Submitted:

04 June 2024

Posted:

05 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- A global path planning strategy that integrates the Traveling Salesman Problem (TSP) and the Capacitated Vehicle Routing Problem (CVRP) methodologies, prioritizing the harvest points based on vehicle payload capacity constraints while considering closeness between crop harvest locations.

- A local path planning coordinated with a global one that explores scheduled harvesting points based on to achieve feasible and kinematically compatible paths with SSMR dynamics, accounting for obstacle avoidance and terrain traversability posed by low-traction surfaces.

- The proposed strategy can generate paths that avoid difficult-to-crossing regions typical of agricultural farms, intending to reduce robot resources and prevent situations where robots get stuck.

- The proposed planner can be used as a reference for motion controllers, enabling efficient driving over shortened and qualified paths, potentially reducing exposure times of products to the environment and thus the mistreatment of the agricultural harvest.

2. Related Work

3. Motion Models for Assisted Harvesting Tasks

3.1. Model of the Skid-Steer Mobile Robot

3.2. Model of the Terrain Traversability

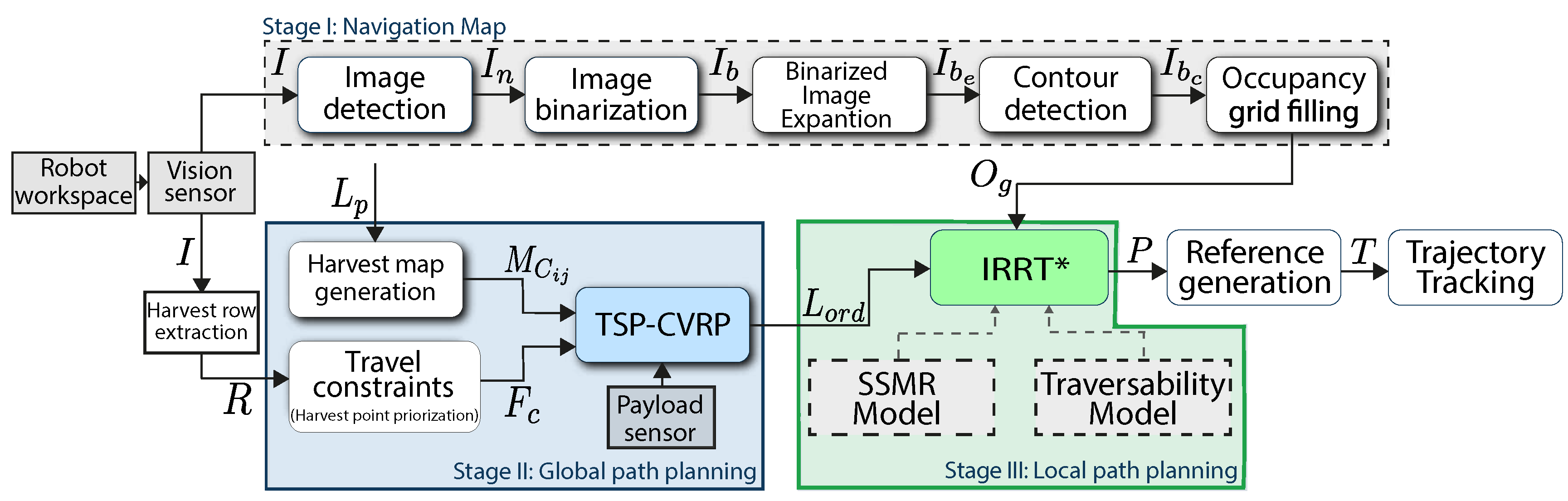

4. Integration of Route and Path Planning

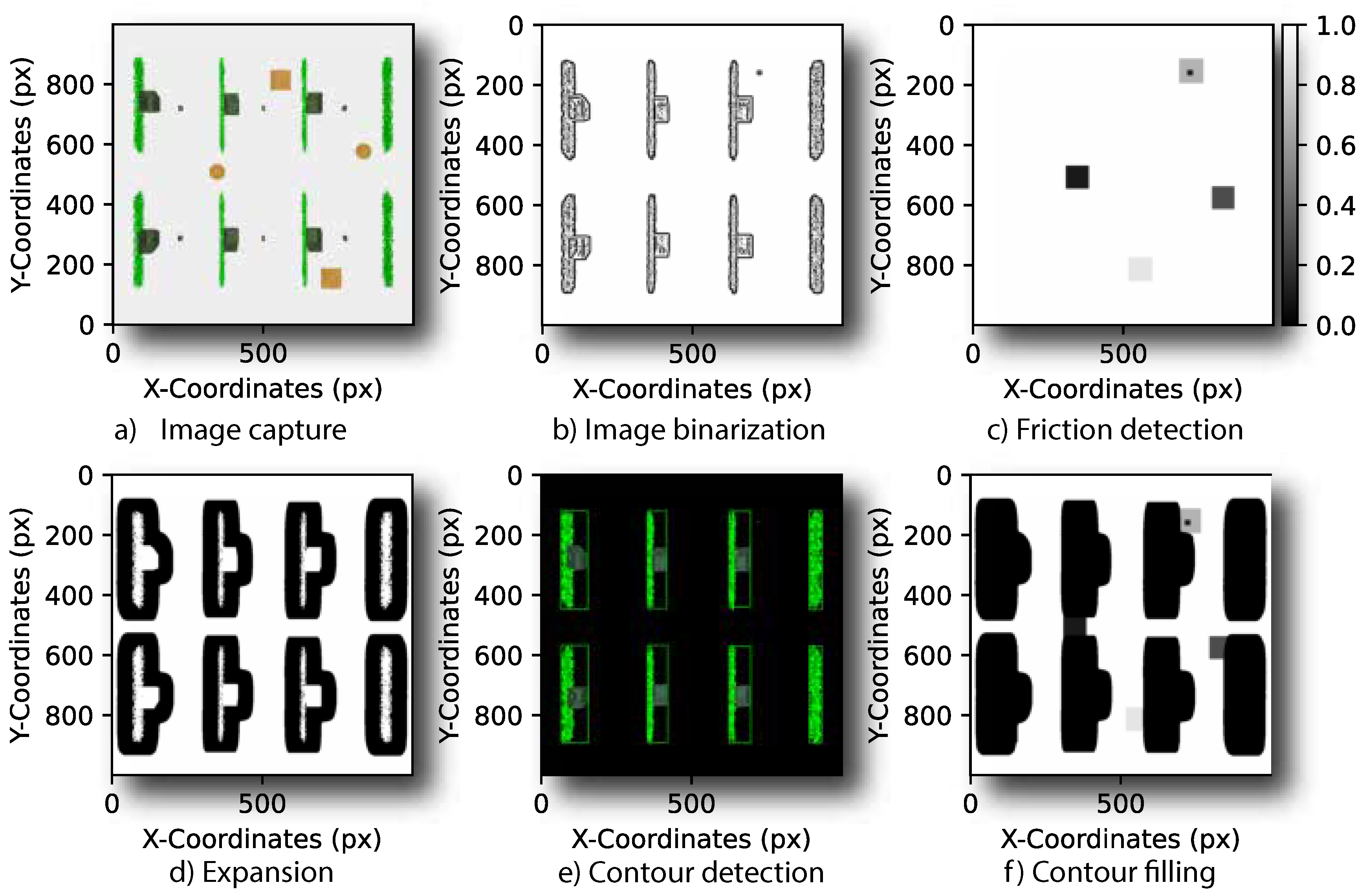

4.1. Processing of the Navigation Map

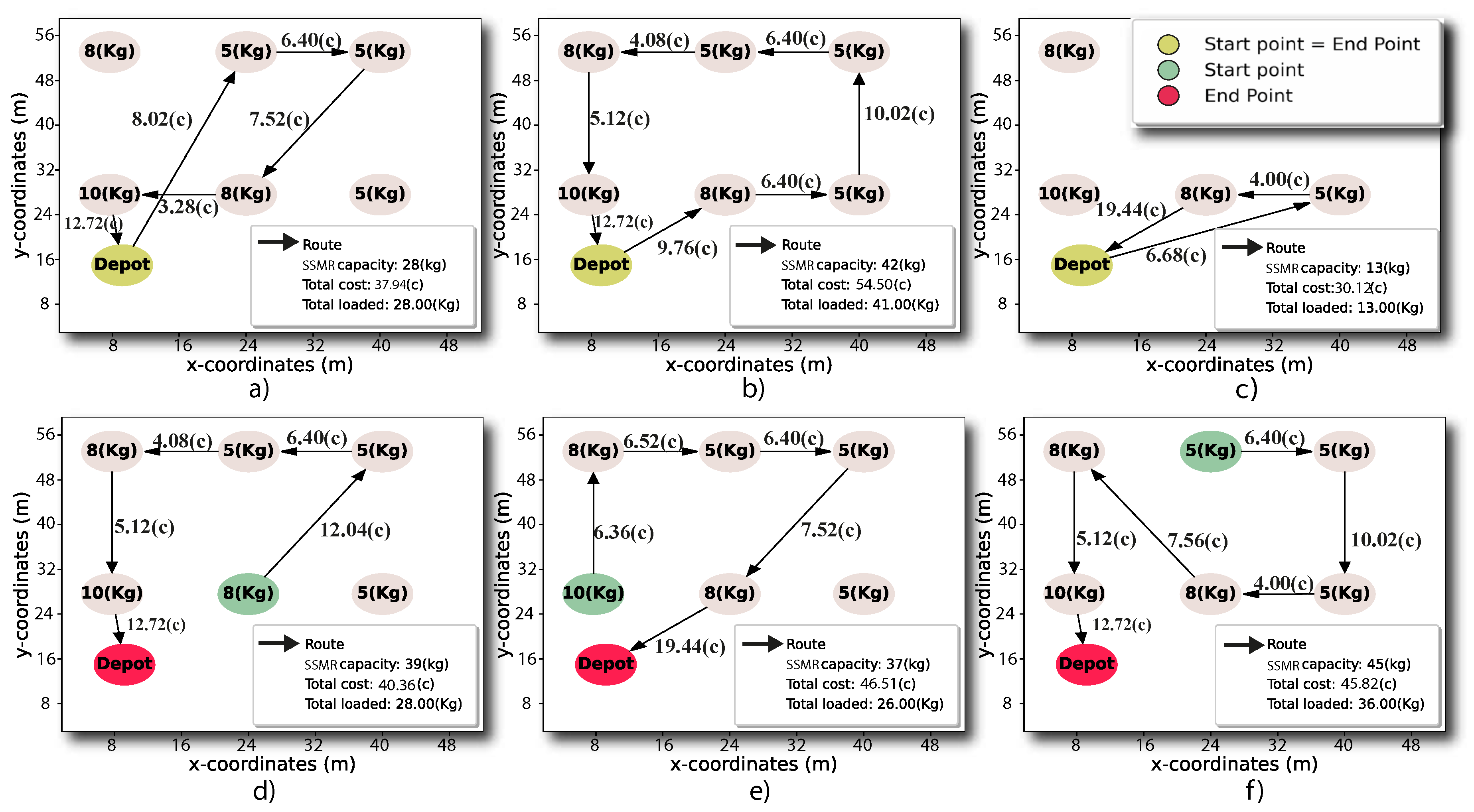

4.2. Global Path Planning

| Algorithm 1 Improved TSP-CVRP |

|

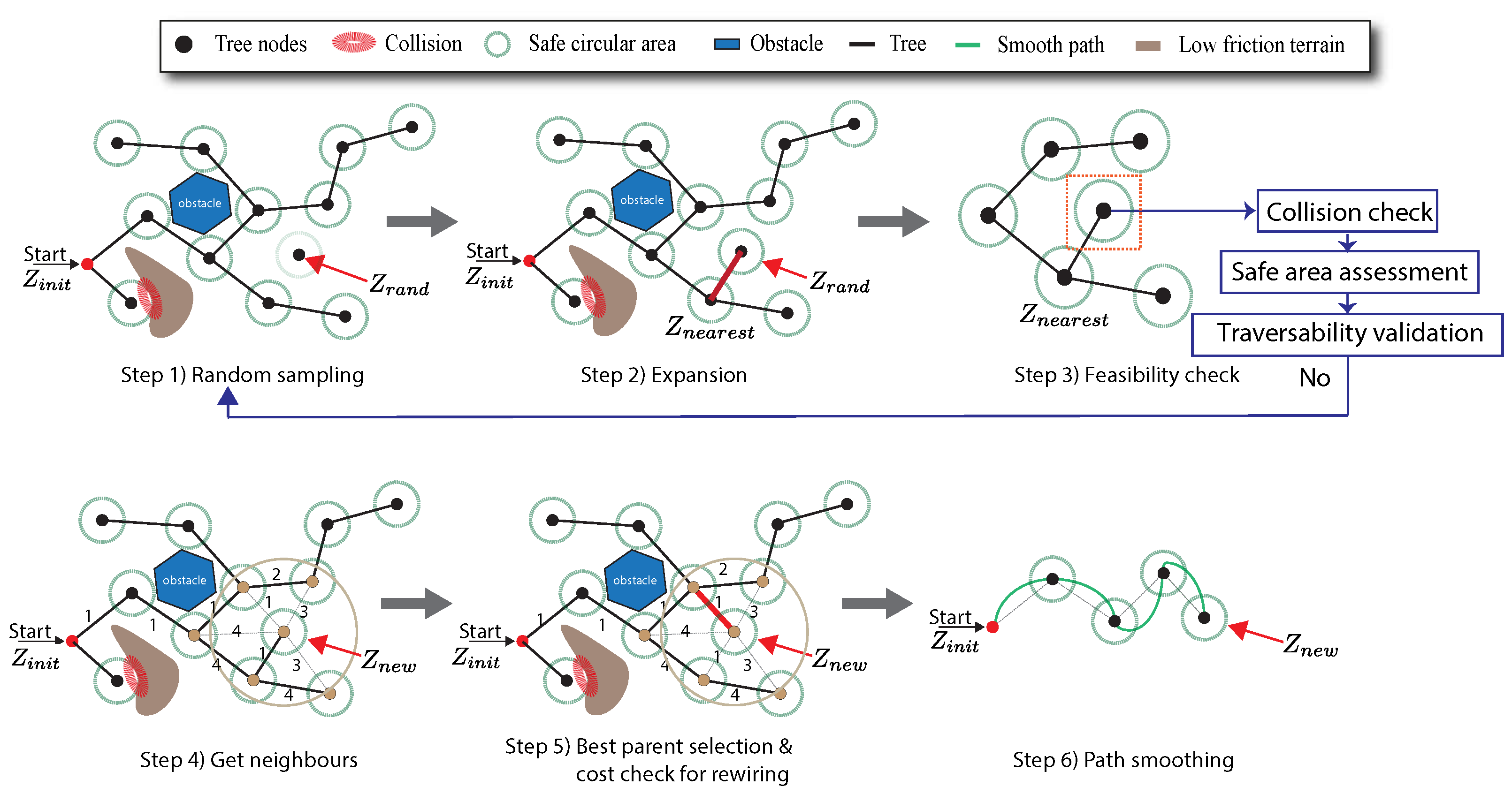

4.3. Local Path Planning

| Algorithm 2 Informed () |

|

| Algorithm 3 Traversability Checking |

|

4.4. Motion Controller for the Assessment of Path Planning

5. Experiments Results and Analysis

5.1. Performance Metrics

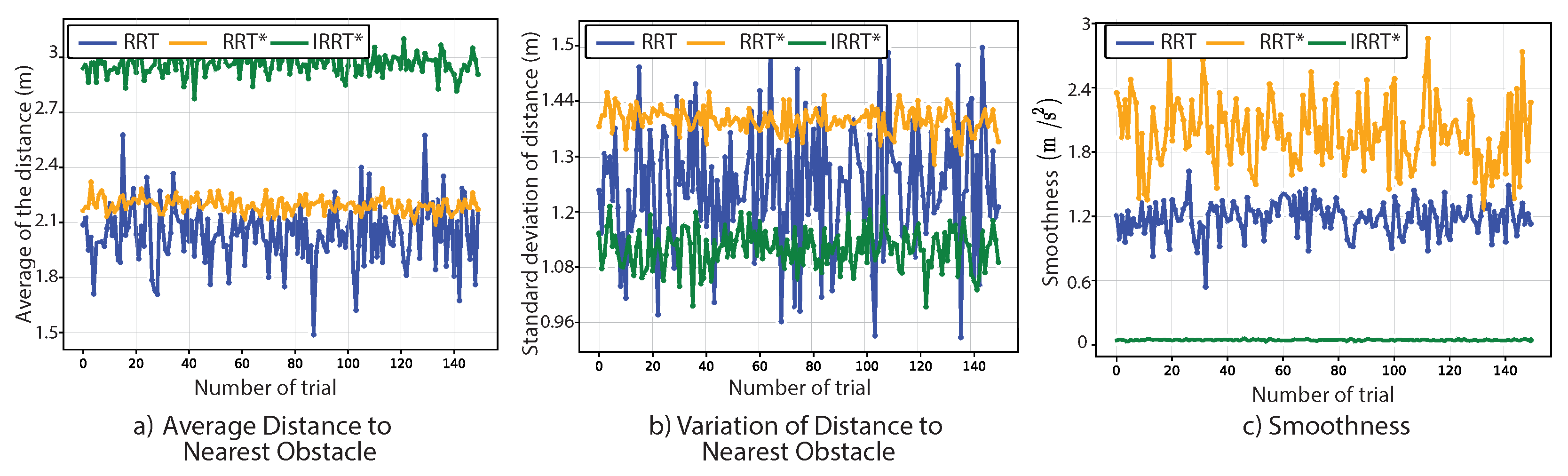

5.1.1. Obstacle Avoidance [65]

5.1.2. Path Smoothness [64]

5.1.3. Controller Effort [53]

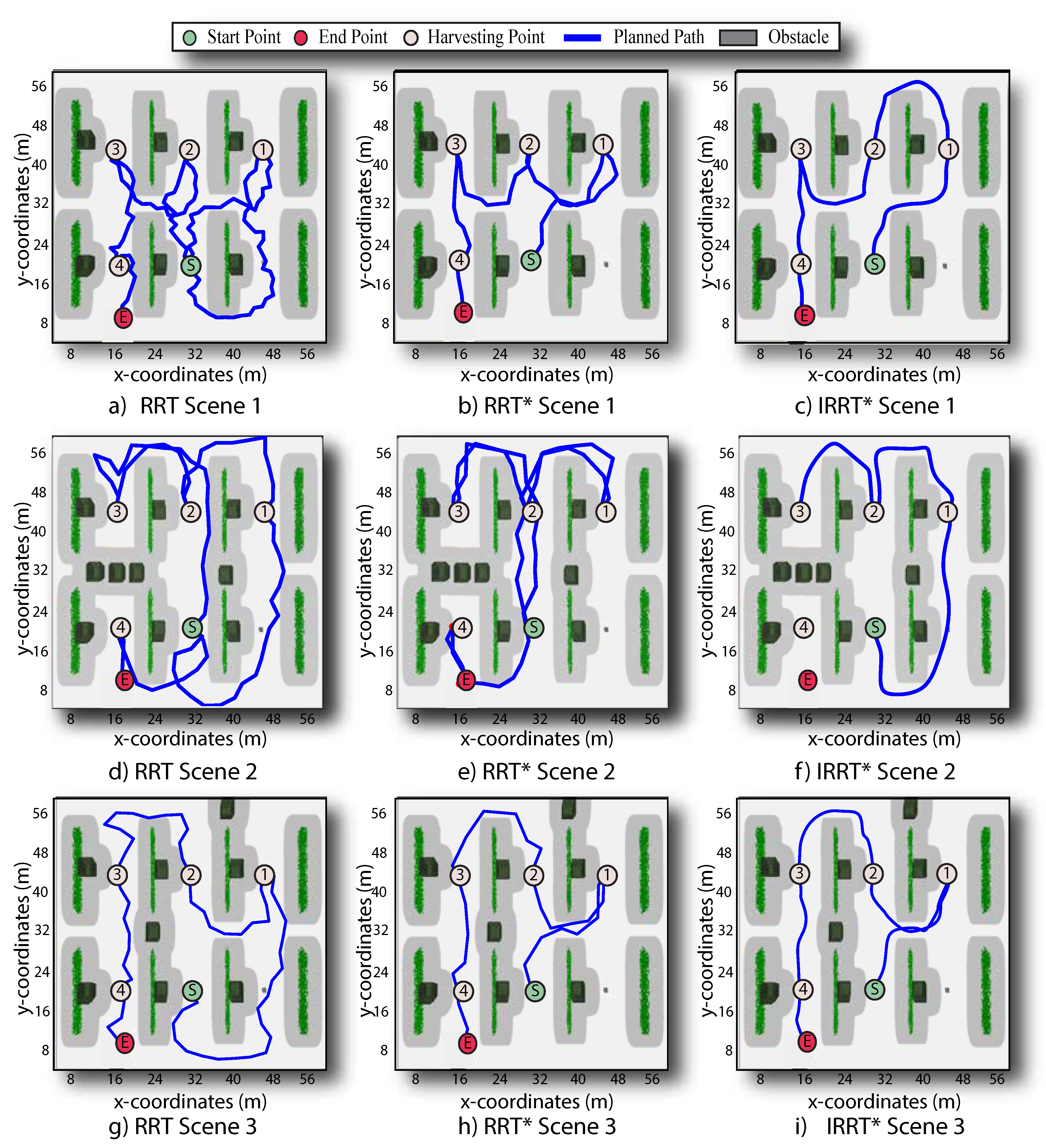

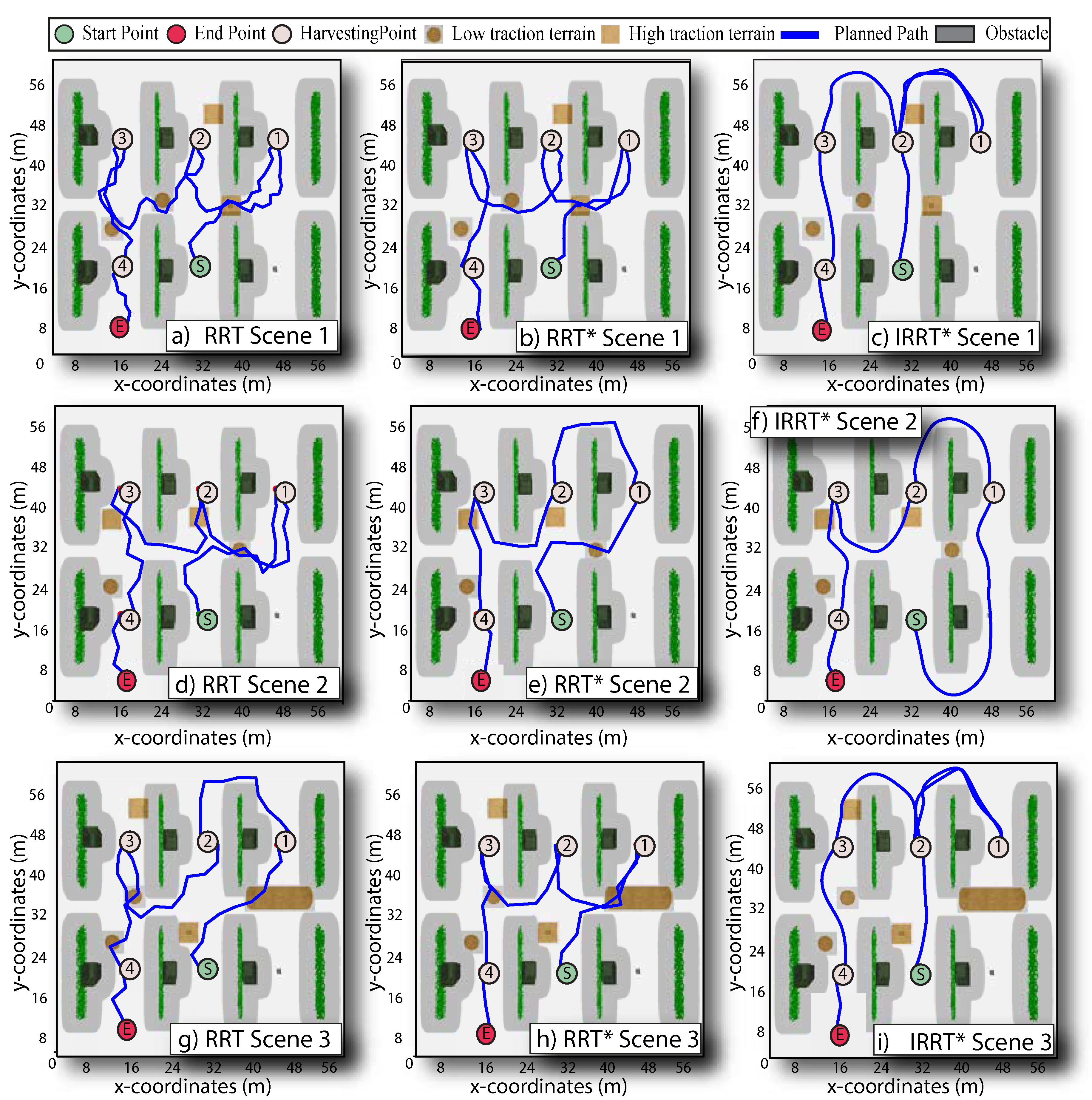

5.2. Global Path Planning Evaluation

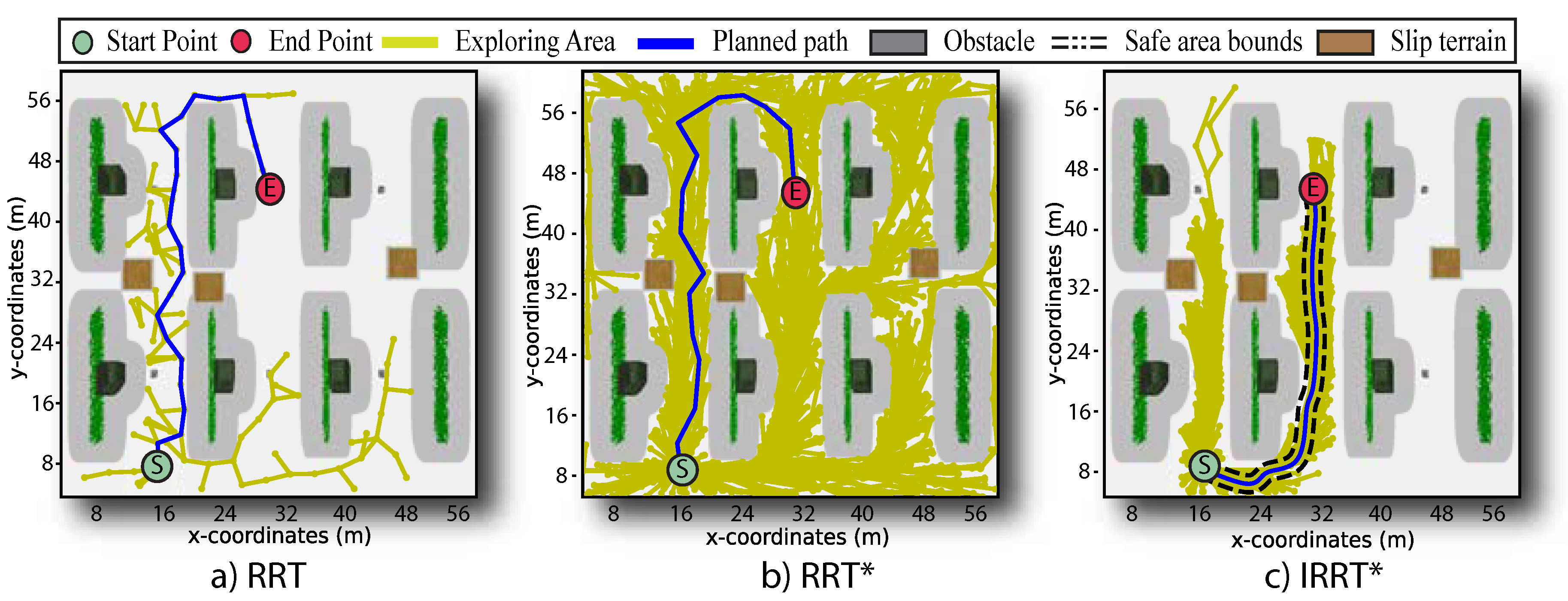

5.3. Local Path Planning Evaluation

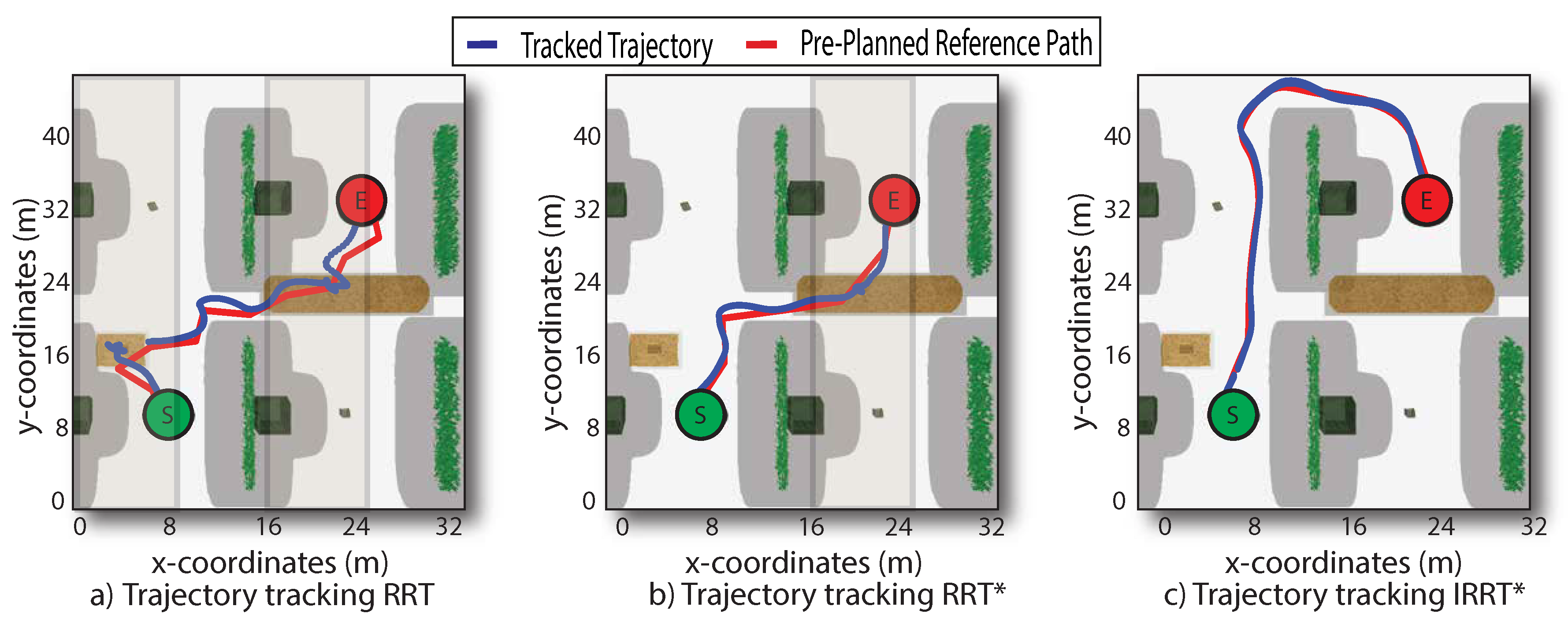

5.4. Evaluation of Path Tracking Performance

6. Conclusions

Acknowledgments

Abbreviations

| TSP | Traveling Salesman Problem |

| IRRT | Informed Rapidly-exploring Random Tree |

| CVRP | Capacitated Vehicle Routing Problem |

| SSMR | Skid-Steer Mobile Robot |

| FAO | Food and Agriculture Organization |

| PRM | Probabilistic Road Mapping |

| RGB | Red-Green-Blue |

References

- Friedrich, T. A new paradigm for feeding the world in 2050 the sustainable intensification of crop production. Resource Magazine 2015, 22, 18–18. [Google Scholar]

- Prado, A.J.; Auat Cheein, F.A.; Blazic, S.; Torres-Torriti, M. Probabilistic self-tuning approaches for enhancing performance of autonomous vehicles in changing terrains. Journal of Terramechanics 2018, 78, 39–51. [Google Scholar] [CrossRef]

- Dominguez, X.; Prado, A.; Arboleya, P.; Terzija, V. Evolution of knowledge mining from data in power systems: The Big Data Analytics breakthrough. Electric Power Systems Research 2023, 218, 109193. [Google Scholar] [CrossRef]

- Prado, J.; Yandun, F.; Torres Torriti, M.; Auat Cheein, F. Overcoming the Loss of Performance in Unmanned Ground Vehicles Due to the Terrain Variability. IEEE Access 2018, 6, 17391–17406. [Google Scholar] [CrossRef]

- Wang, M.; Niu, C.; Wang, Z.; Jiang, Y.; Jian, J.; Tang, X. Model and Parameter Adaptive MPC Path Tracking Control Study of Rear-Wheel-Steering Agricultural Machinery. Agriculture 2024, 14. [Google Scholar] [CrossRef]

- Pan, W.; Wang, J.; Yang, W. A Cooperative Scheduling Based on Deep Reinforcement Learning for Multi-Agricultural Machines in Emergencies. Agriculture 2024, 14. [Google Scholar] [CrossRef]

- Guevara, L.; Khalid, M.; Hanheide, M.; Parsons, S. Probabilistic model-checking of collaborative robots: A human injury assessment in agricultural applications. Computers and Electronics in Agriculture 2024, 222, 108987. [Google Scholar] [CrossRef]

- Sánchez-Ibáñez, J.R.; Pérez-del Pulgar, C.J.; García-Cerezo, A. Path Planning for Autonomous Mobile Robots: A Review. Sensors 2021, 21. [Google Scholar] [CrossRef] [PubMed]

- Furchì, A.; Lippi, M.; Carpio, R.F.; Gasparri, A. Route Optimization in Precision Agriculture Settings: A Multi-Steiner TSP Formulation. IEEE Transactions on Automation Science and Engineering 2023, 20, 2551–2568. [Google Scholar] [CrossRef]

- Graf Plessen, M. Coupling of crop assignment and vehicle routing for harvest planning in agriculture. Artificial Intelligence in Agriculture 2019, 2, 99–109. [Google Scholar] [CrossRef]

- He, P.; Li, J. The two-echelon multi-trip vehicle routing problem with dynamic satellites for crop harvesting and transportation. Applied Soft Computing 2019, 77, 387–398. [Google Scholar] [CrossRef]

- Dhirendra Prajapati, Felix T. S. Chan, Y.D.; Pratap, S. Sustainable vehicle routing of agro-food grains in the e-commerce industry. International Journal of Production Research 2022, 60, 7319–7344. [Google Scholar] [CrossRef]

- Yang, S.; Jia, B.; Yu, T.; Yuan, J. Research on Multiobjective Optimization Algorithm for Cooperative Harvesting Trajectory Optimization of an Intelligent Multiarm Straw-Rotting Fungus Harvesting Robot. Agriculture 2022, 12. [Google Scholar] [CrossRef]

- Gangadharan, M.M.; Salgaonkar, A. Ant colony optimization and firefly algorithms for robotic motion planning in dynamic environments. Engineering Reports 2020, 2, e12132. [Google Scholar] [CrossRef]

- Jia, W.; Zhang, Y.; Lian, J.; Zheng, Y.; Zhao, D.; Li, C. Apple harvesting robot under information technology: A review. International Journal of Advanced Robotic Systems 2020, 17, 1729881420925310. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Liu, H.; Li, J.; Wang, P.; Yang, X. A Full-Coverage Path Planning Method for an Orchard Mower Based on the Dung Beetle Optimization Algorithm. Agriculture 2024, 14. [Google Scholar] [CrossRef]

- Janos, J.; Vonasek, V.; Penicka, R. Multi-Goal Path Planning Using Multiple Random Trees. IEEE Robotics and Automation Letters 2021, 6, 4201–4208. [Google Scholar] [CrossRef]

- Yahia, H.S.; Mohammed, A.S. Path planning optimization in unmanned aerial vehicles using meta-heuristic algorithms: a systematic review. Environmental Monitoring and Assessment 2023, 195. [Google Scholar] [CrossRef]

- Carpio, R.F.; Maiolini, J.; Potena, C.; Garone, E.; Ulivi, G.; Gasparn, A. MP-STSP: A Multi-Platform Steiner Traveling Salesman Problem Formulation for Precision Agriculture in Orchards. 2021 IEEE International Conference on Robotics and Automation (ICRA), 2021, pp. 2345–2351. [CrossRef]

- Pak, J.; Kim, J.; Park, Y.; Son, H.I. Field Evaluation of Path-Planning Algorithms for Autonomous Mobile Robot in Smart Farms. IEEE Access 2022, 10, 60253–60266. [Google Scholar] [CrossRef]

- Tagliavini, L.; Colucci, G.; Botta, A.; Cavallone, P.; Baglieri, L.; Quaglia, G. Wheeled Mobile Robots: State of the Art Overview and Kinematic Comparison Among Three Omnidirectional Locomotion Strategies. Journal of Intelligent and Robotic Systems: Theory and Applications 2022, 106. [Google Scholar] [CrossRef]

- Castro, G.G.R.d.; Berger, G.S.; Cantieri, A.; Teixeira, M.; Lima, J.; Pereira, A.I.; Pinto, M.F. Adaptive Path Planning for Fusing Rapidly Exploring Random Trees and Deep Reinforcement Learning in an Agriculture Dynamic Environment UAVs. Agriculture 2023, 13. [Google Scholar] [CrossRef]

- Claussmann, L.; Revilloud, M.; Gruyer, D.; Glaser, S. A Review of Motion Planning for Highway Autonomous Driving. IEEE Transactions on Intelligent Transportation Systems 2020, 21, 1826–1848. [Google Scholar] [CrossRef]

- Xu, J.; Tian, Z.; He, W.; Huang, Y. A Fast Path Planning Algorithm Fusing PRM and P-Bi-RRT. 2020 11th International Conference on Prognostics and System Health Management (PHM-2020 Jinan), 2020, pp. 503–508. [CrossRef]

- Mashayekhi, R.; Idris, M.Y.I.; Anisi, M.H.; Ahmedy, I.; Ali, I. Informed RRT*-Connect: An Asymptotically Optimal Single-Query Path Planning Method. IEEE Access 2020, 8, 19842–19852. [Google Scholar] [CrossRef]

- Kontoudis, G.P.; Vamvoudakis, K.G. Kinodynamic Motion Planning With Continuous-Time Q-Learning: An Online, Model-Free, and Safe Navigation Framework. IEEE Transactions on Neural Networks and Learning Systems 2019, 30, 3803–3817. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhou, L.; Liu, H. Lalo-Check: A path optimization framework for sampling-based motion planning with tree structure. IEEE Access 2019, 7, 100733–100746. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, Y.; Yao, X. An Improved Path Planning Algorithm for Unmanned Aerial Vehicle Based on RRT-Connect. 2018 37th Chinese Control Conference (CCC), 2018, pp. 4854–4858. [CrossRef]

- Xie, J.; Carrillo, L.R.G.; Jin, L. Path planning for UAV to cover multiple separated convex polygonal regions. IEEE Access 2020, 8, 51770–51785. [Google Scholar] [CrossRef]

- Cheein, F.A.; Torres-Torriti, M.; Hopfenblatt, N.B.; Prado, A.J.; Calabi, D. Agricultural service unit motion planning under harvesting scheduling and terrain constraints. Journal of Field Robotics 2017, 34, 1531–1542. [Google Scholar] [CrossRef]

- Peng, K.; Du, J.; Lu, F.; Sun, Q.; Dong, Y.; Zhou, P.; Hu, M. A Hybrid Genetic Algorithm on Routing and Scheduling for Vehicle-Assisted Multi-Drone Parcel Delivery. IEEE Access 2019, 7, 49191–49200. [Google Scholar] [CrossRef]

- Praveen, V.; Keerthika, D.P.; Sivapriya, G.; Sarankumar, A.; Bhasker, B. Vehicle Routing Optimization Problem: A Study on Capacitated Vehicle Routing Problem. Materials Today: Proceedings 2022, 64, 670–674. [Google Scholar] [CrossRef]

- Khajepour, A.; Sheikhmohammady, M.; Nikbakhsh, E. Field path planning using capacitated arc routing problem. Computers and Electronics in Agriculture 2020, 173, 105401. [Google Scholar] [CrossRef]

- Patle, B.K.; L, G.B.; Pandey, A.; Parhi, D.R.; Jagadeesh, A. A review: On path planning strategies for navigation of mobile robot. Defence Technology 2019, 15, 582–606. [Google Scholar] [CrossRef]

- Ye, L.; Wu, F.; Zou, X.; Li, J. Path planning for mobile robots in unstructured orchard environments: An improved kinematically constrained bi-directional RRT approach. Computers and Electronics in Agriculture 2023, 215, 108453. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.; Zhang, P.; Gao, Q.; Han, X. A Hybrid A* Path Planning Algorithm Based on Multi-objective Constraints. 2022 Asia Conference on Advanced Robotics, Automation, and Control Engineering (ARACE), 2022, pp. 1–6. [CrossRef]

- Wang, N.; Li, X.; Zhang, K.; Wang, J.; Xie, D. A Survey on Path Planning for Autonomous Ground Vehicles in Unstructured Environments. Machines 2024, 12. [Google Scholar] [CrossRef]

- Papadakis, P. Terrain traversability analysis methods for unmanned ground vehicles: A survey. Engineering Applications of Artificial Intelligence 2013, 26, 1373–1385. [Google Scholar] [CrossRef]

- Al-Milli, S.; Seneviratne, L.D.; Althoefer, K. Track terrain modelling and traversability prediction for tracked vehicles on soft terrain. Journal of Terramechanics 2010, 47, 151–160. [Google Scholar] [CrossRef]

- Fernandez, B.; Herrera, P.J.; Cerrada, J.A. A Simplified Optimal Path Following Controller for an Agricultural Skid-Steering Robot. IEEE Access 2019, 7, 95932–95940. [Google Scholar] [CrossRef]

- Pragr, M.; Bayer, J.; Faigl, J. Autonomous robotic exploration with simultaneous environment and traversability models learning. Frontiers in Robotics and AI 2022, 9. [Google Scholar] [CrossRef] [PubMed]

- Dereci, U.; Karabekmez, M.E. The applications of multiple route optimization heuristics and meta-heuristic algorithms to solid waste transportation: A case study in Turkey. Decision Analytics Journal 2022, 4. [Google Scholar] [CrossRef]

- Prado, A.J.; Torres-Torriti, M.; Cheein, F.A. Distributed Tube-Based Nonlinear MPC for Motion Control of Skid-Steer Robots With Terra-Mechanical Constraints. IEEE Robotics and Automation Letters 2021, 6, 8045–8052. [Google Scholar] [CrossRef]

- Jiang, J.; Han, Z.; Li, J.; Wang, Y.; Wang, J.; Xu, S. Global Path Planning of UGVs in Large-Scale Off-Road Environment Based on Improved A-star Algorithm and Quadratic Programming. 2023 IEEE Intelligent Vehicles Symposium (IV), 2023, pp. 1–7. [CrossRef]

- Huang, C.; Tang, B.; Guo, Z.; Su, Q.; Gai, J. Agile-RRT*: A Faster and More Robust Path Planner With Enhanced Initial Solution and Convergence Rate in Complex Environments. IEEE Access 2024, 12, 58703–58714. [Google Scholar] [CrossRef]

- Fuad, M.; Wahyuni, S. Path Planning and Smoothing in Maze Exploration Using Virtual Mobile Robot-Based Modified Probabilistic Road Map. 2022 IEEE 8th Information Technology International Seminar (ITIS), 2022, pp. 15–20. [CrossRef]

- Elbanhawi, M.; Simic, M. Sampling-Based Robot Motion Planning: A Review. IEEE Access 2014, 2, 56–77. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Hou, J.; Chen, L.; Hu, N. A Path Planning Method for Underground Intelligent Vehicles Based on an Improved RRT* Algorithm. Electronics (Switzerland) 2022, 11. [Google Scholar] [CrossRef]

- Chen, X.; Ruan, X.; Zhu, X. Intelligent RRT Exploration Mapping Method Based on Evolutionary Cognition in Unknown Environment. 2020 IEEE 9th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), 2020, Vol. 9, pp. 1013–1017. [CrossRef]

- Dong, G.; Qin, R.; Han, L.; Chen, J.; Xu, K.; Ding, X. Ground Contact Parameter Estimation Guided Gait Planning for Hexapod Robots. 2022 IEEE International Conference on Robotics and Biomimetics (ROBIO), 2022, pp. 1–6. [CrossRef]

- Sender, T.; Brudnak, M.; Steiger, R.; Vasudevan, R.; Epureanu, B. A Regret-Informed Evolutionary Approach for Generating Adversarial Scenarios for Black-Box Off-Road Autonomy Systems. IEEE Robotics and Automation Letters 2024, 9, 5354–5361. [Google Scholar] [CrossRef]

- Höffmann, M.; Patel, S.; Büskens, C. Optimal Coverage Path Planning for Agricultural Vehicles with Curvature Constraints. Agriculture 2023, 13. [Google Scholar] [CrossRef]

- Álvaro Javier Prado. ; Torres-Torriti, M.; Yuz, J.; Cheein, F.A. Tube-based nonlinear model predictive control for autonomous skid-steer mobile robots with tire terrain interactions. Control Engineering Practice 2020, 101. [Google Scholar] [CrossRef]

- Popov, V.L. , Heidelberg, 2017; pp. 151–172. doi:10.1007/978-3-662-53081-8_10.Friction. In Contact Mechanics and Friction: Physical Principles and Applications; Springer Berlin Heidelberg: Berlin, Heidelberg, 2017; pp. 151–172. [Google Scholar] [CrossRef]

- Jazar, R.N.; Jazar, R.N. Road dynamics. Advanced Vehicle Dynamics.

- K. V. Narasimha Rao, R. Krishna Kumar, R.M.; Misra, V.K. A study of the relationship between Magic Formula coefficients and tyre design attributes through finite element analysis. Vehicle System Dynamics 2006, 44, 33–63. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Xu, L.; Zhang, X. An Occupancy Information Grid Model for Path Planning of Intelligent Robots. ISPRS International Journal of Geo-Information 2022, 11. [Google Scholar] [CrossRef]

- Gammell, J.D.; Barfoot, T.D.; Srinivasa, S.S. Informed Sampling for Asymptotically Optimal Path Planning. IEEE Transactions on Robotics 2018, 34, 966–984. [Google Scholar] [CrossRef]

- Qi, J.; Yang, H.; Sun, H. MOD-RRT*: A Sampling-Based Algorithm for Robot Path Planning in Dynamic Environment. IEEE Transactions on Industrial Electronics 2021, 68, 7244–7251. [Google Scholar] [CrossRef]

- Auat Cheein, F.A.; Scaglia, G.; Torres-Torriti, M.; Guivant, J.; Prado, A.J.; Arnò, J.; Escolà, A.; Rosell-Polo, J.R. Algebraic path tracking to aid the manual harvesting of olives using an automated service unit. Biosystems Engineering 2016, 142, 117–132. [Google Scholar] [CrossRef]

- Álvaro Javier Prado. ; Michałek, M.M.; Cheein, F.A. Machine-learning based approaches for self-tuning trajectory tracking controllers under terrain changes in repetitive tasks. Engineering Applications of Artificial Intelligence 2018, 67, 63–80. [Google Scholar] [CrossRef]

- Shamshiri, R.; Hameed, I.; Pitonakova, L.; Weltzien, C.; Balasundram, S.; Yule, I.; Grift, T.; Chowdhary, G. Simulation software and virtual environments for acceleration of agricultural robotics: Features highlights and performance comparison. International Journal of Agricultural and Biological Engineering 2018, 11, 15–31. [Google Scholar] [CrossRef]

- Perron, L.; Didier, F.; Gay, S. The CP-SAT-LP Solver. 29th International Conference on Principles and Practice of Constraint Programming (CP 2023); Yap, R.H.C., Ed.; Schloss Dagstuhl – Leibniz-Zentrum für Informatik: Dagstuhl, Germany, 2023. [Google Scholar] [CrossRef]

- Sunil, K.; Afzal, S. A novel hybrid framework for single and multi-robot path planning in a complex industrial environment. Journal of Intelligent Manufacturing 2024, 35, 587–612. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, T.; Du, L.; Hu, Y.; Liu, H. Local Path Planning of Autonomous Vehicle Based on an Improved Heuristic Bi-RRT Algorithm in Dynamic Obstacle Avoidance Environment. Sensors 2022, 22. [Google Scholar] [CrossRef] [PubMed]

| 1 |

| Traversability model | |

|---|---|

| Coefficient of static friction | |

| Normal force | |

| Frictional force | |

| Navigation map | |

| I | Image captured by a vision sensor |

| Occupancy grid representing the environment (pixels) | |

| Global path planning | |

| Harvest points | |

| List of locations and weights of | |

| R | List of harvest rows for in each isle |

| Q | Maximum payload capacity of the vehicle |

| w | Harvest weight on each harvest point |

| q | Harvest demand on each harvest point |

| Route with ordered to be visited | |

| Local path planning | |

| Initial path planning state | |

| Tree | |

| New sample point in the | |

| best node in terms of closeness to a neighbourhood | |

| The nearest node from | |

| New node added to | |

| Traction force | |

| Neighbourhood of nodes around | |

| Parameter | RRT | ||

|---|---|---|---|

| N Iterations | 500 | 500 | 500 |

| Safe navigation bounds | 0.3m | 0.3m | 0.3m |

| Neighbour size | 2.5m | 2.5m | 2.5m |

| r Extended ratio | 1.2m | 1.2m | 1.2m |

| Sample rate | 0.2 | 0.2 | 0.2 |

| Normal force per wheel | - | - | 400N |

| Method | Path planning | Obstacle avoidance | |||

| Path length [m] |

Travel time [s] |

Smoothness [] |

Obstacle proximity [m] |

Distance variability [m] |

|

| RRT | 47.4 | 1.8 | 1.97 | 2.0 | ± 0.31 |

| 41.7 | 41.6 | 1.18 | 2.2 | ± 0.35 | |

| 64.4 | 15.2 | 0.046 | 2.9 | ± 0.28 | |

| Method |

[m] |

[m] |

[] |

|

|---|---|---|---|---|

| RRT | 178.96 | 132.06 | 93.4 | 311.02 |

| 84.30 | 131.03 | 47.7 | 215.33 | |

| 28.21 | 173.71 | 22.3 | 201.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).