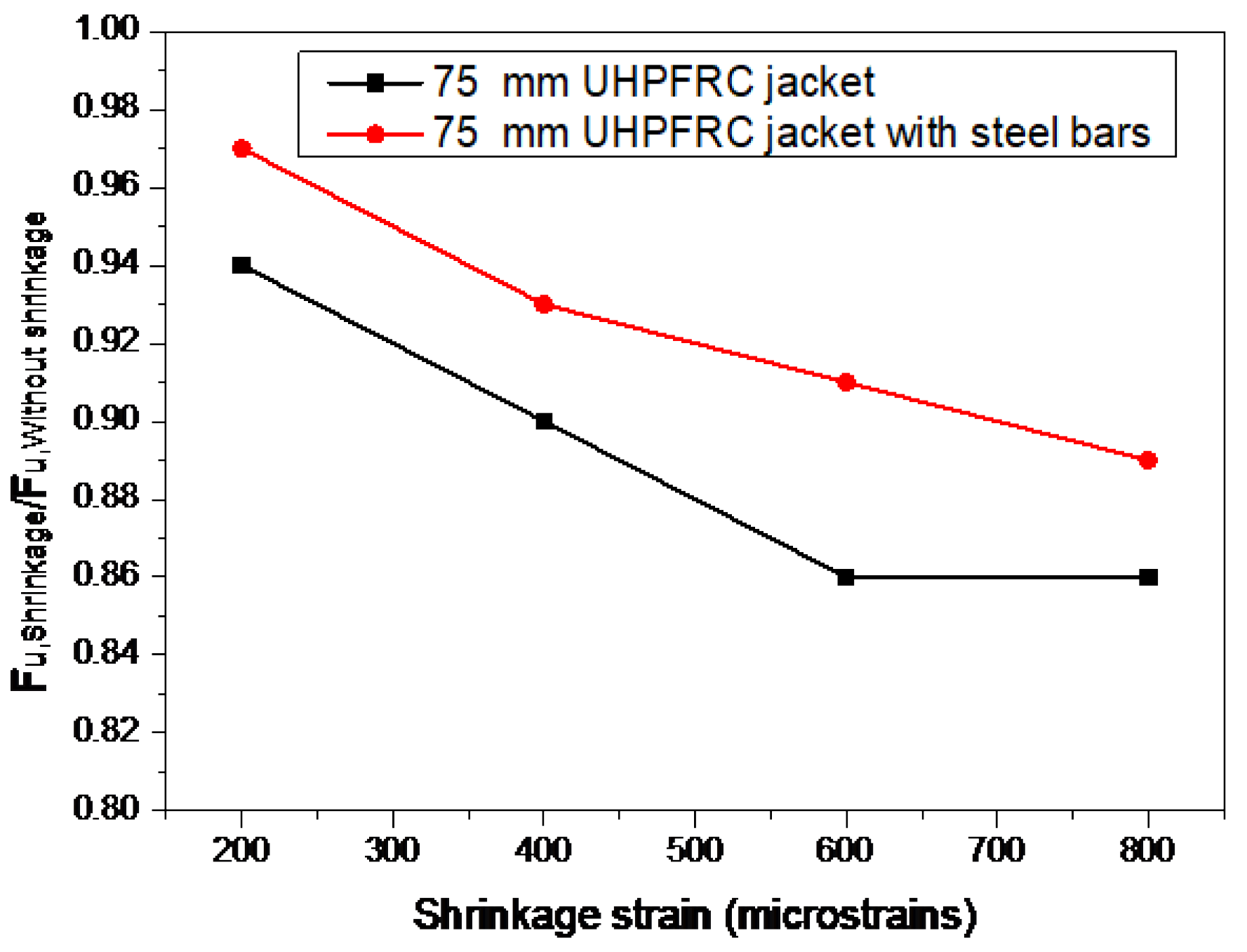

The reduction of the ultimate load capacity has been quantified, and the ratios of the ultimate load with and without shrinkage (F

u, Shrinkage/ F

u, Without shrinkage) have been calculated for both cases of jacket columns with 75mm thick UHPFRC thick jacket with and without the additional steel bars and the results are presented in

Figure 11.

The results of

Figure 11, show that in the case of 75mm thick UHPFRC jacket without steel bars, a reduction of the ultimate load of almost 15% has been observed for shrinkage strain equal to 800 microstrains. The detrimental effect of the concrete shrinkage is limited by the presence of the steel bars of the jackets as in the case of the jacketed column with 75mm thick UHPFRC jacket with additional steel bars, higher values of the ratio F

u, Shrinkage/ F

u, Without shrinkage have been derived as compared to the respective values of the jacketed column with 75 mm UHPFRC jacket without steel bars.

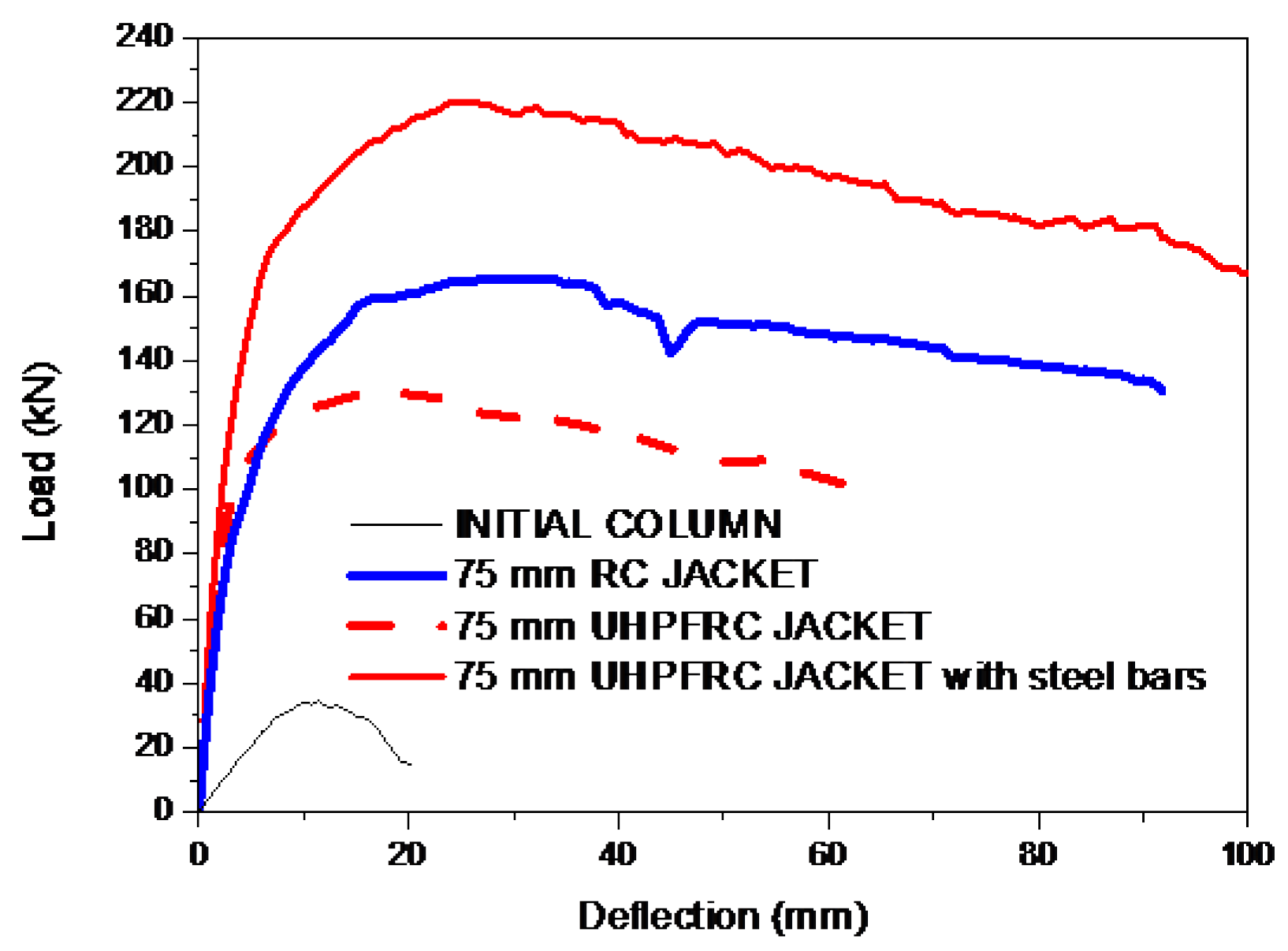

4. Evaluation of the Effectiveness of the use of UHPFRC Jackets and Comparisons with the use of Conventional RC Jackets

In this section, a critical evaluation of the performance of jacketed columns with conventional RC jacket, with UHPFRC jacket, and with UHPFRC jacket with additional steel bars is presented. In all the examined cases, a 75 thick jacket has been used and a shrinkage strain equal to 400 microstrains was applied to the elements of the jacket. The load deflection results for all these cases, together with the results of the initial column, are presented in

Figure 12.

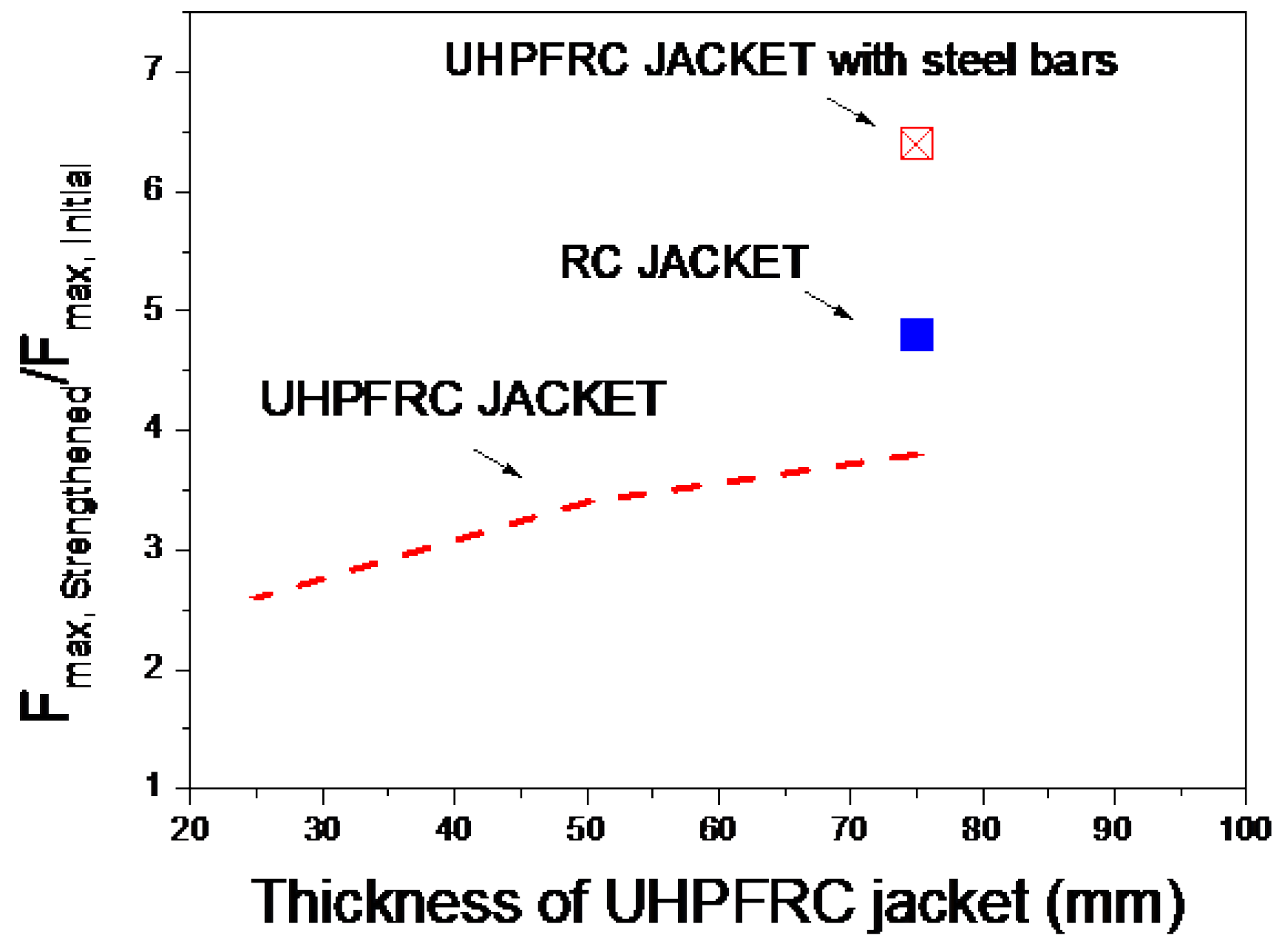

The ratio of the ultimate load capacity of the strengthened over the respective results of the initial column (F

u,Strengthened/F

u,Initial) for all the different examined techniques are presented in

Figure 13.

The results of

Figure 12 show that in all the strengthening techniques the stiffness and the strength are significantly increased as compared to the respective results of the initial column. The addition of UHPFRC jacket leads to higher stiffness enhancement as compared to the respective results of the column strengthened with RC jacket. The highest stiffness and strength enhancement are achieved by the addition of UHPFRC jacket with additional steel bars. From the comparisons of the ultimate load increment ratios (F

u,Strengthened/F

u,Initial) (

Figure 13) it is evident that the increment of the ultimate load in case of UHPFRC jacket with steel bars is significantly higher than in all the other techniques as the ultimate load is 6.4 times higher than the load of the initial column. The respective increment values for the RC jacket and for the UHPFRC jacket (without additional steel bars) are 4.8 and 3.8 respectively. These results highlight the significant contribution of the steel bars to the structural performance of the jacketed column which, in combination with the UHPFRC, leads to the most effective strengthening method.

5. Conclusions

This study is focused on the effectiveness of the use of UHPFRC jackets for the structural strengthening of existing RC columns. An extensive numerical investigation has been conducted on parameters such as the thickness of the jackets, the presence of steel reinforcing bars, and the shrinkage of the UHPFRC jackets. A critical comparison of this technique with the use of conventional RC jackets has also been conducted and the following conclusions were drawn.

The thickness of the UHPFRC jacket significantly affects the stiffness and the ultimate load capacity which are increasing as the jackets’ thickness is increased. The ultimate load capacity is increased 2.6-3.8 times for UHPFRC thickness of 25mm-75mm as compared to the respective load of the initial (prior to strengthening) RC column.

The addition of steel bars reinforcement to the UHPFRC jackets is leading to a significantly higher load capacity enhancement. In the case of the RC column strengthened with a 75 mm thick UHPFRC jacket, an ultimate load capacity of 131 kN is achieved, and this value is further increased to 220 kN (68% increment) by the addition of steel bars to the UHPFRC jacket.

UHPFRC jacket shrinkage is leading to a reduction of the ultimate load capacity of the strengthened columns due to the development of tensile stresses in a direction normal to the loading condition and a subsequent biaxial stress state. A reduction of the ultimate load of almost 15% is observed for an imposed shrinkage strain of 800 microstrains. The detrimental effect of the concrete shrinkage is limited by the presence of steel reinforcing bars at the UHPFRC jackets.

The comparison of the UHPFRC jackets with traditional RC jackets shows that the use of UHPFRC leads to higher stiffness enhancement as compared to the respective results of the column strengthened with RC jackets. The highest load enhancement is achieved for columns strengthened with UHPFRC jacket with steel bars where the ultimate load is found to be 6.4 times higher than the load of the initial column. In the case of RC jacket and UHPFRC jacket (without additional steel bars) the respective ultimate load increments are 4.8 and 3.8 respectively.

References

- Bett, B.J.; Klingner, R.E.; Jirsa, J.O. Lateral load response of strengthened and repaired reinforced concrete columns. ACI Struct. J. 1988, 85(5), 499–508.

- Bracci, J.M.; Reinhorn, A.M.; Mander, J.B. Evaluation of seismic retrofit of RC frame structures: Part II. Experimental performance and analytical study of a retrofitted structural model. Technical Report No. NCEER-92-0031, State University of New York at Buffalo, National Center for Earthquake Engineering Research, 1992.

- Ersoy, U.; Tankut, A.T.; Suleiman, R. Behaviour of jacketed columns. ACI Struct. J. 1993, 90(3), 288–293.

- Rodriguez, M.; Park, R. Seismic Load Tests on Reinforced Concrete Columns Strengthened by Jacketing. ACI Struct. J. 1994, 91. [CrossRef]

- Stoppenhagen, D.R.; Jirsa, J.O.; Wyllie, L.A. Seismic repair and strengthening of a severely damaged concrete frame. ACI Struct. J. 1995, 92(2), 177–187.

- Dritsos, S.E.; Taylor, C.A.; Vandoros, K.G. Seismic strengthening of reinforced concrete structures by concrete jacketing. Proceedings of the 7th International Conference on Structural Faults and Repair, Edinburgh, 1997.

- Dritsos, S.E.; Vandoros, K.G.; Taylor, C.A. Shaking table tests on a retrofitted, small scale, reinforced concrete model. Proceedings of the 6th SECED Conference on Seismic Design Practice into the Next Century, Oxford, 1998.

- Gomes, A.M.; Appleton, J. Repair and strengthening of reinforced concrete elements under cyclic loading. Proceedings of the 11th European Conference on Earthquake Engineering, Paris, 1998.

- Julio, E.S. Influence of the interface on the behavior of columns strengthened by reinforced concrete jacketing. Ph.D. Dissertation, University of Coimbra, Portugal, 2001 (in Portuguese).

- Julio, E.S.; Branco, F.; Silva, V.D. Reinforced concrete jacketing—Interface influence on monotonic loading response. ACI Struct. J. 2005, 102(2), 252–257.

- Julio, E.N.B.S.; Branco, F.A.B. Reinforced Concrete Jacketing--Interface Influence on Cyclic Loading Response. ACI Struct. J. 2008, 105. [CrossRef]

- Vandoros, K.G. Experimental investigation of the behavior of columns strengthened with reinforced concrete jackets under cyclic loads. Ph.D. Dissertation, University of Patras, Greece, 2005 (in Greek).

- Vandoros, K.G.; Dritsos, S.E. Interface treatment in shotcrete jacketing of reinforced concrete columns to improve seismic performance. Struct. Eng. Mech. 2006, 23, 43–61. [CrossRef]

- Vandoros, K.G.; Dritsos, S.E. Concrete jacket construction detail effectiveness when strengthening RC columns. Constr. Build. Mater. 2006, 22, 264–276. [CrossRef]

- Bousias, S.N.; Biskinis, D.; Fardis, M.N.; Spathis, A.-L. Strength, Stiffness, and Cyclic Deformation Capacity of Concrete Jacketed Members. ACI Struct. J. 2007, 104. [CrossRef]

- Lampropoulos, A.; Dritsos, S. Concrete Shrinkage Effect on Columns Strengthened with Concrete Jackets. Struct. Eng. Int. 2010, 20, 234–239. [CrossRef]

- Lampropoulos, A.P.; Dritsos, S.E. Modeling of RC columns strengthened with RC jackets. Earthq. Eng. Struct. Dyn. 2011, 40, 1689–1705. [CrossRef]

- Lampropoulos, A.P.; Tsioulou, O.T.; Dritsos, S.E. Monolithic Coefficient Values for Design when Seismically Strengthening RC Columns with Jackets. J. Earthq. Eng. 2012, 16, 1023–1042. [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [CrossRef]

- Rossi, P.; Arca, A.; Parant, E.; Fakhri, P. Bending and compressive behaviours of a new cement composite. Cem. Concr. Res. 2005, 35, 27–33. [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.; Johari, M.M.; Voo, Y.L. Evaluation of Bond Strength between Normal Concrete Substrate and Ultra High Performance Fiber Concrete as a Repair Material. Procedia Eng. 2013, 54, 554–563. [CrossRef]

- Hassan, A.; Jones, S.; Mahmud, G. Experimental test methods to determine the uniaxial tensile and compressive behaviour of ultra high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2012, 37, 874–882. [CrossRef]

- Lampropoulos, A.; Nicolaides, D.; Paschalis, S.; Tsioulou, O. Experimental and Numerical Investigation on the Size Effect of Ultrahigh-Performance Fibre-Reinforced Concrete (UHFRC). Materials 2021, 14, 5714. [CrossRef]

- Yoo, D.-Y.; Shin, H.-O.; Yang, J.-M.; Yoon, Y.-S. Material and bond properties of ultra high performance fiber reinforced concrete with micro steel fibers. Compos. Part B: Eng. 2014, 58, 122–133. [CrossRef]

- Kang, S.-T.; Kim, J.-K. The relation between fiber orientation and tensile behavior in an Ultra High Performance Fiber Reinforced Cementitious Composites (UHPFRCC). Cem. Concr. Res. 2011, 41, 1001–1014. [CrossRef]

- Tanarslan, H. Flexural strengthening of RC beams with prefabricated ultra high performance fibre reinforced concrete laminates. Eng. Struct. 2017, 151, 337–348. [CrossRef]

- Lampropoulos, A.; Paschalis, S.; Tsioulou, O.; Dritsos S. Strengthening of reinforced concrete beams using ultra high-performance fibers reinforced concrete (UHPFRC). Eng Struct. 2015, 106, 370–384.

- Paschalis, S.A.; Lampropoulos, A.P. Investigation of key parameters affecting the use of Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) as strengthening material. Structures 2024, 62. [CrossRef]

- Dagenais, M.A.; Massicotte, B. Cyclic behavior of lap splices strengthened with ultra high performance fiber-reinforced concrete. J Struct Eng. 2017, 143, 04016163.

- Murthy, A.R.; Karihaloo, B.; Priya, D.S. Flexural behavior of RC beams retrofitted with ultra-high strength concrete. Constr. Build. Mater. 2018, 175, 815–824. [CrossRef]

- Al-Osta, M.; Isa, M.; Baluch, M.; Rahman, M. Flexural behaviour of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr Build Mater. 2017, 134, 279–296.

- Safdar, M.; Matsumoto, T.; Kakuma, K. Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC). Compos. Struct. 2016, 157, 448–460. [CrossRef]

- Farhat, F.; Nicolaides, D.; Kanellopoulos, A.; Karihaloo, B. High performance fibre-reinforced cementitious composite (CARDIFRC) – Performance and application to retrofitting. Eng. Fract. Mech. 2006, 74, 151–167. [CrossRef]

- Bruhwiler, E.; Denarie, E. Rehabilitation of concrete structures using Ultra-High Performance Fibre Reinforced Concrete. The Second International Symposium on Ultra High Performance, 2008, Kassel, Germany. [CrossRef]

- Yin, H.; Teo, W.; Shirai, K. Experimental investigation on the behaviour of reinforced concrete slabs strengthened with ultra-high performance concrete. Constr. Build. Mater. 2017, 155, 463–474. [CrossRef]

- Elsayed, M.; Tayeh, B.A.; Elmaaty, M.A.; Aldahshoory, Y. Behaviour of RC columns strengthened with Ultra-High Performance Fiber Reinforced concrete (UHPFRC) under eccentric loading. J. Build. Eng. 2021, 47, 103857. [CrossRef]

- Dadvar, S.A.; Mostofinejad, D.; Bahmani, H. Strengthening of RC columns by ultra-high performance fiber reinforced concrete (UHPFRC) jacketing. Constr. Build. Mater. 2019, 235, 117485. [CrossRef]

- Lampropoulos, A.; Paschalis, S.; Dritsos, S. UHPFRC versus RC jackets for the seismic upgrade of columns. In: IABSE Conference: Structural Engineering: Providing Solutions to Global Challenges, 23-25 Sep 2015, Geneva, Switzerland.

- Cervenka, V.; Jendele, L.; Cervenka, J. ATENA Program Documentation: Part 1 Theory. Czech Republic, Prague, 2013.

- Model Code 1990. CEB-FIP; 1993 Thomas Telford, London. UK.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).