1. Introduction

Construction is one of the oldest known activities in humanity. The production and application of concrete for use in buildings is present throughout the planet, regardless of the economic and geographical condition of each country, having in its composition the Portland cement, which is the second most consumed material in the world, behind only water (1). Thus, considering its high consumption, research seeks for long years to evaluate various conditions of technological performance (2), durability (3), potential for application of new materials (4), and issues related to its sustainability (5) materials, such as concrete and mortars. Construction and demolition waste is one of the main sources of production of recycled aggregates worldwide, due to its high availability and compatibility (6), (7).

Currently, focusing on the preservation of the environment intensified the reuse of solid waste in construction requiring regulations that sustain and guide the procedures for proper disposal and reuse of waste. The reuse directly ensures the reduction of extraction of natural resources. It is estimated that civil construction consumes between 14% and 50% of the available natural resources on the planet (8).

Numerous studies have been developed to evaluate the use of recycled aggregates in construction. It is a consensus in the scientific community that the generation of construction and demolition waste is considered unsustainable activity, because it causes constant deterioration to the environment. Up to 48% of total municipal solid waste generated on a global scale is estimated (9). The growth of the construction industry has considerably increased the consumption of natural raw materials and the production of waste, intensifying problems derived from inadequate procedures, such as the uncontrolled disposal of this waste in large cities (10). In Brazil, for example, construction companies are responsible for 52% of the civil construction waste generated, while the rest is generated informally. In addition, because they are bulky and high density materials, the disposal of construction waste generates a great environmental impact, irreversible (11).

Construction and demolition waste (class A) have become increasingly one of the targets of the technical-scientific environment, using it as an aggregate for numerous uses in construction and other (12). The use of this waste becomes an important tool in combating environmental degradation, directly and indirectly, by reducing the consumption of inputs from civil construction from the process of crushing rocks, gravel and artificial sand. And, on the other hand, through recycling not only adds value to the final product but also reinserts a material would be disposed in landfills for many years.

Studies have found that materials produced with recycled aggregates meet the required standards and specifications. Although, in several cases, there is a decrease in mechanical strength from substitution above 30%, with exceptions (13). Research shows improvement in the mechanical properties of these materials with the use of recycled aggregate. It was observed an increase in the compressive strength of concrete blocks with recycled small aggregates when compared to the reference blocks (14). They justified these best results by the presence of non-hydrated cement particles in the recycled aggregate, which could contribute to a better connection between the cement paste and the aggregates, due to its greater porosity. Other studies observed the mechanical performance of concrete produced with recycled aggregates and obtained similar results (15).

On the other hand, the type of recycled aggregate affects the performance of materials differently. Thus, (16) highlighted an increase in impact resistance when recycled coarse aggregates were used in concrete blocks. They also pointed out that the incorporation of recycled fine aggregates from construction and demolition waste can increase the mechanical strength of concrete due to the particles of non-hydrated cement in the recycled material. Remembering that the loss of mechanical strength is a limiting factor for the use of recycled aggregates and is greater when the water/cement ratio is lower. Notwithstanding the above, some authors justified the increase of compressive strength in concretes with recycled fine aggregates due to the pozzolanic effect of fine particles.

The higher content of fines in recycled aggregates can improve the transition zone between the cementitious matrix and the aggregate, which contributes to greater concrete compaction. Second (17) fine particles provide better packaging. As the recycled aggregate has greater absorption promotes greater adhesion between the cement paste and the aggregate, through the absorption of the paste and the precipitation of the hydration crystals in the pores of the aggregate. The presence of old mortar particles adhered to the grains of the recycled aggregate is a relevant characteristic that affects the behavior of the concrete, this presence can correlate a higher water absorption, higher porosity and lower resistance of the recycled concrete (18).

The use of recycled aggregates in paving is the best accepted alternative in the technical environment (19). The simplest form of recycling is the application of the rubble in the form of running gravel, on bases, sub-bases and primary paving coatings. The use of construction and demolition waste in the base layers, sub-base and primary coating, have numerous advantages and have significantly lower construction cost than those produced with graded gravel or added to the soil (20).

Artificial rocks are innovative materials that are manufactured with a polymer resin and a high percentage of natural aggregates, which can be replaced to some extent by waste. The mechanical properties of artificial rock surpass natural stones, since the use of resin in their production results in a less porous material, with a lower water absorption rate and better mechanical strength, making them suitable for more demanding applications, as as floors and walls (21,22).

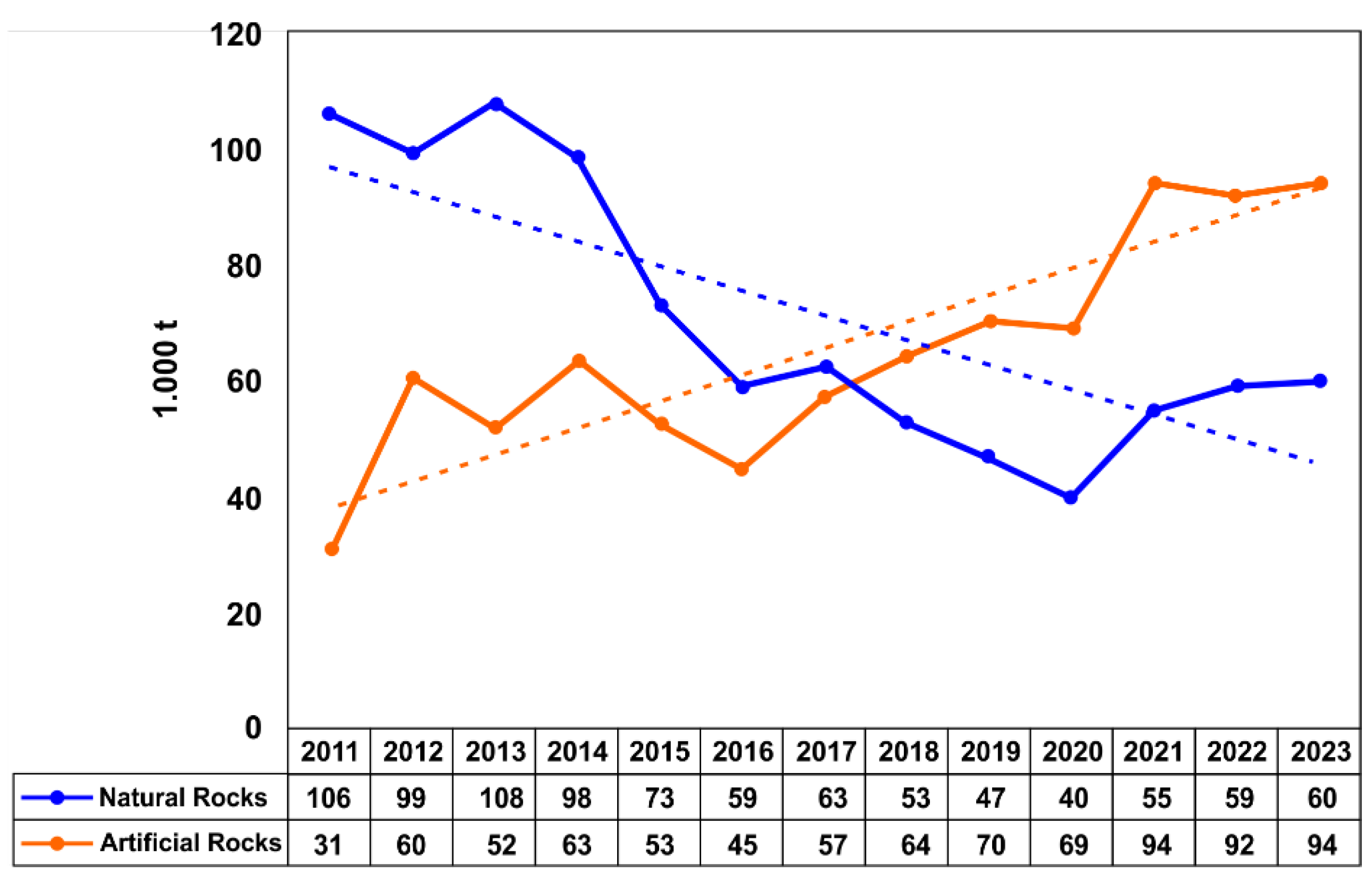

Artificial rock is highly attractive for domestic environments due to its variety and consistency of colors and resistance to scratches, chips and stains. The popularity of artificial rock has increased rapidly worldwide. When analyzing the Brazilian market for ornamental stones, ABIROCHA (23) shows that imports of artificial rocks are twice as large as imports of natural stones, according to

Figure 1, pointing out their incipience and highlighting the relevance of research conducted in this area, for the development of new materials for the Brazilian market.

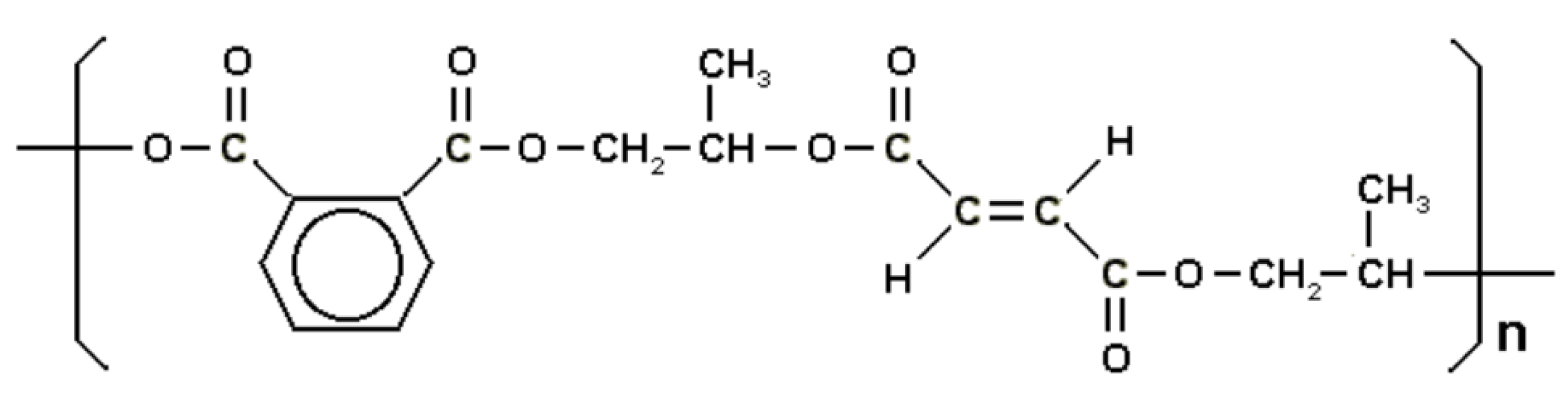

However, it is deficient studies that seek to use the waste of civil construction and demolition in the elaboration of artificial rocks for use as finishing: kitchen and bathroom countertops, stair cladding and others; replacing natural (ornamental) rocks and even several artificial rocks commercialized today. Due to this scenario, this research seeks this niche; replace, in the production of artificial rocks, the standard raw material (waste of ornamental stones) by construction and demolition waste; results compared to numerous studies already developed in the area of artificial rocks. The choice of a thermosetting orthophthalic polyester resin for the polymer matrix occurred due to the relation: cost benefit. The resins produced with orthophthalic anhydride, that is, the so-called orthophthalic, are applied in most cases due to their low cost, although they have limited thermal stability and chemical resistance (24). Thus, its low cost combined with the primary conditions of mechanical, physical and chemical resistance were initially perfect for research.

A guiding study on artificial rocks was conducted in Taiwan (25), where it was presented results of the production of artificial stone slabs using glass waste, stone fragments and vacuum vibratory compaction. This research elaborated artificial stone plates with unsaturated polymer resin, glass powder and fine granite aggregates. The tests showed the composition with 50% glass powder and 50% granite aggregates with better results: compression (148.8 MPa), water absorption (below 0.02%), density (2,.45) and bending (51.1 MPa). In Turkey in 2018, a survey produced and characterized a polymer matrix composite hybrid (26). O composite elaborated by this research made use of epoxy resin, fiberglass and granite residue that went through mixer in propeller with vacuum and were poured into silicone mold. The composition called F5505 with 40% resin, 55% granite and 5% fiberglass obtained the best results in terms of high theoretical density, hardness, flexural strength, bending modulus and impact strength. Malaysia 2020, another research characterized and evaluated dolomite and kaolin as charge in Poly art marble properties. Twelve types of composition were molded with different percentages of polyester resin, dolomite and kaolin. The best results pointed to 3 types of compositions: D60K15 (resin 25% + Dolomite 60% + Kaolin 15%) better water absorption (0.11%); D60K10 (resin 30% + Dolomite 60% + Kaolin 10%) better compression (105.43 MPa) and flexion (34.1 MPa); D70% (resin + Dolomite 70%) best result for hardness Barcol (27).

Among the negative impacts of the large amount of CDW generated is the rapid occupation of landfills for the accommodation of waste in the environment, being the illegal dumping often used worldwide, such as China, Malaysia, Hong Kong, Israel and Brazil. Big cities like Shenzhen (China) and Chennai (India) and parents like Sri Lanka, were seriously affected by disastrous events due to the inadequate disposal of construction waste (28). This shows that the environmentally adequate disposal of waste is a challenge that grows due to economic development, a problem that affects even developed countries in Europe, where the results of waste management plans, differ depending on the quality of their implementation (29). The amount of CDW is a significant portion of municipal solid waste, studies by several authors, including: (30) e (31) show that there are concerns worldwide relating to the CDW with public policies, whether by economic, social or environmental bias.

In Brazil, about 48 million tons of construction and demolition waste (CDW) were produced in 2021, according to the Solid Waste Panorama in Brazil, published by the Brazilian Association of Public Cleaning Companies and Special Waste (32), that means 38.4 million tons could be recycled or reused. This same study shows that between 10% and 30% of the construction materials purchased for the work are discarded. This means that 10% to 30% of the investment made in construction is wasted. It pays to acquire, transport, break, collect and remove.

According to information from the Brazilian Association for the Recycling of Civil Construction and Demolition Waste, it is estimated that in 2021 520kg of waste per inhabitant per day was produced, however, of about 290.5 tons of rubble generated daily in the country, only 21% are recycled (33).

The recycling of solid construction waste varies depending on the waste that will be treated. This research addresses the Solid Waste Recycling of Civil Construction and Construction and Demolition Waste, established by resolution CONAMA 307, Class A waste (reusable or recyclable waste such as building aggregates, demolition, repairs and renovations of buildings, ceramic components, bricks, blocks, tiles, mortar and concrete, paving and precast) (34).

The recycling of construction waste has advantages related to environmental, technological and economic spheres. Among the advantages, include the reuse of materials, reducing the use of non-renewable resources; the reduction of inadequate disposal; the processing of products; and savings in replacing the purchase of natural raw material.

Considering the high use of concrete worldwide, the demand for aggregates of different diameters extracted from natural rocks and/or river beds (sand and gravel), causes a number of environmental damage, waste from this production chain. Moreover, in the not-so-distant future, the scarcity of these natural resources is evident, which will certainly cause serious economic damage, especially to developing countries such as Brazil.

More than cost efficiency, recycling contributes to the industry’s environmental goals. The 2022 Global Status Report for Buildings and Construction, United Nations Environment Program (35), points out that carbon dioxide (CO2) emissions in the sector hit a record 10 billion tons in 2021, 5% higher than in the previous year. The International Energy Agency’s Global Status Report 2019 (36), indicates that construction “accounted for 36% of final energy use and 39% of energy and process-related carbon dioxide emissions in 2018”.

In addition, according to the UN (37), construction accounts for about 11% of global CO2 emissions from human activities. This includes emissions associated with the production of building materials, the construction and demolition of buildings, and the operation and maintenance of buildings throughout their service life.

In this context, in order to relieve the pressure on the environment caused by the construction industry and also by the ornamental stone mining industry, this research seeks new variables for the disposal of waste from construction having in the composition of artificial rocks the addition of this waste an odd possibility to be analyzed, in an unprecedented way; directly evidencing the concept of sustainable development (environmental and economic), replacing the concept of end-of-life of linear economy, by new circular flows of reuse, restoration and renewal, in a process integrated circular economy. This possibility seeks not only to reduce costs in the production of artificial rocks, but also to promote the use, on a large scale, and with great added value, of solid waste from one of the fastest growing sectors on the planet, construction, which has massively its final disposal in landfills.

3. Results and Discussion

3.1. CDW Chemical Characterization (XRF – X-Ray Fluorescence)

Table 5 shows, in percentage, the chemical composition performed by XRF of the CDW. The base of the composition, with 77.63% is related to the presence of oxides: Al

2O

3, CaO and SiO

2; situation already expected, in view of being a residue with high concentrations of concreting and asphalting.

The basis of the composition of CDW is similar to the basis of the chemical composition of clinker (

Table 6), which in turn is the basis of the composition of cement (49)

Another portion of the RDC composition, with 10.54% is related to the presence of Fe2O3, SO3, Na2O, K2O and MgO.

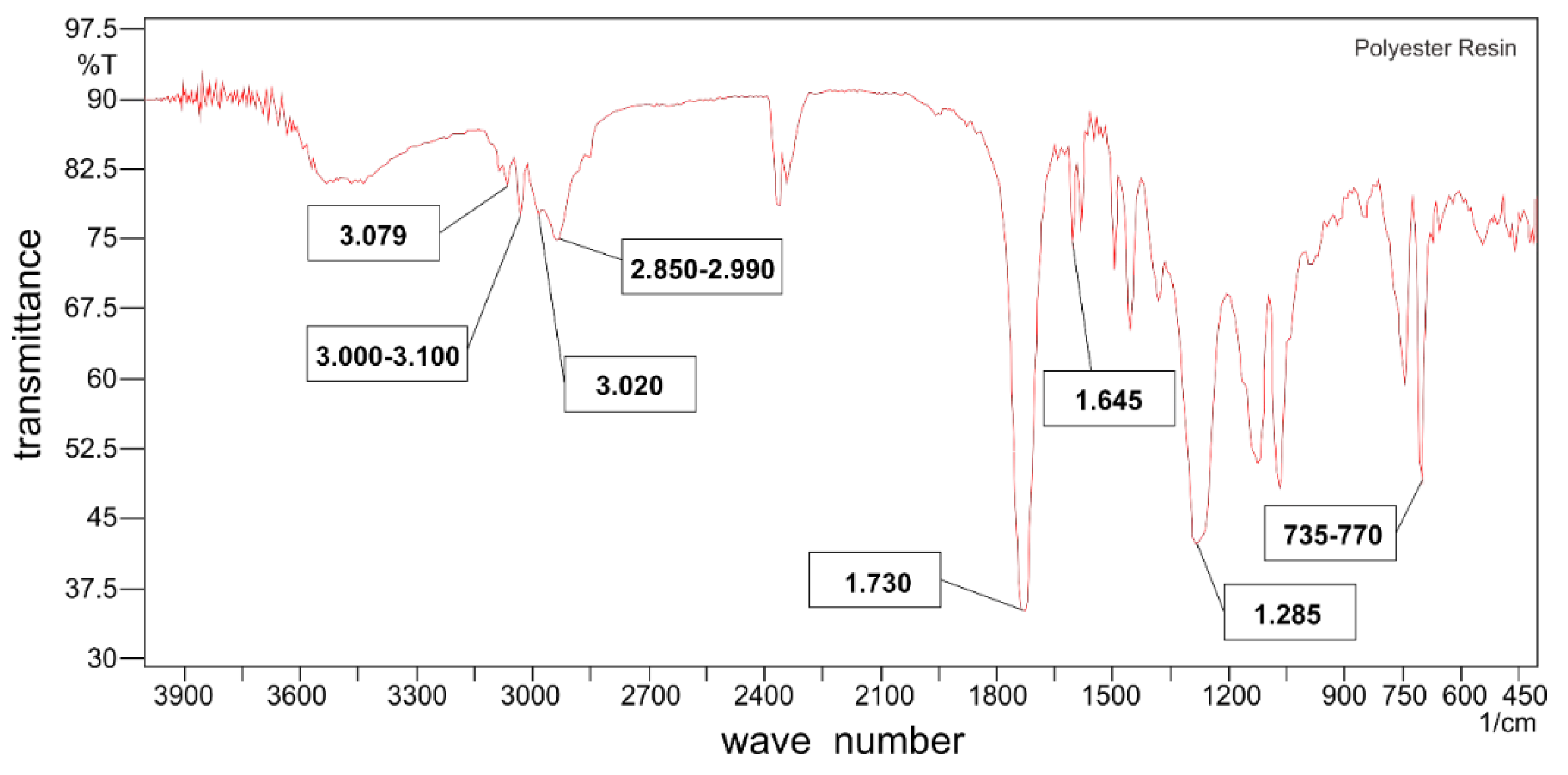

3.2. Characterization of Functional Groups - Resin (Fourier Transform Infrared Spectroscopy)

The Fourier transform infrared spectrum, presented in

Figure 5, presents the characteristic bands of the functional groups present in the polymer, which are listed in

Table 7.

The band at 744 cm-1 in the FTIR spectrum is related to ortho substituted benzene, due to the presence of phthalic anhydride in the resin, in order to regulate the amount of crosslinking. The double bond favors the formation of cross-linking, leaving the material with greater mechanical strength.

3.3. Physical Indexes and Flexural Resistance by 3-Point Loading

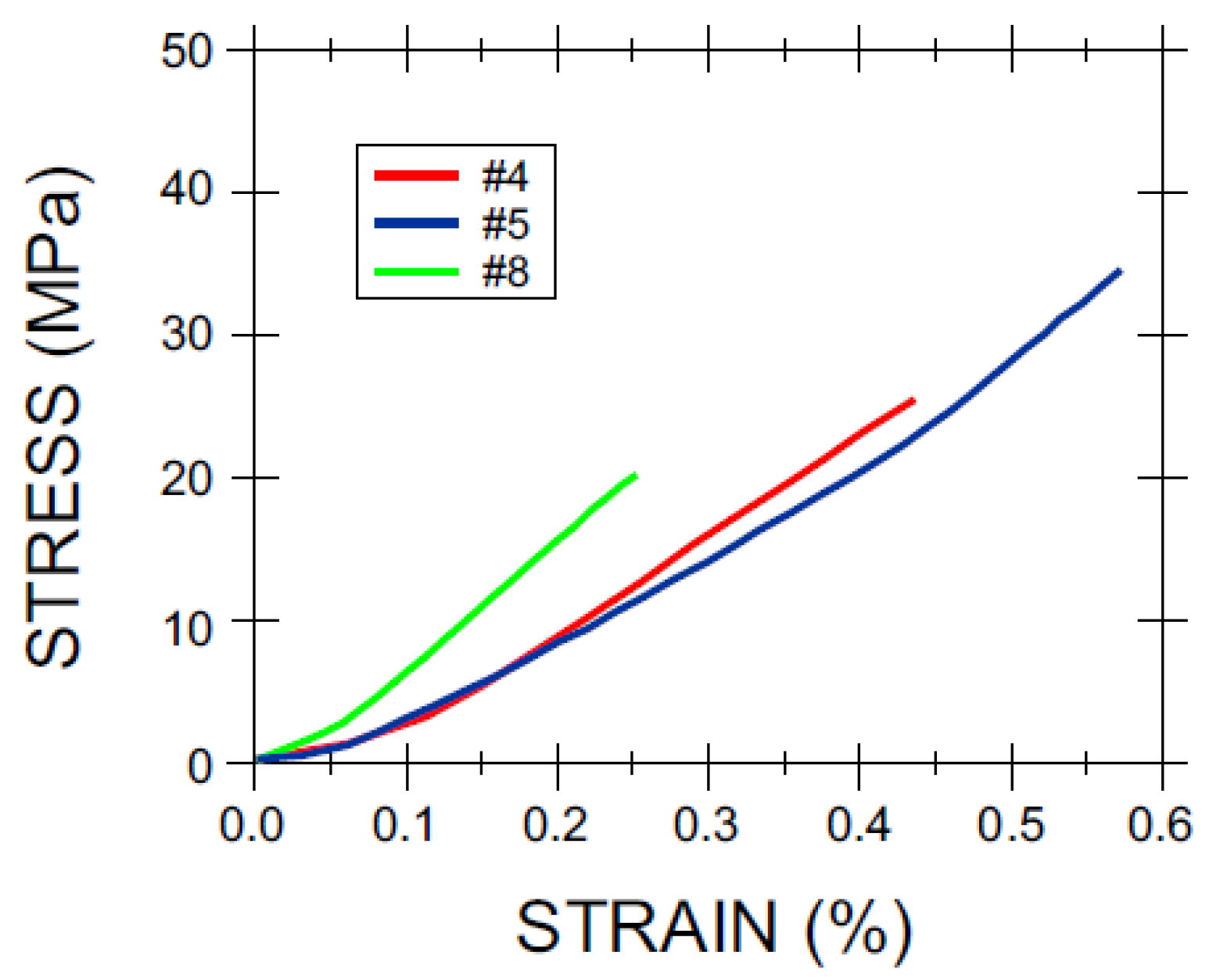

Table 8 presents the results of the physical indices as well as the results of the bending in 3 points, among the 3 best mixtures (4, 5 and 8), confirming the composition 5 (1/2 coarse particles and 1/2 fine particles) with better compaction and mechanical strength (

Figure 6).

3.4. Flexural Resistance Due to 3-Point Loading (CDW-5 and Resin)

Table 9 presents the maximum flexural strengths due to 3-point loading of CDW-5 artificial stone and polyester resin.

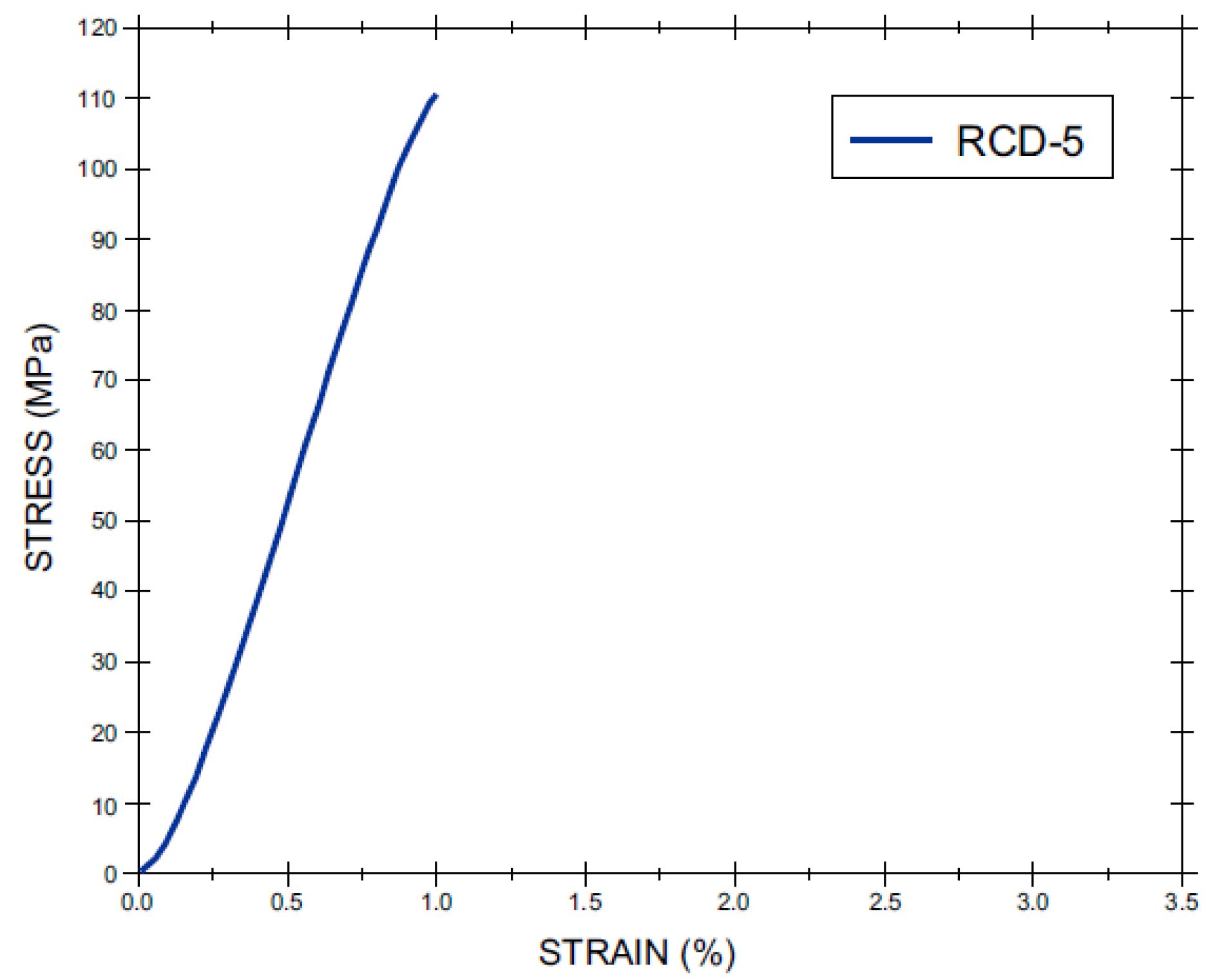

Figure 7 shows the stress X strain curves obtained by the 3-point load bending strength test of the RCD-5 artificial stone and the polyester resin. The mechanical strength, or stress in which the material breaks, is the most important property of structural materials (50).

The hydration reaction of RCD in the presence of resin, consequently seeks the formation of hydrated calcium silicates and calcium hydroxide. In the presence of calcium sulfate, a substance called etringite is formed, which is a mixed oxide of calcium, aluminum and hydrated iron commonly associated with sulfate ions; present in the characterization of CDW by XRF. This substance is important because it forms chemical bonds with the other substances, making it harden (51).

When confronting the result (34.74 MPa +2.55) found in the resistance to bending by loading in 3 points of artificial stone RCD-5 with other results, similar artificial stones, found in the literature, Lee et al (25) 27.9-52.7 MPa; Ribeiro et al (52) 21.5 MPa; Hamizah et al (27) 34.1 MPa; Peixoto et al (53) 25.4 MPa; We concluded the standardization of the good performance of CDW-5 elaborated with 85% of RCD and 15% of polyester resin.

The standard ABNT/NBR 15845-6 (45) stipulates that the minimum flexural strength in a 3-point bending test should be 10 MPa for stones used in flooring, while ASTM C503 (54) has a value of 7 MPa, but according to Chiodi Filho and Rodriguez (55), ornamental stones used as coatings in construction, with flexural strength above 20 MPa, are classified as high strength materials. The RCD-5 presented a flexural result above this value (347.40 Kg/cm2), and can be classified as an artificial stone of high resistance, allowing its use in worktops and countertops.

3.5. Uniaxial Compression Strength

Figure 8 shows the maximum uniaxial compressive strength of CDW-5.

When comparing the result (111.96 MPa +5.24) found in the uniaxial compressive strength of artificial stone CDW-5 with other results of similar artificial stones found in the literature Lee et al (25) 78.70-151.30 MPa; Ribeiro et al (52) 77.9 MPa; Hamizah et al (27) 105,43 MPa; Agrizzi et al (56) 100.70 MPa; the same standardization already found in the flexural strength also found for the compressive strength, confirming the good performance of CDW-5.

Again, Chiodi Filho and Rodriguez (55), indicate that ornamental stones used as coatings in construction, with uniaxial compressive strength between 700 and 1,300 kg/cm2, are classified as medium strength materials. The CDW-5 showed results to uniaxial compression of 1,119.60 kg/cm² proving its potential for use in construction.

3.6. Scanning Electron Microscopy (SEM) Analysis

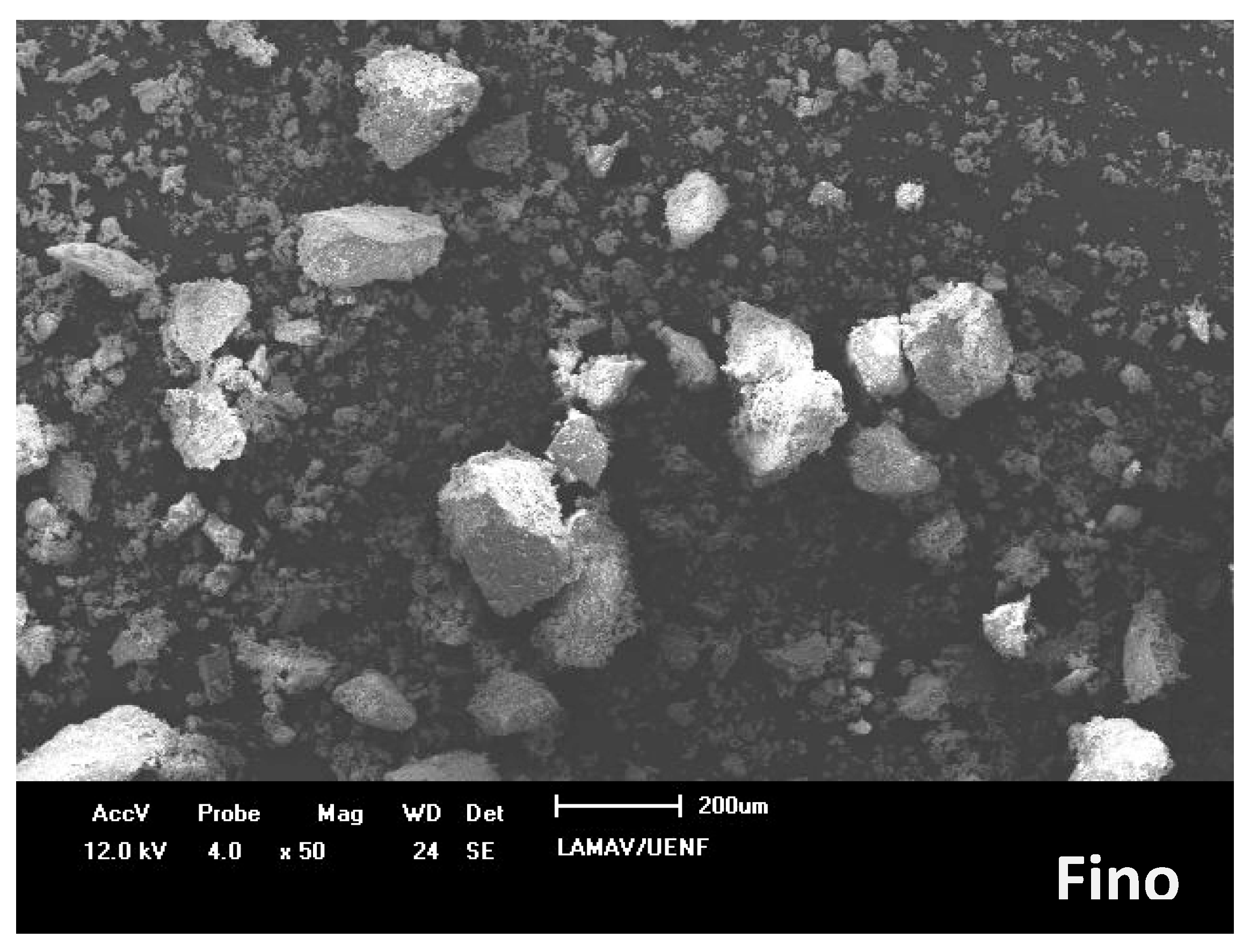

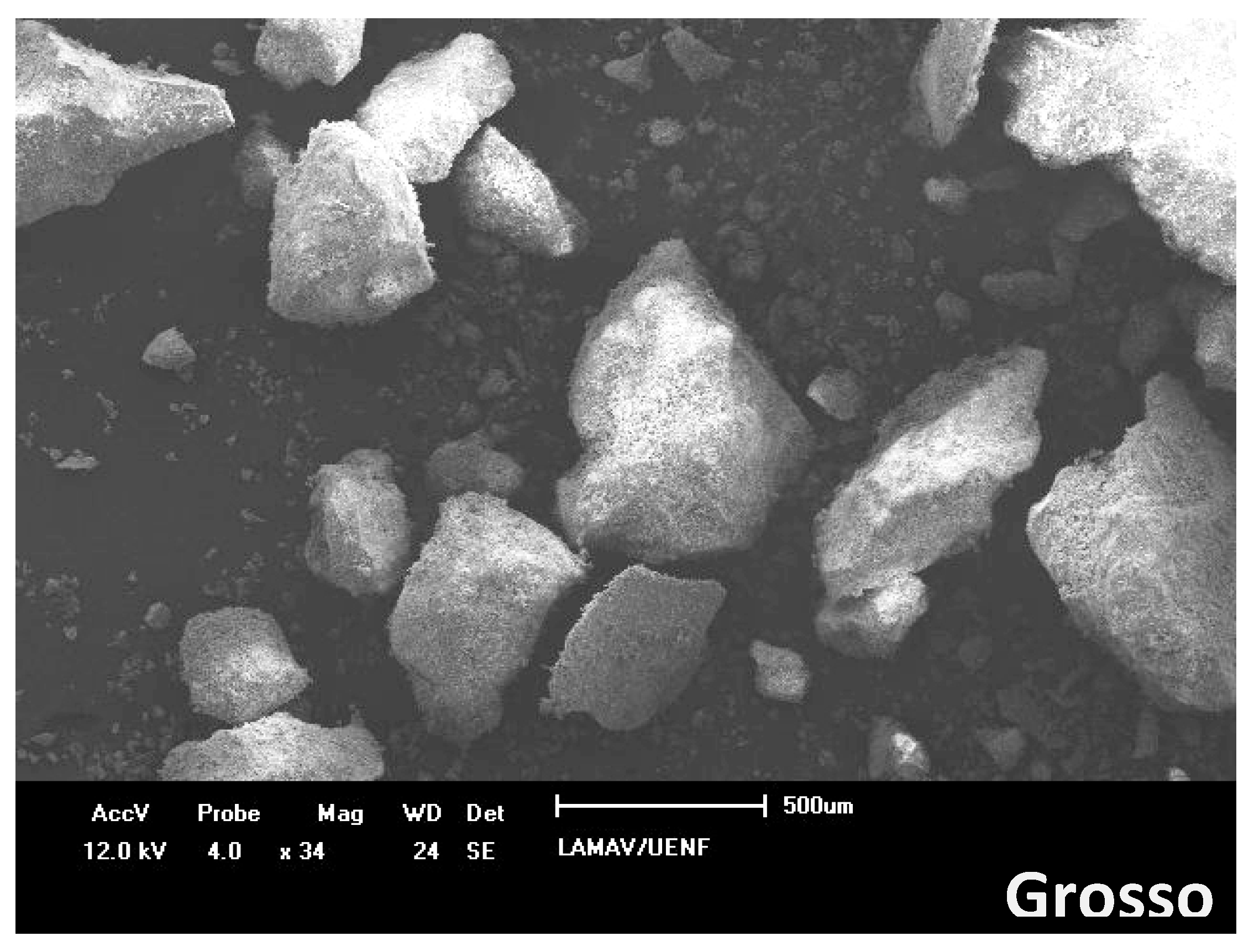

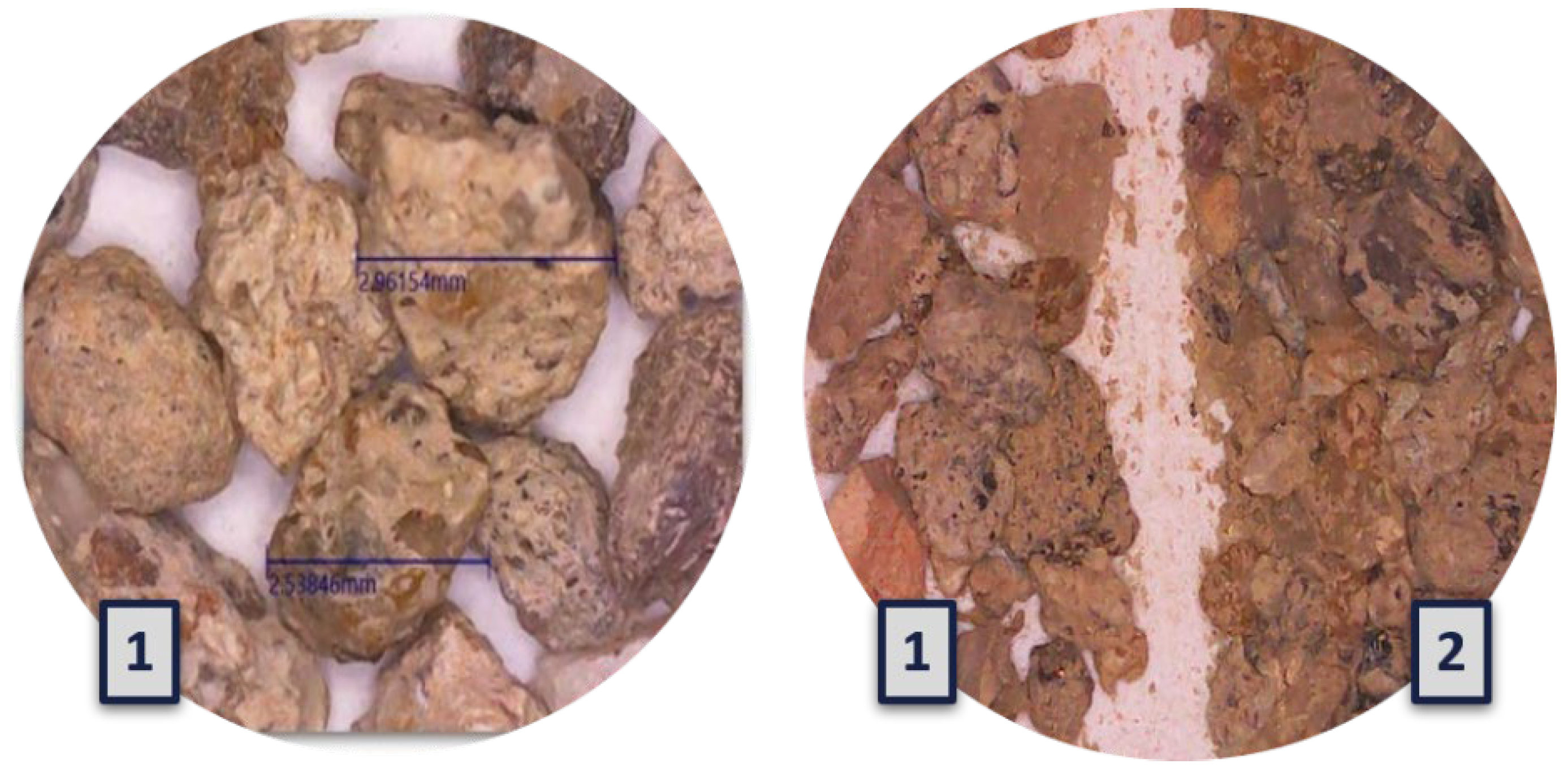

Figure 9,

Figure 10 and

Figure 11 show the micrographs of the CDW particle sizes (fine, medium and coarse) present in this research obtained by SEM.

In both micrographs it is possible to point out the morphology of the grains with rough surfaces, irregular shapes and protuberances on the contours. The shape of the grains, the surface roughness and the protrusions are responsible for the highest values of mechanical resistance, considering that these characteristics favor not only better internal locking, as well as better adhesion between the resin and the grains.

Figure 12 shows how the morphology of the grains of the RCD (thick) are shaped like a puzzle, forming a natural compaction as soon as the voids are filled, later, by fine grain size.

The morphology of the particles can change the packaging condition. The less spherical the particle, the lower the packing density of a distribution that contains it, because the friction between the particles from the contact of their irregular surfaces is verified. The smaller the size of the irregular particles, the greater this effect, due to the greater specific surface area (57).

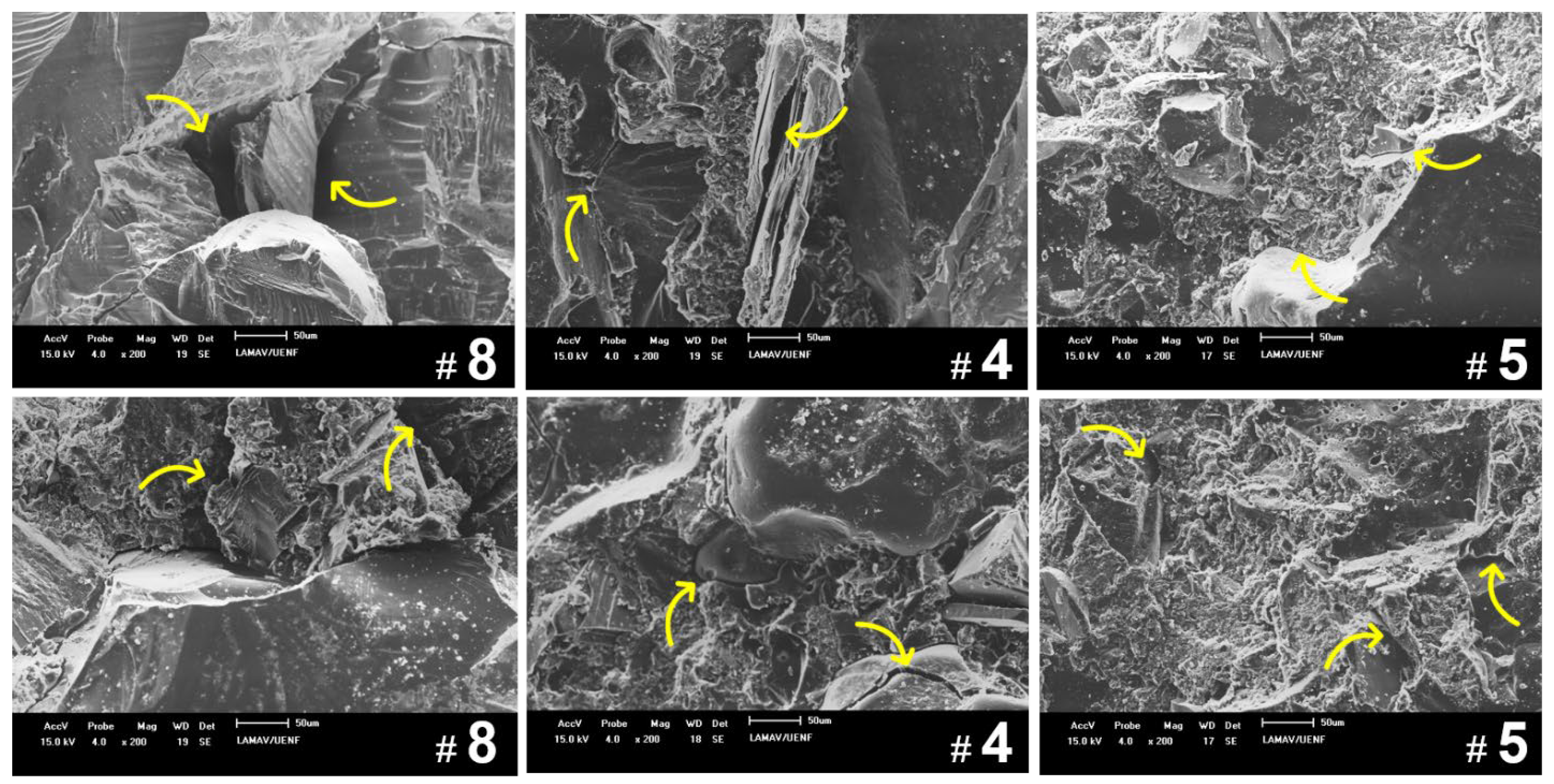

Figure 13 presents the micrographs, obtained by SEM, of the fracture surfaces of the specimens (compositions 4, 5 and 8) from the flexion test.

The progression of packaging following micrographs is latent. Composition 8 presents cracks along the anchorage between the lattices, the interaction with the resin leaves empty “spaces” along the fracture. Composition 4 has an improved behavior as a function of position 8, its cracks are smaller and the interaction residue/ resin has a better adhesion, this translates into a more positive result compared to composition 8. But composition 5, even though scoring some micro flaws in the surface analyzed, it has infinitely a better anchoring of the lattice to the polymer matrix. The coating of the resin is more efficient with the granulometry proposed for this composition, translating into better results of density and mechanical strength. The quality of the interfacial interaction is directly related to the improvement of the mechanical strength of a composite. This is due to the fact that good interfacial wettability means higher adhesive strength (58).

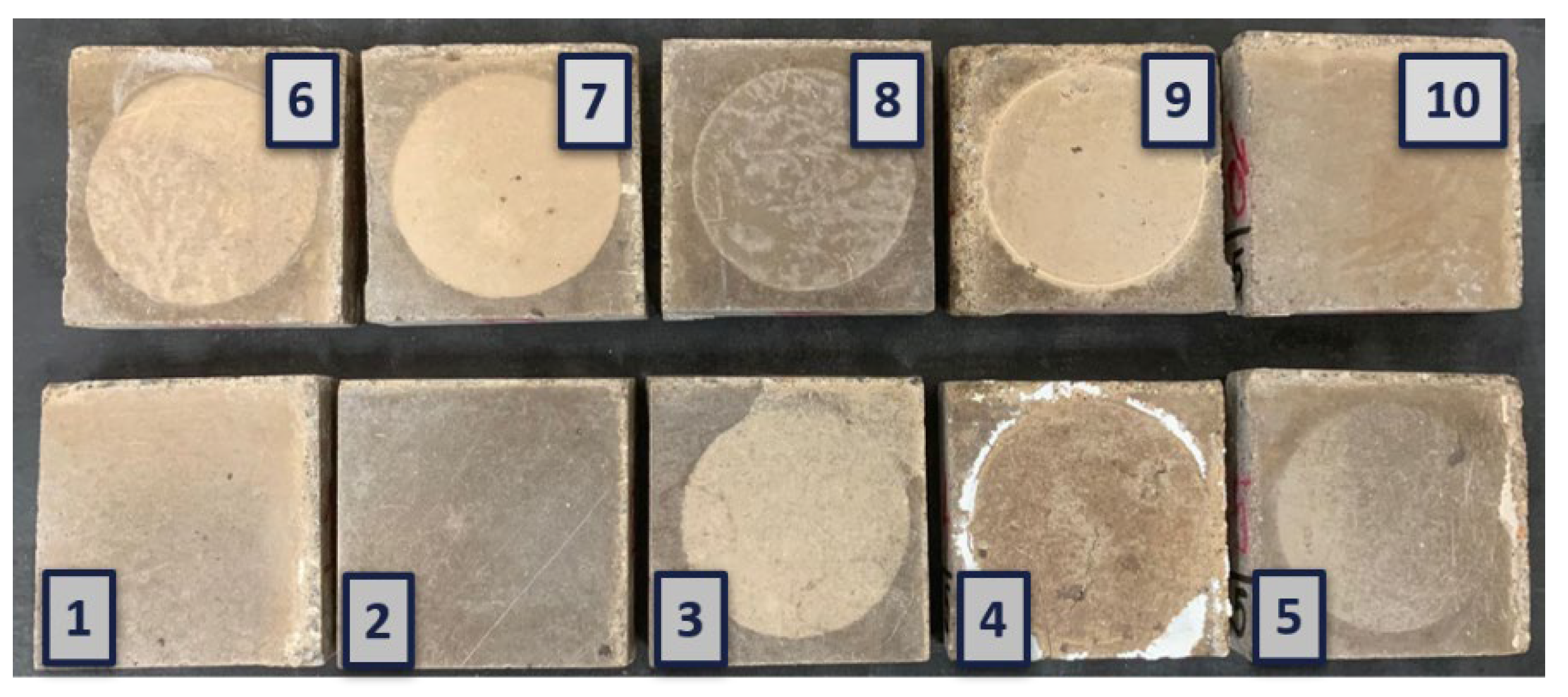

3.7. Resistance to Chemical Attack

The reagents used in this test simulate the chemical composition of some substances present in food and cleaning products in general.

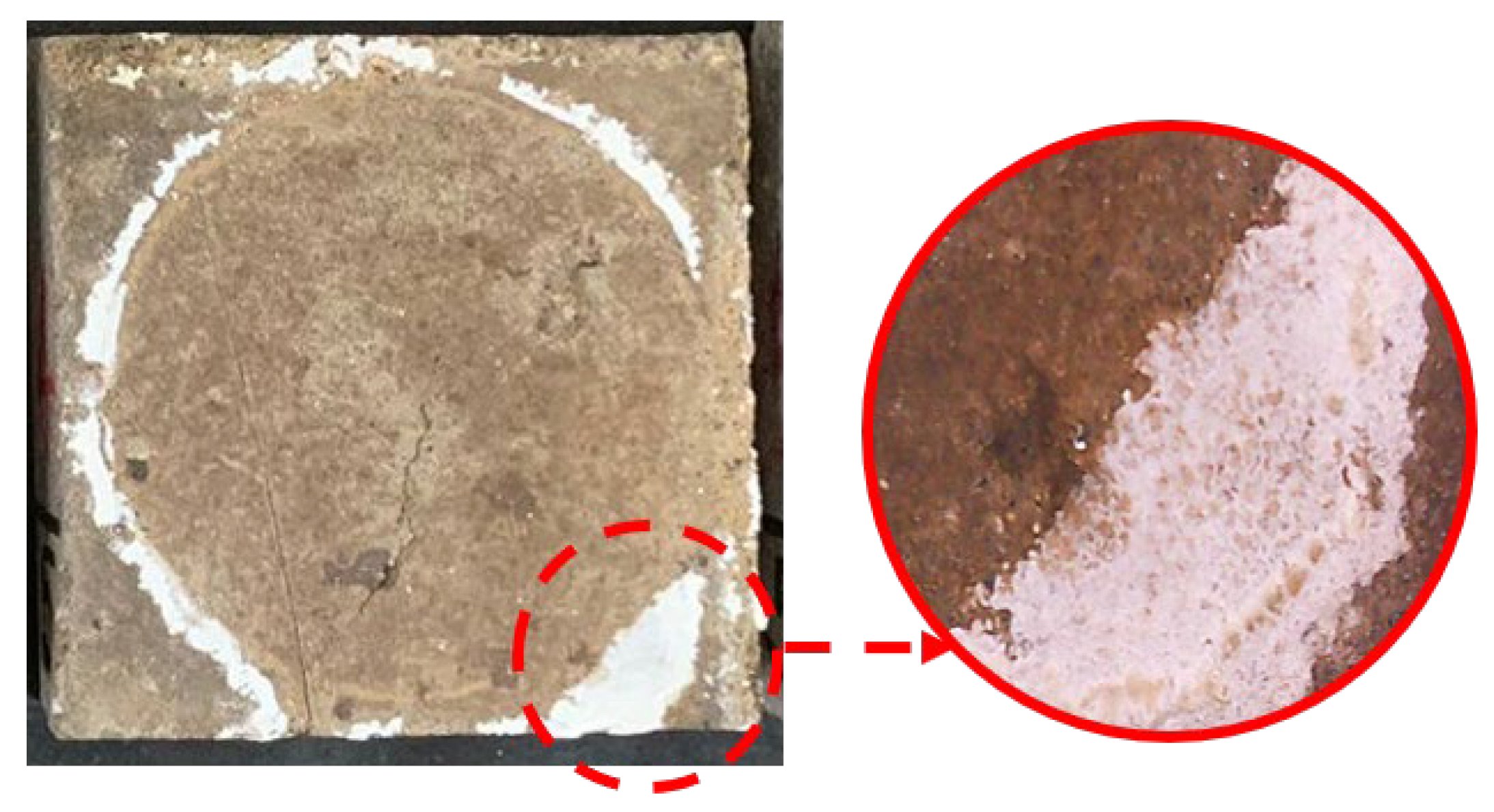

Observing the results presented in

Figure 14, we can observe chromatic changes in several specimens that had exposure for 24h, as well as, for 96h; except the specimens 01 (ammonium chloride); 02 (sodium hypochlorite) and 10 (distilled water).

These chromatic modifications can be justified due to the composition of orthophthalic polyester resin, as they are used as modifiers acid, phthalic or its anhydride, so their chemical properties are inferior to the others, due to the difficulty of obtaining high molecular weight polymers (short molecular chains -

Figure 15 Phthalic anhydride has a strong tendency to regenerate from phthalic acid esters (reversible reaction), fact that increases the presence of low molecular weight species, highly sensitive to chemical attack (59).

Table 10 presents the results of visual inspection of the effects of chemical attack by reagent, requirements present in the NBR that guides the test, the absence of dissolution and mineral detachment is noted.

A punctual observation is necessary to the effect of chemical attack on the specimen n. 4 that was exposed for 24 hours to lactic acid, because in addition to the chromatic modification a layer of irregular whitish colour was formed by the liquid part that possibly leaked from the container onto the specimen during the test period, the presence of this irregular form probably occurred by the oxidation reaction of the primary carbon present in the reagent (60). There was no mineral detachment, as can be observed in

Figure 16.

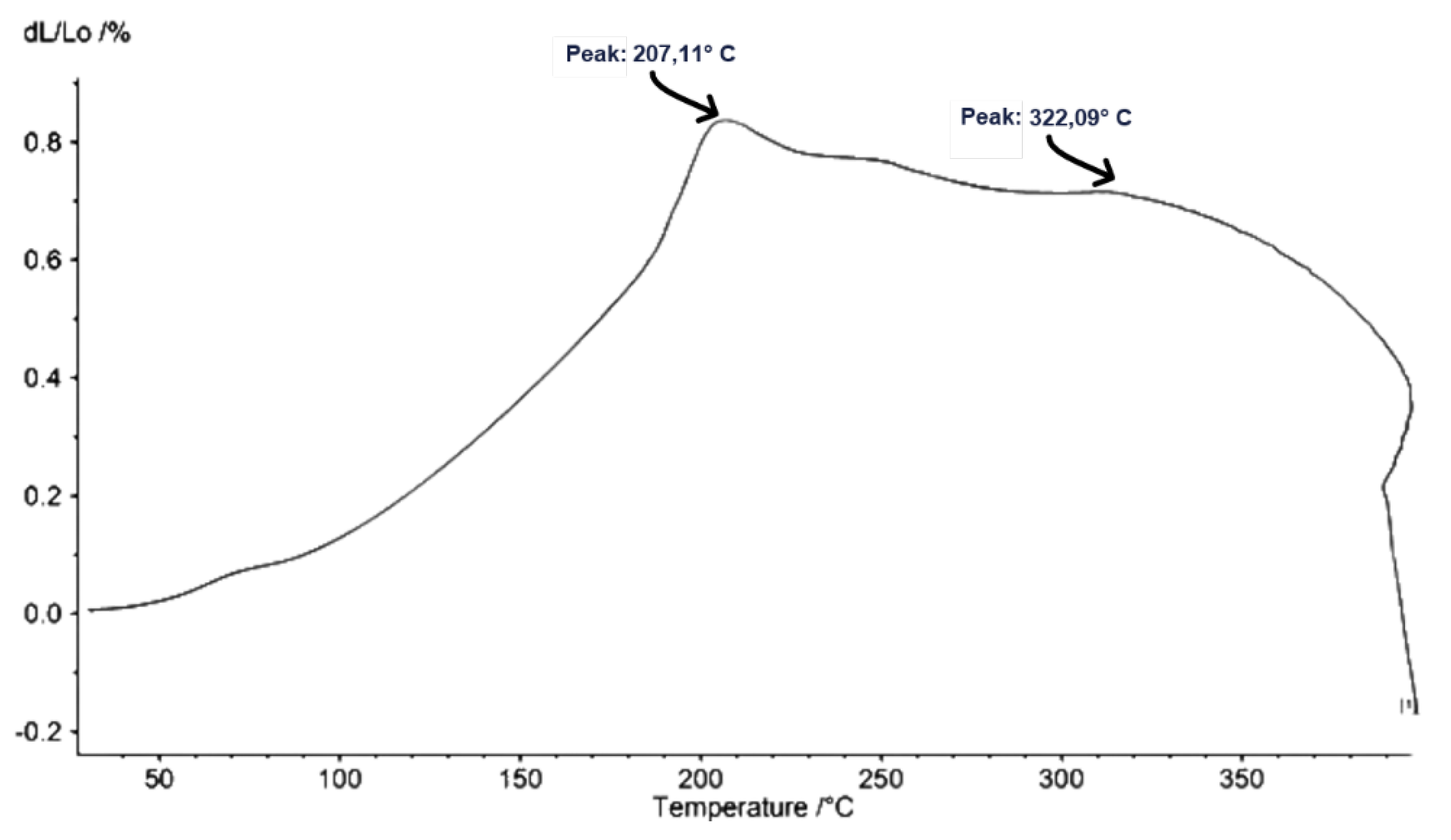

3.8. Thermal Analysis by Dilatometry

The dilatometric analysis measures the dimensional changes (contraction and expansion) that a material undergoes, as a function of temperature, when subjected to a controlled program of temperature in controlled atmosphere. In the development of artificial stone, thermal transformations occur in the curing phase due to the matrix/residue polymerization reaction (61).

Figure 17 shows the dilatometric curve of the artificial stone CDW-5.

We can observe the structural behavior in heated environment in the temperature range of 0-350 and C. In the range of 0-200 and C the materials are adapting to the heated environment, expanding the pores and causing the structure to lose moisture. The first peak happens at 207 C where up to 322 C temperature (second peak) the material has its moment of retraction. From the second peak the material begins to decompose slowly, with weight loss, mostly of the resin, as reported in other research (62). Chiodi Filho and Rodriguez (55), indicate that the ornamental stones used as coatings in civil construction, with coefficient of thermal expansion between 8-10 are considered of medium standard, where the CDW-5 presented 8.33.

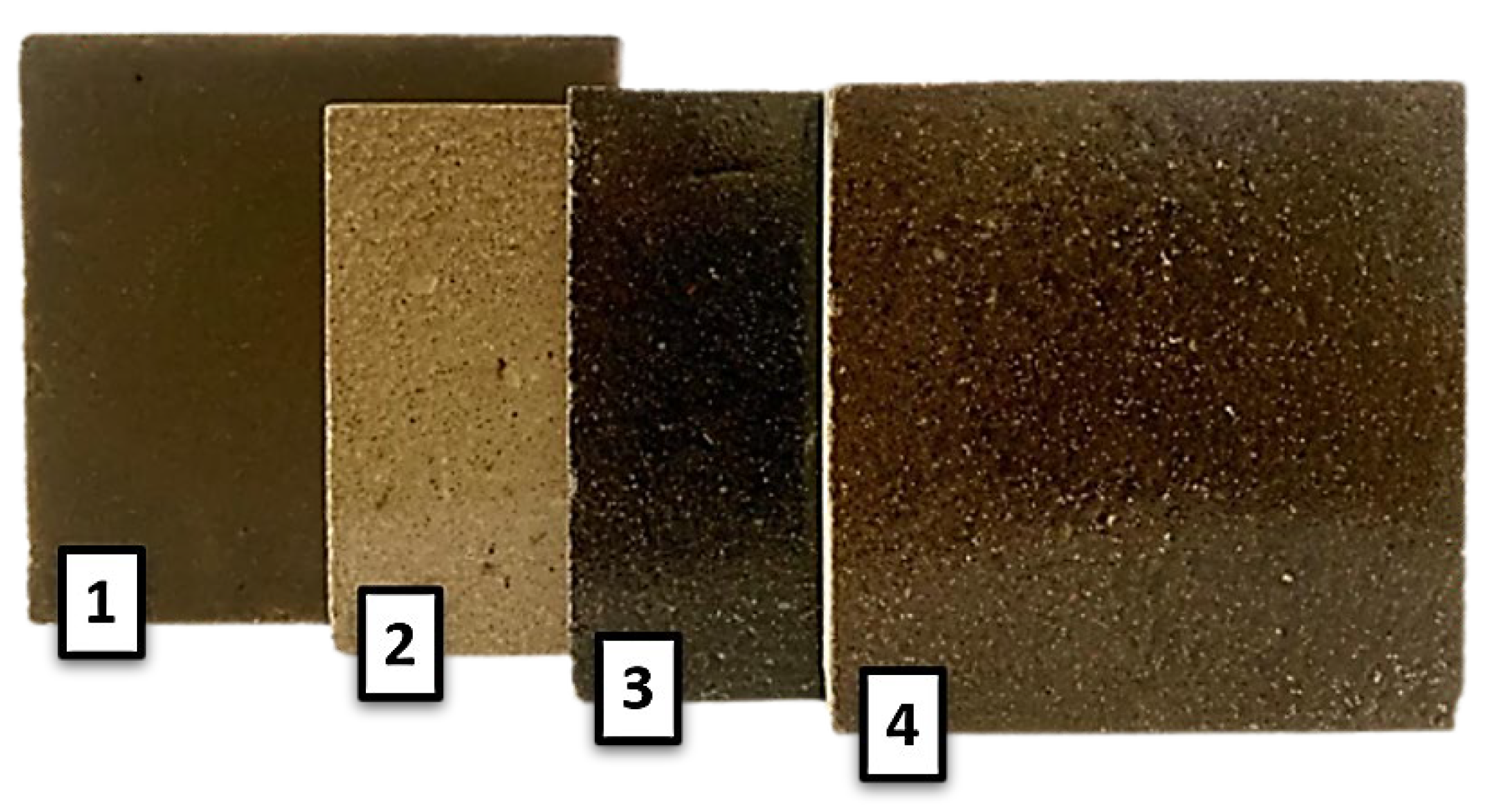

3.9. Final Product (Prototype)

Figure 18 presents the plates that received final finishing (sanding, waterproofing, polishing and pigmentation) to better represent the proposal of artificial rock produced with CDW and polyester resin, for use in kitchen countertops, leisure areas and bathrooms, as well as as flooring on stairs, for example.

3.10. Applicability

As a final note, through the website of the Brazilian Association of the Ornamental Rocks Industry (ABIROCHAS, 2024), we can through the section “Guides to Specification and Application of Ornamental Rocks and Coating”as a function of the results of the physical and mechanical index tests (bending 3 points and compression) determine the applications of RCD-5, as presented in

Table 11 and

Table 12.

3.11. Comparative

Table 13 presents comparative data between the results of bulk density, water absorption, flexural and compressive strength of CDW-5 and artificial rocks produced in several studies.

Figure 1.

Demonstration of the evolution of imports of rocks (period 2011 to 2023).

Figure 1.

Demonstration of the evolution of imports of rocks (period 2011 to 2023).

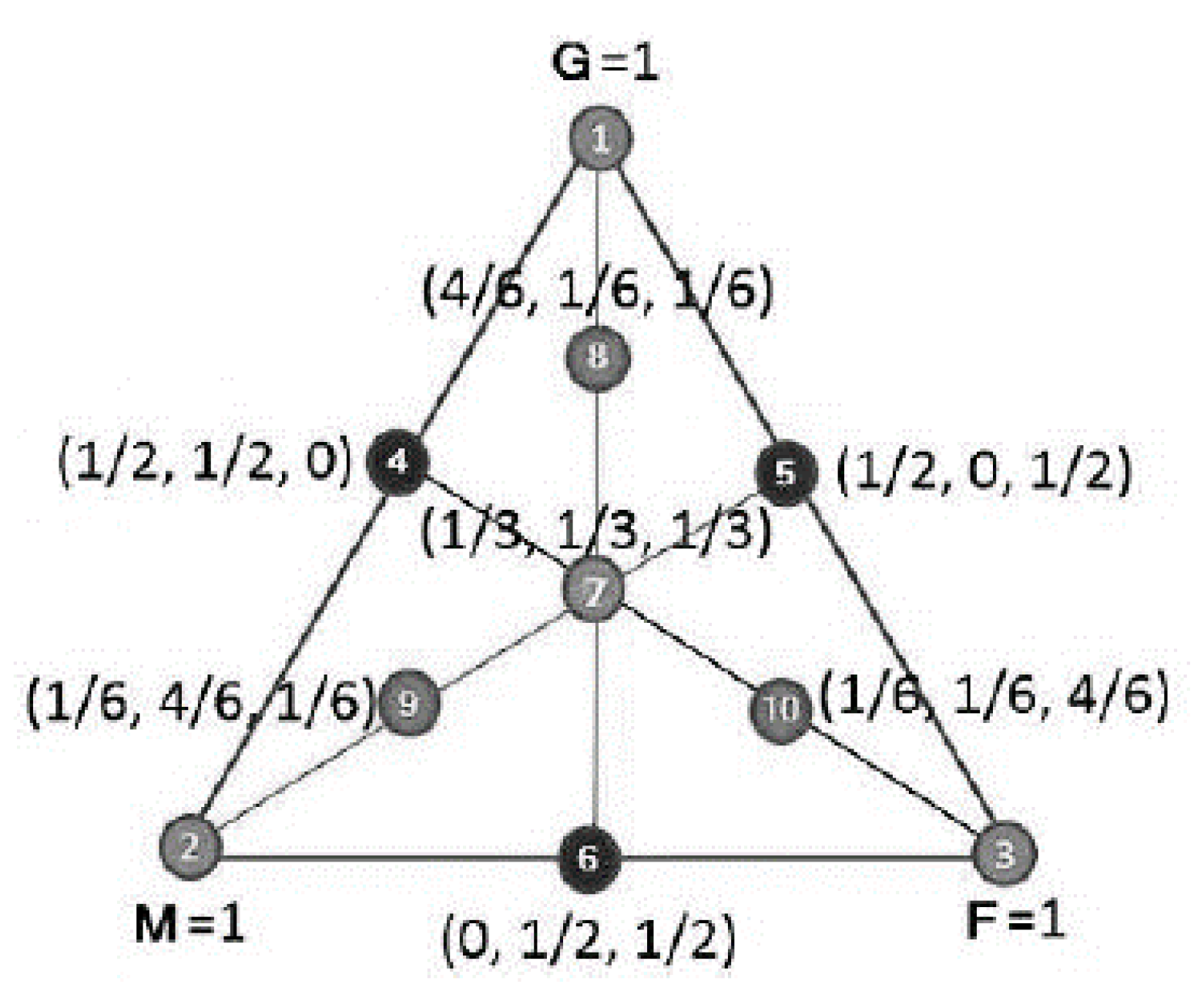

Figure 2.

Ternary diagram of the simplex centroid model.

Figure 2.

Ternary diagram of the simplex centroid model.

Figure 3.

Stages of manufacturing artificial stone slabs: (1) mixer; (2) vacuum molding in the mixer; (3) vacuum molding on the shaker; (4) vacuum compaction molding.

Figure 3.

Stages of manufacturing artificial stone slabs: (1) mixer; (2) vacuum molding in the mixer; (3) vacuum molding on the shaker; (4) vacuum compaction molding.

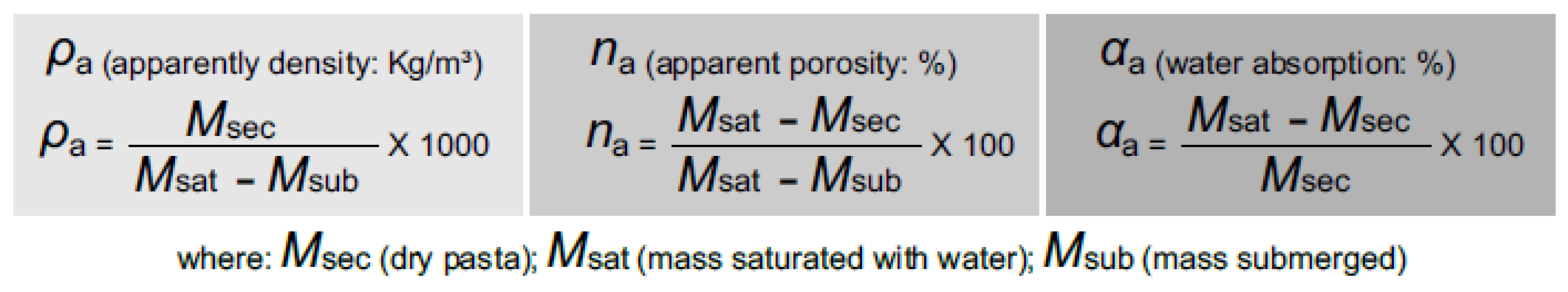

Figure 4.

Expressions for determination: apparent density, water absorption and apparent porosity.

Figure 4.

Expressions for determination: apparent density, water absorption and apparent porosity.

Figure 5.

Fourier Transform Infrared Spectrum (Polyester Resin).

Figure 5.

Fourier Transform Infrared Spectrum (Polyester Resin).

Figure 6.

Diagram (Bending Rupture Stress X Bending Deformation) Compositions 4, 5 and 8.

Figure 6.

Diagram (Bending Rupture Stress X Bending Deformation) Compositions 4, 5 and 8.

Figure 7.

Diagram (Bending Rupture Stress X Bending Deformation) RCD-5 and Polyester Resin.

Figure 7.

Diagram (Bending Rupture Stress X Bending Deformation) RCD-5 and Polyester Resin.

Figure 8.

Diagram (Stress X Strain - Compression) CDW-5.

Figure 8.

Diagram (Stress X Strain - Compression) CDW-5.

Figure 9.

CDW micrograph – grain size: fine (x50).

Figure 9.

CDW micrograph – grain size: fine (x50).

Figure 10.

CDW micrograph – granulometry: médium (x50).

Figure 10.

CDW micrograph – granulometry: médium (x50).

Figure 11.

CDW micrograph – granulometry: coarse (x34).

Figure 11.

CDW micrograph – granulometry: coarse (x34).

Figure 12.

CDW Digital Micrograph: (1) coarse grain size; (2) packaging – coarse/fine granulometry.

Figure 12.

CDW Digital Micrograph: (1) coarse grain size; (2) packaging – coarse/fine granulometry.

Figure 13.

Micrographs of fractures: compositions – 8, 4 and 5 (x200).

Figure 13.

Micrographs of fractures: compositions – 8, 4 and 5 (x200).

Figure 14.

Chromatic Modifications - Test Specimens: (1) ammonium chloride; (2) sodium hypochlorite; (3) citric acid; (4) lactic acid; (5) acetic acid; (6) 3% hydrochloric acid; (7) 18% hydrochloric acid; (8) potassium hypochlorite 30g/L; (9) potassium hypochlorite 100g/L; (10) distilled water.

Figure 14.

Chromatic Modifications - Test Specimens: (1) ammonium chloride; (2) sodium hypochlorite; (3) citric acid; (4) lactic acid; (5) acetic acid; (6) 3% hydrochloric acid; (7) 18% hydrochloric acid; (8) potassium hypochlorite 30g/L; (9) potassium hypochlorite 100g/L; (10) distilled water.

Figure 15.

Orthophthalic polyester molecular chain.

Figure 15.

Orthophthalic polyester molecular chain.

Figure 16.

Digital microscopy (Detail chemical attack N.04 – Lactic Acid).

Figure 16.

Digital microscopy (Detail chemical attack N.04 – Lactic Acid).

Figure 17.

CDW-5 dilatometric curve.

Figure 17.

CDW-5 dilatometric curve.

Figure 18.

CDW-5 Artificial Stone: (1) Raw Slab; (2) White Pigment Stone; (3) Black Pigment Stone; (4) Natural Stone.

Figure 18.

CDW-5 Artificial Stone: (1) Raw Slab; (2) White Pigment Stone; (3) Black Pigment Stone; (4) Natural Stone.

Table 1.

Granulometric compositions.

Table 1.

Granulometric compositions.

| Class |

Sieve (Mesh #) |

Granulometric Range (mm) |

| Coarse |

10 - 40 |

2.000 – 0.420 |

| Medium |

40 - 200 |

0.420 – 0.075 |

| Fine |

< 200 |

< 0.075 |

Table 2.

Density Vibrada - 10 mixtures.

Table 2.

Density Vibrada - 10 mixtures.

| Mixture |

Coarse (%) |

Medium (%) |

Fine (%) |

Vibrada Density (g/cm3) |

| 1 |

1 |

0 |

0 |

1.5692 +0.0081 |

| 2 |

0 |

1 |

0 |

1.6301 +0.0199 |

| 3 |

0 |

0 |

1 |

1.4936 +0.0047 |

| 4 |

1/2 |

1/2 |

0 |

1.7798 +0.0047 |

| 5 |

1/2 |

0 |

1/2 |

1.7403 +0.0163 |

| 6 |

0 |

1/2 |

1/2 |

1.5544 +0.0040 |

| 7 |

1/3 |

1/3 |

1/3 |

1.6564 +0.0101 |

| 8 |

2/3 |

1/6 |

1/6 |

1.7386 +0.0222 |

| 9 |

1/6 |

2/3 |

1/6 |

1.6482 +0.0201 |

| 10 |

1/6 |

1/6 |

2/3 |

1.6005 +0.0101 |

Table 3.

Dry apparent density – 03 best mixtures.

Table 3.

Dry apparent density – 03 best mixtures.

| Packaging |

Coarse |

Medium |

Fine |

Density |

| 4 |

1/2 |

1/2 |

--- |

2.510 g/cm³ |

| 5 |

1/2 |

--- |

1/2 |

2.308 g/cm³ |

| 8 |

4/6 |

1/6 |

1/6 |

2.308 c/cm³ |

Table 4.

Values (VV% and MAR%).

Table 4.

Values (VV% and MAR%).

| Packaging |

VV% |

MAR% |

| 4 |

29.09 |

13.14 |

| 5 |

24.67 |

12.22 |

| 8 |

24.67 |

12.22 |

Table 5.

Chemical Analysis by XRF (Civil Construction and Demolition Waste).

Table 5.

Chemical Analysis by XRF (Civil Construction and Demolition Waste).

| Determination of Chemical Analysis by XRF Spectrometry - PR-CR-098 (Sample: CDW) % |

| Al2O3

|

CaO |

Fe2O3

|

K2O |

MgO |

Mno |

Na2O |

P2O5

|

SiO2

|

|

| 9.752 |

22.308 |

3.276 |

1.782 |

1.948 |

0.056 |

1.007 |

0.219 |

45.568 |

|

| TiO2

|

BaO |

Co2O3

|

PbO |

SrO |

ZnO |

ZrO2/Hf |

CI |

SO3

|

Fire Loss |

| 0.472 |

0.061 |

<0.050 |

<0.050 |

0.111 |

<0.050 |

<0.050 |

0.891 |

2.533 |

9.987 |

Table 6.

Chemical composition of clinker.

Table 6.

Chemical composition of clinker.

| Chemical Composition - Clinker (%) |

| CaO |

SiO2

|

Al2O3

|

Fe2O3

|

MgO |

Na2O |

SO3

|

| 61-67 |

17-24 |

3-8 |

1-6 |

0.1-4 |

0.5-1.5 |

1-3 |

Table 7.

Characteristic bands of functional groups – Polyester Resin.

Table 7.

Characteristic bands of functional groups – Polyester Resin.

| Wave Number |

Bands |

| 3.000 - 3.100 |

Aromatic C-H stretch |

| 3.079 |

Stretch = asymmetrical CH2

|

| 3.020 |

Stretch = asymmetrical CHR |

| 2.990 - 2.850 |

-CH3 e -CH2

|

| 1.730 |

Stretch = CH2

|

| 1.645 |

RCH = CH2

|

| 1.285 |

C-0 ester stretch |

| 770 - 735 |

Replaced ortho benzene |

Table 8.

Physical Indices and Flexion 3 points.

Table 8.

Physical Indices and Flexion 3 points.

| Composition |

Density |

Porosity |

Water |

|

Plates |

| Apparent |

Apparent |

Absorption |

Volume |

Inflection |

|

Ꝓa (g/cm3) |

ηa (%) |

αa (%) |

m³ |

MPa |

| # 4

|

2.129 |

1.46 |

0.66 |

0.0309 |

24.66 |

| 1/2 coarse +1/2 medium |

+0.12 |

+0.30 |

+0.14 |

+0.002 |

+2.31 |

| # 5

|

2.256 |

1.55 |

0.69 |

0.0296 |

34,74 |

| 1/2 coarse +1/2 fine |

+0,10 |

+0.28 |

+0.13 |

+0.002 |

+2.55 |

| # 8

|

2.252 |

2.32 |

1.03 |

0.0308 |

20.55 |

| 2/3 coarse +1/6 medium +1/6 fine |

+0.98 |

+0.28 |

+0.13 |

+0.001 |

+2.41 |

Table 9.

Flexural strength 3 points: RCD-5 and Polyester Resin.

Table 9.

Flexural strength 3 points: RCD-5 and Polyester Resin.

| Material |

Flexural Strength 3 points |

| CDW-5 |

34.74 MPa +2.55 |

| Polyester Resin |

80.24 MPa +7.74 |

Table 10.

Effects of chemical attack by reagent.

Table 10.

Effects of chemical attack by reagent.

| CP |

REAGENT |

EXPOSURE |

MODIFICATION |

DISSOLUTION |

DETACHMENT |

| CHROMATIC |

MINERAL |

| 1 |

Ammonium Chloride |

24h |

absent |

absent |

absent |

| 2 |

Sodium Hypochlorite |

absent |

absent |

absent |

| 3 |

Citric Acid |

presente |

absent |

absent |

| 4 |

Lattic Acid |

presente |

absent |

absent |

| 5 |

Acetic Acid |

presente |

absent |

absent |

| 6 |

Hydrochloric Acid 3% |

96h |

presente |

absent |

absent |

| 7 |

Hydrochloric Acid 18% |

presente |

absent |

absent |

| 8 |

Potassium Hypochlorite 30g/L |

presente |

absent |

absent |

| 9 |

Potassium Hypochlorite 100g/L |

present |

absent |

absent |

| 10 |

distilled water |

absent |

absent |

absent |

Table 11.

Adapted application (CDW-5).

Table 11.

Adapted application (CDW-5).

| ROCKS FOR COATING OF TOPS / COUNTERTOPS* |

| Type of Coating |

Technological Parameters |

| TOPS/ COUNTERTOPS |

Water Absorption (>0.4%) |

Rupture Module (>8 MPa) |

| Class |

Possibilities of Using the Rock Evaluated |

| A2D1 |

- ▪

Necessary the application of sealant hydro-oil-repellent on the face and edges of kitchen and bathroom sinks, as well as counters and bar tables, bakeries and congeners. |

| (*) Plates with minimum thickness of 2cm |

Table 12.

Adapted application (CDW-5).

Table 12.

Adapted application (CDW-5).

| FLOORING ROCKS |

| Type of Coating |

Technological Parameters |

| FLOORS |

Water Absorption (>0.4%) |

Amsler Abrasive Wear (0.85 mm to 2 mm) |

| Class |

Possibilities of Using the Rock Evaluated |

| A2B2 |

- ▪

Residential and commercial areas, only with eventual wetting. - ▪

Residential areas have low pedestrian traffic. Commercial areas have medium pedestrian traffic. Public areas have high pedestrian traffic. - ▪

Internal social environments (rooms and bedrooms) and commercial (offices, shops, offices etc.) receive occasional wetting. Indoor service environments, kitchens and baths and outdoor environments, receive frequent wetting. |

Table 13.

CDW-5 X Rochas Artificiais found in literature.

Table 13.

CDW-5 X Rochas Artificiais found in literature.

| Authors |

Apparent Density (g/cm³) |

Water Absorption (%) |

Flexural Strength (MPa) |

Compressive Strength (MPa) |

| Lee, M. Y. et al. (2008) |

2.05 – 2.44 |

0.01 – 0.2 |

27.9 – 52.7 |

78.70 – 151.30 |

| Ribeiro, C. E. G. et al. (2014) |

2.27 ± 0.02 |

0.19 ± 0.02 |

4.21 ± 0.52 |

14.17 ± 1.03 |

| Carvalho et al (2015) |

2.68 ± 0.03 |

0.17 ± 0.04 |

57.57 ± 3.21 |

N.D. |

| Ribeiro, C. E. G. et al. (2015) |

2.27 |

0.19 ± 0.02 |

21.5 ± 1.9 |

77.9 ± 6.1 |

| RMC Tradicional (2015) |

2.52 – 2.57 |

0.09 – 0.32 |

13.6 – 17.2 |

97 - 131 |

| Barani, K.; Esmaili, H. (2016) |

2.68 |

0.64 |

45 |

90 |

| Silva, F. S. (2016) |

2.23 ± 0,02 |

0.05 ± 0,01 |

31.8 ± 2,5 |

85.2 ± 7.8 |

| Vilela, N. F. (2016) |

2.35 ± 0,08 |

0.35 ± 0.09 |

30 ± 1.44 |

N.D. |

| Aguiar, M. C. (2016) |

1.53 |

2.00 ± 0.19 |

37.75 ± 3.4 |

71.62 ± 1.31 |

| Peng, L.; Qin, S. (2018) |

2.41 |

0.01 |

73.5 |

170.9 |

| Gomes et al (2018) |

2.12 ± 0.01 |

0.38 ± 0.06 |

30 ± 3 |

N.D. |

| Demartini et al (2018) |

2.1 ± 0.06 |

0.06 ± 0.01 |

33.93 ± 0.49 |

96.49 ± 2.82 |

| Carvalho, E. A. S. et al (2018)

|

2.25 ± 0.08 |

0.25 ± 0.02 |

32 ± 3 |

N.D. |

| Hamizah et al (2020) |

N.D. |

0.11 |

34.10 |

105.43 |

| Gomes (2020) |

2.24 |

0.19 |

32.0 |

N.D. |

| Silva (2023) |

N.D. |

0.13 |

32.77 |

N.D. |

| Barreto (2023) |

2.22 |

0.11 |

34.36 |

N.D. |

| CDW-5 (2023) |

2.25 |

0.69 |

34.74 |

111.96 |