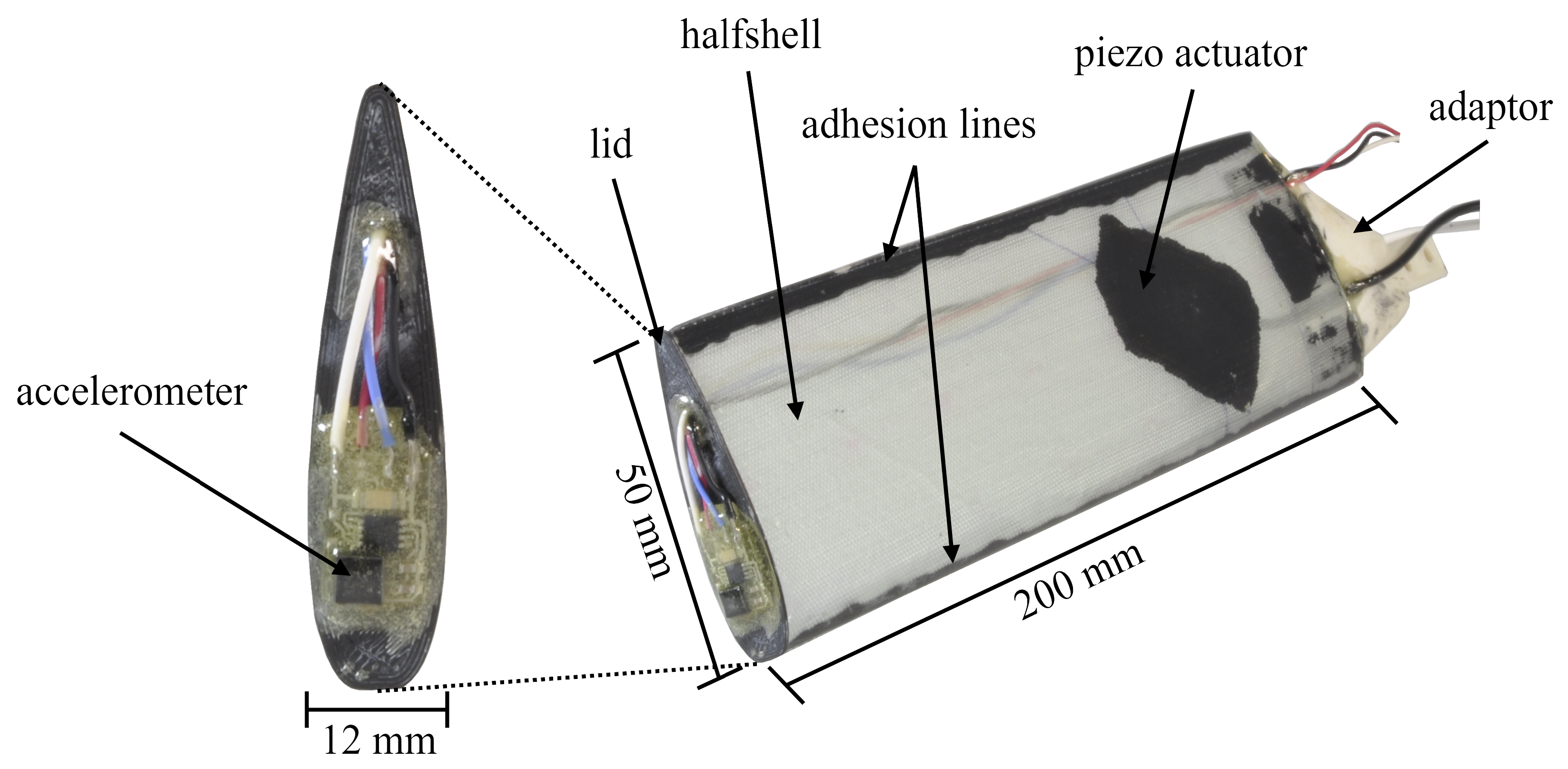

In the following, the design of the specimens and the components of the test rig used in the research for this paper are described. The main focus lies on the parts that are relevant for the induction of a natural icing process of the rotating specimens and the measurement of the ice layer.

2.2. Test Rig Set-Up

The complete set-up of the test rig in detail is presented in [

15]. Here the focus lies on the relevant parts for the icing and laser profile scanning system.

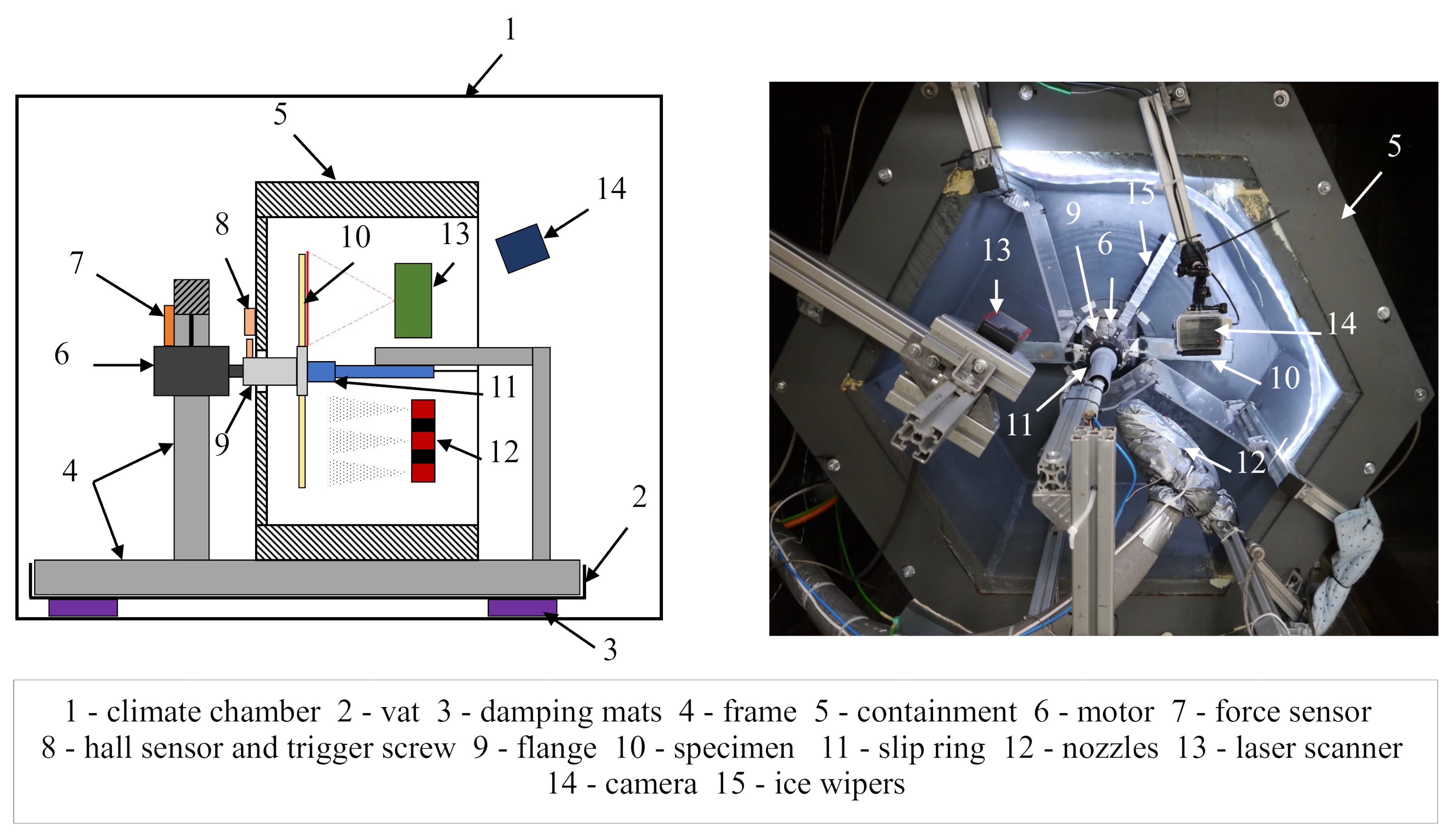

Figure 2.

Sketch (left) and front view (right) of the test rig.

Figure 2.

Sketch (left) and front view (right) of the test rig.

The test rig is situated inside a climate chamber (1) to have control over the temperature conditions. Specimens can be mounted on the flange of a motor (9) and rotated at various velocities by a Kollmorgen AKM52L servomotor (6). Its speed can be set by an analog voltage signal that is fed to the corresponding Kollmorgen S712 frequency inverter that controls the motor.

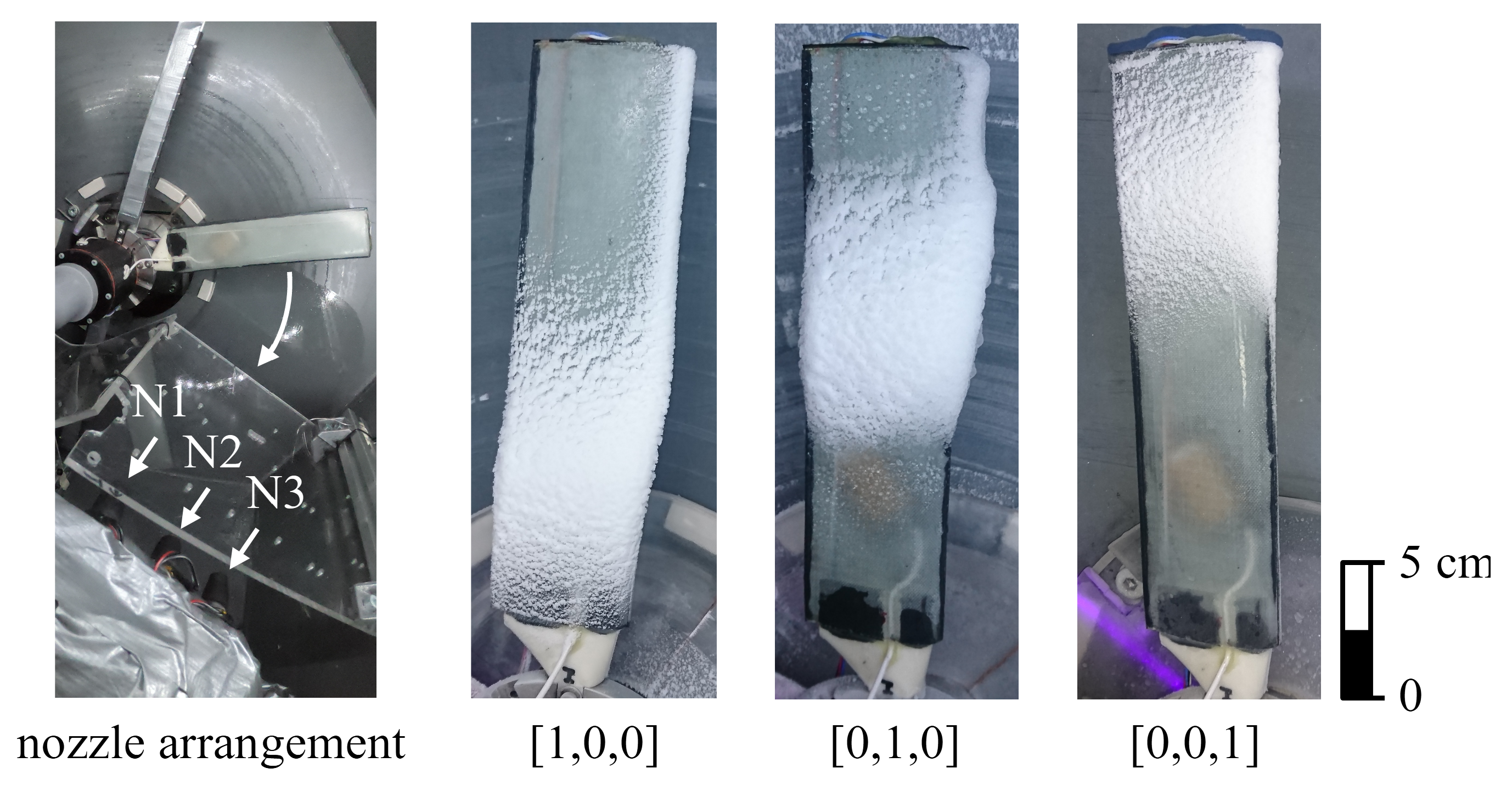

A system of three nozzles (12) perpendicular to the rotation plane allows the icing of the specimens at different radial positions. The water spraying process was performed continually, even during the measurements, to prevent the nozzles from freezing. The mass flow through the nozzles was manually controlled by adjusting their spray heads to values ranging from 3.5 to 4.5

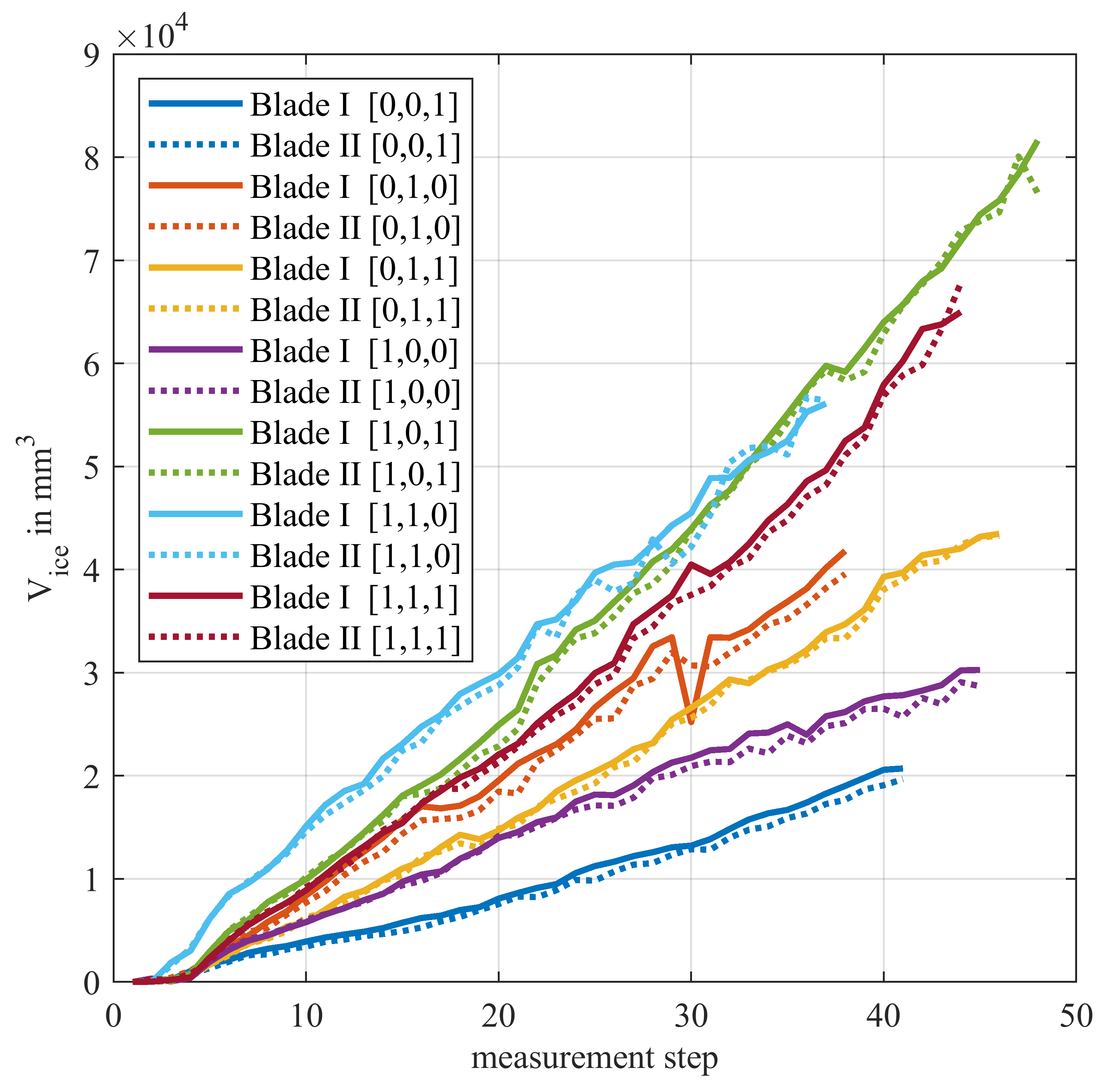

. The value was increased from the inner to the outer nozzle to counter the higher circumferential velocity with growing radius that leads to less ice accumulated for the same mass flow of water. The nozzles were operated at the lower end of their mass flow spectrum to create a very fine mist of water, which made them susceptible to the stress of the high temperature gradients and led to frequent changes in the spraying properties. The nozzle setup is expressed by a binary vector whose values from left to right correspond to the nozzles from the inside to the outside and with a value of 1 meaning they are active.

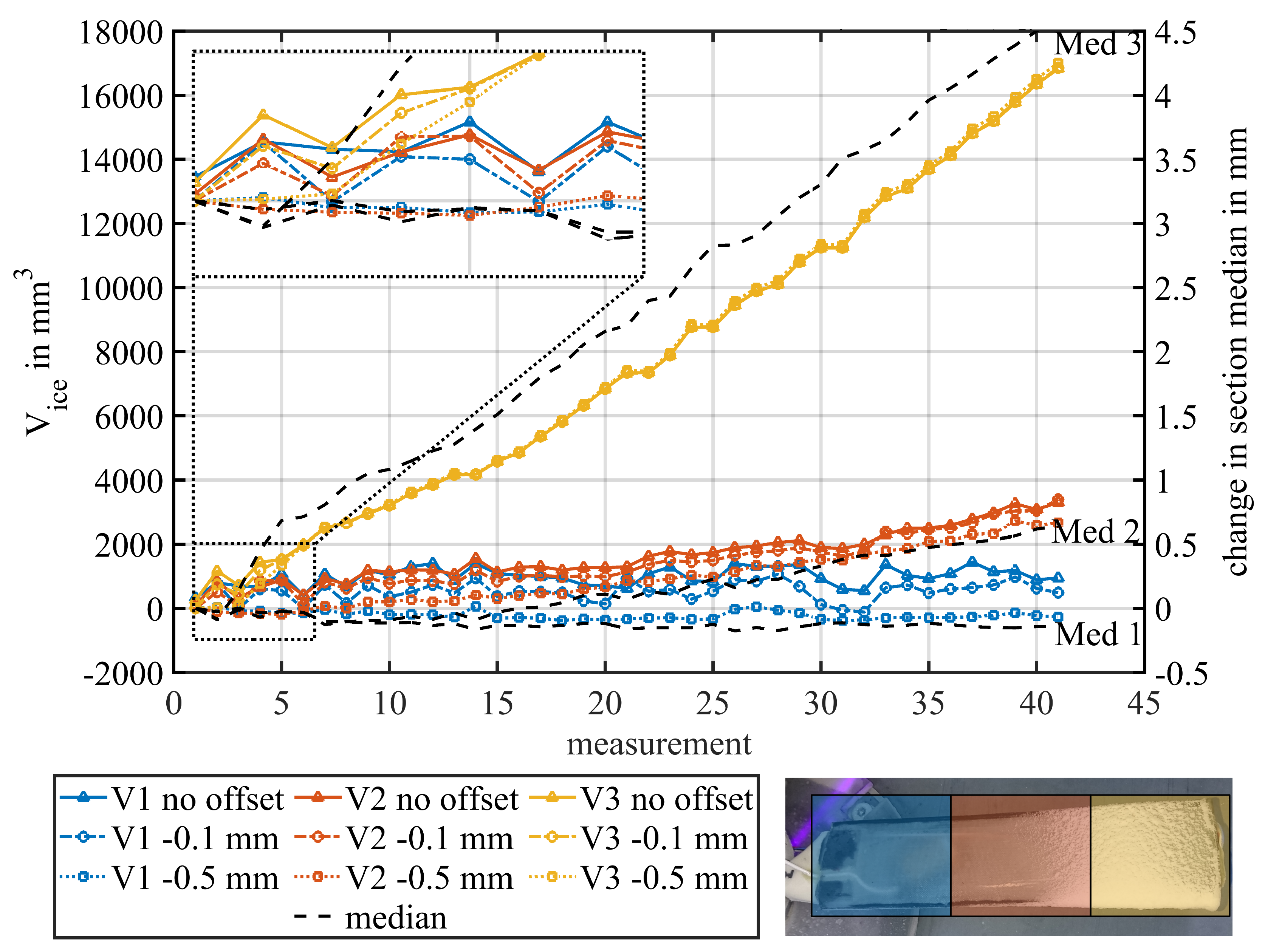

Figure 3 shows the resulting icing for each nozzle operating separately. The main icing areas are clearly visible.

The laser scanner (13), a Keyence LJ-V7300, provides information about the distance of an object that is crossing its measurement line by triangulation. It was developed for industrial high speed scanning applications like orientation detection, quality assessment or 3D-inspections. The device is oriented perpendicular to the rotation plane, but small deviations are negligible, because the calculation of the icing volume is based on the differences between the profiles of two measurements, therefor the absolute values do not matter. However, the alignment of the laser scanning line with the centre of the rotation is much more important to achieve correct results. The scanner is triggered to start and stop by a hall sensor (8) that detects a change in the magnetic field induced by a screw in the flange when passing by. The optical nature of the measurement method makes it best suited for opaque structures. There exist different types of ice that evolve under specific conditions for parameters like drop size, temperature and relative velocity on impact [

7]. With its glossy form, clear ice, that occurs at temperatures close to 0 °C, can lead to high refraction of the laser beam and cause trouble in its detection.

An important point to consider with this and similar measurement techniques is the decreasing circumferential resolution

with increasing radius

. This is linked directly to the angular resolution

that can be controlled with the number of single line measurements that are performed within one full rotation. The angular resolution therefore should be determined by the required resolution at the outermost part of the rotor:

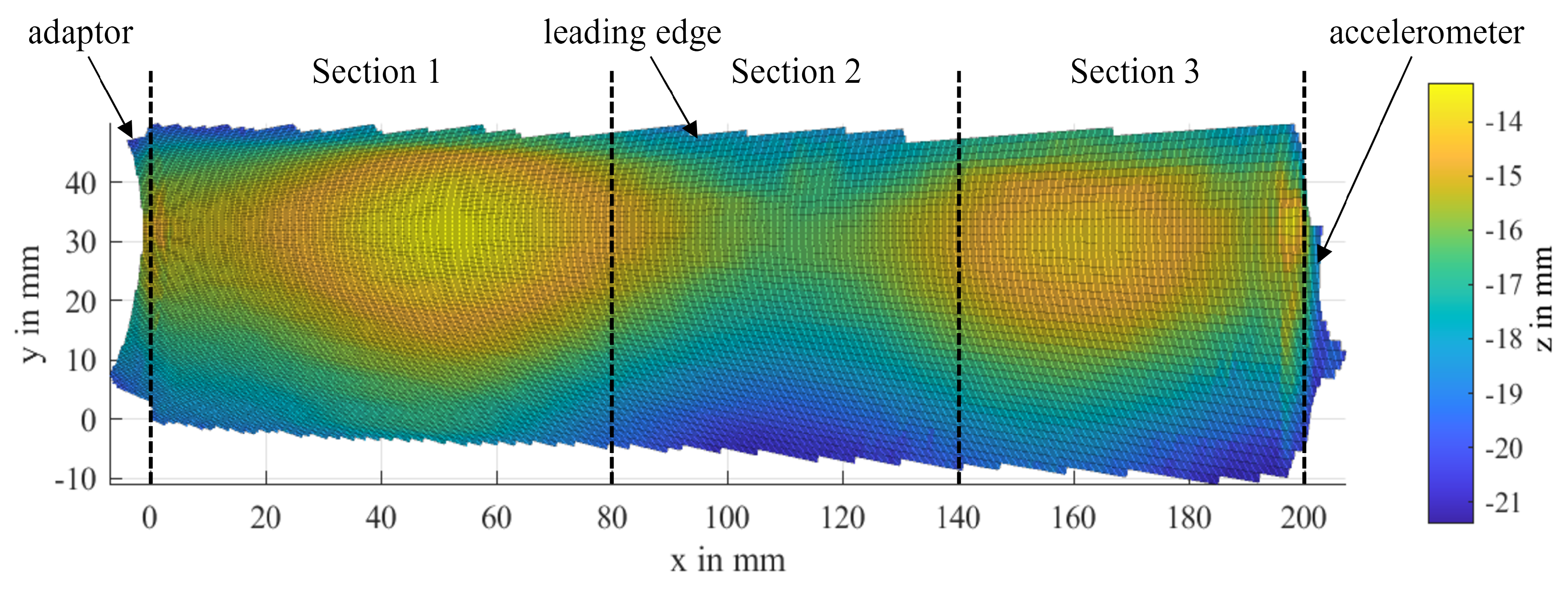

2.4. Preprocessing and Presentation of the Ice Distribution

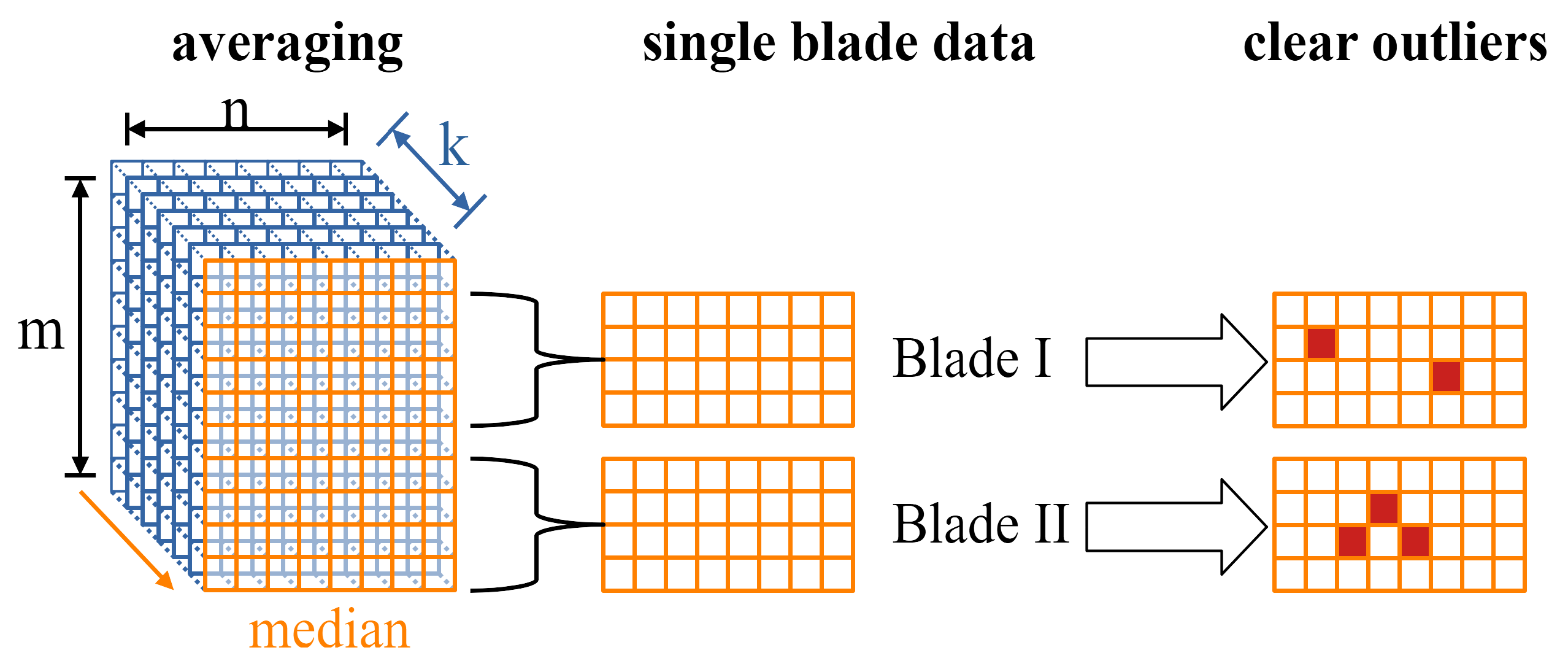

All processing code was written in Matlab for an easy adaption of the algorithm and due to the availability of several useful functions for this project. An overview of the main steps of the preprocessing is given in

Figure 5.

First, the values where the laser is measuring into the void are replaced with ’NaN’ to segregate them clearly from the actual data. Furthermore, auxiliary elements of the rotor are removed in this step. After that, each single rotation array is scanned for big coherent data blocks, utilising the function "bwconncomp" from the Matlab Image Processing Toolbox. This step is necessary to detect and remove data sets that contain more than one rotation, when the laser scanner does not catch the signal from the trigger to stop the measurement. Then, the remaining arrays of the current measurement are concatenated into the third dimension where each page stores the data of one full rotation. The number of valid entries for each point during the measurement is counted along the third dimension of the array to remove random noise in the form of small bits of data that is disconnected from the blades. Furthermore, measurements that are heavily shifted against the majority of the data are detected and omitted, by evaluating the overlap of the locations of the data entries in the arrays of the measurements. Then the average blade profile is determined, using the median along the third dimension of the remaining data array to reduce the influence of outliers.

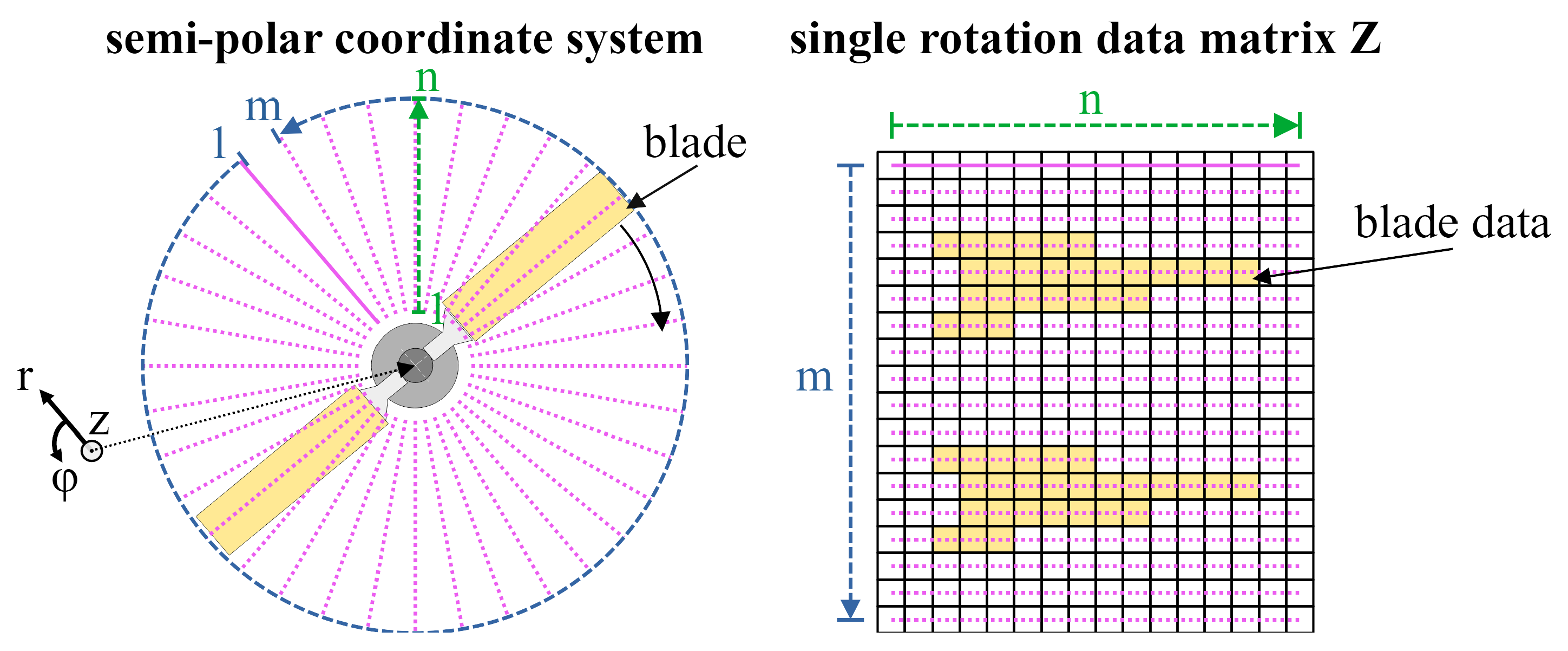

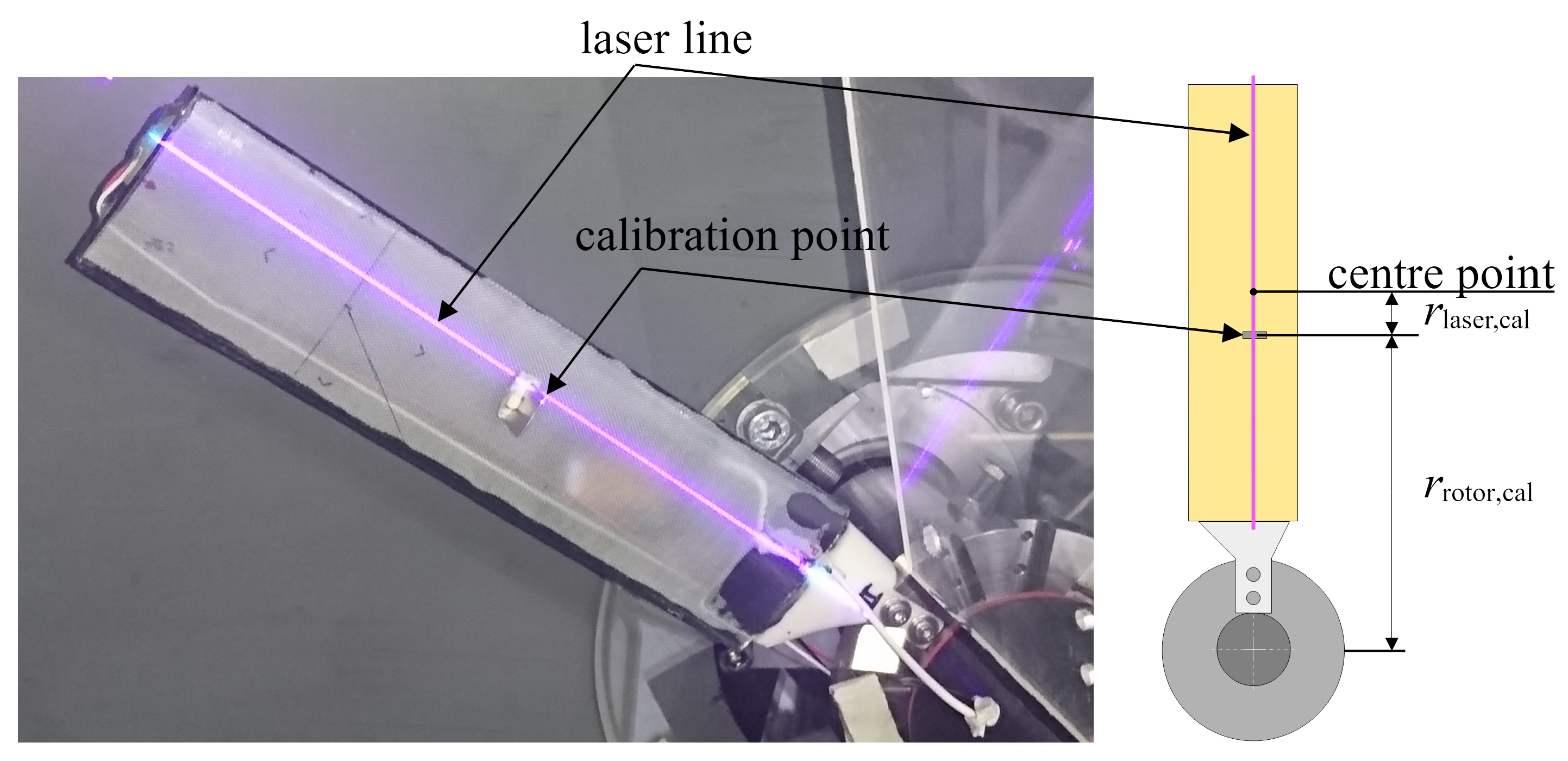

The laser scanner inherently delivers the data in a semi-polar coordinate system, where the information about radius and angle are contained in the indices of the column and the row of each entry. The radial resolution was 0.3 mm with values of the raw data running from -120 mm to 120 mm. The angular resolution is given by the number of m lines that are obtained within each rotation. A transformation into a Cartesian coordinate system is necessary for the further processing and makes the handling and displaying of the data much easier. Therefor two additional matrices X and Y of the same dimension as Z are needed to provide the x and y coordinates of the measurement points. In this step, the relative positioning of the laser and the rotor blades must be considered with a calibration value that is determined by mounting a small plate upright on a rotor blade, which creates a sharp peak in the laser scanner data,

Figure 6. The difference between the measured peak and its real distance from the centre of rotation yields the calibration value C. The entries of the matrices X and Y are calculated with the following equations in which

represents the row index, m the total number of rows and

the column index. The assignment of the sine and cosine operations to the matrices can be chosen arbitrarily, this only affects the orientation of the resulting coordinate system.

After the calculation of the x and y coordinates, the single blade profile data can be extracted from the matrix without losing information. To achieve a standardized orientation for later calculations, the single blade data is shifted to the origin of the coordinate system and its root edge is aligned with the y-axis. This compensates for possible deviations in the position of the blades due to slight variations in the trigger of the laser measurement.

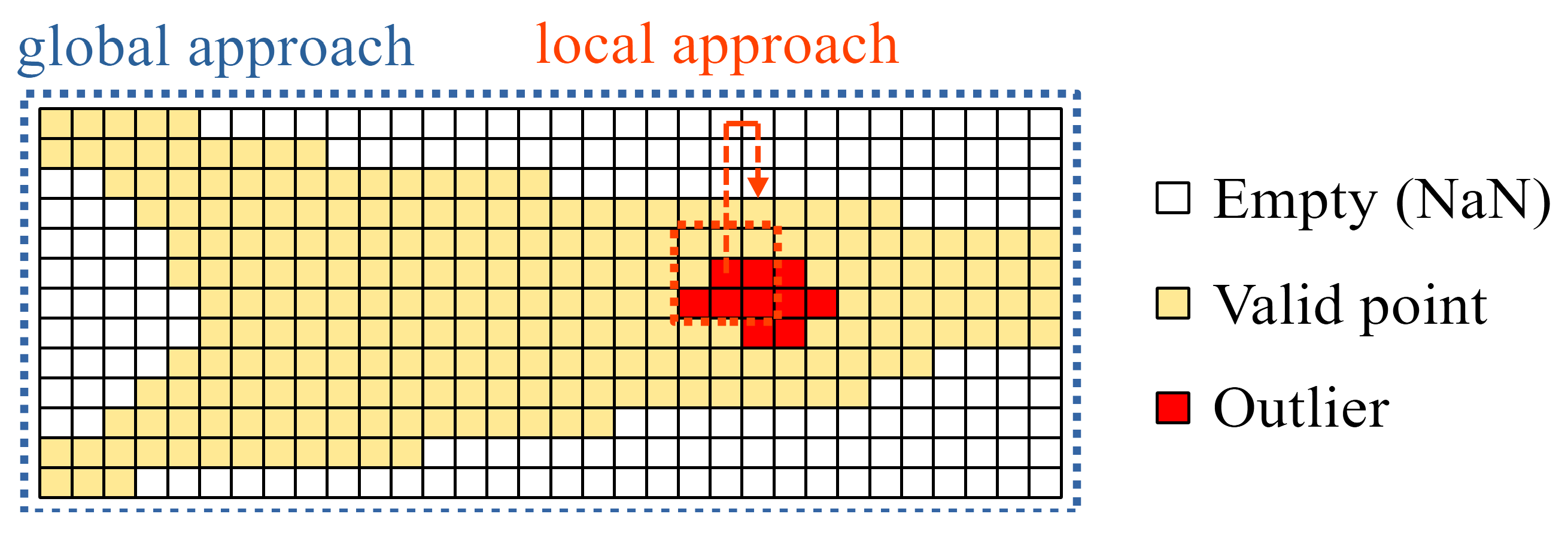

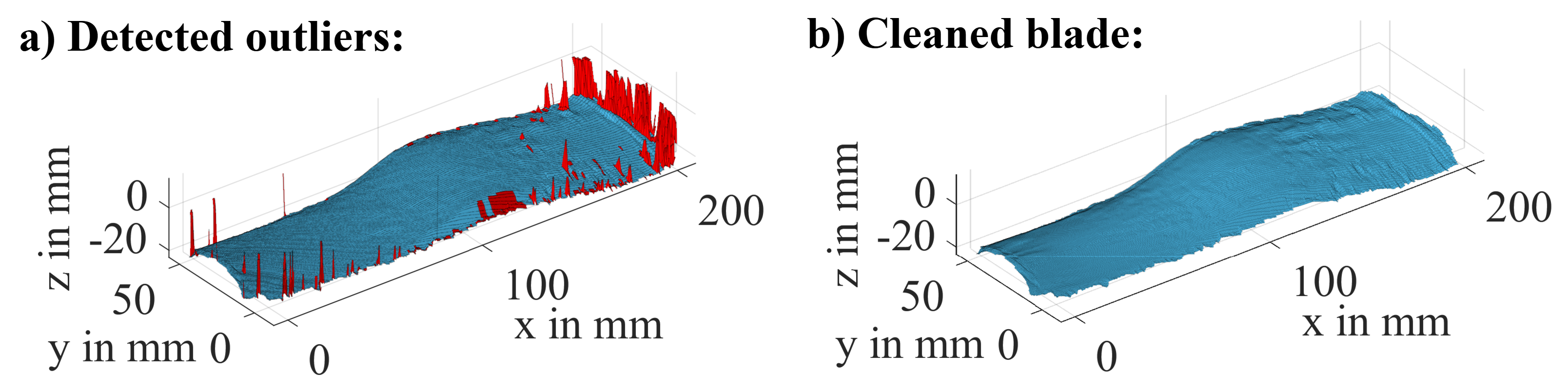

Now the measurement data must be cleared from remaining measurement errors because outliers in the point cloud can heavily influence the later computation of the volume, particularly for thin ice layers with a small overall volume. A several layered process of outlier detection and removal is deployed, which combines global and local approaches as depicted in

Figure 7, using their individual advantages to compensate for the disadvantages of each other. The local approach evaluates the value of a point against its vicinity, which takes local effects into consideration, e.g. the given shape of the blades or ice accumulation. However, it is not useful when there are many outliers in a small area, because they "hide" each other when their values are of same magnitude. A global approach is less sensitive to such effects, but can be too coarse to reliably detect all outliers and, in this specific case, is biased to the blades root because the radially decreasing resolution means that more data points are collected there.

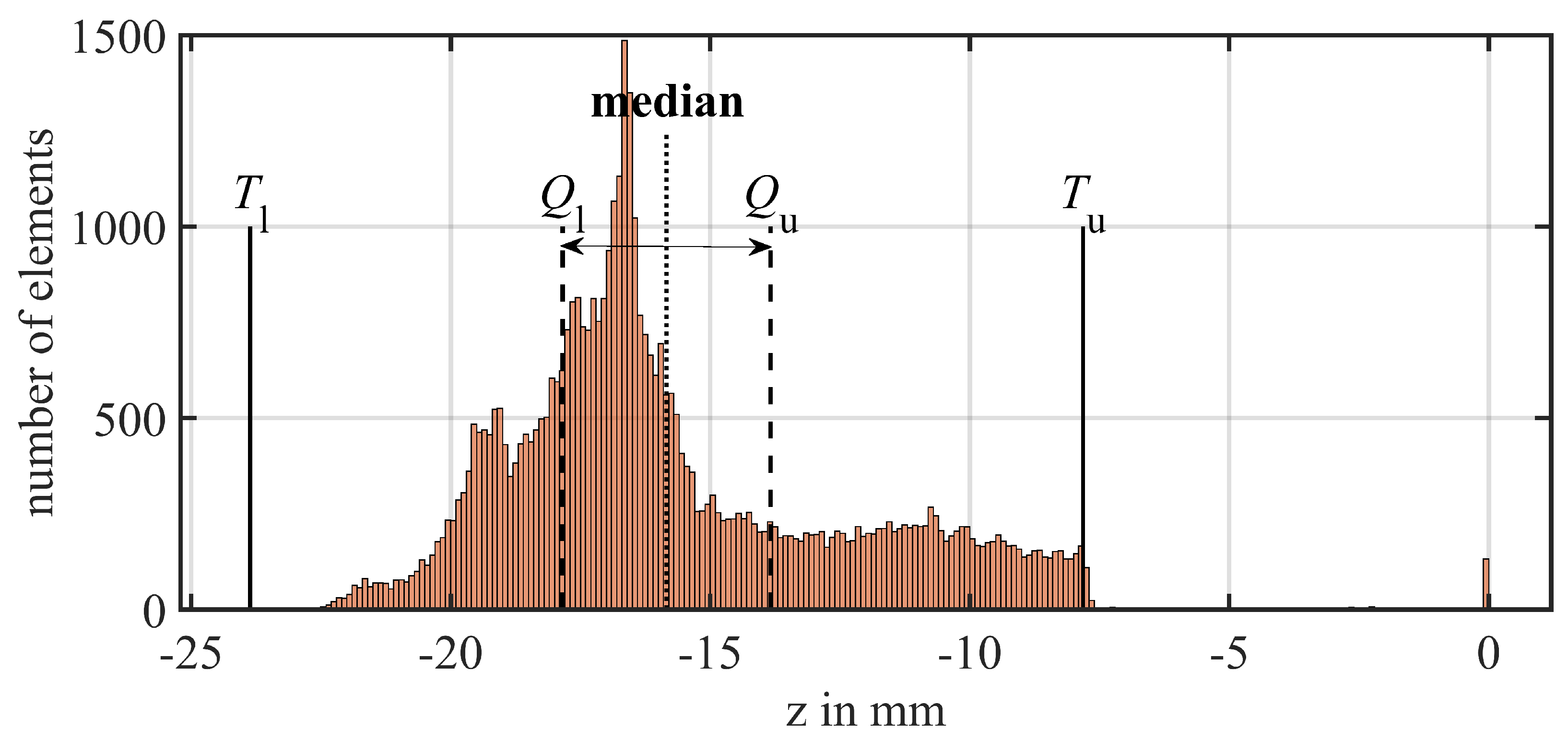

As a global technique, the Matlab function "isoutlier" is used to filter for the most obvious overall outliers. In this case, the quartile method is best suited to define incorrect values because the data is not normally distributed which can be seen in the histogram for an iced blade in

Figure 8. It defines upper and lower thresholds

and

for the data based on the inter quartile range, which is the distance between the median

of the lower half of the sorted samples to the median

of the upper half of the samples:

The local approach compares each data point to its surroundings, and was realized as a custom written function

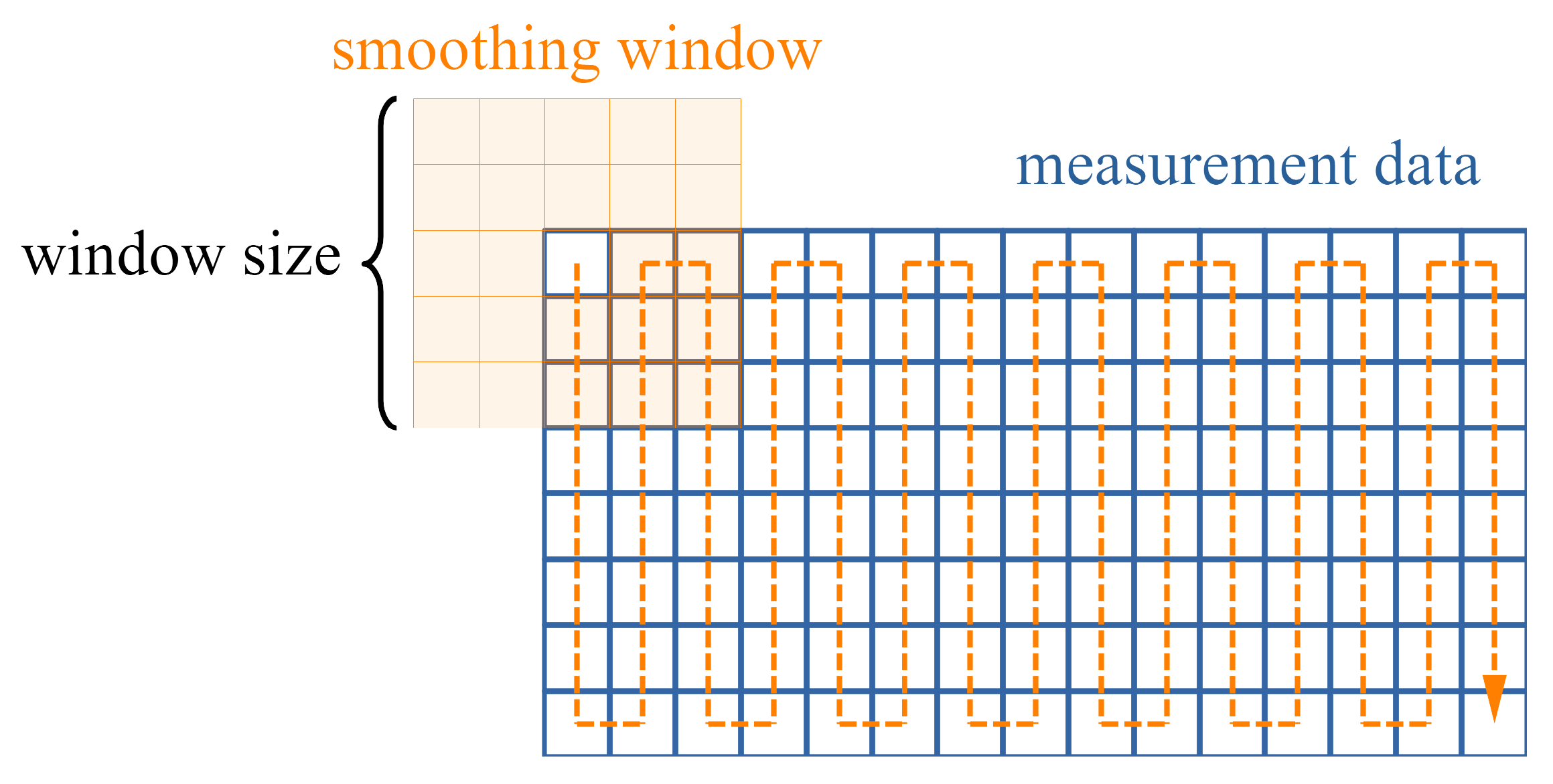

1. For each point in the input array, the average is calculated within a specified window around the current point, that slides over the array and adapts to its the borders, as depicted in

Figure 9. The absolute differences between the original and the averaged points are evaluated, using different thresholds, that were estimated based on the maximum slopes of the ice free blade geometry, the used window size and some inspection of the data.

In a first step, the global approach is used to filter for the most obvious outliers and exclude them from the following local evaluations. To reduce the number of false detection, as discussed earlier, the result is double checked with the local technique but using a big window size (21x21) and a high threshold of . All data points below the threshold are removed from the outlier pool again. The second step consists solely of the local approach, but with a smaller window size of 11x11. Outliers are now defined as points with a higher absolute difference to their corresponding average of . Last, the window is reduced to the immediate vicinity of the points (3x3) and the threshold is lowered to . Found outliers are omitted in the averaging process, therefore the average can change each time the method is applied, thus the process is looped until no new outliers are found. Small bits of data (less than 10 samples) that gets disconnected from the main block during the process are also labeled as outliers, because they lack trusted points around them to compare them with. When the detection process is finished, the outliers are replaced with linearly interpolated values. The Matlab function "fillmissing" is applied row and column wise to consider the properties of the specimens in longitudinal and transversal direction. End values are not extrapolated because this can quickly lead to escalating distortions in the data when there are several missing values in a row. To give additional weight to the direct surrounding, a smoothed data set with a window size of 3x3 is used as well. The filling process is looped two times because the independent use of the row and column wise filling can lead to the closing of gaps that were treated as end values and therefor not replaced the first time.

2.5. Ice Volume Reconstruction Using MATLAB Alpha Shape Function

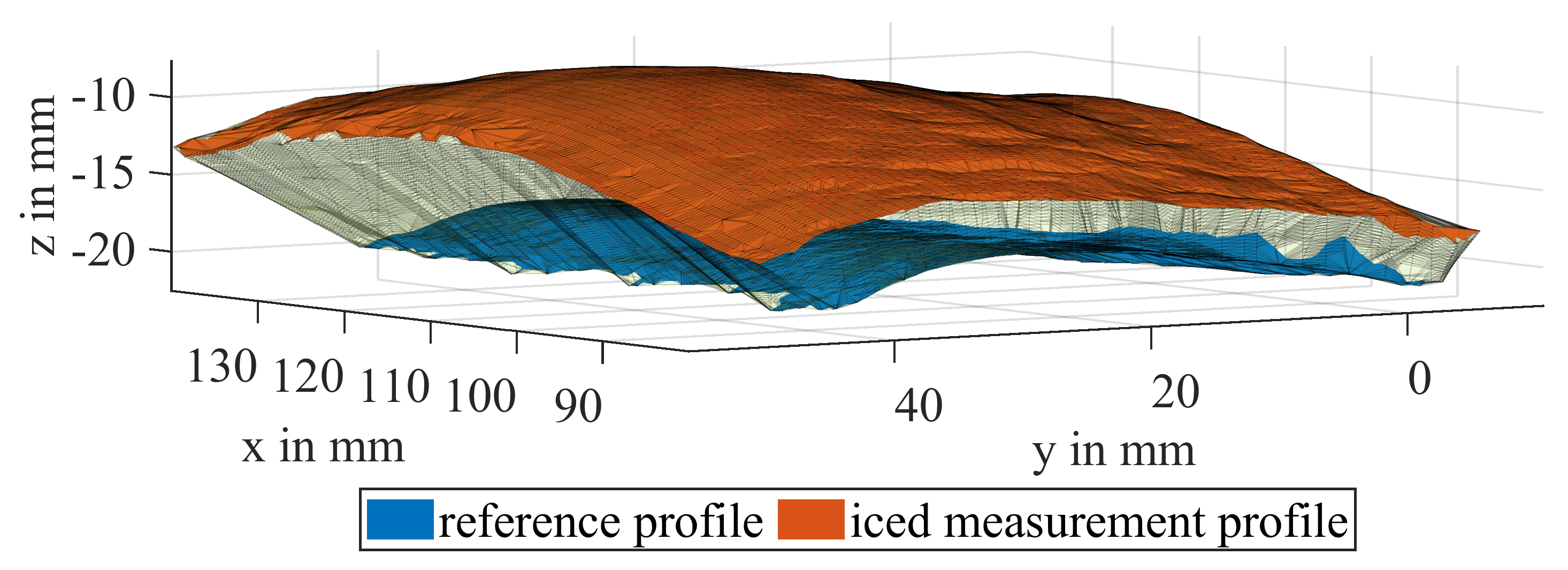

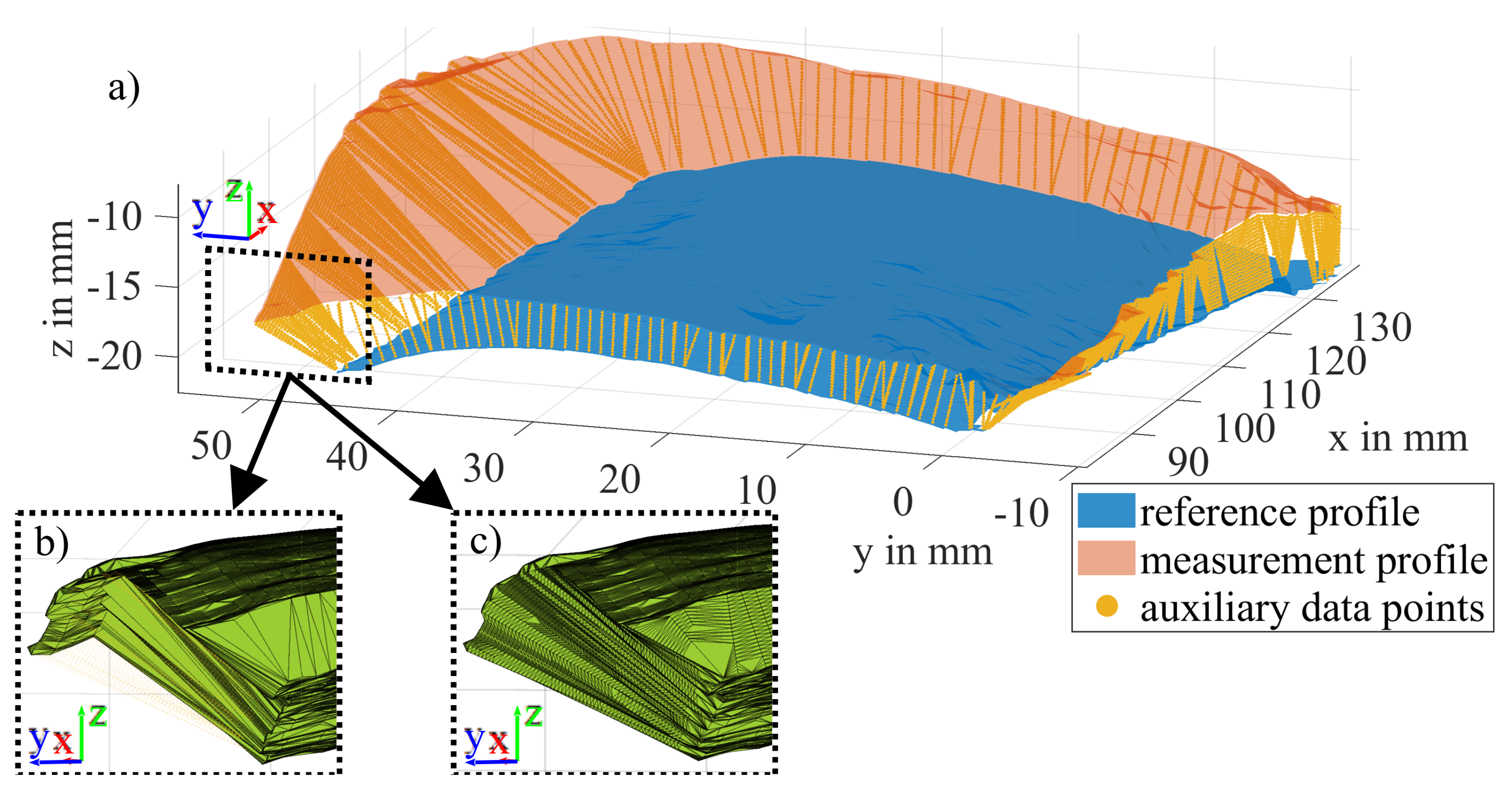

The calculation of the ice volume requires the construction of a closed shape around a cloud of measured data points in 3D space, as depicted in

Figure 10 for the iced middle part of a blade. The thickness of the ice layer (red) varies across the blade, up to a maximum value of approximately 10 mm. Together with the reference profile (blue) the volume of interest is encapsulated. To extract the volume information from the point clouds, an alpha shape is created, which is a more general concept of the convex hull of a set of points P. Using the parameter

= [0,inf] a polytope is generated, whose facet size is dependent on the inverse of

. It can be imagined as the radius of an "eraser" that removes connections of the polytope where it can fit without enclosing a point of P [

22]. Another intuitive approach is the tightness of the fitting boundary that envelops the point cloud. The correspondent alpha shape to

= inf is the convex hull of P. With a decreasing

, the tightness of the fit of the enclosing shape is increased, until it ultimately contains only the points of P at

= 0.

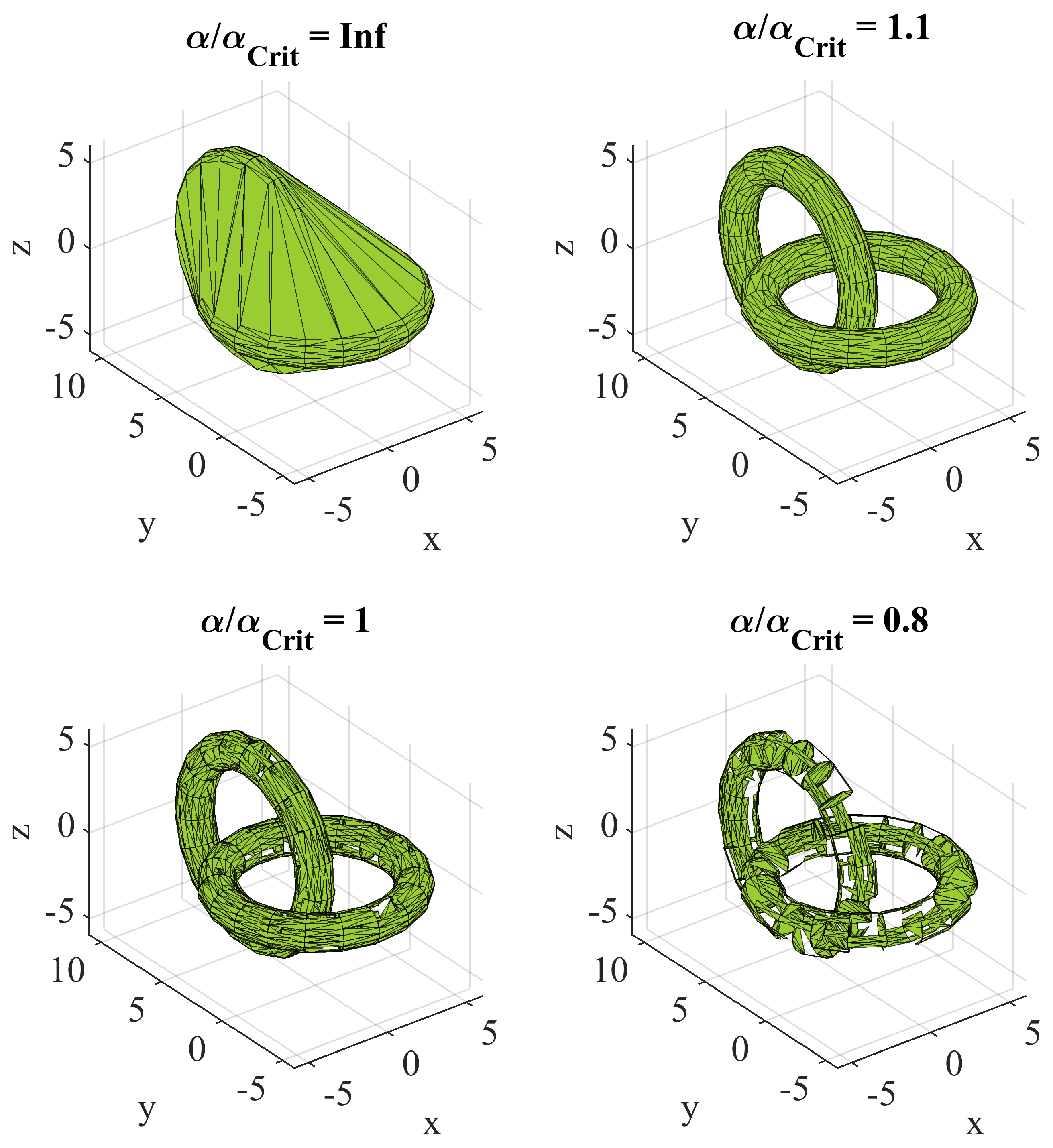

Between these two extrema there exist many different alpha shapes as illustrated exemplary in

Figure 11. To use this mathematical construct as a tool for surface recreation requires to carefully select the alpha parameter and process the data. The main steps are described in this chapter as well as the used configurations for this special case, but they can be adapted to fit different kinds of application.

Matlab provides an in-built function to compute an alpha shape object from point cloud data. If no specified radius

is given to the function, it will determine it as the minimum radius

that is necessary to envelop all points. However, this does not necessarily guarantee that the resulting shape forms a closed volume around all points and is free from holes or interior surfaces. Depending on the sampling density a value slightly higher than

should be chosen. This can also help to suppress the creation of boundary facets that cut through the volume. In the case of irregularly distributed data points

must be selected carefully to suppress holes while keeping as many small details in the resulting shape as possible (see

Figure 12).

Due to the complex shape of the ice and the blade geometry in general, several steps are necessary to receive good results for the icing volume. The general approach consists of these main steps that are described in detail hereinafter:

Define the reference profile (first measurement of the series) and offset it, concatenate the reference with another measurement profile and determine

Reconstruct edge icing by connecting the borders of the reference and the measurement surfaces with auxiliary points

Create the alpha shape for the concatenation of reference, measurement and auxiliary points using slightly bigger than and extract the volume

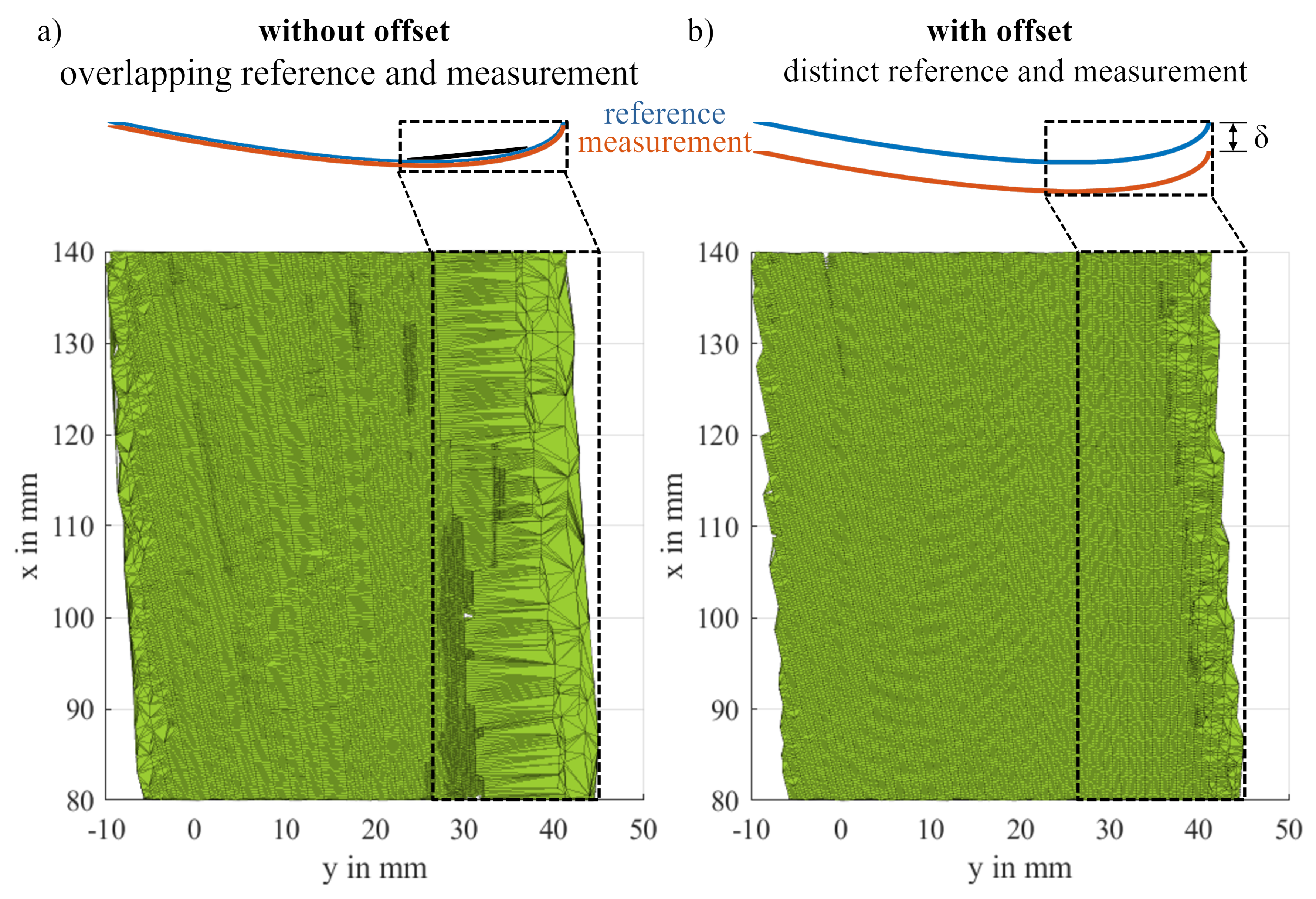

2.5.1. Definition of a Reference Surface and Determination of

The reference surface is defined as the first profile of each measurement series. To ensure a proper working of the alpha shape algorithm for small differences between the reference surface and a measurement surface, we offset the reference data slightly by a value in the opposite direction of the icing. This leads to a better distinction between the reference profile and the surfaces of small layers of ice or ice free parts of the blades and thus prevents the facets of the alpha shape to span over the concave leading edge of the blades. The offset should be chosen as low as possible but it should be higher than deviations in the measurement of the laser scanner, e.g. due to slight out of plane motions of the rotor. The resulting volume offset is calculated from the alpha shape around the reference data with and without the offset and must be subtracted from all other measurements to compensate for the offset. For bigger layers of ice that exceed the original blade surface an additional error can be expected due to a slight change in the angle of the lines that connect the borders of both surfaces but this is assumed to be negligible compared to the impact of bad connections in the alpha shape and other uncertainties like measurement noise.

Additionally, the offset volume can be used to validate the algorithm that is used to construct the alpha shape. The linear shift leads to a volume

that can be compared to the analytical solution from the surface area

A and the offset distance

:

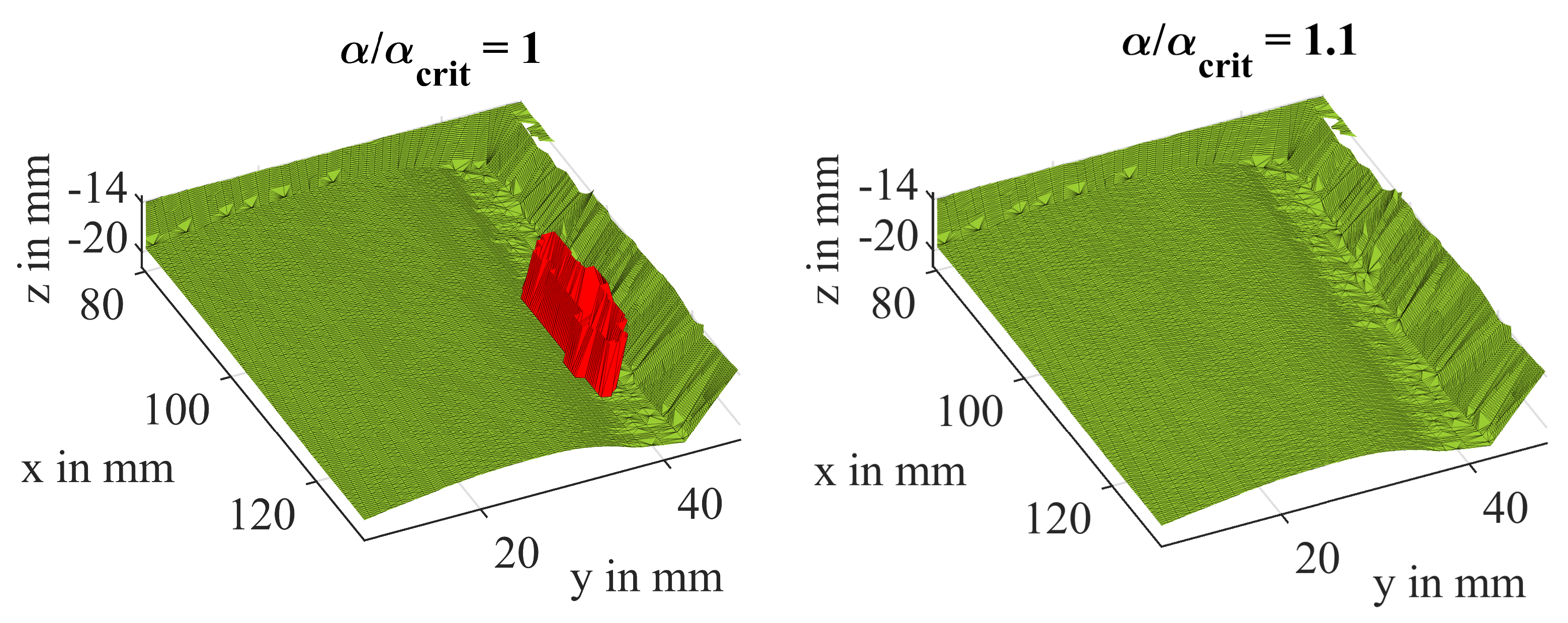

Figure 13 shows the effect of the offset by comparing different ways to create the alpha shape for a section in the middle of the specimens. An ice free measurement was chosen for the demonstration, the correct result for the ice volume therefor would be zero. All values for

were determined automatically by Matlab. For a better visualisation of the effects, the pictures show the bottom side of the resulting volume, the leading edge is on the right side. The left picture shows the resulting shape from the measurement data and the unchanged reference. The resulting shape fills a big portion of the concave leading edge which leads to an overestimation of the volume. To the right, the shape of the measurement with an offset reference is portrayed. The facets in the leading edge are much finer than before. This is due to a smaller

, which results in a better approximation of the measured volume. However, just reducing

for the case without an offset to get smaller facets can lead to a fragmented shape that does not envelop all data points.

The Matlab function "alphaShape" needs the point coordinates as an input. They can be presented as a matrix with three columns, in which each row contains the coordinate values of a point in the order x, y and z. The reference and measurement data are concatenated and handed over to the function. Due to the fact, that no is defined, Matlab will set it to automatically. The value is derived from the alpha spectrum, that lists alphas that produce distinct shapes for the given data, where there is a notable change in the resulting shape. It then can be extracted from the properties of the resulting alpha shape object.

2.5.2. Recreation of Leading and Trailing Edge Icing

With the progressive icing of the blades, the shape of the surface is changing. Especially the leading edge experiences much more icing due to its "cutting" motion through the mist. If the formed ice exceeds the reference surface, this can lead to overhangs as depicted in

Figure 14, which in turn can implicate significant underestimations of the actual volume. This problem arises from the demand for a small alpha-radius to obtain a detailed recreation of the surface structure. A straightforward solution to this is to fill the area between the two surfaces with auxiliary data points that "guide" the alpha shape as desired while using a small alpha-radius. In this case, straight lines were constructed between the border points of both surfaces. For each point in the data set that has more border samples, the closest neighbor in the other set is determined and the connection line filled with equidistant points with a given target density of four points per millimeter, which is slightly smaller than the radial resolution of the measurement system.

2.5.3. Create the Alpha Shape and Extract the Volume

As mentioned earlier, a set of points has a whole family of corresponding alpha shape objects to choose from, depending on . The final alpha shape is created from the concatenation of the reference, measurement and auxiliary points, with . It should be noted that the used factor was chosen arbitrarily based on the results of different examples and might differ for other experimental set-ups and data structures. A strict definition for might lead to good results when changes in the spatial arrangement and differences in the density of the measured points are within a small range, which is not given for the present experimental design. also varies strongly with the amount of ice on the rotor blades.