1. Introduction

Increasingly destructive environmental impacts have been observed, alongside the urgent need to stop climate change, specially driven by the large volume of greenhouse gas emissions (GHGs) [

1,

2,

3,

4]. One of the contributions that stands out in the quest for reducing these emissions is e-mobility, referring to the use of vehicles powered by electricity, whether from the grid or distributed energy resources (DERs), replacing traditional vehicles that use combustion engines. The transportation sector plays a significant role in GHG emissions due to its high dependence on fossil fuels such as gasoline and diesel [

5,

6]. A massive transition to electric-driven transports can significantly reduce the carbon footprint and gradually contribute to sectoral decarbonization. Although, the number of public charging points are increasingly necessary in order to accomplish such transition [

7].

Furthermore, e-mobility provides greater energy efficiency. Electric vehicles (EVs) convert a larger portion of grid energy into useful work, compared to combustion engine vehicles [

4,

8,

9]. When the increasing of renewable energy generation in electricity production is considered, the environmental footprint of electric vehicles becomes even more positive, making them a more sustainable alternative. That is the case for Brazil, where renewable energy generation represents more than eighty percent of electricity offer [

10,

11]. Although e-mobility is remarked as a promising solution when massively applied in countries where renewable energy generation is significant, several studies address a considerable impact of EVSE insertion in the energy distribution systems. Even though several charging and integration methodologies have emerged in the last decade, including the possibility for vehicle-to-grid operations (V2G), these impacts on the distribution grid are still expected to be significant in the following years [

9,

12,

13,

14,

15,

16].

A second issue on the path throughout e-mobility advance is related to the importance of the business models applied [

17]. Whereas public or private endeavor, distribution system operators (DSOs) and charge point operators (CPOs) must pace with the long term economical outcomes of gradually increasing the number of charge points (CPs). Increase of the local grid capacity and maintenance costs are also significant and must be considered. Hence, a business model in the sector must cover the costs related to infrastructure scalability, energy consume and CP maintenance while still enabling an economically viable service for the EV drivers.

DSOs and CPOs can rely on microgrid-based solutions (MGs) with local photovoltaic energy generation (PV) and demand-response strategies [

18], along with dynamic pricing in order to mitigate the impacts on the energy grid and to create an economically viable service [

19]. MGs constitute a reliable and robust complement to ensure resilience and reliability in power supply to consumers, owing to issues such as instability in the main grid, including degradation of electrical power quality, periods of high load demand, and islanding occurrences [

20,

21].

The scenery in Brazil has its own characteristics, which completely differs from current reviews over European, Asian and North-American EV markets [

22,

23]. In Brazil, the advance of e-mobility must yet to overcome particular difficulties. In this context, the low demand for charging infrastructure and EV market prices (which are not yet truly competitive when traditional combustion engine vehicles are considered) can be highlighted, as discussed by the authors in [

24].

Although, as occurs in many other countries, there are governmental policies in Brazil which support initiatives designed to overcome the aforementioned issues. For instance, The Brazilian Electricity Regulatory Agency (ANEEL), through its Research and Development (R&D) programs, promotes the advancement of new technologies and business models in order to innovate regulations and benefit society, supporting cases developed by companies in the energy sector. This paper presents the solution developed in the context of the Equatorial case. The Equatorial Group is a major DSO which also operates in the energy generation and transmission sectors.

This case will implement e-mobility hubs (e-MHs) based on MGs with grid-tied and islanded capabilities as well as the validation with HIL. The validation scheme is designed to accelerate the testing process of the solution and to mitigate risks through real-time simulation, ensuring the effectiveness and reliability of the strategy before its practical implementation.

In this sense, the major contribution of this paper is a cost-driven, real-time management strategy for e-MHs in Brazil, which aggregates the following characteristics:

Mitigation of e-MH overload in case of sudden consume increase and reduction on local protective device triggering occurrence;

Capacity of prioritizing EV charging operations and overlook their power limits according to local grid-conditions, dynamic pricing;

EVSE scalability, minimizing infrastructure alterations for future installation of new charging stations;

Islanded operation with a set of control rules which guarantees safe operation for photovoltaics, avoiding generation surplus.

This paper is structured as follows. In

Section 2, an overview of the e-MH structure considered in the project is presented.

Section 3 describes the management strategy developed. Next,

Section 4 describes the implementation using HIL.

Section 5 describes and analyzes the tests scenarios considered. Finally,

Section 6 outlines the conclusions of this work.

2. Foreseen Microgrid and Their Structure - The Equatorial Case

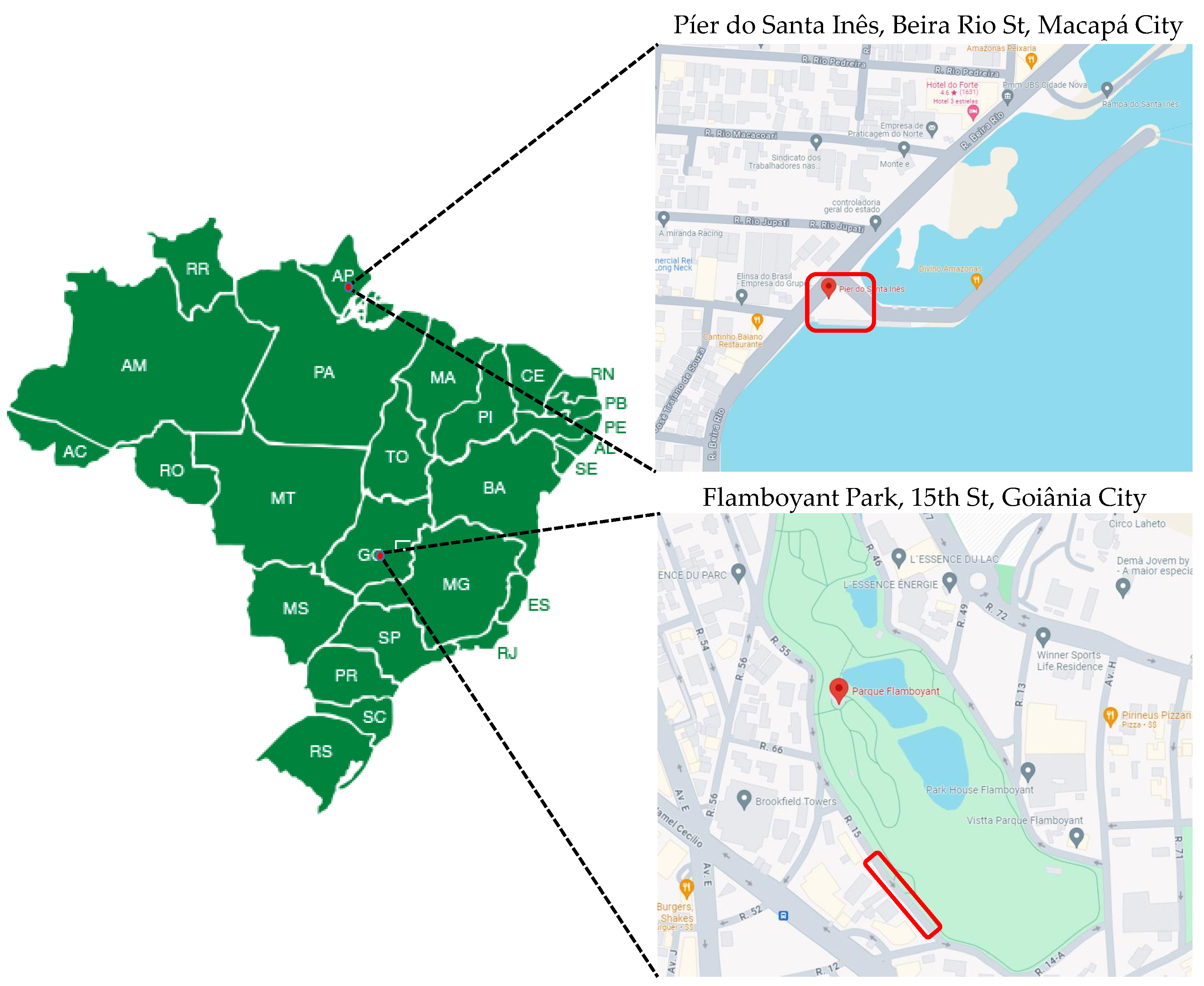

The case presented by this paper will be implemented in two different regions in Brazil. Both are attended by Equatorial:

Region 1: Macapá, the capital of Amapá state, located at North area;

Region 2: Goiânia, the capital of Goiás state, located at Central-West area.

The

Figure 1 shows the e-MH installation locations as well as city locations in Brazil. In Amapá city, a e-MH will be installed with a CP composed by two charging stations. In Region 2, on the other hand, the e-MH will be installed at a public location, with a single charging station.

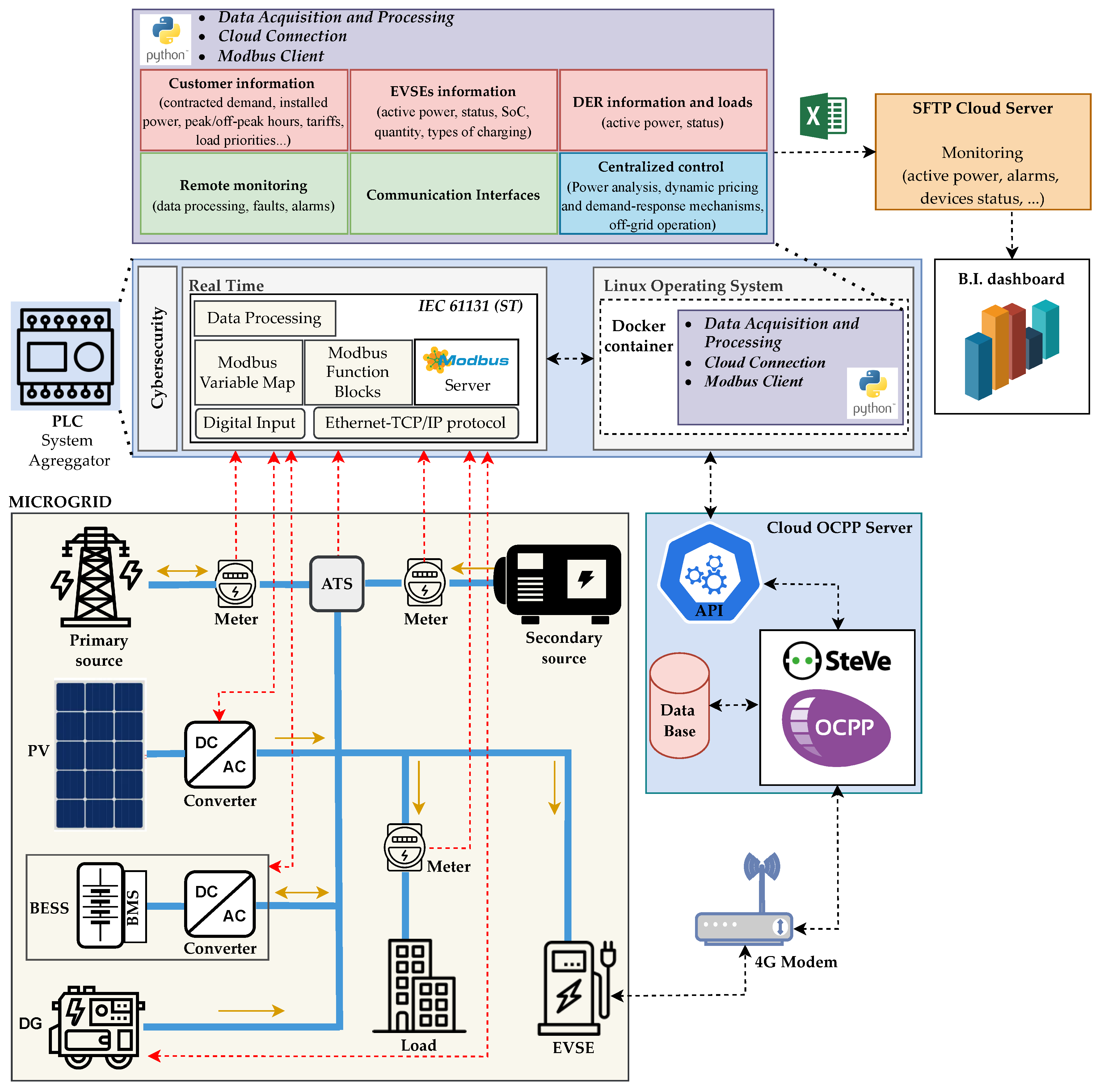

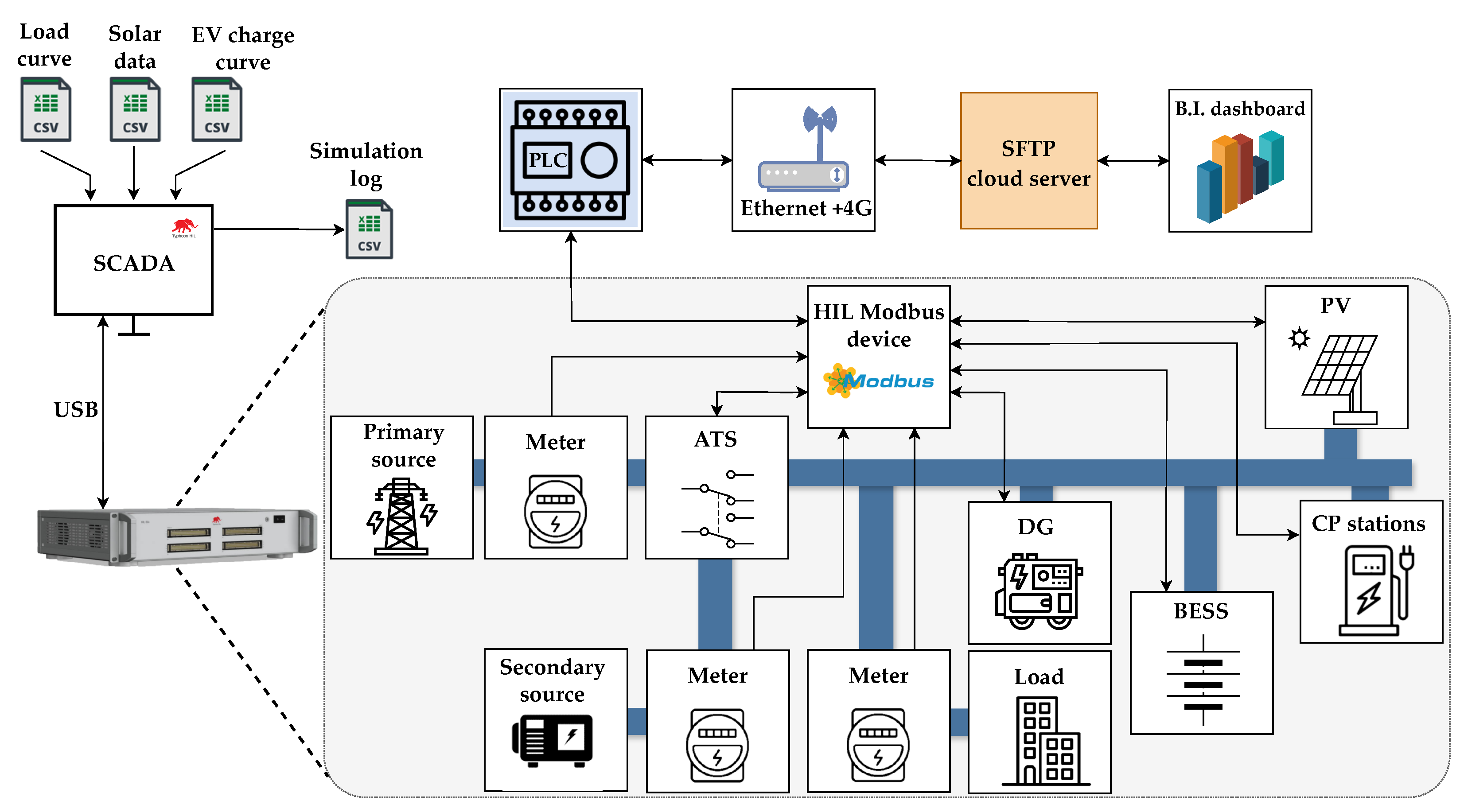

In order to present all infrastructure devices which will be used in the project,

Figure 2 shows how its components are distributed in the e-MH.

Figure 2 also shows the communication mesh that link these components to a programmable logic controller (PLC) which will host the centralized controller. This controller has all functionalities to manage the e-MH, discussed in

Section 3.

In this context, the PLC is responsible for acquire and monitor data from energy meters, EVSE and DERs: battery energy storage system (BESS), with respective Battery Management System (BMS), Photovoltaic (PV) and Dispatchable generator (DG). Moreover, the PLC is also used to establish the parameters and restrictions for energy consume and energy generation.

The energy meters allows tracking the power provided by the e-MH primary energy source (distribution grid) and secondary source. A third energy meter tracks the power drawn by the local loads. This tracking, used for both operation modes (islanded or connected) is essential for the controller in order to execute the decision making. When the primary source is absent, the secondary source is started by the automatic transfer switch (ATS). The ATS also sends signal to the PLC, through its digital input module, indicating if the e-MH is operating in connected or islanded mode.

There are two AC-DC converters planed for each e-MH site, for BESS and PV respectively. The PLC receives the power measurements provided by both converters and control their operation. For the PV, the PLC may limit the energy generation by saturating the output for the maximum power point tracking algorithm (MPPT), which acts on the converter control. As for the BESS, PLC is responsible for deciding its operation mode (charging or discharging) and for controlling its power reference.

In the upper portion of

Figure 2 it is possible to observe the PLC application structure. This architecture is divided in two sections: real-time (RT) and Linux operational system.

The communication between PLC, meters, converters and DG is implemented through RT functions, following IEC 61131-3 specification. The RT portion also hosts a TCP modbus server with an equivalent memory space for all maps from the equipment which will be installed on site. Therefore, all values read from equipment on site are copied to the modbus server map. On the Linux portion, a Docker container is used to execute the Python application. This application includes the controller functionalities for the e-MH energy management (acquisition, processing and data monitoring), TCP modbus client, an API client, the customer information and the system logger. With this implementation, it is possible to exchange information between RT and Linux through TCP modbus.

Therefore, the modbus client at Linux executes a request command when it is necessary to read or write a value to the modbus server running at the RT portion. For example, if a meter measurement is necessary for the energy management running in the Python application, its modbus client will read the last measurement available for that meter at the modbus server, running at the RT portion.

For the operation, the PLC communicates with two cloud-based servers: an OCPP server (from Open Charge Point Protocol acronym) and a SFTP server (from Secure File Transfer Protocol). The communication between EVSE and the controller does not depend on the RT functions, as observed in

Figure 2. This communication is handled by the OCPP server, which is, in fact, an SteVE instance. SteVE (name derived from Steckdosenverwaltung, socket administration, in German) is a java-based software distributed under general public licence (GPL). Its development started at the RWTH Aachen University in 2013 and its aim is to support the deployment of electric mobility [

25]. This software package contains all major functionalities described in the OCPP protocol, hence, allowing the remote control of EVSE as well as authentication and transaction-related data storage. SteVE also has an adjacent API implemented, which will be extended in order to allow requests to be made automatically by the PLC, using a 4G modem.

For monitoring consumption and energy generation, as well as providing alarms and fault identification, the Python gathers essential information such as energy consumption, generation, and event logs, device status, which are then securely sent to an SFTP server. Power BI processes this data into interactive dashboards and reports, allowing for detailed real-time monitoring and analysis of the energy system.

Table 1 shows installed and contracted capacity values for the e-MH considered. The equipment operational limits are shown in

Table 2. These constitute some of the major parameters considered by the controller while solving the power dispatch calculation and taking decisions concerning the e-MH management.

Finally, with the e-MH structure of the project presented, the following section aims to detail the implementation of the centralized controller, demonstrating how its functionalities were designed to operate while managing the e-MH.

3. Management Strategy

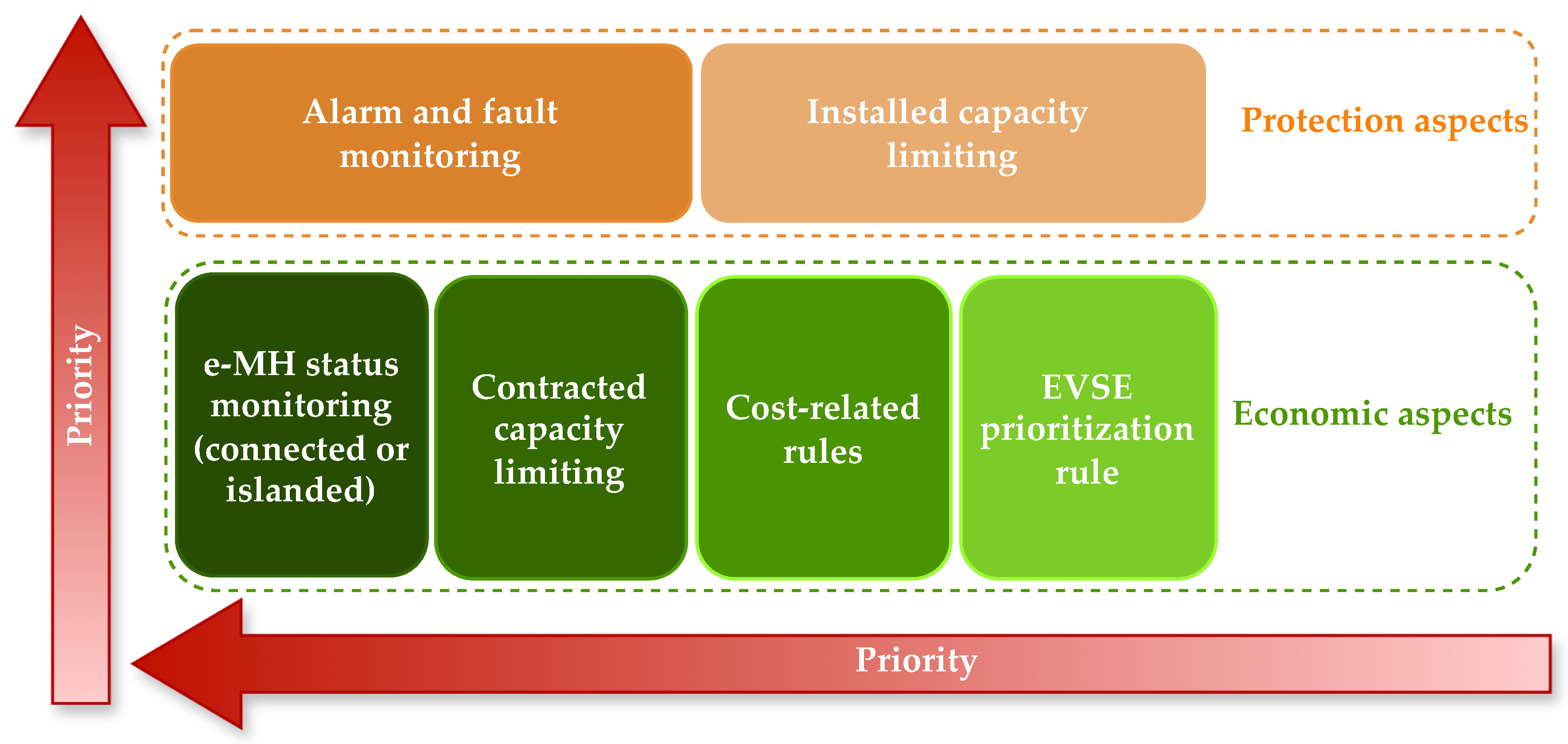

This section will explore the e-MH management strategy for the Equatorial case. This strategy has two distinct functionality groups: protection functionalities and economic functionalities. At

Figure 3, the protection functionalities guarantees the e-MH safety by prioritizing the detection of possible issues and preventing the e-MH from danger or compromising events. That includes alarm monitoring and fail identification, which can mitigate possible problems on the e-MH operation. Thus, given its importance, the protection group receives the higher priority.

The economic group is focused on efficiency and optimization while using energy resources. For this group, the management strategy considers variables as e-MH grid status (connected or islanded), peak-demand hours, contracted capacity, energy prices (which may vary dynamically), BESS state of charge (SoC). Other factors are also considered part of the strategy as well as reducing the consume of diesel and maximizing BESS life expectancy.

It is also important to establish the inner-group priorities. For the protection group, alarm and fault monitoring have more priority than installed capacity limiting even when e-MH is islanded, given its importance in case, for example, of a failed protective device. Similarly, considering the economic aspects group, the e-MH status monitoring is the rule with higher priority, followed by contracted capacity limiting, cost-related rules and EVSE prioritization rule. This hierarchy seeks to balance economic aspects, operation reliability and yet to allow charge prioritization. The following sections give a detailed view for each of the functionalities.

3.1. Alarm and Fault Monitoring

The

Table 3 resumes the eight alarm types monitored that could be activated by the controller proposed. The

Table 3 also shows the alarm activation conditions. The controller constantly evaluates its activation conditions. Besides logging its occurrence, the controller also try to mitigate the problem detected in case of an alarm triggered. This section continues by explaining each alarm.

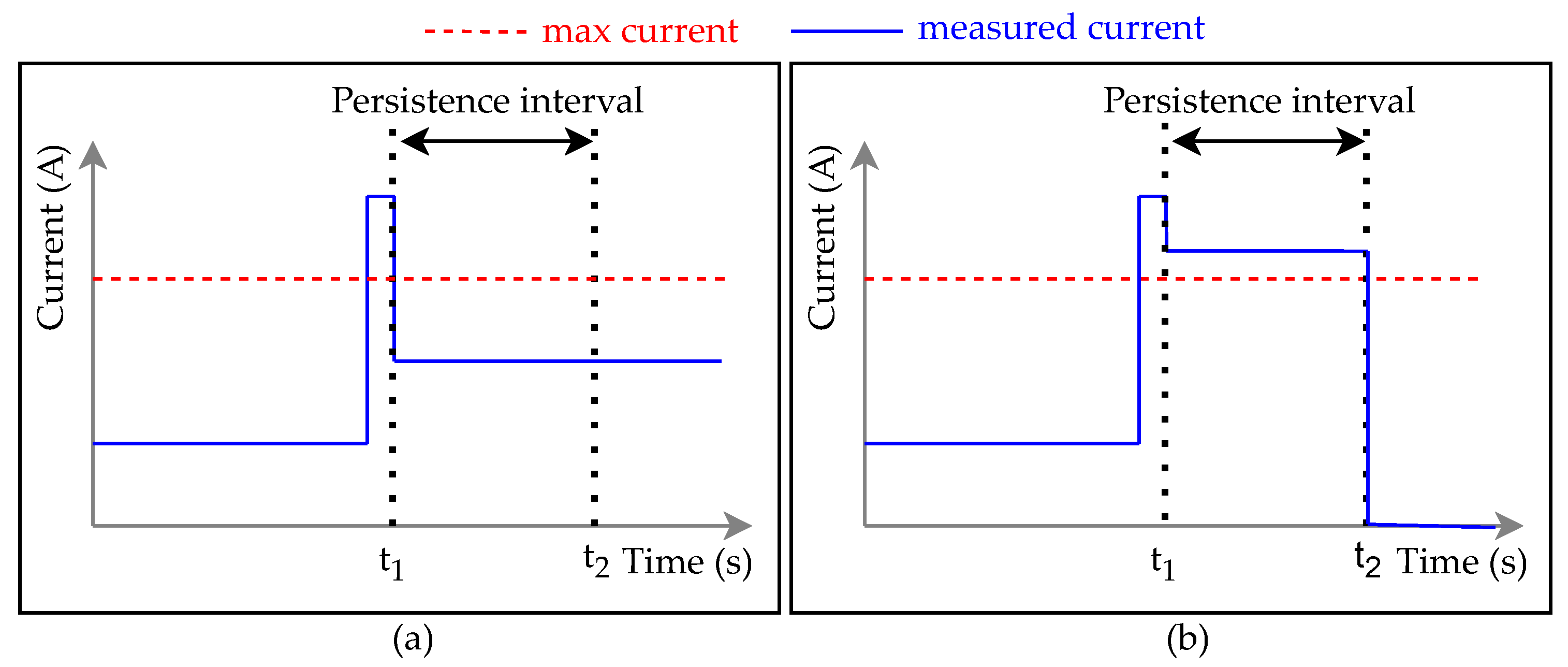

3.1.1. Alarm 1

The first alarm concerns the identification of an overcurrent occurrence, as illustrated by

Figure 4. The consumer unit meter records the measured currents, and the controller compares them with a preconfigured value. If the measured value exceeds the configured maximum value, the alarm is activated and the power available to the CP is reduced to a protective value. This reduction should be followed by a decrease in the measured currents at the input. Currents are then evaluated for a time interval,from

to

. The power available to the CP remains at a protective value if there is no more overcurrent occurrence in this interval. Otherwise, the power available to the CP will be reduced to zero, stopping its operation.

3.1.2. Alarm 2

The alarm 2 is triggered whenever a meter sends an error status. The power available to the CP is reduced to a protective value whenever such error is identified. Also, in that case, DER power references are reduced to zero if the e-MH is operating in connected mode. For islanded case, the BESS reference is only reduced after the PV power is checked to be zero.

3.1.3. Alarm 3

Alarm 3 is activated when there is a fail status coming from the PV converter. After its activation, the controller sets the PV power limit to zero. If the e-MH is operating in islanded mode, the controller also reduces BESS power reference to zero in case PV power actually reduces to zero.

3.1.4. Alarm 4

Alarm 4 is similar to alarm 3. It is triggered whenever the BESS converter sends an error status. In that case, if e-MH is operating in connected mode, the controller only reduces the BESS power reference. For the islanded mode, on the other hand, it is necessary to reduce PV power to zero prior to reduce BESS power to zero.

3.1.5. Alarm 5

Alarm 5 is triggered when an error status is captured for the DG. In that case, controller will set its power reference to zero. By default, the DG is only used when e-MH is in connected mode, therefore this alarm can only occur while in connected mode. The DG is not considered for islanded mode in order to keep power balance and avoid energy generation to exceed the power drawn by the local loads and CP in case one of them have a sudden reduction in their use.

3.1.6. Alarm 6

Alarm 6 is triggered when a faulted status is captured for a charging connector, being immediately removed from the prioritization rule. Its power limit is also reduced to zero. This occurrence is logged and later used to schedule corrective maintenance. This data may also be used to inform the drivers that connector is not available in the area through driving assistance applications.

3.1.7. Alarm 7

The alarm 7 is activated whenever there is communication is lost between PLC and meters or between PLC and DERs. Loss of communication with meters will also result in activation of the alarm 2 and its protective measures. This approach is also used for any of the DERs, which would trigger alarms 3 to 5 as well as their protective measures, as described in

Section 3.1.3 -

Section 3.1.5.

3.1.8. Alarm 8

Alarm 8 is triggered when there is communication loss between OCPP server and PLC. In this situation, controller is not able to send requests to the API. Therefore, in that case, controller must consider the last connector status received and last power references set for the connectors until communication resumes. By looking at the monitoring data, CPO should be able to identify this communication fault in case becomes persistent, reconfigure CP for stand alone operation and schedule corrective maintenance.

3.2. e-MH Status Monitoring

The controller identifies whether the e-MH is operating in connected or islanded mode. In connected mode, contracted capacity limiting, cost-related rules and EVSE prioritization functionalities are applied. In islanded mode, the functionalities of installed capacity limiting and EVSE prioritization are applied. The controller also incorporates a strategy that allows BESS to be recharged using the energy generated by the PV plant when the e-MH is operating in islanded mode, as represented by

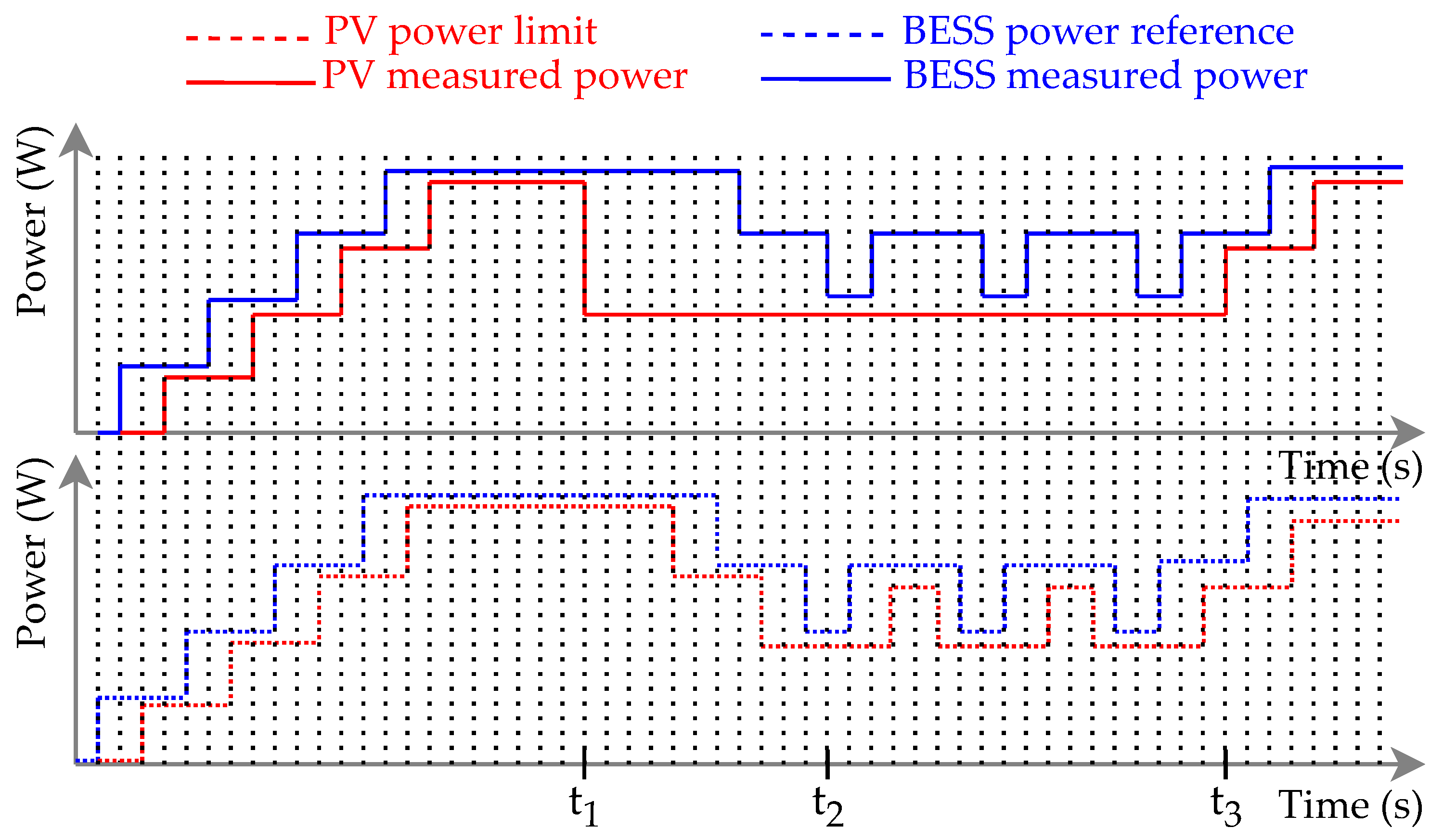

Figure 5. The goal is to ensure that the BESS is recharged almost exclusively with energy produced by the PV plant, in a safe manner.

Upon identifying that the e-MH is in islanded mode, the first action taken by the controller is to limit the available power for the CP to a maximum value, which is previously configured by the CPO in the consumer information parameters. Initially, the BESS power reference and PV generation limit are reduce to zero. From this moment on, the BESS begins to increase its reference power. When the measured power of the BESS reaches the reference, the controller increases the generation limit power of the PV system to 90% of the increment made in the BESS. In

Figure 5, it can be observed that the PV generation limit is always smaller than BESS power reference. This increment is repeated periodically for both BESS and PV generation while there is enough solar irratiation for PV generation to reach its limit. In that case, BESS power reference may be increased until reaches 60% of its rated power. However, if a decrease in solar irradiance occurs during this process of increment, the controller starts to decrease the PV generation limit, as shown at time instant

at

Figure 5. In that case, the reference power for BESS is also decreased, subsequently. The values of the decrements made for the PV system and BESS are the same as those applied during the increment. At

, BESS charging power is again close to power provided by PV generation.

In the example given in

Figure 5, after

, the controller starts increasing the BESS reference again. Once BESS power becomes close to the reference power, the PV generation limit is incremented again to check if the PV could increase its generation. However, unlike the condition before

, the PV power does not increase because the solar irradiation is still low. After this moment, the PV generation limit is decremented again, followed by a decrement of the BESS reference. In this way, the controller always checks if there is enough PV generation to recharge the BESS, assessing if the power generated by the PV is following the power measured in the BESS as desired. This check is done by periodically increasing BESS power reference followed by the an increase in PV generation limit, as shown between the intervals

and

.

At , after the increment on PV generation limit, the generated power increased, allowing another increment in the reference power of the BESS, and so the cycle repeats. It is worth noting that the BESS recharge is not entirely done by the power generated by the PV. However, as mentioned earlier, the strategy aims to minimize the use of the secondary source as much as possible to recharge the BESS in islanded mode.

Lastly, in islanded mode, the BESS is discharged only when the sum of the measured power in the load and EVSEs exceeds the discharge limit configured, established at 60% of the nominal power of the BESS.

3.3. Safety and Protection Rules

The contracted capacity must not be exceeded while e-MH is operating in connected mode. That is essential to avoid extra costs due to penalties for excessive energy consumption. On the other hand, the installed capacity must not be exceeded while e-MH is operating in islanded mode. That is important to prevent overload that could compromise all equipment in the circuit. Thus, both functionalities play crucial roles, whether e-MH is connected or islanded.

The strategy explained below applies to both functionalities i.e. both operating modes. Equation

1 is used to determine the threshold value to active the functionality. The value of

represents a power limit, calculated by multiplying two factors. The first factor,

, represents the value of the installed or contracted capacity, depending on the context in which the equation is applied. For example, if we are dealing with the installed capacity limiting functionality,

would represent the installed capacity. Similarly, if we are dealing with the contracted capacity limiting functionality,

would represent the contracted capacity. The second factor,

, is a ratio that indicates how far the power limit is from the actual contracted or installed capacity. For example, if

=0.9, this means that the power limit is a 10% of the contracted or installed capacity. This equation provides a flexible way to adjust the power limit based on the specific requirements of the e-MH and its operational conditions.

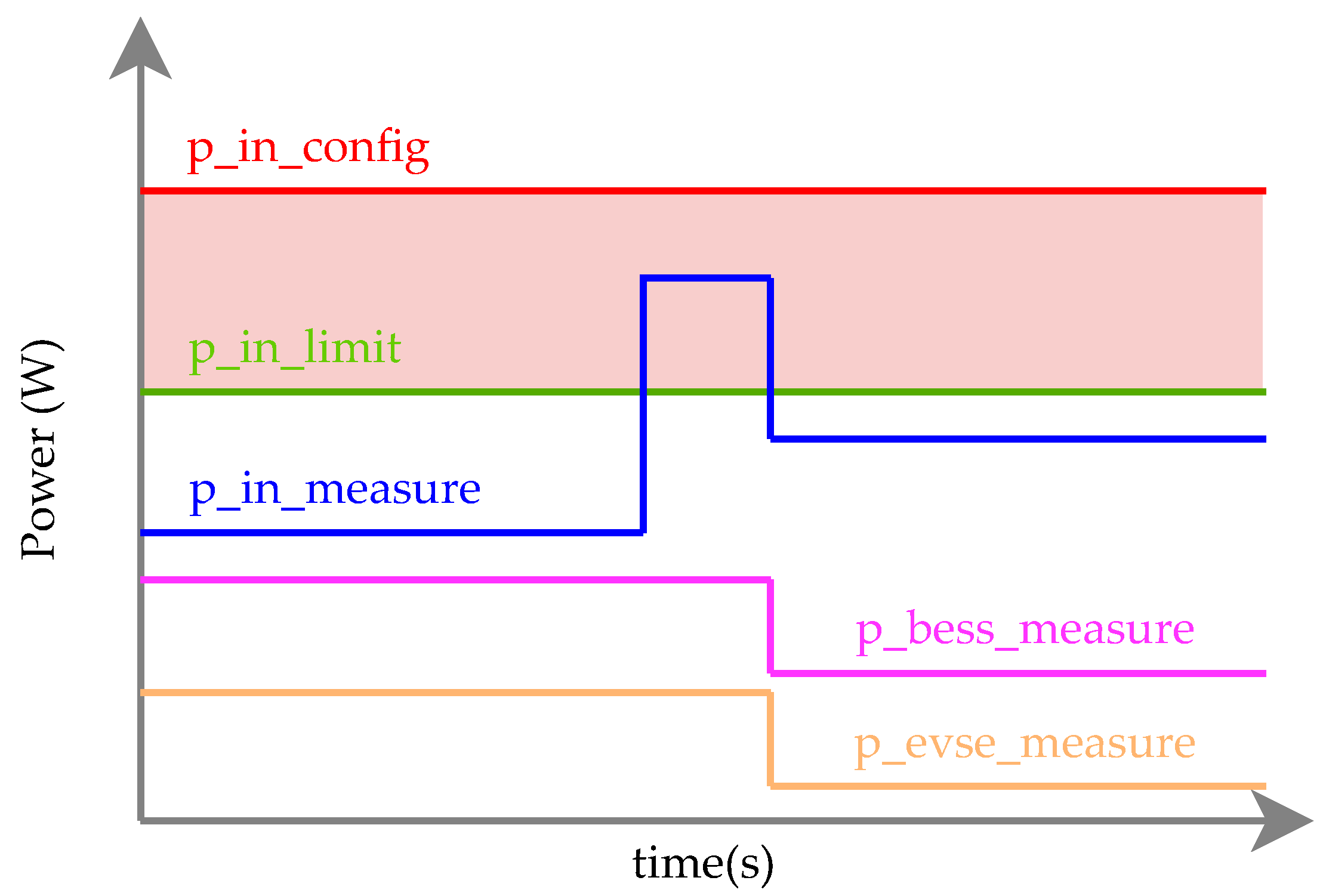

Figure 6 provides a better understanding of what has been presented and also helps understanding the next equations of this strategy.

As shown in

Figure 6, the strategy aims at constantly check if input power of the e-MH (

) has exceeded

. The controller intervene in BESS power reference (equations

2 and

3) and in the CP available power (equations

4 and

5) if

exceeds

.

In case of overload, if the BESS is in discharge mode, its reference power (

) is reduced to decrease

. On the other hand, if the BESS is in charge mode and overload occurs, its reference power is increased to help compensate for the increase in e-MH demand, always respecting BESS rated power (

). Subsequently, the controller also reduces the available power to the CP (

). The value calculated for the CP is divided among its busy connectors using the prioritization rule, as will be detailed in

Section 3.4. Therefore, both adjustments result in

returning to a value below

.

In equations

4 and

5, the value zero is assigned to

if there was a need to increase

and if this increase causes

to be greater than

. Otherwise, the value 1 is assigned. On the other hand,

indicates whether the BESS is able to change

. These conditions are listed below:

The power limit acts as a safety margin to prevent from reaching values close to the contracted or installed capacity. However, it is important to highlight that this margin does not guarantee that input power will never exceed the limits in transient situations since it depends on factors as the value chosen for , load variation and communication delay for the measurements. The appropriate choice of should be evaluated based on the e-MH characteristics, considering its responsiveness to load variations.

Finally, since the contracted capacity must be below installed capacity, both functionalities will prevent the measured power to reach installed capacity.

3.4. EVSE Prioritization Rule

The recharge prioritization functionality creates a list with all busy connectors, which are sorted according to the time since each authentication. The first element of this list corresponds to the connector that has been busy for the longest time. The last element corresponds to the connector which is busy for the shortest time. Additionally, the functionality establishes that each connector in this list should receive a weight, with the value of each weight related to the time the connector is occupied. For example, the first element of the list has a higher weight, while the last element of the list has a lower weight.

The CP power is distributed among the connectors according to the weights given in the prioritization rule. The connector with the highest weight receives a larger share of the CP power, while the connector with the lowest weight receives the smallest share. The list is updated every time a connector has its status changed. The controller reorganizes the list, updates the weight assigned to each connector, and redistributes the power.

The EVSE prioritization offers an advantage by allowing busy connectors for longer periods to receive a larger share of the available power. This approach speeds up the charging process and minimizes waiting time for a parking space at the charger.

3.5. Cost-Related Rules

This functionally defines which criteria are used to determine the dispatch of power from the DG, to charge and discharge the BESS and to establish the CP power limit in connected mode. These criteria uses the energy tariffs for the electrical grid, DG, BESS, and CP. The controller verifies whether the e-MH is operating during peak hours or not, the amount of fuel in the DG, BESS SoC and e-MH input power.

The tariffs can be changed during the operation of the e-MH e.g. in dynamic pricing application. These changes also prompt the controller to adjust the power balance during the operation.

Table 4 presents the description of the parameters and variables used to define the minimum criteria. Subsequently, the minimum criteria for the use of the DG and BESS are presented.

Minimal criteria for DG use:

- 1.

-

If :

Minimal criteria for BESS use in discharge mode:

- 1.

-

If

Minimal criteria for BESS use in charge mode:

After defining the minimum criteria, the cost rules are used to control the e-MH power dispatch.

Table 4 presents the description of the parameters for this functionality.

When , no power should be dispatched by the DG. In that case, only CP power limit and BESS reference are defined, based on the tariffs and .

On the other hand, if , DG power reference is also defined:

- 1.

-

If :

-

If (:

- (a)

-

If :

- (b)

-

If :

-

If (:

- (a)

- (b)

- 2.

-

If :

-

If :

- (a)

-

If :

-

If :

- (i)

- (ii)

-

If :

- (i)

- (ii)

- (b)

-

If :

-

If :

- (a)

- (b)

- (c)

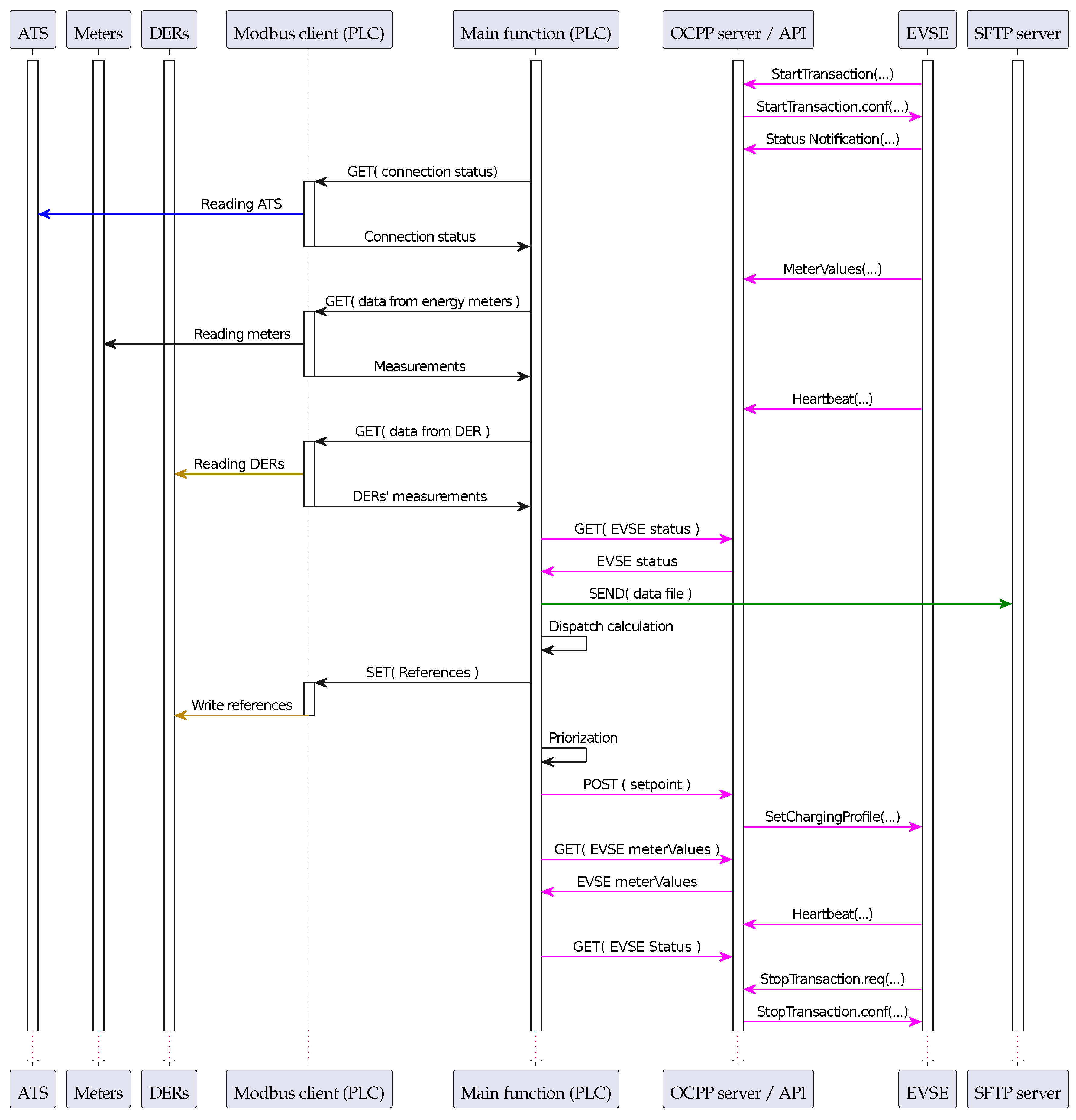

3.6. Data Acquisition and Data Flux

A significant part of the control strategy proposed relies on the communication between the PLC, e-MH equipment, and cloud servers.

Figure 7 presents a simplified sequence diagram for the project. The diagram shows the order in which the PLC executes his tasks and which type of information is exchanged. In general, data from equipment on site will be acquired by using modbus or using PLC digital input channel. In the sequence, data from EVSE is acquired through API requests. Once all necessary data is acquired and copied to SFTP server, the PLC application calculates the power dispatch and sends the DER references using modbus. In the sequence, prioritization rule is executed using the CP power limit computed so the EVSE setpoints can be posted back to the OCPP API, which relays them to the charging connectors.

It is important to observe that communication delays must be considered in the control processes. Communication delay may be attributed to a range of factors including physical distance between equipment, processing capacity, communication bandwidth among other causes [

26,

27,

28,

29]. Although unlikely to happen, a large delay in communication (>>5s) could cause safety issues. To mitigate the problems in such case, the controller implementation considers an upper limit on the communication delay. If delay exceeds this threshold, an alarm signal is generated by the controller and the appropriate actions are taken, as detailed in

Section 3.1.

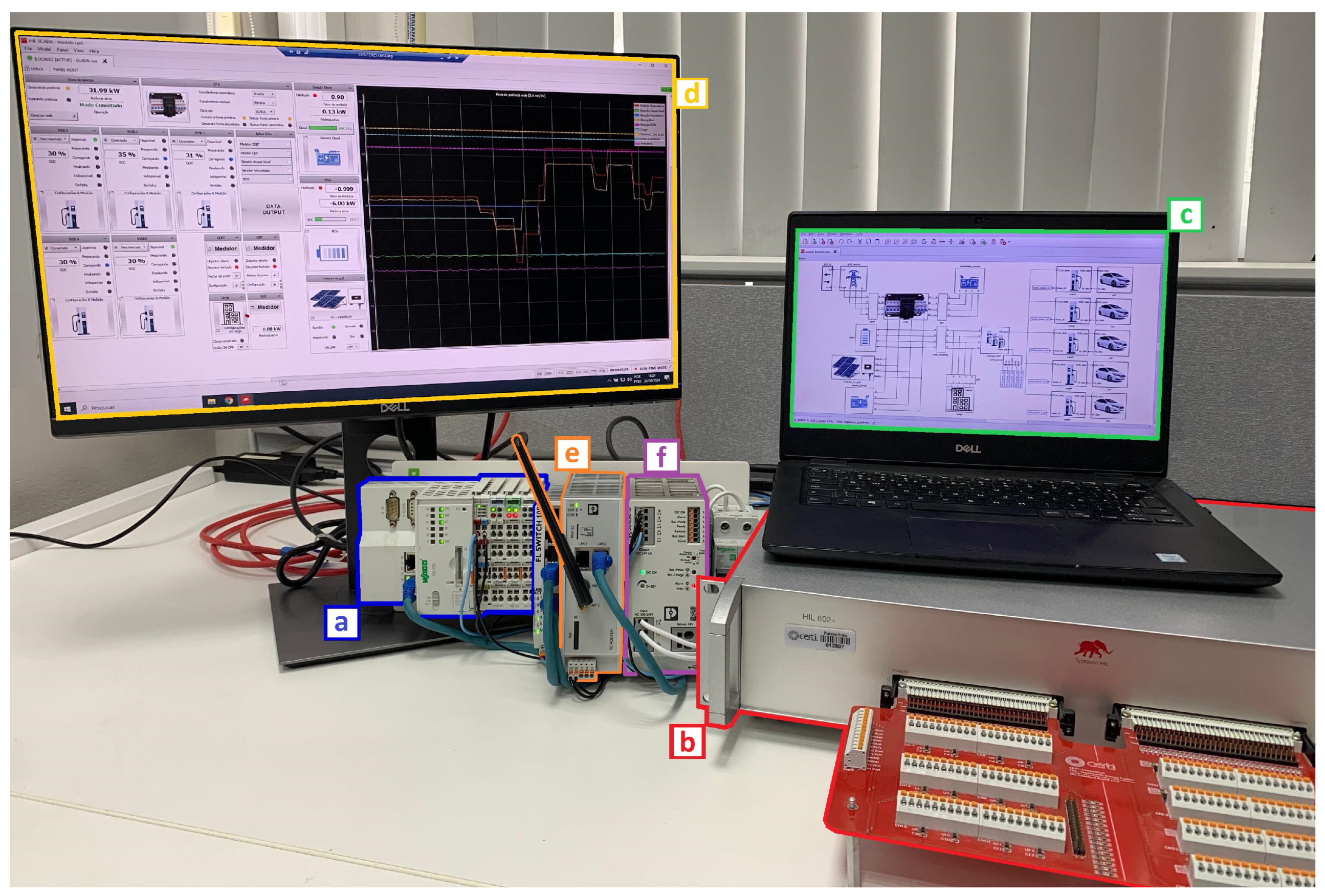

4. Hardware-in-the-Loop Implementation

This section presents a HIL implementation for the project infrastructure and management solution proposed. The HIL technology was introduced on the last decades and its use is becoming a standard step in design and optimization for automatic control development. This technology is specially useful for power systems, where, in practice, equipment replacement capacity is low and tests may involve risks of varied types.

In many cases, tests using simulations in real time with HIL also require less time and spend less financial resources when compared to practical tests [

30,

31]. Thus, the e-MH described at

Section 2 was modeled using Typhoon HIL 602+ (HIL device) as represented in

Figure 8.

For the HIL model, all communication between the PLC and CP was implemented using Modbus, reducing the communication complexity by skipping the cloud OCPP server. However, since transport delay is an important aspect to be considered in the management strategy proposed, time delay blocks were included for all components in the HIL model which communicate with the PLC. These blocks were configured to represent the total amount of time delay expected after the project commissioning.

For the validation, comma-separated value files (CSV) are used to input real data in the simulation. That is the case for the local load curve, the EV charge curve and solar irradiation. The initial time of the day is configurable through the SCADA main script so the tests can comprise a wide range of scenarios. These input values can also be overthrow if a fix value is necessary.

For the tests, the PLC application periodically accesses data received from all meters, DERs, ATS and CP while the real-time simulation is running in the HIL device. The HIL device uses a FPGA-based multi-core processor optimized for time-exact simulation of electrical domain models [

32]. In the model implemented (HIL model), the electrical and signal processing components are distributed for different processing units (CPUs) in order to enable parallel computing. This partitioning reduces memory usage and allows the use of a smaller base time step in the FPGA solver, which is important to faithfully reproduce the electric circuit behaviour.

The base time step must be chosen observing the mathematical complexity and the level of detail targeted for the model. For the case presented in this paper, it is important to achieve accurate power flux for the 60 Hz electrical system and to represent the communication between PLC and each of the e-MH components. Also, the project does not include power converter design validation nor islanding detection algorithms i.e. it is not necessary to analyze high frequency switching effects. Moreover, the hardware components considered for the actual e-MH installation are commercially available already, thus can be considered individually validated. Hence, the electrical components used in the HIL model are based on averaged model present in the Typhoon standard libraries. Therefore, the base time step chosen for the FPGA solver is s. This value is small enough when compared to the electric system period ().

The HIL device also uses various execution rates, which must be a base time step multiple number. This resource is useful because some model components have an inner control mesh or signal processing block that requires frequency decoupling e.g. DG control or the PV MPPT. For the case presented in this paper, the main execution rate is and inner control meshes uses .

Overall, during a HIL simulation, the proposed controller constantly calculates the power dispatch for all controllable components considering the data acquired from HIL and the functionalities described in

Section 3.

5. e-MH Test Setup

In this section, five test scenarios are used to demonstrate the e-MH operation while governed by the proposed controller using the HIL implementation described in the

Section 4. The experimental setup used can be observed in

Figure 9. The PLC used is the Wago PFC200.

In all scenarios, the customer information is fed to the controller as described in

Figure 2, which also includes the power limits to be considered. The results use the same signal convention from

Section 3. The BESS power is represented as negative value for charging operation and as a positive value for discharging operation. In contrast, the consumer unit meter gives a negative power measurement when the e-MH is delivering energy to the grid.

The controller constantly checks for possible modifications in the input parameters. Hence, items of the customer information can be modified during the operation, in order to modify the controller behaviour itself, according to the features described in

Section 3. For instance, in all scenarios of this Section, the values for the energy tariffs starts normalized such that

. However, the prices could be modified on the run according to a DSO or CPO order. This modification would then lead to changes in the controller behavior, as commonly adopted in demand-response and dynamic pricing strategies.

For each of the scenarios described in the following sections, the HIL device is started through the SCADA panel, starting the real time simulation and, at the same time, data collection, which is copied to the CSV file. After model initialization in the HIL device, the PLC is started, starting its communication with HIL, using the TCP modbus protocol. Lastly, unless explicitly mentioned otherwise, consumer unit parameters and component rated power are the same as in

Table 1 and

Table 2, respectively.

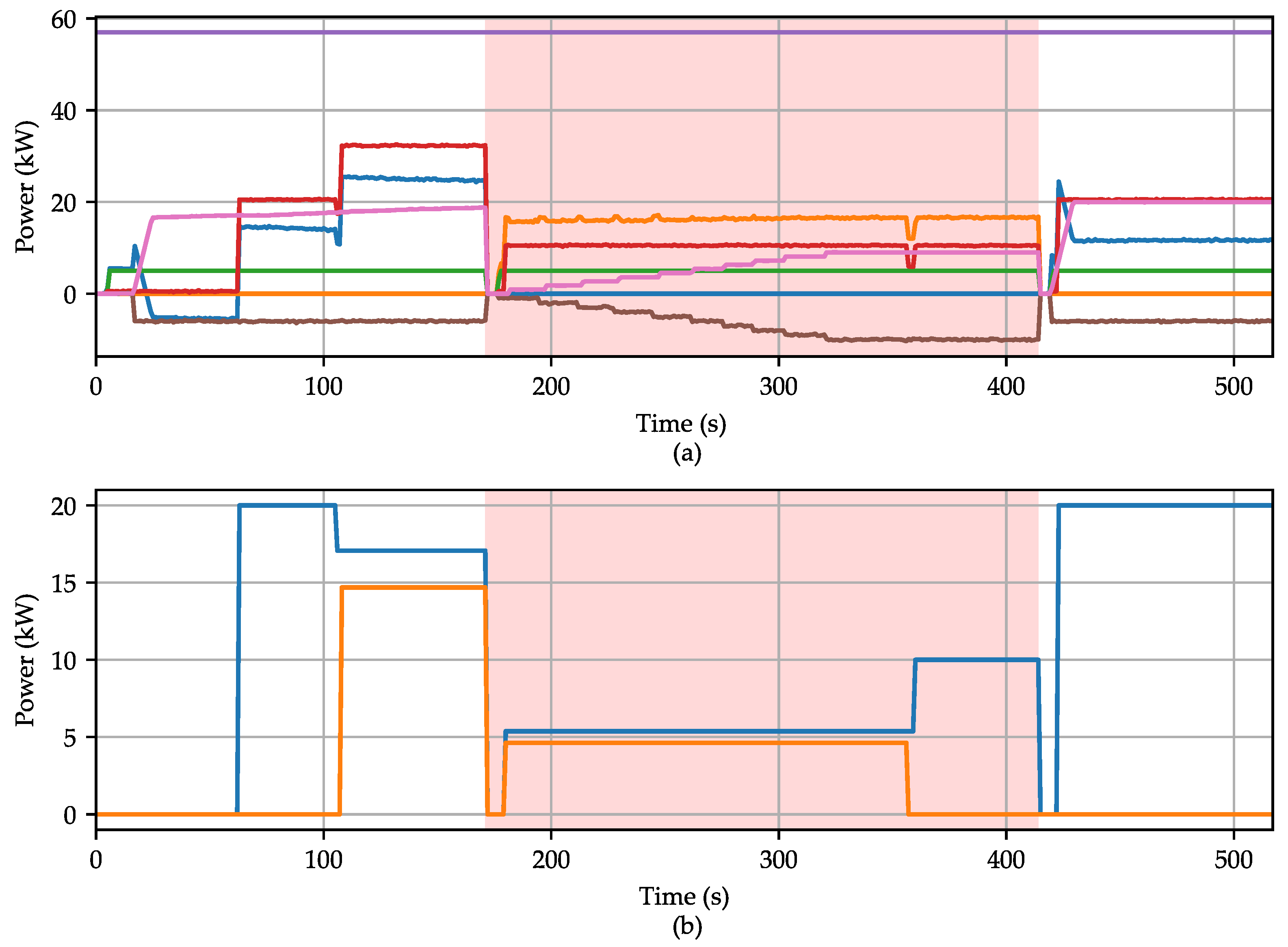

5.1. Scenario 1 - Islanding and Re-Connection

The first scenario major objective is to demonstrate the general behavior of the controller for EV charging operations in connected and islanded modes.

Figure 10 presents the results for Scenario 1.

When operation starts, the controller increases the PV limit to its rated power at the same time as charges the BESS at a slow rate. Since the local loads are the only other component draining power from the e-MH and solar irradiation is high enough at the moment, the energy surplus is delivered to the grid. After 60 seconds, an EV charging operation starts, using connector 1, as observed in

Figure 10b.

Initially, since there is only one connector in use, the controller allows maximum power (20 kW) for connector 1. However, as a second EV requests to recharge using connector 2 after 110 seconds, the controller decreases power reference for connector 1 in order to keep the e-MH consumption within power restrictions. It is important to observe once more that allowable power for the CP does not account current PV generation, because its intermittence is expected.

An islanding event occurs at 175 seconds, stopping all operation for a few seconds. When ATS switches to the secondary source, the charging operations are resumed and the original priority order is kept. Local loads are also attended. However, CP power is limited to a 10 kW maximum while the e-MH is operating in islanded mode. The controller also resets BESS charging and PV operation using the mechanism described in

Section 3.2. This mechanism will be better detailed through the results shown at

Section 5.3.

After 350 seconds, the EV at connector 2 stops its charging procedure so the controller can now increase the power allowed to connector 1 without increasing overall CP energy consume, as observed at

Figure 10a. When e-MH is reconnected, at 415 seconds, the controller can again set the PV connector 1 limits to their respective rated power. Also, the BESS charging operation is again set to slow charge.

Therefore, as observed through

Figure 10a and

Figure 10b, the controller proposed prioritizes the charging operations according to the order of occupation and maintain this information as long as EVs are still connected to the CP. In terms of BESS use, slow charge operation is preferred when e-MH is connected to the grid in order to maximize battery life. In islanded operation mode, the controller reduces CP maximum power and regulates BESS charging according to PV power availability. Overall, in islanded mode, the proposed controller reduces energy consumption and avoids energy generation surpass.

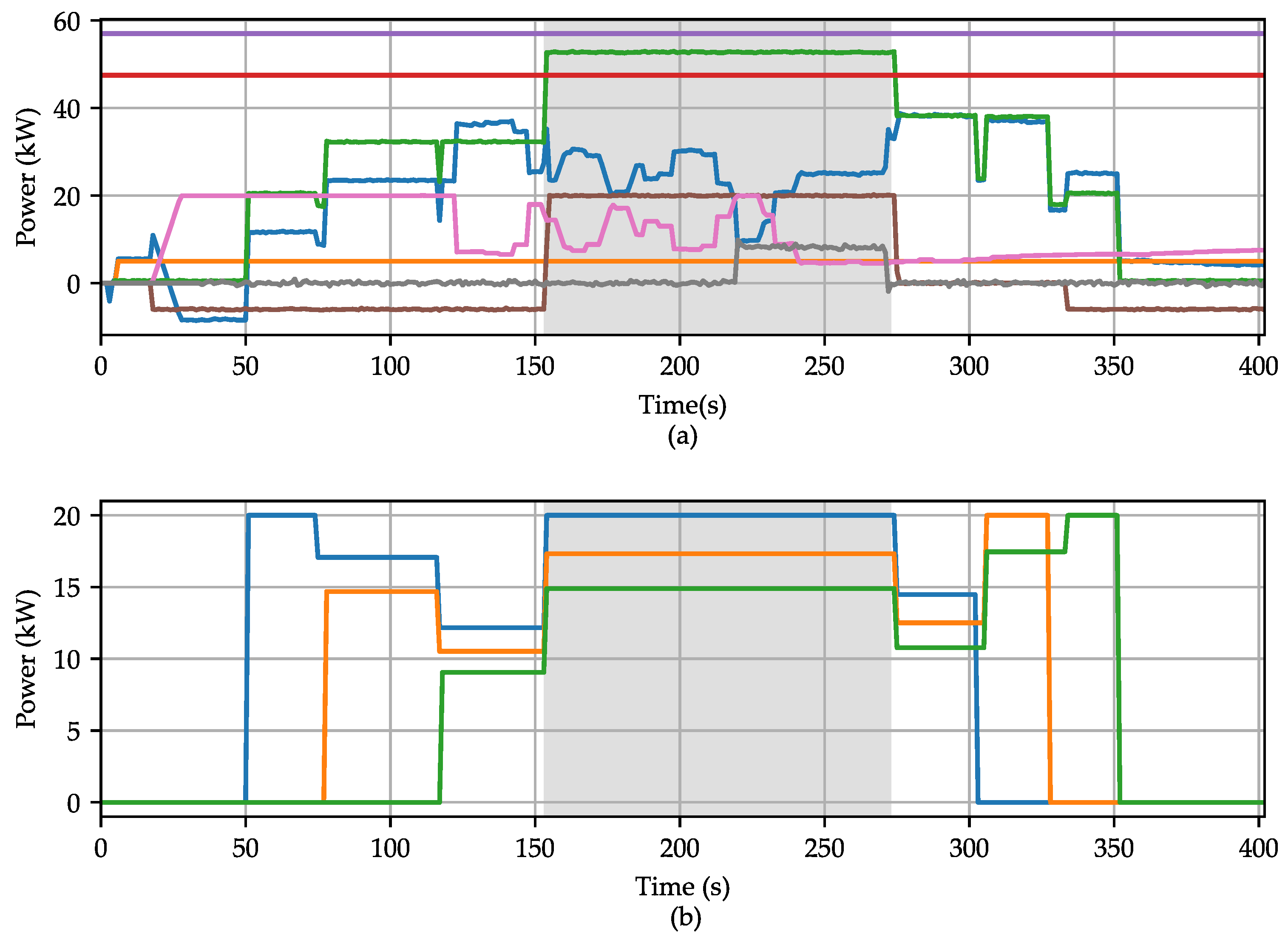

5.2. Scenario 2 - Peak Demand Period

Figure 11 presents the results obtained for the test scenario 2. Its major objective is to demonstrate the proposed strategy concerning demand peak time and demand-side actions i.e. using the cost-related rules presented in

Section 3.5. In addition, for Scenario 2, the DG is also considered.

As in the initial seconds of Scenario 1, PV limit is set to its rated power at the same time as BESS is set to charge at a slow rate, as shown by

Figure 11a. The behavior concerning EV charging is also similar to the previous test. More priority is given to EVs connected first, as can be observed in

Figure 10b. At 125 seconds, solar irradiation starts to vary, which causes PV generation to oscillate between 5 and 20 kW.

After 150 seconds, the peak demand period starts. At this moment, the controller changes BESS to discharge mode, providing more power to the CP, dispatching more power to the EVs, without increase energy consumption from the grid. After 220 seconds, the grid energy tariff () is increased. Also, the tariff value for DG use () is decreased (i.e. ), simulating a demand-side action in order to compensate solar generation decrease and overall consume at the grid during peak demand time. Therefore, at this moment the controller sets the DG power reference to 10 kW in order to supply part of the energy consume at the e-MH as PV generation decays.

When the peak demand period finishes at 275 seconds, all tariffs are set to their original values i.e. . Therefore, there is no longer advantage in DG use in terms of costs. Also, since BESS is no longer in discharging operation, the power allowed for EV charging is decreased to around 40 kW. After 330 seconds, CP consumption reduces and PV generation increases so the controller resumes BESS slow charging operation setting is reference to -5 kW. The last charging connector is released at 355 seconds, making overall energy consume to decrease under 5 kW with a slightly increase in PV generation.

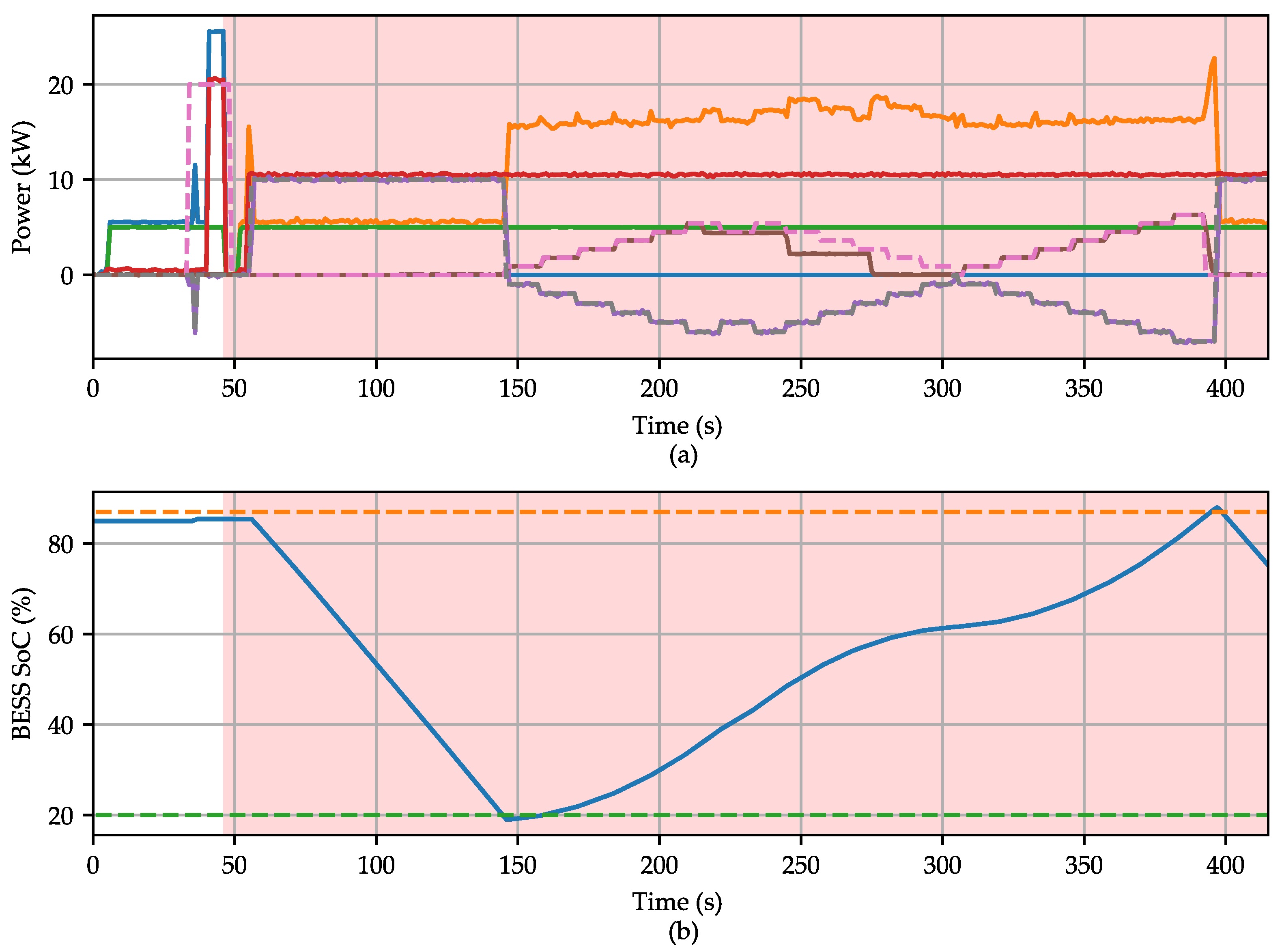

5.3. Scenario 3 - Islanded Operation

The third scenario considered, shown in

Figure 12 is focused on the islanded operation and gives a detailed view on BESS and PV operation. For this scenario, the BESS model capacity at HIL was significantly reduced in order to demonstrate a complete cycle of charge within a short period of time. Also, BESS SoC was set to start at 85%.

Once more, at the beginning of the test, an EV is connected to the CP. After 45 seconds, islanding occurs, stopping all operation for a few seconds. When ATS switches to the secondary source, the EV charging operation is resumed, drawing 10 kW from the secondary energy source. Since the BESS is initially fully charged (

) and PV generation is not considered on CP power calculation, the PV generation limit is kept at zero, avoiding undesirable generation surpass. The controller also sets the BESS reference to discharge mode in order to reduce the power drawn from the secondary source, which is reduced from 10 kW to 5 kW, as shown in

Figure 12a.

After about 145 seconds, BESS SoC reaches its inferior operation limit (20%), as observed in

Figure 12b. Therefore, the controller starts to charge the BESS using PV generation by slowly increasing BESS and PV power (as described in

Section 3.2) in coordinated steps of 1 kW. After 240 seconds, solar irradiation reduces so PV generation start to decay behind its limit for the next 70 seconds, as observed at

Figure 12a. Thus, the controller also changes PV limit and BESS reference in order to reduce power drawn from secondary source (which, in this case, would be consumed by the BESS) at the same time as guarantees that all power generated by the PV will be consumed by the BESS charging operation.

At 310 seconds, solar irradiation increases again and the BESS is not yet fully charged. Hence, the controller restart to increase BESS reference and PV power limit until BESS gets fully charged, which occurs at 395 seconds, as shown by

Figure 12b. At this moment, PV limit is again set to zero and BESS starts a new discharging cycle, which reduces the power drawn from secondary source.

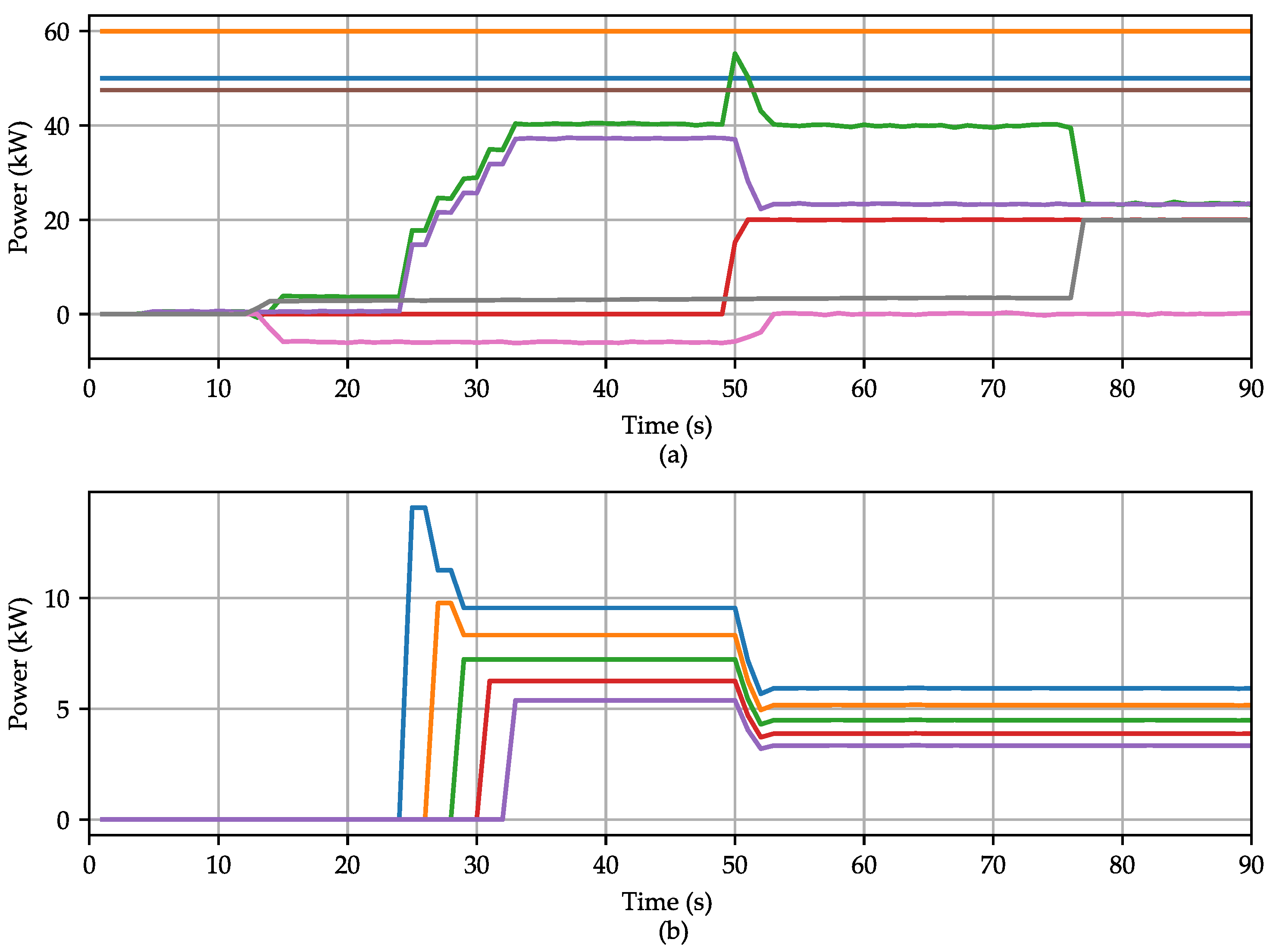

5.4. Scenario 4 - Power Surpass

The Scenario 4 is focused in actions taken by the controller in case of an unexpected increase on local loads, causing the power drawn from the grid to surpass the input power limit by using the safety and protection rules described at

Section 3.3. In order to cause it, the local load rated power was increased to 20 kW in the HIL model and kept disconnected at the start of test. The model was also configured to simulate the solar irradiation at the early morning, maintaining PV generation under 5 kW at the start of the test. The results for such test are demonstrated in

Figure 13.

Five EVs were simultaneously connected to the CP (seen at

Figure 13a), while BESS was kept in slow charge mode, which elevates overall consume to 40 kW, as observed at

Figure 13a. In order to provoke the limit surpass, at 49 seconds, the local load is connected to the e-MH, rapidly increasing the power drawn from the grid. When the e-MH power consume surpasses the input power limit, set in the consumer unit parameters, the proposed controller stops to charge the BESS and reduces the power allowed to the CP to about 24 kW. Consequently, all EVs have their power limit reduced while prioritization order is maintained, as shown in

Figure 13b.

By reducing the power destined for EV charging and stopping BESS operation the controller brings the overall power drawn from the grid back to acceptable values, around 40 kW. After 76 seconds, solar irradiation increases and PV generation reaches its rated power. Again, since PV power is not accounted for EV use, the power allowed to the CP is kept at 24 kW. In this case, PV generation is used to decrease e-MH energy consume.

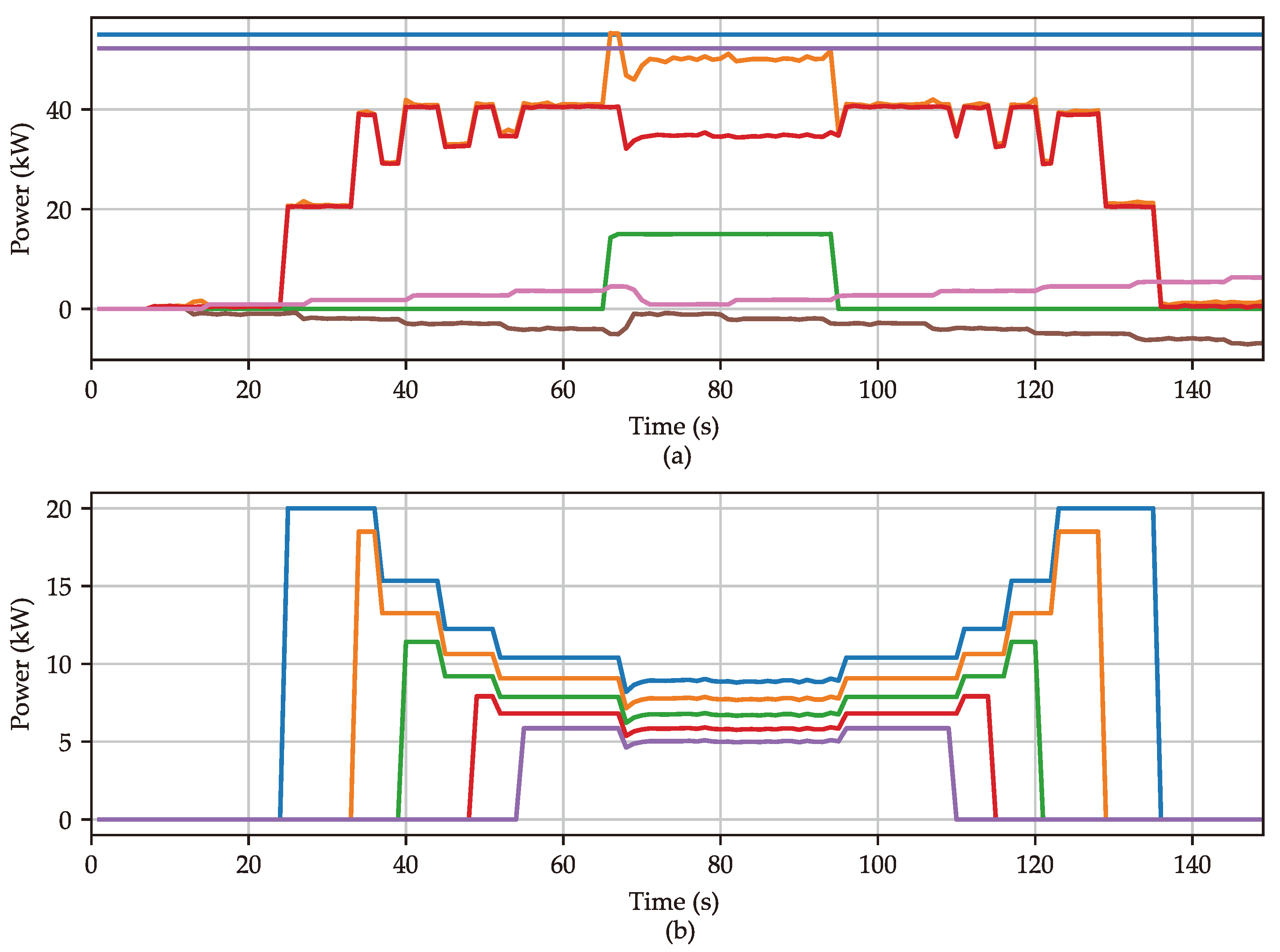

5.5. Scenario 5 - Power Surpass in Islanded Operation

The

Figure 14 shows the results for test Scenario 5. Similarly to the test shown in the

Section 5.4, this scenario is intended to validate the controller behavior when an unexpected increase on local loads occurs, causing the power drawn from the secondary source to surpass the input power limits configured for islanded operation.

In this case, the local load rated power was increased to from 5 to 15 kW in the HIL model and kept disconnected at the start of test. Also, the limit of power allowed to the CP in islanded mode was increased from 10 kW to 40 kW.

In the beginning, PV power limit and BESS reference are slowly increased, in a coordinated way, with 1 kW steps, avoiding excessive generation. After 25 seconds, the first EV is connected followed sequentially by the remaining connectors. In this case, because each EV is connected after a certain period of time, it is possible to observe that the controller proposed first reduces power already in use prior to allows the power limit to recently connected EV. This behavior can again be observed through the CP power oscillation in the first 60 seconds at

Figure 14a.

After 65 seconds, the local load is connected to the e-MH, increasing the power drawn from the secondary source. When the power drawn surpasses the input power limit set, the proposed controller reduces the power allowed to the CP to about 32 kW. Once again, all EVs have their power limit reduced while prioritization order is maintained, as shown in

Figure 14b. In this event the BESS charging operation and PV generation are also stopped. By reducing the power allowed for EV charging, the controller brings the overall power drawn from the secondary source back to acceptable values, around 46 kW until the local load is disconnected from the e-MH, after 94 seconds. At this moment, power allowed to the CP can again be increased from 32 to 40 kW and kept until EVs start do release the connectors after 110 seconds, as demonstrated in

Figure 14b.

6. Conclusions

This paper proposed a centralized control strategy for managing e-MHs based in MGs, capable of operating connected or islanded from the electrical grid, composed of EVSE, DG, PV and BESS, through a real case study.

In

Section 3, the features that define the controller strategy were presented. Communication between the PLC and the equipment provides the functionalities with the necessary data to make decisions based on a series of management rules. As a result, the functionalities work by constantly defining the PV generation limit, BESS and DG power references and the power allowed to EVSE.

To validate the proposed strategy, the equipment from the real scenario was modeled using HIL. The most significant scenarios were considered, as shown in

Section 5. It was possible to observe that the power allocated to the CP was distributed among the connectors according to their order of connection, thus validating the recharge prioritization rule.

In scenario 2, the changes occurred in power dispatch during peak hours demonstrated that the proposed solution fits the use of demand-response strategies. Another important aspect addressed in this work was the incorporation of dynamic pricing mechanisms, as also demonstrated in scenario 2. A variation in grid and DG tariffs was considered during HIL validation, which resulted in changes in the dispatch calculation.

In islanded operation, the proposed strategy prioritizes BESS charge with PV as much as possible, using drawing less power from the secondary source. The strategy allows charging the BESS with a renewable energy source, avoiding excessive fuel consumption in cases where the secondary source is a grid-forming DG. Consequently, the proposed controller can also reduce costs while ensures that the e-MH safely operates in islanded mode.

Considering scenarios 4 and 5, the power limit value configured in

Figure 6 influences the safety margin so that the measured power is kept below contracted capacity in connected mode and is also kept below the installed capacity for both operation modes. During a high load variation, a shorter safety margin allows greater risk during the transient. However, it also allows better use of the power capacity. A greater safety margin reduces the risk. However, it also reduces capacity use. Therefore, choosing the appropriate value for threshold, works as a regulating tool. It balances operational security of the e-MH with efficiency and optimal utilization of the available resources. This regulation must be evaluated based on the specific characteristics of the e-MH structure and its operating conditions.

Author Contributions

The authors contributed equally in the research: Conceptualization, W.C.L., M.O.G. and R.A.S.K.; investigation and methodology, W.C.L. and M.O.G.; validation, W.C.L., M.O.G. and R.A.S.K.; writing—original draft preparation, W.C.L. and M.O.G.; writing—review and editing, M.O.G., B.B.C. and R.A.S.K.; team administration, B.B.C.; project administration, D.d.S.N., R.A.S.K. and M.I.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Research and Development project PD-06072-0700/2023, granted by the Brazilian Electricity Regulatory Agency (ANEEL) and Equatorial Energia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Research Program and Technological Development of the electricity sector regulated by ANEEL and Equatorial Energia for their financial support. This paper is related to the project PD-06072-0700/2023, which is cooperated between CERTI Foundation and Equatorial Energia.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; nor in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ANEEL |

Brazilian Electricity Regulatory Agency |

| API |

Application Programming Interface |

| ATS |

Automatic Transfer Switch |

| BESS |

Battery Energy Storage System |

| BI |

Business Intelligence |

| BMS |

Battery Management System |

| CP |

Charge Point |

| CPO |

Charge Point Operator |

| CPU |

Processing Unit |

| CSV |

Comma separated values |

| DER |

Distributed Energy Resource |

| DG |

Dispatchable Generator |

| DSO |

Distribution System Operator |

| e-MH |

e-Mobility Hub |

| EV |

Electric Vehicle |

| EVSE |

Electric Vehicle Supply Equipment |

| FPGA |

Field-Programmable Gate Array |

| GHG |

Greenhouse gas |

| GPL |

General Public Licence |

| HIL |

Hardware-in-the-loop |

| MG |

Microgrid |

| MPPT |

Maximum power point tracking |

| OCPP |

Open Charge Point Protocol |

| PLC |

Programmable Logic Controller |

| PV |

Photovoltaics |

| RFID |

Radio Frequency Identification |

| R&D |

Research and Development |

| RT |

Real-Time |

| SFTP |

Secure File Transfer Protocol |

| SoC |

State of Charge |

| SCADA |

Supervisory Control and Data Acquisition |

| UPS |

Uninterruptible power supply |

| V2G |

Vehicle-to-Grid |

References

- UN. COP28 and International Energy Agency Reaffirm 1.5 °C—Aligned Energy Transition. https://www.cop28.com/en/news/2023/12/COP28-and-International-Energy-Agency, 2023. Accessed in 15-April-2024.

- Icaza, D.; Vallejo-Ramirez, D.; Guerrero Granda, C.; Marín, E. Challenges, Roadmaps and Smart Energy Transition towards 100Renewable Energy Markets in American Islands: A Review. Energies 2024, 17. [Google Scholar] [CrossRef]

- Soto, E.A.; Wollega, E.; Vizcarrondo Ortega, A.; Hernandez-Guzman, A.; Bosman, L. Reduction in Emissions by Massive Solar Plant Integration in the US Power Grid. Energies 2024, 17. [Google Scholar] [CrossRef]

- Balazadeh Meresht, N.; Moghadasi, S.; Munshi, S.; Shahbakhti, M.; McTaggart-Cowan, G. Advances in Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles: A Review. Energies 2023, 16. [Google Scholar] [CrossRef]

- Birol, F.; others. World Energy Outlook 2023. International Energy Agency: Paris, France, 2023. [Google Scholar]

- Ustun, T.S.; Hussain, S.M.S.; Kikusato, H. IEC 61850-Based Communication Modeling of EV Charge-Discharge Management for Maximum PV Generation. IEEE Access 2019, 7, 4219–4231. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2023: Catching up with Climate Ambitions; OECD Publishing, 2023. [Google Scholar]

- Mateichyk, V.; Kostian, N.; Smieszek, M.; Gritsuk, I.; Verbovskyi, V. Review of Methods for Evaluating the Energy Efficiency of Vehicles with Conventional and Alternative Power Plants. Energies 2023, 16. [Google Scholar] [CrossRef]

- Khalid, M.R.; Khan, I.A.; Hameed, S.; Asghar, M.S.J.; Ro, J.S. A Comprehensive Review on Structural Topologies, Power Levels, Energy Storage Systems, and Standards for Electric Vehicle Charging Stations and Their Impacts on Grid. IEEE Access 2021, 9, 128069–128094. [Google Scholar] [CrossRef]

- EPE. Brazilian Energy Balance 2023: Final Report. http://www.epe.gov.br/en/publications/publications/brazilian-energy-balance, 2023. Accessed 01-April-2024.

- Seminario-Córdova, R. Latin America towards Sustainability through Renewable Energies: A Systematic Review. Energies 2023, 16. [Google Scholar] [CrossRef]

- Wan, M.; Yu, H.; Huo, Y.; Yu, K.; Jiang, Q.; Geng, G. Feasibility and Challenges for Vehicle-to-Grid in Electricity Market: A Review. Energies 2024, 17. [Google Scholar] [CrossRef]

- Prussi, M.; Cota, A.F.; Laveneziana, L.; Chiantera, G.; Guglielmi, P. Electric Vehicle Charging from Tramway Infrastructure: A New Concept and the Turin Case Study. Energies 2024, 17. [Google Scholar] [CrossRef]

- Jia, H.; Ma, Q.; Li, Y.; Liu, M.; Liu, D. Integrating Electric Vehicles to Power Grids: A Review on Modeling, Regulation, and Market Operation. Energies 2023, 16. [Google Scholar] [CrossRef]

- Leal, W.C.; Godinho, M.O.; Bastos, R.F.; de Aguiar, C.R.; Fuzato, G.H.F.; Machado, R.Q. Cascaded Interleaved DC–DC Converter for a Bidirectional Electric Vehicle Charging Station. IEEE Transactions on Industrial Electronics 2024, 71, 3708–3717. [Google Scholar] [CrossRef]

- Godinho, M.O.; Leal, W.C.; Moreto, R.F.; de Aguiar, C.R.; Machado, R.Q. SoC-Adaptive Power Sharing Strategy Applied to DC Microgrids Supplied by Multiple Energy Storage Systems. IEEE Journal of Emerging and Selected Topics in Industrial Electronics 2023, 4, 1224–1234. [Google Scholar] [CrossRef]

- Goncearuc, A.; Sapountzoglou, N.; De Cauwer, C.; Coosemans, T.; Messagie, M.; Crispeels, T. Business Model Quantification Framework for the Core Participants of the EV Charging Market. World Electric Vehicle Journal 2021, 12. [Google Scholar] [CrossRef]

- Kazemi, B.; Kavousi-Fard, A.; Dabbaghjamanesh, M.; Karimi, M. IoT-Enabled Operation of Multi Energy Hubs Considering Electric Vehicles and Demand Response. IEEE Transactions on Intelligent Transportation Systems 2023, 24, 2668–2676. [Google Scholar] [CrossRef]

- Zhou, S.; Qiu, Y.; Zou, F.; He, D.; Yu, P.; Du, J.; Luo, X.; Wang, C.; Wu, Z.; Gu, W. Dynamic EV Charging Pricing Methodology for Facilitating Renewable Energy With Consideration of Highway Traffic Flow. IEEE Access 2020, 8, 13161–13178. [Google Scholar] [CrossRef]

- Najafi, J.; Anvari-Moghaddam, A.; Mehrzadi, M.; Su, C.L. An Efficient Framework for Improving Microgrid Resilience Against Islanding With Battery Swapping Stations. IEEE Access 2021, 9, 40008–40018. [Google Scholar] [CrossRef]

- Safder, M.U.; Sanjari, M.J.; Hamza, A.; Garmabdari, R.; Hossain, M.A.; Lu, J. Enhancing Microgrid Stability and Energy Management: Techniques, Challenges, and Future Directions. Energies 2023, 16. [Google Scholar] [CrossRef]

- Jian, L.; Yongqiang, Z.; Larsen, G.N.; Snartum, A. Implications of road transport electrification: A long-term scenario-dependent analysis in China. eTransportation 2020, 6, 100072. [Google Scholar] [CrossRef]

- Horváth, G.; Bai, A.; Szegedi, S.; Lázár, I.; Máthé, C.; Huzsvai, L.; Zakar, M.; Gabnai, Z.; Tóth, T. A Comprehensive Review of the Distinctive Tendencies of the Diffusion of E-Mobility in Central Europe. Energies 2023, 16. [Google Scholar] [CrossRef]

- Bitencourt, L.; Dias, B.; Soares, T.; Borba, B.; Quirós-Tortós, J.; Costa, V. Understanding Business Models for the Adoption of Electric Vehicles and Charging Stations: Challenges and Opportunities in Brazil. IEEE Access 2023, 11, 63149–63166. [Google Scholar] [CrossRef]

- OCA. Open Charge Point Protocol 2.0. 1-Part 2-Specification. Open Charge Alliance, 2020.

- Nawaz, F.; Pashajavid, E.; Fan, Y.; Batool, M. A Comprehensive Review of the State-of-the-Art of Secondary Control Strategies for Microgrids. IEEE Access 2023, 11, 102444–102459. [Google Scholar] [CrossRef]

- Yao, W.; Wang, Y.; Xu, Y.; Deng, C.; Wu, Q. Distributed Weight-Average-Prediction Control and Stability Analysis for an Islanded Microgrid With Communication Time Delay. IEEE Transactions on Power Systems 2022, 37, 330–342. [Google Scholar] [CrossRef]

- Shyam, A.B.; Anand, S.; Sahoo, S.R. Effect of Communication Delay on Consensus-Based Secondary Controllers in DC Microgrid. IEEE Transactions on Industrial Electronics 2021, 68, 3202–3212. [Google Scholar] [CrossRef]

- De Klerk, M.L.; Saha, A.K. A Review of the Methods Used to Model Traffic Flow in a Substation Communication Network. IEEE Access 2020, 8, 204545–204562. [Google Scholar] [CrossRef]

- Kraemer, R.A.S.; Dias, D.P.; da Silva, A.C.; Martins, M.A.I.; Ludwig, M.A. Cost and Cybersecurity Challenges in the Commissioning of Microgrids in Critical Infrastructure: COGE Case Study. Energies 2022, 15. [Google Scholar] [CrossRef]

- Morello, R.; Di Rienzo, R.; Roncella, R.; Saletti, R.; Baronti, F. Hardware-in-the-Loop Platform for Assessing Battery State Estimators in Electric Vehicles. IEEE Access 2018, 6, 68210–68220. [Google Scholar] [CrossRef]

- Typhoon HIL Inc. Typhoon HIL602+ Brochure, 2022.

Figure 1.

Locations where e-MHs will be installed.

Figure 1.

Locations where e-MHs will be installed.

Figure 2.

Architecture for the e-MH: DERs, data acquisition and processing, monitoring, communication and cloud servers.

Figure 2.

Architecture for the e-MH: DERs, data acquisition and processing, monitoring, communication and cloud servers.

Figure 3.

Centralized controller features.

Figure 3.

Centralized controller features.

Figure 4.

Activation criteria for alarm 1. (a) Overcurrent occurrence followed by current reduction (after CP power decrease); (b) Persistence of overcurrent followed by CP shutdown.

Figure 4.

Activation criteria for alarm 1. (a) Overcurrent occurrence followed by current reduction (after CP power decrease); (b) Persistence of overcurrent followed by CP shutdown.

Figure 5.

BESS and PV power management when e-MH is in islanded operation mode.

Figure 5.

BESS and PV power management when e-MH is in islanded operation mode.

Figure 6.

Capacity limiting functionality example. The controller reduces BESS and EVSE power in case overload is detected.

Figure 6.

Capacity limiting functionality example. The controller reduces BESS and EVSE power in case overload is detected.

Figure 7.

Simplified sequence diagram for the proposed management strategy.

Figure 7.

Simplified sequence diagram for the proposed management strategy.

Figure 8.

HIL architecture and communication implemented for evaluation of the proposed management strategy.

Figure 8.

HIL architecture and communication implemented for evaluation of the proposed management strategy.

Figure 9.

Experimental setup. (a) PLC; (b) HIL device; (c) HIL model; (d) SCADA panel; (e) 4G communication modem; (f) UPS.

Figure 9.

Experimental setup. (a) PLC; (b) HIL device; (c) HIL model; (d) SCADA panel; (e) 4G communication modem; (f) UPS.

Figure 10.

Test scenario 1 - simultaneous charging of two EVs with islanded period (in pale red). (a) Contracted capacity (purple); Power measured by consumer unit meter (blue); Power measured by secondary source meter (orange); Charge point power (red); PV power (pink); BESS power (brown); Local load power (green); (b) Connector 1 charging power (blue); Connector 2 charging power (orange).

Figure 10.

Test scenario 1 - simultaneous charging of two EVs with islanded period (in pale red). (a) Contracted capacity (purple); Power measured by consumer unit meter (blue); Power measured by secondary source meter (orange); Charge point power (red); PV power (pink); BESS power (brown); Local load power (green); (b) Connector 1 charging power (blue); Connector 2 charging power (orange).

Figure 11.

Test scenario 2 – simultaneous charging of three EVs with peak demand period (in light gray). (a) Contracted capacity (purple); Input power limit (red); PV power (pink); Power measured by consumer unit meter (blue); Charge point power (green); BESS power (Brown); Local load power (orange); Dispatchable generator power (grey); (b) Connector 1 charging power (blue); Connector 2 charging power (orange); Connector 3 charging power (green).

Figure 11.

Test scenario 2 – simultaneous charging of three EVs with peak demand period (in light gray). (a) Contracted capacity (purple); Input power limit (red); PV power (pink); Power measured by consumer unit meter (blue); Charge point power (green); BESS power (Brown); Local load power (orange); Dispatchable generator power (grey); (b) Connector 1 charging power (blue); Connector 2 charging power (orange); Connector 3 charging power (green).

Figure 12.

Test scenario 3 - Islanded operation (in pale red). (a) Power measured by consumer unit meter (blue); Power measured by secondary source meter (orange); Charge point power (red); PV power (brown); BESS power (purple); Local load power (green); BESS power reference (grey, dashed); PV power limit (pink, dashed) (b) BESS SoC (blue); BESS SoC upper operation limit (orange); BESS SoC inferior operation limit (green).

Figure 12.

Test scenario 3 - Islanded operation (in pale red). (a) Power measured by consumer unit meter (blue); Power measured by secondary source meter (orange); Charge point power (red); PV power (brown); BESS power (purple); Local load power (green); BESS power reference (grey, dashed); PV power limit (pink, dashed) (b) BESS SoC (blue); BESS SoC upper operation limit (orange); BESS SoC inferior operation limit (green).

Figure 13.

Test scenario 4 - Simultaneous charge of five EVs with input power limit surpass. (a) Installation capacity (orange); contracted capacity(blue); Input power limit (brown); Consumer unit meter (green); Charge point power (purple); Local load power (red); BESS power (pink); PV power (grey); (b) Connector 1 (blue); Connector 2 (orange); Connector 3 (green); Connector 4 (red); Connector 5 (purple).

Figure 13.

Test scenario 4 - Simultaneous charge of five EVs with input power limit surpass. (a) Installation capacity (orange); contracted capacity(blue); Input power limit (brown); Consumer unit meter (green); Charge point power (purple); Local load power (red); BESS power (pink); PV power (grey); (b) Connector 1 (blue); Connector 2 (orange); Connector 3 (green); Connector 4 (red); Connector 5 (purple).

Figure 14.

Scenario 5 - Simultaneous charge of five EVs with input power limit surpass in islanded mode. (a) Installation power (blue); Input Power limit (purple); Power measured by secondary source meter (orange); Charge point power (red); Local load power (green); BESS power (Brown); PV power (pink); (b) Connector 1 (blue); Connector 2 (orange); Connector 3 (green); Connector 4 (red); Connector 5 (purple).

Figure 14.

Scenario 5 - Simultaneous charge of five EVs with input power limit surpass in islanded mode. (a) Installation power (blue); Input Power limit (purple); Power measured by secondary source meter (orange); Charge point power (red); Local load power (green); BESS power (Brown); PV power (pink); (b) Connector 1 (blue); Connector 2 (orange); Connector 3 (green); Connector 4 (red); Connector 5 (purple).

Table 1.

Consumer unit capacity.

Table 1.

Consumer unit capacity.

| Consumer unit limitations |

Rated power (kW) |

| Installed capacity |

60.0 |

| Contracted capacity |

50.0 |

Table 2.

Equipment operational limits.

Table 2.

Equipment operational limits.

| Device |

Rated power (kW) |

| PV |

20.0 |

| BESS |

20.0 |

| Load |

5.0 |

| CC-CA Converter (PV) |

20.0 |

| CC-CA Converter (BESS) |

20.0 |

| Dispatchable Generator (DG) |

30.0 |

| EVSE |

20.0 |

Table 3.

Alarms with respective activation criteria and post-activation procedures.

Table 3.

Alarms with respective activation criteria and post-activation procedures.

| Alarm |

Activation |

Post-activation procedures |

| 1 |

Current A, B or C > max. value configured |

Limit CP power to a protection value1

Reduce BESS reference to 0

Reduce PV power limit to 0

Reduce DG power reference to 0 |

| 2 |

Meter error status detected |

Limit CP power to a protection value;

Reduce BESS reference to 0

Reduce PV power limit to 0

Reduce DG power reference to 0 |

| 3 |

PV DC-AC converter error status detected |

Reduce PV power limit to 0

Reduce BESS reference to 02

|

| 4 |

BESS error status detected |

Reduce BESS reference to 0

Reduce PV power limit to 02

|

| 5 |

DG error status detected |

Reduce DG power reference to 0 |

| 6 |

EVSE fault status detected |

Reduce connector power limit to zero

Exclude connector from EVSE prioritization |

| 7 |

Communication timeout between PLC and e-MH components |

Activate alarms 2, 3, 4, or 5 |

| 8 |

Communication timeout between PLC and OCPP server |

Consider previous EVs status and power references |

Table 4.

Parameters and variables used at the cost-related rules.

Table 4.

Parameters and variables used at the cost-related rules.

| Parameters |

Description |

|

Utility grid energy tariff per kWh |

|

DG use cost per kWh |

|

BESS use cost per kWh |

|

EV charging tariff per kWh |

|

DG fuel tank capacity in liters |

|

Contracted capacity activation limit in kW |

|

Inferior operation limit for BESS as percentage |

|

Upper operation limit for BESS as percentage |

|

Peak demand period starting time |

|

Peak demand period ending time |

|

Number of busy connectors at the CP |

|

BESS slow recharge ratio |

|

DG rated power in kW |

|

BESS rated power in kW |

|

Charging connector rated power in kW |

| Variables |

Description |

|

DG remaining fuel as percentage |

|

Measurement of the power drawn from the grid in kW |

|

Current BESS SoC as percentage |

|

Current time |

|

PV power measurement in kW |

|

DG power reference in kW |

|

BESS power reference in kW |

|

Power measured at the local load in kW |

|

Power allowed to CP in kW |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).