Submitted:

03 June 2024

Posted:

04 June 2024

You are already at the latest version

Abstract

Keywords:

Introduction

Areca leaf sheath

- Preparation: Acquire food-grade paperboard.

- Printing: Desired designs were printed on the paperboard.

- Cutting: Die-cut the paperboard into cup blanks and bottoms.

- Shaping: Form the cylindrical shape, seal the side seam, and attach the bottom.

- Coating: A thin layer of PE was coated inside the cups.

- Curling: Roll the top edge to form a rim.

- Cleaning: Distilled water was used to clean the sheaths of areca leaves that were gathered.

- Drying: For eight to twelve hours, the leaves were exposed to sunlight.

- Hydraulic press molding: Dried leaves were pressed and stamped for 40–60 seconds in a hydraulic press mold machine with the top and lower die temperatures set to 110–115 ˚C and 35–45 ˚C, respectively [26].

Conclusions

References

- “Paper Cup Market Size, Value, Opportunities and Industry Trends by 2030.” Data Bridge Market Research, https://www.databridgemarketresearch.com, All right reserved 2024, 1 Jan. 2023, www.databridgemarketresearch.com/reports/global-paper-cup-market.

- https://greenssteel.co.uk/blogs/news/shocking-report-why-its-dangerous-to-drink-coffee-tea-from-paper-cups#:~:text=WAIT%2C%20DID%20HE%20JUST%20SAY,and%20nitrate%20at%20high%20temperatures.

- Kumar, P. Role of Plastics on Human Health. Indian journal of pediatrics 2018, 85, 384–389. [Google Scholar] [CrossRef] [PubMed]

- Castle, L et al. Migration studies from paper and board food packaging materials. 1. Compositional analysis. Food additives and contaminants 1997, 14, 35–44. [Google Scholar] [CrossRef] [PubMed]

- “Drinking hot beverages from paper cups poses health risks, shows study.” News-Medical, 19 Nov. 2020, www.news-medical.net/news/20201119/Drinking-hot-beverages-from-paper-cups-poses-health-risks-shows-study.aspx.

- Zimmermann, Lisa. “New research on chemical migration from plastic, paper, can coating, and reusables | Food Packaging Forum.” Food Packaging Forum, 12 July 2022, www.foodpackagingforum.org/news/new-research-on-chemical-migration-from-plastic-paper-can-coating-and-reusables.

- Potential health effects of PFAS chemicals | ATSDR. www.atsdr.cdc.gov/pfas/health-effects/index.html.

- Diamanti-Kandarakis E., Bourguignon J.P., Giudice L.C., Hauser R., Prins G.S., Soto A.M., Zoeller R.T., Gore A.C. Endocrine-disrupting chemicals: an Endocrine Society scientific statement. Endocr Rev. 2009, 30, 293–342. [Google Scholar]

- Weber Lozada, K., & Keri, R. A. Bisphenol A increases mammary cancer risk in two distinct mouse models of breast cancer. Biology of reproduction 2011, 85(3), 490–497. [Google Scholar] [CrossRef] [PubMed]

- Weinhouse, Caren et al. Dose-dependent incidence of hepatic tumors in adult mice following perinatal exposure to bisphenol A. Environmental health perspectives 2014, 122, 485–91. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Bermejo M, Mas-Pérez I, Murillo-Llorente MT. The Role of the Bisphenol A in Diabetes and Obesity. Biomedicines 2021, 9, 666. [Google Scholar] [CrossRef] [PubMed]

- Shen, Ru et al. Maternal di-(2-ethylhexyl) phthalate exposure during pregnancy causes fetal growth restriction in a stage-specific but gender-independent manner. Reproductive toxicology (Elmsford, N.Y.) 2017, 67, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Voss, Cristina et al. Lifelong exposure to di-(2-ethylhexyl)-phthalate induces tumors in liver and testes of Sprague-Dawley rats. Toxicology 2005, 206, 359–71. [Google Scholar] [CrossRef] [PubMed]

- “Areca catechu.” Wikipedia, 18 Apr. 2024, en.wikipedia.org/wiki/Areca_catechu.

- Bavappa K V A, Nair M K and Kumar T P 1982 The Arecanut Palm (Kerala, India: Central Plantation Crops Research Institute).

- G, Sriram. Business Forecast for Areca Palm Leaf Plates in the Next 5 Years Globally. 4 Mar. 2024, www.linkedin.com/pulse/business-forecast-areca-palm-leaf-plates-next-5-years-sriram-g-nlcnc.

- Subramanian V & Govindarajan V S. Technology research on areca. Areca J 1962, 13, 125–128. [Google Scholar]

- Bhandare AM, Kshirsagar AD, Vyawahare NS, Hadambar AA, Thorve VS. Potential analgesic, anti-inflammatory and antioxidant activities of hydroalcoholic extract of Areca catechu L. nut. Food Chem Toxicol. 2010, 48, 3412–7. [Google Scholar] [CrossRef] [PubMed]

- Gautam R, Saklani A, Jachak SM. Indian medicinal plants as a source of antimycobacterial agents. J Ethnopharmacol. 2007, 110, 200–34. [Google Scholar]

- Abbas G, Naqvi S, Erum S, Ahmed S, Atta ur R, Dar A. Potential antidepressant activity of Areca catechu nut via elevation of serotonin and noradrenaline in the hippocampus of rats. Phytother Res. 2013, 27, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Kafle S, Shanbhag T, Shenoy S, Amuthan A, Prabhu K, Mohan S, et al. Antifertility effect of Areca catechu in male albino rats. Int J Pharmacol Clin Sci. 2011, 10, 79–82. [Google Scholar]

- Peng W, Liu YJ, Wu N, Sun T, He XY, Gao YX, et al. Areca catechu L. (Arecaceae): a review of its traditional uses, botany, phytochemistry, pharmacology and toxicology. J Ethnopharmacol. 2015, 164, 340–56. [Google Scholar] [CrossRef] [PubMed]

- Azzez S, Amudhan S, Adiga S, Rao N, Rao N, Udupa LA. Wound healing profile of Areca catechu extracts on different wound models in Wistar rats. Kuwait Med J. 2007, 39, 48–52. [Google Scholar]

- Kalita P, Dixit U S, Mahanta P and Saha U K 2006 Effect of Moisture and Temperature on Arecanut Leaf Sheath Products Proc of the 3rd BSME-ASME Int. Conf. on Thermal Engineering.

- Shashikumar, & Krishnappa, Manjunatha. (2016). Physical Properties of Arecanut Sheath.

- Kalita P, Dixit U S, Mahanta P and Saha U K. A novel energy efficient machine for plate manufacturing from areca palm leaf sheath. J. Sci. Ind. Res. 2008, 67, 807–11. [Google Scholar]

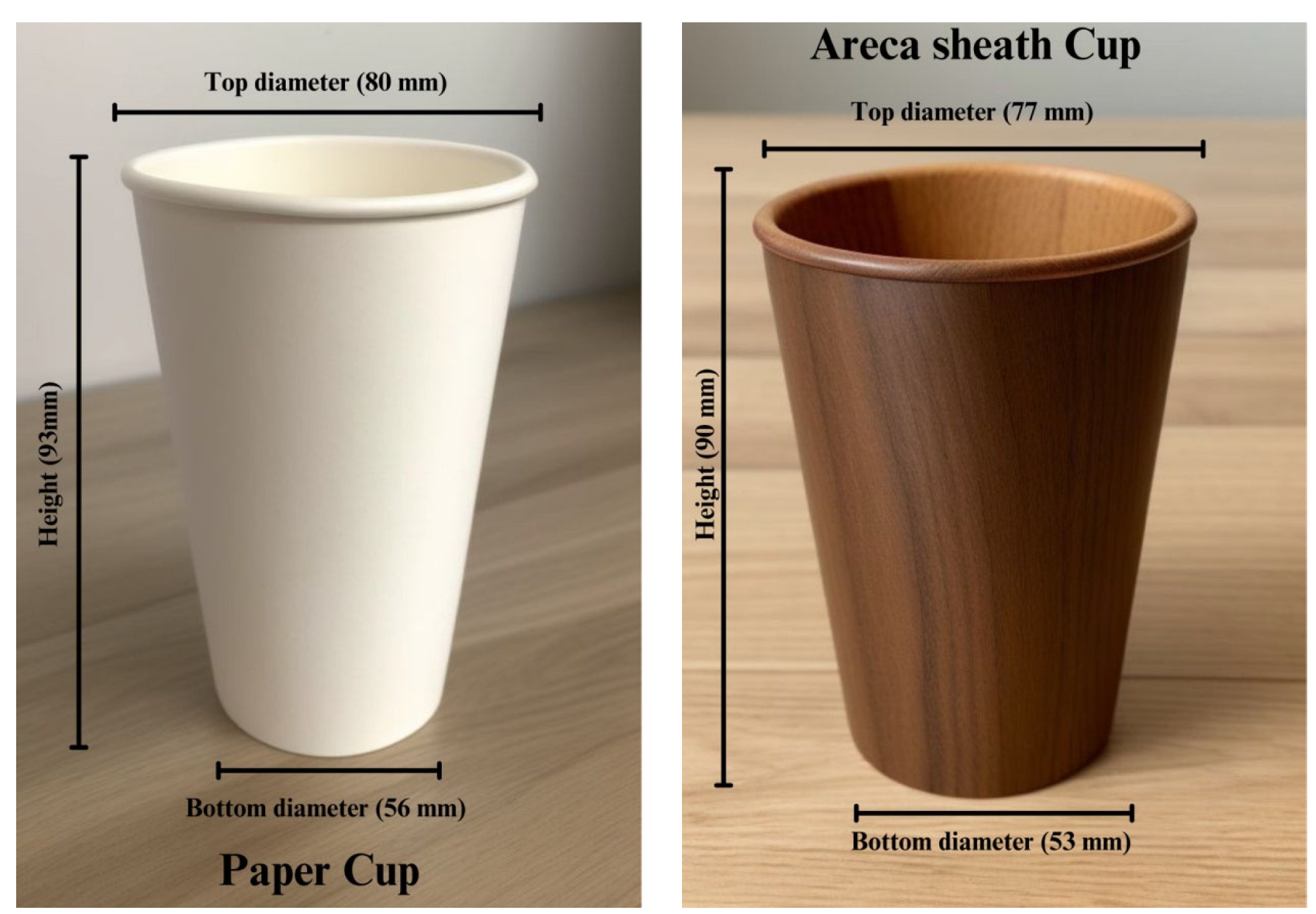

| Cups | Volume (ml) | Height (mm) | Top diameter (mm) | Bottom diameter (mm) | Bottom knurling height (mm) |

|---|---|---|---|---|---|

| Paper cup | 240 | 93 | 80 | 56 | 6 |

| Areca cup | 240 | 90 | 77 | 53 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).