Submitted:

31 May 2024

Posted:

04 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Fundamentals and Sensing Strategies

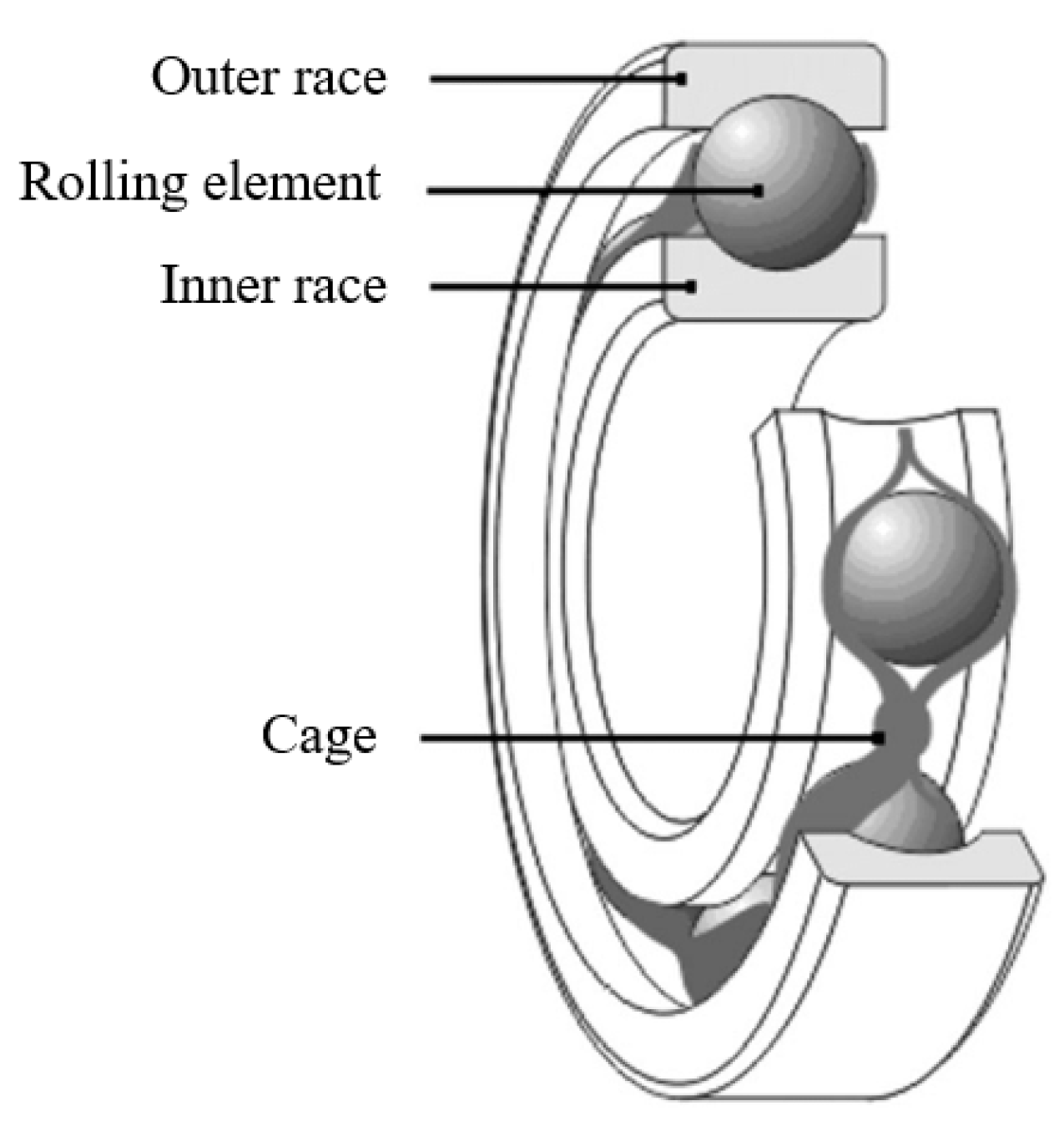

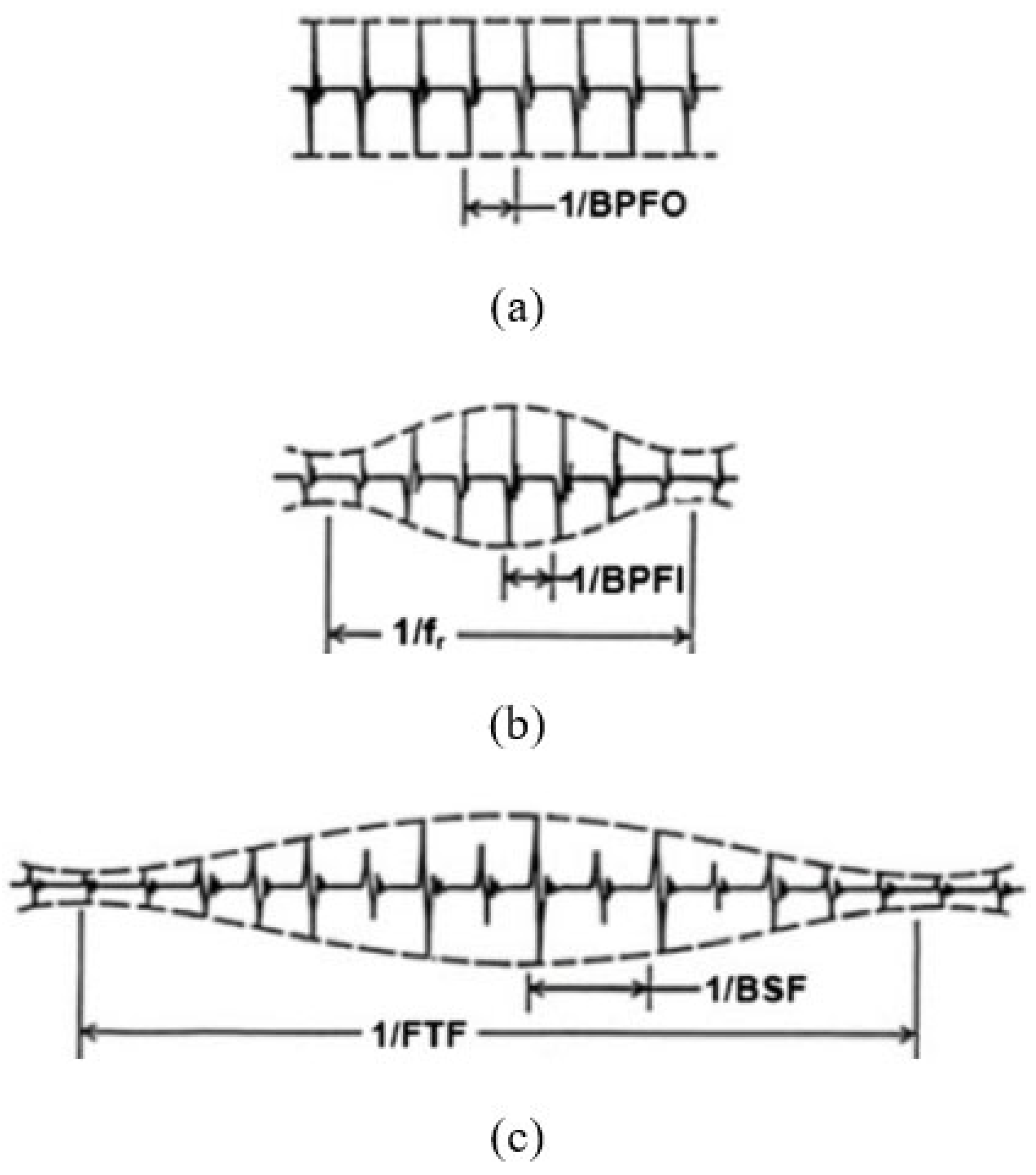

2.1. Defect Frequencies of Rolling Element Bearings

2.2. Condition Monitoring Approaches

2.2.1. Vibration-Based Monitoring

2.2.2. Acoustic Emission-Based Monitoring

2.2.3. Temperature-Based Monitoring

2.2.4. Other Approaches

2.3. Influence of Sensor Integrity

3. Signal Processing and Feature Extraction Techniques

3.1. Time Domain Methods

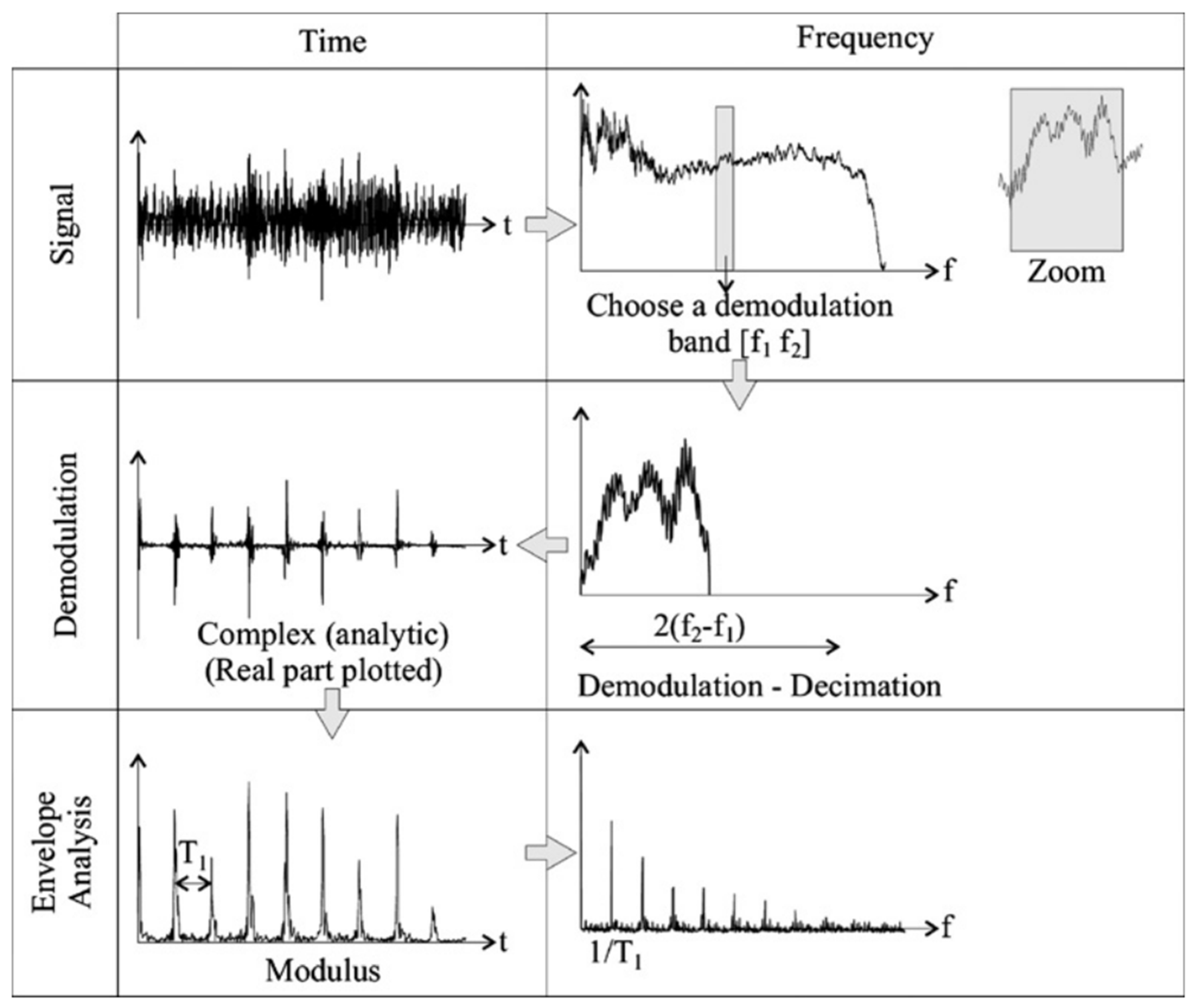

3.2. Frequency Domain Methods

3.3. Time-Frequency Domain Methods

4. Information Fusion

4.1. Data-Level Fusion

4.2. Feature-Level Fusion

4.3. Decision-Level Fusion

4.4. Multi-Level Fusion

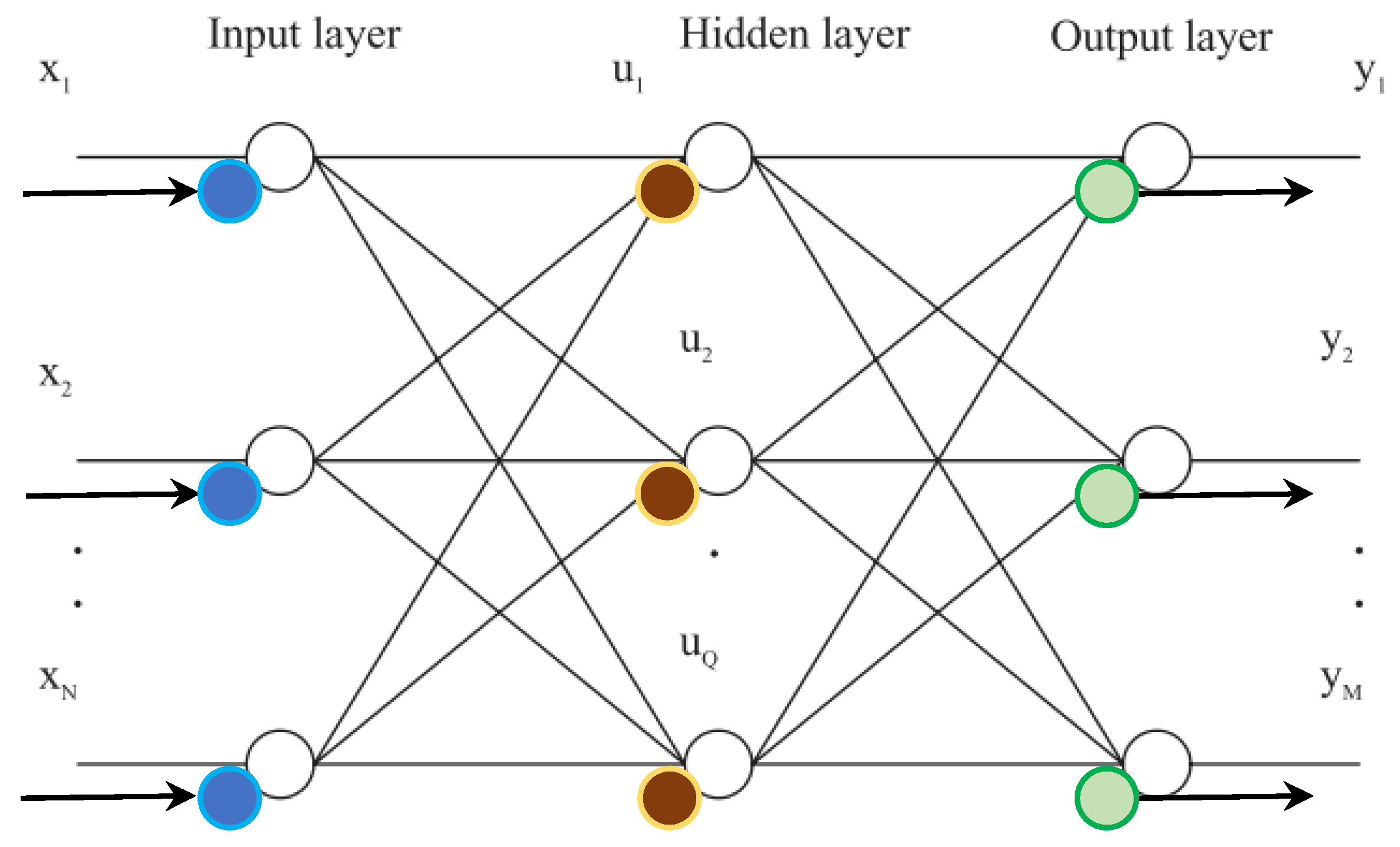

5. Intelligent Algorithms and Applications

5.1. Machine Learning Classifiers

5.2. Metaheuristic Optimisation Techniques

6. Conclusions and Future Perspectives

- Envelope spectrum has proven to be an efficient benchmarking technique in the defect detection and diagnosis of bearings. The selection of an optimal frequency band for demodulation is crucial for this. While various techniques have been explored, many are time-consuming or require specialized expertise. Further research leveraging metaheuristic optimisation for automatic demodulation band selection could enhance efficiency in this area.

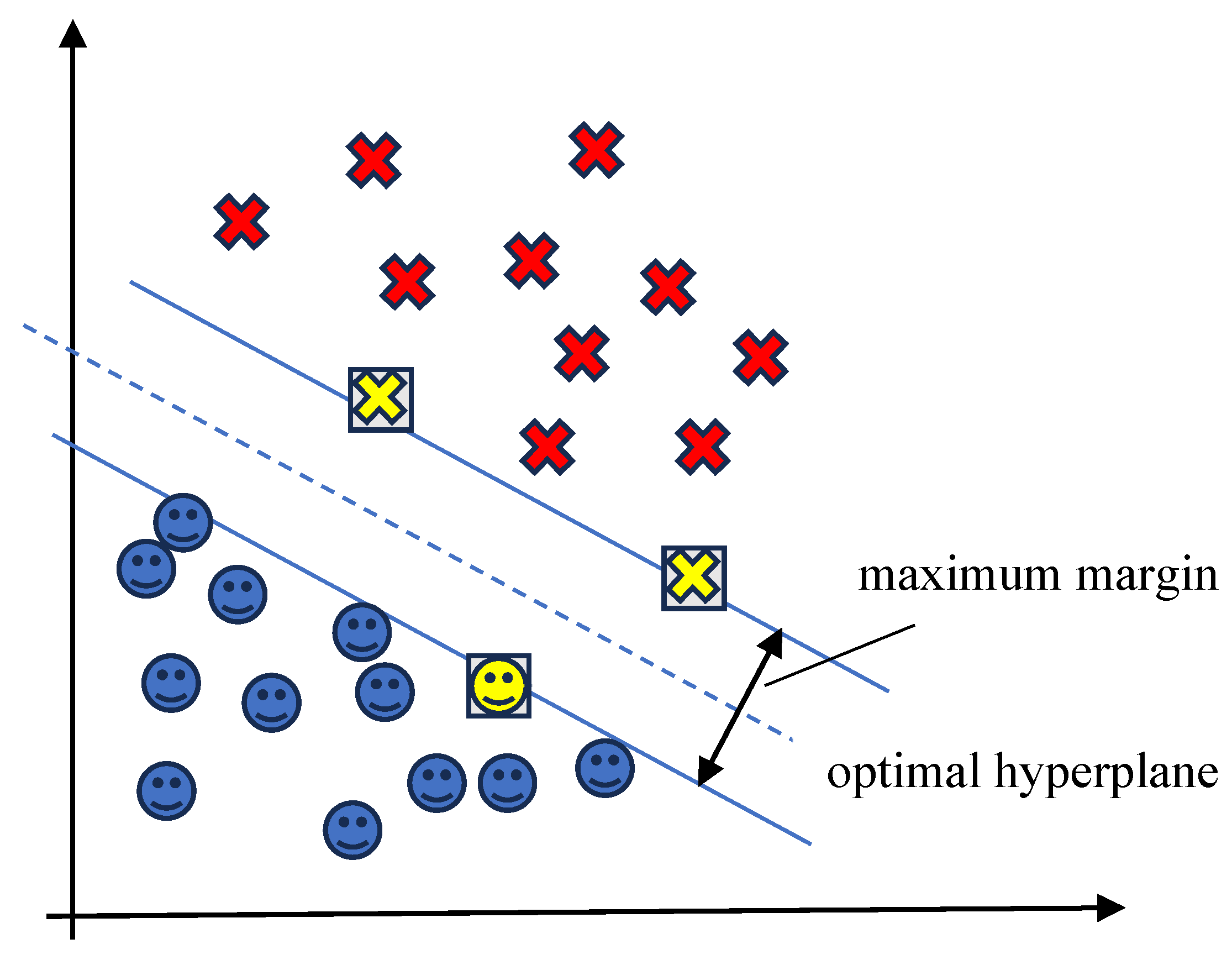

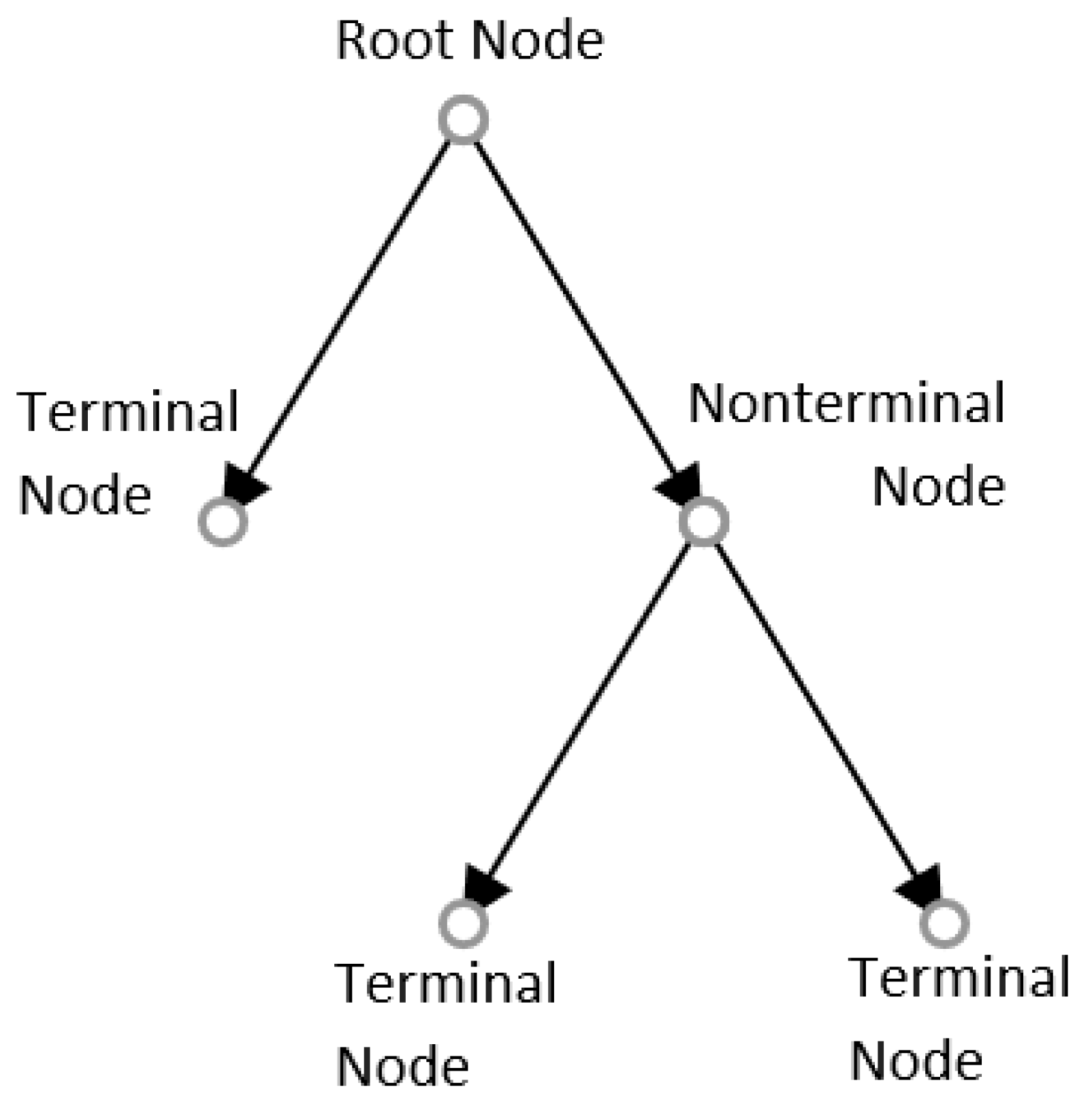

- AI-based fault diagnosis techniques have become prominent due to their rapid development in the ability to significantly enhance the accuracy, efficiency, and reliability. Machine learning classifiers are often used for diagnostic tasks due to their ability to achieve high accuracy without extensive domain knowledge. The classifier can be trained well for fault identification through extraction of relevant features pertaining to bearing health condition from historic data. It would be more practical for a signal integrity assessment technique to work on a variety of issues so it can be used as a standard preprocessing step to fault diagnosis. Research in the area will benefit from the development of a classification model that accurately captures the nonrigid nature of the decision boundary of signals to efficiently segregate anomalies.

- Multi-sensor monitoring systems were found to be advantageous as they increased the general reliability of fault detection and diagnosis. The use of heterogeneous sensors in conjunction can also aid in further increasing the reliability. While information fusion of different sensors has been achieved on different levels, it is most common for decision-level fusion to take place. However, conflicting results in sensor diagnoses can occur due to misclassification in learning models or sensor integrity issues, highlighting the need for further research to address these challenges.

References

- F. Cong, J. Chen, G. Dong, and M. Pecht, “Vibration model of rolling element bearings in a rotor-bearing system for fault diagnosis,” J. Sound Vib., vol. 332, no. 8, pp. 2081–2097, 2013. [CrossRef]

- J. Ben Ali, N. Fnaiech, L. Saidi, B. Chebel-Morello, and F. Fnaiech, “Application of empirical mode decomposition and artificial neural network for automatic bearing fault diagnosis based on vibration signals,” Appl. Acoust., vol. 89, pp. 16–27, 2015. [CrossRef]

- T. Wang, M. Liang, J. Li, and W. Cheng, “Rolling element bearing fault diagnosis via fault characteristic order (FCO) analysis,” Mech. Syst. Signal Process., vol. 45, no. 1, pp. 139–153, 2014. [CrossRef]

- R. B. Randall, Vibration-based Condition Monitoring: Industrial, Aerospace and Automotive Applications, 1st ed. John Wiley & Sons, 2011.

- E. Mollasalehi, “Data-driven and Model-based Bearing Fault Analysis - Wind Turbine Application,” University of Calgary, 2017.

- B. Khaleghi, A. Khamis, F. O. Karray, and S. N. Razavi, “Multisensor data fusion: A review of the state-of-the-art,” Inf. Fusion, vol. 14, no. 1, pp. 28–44, Jan. 2013. [CrossRef]

- Z. Duan, T. Wu, S. Guo, T. Shao, R. Malekian, and Z. Li, “Development and trend of condition monitoring and fault diagnosis of multi-sensors information fusion for rolling bearings: a review,” Int. J. Adv. Manuf. Technol., pp. 803–819, 2018. [CrossRef]

- R. Liu, B. Yang, E. Zio, and X. Chen, “Artificial intelligence for fault diagnosis of rotating machinery: A review,” Mech. Syst. Signal Process., vol. 108, pp. 33–47, Aug. 2018. [CrossRef]

- K. C. Gryllias and I. A. Antoniadis, “A Support Vector Machine approach based on physical model training for rolling element bearing fault detection in industrial environments,” Eng. Appl. Artif. Intell., vol. 25, no. 2, pp. 326–344, 2012. [CrossRef]

- W. Caesarendra and T. Tjahjowidodo, “A review of feature extraction methods in vibration-based condition monitoring and its application for degradation trend estimation of low-speed slew bearing,” Machines, vol. 5, no. 4, p. 21, 2017. [CrossRef]

- A. Moshrefzadeh, “Condition monitoring and intelligent diagnosis of rolling element bearings under constant/variable load and speed conditions,” Mech. Syst. Signal Process., vol. 149, p. 107153, 2021. [CrossRef]

- C. Malla and I. Panigrahi, “Review of Condition Monitoring of Rolling Element Bearing Using Vibration Analysis and Other Techniques,” J. Vib. Eng. Technol., vol. 7, no. 4, pp. 407–414, Aug. 2019. [CrossRef]

- O. Alshorman, M. Irfan, N. Saad, D. Zhen, N. Haider, A. Glowacz, and A. Alshorman, “A Review of Artificial Intelligence Methods for Condition Monitoring and Fault Diagnosis of Rolling Element Bearings for Induction Motor,” Shock Vib., vol. 2020, no. Cm, 2020. [CrossRef]

- A. H. Boudinar, N. Benouzza, A. Bendiabdellah, and M. Khodja, “Induction Motor Bearing Fault Analysis Using a Root-MUSIC Method,” IEEE Trans. Ind. Appl., vol. 52, no. 5, pp. 3851–3860, 2016. [CrossRef]

- S. Singh, C. Q. Howard, and C. H. Hansen, “An extensive review of vibration modelling of rolling element bearings with localised and extended defects,” J. Sound Vib., vol. 357, pp. 300–330, 2015. [CrossRef]

- W. A. Smith and R. B. Randall, “Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study,” Mech. Syst. Signal Process., vol. 64–65, pp. 100–131, 2015. [CrossRef]

- R. B. Randall and J. Antoni, “Rolling element bearing diagnostics-A tutorial,” Mech. Syst. Signal Process., vol. 25, no. 2, pp. 485–520, 2011. [CrossRef]

- M. Kande, A. Isaksson, R. Thottappillil, and N. Taylor, “Rotating Electrical Machine Condition Monitoring Automation—A Review,” Machines, vol. 5, no. 4, p. 24, Oct. 2017. [CrossRef]

- G. Wild, L. Pollock, A. K. Abdelwahab, and J. Murray, “Need for Aerospace Structural Health Monitoring: A review of aircraft fatigue accidents,” Int. J. Progn. Heal. Manag., vol. 12, no. 3, pp. 1–16, 2021.

- A. Jablonski, Condition Monitoring Algorithms in MATLAB®. Cham: Springer International Publishing, 2021. [CrossRef]

- H. Hong and M. Liang, “Fault severity assessment for rolling element bearings using the Lempel–Ziv complexity and continuous wavelet transform,” J. Sound Vib., vol. 320, no. 1, pp. 452–468, 2009. [CrossRef]

- S. Suh, P. Lukowicz, and Y. O. Lee, “Generalized multiscale feature extraction for remaining useful life prediction of bearings with generative adversarial networks,” Knowledge-Based Syst., vol. 237, p. 107866, 2022. [CrossRef]

- R. B. Randall and W. A. Smith, “Detection of faulty accelerometer mounting from response measurements,” J. Sound Vib., vol. 477, p. 115318, Jul. 2020. [CrossRef]

- A. M. Al-Ghamd and D. Mba, “A comparative experimental study on the use of acoustic emission and vibration analysis for bearing defect identification and estimation of defect size,” Mech. Syst. Signal Process., vol. 20, no. 7, pp. 1537–1571, 2006. [CrossRef]

- B. Guo, S. Song, A. Ghalambor, and T. R. Lin, An Introduction to Condition-Based Maintenance. 2014. [CrossRef]

- A. Choudhury and N. Tandon, “Application of acoustic emission technique for the detection of defects in rolling element bearings,” Tribol. Int., vol. 33, no. 1, pp. 39–45, 2000. [CrossRef]

- M. Elforjani and D. Mba, “Accelerated natural fault diagnosis in slow speed bearings with Acoustic Emission,” Eng. Fract. Mech., vol. 77, no. 1, pp. 112–127, 2010. [CrossRef]

- W. Caesarendra, B. Kosasih, A. K. Tieu, H. Zhu, C. A. S. Moodie, and Q. Zhu, “Acoustic emission-based condition monitoring methods: Review and application for low speed slew bearing,” Mech. Syst. Signal Process., vol. 72–73, pp. 134–159, 2016. [CrossRef]

- B. Van Hecke, J. Yoon, and D. He, “Low speed bearing fault diagnosis using acoustic emission sensors,” Appl. Acoust., vol. 105, pp. 35–44, 2016. [CrossRef]

- C. Liu, X. Wu, J. Mao, and X. Liu, “Acoustic emission signal processing for rolling bearing running state assessment using compressive sensing,” Mech. Syst. Signal Process., vol. 91, pp. 395–406, 2017. [CrossRef]

- N. Tandon and A. Parey, “Condition Monitoring of Rotary Machines,” 2006, pp. 109–136. [CrossRef]

- A. M. D. Younus and B. S. Yang, “Intelligent fault diagnosis of rotating machinery using infrared thermal image,” Expert Syst. Appl., vol. 39, no. 2, pp. 2082–2091, 2012. [CrossRef]

- O. Janssens, R. Schulz, V. Slavkovikj, K. Stockman, M. Loccufier, R. Van De Walle, and S. Van Hoecke, “Thermal image based fault diagnosis for rotating machinery,” Infrared Phys. Technol., vol. 73, pp. 78–87, 2015. [CrossRef]

- Z. Liu, J. Wang, L. Duan, T. Shi, and Q. Fu, “Infrared Image Combined with CNN Based Fault Diagnosis for Rotating Machinery,” in 2017 International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Aug. 2017, pp. 137–142. [CrossRef]

- A. Mehta, D. Goyal, A. Choudhary, B. S. Pabla, and S. Belghith, “Machine Learning-Based Fault Diagnosis of Self-Aligning Bearings for Rotating Machinery Using Infrared Thermography,” Math. Probl. Eng., vol. 2021, 2021. [CrossRef]

- T. Wu, H. Wu, Y. Du, and Z. Peng, “Progress and trend of sensor technology for on-line oil monitoring,” Sci. China Technol. Sci., vol. 56, no. 12, pp. 2914–2926, 2013. [CrossRef]

- S. Y. Wang, D. X. Yang, and H. F. Hu, “Evaluation for bearing wear states based on online oil multi-parameters monitoring,” Sensors (Switzerland), vol. 18, no. 4, 2018. [CrossRef]

- Y. H. Kim, A. C. C. Tan, J. Mathew, and B. S. Yang, “Condition monitoring of low speed bearings: A comparative study of the ultrasound technique versus vibration measurements,” Proc. 1st World Congr. Eng. Asset Manag. WCEAM 2006, pp. 182–191, 2006. [CrossRef]

- J. Lineham, “Ultrasonic probes for inspecting bearings,” World Pumps, vol. 2008, no. 503, pp. 34–36, 2008. [CrossRef]

- J. Zarei and J. Poshtan, “Bearing fault detection using wavelet packet transform of induction motor stator current,” Tribol. Int., vol. 40, no. 5, pp. 763–769, 2007. [CrossRef]

- J. Park, S. Kim, J. H. Choi, and S. H. Lee, “Frequency energy shift method for bearing fault prognosis using microphone sensor,” Mech. Syst. Signal Process., vol. 147, p. 107068, 2021. [CrossRef]

- B. Samanta and K. R. Al-Balushi, “Artificial neural network based fault diagnostics of rolling element bearings using time-domain features,” Mech. Syst. Signal Process., vol. 17, no. 2, pp. 317–328, Mar. 2003. [CrossRef]

- V. Girondin, M. Loudahi, H. Morel, K. M. Pekpe, and J. P. Cassar, “Vibration-based fault detection of accelerometers in helicopters,” in IFAC Proceedings Volumes (IFAC-PapersOnline), Jan. 2012, vol. 8, no. PART 1, pp. 720–725. [CrossRef]

- D. Abboud, M. Elbadaoui, S. Becquerelle, and M. Lalmi, “Detection of Sensor Detachment in Aircraft Engines Using Vibration Signals,” in Proceedings of the 10th International Conference on Rotor Dynamics -- IFToMM, 2019, pp. 351–365.

- L. Song, H. Wang, and P. Chen, “Automatic signal quality check and equipment condition surveillance based on trivalent logic diagnosis theory,” Meas. J. Int. Meas. Confed., vol. 136, pp. 173–184, Mar. 2019. [CrossRef]

- S. Bagavathiappan, B. B. Lahiri, T. Saravanan, J. Philip, and T. Jayakumar, “Infrared thermography for condition monitoring – A review,” Infrared Phys. Technol., vol. 60, pp. 35–55, Sep. 2013. [CrossRef]

- Z. Shen, Z. He, X. Chen, C. Sun, and Z. Liu, “A monotonic degradation assessment index of rolling bearings using fuzzy support vector data description and running time,” Sensors (Switzerland), vol. 12, no. 8, pp. 10109–10135, Jul. 2012. [CrossRef]

- K. F. Tom, “A Primer on Vibrational Ball Bearing Feature Generation for Prognostics and Diagnostics Algorithms,” Adelphi, 2015.

- D. Dyer and R. M. Stewart, “Detection of Rolling Element Bearing Damage By Statistical Vibration Analysis.,” Am. Soc. Mech. Eng., vol. 100, no. 77-DET-83, pp. 229–235, 1977.

- S. Fu, K. Liu, Y. Xu, and Y. Liu, “Rolling bearing diagnosing method based on time domain analysis and adaptive fuzzy C -means clustering,” Shock Vib., vol. 2016, 2016. [CrossRef]

- D. Goyal, Vanraj, B. S. Pabla, and S. S. Dhami, “Condition Monitoring Parameters for Fault Diagnosis of Fixed Axis Gearbox: A Review,” Arch. Comput. Methods Eng., vol. 24, no. 3, pp. 543–556, 2017. [CrossRef]

- R. B. W. Heng and M. J. M. Nor, “Statistical analysis of sound and vibration signals for monitoring rolling element bearing condition,” Appl. Acoust., vol. 53, no. 1–3, pp. 211–226, 2002. [CrossRef]

- B. Sreejith, A. K. Verma, and A. Srividya, “Fault diagnosis of rolling element bearing using time-domain features and neural networks,” IEEE Reg. 10 Colloq. 3rd Int. Conf. Ind. Inf. Syst. ICIIS 2008, no. 1, pp. 1–6, 2008. [CrossRef]

- P. Gupta and M. K. Pradhan, “Fault detection analysis in rolling element bearing: A review,” in Materials Today: Proceedings, 2017, vol. 4, no. 2, pp. 2085–2094. [CrossRef]

- F. R. Kschischang, “The Hilbert Transform,” University of Toronto, Toronto, 2006.

- E. Bechhoefer and P. Menon, “Bearing Envelope Analysis Window Selection,” in Annual Conference of the Prognostics and Health Management Society, 2009, pp. 1–7. [CrossRef]

- P. Boškoski and A. Urevc, “Bearing fault detection with application to PHM Data Challenge,” Int. J. Progn. Heal. Manag., vol. 2, no. 1, pp. 1–10, 2011. [CrossRef]

- E. Bechhoefer, M. Kingsley, and P. Menon, “Bearing envelope analysis window selection Using spectral kurtosis techniques,” 2011 IEEE Int. Conf. Progn. Heal. Manag. PHM 2011 - Conf. Proc., pp. 1–6, 2011. [CrossRef]

- V. Kannan, H. Li, and D. V. Dao, “Demodulation Band Optimization in Envelope Analysis for Fault Diagnosis of Rolling Element Bearings Using a Real-Coded Genetic Algorithm,” IEEE Access, vol. 7, pp. 168828–168838, 2019. [CrossRef]

- O. Janssens, V. Slavkovikj, B. Vervisch, K. Stockman, M. Loccufier, S. Verstockt, R. Van de Walle, and S. Van Hoecke, “Convolutional Neural Network Based Fault Detection for Rotating Machinery,” J. Sound Vib., vol. 377, pp. 331–345, 2016. [CrossRef]

- Z. Feng, M. Liang, and F. Chu, “Recent advances in time–frequency analysis methods for machinery fault diagnosis: A review with application examples,” Mech. Syst. Signal Process., vol. 38, no. 1, pp. 165–205, Jul. 2013. [CrossRef]

- H. Li, H. Zheng, and L. Tang, “Wigner-Ville Distribution Based on EMD for Faults Diagnosis of Bearing,” in Fuzzy Systems and Knowledge Discovery, 2006, pp. 803–812.

- M. Cocconcelli, R. Zimroz, R. Rubini, and W. Bartelmus, “STFT Based Approach for Ball Bearing Fault Detection in a Varying Speed Motor,” in Condition Monitoring of Machinery in Non-Stationary Operations, Berlin, Heidelberg: Springer Berlin Heidelberg, 2012, pp. 41–50. [CrossRef]

- M. Cocconcelli, R. Zimroz, R. Rubini, and W. Bartelmus, “Kurtosis over Energy Distribution Approach for STFT Enhancement in Ball Bearing Diagnostics,” in Condition Monitoring of Machinery in Non-Stationary Operations, Berlin, Heidelberg: Springer Berlin Heidelberg, 2012, pp. 51–59. [CrossRef]

- G. Manhertz and A. Bereczky, “STFT spectrogram based hybrid evaluation method for rotating machine transient vibration analysis,” Mech. Syst. Signal Process., vol. 154, p. 107583, Jun. 2021. [CrossRef]

- N. Ali Khan, I. Ahmad Taj, M. Noman Jaffri, and S. Ijaz, “Cross-term elimination in Wigner distribution based on 2D signal processing techniques,” Signal Processing, vol. 91, no. 3, pp. 590–599, 2011. [CrossRef]

- W. Y. Liu, J. G. Han, and J. L. Jiang, “A novel ball bearing fault diagnosis approach based on auto term window method,” Meas. J. Int. Meas. Confed., vol. 46, no. 10, pp. 4032–4037, 2013. [CrossRef]

- H. Li and Y. Chen, “Machining process monitoring,” in Handbook of Manufacturing Engineering and Technology, Springer Publishing Company, 2015, pp. 940–981. [CrossRef]

- Z. K. Peng and F. L. Chu, “Application of the wavelet transform in machine condition monitoring and fault diagnostics: a review with bibliography,” Mech. Syst. Signal Process., vol. 18, no. 2, pp. 199–221, 2004. [CrossRef]

- J. H. Navarro-Devia, Y. Chen, D. V. Dao, and H. Li, “Chatter detection in milling processes—a review on signal processing and condition classification,” Int. J. Adv. Manuf. Technol. 2023 1259, vol. 125, no. 9, pp. 3943–3980, Feb. 2023. [CrossRef]

- X. Zhang, Z. Liu, J. Wang, and J. Wang, “Time–frequency analysis for bearing fault diagnosis using multiple Q-factor Gabor wavelets,” ISA Trans., vol. 87, pp. 225–234, 2019. [CrossRef]

- P. Liang, W. Wang, X. Yuan, S. Liu, L. Zhang, and Y. Cheng, “Intelligent fault diagnosis of rolling bearing based on wavelet transform and improved ResNet under noisy labels and environment,” Eng. Appl. Artif. Intell., vol. 115, no. August, p. 105269, 2022. [CrossRef]

- V. K. Rai and A. R. Mohanty, “Bearing fault diagnosis using FFT of intrinsic mode functions in Hilbert–Huang transform,” Mech. Syst. Signal Process., vol. 21, no. 6, pp. 2607–2615, Aug. 2007. [CrossRef]

- J. Cheng, Y. Yang, and Y. Yang, “A rotating machinery fault diagnosis method based on local mean decomposition,” Digit. Signal Process., vol. 22, no. 2, pp. 356–366, Mar. 2012. [CrossRef]

- C. Junsheng, Y. Dejie, and Y. Yu, “The application of energy operator demodulation approach based on EMD in machinery fault diagnosis,” Mech. Syst. Signal Process., vol. 21, no. 2, pp. 668–677, Feb. 2007. [CrossRef]

- F. Castanedo, “A Review of Data Fusion Techniques,” Sci. World J., vol. 2013, pp. 1–19, 2013. [CrossRef]

- G. Niu, T. Han, B. S. Yang, and A. C. C. Tan, “Multi-agent decision fusion for motor fault diagnosis,” Mech. Syst. Signal Process., vol. 21, no. 3, pp. 1285–1299, Apr. 2007. [CrossRef]

- H. Wang, S. Li, L. Song, and L. Cui, “A novel convolutional neural network based fault recognition method via image fusion of multi-vibration-signals,” Comput. Ind., vol. 105, pp. 182–190, 2019. [CrossRef]

- M. Xia, T. Li, L. Xu, L. Liu, and C. W. De Silva, “Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks,” IEEE/ASME Trans. Mechatronics, vol. 23, no. 1, pp. 101–110, Feb. 2018. [CrossRef]

- L. Jing, T. Wang, M. Zhao, and P. Wang, “An adaptive multi-sensor data fusion method based on deep convolutional neural networks for fault diagnosis of planetary gearbox,” Sensors (Switzerland), vol. 17, no. 2, 2017. [CrossRef]

- Z. Chen and W. Li, “Multisensor Feature Fusion for Bearing Fault Diagnosis Using Sparse Autoencoder and Deep Belief Network,” IEEE Trans. Instrum. Meas., vol. 66, no. 7, pp. 1693–1702, Jul. 2017. [CrossRef]

- J. Tao, Y. Liu, and D. Yang, “Bearing Fault Diagnosis Based on Deep Belief Network and Multisensor Information Fusion,” Shock Vib., vol. 2016, 2016. [CrossRef]

- Vanraj, S. S. Dhami, and B. S. Pabla, “Hybrid data fusion approach for fault diagnosis of fixed-axis gearbox,” Struct. Heal. Monit., vol. 17, no. 4, pp. 936–945, 2018. [CrossRef]

- M. S. Safizadeh and S. K. Latifi, “Using multi-sensor data fusion for vibration fault diagnosis of rolling element bearings by accelerometer and load cell,” Inf. Fusion, vol. 18, pp. 1–8, 2014. [CrossRef]

- J. H. Zhong, P. K. Wong, and Z. X. Yang, “Fault diagnosis of rotating machinery based on multiple probabilistic classifiers,” Mech. Syst. Signal Process., vol. 108, pp. 99–114, 2018. [CrossRef]

- A. Stief, J. R. Ottewill, J. Baranowski, and M. Orkisz, “A PCA and Two-Stage Bayesian Sensor Fusion Approach for Diagnosing Electrical and Mechanical Faults in Induction Motors,” IEEE Trans. Ind. Electron., vol. 66, no. 12, pp. 9510–9520, 2019. [CrossRef]

- J. Wang, P. Fu, L. Zhang, R. X. Gao, and R. Zhao, “Multi-level information fusion for induction motor fault diagnosis,” IEEE/ASME Trans. Mechatronics, p. 1, 2019. [CrossRef]

- O. Mey, A. Schneider, O. Enge-Rosenblatt, D. Mayer, C. Schmidt, S. Klein, and H. G. Herrmann, “Condition monitoring of drive trains by data fusion of acoustic emission and vibration sensors†,” Processes, vol. 9, no. 7, pp. 1–13, 2021. [CrossRef]

- D. Han, J. Tian, P. Xue, and P. Shi, “A novel intelligent fault diagnosis method based on dual convolutional neural network with multi-level information fusion,” J. Mech. Sci. Technol., vol. 35, no. 8, pp. 3331–3345, 2021. [CrossRef]

- Y. Zhang, C. Li, R. Wang, and J. Qian, “A novel fault diagnosis method based on multi-level information fusion and hierarchical adaptive convolutional neural networks for centrifugal blowers,” Meas. J. Int. Meas. Confed., vol. 185, no. July, p. 109970, 2021. [CrossRef]

- W. Yan, J.-W. Tan, Z. Hong, and S. Xian-Bin, “Fault Diagnosis Model Based on Multi-level Information Fusion for CNC Machine Tools,” Int. J. Hybrid Inf. Technol., vol. 9, no. 8, pp. 367–376, 2016. [CrossRef]

- I. El Naqa and M. J. Murphy, “What Is Machine Learning?,” in Machine Learning in Radiation Oncology, Cham: Springer International Publishing, 2015, pp. 3–11. [CrossRef]

- P. Cunningham, M. Cord, and S. J. Delany, “Supervised Learning,” in Machine Learning Techniques for Multimedia, Berlin, Heidelberg: Springer Berlin Heidelberg, 2019, pp. 21–49. [CrossRef]

- D. Greene, P. Cunningham, and R. Mayer, “Unsupervised Learning and Clustering,” in Machine Learning Techniques for Multimedia, Berlin, Heidelberg: Springer Berlin Heidelberg, 2008, pp. 51–90. [CrossRef]

- P. Dayan and Y. Niv, “Reinforcement learning: The Good, The Bad and The Ugly,” Curr. Opin. Neurobiol., vol. 18, no. 2, pp. 185–196, Apr. 2008. [CrossRef]

- Ujjwalkarn, “A Quick Introduction to Neural Networks,” the data science blog, 2016.

- B. Samanta, “Gear fault detection using artificial neural networks and support vector machines with genetic algorithms,” Mech. Syst. Signal Process., vol. 18, no. 3, pp. 625–644, 2004. [CrossRef]

- F. Jia, Y. Lei, L. Guo, J. Lin, and S. Xing, “A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines,” Neurocomputing, vol. 272, pp. 619–628, Jan. 2018. [CrossRef]

- X. Chen, B. Zhang, and D. Gao, “Bearing fault diagnosis base on multi-scale CNN and LSTM model,” J. Intell. Manuf., vol. 32, no. 4, pp. 971–987, 2021. [CrossRef]

- C.-H. Shen, “ACOUSTIC BASED CONDITION MONITORING,” University of Akron, 2012.

- C. Cortes and V. Vapnik, “Support-Vector Networks,” Mach. Learn., vol. 20, no. 3, pp. 273–297, 1995.

- C. M. Bishop, Pattern recognition and machine learning. Springer New York, 2006.

- J. Yang, Y. Zhang, and Y. Zhu, “Intelligent fault diagnosis of rolling element bearing based on SVMs and fractal dimension,” Mech. Syst. Signal Process., vol. 21, no. 5, pp. 2012–2024, 2007. [CrossRef]

- Z. Wang, L. Yao, and Y. Cai, “Rolling bearing fault diagnosis using generalized refined composite multiscale sample entropy and optimized support vector machine,” Meas. J. Int. Meas. Confed., vol. 156, p. 107574, 2020. [CrossRef]

- B. Schölkopf, R. Williamson, A. Smola, J. Shawe-Taylor, and J. Piatt, “Support vector method for novelty detection,” Adv. Neural Inf. Process. Syst., pp. 582–588, 2000.

- D. Fernández-Francos, D. Marténez-Rego, O. Fontenla-Romero, and A. Alonso-Betanzos, “Automatic bearing fault diagnosis based on one-class v-SVM,” Comput. Ind. Eng., vol. 64, no. 1, pp. 357–365, 2013. [CrossRef]

- V. Kannan, D. V. Dao, and H. Li, “An information fusion approach for increased reliability of condition monitoring With homogeneous and heterogeneous sensor systems,” Struct. Heal. Monit., p. 147592172211124, Jul. 2022. [CrossRef]

- B. de Ville, “Decision trees,” Wiley Interdiscip. Rev. Comput. Stat., vol. 5, no. 6, pp. 448–455, Nov. 2013. [CrossRef]

- L. Breiman, “Random Forests,” Mach. Learn., vol. 45, no. 1, pp. 5–32, 2001. [CrossRef]

- M. Bramer, Principles of Data Mining, 3rd ed. London: Springer London, 2016. [CrossRef]

- M. Cerrada, G. Zurita, D. Cabrera, R. V. Sánchez, M. Artés, and C. Li, “Fault diagnosis in spur gears based on genetic algorithm and random forest,” Mech. Syst. Signal Process., vol. 70–71, pp. 87–103, 2016. [CrossRef]

- M. Seera, M. L. D. Wong, and A. K. Nandi, “Classification of ball bearing faults using a hybrid intelligent model,” Appl. Soft Comput. J., vol. 57, pp. 427–435, 2017. [CrossRef]

- V. Vakharia, V. K. Gupta, and P. K. Kankar, “Efficient fault diagnosis of ball bearing using ReliefF and Random Forest classifier,” J. Brazilian Soc. Mech. Sci. Eng., vol. 39, no. 8, pp. 2969–2982, Aug. 2017. [CrossRef]

- D. H. Pandya, S. H. Upadhyay, and S. P. Harsha, “Fault diagnosis of rolling element bearing with intrinsic mode function of acoustic emission data using APF-KNN,” Expert Syst. Appl., vol. 40, no. 10, pp. 4137–4145, 2013. [CrossRef]

- V. Muralidharan and V. Sugumaran, “A comparative study of Naïve Bayes classifier and Bayes net classifier for fault diagnosis of monoblock centrifugal pump using wavelet analysis,” Appl. Soft Comput. J., vol. 12, no. 8, pp. 2023–2029, 2012. [CrossRef]

- J. F. Zhang and Z. C. Huang, “Kernel Fisher discriminant analysis for bearing fault diagnosis,” 2005 Int. Conf. Mach. Learn. Cybern. ICMLC 2005, no. August, pp. 3216–3220, 2005. [CrossRef]

- D. G. Ece and M. Başaran, “Condition monitoring of speed controlled induction motors using wavelet packets and discriminant analysis,” Expert Syst. Appl., vol. 38, no. 7, pp. 8079–8086, Jul. 2011. [CrossRef]

- S. Yusuf, D. J. Brown, A. MacKinnon, and R. Papanicolaou, “Fault classification improvement in industrial condition monitoring via hidden markov models and naïve bayesian modeling,” ISIEA 2013 - 2013 IEEE Symp. Ind. Electron. Appl., pp. 75–80, 2013. [CrossRef]

- V. U. Patel, “Condition Monitoring of Induction Motor for Broken Rotor Bar using Discrete Wavelet Transform & K-nearest Neighbor,” in 2019 3rd International Conference on Computing Methodologies and Communication (ICCMC), Mar. 2019, no. Iccmc, pp. 520–524. [CrossRef]

- Y. Zhang and R. B. Randall, “Rolling element bearing fault diagnosis based on the combination of genetic algorithms and fast kurtogram,” Mech. Syst. Signal Process., vol. 23, no. 5, pp. 1509–1517, 2009. [CrossRef]

- L. Wang, Y. Shao, and Z. Cao, “Optimal demodulation subband selection for sun gear crack fault diagnosis in planetary gearbox,” Meas. J. Int. Meas. Confed., vol. 125, no. April, pp. 554–563, 2018. [CrossRef]

- M. Kang, J. Kim, B.-K. Choi, and J.-M. Kim, “Envelope analysis with a genetic algorithm-based adaptive filter bank for bearing fault detection,” J. Acoust. Soc. Am., vol. 138, no. 1, pp. EL65–EL70, 2015. [CrossRef]

- J. Gaffney, D. A. Green, and C. E. M. Pearce, “Binary Versus Real Coding for Genetic Algorithms: A False Dichotomy?,” ANZIAM J., vol. 51, pp. 347–359, 2010.

- R. L. Haupt and S. E. Haupt, Practical Genetic Algorithms, 2nd ed. Wiley-Interscience, 2004.

- X. Yan and M. Jia, “A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing,” Neurocomputing, vol. 313, pp. 47–64, Nov. 2018. [CrossRef]

- M. Unal, M. Onat, M. Demetgul, and H. Kucuk, “Fault diagnosis of rolling bearings using a genetic algorithm optimized neural network,” Measurement, vol. 58, pp. 187–196, Dec. 2014. [CrossRef]

- X. Li, A. Zheng, X. Zhang, C. Li, and L. Zhang, “Rolling element bearing fault detection using support vector machine with improved ant colony optimization,” Measurement, vol. 46, no. 8, pp. 2726–2734, Oct. 2013. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).