1. Introduction

Acacia dealbata Link, commonly known as Mimosa in Portugal, is a hardwood species native to Australia. It is highly invasive due to its rapid growth rate and prolific seed production [

1], significantly increasing fuel loads in colonized native forests [

2,

3]. According to the national forest inventory [

4], the area covered by species of the

Acacia genus, unlike other forest species such as

Pinus pinaster Link, increased by 3.7 ha between 1995 and 2005 and now occupies 8.4 thousand ha in continental Portugal. One control method is through harvesting, resulting in a potential residual reserve of mimosa.

Efforts to extract value from this species and offset operational costs have led researchers to explore various applications, such as fuel production [

5], paper pulp [

6], and textile dyeing [

7]. On the other hand, the use of Mimosa in construction faces challenges due to its wild growth characteristics, including the predominance of young trees (10-20 years old) with irregular shapes and small transverse sections, which consequently yield low timber volume and limit its suitability for manufacturing boards and engineered wood products.

One promising avenue for integrating Mimosa into construction involves utilizing small-diameter juvenile wood (

sjw hereafter) logs, a by-product of forest management supported by existing research [

8,

9,

10]. Environmental, economic, and technical considerations advocate for the utilization of

sjw due to its potential to diversify wood usage, prolong its lifespan beyond a mere primary by-product, and decrease energy consumption during processing, drying and transportation, as observed by Ramage et al. [

11], rationalizing the supply chain and enhances environmental sustainability. Furthermore, Green et al. [

12] and Larson et al. [

13] have demonstrated that a low level of processing for

sjw can be advantageous because it does not reduce the exterior resistant material (mature outer wood) and does not weaken the area surrounding the knots.

However, post-felling Mimosa

log often develops local cracks due to environmental interactions, which compromise durability, promote water accumulation, facilitate biological colonization, and increase susceptibility to fire by expanding the exposed perimeter. Studies suggest that the formation of cracks impacts the mechanical performance of beams [

14] or connectors [

15]. Furthermore, a high percentage of juvenile wood increases vulnerability to brittle failure and longitudinal shrinkage [

16]. Evans [

17] defines cracks resulting from drying stresses as "checks" or "splits," depending on their appearance on one or both sides of the wood piece respectively. Other definitions, such as "collapse" or "honeycomb," are associated with failures within the drying process [

18]. Despite extensive research on cracking phenomena using small samples under controlled conditions [

19,

20], scale effects such as moisture content gradient (MCG) influence cracking in massive pieces like logs, primarily in the tangential plane [

21].

Internal stresses from the drying process, alongside incidental stress tree growth [

22] and internal factors like anisotropy or anatomical characteristics, contribute to cracking formation, further influencing susceptibility to cracking [

19]. Control of environmental drying conditions, facilitated by appropriate kiln-drying protocols or pretreatments, can significantly reduce drying defects [

23,

24].

Due to the availability and yielding limitations of

sjw Mimosa logs, a practical alternative is air-drying, which can be carried out in areas near the harvest. This reduces energy consumption in transportation and sawing [

25], further improving the material’s environmental impact. Evans et al. [

26] determined that the type of drying (air or kiln) does not significantly affect the formation of cracks in radiata and slash pine logs 125/150 mm in diameter and 700 mm in length. However, greater crack depths in air-dried logs were observed. The duration of air drying depends on the species, size (diameter and length), local environmental conditions of temperature and relative humidity during storage, and the time of year when stacking begins. In California, Simpson et al. [

27] used air-dried Ponderosa pine and Douglas-fir logs with diameters ranging from 102 to 203 mm and lengths of 2.4 m, achieved moisture content values close to 20% in twenty days when starting in summer (July) and in one hundred forty days when starting in autumn (October). This also conditions the use of logs in construction, as achieving conventional moisture content values for use (around 12%, for example) requires longer drying times or the assistance of artificial drying to reach service values.

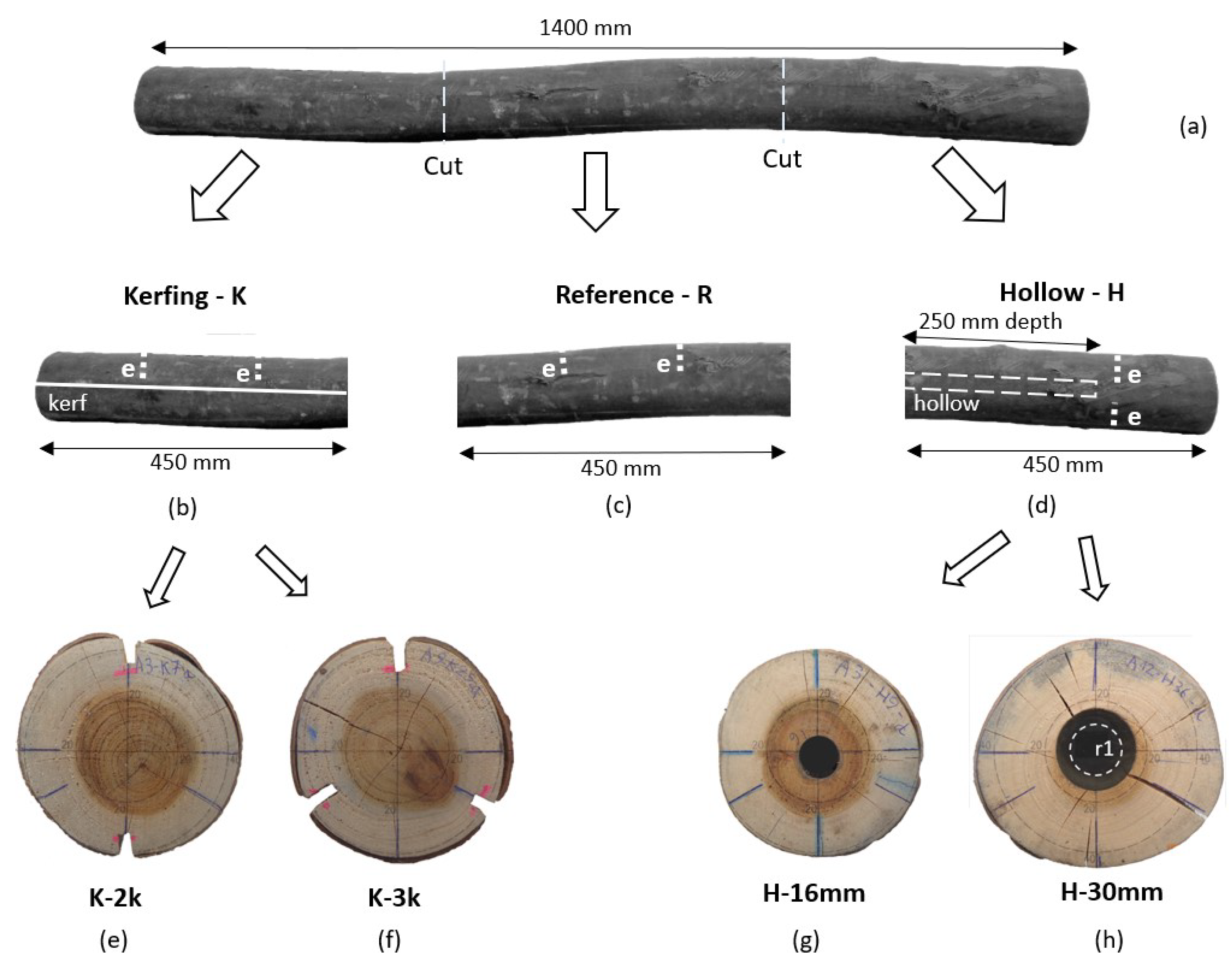

Some researchers have conducted comparative studies on various "destructive" treatments to reduce or control cracking in logs [

26]. One approach involves "kerfing" on the outer surface to release drying stresses. This method includes options such as creating one or more cuts along or kerfing to a certain depth depending on the log diameter [

28,

29] or making numerous small incisions distributed regularly over the surface [

17,

28]. Another strategy entails drilling a central hollow along the entire length of the log [

30,

31], which reduces the thickness and humidity gradient while increasing the exposed surface area. However, Lim et al. [

32] found that the complete removal of material may compromise load capacity, potentially leading to failure under punctual load conditions.

Despite limited studies,

Acacia gender wood exhibits noteworthy physical-mechanical properties, underscoring its potential for diversifying the timber supply chain amidst increasing demand. In Portugal, Martins [

33] obtains mean values of density 647 kg/

, 13,900 MPa of MOE, and a bending strength of 65 MPa for

Acacia melanoxylon (Blackwood), demonstrating its applicability for Glulam. In Chile, a technical report from the Forestry Institute [

34] reports mean density values of 495 kg/

, 11,515 MPa of MOE, and 65.7 MPa of flexural strength for

Acacia dealbata, which are higher than those of the reference species for use in construction (

Pinus radiata Link). Also, using conventional kiln-drying on 25 and 50-mm boards of Acacia melanoxylon and Acacia dealbata, Ananias et al. [

35] achieved satisfactory results with wood free of cracks or “collapse”. These results present an opportunity to explore the suitability of Mimosa logs in truss structures, which utilize smaller, shorter (therefore, lighter) axially loaded components. However, controlling or reducing drying cracks is necessary, especially at the ends where connections are inserted.

This study aims to control and/or reduce cracks at the ends of wild sjw Mimosa logs by combining air drying with two treatments: longitudinal kerfing and central hollowing. It is part of a larger study to evaluate applicability in construction using low-processed air-dried logs.

4. Discussion

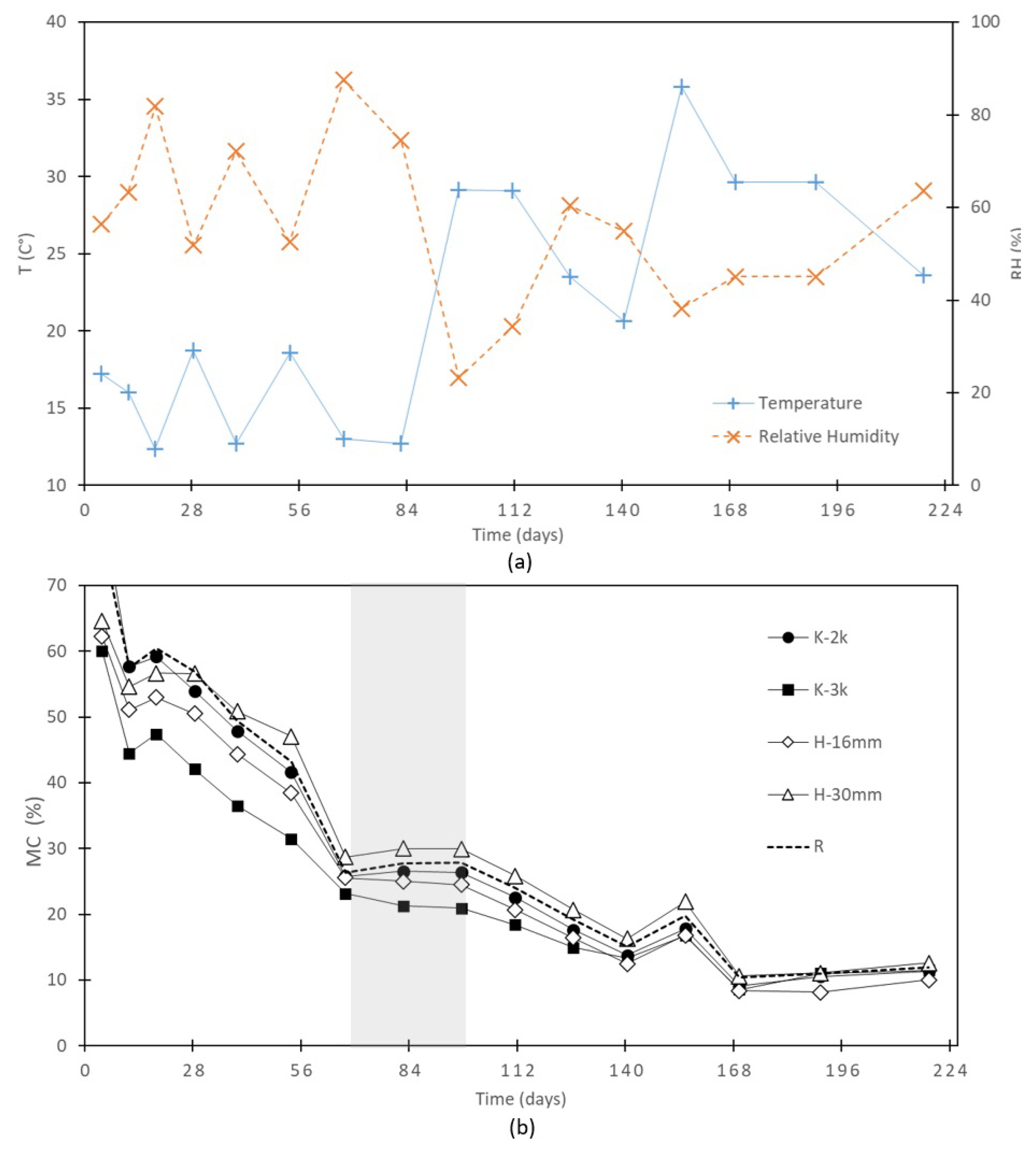

In air-drying logs, moisture content varies according to environmental conditions [

27]. Due to the element’s size and the logs’ anatomical characteristics, an internal moisture gradient forms, creating an uneven distribution of internal stresses. Exacerbated by anisotropic shrinkage, these stresses affect the weaker different tangential planes, leading to tangential cracking [

21].

In this study, the moisture content removal rate pattern matches the descriptions in the literature: above the fibre saturation point (FSP), free water is rapidly eliminated until the moisture content (MC) approaches 30%, after which the bound water in the tissue is removed at a slower rate ([

27,

43].

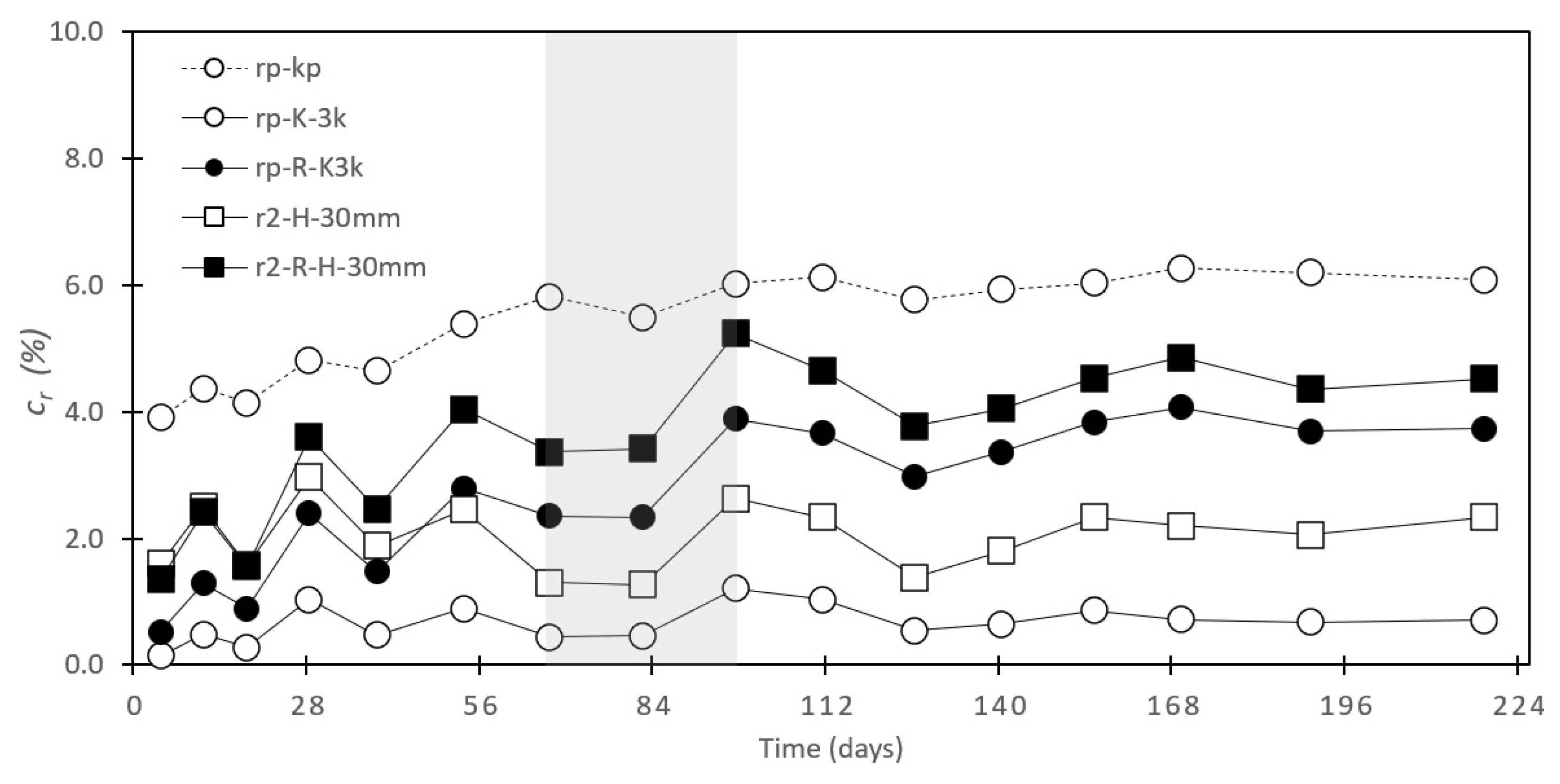

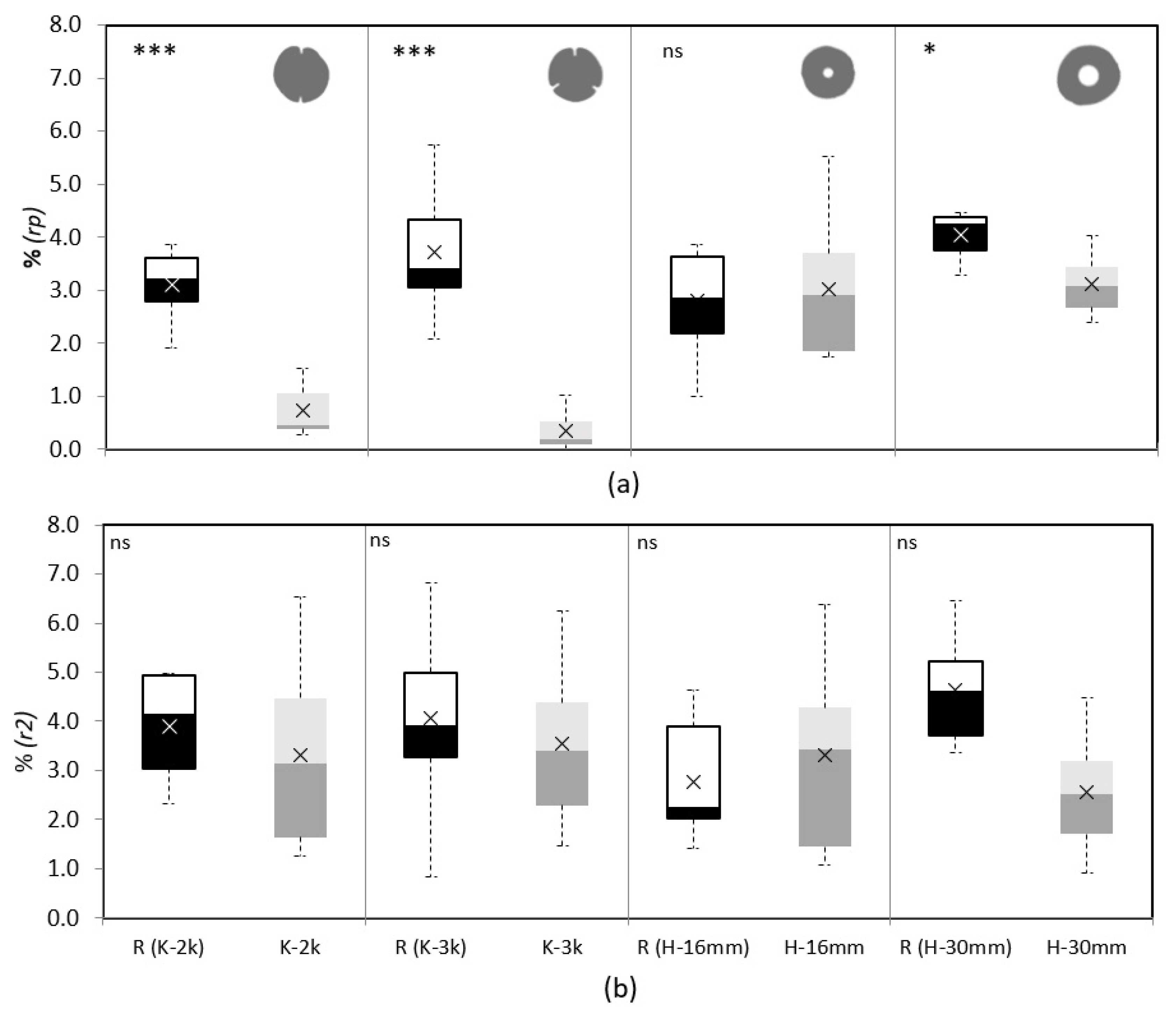

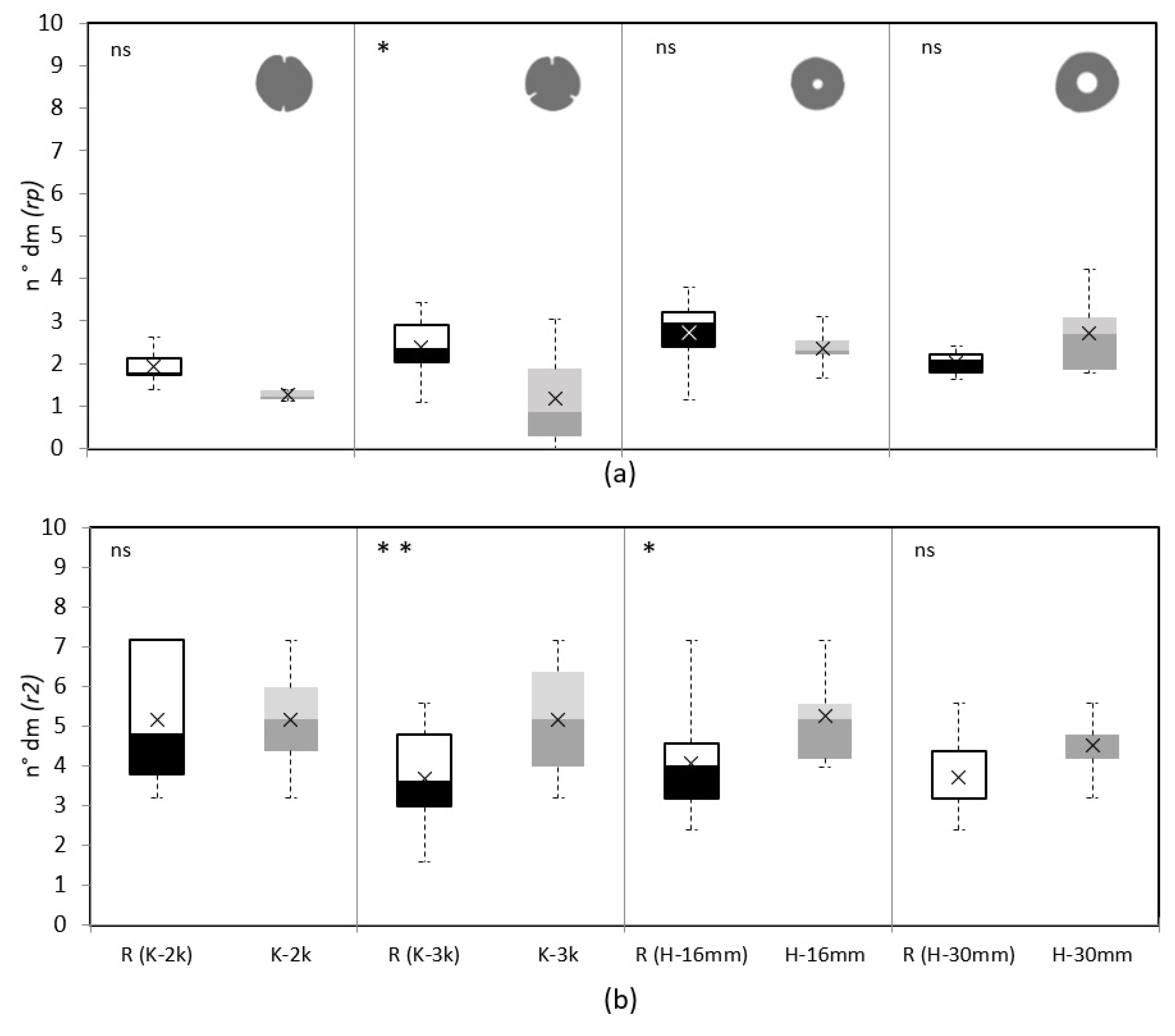

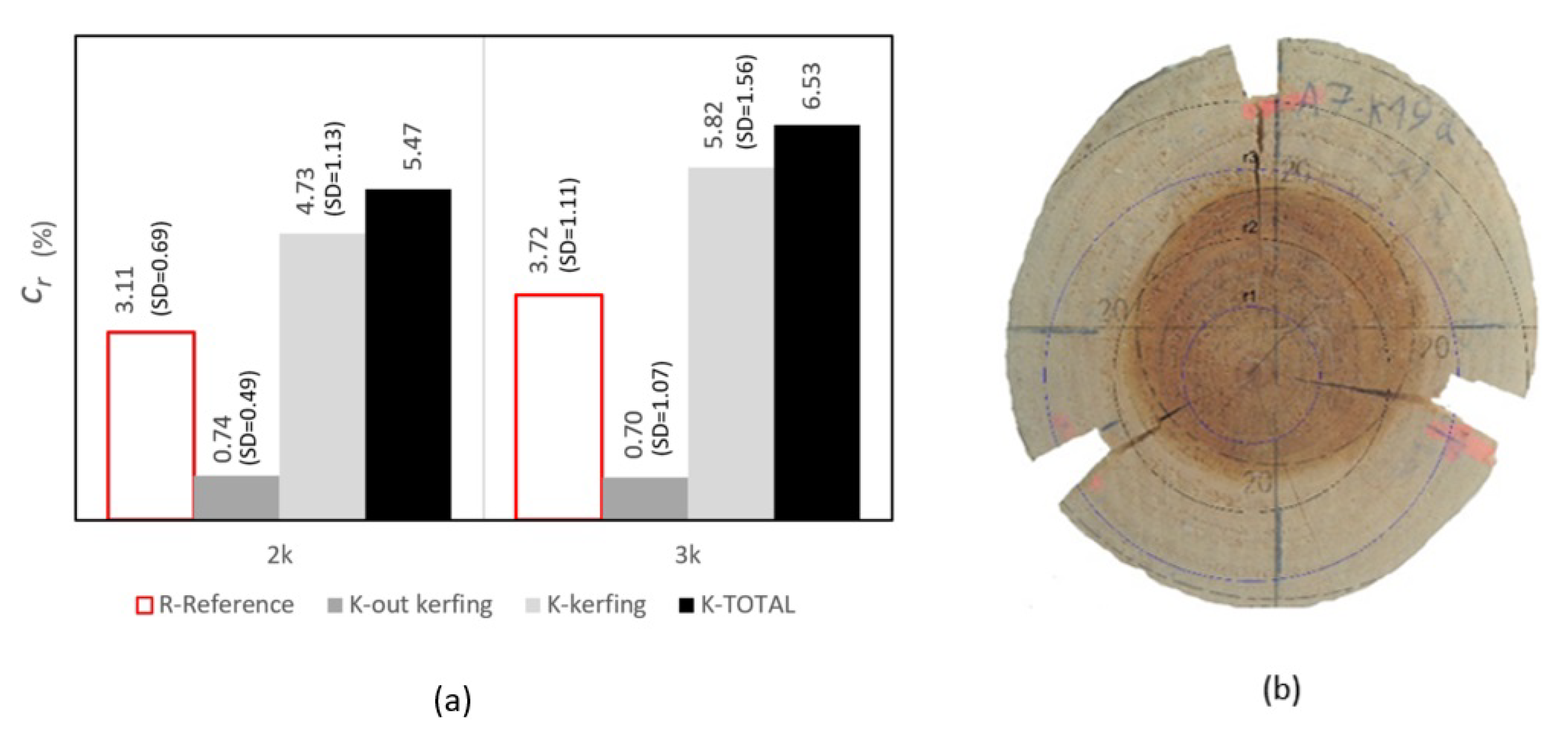

The cracking formation profile overlaid on the described pattern demonstrates that cracks form directly related to environmental conditions. By observing the reduction curves, we can confirm that the treatments partially mitigate crack formation, thereby reducing the impact of environmental factors. The treatments contributed to reducing cracking, although their effectiveness varied depending on the specific treatment and the location observed. Regarding total cracks, both kerfing treatments were significantly effective in the outer rings (

Figure 12). In contrast, the larger perforation (H-30mm) treatment was moderately effective in the inner rings adjacent to the perforation (

Figure 12). About the number of cracks, no differences were observed compared to the references, except for the K-3k, which reduced the number at the external level of the log but simultaneously significantly increased the number of cracks in an inner ring, which can be associated with the "promoter" effect of the kerfs: the number of naturally occurring cracks is augmented by those artificially triggered by the kerfs, leading to an overall increase in the total number of cracks.

When examining the performance over time, before reaching the FSP, the K-3k variant shows greater water loss than the reference, achieving MC values near 30% approximately 15 days earlier than the other samples. In line with Lee et al. [

44], this suggests that incisions or cuts affect the moisture distribution within the log, influencing the formation of the moisture gradient. The three kerfs reduce the distance between the core and the outer wood, diminishing the moisture differential, facilitating water transport, and increasing the moisture exchange area along the entire piece. This results in greater effectiveness on the log’s exterior, as

Figure 12 shows for the perimetral ring,

rp.

The results also indicate that, throughout the air-drying process, the kerfs itself not only absorb the tangential dimensional variations of the untreated areas but also actively capture more cracks: at the beginning of the process, an "instant" crack is activated adjacent to the notches, which affects almost 4% of the perimeter (

Figure 12). Then, this percentage increases slowly but gradually and continues until it stabilizes after passing through the transition zone between above and below the FSP.

Figure 12.

Relative cracking of K-3k over and H-30mm over . rp-kp: Over the perimeter of the treated piece, this includes the sum of the cracking in the untreated zone (between kerfs) plus the three notches (subtracting the thickness of the cutting discs); rp-K-3k: Over the perimeter , this includes only the contribution of cracking in the untreated zone (between the notches); rp-R-K-3k: The cracking over the perimeter of the respective untreated reference pieces; r2-H-30mm: On ring 2, , the cracking of the treated piece; r2-R-H-30mm: On ring 2, , the cracking of the untreated reference piece.

Figure 12.

Relative cracking of K-3k over and H-30mm over . rp-kp: Over the perimeter of the treated piece, this includes the sum of the cracking in the untreated zone (between kerfs) plus the three notches (subtracting the thickness of the cutting discs); rp-K-3k: Over the perimeter , this includes only the contribution of cracking in the untreated zone (between the notches); rp-R-K-3k: The cracking over the perimeter of the respective untreated reference pieces; r2-H-30mm: On ring 2, , the cracking of the treated piece; r2-R-H-30mm: On ring 2, , the cracking of the untreated reference piece.

Evans et al. [

26] studied differences in the number and depth of kerfs and observed that two kerfs instead of one and deeper (20% of the diameter each) reduce the mean depth, width, and length of checks. In this study, due to variations in the logs’ shape and diameter, the kerf depth was 15 mm, ranging from 10% to 20% of the diameter per kerf. However, although the total perimeter cracks were significantly reduced, the K-2k variant did not show a difference in water loss compared to the reference. This suggests that the number of kerfs might be a variable to consider for MC reduction in future research.

The MC curve for the H-30mm variant remained mostly above the reference, indicating it was less effective in transporting and eliminating free and bound water. This may be due to a lack of air circulation within the central hollow, potentially accumulating water vapour. This contrasts with studies such as Park et al. [

31], which showed that a complete hollowing treatment and sealing of the ends reduce the moisture gradient and, consequently, the surface tensions that trigger cracking.

However, a significant reduction in total cracking in the ring adjacent to the perforation was observed for H-30mm (

Figure 12). One reason is the reduction in heartwood due to the larger perforation diameter. In all studied logs, heartwood accounted for 31.05% (SD=8.63) of the total area in the reference pieces. According to Moore et al. [

16] and others, heartwood has distinct characteristics from sapwood that influence its performance. It contains a high content of juvenile wood with lower density, modulus of elasticity, and rupture compared to mature outer wood, consistent with the larger size and number of relative cracks around ring 1,

, near the pith.

Both treatments shorten the moisture gradient distance and, therefore, its steepness, locally reducing the stresses that trigger cracking. In untreated pieces, these stresses are abruptly released at the ends as checking and splitting. As described, these effects emerge, develop, and consolidate during drying, compromising the piece’s integrity. However, from a drying perspective, these cracks serve as moisture exchange interfaces, accelerating the drying process ([

25]) and hypothetically "capturing" the tangential shrinkage/swelling variation at the log end.

In kiln drying, environmental variables (temperature and relative humidity) are controlled to prevent tangential stresses from exceeding the threshold that causes wood tissue failure [

43]. In air drying, while some general aspects (using well-ventilated enclosures or protecting from rain and direct sunlight) can be controlled, this is not feasible to the same extent. Another strategy to evaluate is manipulating the drying effect, i.e., cracking. As observed with the kerfing treatment, the kerfs guided crack formation in more than two-thirds of the specimens, creating quadrants. In some cases, no visible cracks formed within these quadrants, while in others, cracks did appear—some minor and others severe, like checking.

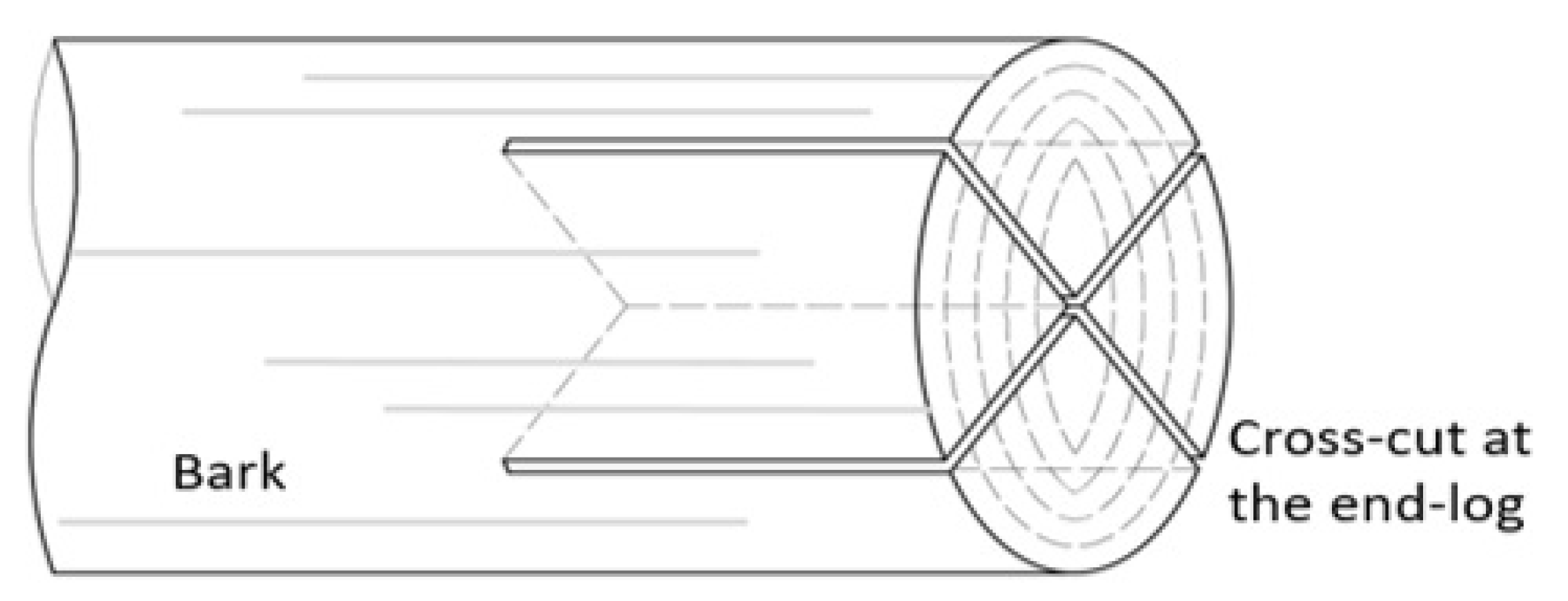

A proposed solution, hypothetically capturing tangential stresses in the kerfs, involves an artificial cross-splitting as

Figure 13 exposes. These cross-knifings extend throughout the extreme section to a defined depth, combining the advantages of both treatments studied. The two diameters would capture naturally formed checks or splits, and the exposed area by the cut depth would accelerate log drying.

The four formed quadrants might house a connection. Dias et al. [

45] demonstrated that using four glued bars arranged around the perimeter of round timber logs subjected to tension can achieve high structural performance. Fastener connections can also be evaluated, provided critical distances to loaded edges are measured from the end of the executed kerf. Additionally, the early work of Huybers [

46]suggests a practical approach for controlling log end expansion using a wire lacing tool.

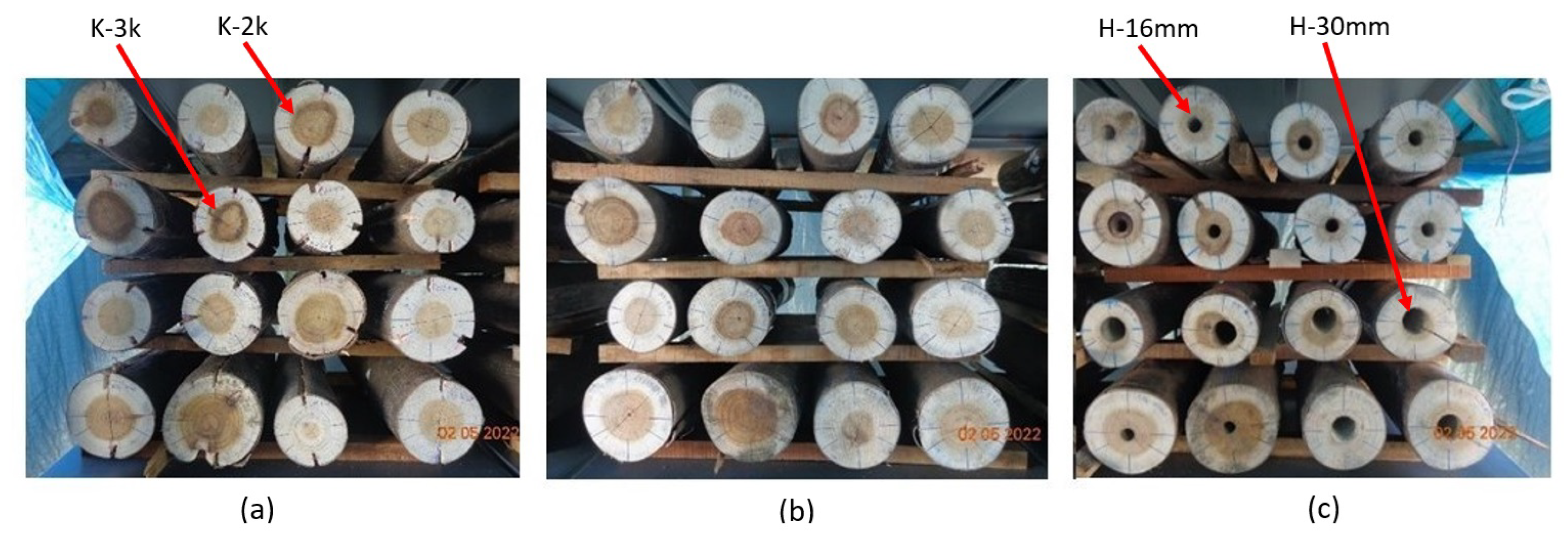

Figure 2.

Samples Arrangement for the Air-Drying Process: (a) Kerfing treatment samples, (b) Reference samples and (c) Hollowing treatment samples.

Figure 2.

Samples Arrangement for the Air-Drying Process: (a) Kerfing treatment samples, (b) Reference samples and (c) Hollowing treatment samples.

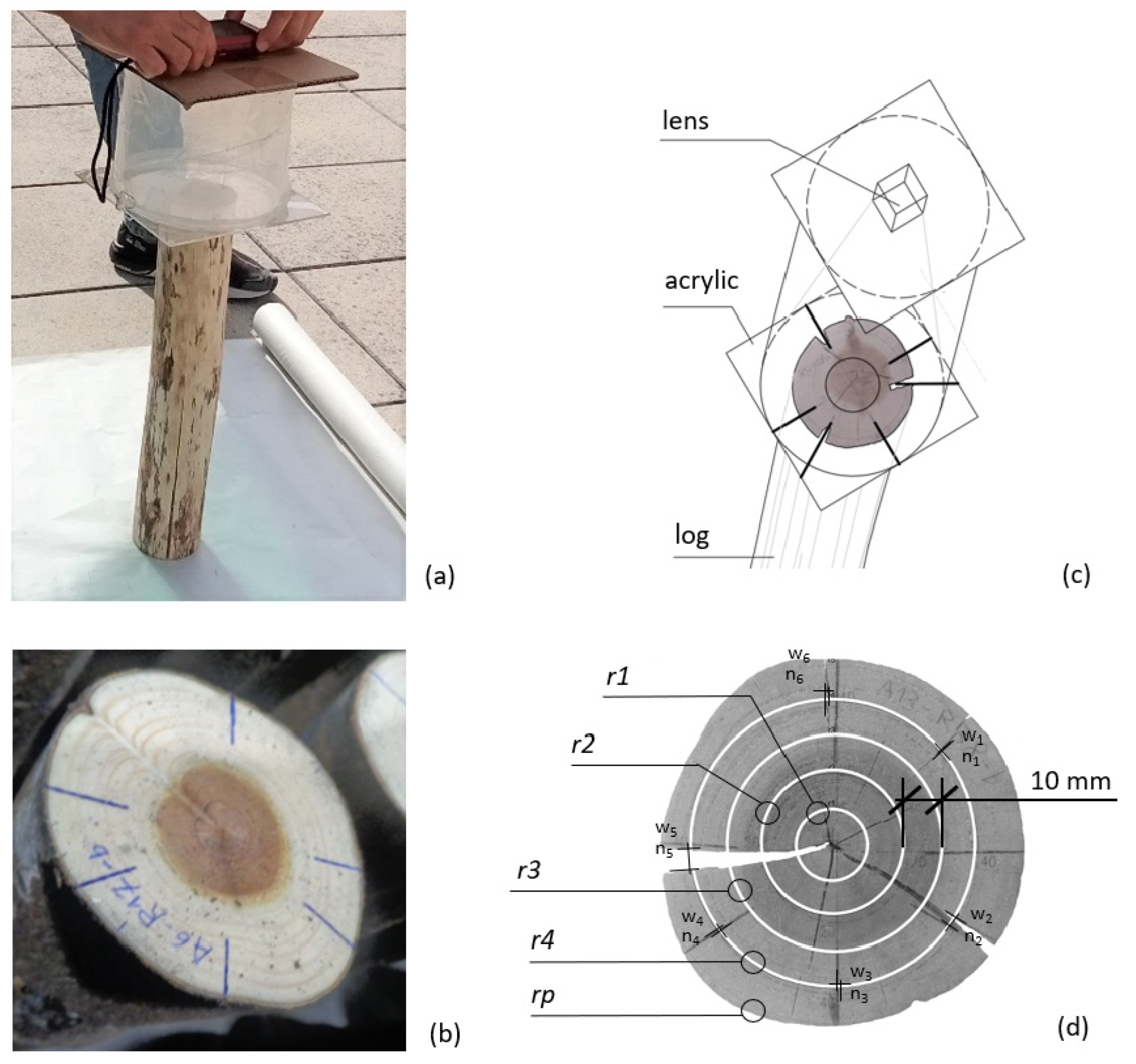

Figure 3.

Measurement of Cracking on Log End-Faces: (a) Device used to maintain a distance of 200 mm, (b) Reference axes drawn over each log end-face, (c) Overlaid acrylic for orientation and scale purposes and (d) Description of the circular concentric rings overlaid on a log end-face

Figure 3.

Measurement of Cracking on Log End-Faces: (a) Device used to maintain a distance of 200 mm, (b) Reference axes drawn over each log end-face, (c) Overlaid acrylic for orientation and scale purposes and (d) Description of the circular concentric rings overlaid on a log end-face

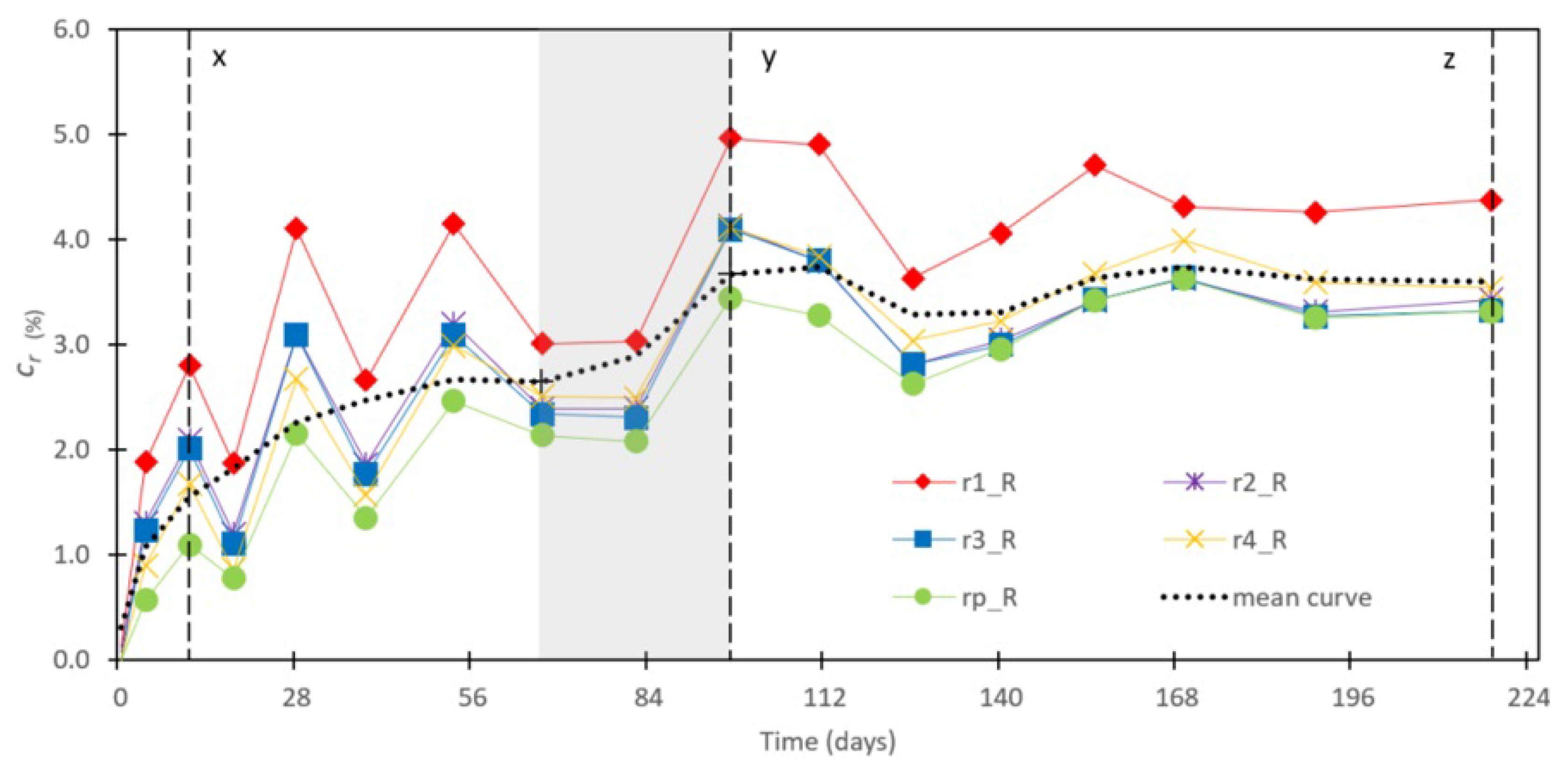

Figure 5.

Relative cracking (cr) evolution per each ring only over the 30 end faces of the Reference samples (R). The grey rectangular area indicates the pass from close to 30% MC until below this value. x: Early end-faces cracking; y: max cracking; z: final measurement.

Figure 5.

Relative cracking (cr) evolution per each ring only over the 30 end faces of the Reference samples (R). The grey rectangular area indicates the pass from close to 30% MC until below this value. x: Early end-faces cracking; y: max cracking; z: final measurement.

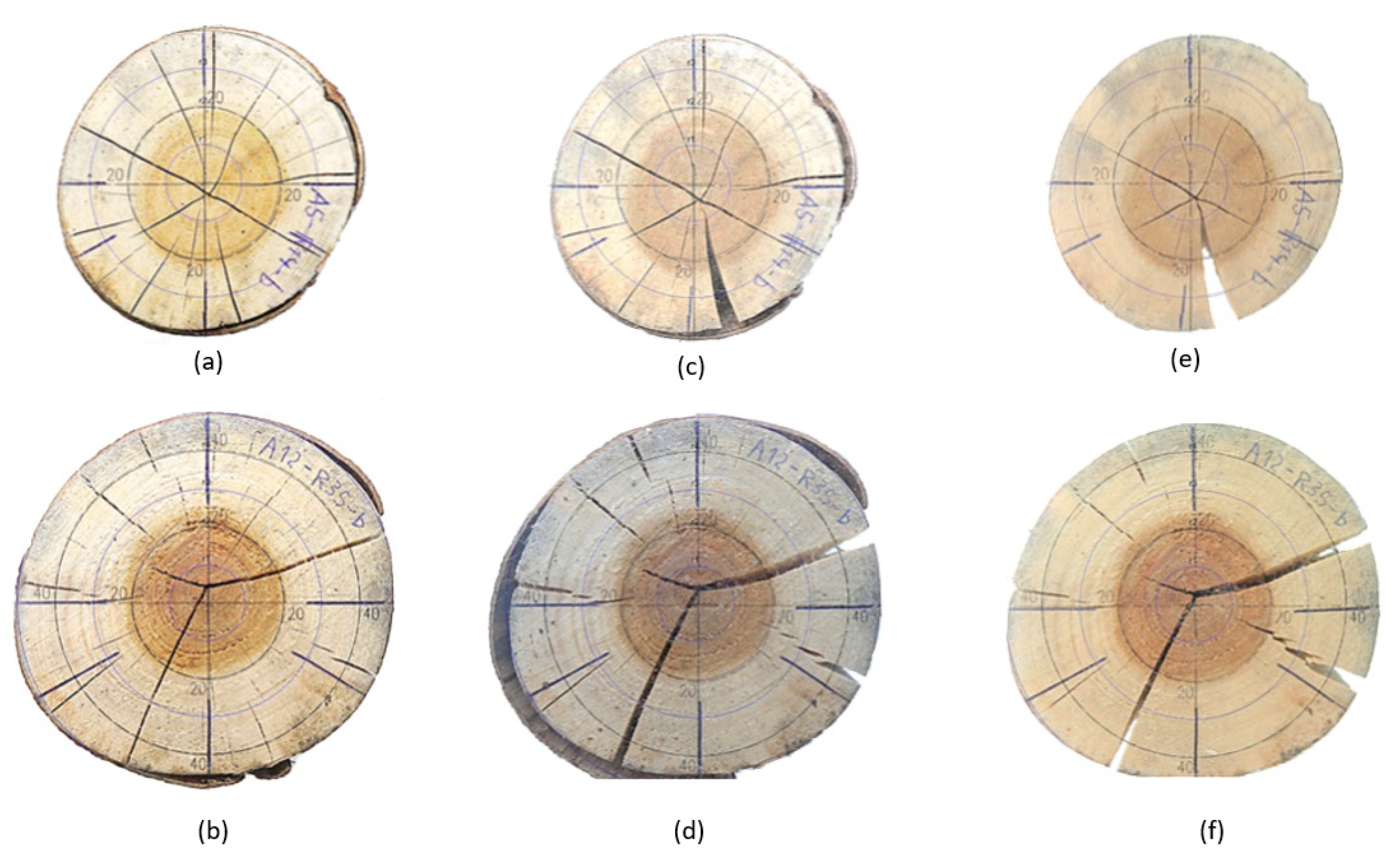

Figure 6.

Typical cracking formation at three measurement points: Early end-face cracking with (a) and (b); Maximum cracking with (c), and (d); and Final cracking at EMC: (e), and (f). The pictures correspond to the end faces of logs 5b/12b.

Figure 6.

Typical cracking formation at three measurement points: Early end-face cracking with (a) and (b); Maximum cracking with (c), and (d); and Final cracking at EMC: (e), and (f). The pictures correspond to the end faces of logs 5b/12b.

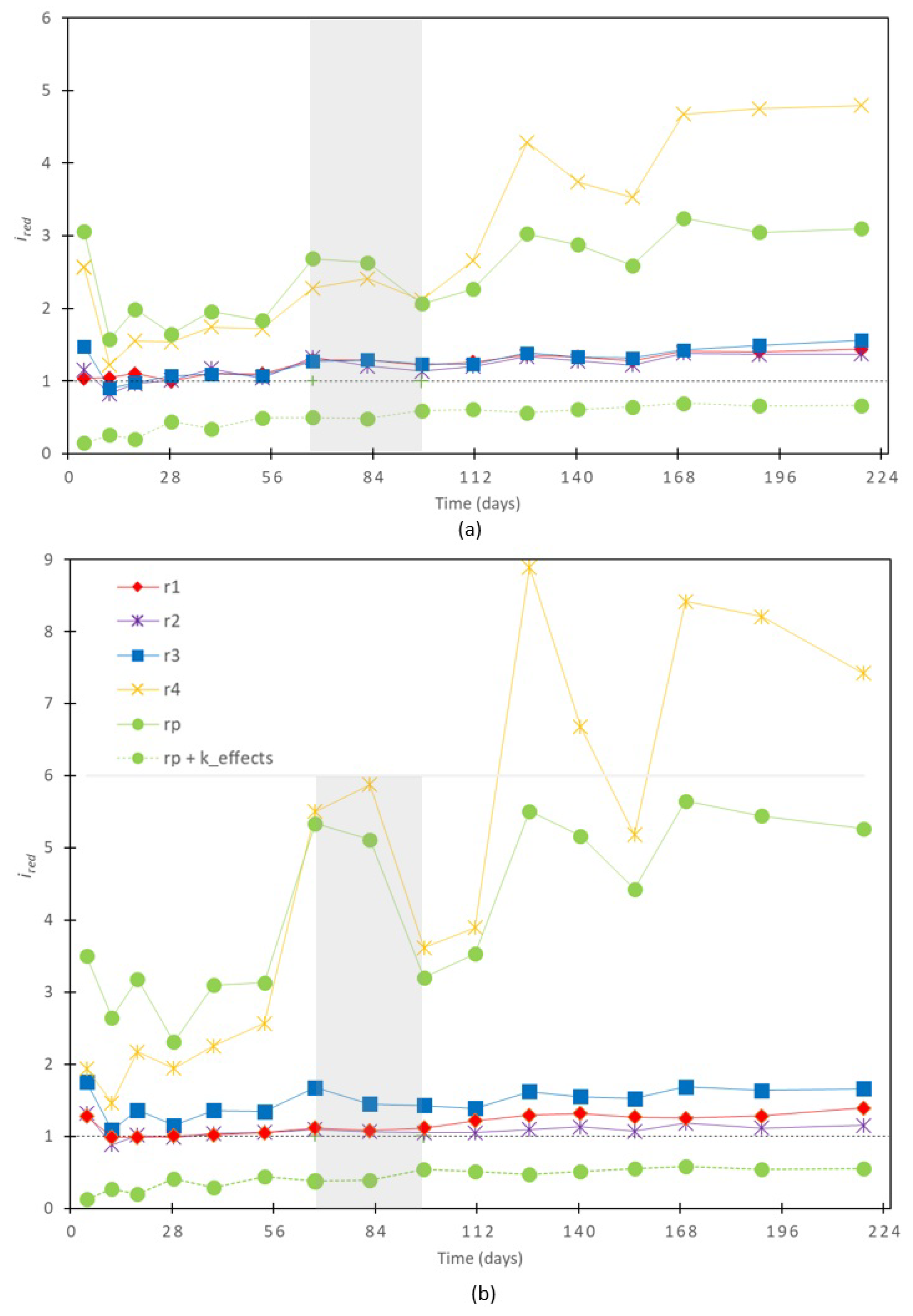

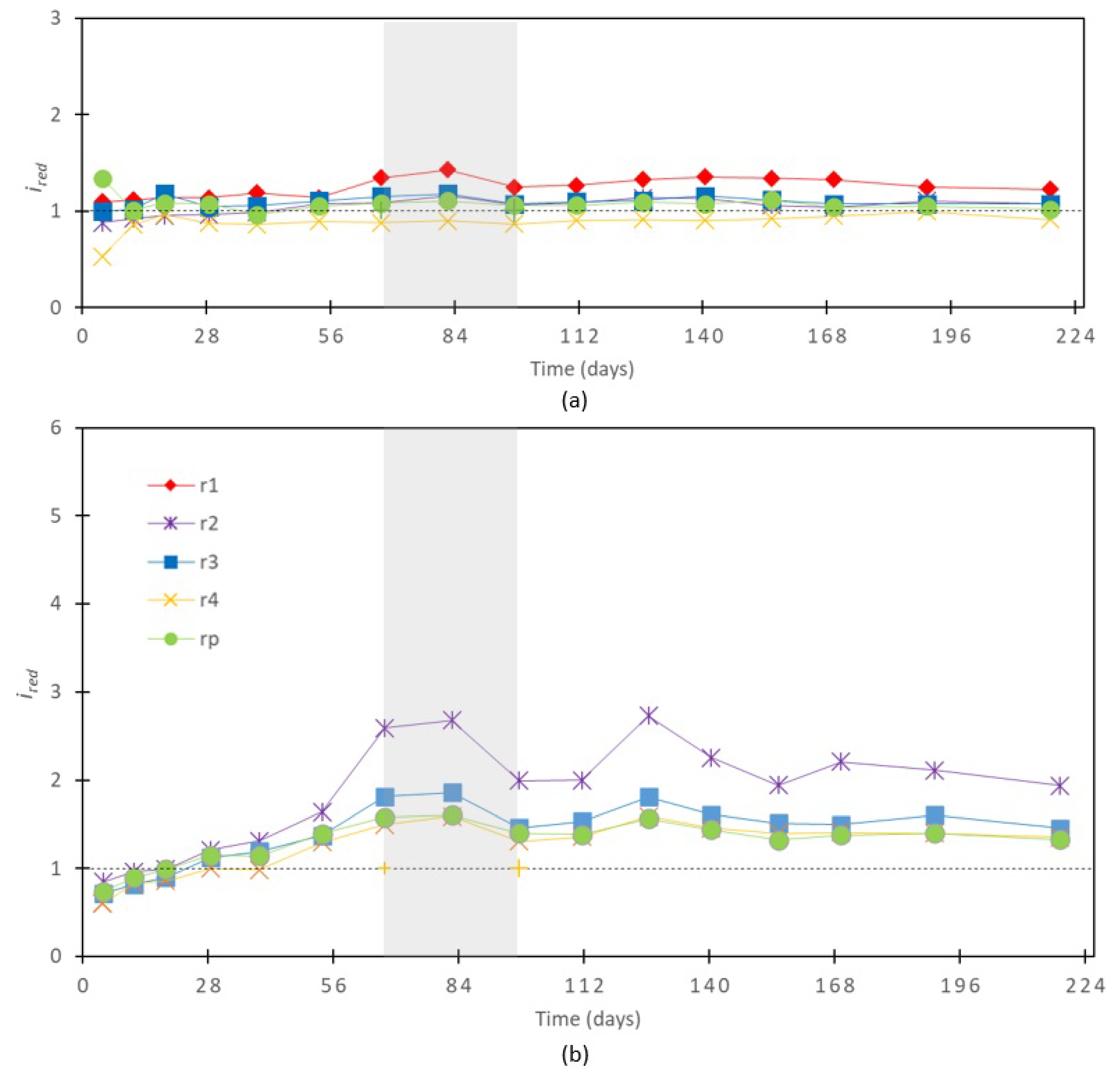

Figure 7.

Curves of reduction indicator "ired" of both K-2k (a) and K-3k (b) treatment for each ring. The grey rectangular area indicates the pass from close to 30% MC until below this value.

Figure 7.

Curves of reduction indicator "ired" of both K-2k (a) and K-3k (b) treatment for each ring. The grey rectangular area indicates the pass from close to 30% MC until below this value.

Figure 8.

Curves of reduction indicator "ired" of both H-16mm (a) and H-30mm (b) treatment for each ring. The grey rectangular area indicates the pass from close to 30% MC until below this value.

Figure 8.

Curves of reduction indicator "ired" of both H-16mm (a) and H-30mm (b) treatment for each ring. The grey rectangular area indicates the pass from close to 30% MC until below this value.

Figure 9.

Boxplots comparing the end-faces of untreated samples in black/white, R, with their treated otherface in two shades of grey, K-2k, K-3k, H-16mm, and H-30mm, for the variable relative cracking, , on peripheral ring, (a) and ring 2, (b). In the top left corner, the significance level for the t-test is indicated, with: * = p < 0.05; ** = p < 0.01; *** = p < 0.001; ns = not significant. The cross on each box indicates the mean value.

Figure 9.

Boxplots comparing the end-faces of untreated samples in black/white, R, with their treated otherface in two shades of grey, K-2k, K-3k, H-16mm, and H-30mm, for the variable relative cracking, , on peripheral ring, (a) and ring 2, (b). In the top left corner, the significance level for the t-test is indicated, with: * = p < 0.05; ** = p < 0.01; *** = p < 0.001; ns = not significant. The cross on each box indicates the mean value.

Figure 10.

Boxplots comparing the end-faces of untreated samples in black/white, R, with their treated otherface in two shades of grey, K-2k, K-3k, H-16mm, and H-30mm, for the variable number of cracking () on peripheral ring, (a) and ring 2, (b). In the top left corner, the significance level for the t-test is indicated, with: * = p < 0.05; ** = p < 0.01; *** = p < 0.001; ns = not significant. The cross on each box indicates the mean value.

Figure 10.

Boxplots comparing the end-faces of untreated samples in black/white, R, with their treated otherface in two shades of grey, K-2k, K-3k, H-16mm, and H-30mm, for the variable number of cracking () on peripheral ring, (a) and ring 2, (b). In the top left corner, the significance level for the t-test is indicated, with: * = p < 0.05; ** = p < 0.01; *** = p < 0.001; ns = not significant. The cross on each box indicates the mean value.

Figure 11.

(a) Comparison of total cracking () between the final reference face in red line (R) and the final face with Kerfing treatment (K) in black and its variants, K-2k and K-3k. The of the treatment (K) distinguishes between the area external to the kerfs in dark grey and the area absorbed by the kerf in light grey. (b) Image of the "promoter" effect of Kerfing on the end face of log A-7.

Figure 11.

(a) Comparison of total cracking () between the final reference face in red line (R) and the final face with Kerfing treatment (K) in black and its variants, K-2k and K-3k. The of the treatment (K) distinguishes between the area external to the kerfs in dark grey and the area absorbed by the kerf in light grey. (b) Image of the "promoter" effect of Kerfing on the end face of log A-7.

Figure 13.

Cross cutting scheme at the end-face of the log

Figure 13.

Cross cutting scheme at the end-face of the log

Table 1.

Description of the sample sizes for this study. The pairs of ends in the second row refer to pairs formed by an untreated face and a treated face, and the third row indicates their specific variations.

Table 1.

Description of the sample sizes for this study. The pairs of ends in the second row refer to pairs formed by an untreated face and a treated face, and the third row indicates their specific variations.

| |

Reference(R) |

Kerfing (K) |

Hollow (H) |

| Samples |

16 |

16 |

16 |

| End-faces pairs |

- |

16 |

16 |

| Variations |

- |

8 (K-2k) |

8 (K-3k) |

8 (H-16mm) |

8 (H-30mm) |

Table 2.

Descriptive statistics of en-face crack results: relative cracks () and number of cracks (). Includes Mean, standard error (S.Error), standard deviation (SD), maximum (Max) and minimum (Min) values, and count (Count).

Table 2.

Descriptive statistics of en-face crack results: relative cracks () and number of cracks (). Includes Mean, standard error (S.Error), standard deviation (SD), maximum (Max) and minimum (Min) values, and count (Count).

| |

|

( dm) |

| |

r1 |

r2 |

r3 |

r4 |

rp |

r1 |

r2 |

r3 |

r4 |

rp |

| Reference |

| Mean |

5.36 |

3.75 |

3.68 |

3.79 |

3.36 |

6.86 |

4.18 |

3.68 |

2.93 |

2.37 |

| S.Error |

0.47 |

0.27 |

0.24 |

0.20 |

0.18 |

0.32 |

0.26 |

0.21 |

0.19 |

0.14 |

| SD |

2.55 |

1.48 |

1.34 |

0.75 |

0.96 |

1.83 |

1.49 |

1.21 |

0.73 |

0.79 |

| Max |

10.76 |

6.82 |

6.94 |

4.82 |

5.73 |

11.14 |

7.16 |

6.90 |

3.98 |

3.81 |

| Min |

1.03 |

0.84 |

1.13 |

2.63 |

1.01 |

4.77 |

1.59 |

1.59 |

1.99 |

0.77 |

| Count (uts.) |

30 |

30 |

30 |

14 |

30 |

32 |

32 |

32 |

14 |

32 |

| K-2k |

| Mean |

4.61 |

3.31 |

1.99 |

1.24 |

0.74 |

6.57 |

5.17 |

4.05 |

2.29 |

1.39 |

| S.Error |

1.50 |

0.75 |

0.64 |

0.33 |

0.18 |

0.87 |

0.54 |

0.55 |

0.59 |

0.20 |

| SD |

3.97 |

1.98 |

1.70 |

0.67 |

0.49 |

2.47 |

1.53 |

1.55 |

1.19 |

0.57 |

| Max |

11.55 |

6.54 |

5.48 |

1.84 |

1.52 |

9.55 |

7.16 |

6.90 |

3.98 |

2.44 |

| Min |

0.64 |

1.25 |

0.45 |

0.28 |

0.28 |

1.59 |

3.18 |

2.65 |

1.19 |

0.52 |

| Count (uts.) |

7 |

7 |

7 |

4 |

7 |

8 |

8 |

8 |

4 |

8 |

| K-3k |

| Mean |

4.28 |

3.54 |

2.15 |

1.08 |

0.70 |

6.17 |

5.17 |

3.65 |

2.92 |

1.16 |

| S.Error |

1.00 |

0.60 |

0.62 |

0.22 |

0.38 |

0.47 |

0.50 |

0.80 |

0.13 |

0.40 |

| SD |

2.82 |

1.70 |

1.76 |

0.38 |

1.07 |

1.33 |

1.41 |

2.28 |

0.23 |

1.14 |

| Max |

9.23 |

6.25 |

5.13 |

1.37 |

3.20 |

7.96 |

7.16 |

6.90 |

3.18 |

3.06 |

| Min |

0.89 |

1.45 |

0.33 |

0.66 |

0.00 |

4.77 |

3.18 |

0.53 |

2.79 |

0.00 |

| Count (uts.) |

8 |

8 |

8 |

3 |

8 |

8 |

8 |

8 |

3 |

8 |

| H-16mm |

| Mean |

3.78 |

3.31 |

3.22 |

3.33 |

3.03 |

6.68 |

5.25 |

4.24 |

4.24 |

2.36 |

| S.Error |

0.89 |

0.63 |

0.49 |

0.56 |

0.42 |

0.62 |

0.38 |

0.36 |

0.87 |

0.13 |

| SD |

2.68 |

1.88 |

1.48 |

0.97 |

1.26 |

1.96 |

1.20 |

1.15 |

1.51 |

0.41 |

| Max |

8.57 |

6.37 |

6.10 |

4.43 |

5.53 |

9.55 |

7.16 |

5.84 |

5.97 |

3.12 |

| Min |

0.65 |

1.08 |

1.71 |

2.62 |

1.75 |

4.77 |

3.98 |

2.65 |

3.18 |

1.66 |

| Count (uts.) |

9 |

9 |

9 |

3 |

9 |

10 |

10 |

10 |

3 |

10 |

| H-30mm |

| Mean |

- |

2.55 |

2.94 |

3.11 |

3.11 |

- |

4.51 |

4.16 |

3.28 |

2.61 |

| S.Error |

- |

0.52 |

0.36 |

0.43 |

0.25 |

- |

0.34 |

0.59 |

0.25 |

0.38 |

| SD |

- |

1.28 |

0.87 |

0.85 |

0.61 |

- |

0.82 |

1.44 |

0.50 |

0.93 |

| Max |

- |

4.47 |

4.15 |

4.21 |

4.02 |

- |

5.57 |

6.90 |

3.98 |

4.21 |

| Min |

- |

0.92 |

2.03 |

2.20 |

2.38 |

- |

3.18 |

2.65 |

2.79 |

1.79 |

| Count (uts.) |

- |

6 |

6 |

4 |

6 |

- |

6 |

6 |

4 |

6 |

Table 3.

Analysis of Variance and Tukey’s mean comparison test to evaluate differences between the different radial positions for the variable relative cracking () and number of cracks ().

Table 3.

Analysis of Variance and Tukey’s mean comparison test to evaluate differences between the different radial positions for the variable relative cracking () and number of cracks ().

| |

|

|

| |

r1 |

r2 |

r3 |

r4 |

rp |

r1 |

r2 |

r3 |

r4 |

rp |

| r1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| r2 |

0.002 * |

- |

- |

- |

- |

< 0.001 * |

- |

- |

- |

- |

| r3 |

< 0.001 * |

0.999

|

- |

- |

- |

< 0.001 * |

0.569

|

- |

- |

- |

| r4 |

0.026 * |

0.999

|

0.999

|

- |

- |

< 0.001 * |

0.032 * |

0.039 * |

- |

- |

| rp |

< 0.001 * |

0.884

|

0.941

|

0.927

|

- |

< 0.001 * |

< 0.001 * |

< 0.001 * |

0.694

|

- |

| Value-F |

6.96 |

51.29 |

| Value-p |

< 0.001 ** |

< 0.001 ** |