1. Introduction

Pipe systems are built to distribute fluids for different purposes, including large pressurized systems such as those used in water supply networks in towns [

1], as well as small systems for domestic use [

2], industrial plants [

3], and irrigation systems [

4], among others. These pressurized systems are constructed in various configurations to meet distribution needs, coupling pipes with various fittings and components such as valves, flow meters, T-junction, elbows, diameter reduction and expansion [

5]. However, as fluids circulate through the pipes and pass-through various fittings, they experience head losses that are crucial to evaluate during the design process or operational review of pressurized systems [

6].

The analysis of head loss is typically divided into friction losses and local losses [

7], also known as major losses and minor losses, respectively [

8]. Friction losses occur when the fluid rubs against the internal walls of pipes with a constant cross-sectional area. On the other hand, local losses are generated in areas where the flow crosses the fittings, causing alterations or changes in flow paths [

9]. This study focuses on the latter, particularly on the head losses generated in elbows (

Figure 1), as they are extensively manufactured and used to change the direction of flow in the pipes.

This

Figure 1 illustrates the direction of the circulation flow (

Q) and the deflection angle generated by its trajectory (

θ), with a)

θ = 90

o and b)

θ = 45

o.

D represents the hydraulic diameter and

r is the radius of curvature of the fitting.

Local losses in both elbows and other fittings are evaluated using the following general Equation:

where

hL are the local losses (m),

K is an experimental coefficient of the fitting (dimensionless),

V is the average flow velocity (m/s),

g is the gravity (m/s

2). In practice, the

K coefficient is determined based on the geometric parameters such as

D,

θ, and

r/D. Also, it has been observed that

K varies with respect to the behavior of

Q and velocity head (

V2⁄2g) [

10], as well as with the Reynolds number (

Re) [

11].

Research on head losses or loss coefficient in elbows has not ceased in recent years, which can be seen in the experimental work carried out by Silverio [

2], Musa [

5], Yogaraja [

6] and Arteaga [

12]. Likewise, recent research has been reported where numerical models are applied to estimate head losses in elbows, such as the work reported by Selim [

13], Mańko [

14], Meng [

15] and Chang [

16]. However, limited information is available on small-diameter fittings, and these studies necessitate calibration or comparison with experimental data for validation, highlighting the importance of laboratory research.

Although valuable data on head losses and loss coefficients are available, elbow geometry has been shown to be variable because it depends on manufacturing processes and suppliers [

17]. Such is the case of Polyvinyl Chloride (PVC), which is widely used worldwide for the production of hydraulic pipes and fittings [

6]. Given the continuous advancements in manufacturing processes, it is crucial to maintain the evaluation of head losses in hydraulic systems, particularly in small-diameter pipe elbows. Thus, this study aims to investigate head losses in PVC pipe elbows with schedule 40 and evaluate the behavior of head losses and the

K coefficient concerning

Q,

V2⁄2g and

Re parameters. The elbows of interest are those modifying pipe directions by 45 and 90 degrees, commonly used in systems with small nominal diameters for water supply in industries, businesses, and homes. The following sections present the experimental details in materials and methods, the results and discussions of the findings, as well as the conclusions of the research.

2. Materials and Methods

2.1. Experimental System

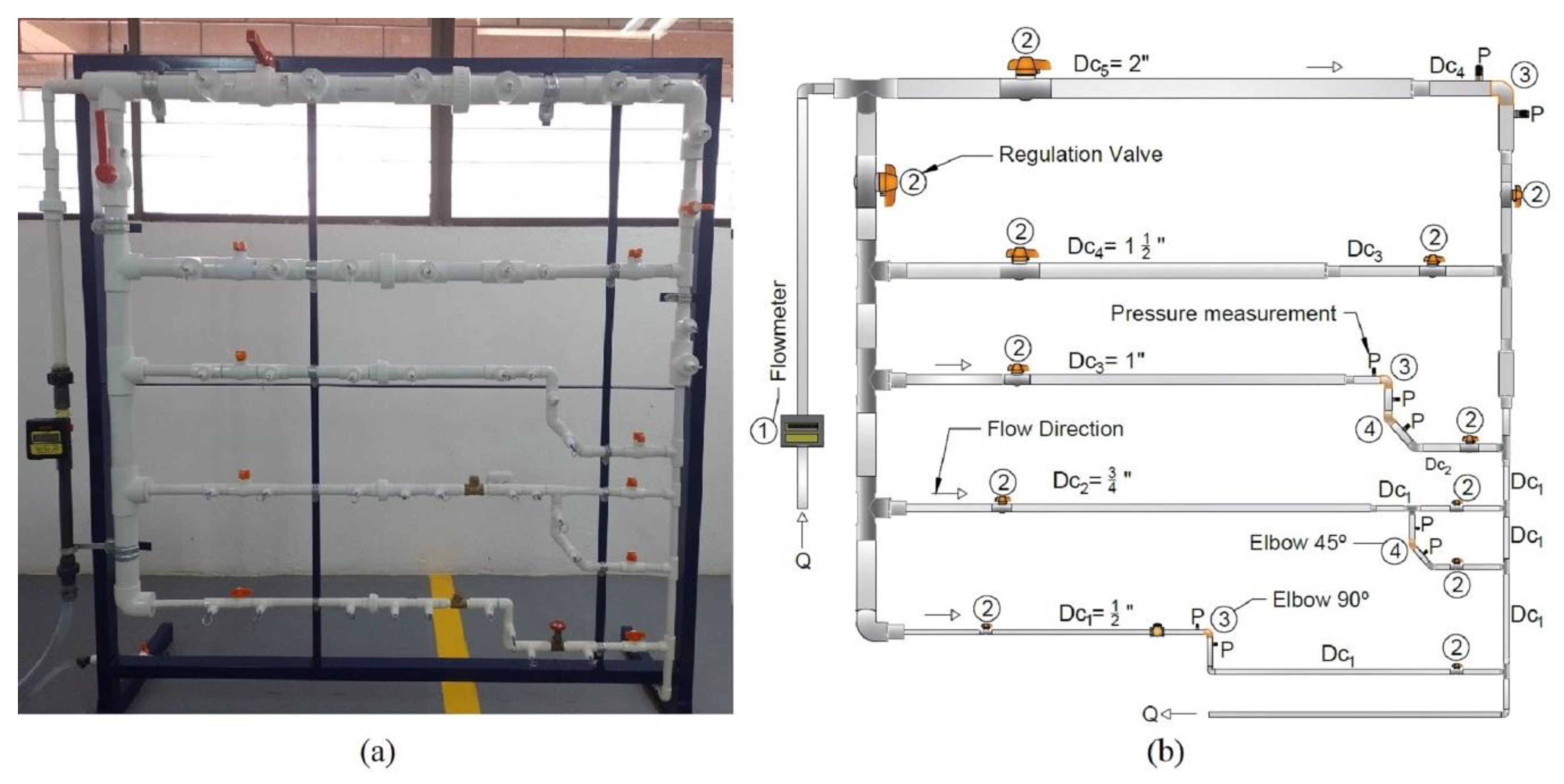

Figure 2a displays the constructed schedule 40 PVC pipes and fittings system, utilized in the laboratory to investigate head losses and the loss coefficient.

Figure 2b provides a representative scheme of the piping system, depicting the components used for testing the study elbows.

This system schematic illustrates the digital flow meter, specifically a Blue White F2000. Pipes with commercial diameters (Dc) of ½, ¾, 1, 1 ½, and 2 inches (”, in) were employed, along with valves to regulate flow in the desired direction. The 90o and 45o elbows under study are situated at nodes 3 and 4, respectively. Pressure head measurements were taken at points P, both before and after the elbows, using a Comark digital manometer.

The details of the studied elbows are presented in

Table 1, showcasing the deflection angle in degrees, commercial diameter (

Dc, in), hydraulic diameter (

D, mm), the ratio of radius of curvature to hydraulic diameter (

r/D), as well as upstream length (

Lu) and downstream length (

Ld), up to which there is a fitting producing head losses.

2.2. Experimental Methodology

Multiple flow rates were supplied to the piping system using an instrumented hydraulic bench with a tank and ¾ hp centrifugal pump. The flows were monitored with the flow meter and were directed through the pipes to each fitting studied. Once the flow was stabilized, pressure head losses (

∆P⁄γ) were measured in the differential manometer for each flow rate, considering an error of ±3% for data selection. From the pressure head loss, the local head loss caused by each elbow was obtained (

hL =

∆P⁄γ). Based on Equation (1) and taking into account the head loss, the following Equation was derived that allowed estimating the loss coefficients of the elbows:

for this purpose, velocities were calculated as a function of flow rate and hydraulic area using the following Equation:

the temperature was also measured with a digital thermometer, enabling the evaluation of fluid density and dynamic viscosity. This allowed for the estimation of the Reynolds number for each flow rate using the following Equation:

where

Re is the Reynolds number (dimensionless),

ρ is the fluid density (kg/m

3),

V is the average flow velocity (m/s),

D is the hydraulic diameter,

μ is the dynamic viscosity of the fluid (kg/m⸱s).

After completing the above steps, tables and graphs were prepared for each studied elbow to present the results.

3. Results and Discussion

In accordance with the exposed methodology, results and discussions are presented for the cases of elbows of 90o and 45o deflection. The data is displayed in tables that provide information obtained from Q, hL, V, K and Re. Likewise, figures are shown that illustrate the behavior of the hL data against V2⁄2g, as well as the coefficient K in relation to the variation of Q and against the development of Re. The temperature was monitored to evaluate the Reynolds number, which resulted in an average of 27.5 oC.

3.1. 90o Deflection Elbows

Table 2 shows the results obtained for the 90

o deflection elbow with

Dc = ½ in, where there are the measured values of 0.391 lps ≤

Q ≤ 0.980 lps, as well as the behavior of the values obtained of

hL,

V,

K and

Re for each

Q. In this case, values of 1.50 m/s ≤

V ≤ 3.77 m/s and 32009 ≤

Re ≤ 80221 resulted. Also, it can be observed that

hL and

Re increase as

Q increases, while the coefficient

K does not present a defined behavior and is variable in proportion to

Q and <

Re. The values of

hL increase from 0.091 m to 0.585 m, while

K presents a minimum value of 0.56 and a maximum value of 0.88.

The results obtained for the 90

o elbow with

Dc = ¾ in are presented in

Table 3, where the measured values of 0.477 lps ≤

Q ≤ 0.980 lps are grouped, as well as the behavior of the determined values of

hL,

V,

K and

Re for each

Q. This scenario includes values of 1.09 m/s ≤

V ≤ 2.24 m/s and 30081 ≤

Re ≤ 61866. Furthermore, it can be observed that

hL increases from 0.062 m to 0.193 m, as

Q and

Re increase.

K does not present a defined behavior in proportion to

Q and

Re. However,

K shows a minimum value of 0.75 that predominates in three flow rates and a maximum value of 0.89.

On the other hand,

Table 4 shows the results obtained for the 90

o elbow with

Dc = 1½ in, where the measured values of 0.391 lps ≤

Q ≤ 0.980 lps are concentrated, as well as the behavior of the values obtained of

hL,

V,

K and

Re for each

Q. Values between 0.26 m/s ≤

V ≤ 0.65 m/s and 13337 ≤

Re ≤ 33426 resulted. It can be seen that

hL and

K do not present a defined behavior in proportion to

Q and

Re. In the case of

hL it presents a minimum value of 0.010 m and a maximum value of 0.018 m, while

K has a minimum value of 0.64 and a maximum value of 4.13. Furthermore, it is shown that the

K values increase for low velocities.

The following figures show graphically the behavior of the head losses and the loss coefficient for these 90o deflection elbows. First, graphs of hL against V2⁄2g are presented, then of K in relation to Q and finally of K versus Re.

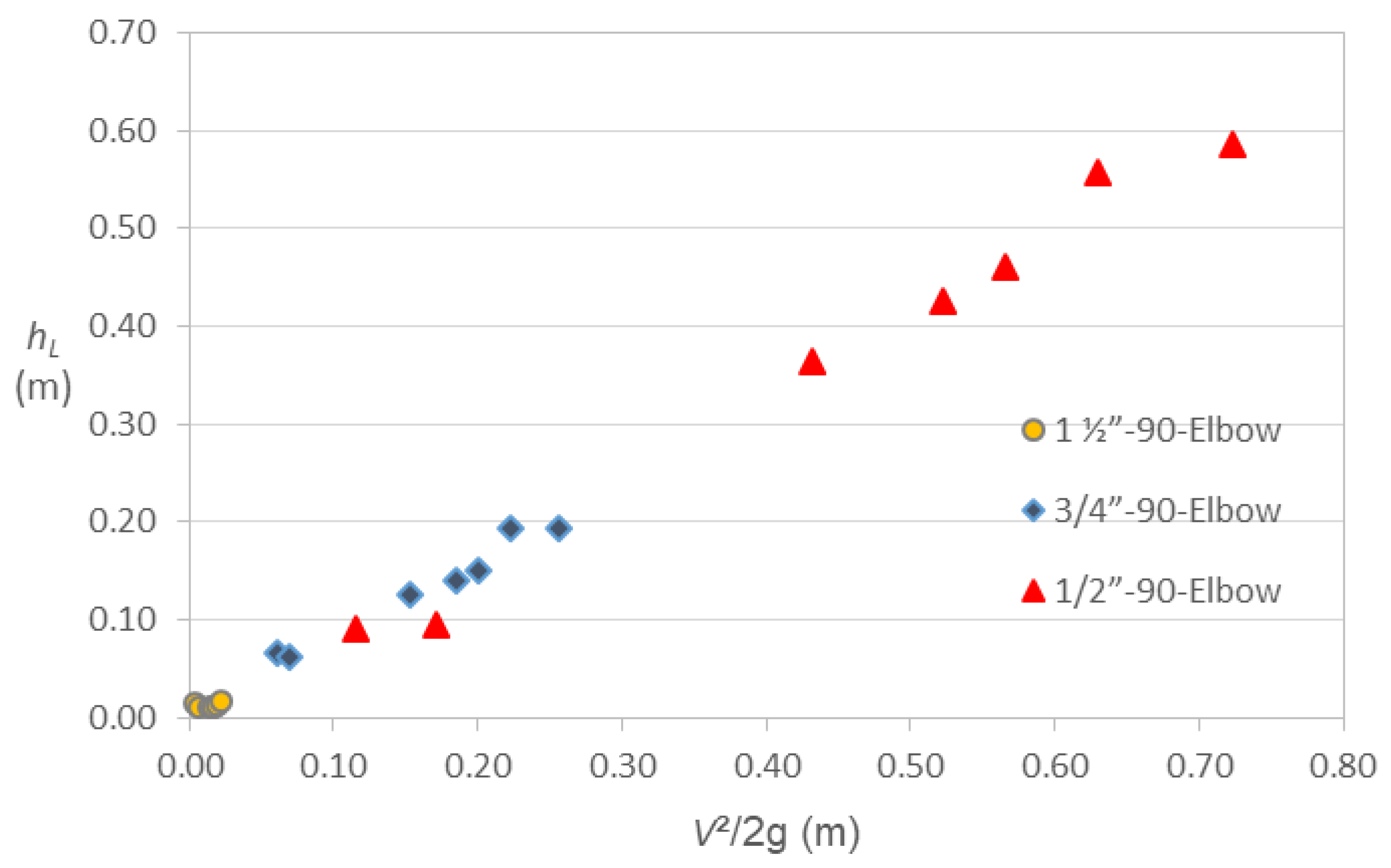

3.1.1. hL versus V2⁄2g for 90o Elbows

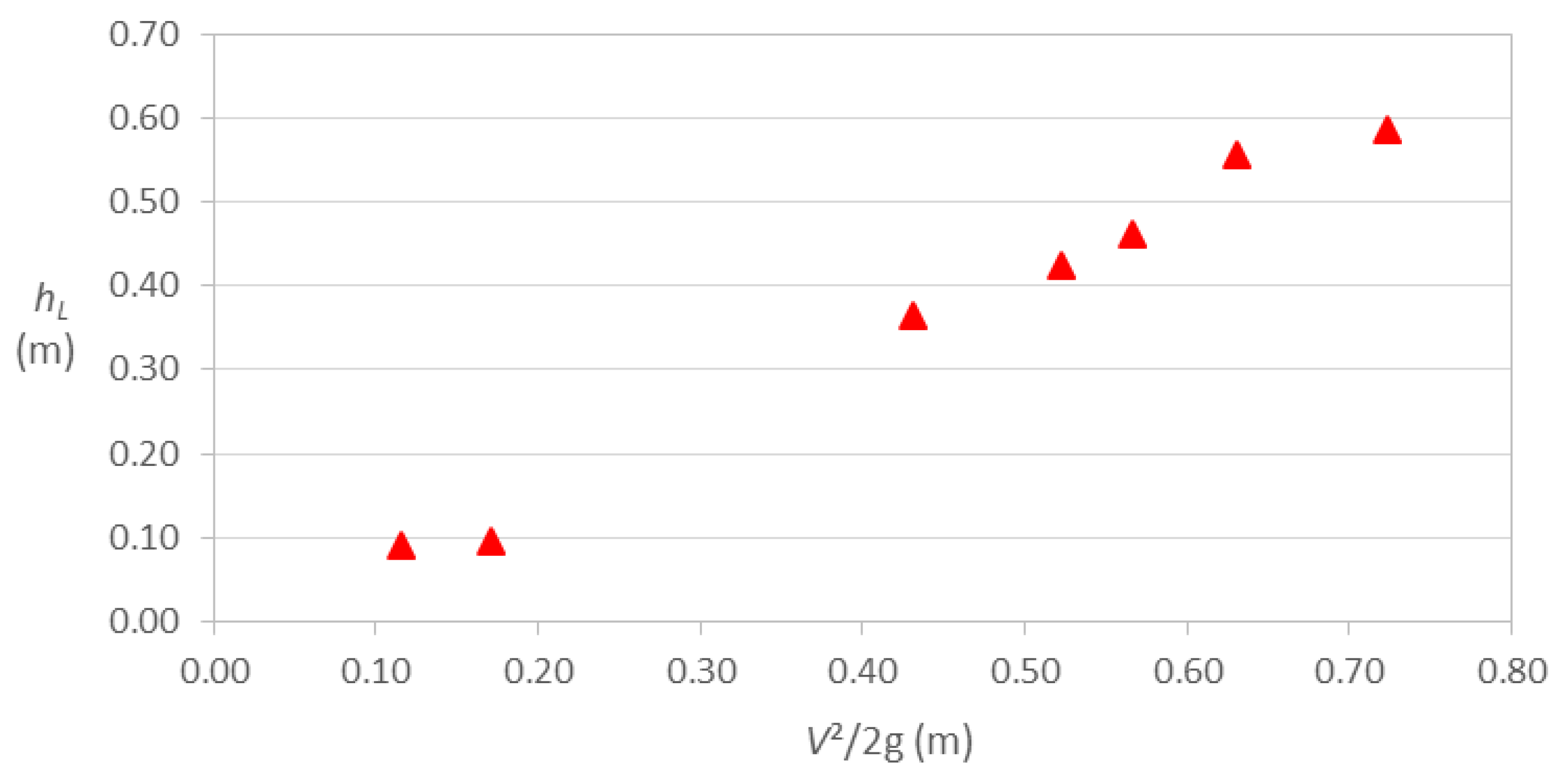

Figure 3 shows the behavior of the head loss values with respect to the velocity head for the elbow with

Dc = ½ in. In this case, the values of

hL are proportional to

V2⁄2g and tend to form an ascending line, as the velocity head increases.

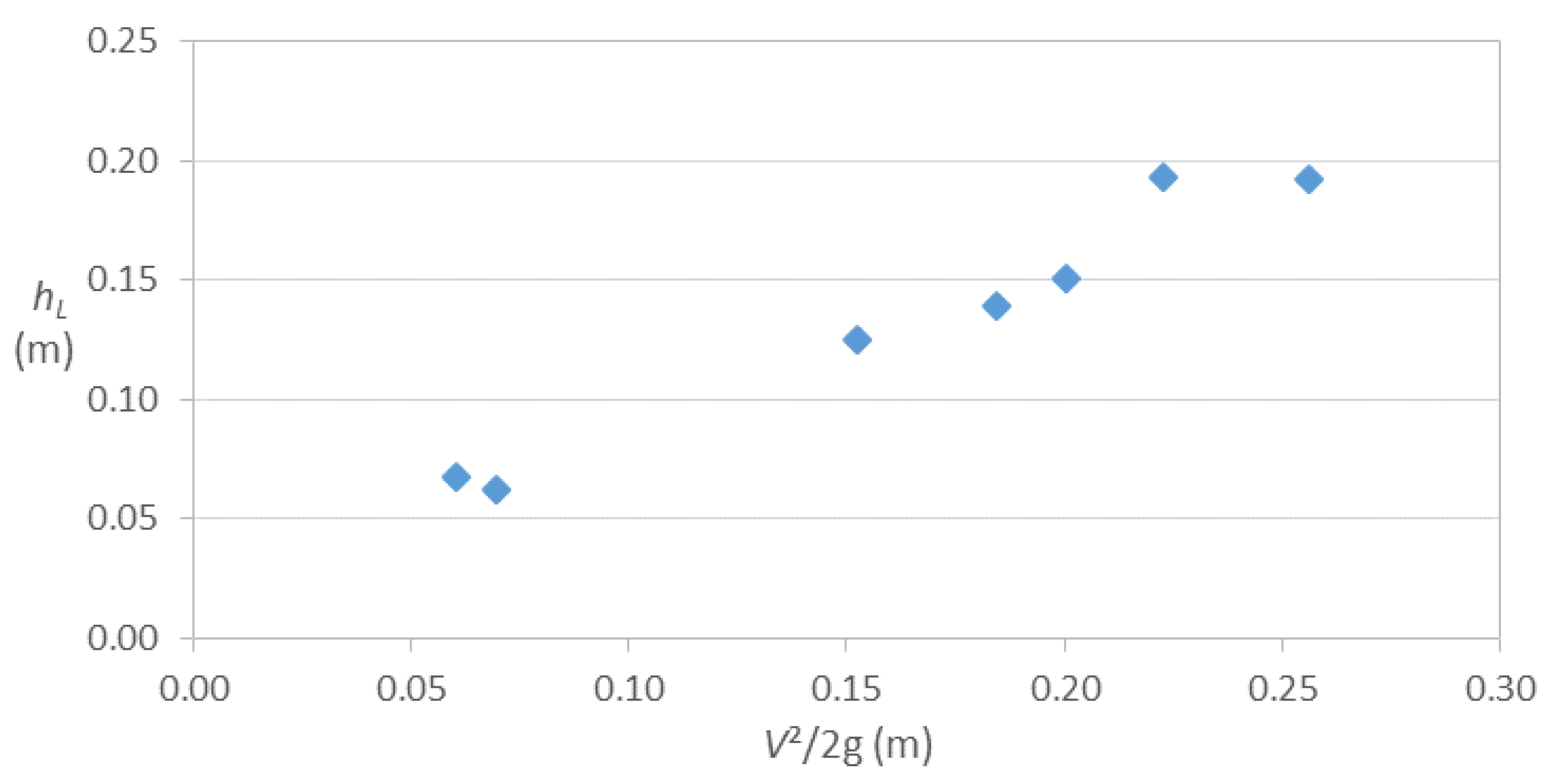

Figure 4 illustrates the behavior of head losses with respect to velocity head for the ¾ in elbow. In this case, the behavior of the losses presents oscillations, with a decrease at low velocities and maintaining a constant value at the last two velocities.

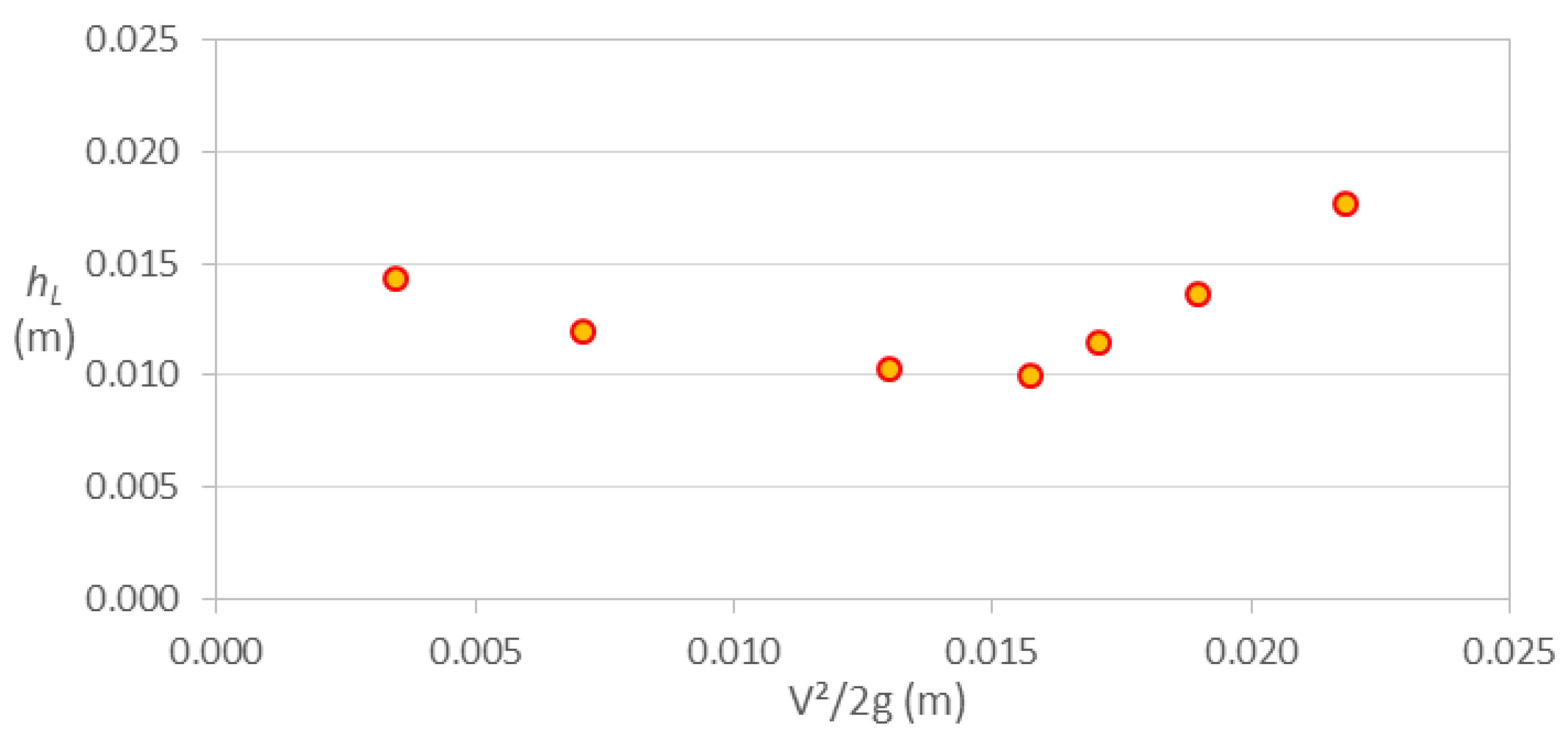

In the graph of

Figure 5, we can see the behavior of the energy losses as the velocity head varies for the elbow with

Dc = 1 ½ in. Very small values of

hL are presented, ranging between 0.01 m and 0.02 m. It is also observed that the losses decrease in the first four values of the velocity head, then increase linearly for the rest of the velocity head values.

Finally,

Figure 6 shows the contrast of the head loss values obtained for the three 90

o deflection elbows, where it can be seen that in general they tend to approach in a straight line. The larger diameter elbows produce very small head losses compared to the other two elbows, while the high losses generated by the smaller diameter elbows are notable, reaching almost 0.60 m for a velocity head close to 0.72 m. Based on the above, it is shown that the head loss and velocity head increase as the diameter of the elbow decreases.

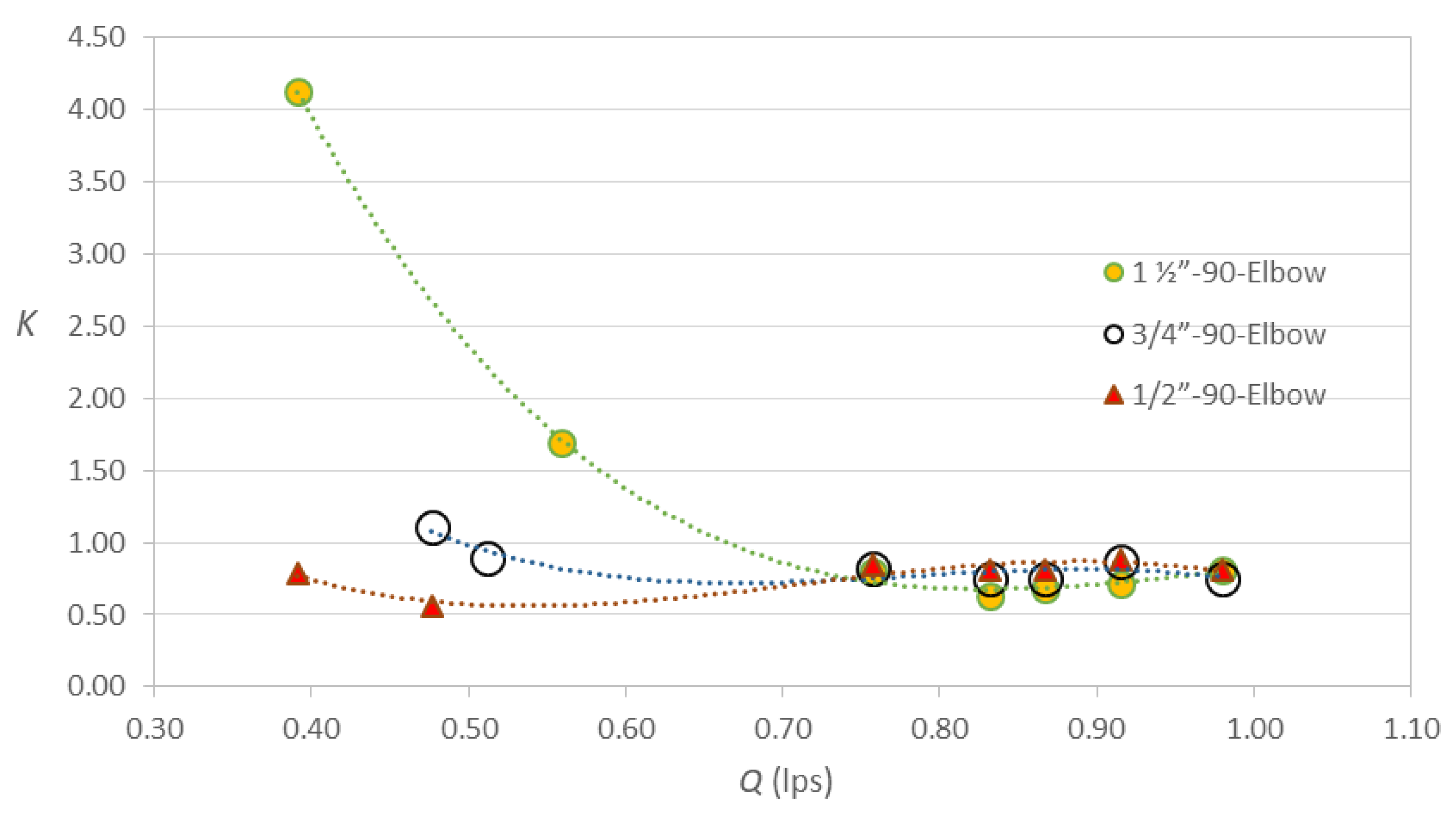

3.1.2. K versus Q for 90º Elbows

Figure 7 illustrates the comparison of the values of the

K coefficient in relation to the intensity of the flow, for the three elbows studied with 90

o deflection. This graph shows that for low flows, the fittings produce a more different

K coefficient, while the elbows generate a more similar coefficient for high flows. It is observed that for the three elbows, the

K values tend to coincide at approximately 0.75, when

Q > 0.75 lps. It is also illustrated that the maximum values of

K occur with

Dc = 1 ½ in, but the minimum values occur with

Dc = ½ in.

From the Equation of the curve of each elbow with 90

o deflection, the loss coefficient (dimensionless) can be estimated as a function of

Q (lps). Equation (5) allows obtaining the loss coefficient for the elbow with

Dc = ½ in:

this Equation is valid for 0.391 lps ≤

Q ≤ 0.980 lps, with a coefficient of determination (

r2) of 0.84.

Also, using Equation (6) the loss coefficient for the elbow with

Dc = 3/4 in is determined:

the Equation is useful for 0.477 lps ≤

Q ≤ 0.980 lps with

r2 = 0.82.

Finally, with Equation (7) the loss coefficient for the elbow with

Dc = 1½ in is estimated:

this Equation is allowed for 0.391 lps ≤

Q ≤ 0.980 lps with

r2 = 0.99.

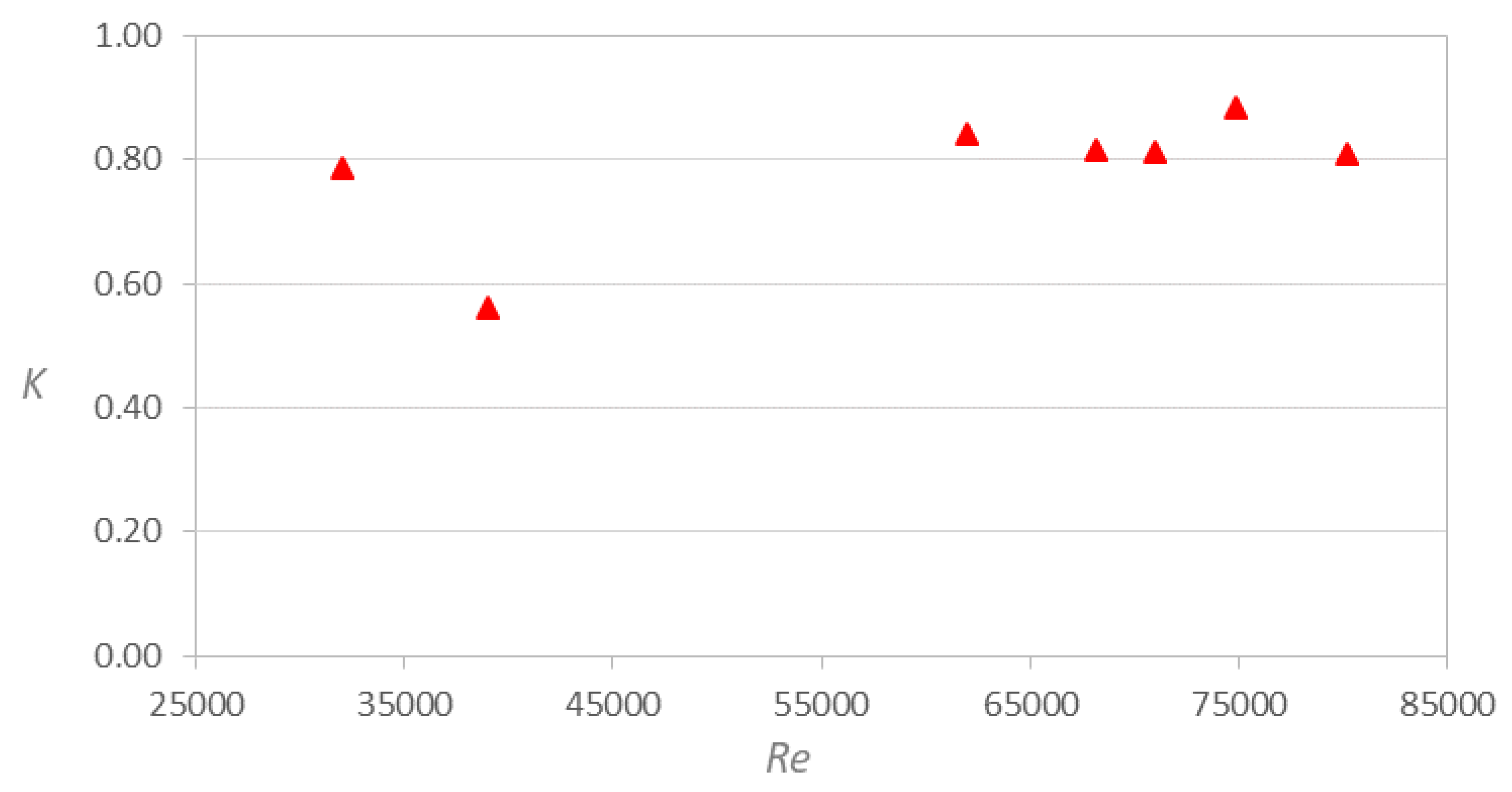

3.1.3. K versus Re for 90o Elbows

Finally, the following Figures illustrate the behavior of the loss coefficient in relation to the variation of the Reynolds number.

Figure 8 shows the behavior of

K according to the variation of

Re for the elbow with

Dc = ½ in. It is observed that the trend of

K is not linear, where a minimum value of approximately 0.56 occurs when

Re approaches 40,000. Likewise, it is obtained that

K ≈ 0.81 for

Re > 55,000.

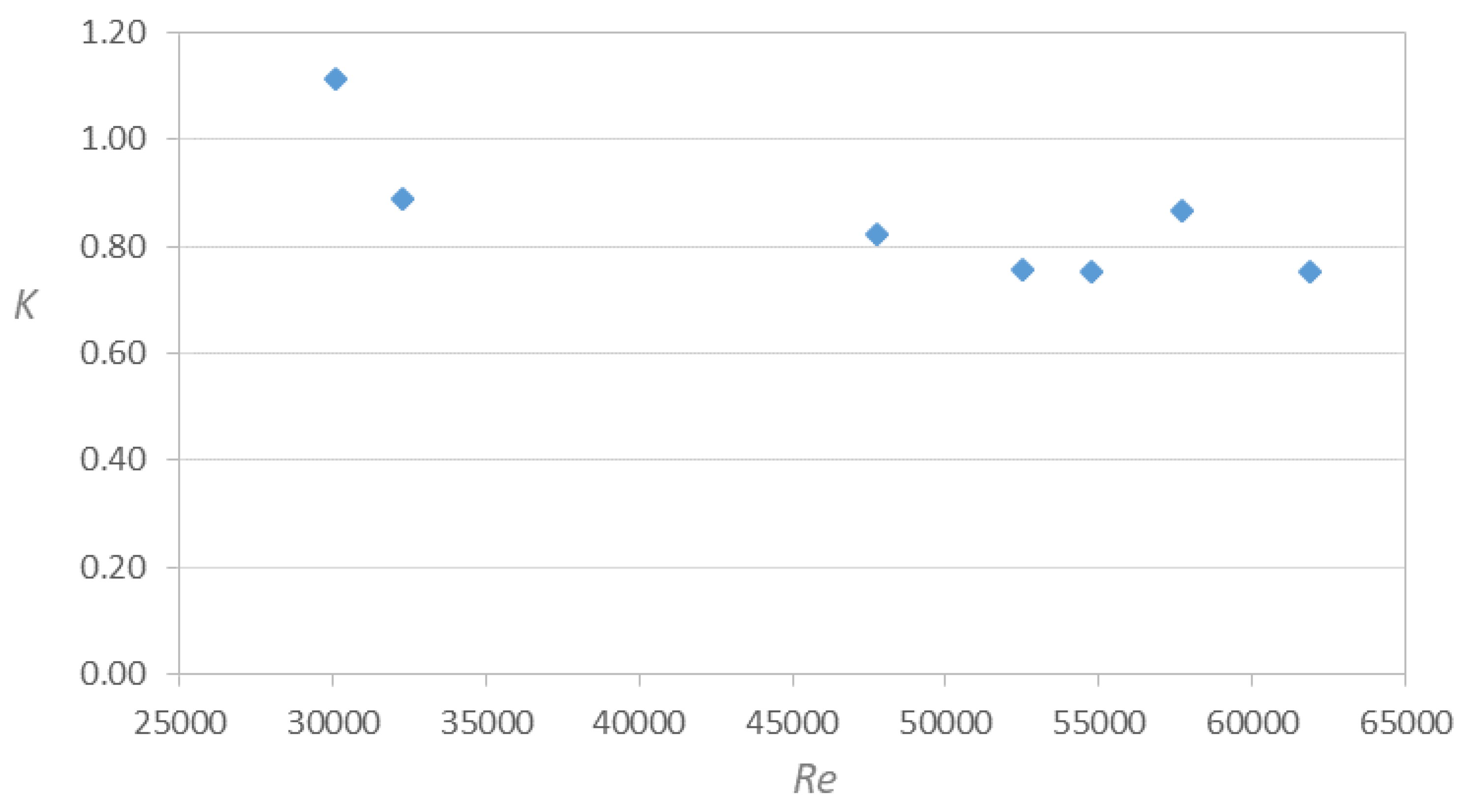

Figure 9 shows the result of the

K values according to

Re for the elbow with

Dc = ¾ in. It can be seen that

K tends to increase at lower values of

Re, presenting the maximum value near 1.10. Likewise, the

K values show oscillations and tend to 0.80 when

Re increases.

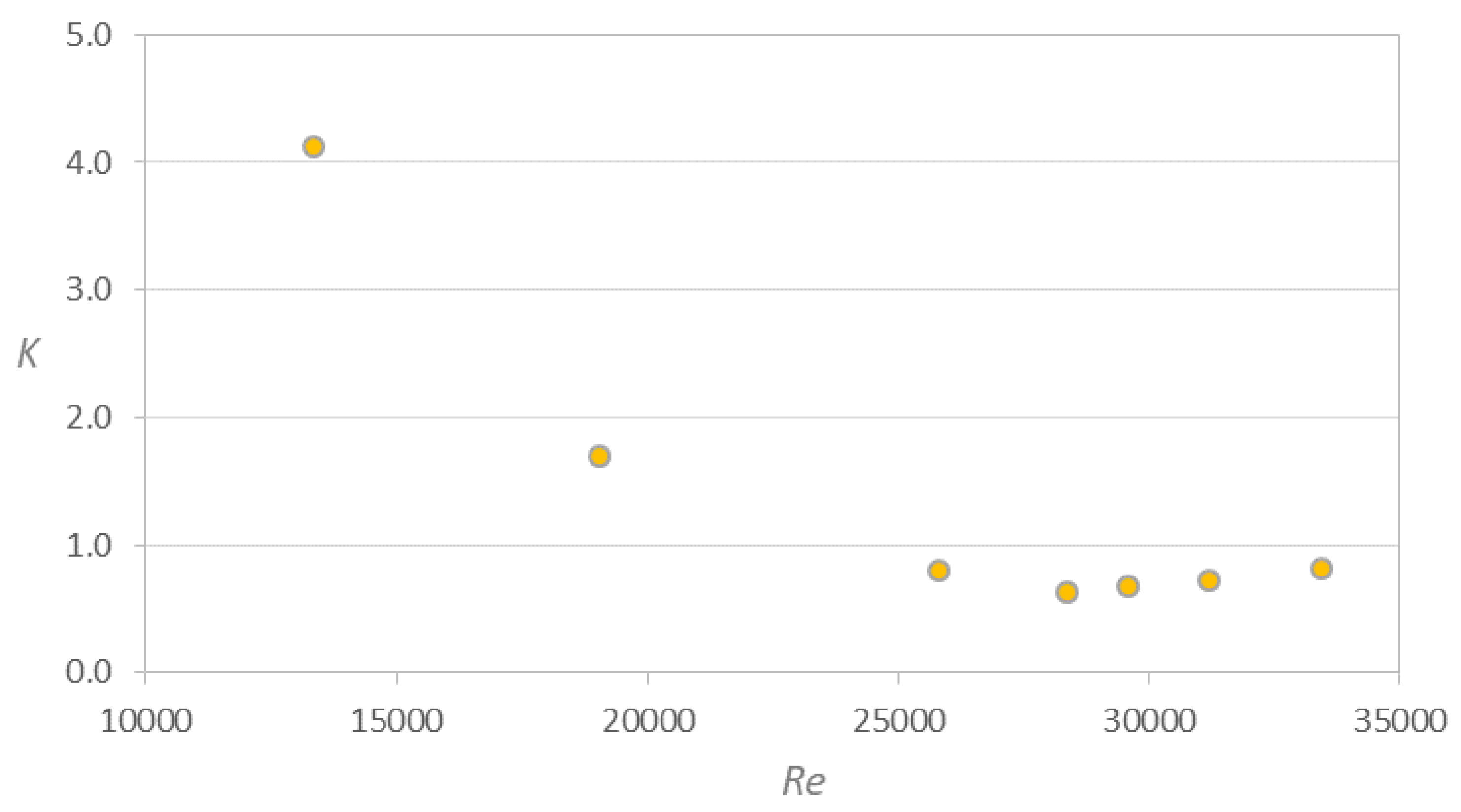

Now,

Figure 10 shows graphically the dispersion of

K in relation to

Re, for the elbow with

Dc = 1 ½ in. It is illustrated that as

Re decreases, the value of

K increases asymptotically to a maximum value near 4.10. Likewise, it is observed that

K tends to approximate values between 0.60 and 0.80, when

Re > 25000.

Finally,

Figure 11 shows the comparison of the

K values according to

Re for the three elbows with 90

o deflection. It is shown that for

Re approximately 39000, the minimum value of the coefficient

K ≈ 0.5 and occurs at the elbow with

Dc = ½ in. However, the maximum value of

K ≈ 4.20 is generated by the elbow with

Dc = 1 ½ in, when

Re ≈ 13000. Meanwhile, for the elbows with

Dc = ½ and 3/4 in, the value of

K tends to remain closes to 0.80, when

Re > 40000.

3.2. 45o Deflection Elbows

Table 5 shows the results obtained for the 45

o elbow with

Dc = ½ in, where the measured values of 0.342 lps ≤

Q ≤ 0.915 lps are concentrated, as well as the behavior of the values obtained for

hL,

V,

K and

Re for each

Q. In this case, values between 1.31 m/s ≤

V ≤ 3.52 m/s and 27986 ≤

Re ≤ 74861 resulted. It can be seen that

hL and

K do not present a defined behavior in proportion to

Q and

Re. The data show that the values of

hL and

K are the minimum when

Q = 0.425 lps and

Re = 34778. However,

hL increases slightly when

Q < 0.425 lps, while if

Q > 0.425 lps,

hL also increases proportionally to

Q and

Re, presenting its maximum value of 0.261 m for the highest value of

Q and

Re. Otherwise, the maximum value of

K = 1.97 occurs when

Q and

Re are minimum, while

K = 0.41 when

Q and

Re are maximum.

The results obtained for the 45

o elbow with

Dc = ¾ in are presented in

Table 6, where the measured values of 0.342 lps ≤

Q ≤ 0.915 lps are grouped, as well as the behavior of the determined values of

hL,

V,

K and

Re for each

Q. This scenario includes values of 0.78 m/s ≤

V ≤ 2.09 m/s and 21582 ≤

Re ≤ 57732. It is shown that

hL has a minimum value of 0.035 m when

Q = 0.559 lps and

Re = 35266, while when these values of

Q and

Re decrease and increase, the value of

hL increases for both cases. The maximum value of

hL = 0.114 m occurs in the minimum values of

Q and

Re. Likewise, it is observed that the loss coefficient does not have a defined behavior with respect to

Q and

Re. The coefficient

K acquires the maximum value of 3.66, for the minimum values of

Q and

Re, while the minimum value

K = 0.40 occurs in the ranges of 0.757 lps ≤

Q ≤ 0.867 lps and 47772 ≤

Re ≤ 54724.

On the other hand, the following Figures show graphically the behavior of the results of the head losses and the loss coefficient in the 45o deflection elbows. First, graphs of hL against V2⁄2g are presented, then of K in relation to Q and finally of K versus Re.

3.2.1. hL versus V2⁄2g for 45o Elbows

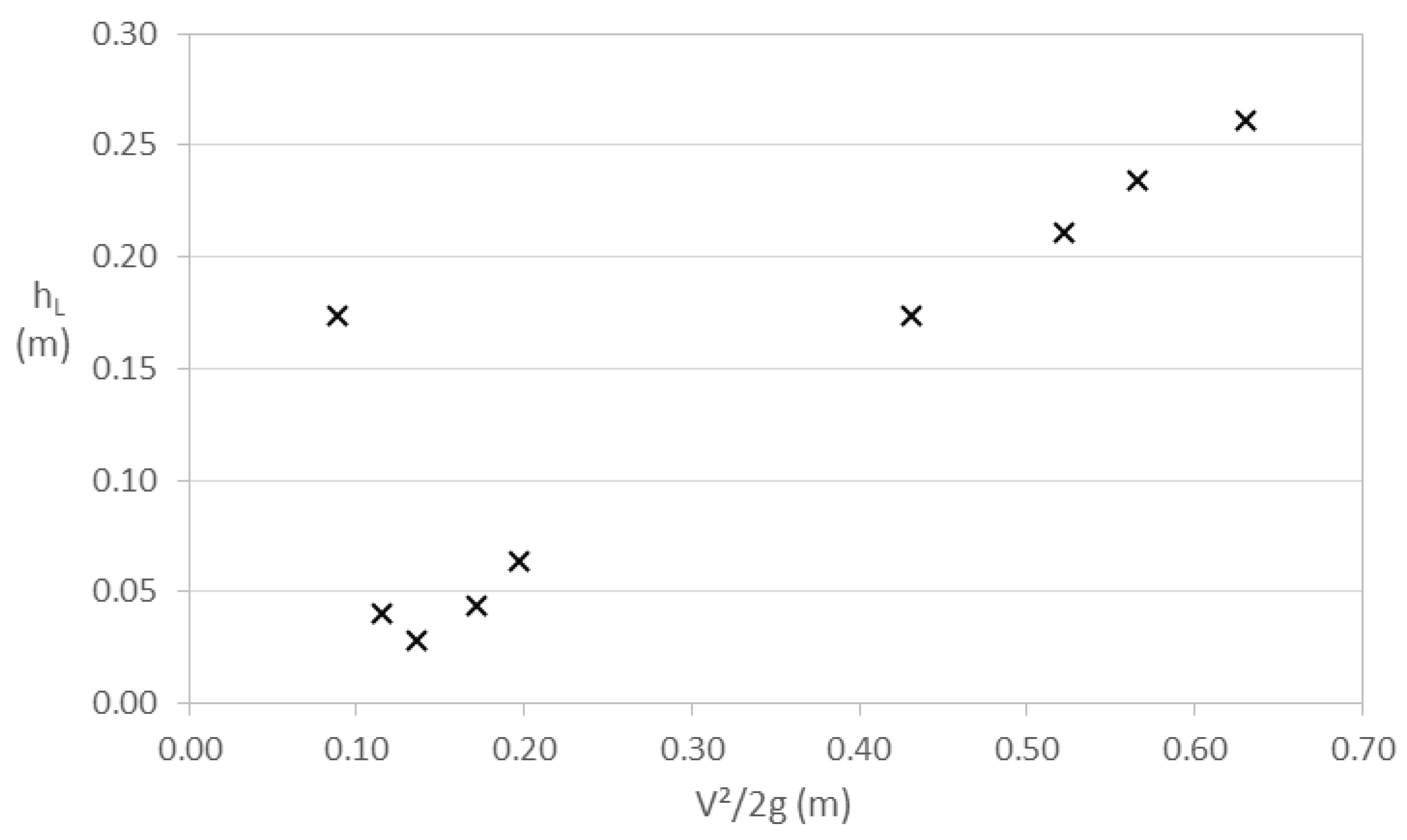

Figure 12 shows a curve of the head loss values with respect to the velocity head for the elbow with

Dc = ½”. In this case, an inflection point is observed, where

hL has the minimum value close to 0.03 m when

V2⁄2g ≈ 0.14 m. Furthermore, the value of

hL increases when

V2⁄2g decreases, but they also increase with a linear trend when

V2⁄2g increases.

hL acquires the maximum value near 0.26 m for the largest value of

V2⁄2g.

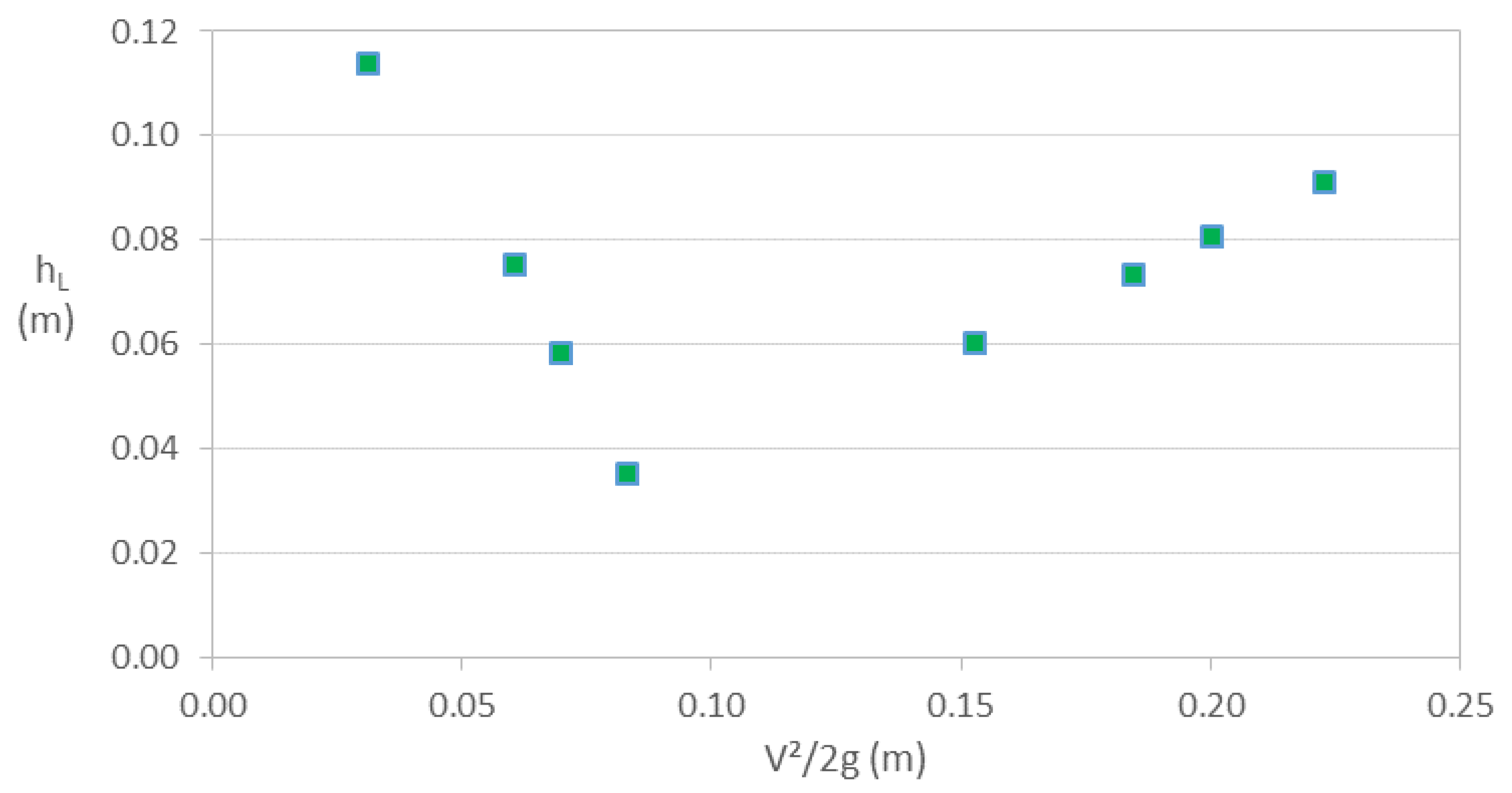

The values of head losses with respect to the velocity head for the elbow with

Dc = ¾ in are illustrated in

Figure 13. It is shown that for lower and higher values of

V2⁄2g = 0.10 m, the head losses increase with a linear trend for both sides. However, the maximum value of

hL ≈ 0.115 m is obtained for the minimum velocity head, while the minimum value of

hL is about 0.035 m and occurs at

V2⁄2g ≈ 0.08 m.

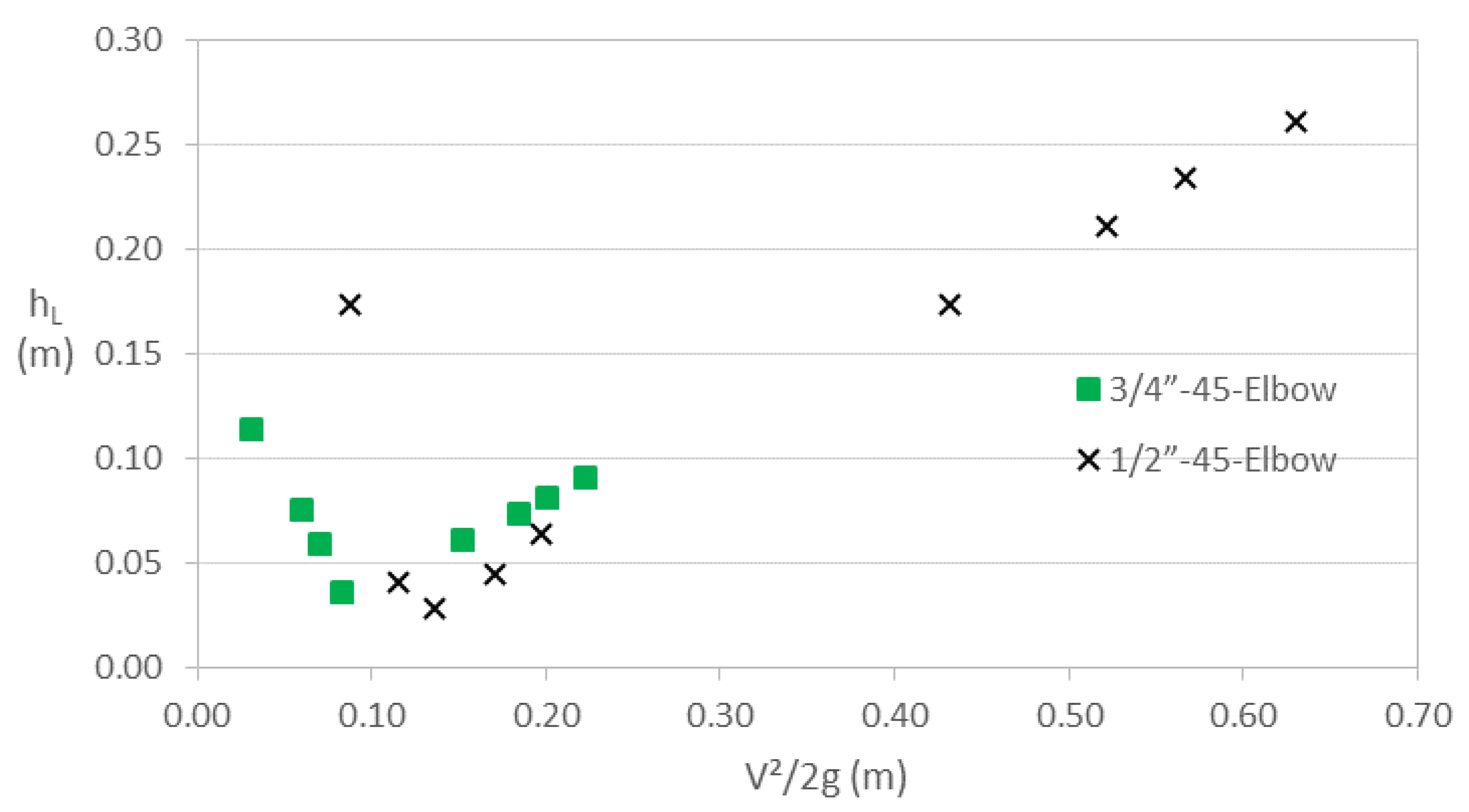

Figure 14 contains the

hL vs

V2⁄2g data for 45

o elbows with diameters ½ and ¾ in. It is observed that the energy losses of both elbows are close for values of

V2⁄2g between 0.10 and 0.22 m, with the losses generated in the elbow with

Dc = ¾ in being slightly greater. Likewise, it can be assumed that the losses of both fittings tend to increase linearly in proportion to the velocity head for

V2⁄2g > 0.13 m.

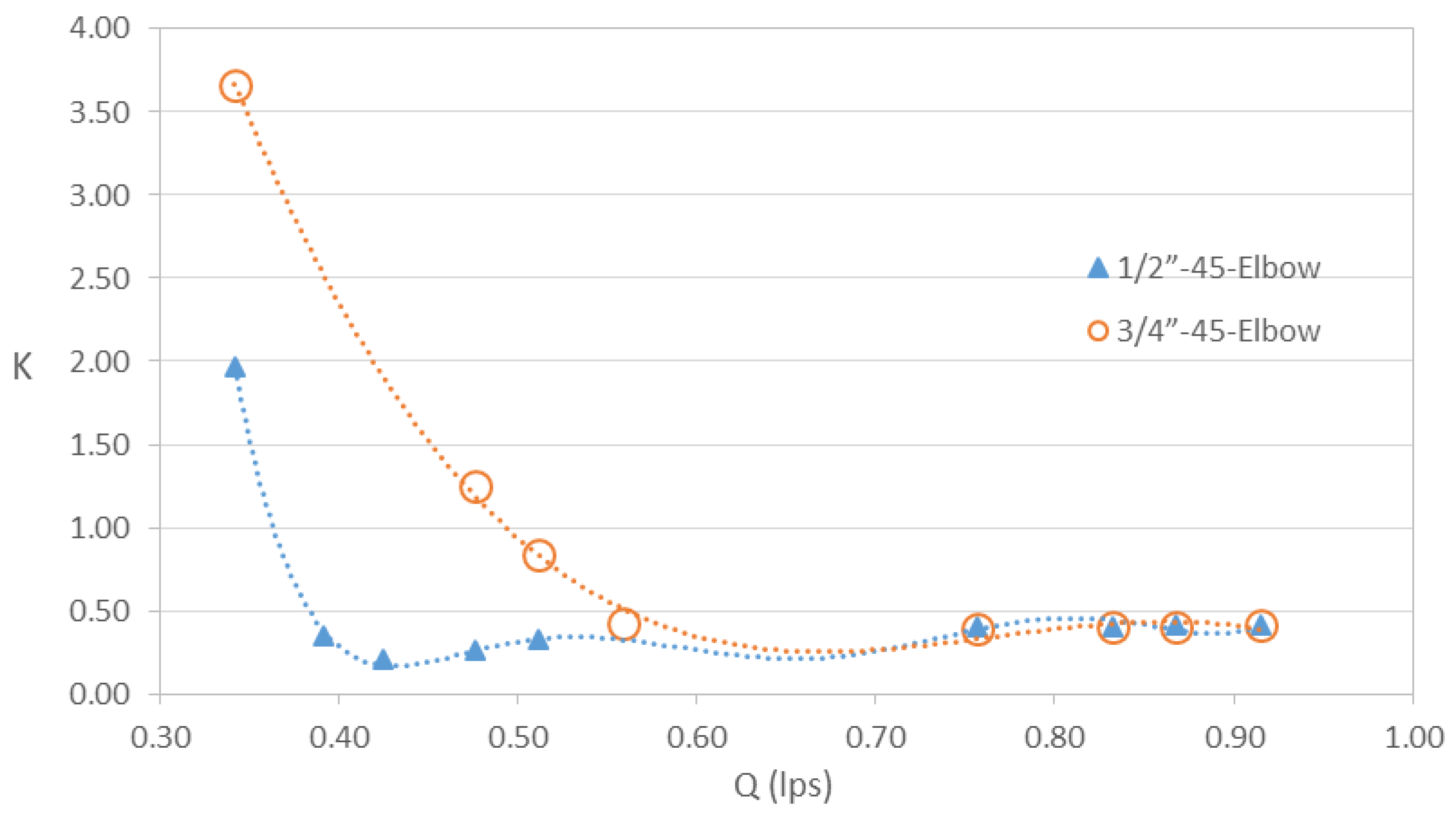

3.2.2. K versus Q for 45o elbows

Figure 15 presents the data for the

K coefficient in relation to

Q for the 45 degree deflection elbows with

Dc = ½ and ¾ in. It is observed that the

K values are different between both fittings for

Q < 0.65 lps, where the ¾ in elbow causes the highest loss coefficients. However, both elbows generate similar

K values, tending to around 0.40 when

Q > 0.75 lps.

Based on the Equation of the curve of each elbow with 45

o deflection, the loss coefficient can be estimated as a function of

Q (lps). Equation (8) allows obtaining the loss coefficient for the elbow with

Dc = ½ in:

this Equation is valid for 0.342 lps ≤

Q ≤ 0.915 lps with

r2 = 0.99.

Likewise, with Equation (9) the loss coefficient for the elbow with

Dc = 3/4 in is determined:

the above Equation is useful for 0.342 lps ≤

Q ≤ 0.915 lps with

r2 = 0.99.

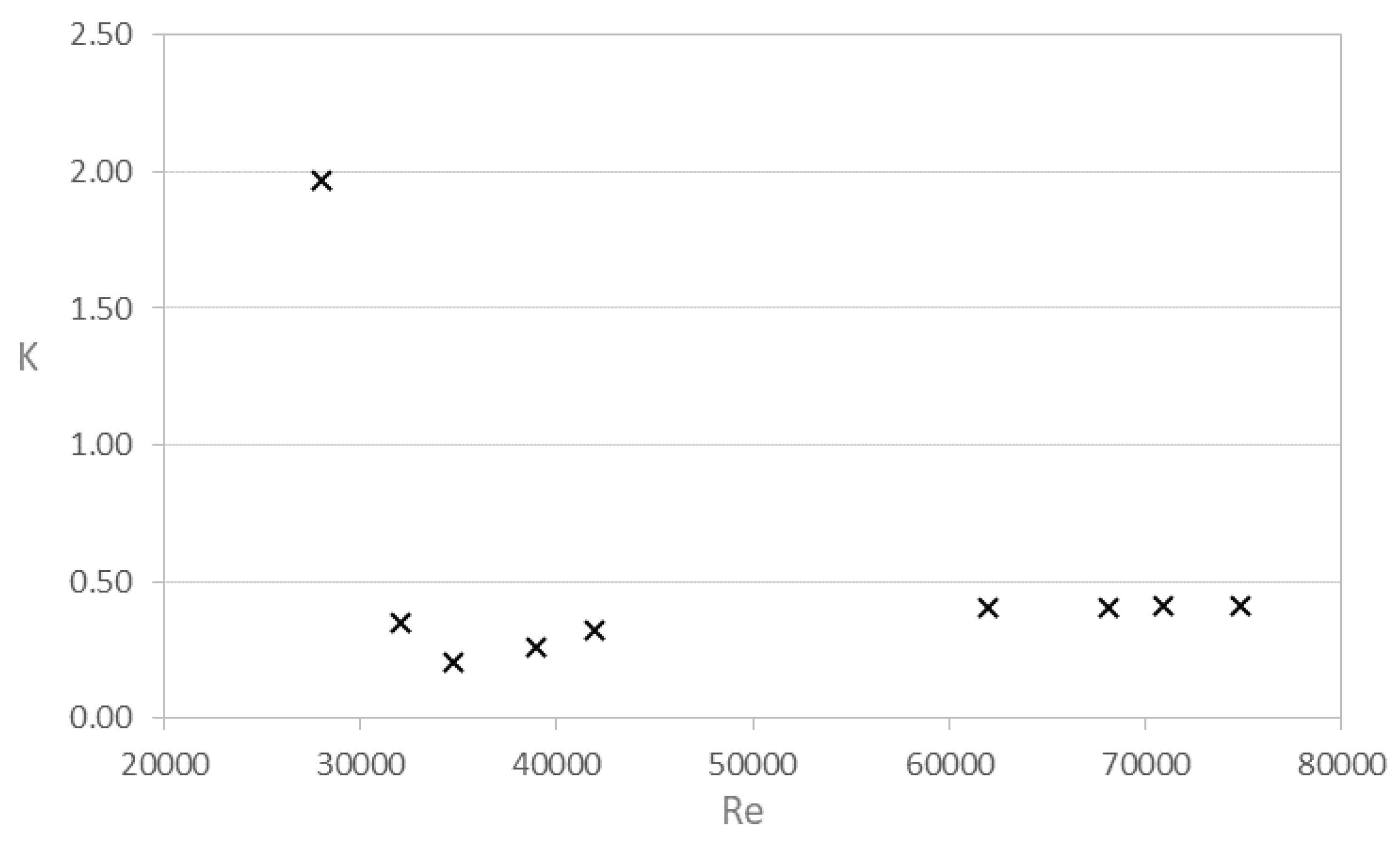

3.2.3. K versus Re for 45o Elbow

Figure 16 shows graphically the dispersion of

K in relation to

Re for the elbow with

Dc = ½ in. It is illustrated that the maximum value of

K is close to 2.0 for the minimum value of

Re ≈ 28000. It is also shown that the values of

K behave between 0.2 and 0.4 for

Re > 30000, but tend to align at 0.4 when

Re > 45000.

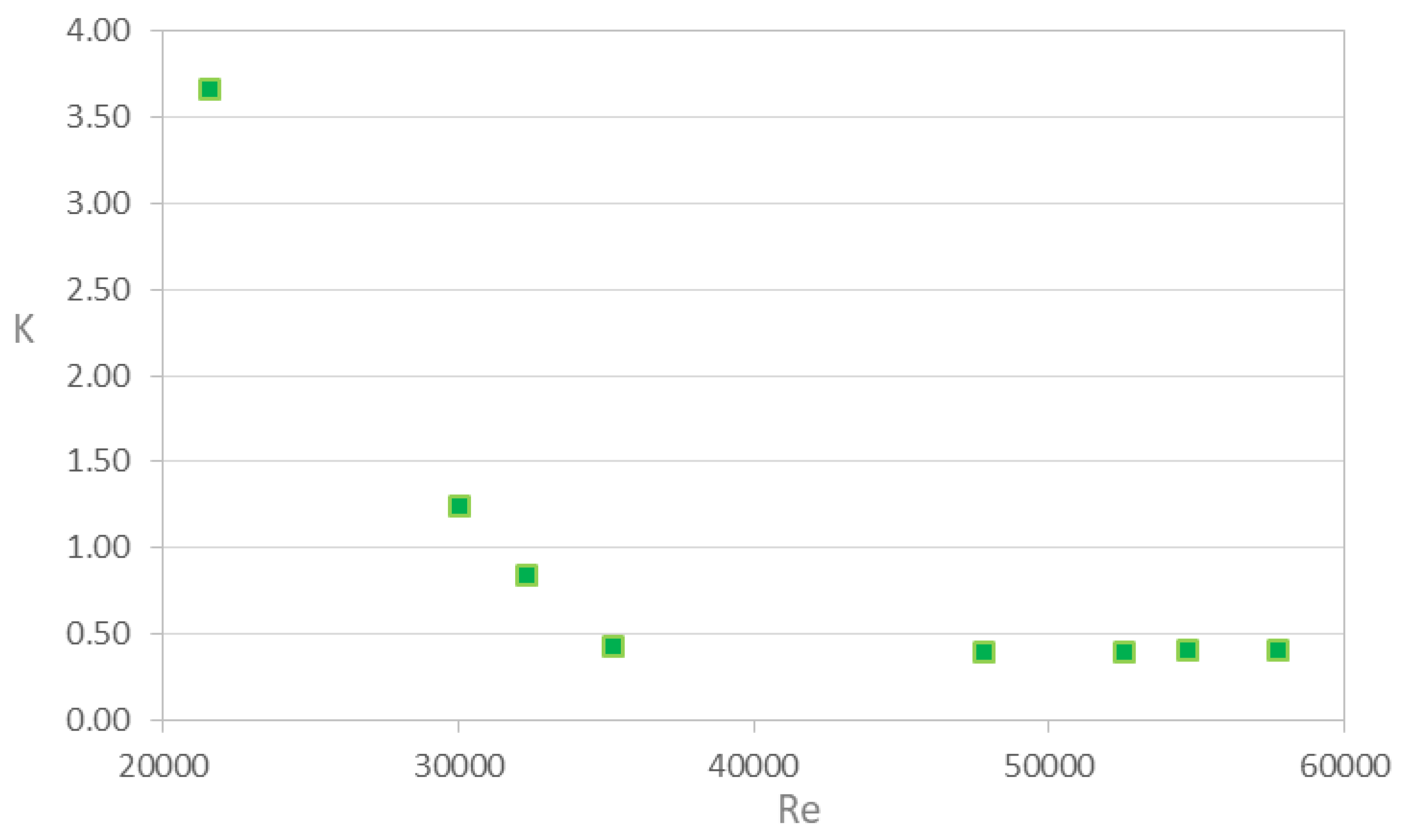

The coefficient

K versus

Re values are illustrated in

Figure 17 for the elbow with

Dc = 3/4 in. It can be seen that the values of

K increase asymptotically when

Re < 35000, with

K reaching a maximum value close to 3.7 for the minimum value of

Re. It is also clear that the coefficient tends to be constant at approximately 0.40, when

Re > 35000.

Finally, Figure 18 shows the comparison of the K values according to Re for the two elbows with 45o deflection. It is observed that both fittings produce values of K with a very similar trend, but the elbow Dc = ½ in generates slightly lower values for a range close to 32000 ≤ Re ≤ 42000. It can be assumed that in general the coefficient K tends asymptotically for Re < 32000, as well as, it can be said that the loss coefficient tends to be constant as at 0.40 when Re > 42000.

3.3. Comparison of the Experimental Coefficient with Literature Data

It should be noted that in the literature there is little information on head losses and the

K coefficient on elbows similar to those studied, where information is reported on small diameters with

r/D ratio ≈ 0.5 and Reynolds number of the flow used. However,

Table 7 presents a comparison of

K values obtained for the five elbows studied, against

K values extracted from the literature for elbows similar to those analyzed.

In the first case of the 90º elbow with

Dc = ½ in, it is shown that the coefficient obtained differs on average -27.6% with respect to that suggested by Mandal [

10]. This may be due to the fact that in this work a material with greater resistance to flow was used (Mild steel), coupled with the fact that the work flows were with low values of

Re. It has been shown that the loss coefficient decreases as

Re increases [

11], as well as that with

Re < 30000 the

K values increase substantially as reported in the works of Ito [

18], Miller [

19] and Crawford [

20].

On the other hand, the values of the loss coefficient for the 90

o elbow with

Dc = ¾ in (case two) present good similarity with the data of Crawford [

20], where a difference of +7.5% was obtained. This slight difference could be generated because this study analyzed aluminum fittings with lower resistance to flow. Furthermore, it may be because in this work a minimum value of

K ≈ 0.65 was obtained, consequently high values of

Re were considered (up to 120,000). At the same time, good similarity was also found with the information from Yogaraja [

6], having a difference of +9.4% on the loss coefficient. These authors do not clearly specify the range of

Re used, only that the flows were with

Re > 2300. However, the general value they provide of

K = 0.85 was produced for

Re ≈ 40000 and

Re ≈ 57000 in the present experimental investigation. Finally, it should be noted that in both works cited in the literature a hydraulic diameter greater than that considered in this study was used (such as 2 and 6 mm, respectively), which may also affect the resulting % difference, since Rahmeyer [

17] specifies that the value of

K decreases with increasing diameter.

In the third case of the 90

o elbow with

Dc = 1½ in, it was found that the

K coefficient differs +22% from what was suggested by Rahmeyer [

17] and +18.9% from what was established by Iwasaki [

21]. These moderate and larger differences in the experimental coefficient can be attributed to the fact that the literature works used high values of the Reynolds number (up to 320,000 and 400,000, respectively), as well as fittings with larger hydraulic diameters (such as 7 and 6 mm, respectively), which could produce lower values of

K.

On the other hand, in the fourth case referring to the 45

o elbow with

Dc = ½ in, a difference of +93.8% was obtained between the experimental coefficient and the general value of

K proposed by Musa [

5]. This large discrepancy may be due to the difference between the hydraulic diameters analyzed, because in the experiment a diameter with +5 mm was used. It could also be caused by the inequality between the used

r/D values, but it cannot be verified because this literature does not specify it. However, if the obtained minimum value of

K = 0.21 is compared against the general value proposed in the literature of

K = 0.16 (both with close

Re), the difference is reduced to +31.3%. In parallel, an opposite difference of -60.5% was found between the experimental coefficient values and the

K values reported by Mandal [

10]. This may be because in this work they used a material with greater resistance to flow (Mild steel), added to the fact that they considered flows with lower values of

Re. Finally, it should be emphasized that the experimental coefficient showed a positive and a negative discrepancy on the

K values suggested in both works of literature, which tend to mediate between them.

In the last case of the 45

o elbow with

Dc = ¾ in, a -26.1% was generated between the values of the experimental coefficient and the general value of

K proposed by Yogaraja [

6]. The non-conformity may be due to the fact that in that literature they considered a larger hydraulic diameter with +13 mm, as well as the possible difference between the

r/D ratios, since they do not specify it. However, it is indicated that the value of

K suggested in the literature (1.11), in the present investigation was found for

Re ≈ 30500.

Finally, it can be observed that in the literature works a length of pipe is considered before (

Lu) and after (

Ld) of the fittings, with a determined magnitude to ensure the development of the flow on both sides of the elbows [17, 20]. In the case of the present study, the lengths

Lu and

Ld of the fittings were shown in

Table 1, where the maximum values for both lengths were 0.19 m. These short distances of

Lu and

Ld usually occur in small systems with very short pipe lengths and the need to place various fittings such as elbows. Therefore, this may also have an impact on the discrepancies mentioned between experimental coefficient data and the

K values reported in the literature.

Table 7.

Comparison of K coefficient results against those reported in literature.

Table 7.

Comparison of K coefficient results against those reported in literature.

Elbow type:

Dc, θ

|

value |

value |

|

|

% Diff 2

|

|

D (mm) |

r/D |

|

|

Autor/Used material |

D (mm) |

r/D |

|

|

Lu

(m) |

Ld

(m) |

| ½ in, 90o

|

18.2 |

0.5 |

32009 ≤

Re ≤ 80221 |

0.56-0.88 |

[10]

Mild steel |

19 |

2.6 |

16393 ≤

Re ≤ 44013 |

0.81-1.18 |

4.5 |

3.0 |

-27.6 |

| ¾ in, 90o

|

23.6 |

0.5 |

32311 ≤

Re ≤ 61866 |

1.11-0.75 |

[20]

Aluminium |

25.4 |

0.65 |

20000 ≤

Re ≤ 120000 |

1.05-0.68 |

3.5 |

2.8 |

+7.5 |

32311 ≤

Re ≤ 61866 |

1.11-0.75 |

[6]

PVC |

29.5 |

ND1

|

Re > 2300 |

0.85 |

1.0 |

1.0 |

+9.4 |

Re ≈40000 and

Re ≈57000 |

0.85 |

0.0 |

| 1 ½ in, 90o

|

43.68 |

0.5 |

19054 ≤

Re ≤ 33426 |

1.69-0.64 |

[17]

PVC |

51 |

0.5 |

19000≤

Re ≤ 320000 |

1.00-0.91 |

6.1 |

6.1 |

+22.0 |

[21]

PVC |

50 |

0.65 |

40000 ≤

Re ≤ 400000 |

0.96-1.00 |

12.0 |

4.0 |

+18.9 |

| ½ in, 45o

|

18.2 |

0.5 |

32009 ≤

Re ≤ 74861 |

0.21-0.41 |

[5]

PVC |

12.7 |

ND1

|

Re = 36000 |

0.16 |

ND1

|

ND1

|

+93.8 |

|

Re =35000 |

0.21 |

+31.3 |

32009 ≤

Re ≤ 74861 |

0.21-0.41 |

[10]

Mild steel |

19 |

5.8 |

27594 ≤

Re ≤ 49406 |

0.66-0.91 |

4.5 |

3.0 |

-60.5 |

| ¾ in, 45o

|

23.6 |

0.5 |

30081 ≤

Re ≤ 57732 |

1.24-0.40 |

[6]

PVC |

36.7 |

ND1

|

Re > 2300 |

1.11 |

1.0 |

1.0 |

-26.1 |

|

Re ≈30500 |

1.11 |

0.0 |

4. Conclusions

In the present investigation, experimental values of head losses and loss coefficient were obtained in schedule 40 PVC pipe elbows, with 90o deflection and commercial diameters of ½, ¾ and 1 ½ in, as well as with 45o deflection and Dc = ½ and ¾ in. The results were presented in tables and graphs illustrating the behavior of hL vs V2⁄2g, K vs Q and K vs Re, which will be useful for the design and review of piping systems with small diameters.

In the case of the 90o elbows with Dc = ½ and ¾, the losses showed proportional dependence on the velocity head, but in the elbow with Dc = 1½ in, the values of hL were proportional when the V2⁄2g > 0.016 m, as well as these were inversely proportional for V2⁄2g < 0.016 m. In the case of 45o elbows, similar behaviors were found to the elbow greater than 90o. In the elbow with Dc = 1/2 in the values of hL were proportional when V2⁄2g > 0.136 m, but these were inversely proportional for V2⁄2g < 0.136 m. Also in the ¾ in elbow, hL were shown to be proportional to V2⁄2g > 0.083 m, but these were shown to be inversely proportional to V2⁄2g < 0.083 m. In both 90o and 45o elbows, head losses increased as the diameter increased, when compared to common velocity head values.

The experimental coefficient in the three 90o elbows showed dependence on the circulation flow, where the values tended to coincide at approximately 0.75 when Q > 0.75 lps, but for flow rates less than 0.75 lps the K coefficient increased inversely proportional to Q, resulting in a higher as the diameter increases. A similar behavior was exhibited by the two 45o elbows, which generated similar K values that tended to 0.40 when Q > 0.75 lps. However, the loss coefficient increases inversely proportionally for flow values less than 0.75, producing higher values in proportion to the diameter. In addition, it should be noted that useful equations are proposed for each of the elbows studied, which allow estimating the value of K based on Q (lps).

The values of the K coefficient in the 90o elbows with Dc = ½ and ¾ in, were shown to remain around 0.80 for Re > 40000, while the K value tended to increase at Re < 40000. However, low values of Re in the 90o elbow with Dc = 1½ in, where the experimental coefficient increases slightly at Re > 28385, but K increases suddenly for Re < 28385. Likewise, the coefficient K of the two 45o elbows reflected a behavior similar to the elbows of 90o with the same diameter, where it tended to remain around 0.40 for Re > 42000, while the value of K tended to increase at Re < 42000.

Finally, it was found that in the literature there is little information available on the K coefficient for small diameters such as those studied. However, the results of the experimental coefficient were compared against K values reported in the literature, where significant similarities and discrepancies were found. The divergences of K values may be caused by differences between the considerations of hydraulic diameters, Re values and elbow materials, but also by the short lengths of pipes, which in this investigation were used before and after each fitting.

Author Contributions

Conceptualization, T.M.AH. and J.J.V.L.; methodology, T.M.AH.; software, F.L.A.I.; validation, J.J.V.L.; formal analysis, T.M.AH. and J.J.V.L; investigation, T.M.AH.; resources, T.M.AH. and F.L.A.I.; data curation, T.M.AH.; writing—original draft preparation, J.J.V.L; writing—review and editing, T.M.AH. and F.L.A.I.; visualization, J.J.V.L.; supervision, T.M.AH.; project administration, T.M.AH. and F.L.A.I.; funding acquisition, T.M.AH. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding

Data Availability Statement

The data presented in this study are available within the article.

Acknowledgments

The authors greatly acknowledge the company Gerfor S.A. Colombia for supporting with accessories and pipes for the construction of the experimental system. Likewise, we appreciate the support provided by the technical team of the Universidad del Sinú - Montería for obtaining the experimental data.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yildirim, G.; Singh, V. A MathCAD procedure for commercial pipeline hydraulic design considering local energy losses. Advances in Engineering Software 2010, 41, 489–496. [Google Scholar] [CrossRef]

- Silverio, N.; Benavidez-Muños, H. Determinación de pérdidas de carga en accesorios "k" de Sistemas Domiciliarios Determination of load in fittings Home Systems "k". Ecuadorian Science Journal 2020, 4, 7–11. [Google Scholar] [CrossRef]

- Al-Tameemi, W. T. M.; Ricco, P. Pressure-Loss Coefficient of 90 deg Sharp-Angled Miter Elbows. Journal of Fluids Engineering 2018, 140, 1–7. [Google Scholar] [CrossRef]

- Sesma, J.; Molina-Martínez, J. M.; Cavas-Martínez, F.; Fernández-Pacheco, D. A mobile application to calculate optimum drip irrigation laterals. Agricultural Water Management 2014, 151, 13–18. [Google Scholar] [CrossRef]

- Musa, N. A.; Oriaifo, M. A.; Isamotu, O. F. Experimental Determination of Flow in Unconventional Elbows: Evaluation of Losses. Journal of Engineering Science and Applications 2020, 13, 1-6. https://www.researchgate.net/publication/343827949_Experimental_Determination_of_Flow_in_Unconventional_Elbows_Evaluation_of_Losses.

- Yogaraja, L.; Liyanagamage, N.; De Silva, K. Comparison of Experimental Results with Empirical Relationships for Energy Losses in Pipe Flow. 2021 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 2021, 522-527. [CrossRef]

- Liu, Sh.; Xue, J.; Fan, M. The calculation of mechanical energy loss for incompressible steady pipe flow of homogeneous fluid. Journal of Hydrodynamics 2013, 25, 912–918. [Google Scholar] [CrossRef]

- Santos-Ruiz, I.; López-Estrada, F. R.; Puig, V.; Valencia-Palomo, G. Simultaneous Optimal Estimation of Roughness and Minor Loss Coefficients in a Pipeline. Mathematical and Computational Applications 2020, 25, 1–12. [Google Scholar] [CrossRef]

- Russi, R. D. Experimental determination of the minor loss coefficient and the hydraulic behavior of different check valves used in internal drinking water distribution systems. Undergraduate thesis in Spanish, Universidad Javeriana, 2015. UJ institutional repository. https://repository.javeriana.edu.co/handle/10554/21384.

- Mandal, S. N.; Das S. K. Pressure Losses in Bends during Two-Phase Gas-Newtonian Liquid Flow. Industrial & Engineering Chemistry Research 2001, 40, 2340-2351. [CrossRef]

- Csizmadia, P.; Hős, H. CFD-based estimation and experiments on the loss coefficient for Bingham and power-law fluids through diffusers and elbows. Computers & Fluids 2014, 99, 116-123. [CrossRef]

- Arteaga-Hernández, T. M.; Feria-Díaz, J. J.; Amed-Salazar, E. J. Experimental Local Loss Coefficients (Km) Of Some Common Fittings Used In Residential Hydraulic Networks. Journal of Positive Psychology & Wellbeing 2023, 7, 464-475. https://mail.journalppw.com/index.php/jppw/article/view/15504.

- Selim Korkmaz, Y.; Kibar, A.; Suleyman Yigit, K. Experimental and Numerical Investigation of Flow in Hydraulic Elbows. Journal of Applied Fluid Mechanics 2021, 14, 1137-1146. [CrossRef]

- Mańko, R.; Laskowski, N. Values of the head loss coefficients of elbows in the press system. Instalar 2022, 12, 22-25. [CrossRef]

- Meng, X.; Qin, Ch.; Li, J. Pressure distribution and similarity theory of an elbow fowmeter based on experiments and CFD simulations. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2022, 45, 1–10. [Google Scholar] [CrossRef]

- Chang, H.; Ji, G.; Yu, D.; Peng, G.; Hong, S.; Du, J. Research on wear characteristics of U-shaped elbows based on CFD-DEM coupling. Frontiers in Energy Research 2023, 11, 1–23. [Google Scholar] [CrossRef]

- Rahmeyer, W. J. Pressure loss data for PVC pipe elbows, reducers, and expansions. ASHRAE Transactions 2003, 109, 230–251. [Google Scholar]

- Ito, H. Pressure losses in smooth pipe bends. Journal of Basic Engineering ASME 1960, 82, 131–140. [Google Scholar] [CrossRef]

- Miller, D. S. Internal flow: a guide to losses in pipe and duct systems. BHRA 1971. https://www.mdl2179trialdocs.com/releases/release201311071200013/TREX-130713.PDF.

- Crawford, N. M.; Cunningham, G.; Spence, S. W. T. An experimental investigation into the pressure drop for turbulent flow in 90◦ elbow bends. Journal of Process Mechanical Engineering 2007, 221, 77-88. [CrossRef]

- Iwasaki, T.; Ojima, J. Pressure loss in elbow pipes of unplasticized polyvinyl chloride. Industrial Health 1996, 34, 389-401. [CrossRef]

Figure 1.

a) Elbow with deflection θ = 90o, b) Elbow with deflection θ = 45o.

Figure 1.

a) Elbow with deflection θ = 90o, b) Elbow with deflection θ = 45o.

Figure 2.

a) Piping system used in the laboratory. b) Representative schematic of the real system.

Figure 2.

a) Piping system used in the laboratory. b) Representative schematic of the real system.

Figure 3.

Head loss against velocity head at the 90o elbow with Dc = ½ in.

Figure 3.

Head loss against velocity head at the 90o elbow with Dc = ½ in.

Figure 4.

Head loss as a function of velocity head in the 90o elbow with Dc = ¾ in.

Figure 4.

Head loss as a function of velocity head in the 90o elbow with Dc = ¾ in.

Figure 5.

Head loss versus velocity head at the 90o elbow with Dc = 1½ in.

Figure 5.

Head loss versus velocity head at the 90o elbow with Dc = 1½ in.

Figure 6.

Comparison of head losses versus velocity head in 90o elbows with Dc = ½, ¾ and 1½ in.

Figure 6.

Comparison of head losses versus velocity head in 90o elbows with Dc = ½, ¾ and 1½ in.

Figure 7.

Comparison of the loss coefficient versus flow in 90o elbows with Dc = ½, ¾ and 1½ in.

Figure 7.

Comparison of the loss coefficient versus flow in 90o elbows with Dc = ½, ¾ and 1½ in.

Figure 8.

Loss coefficient versus Reynolds number in 90o elbow with Dc = ½ in.

Figure 8.

Loss coefficient versus Reynolds number in 90o elbow with Dc = ½ in.

Figure 9.

Loss coefficient versus Reynolds number in 90o elbow with Dc = ¾ in.

Figure 9.

Loss coefficient versus Reynolds number in 90o elbow with Dc = ¾ in.

Figure 10.

Loss coefficient versus Reynolds number in 90o elbow with Dc = 1½ in.

Figure 10.

Loss coefficient versus Reynolds number in 90o elbow with Dc = 1½ in.

Figure 11.

Comparison of the loss coefficient versus Reynolds number in 90o elbows with Dc = ½, ¾ and 1½ in.

Figure 11.

Comparison of the loss coefficient versus Reynolds number in 90o elbows with Dc = ½, ¾ and 1½ in.

Figure 12.

Head loss versus velocity head at 45o elbow with Dc = ½ in.

Figure 12.

Head loss versus velocity head at 45o elbow with Dc = ½ in.

Figure 13.

Head loss versus velocity head at 45o elbow with Dc = ¾ in.

Figure 13.

Head loss versus velocity head at 45o elbow with Dc = ¾ in.

Figure 14.

Comparison of head losses versus velocity head in 45o elbows with Dc = ½ and ¾ in.

Figure 14.

Comparison of head losses versus velocity head in 45o elbows with Dc = ½ and ¾ in.

Figure 15.

Comparison of the loss coefficient versus flow in 90o elbows with Dc = ½ and ¾ in.

Figure 15.

Comparison of the loss coefficient versus flow in 90o elbows with Dc = ½ and ¾ in.

Figure 16.

Loss coefficient versus Reynolds number in 45o elbow with Dc = ½ in.

Figure 16.

Loss coefficient versus Reynolds number in 45o elbow with Dc = ½ in.

Figure 17.

Loss coefficient versus Reynolds number in 45o elbow with Dc = ¾ in.

Figure 17.

Loss coefficient versus Reynolds number in 45o elbow with Dc = ¾ in.

Table 1.

Elbows studied and geometric parameters of influence.

Table 1.

Elbows studied and geometric parameters of influence.

| Fitting and deflection |

Commercial diameter (Dc, in) |

Hydraulic diameter (D, mm) |

r/D |

Lu (m) |

Ld (m) |

| 90o elbow |

1/2 |

18.20 |

0.5 |

0.11 |

0.10 |

| 90o elbow |

3/4 |

23.60 |

0.5 |

0.12 |

0.10 |

| 90o elbow |

1-1/2 |

43.68 |

0.5 |

0.19 |

0.19 |

| 45o elbow |

1/2 |

18.20 |

0.5 |

0.10 |

0.08 |

| 45o elbow |

3/4 |

23.60 |

0.5 |

0.10 |

0.09 |

Table 2.

Results obtained for the 90o elbow with Dc = ½ in (D = 18.20 mm).

Table 2.

Results obtained for the 90o elbow with Dc = ½ in (D = 18.20 mm).

|

Q (lps) |

hL (m) |

V (m/s) |

K |

Re |

| 0.391 |

0.091 |

1.50 |

0.79 |

32009 |

| 0.477 |

0.096 |

1.83 |

0.56 |

39006 |

| 0.757 |

0.363 |

2.91 |

0.84 |

61946 |

| 0.833 |

0.425 |

3.20 |

0.81 |

68124 |

| 0.867 |

0.461 |

3.33 |

0.81 |

70961 |

| 0.915 |

0.557 |

3.52 |

0.88 |

74861 |

| 0.980 |

0.585 |

3.77 |

0.81 |

80221 |

Table 3.

Results found for the 90o elbow with Dc = ¾ in (D = 23.60 mm).

Table 3.

Results found for the 90o elbow with Dc = ¾ in (D = 23.60 mm).

|

Q (lps) |

hL (m) |

V (m/s) |

K |

Re |

| 0.477 |

0.067 |

1.09 |

1.11 |

30081 |

| 0.512 |

0.062 |

1.17 |

0.89 |

32311 |

| 0.757 |

0.125 |

1.73 |

0.82 |

47772 |

| 0.833 |

0.139 |

1.90 |

0.75 |

52536 |

| 0.867 |

0.151 |

1.98 |

0.75 |

54724 |

| 0.915 |

0.193 |

2.09 |

0.87 |

57732 |

| 0.980 |

0.193 |

2.24 |

0.75 |

61866 |

Table 4.

Results obtained for the 90o elbow with Dc = 1½ in (D = 43.68 mm).

Table 4.

Results obtained for the 90o elbow with Dc = 1½ in (D = 43.68 mm).

|

Q (lps) |

hL (m) |

V (m/s) |

K |

Re |

| 0.391 |

0.014 |

0.26 |

4.13 |

13337 |

| 0.559 |

0.012 |

0.37 |

1.69 |

19054 |

| 0.757 |

0.010 |

0.51 |

0.79 |

25811 |

| 0.833 |

0.010 |

0.56 |

0.64 |

28385 |

| 0.867 |

0.012 |

0.58 |

0.67 |

29567 |

| 0.915 |

0.014 |

0.61 |

0.72 |

31192 |

| 0.980 |

0.018 |

0.65 |

0.81 |

33426 |

Table 5.

Results found for the 90o elbow with Dc = ¾ in (D = 23.60 mm).

Table 5.

Results found for the 90o elbow with Dc = ¾ in (D = 23.60 mm).

|

Q (lps) |

hL (m) |

V (m/s) |

K |

Re |

| 0.342 |

0.174 |

1.31 |

1.97 |

27986 |

| 0.391 |

0.041 |

1.50 |

0.35 |

32009 |

| 0.425 |

0.028 |

1.63 |

0.21 |

34778 |

| 0.477 |

0.044 |

1.83 |

0.26 |

39006 |

| 0.512 |

0.064 |

1.97 |

0.32 |

41897 |

| 0.757 |

0.173 |

2.91 |

0.40 |

61946 |

| 0.833 |

0.211 |

3.20 |

0.40 |

68124 |

| 0.867 |

0.234 |

3.33 |

0.41 |

70961 |

| 0.915 |

0.261 |

3.52 |

0.41 |

74861 |

Table 6.

Results obtained for the 45o elbow with Dc = ¾ in (D = 23.60 mm).

Table 6.

Results obtained for the 45o elbow with Dc = ¾ in (D = 23.60 mm).

|

Q (lps) |

hL (m) |

V (m/s) |

K |

Re |

| 0.342 |

0.114 |

0.78 |

3.66 |

21582 |

| 0.477 |

0.075 |

1.09 |

1.24 |

30081 |

| 0.512 |

0.058 |

1.17 |

0.84 |

32311 |

| 0.559 |

0.035 |

1.28 |

0.42 |

35266 |

| 0.757 |

0.060 |

1.73 |

0.40 |

47772 |

| 0.833 |

0.073 |

1.90 |

0.40 |

52536 |

| 0.867 |

0.081 |

1.98 |

0.40 |

54724 |

| 0.915 |

0.091 |

2.09 |

0.41 |

57732 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).