Submitted:

10 June 2024

Posted:

11 June 2024

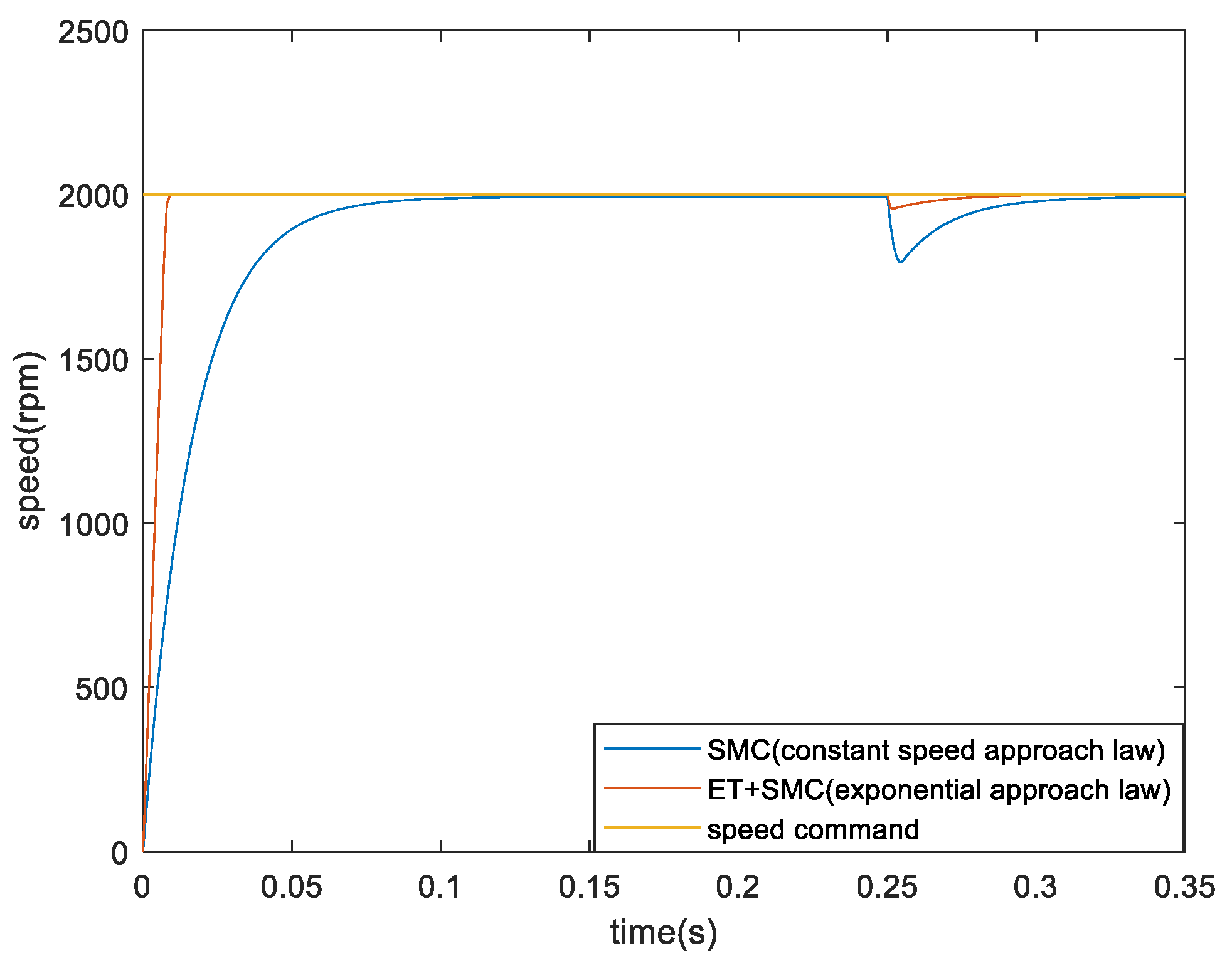

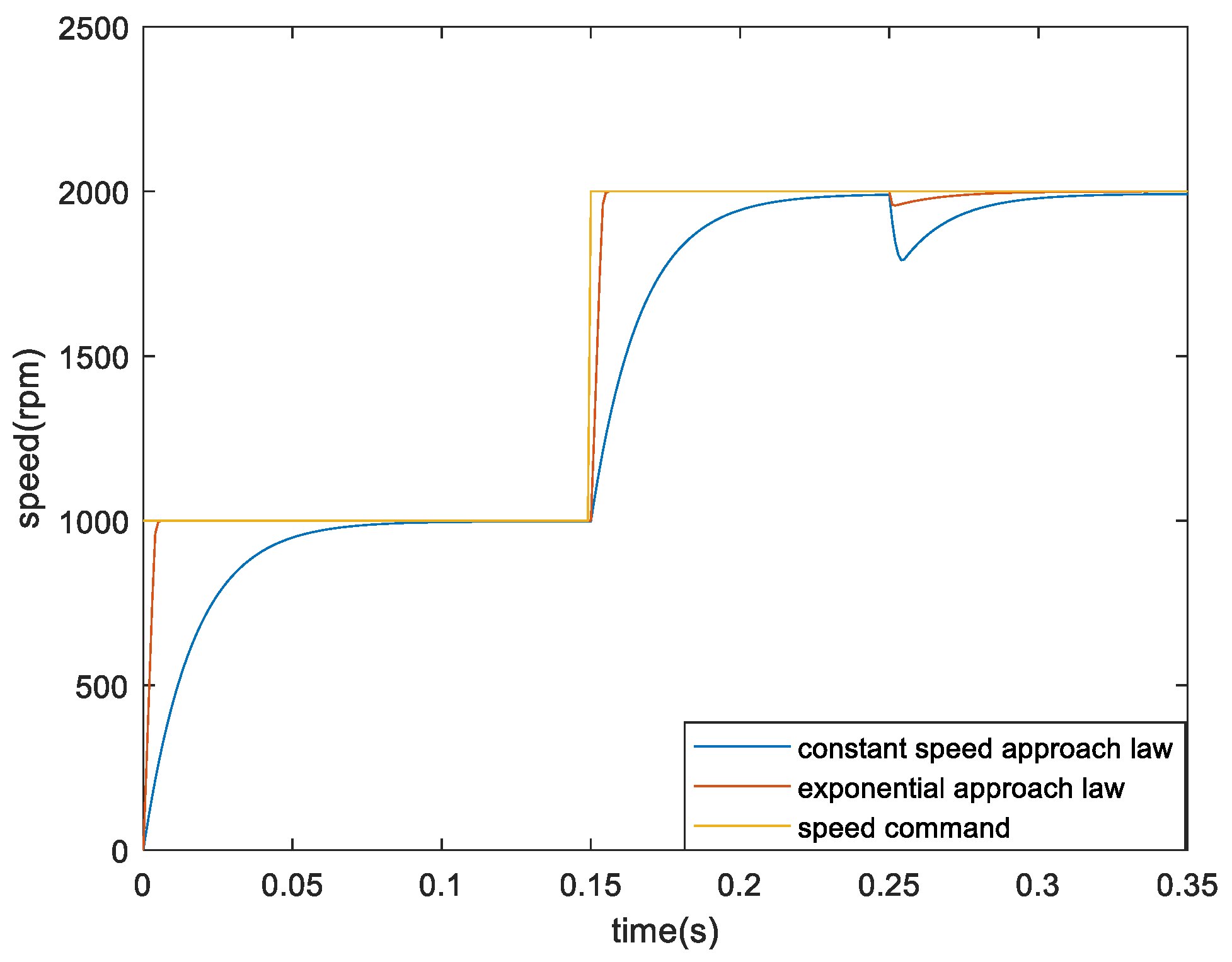

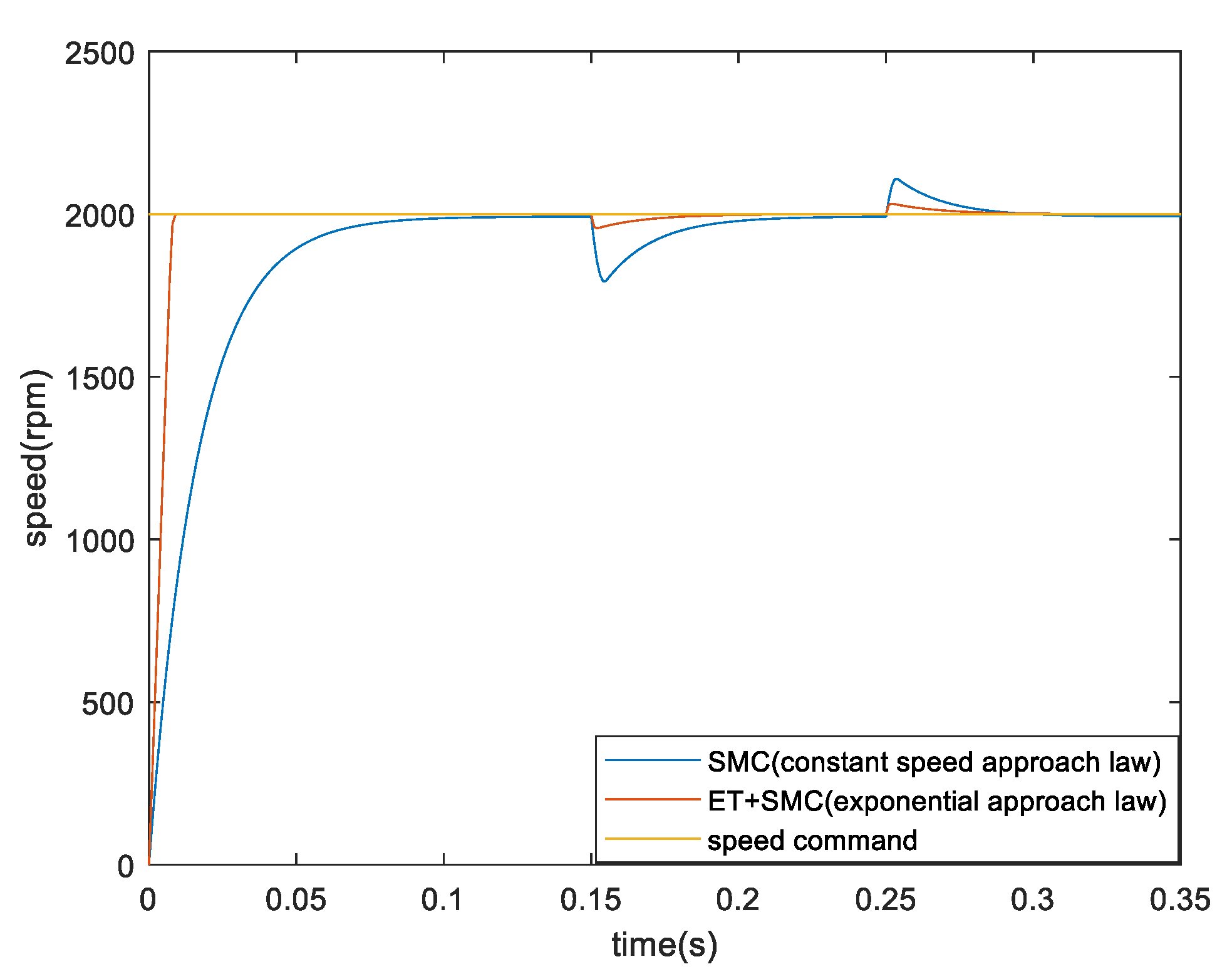

You are already at the latest version

Abstract

Keywords:

1. Introduction

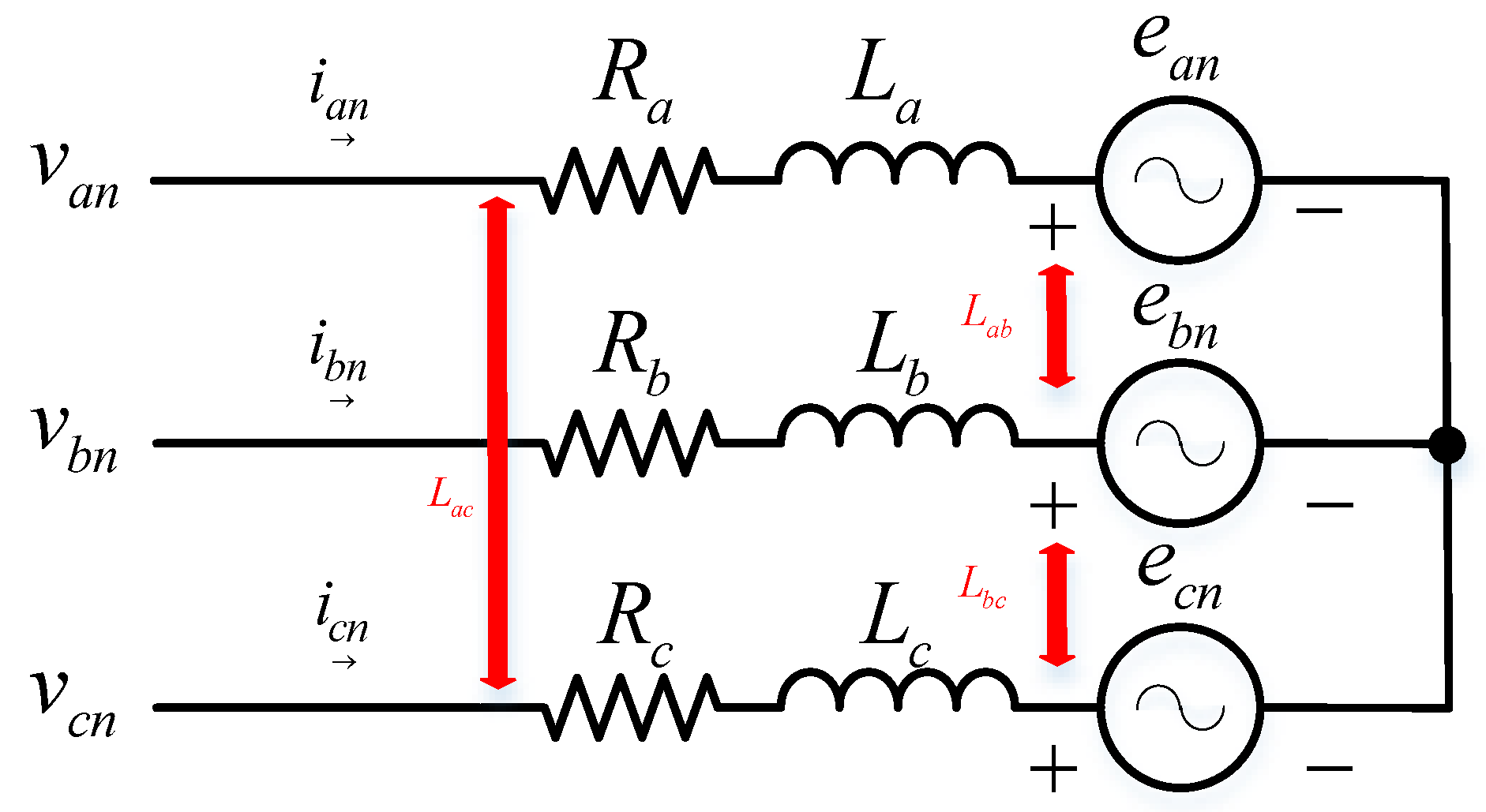

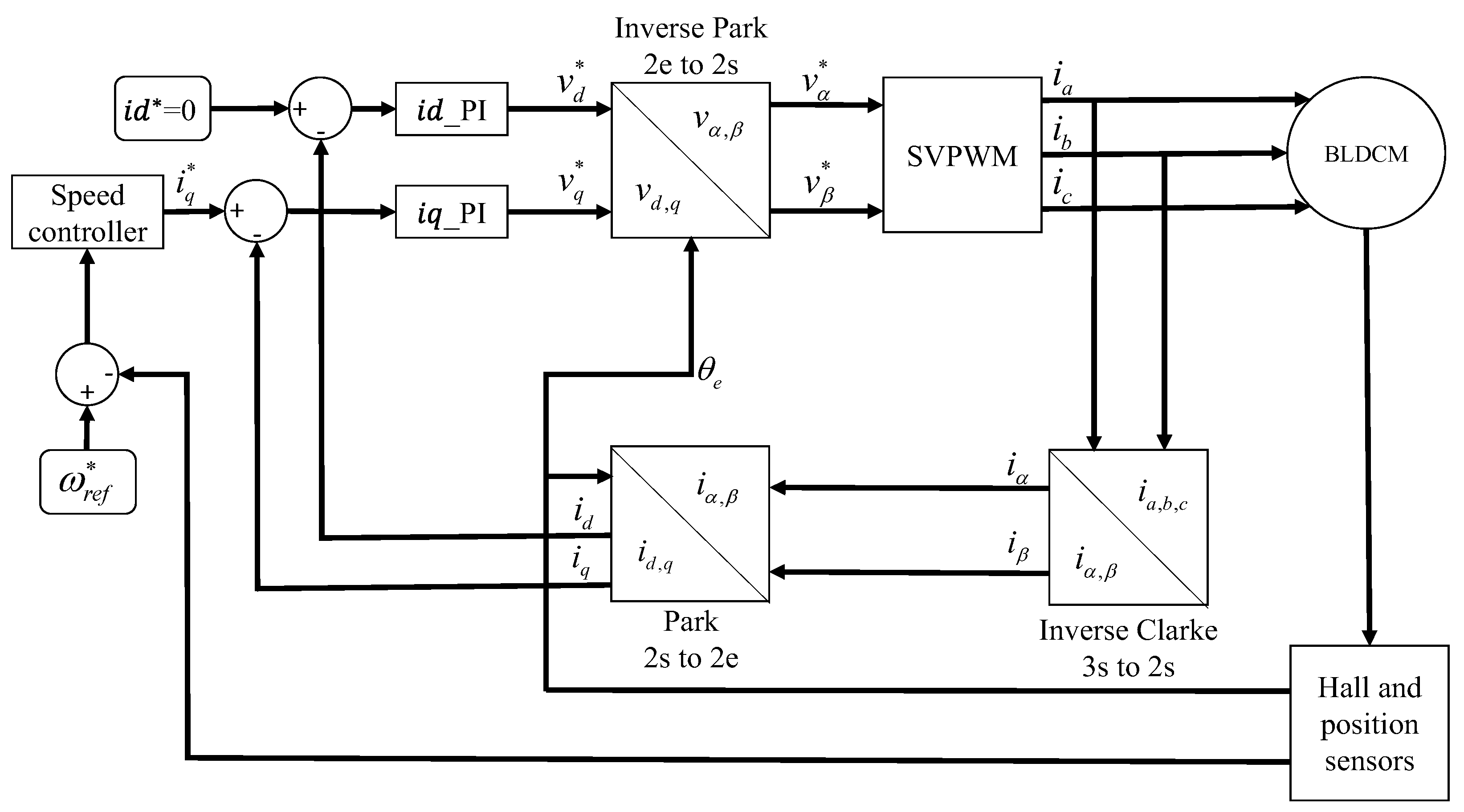

2. BLDCM System

2.1. Mathematical Model of BLDCM

2.2. Dynamic Equations of the FOC System for BLDCMs

3. Proposed Intelligent Algorithm for Drive Control

3.1. Extension Theory

3.1.1. Extension Matter Element Model

3.1.2. Definition of Classical Domain and Neighborhood Domain in ET

3.1.3. Distance and Rank Value

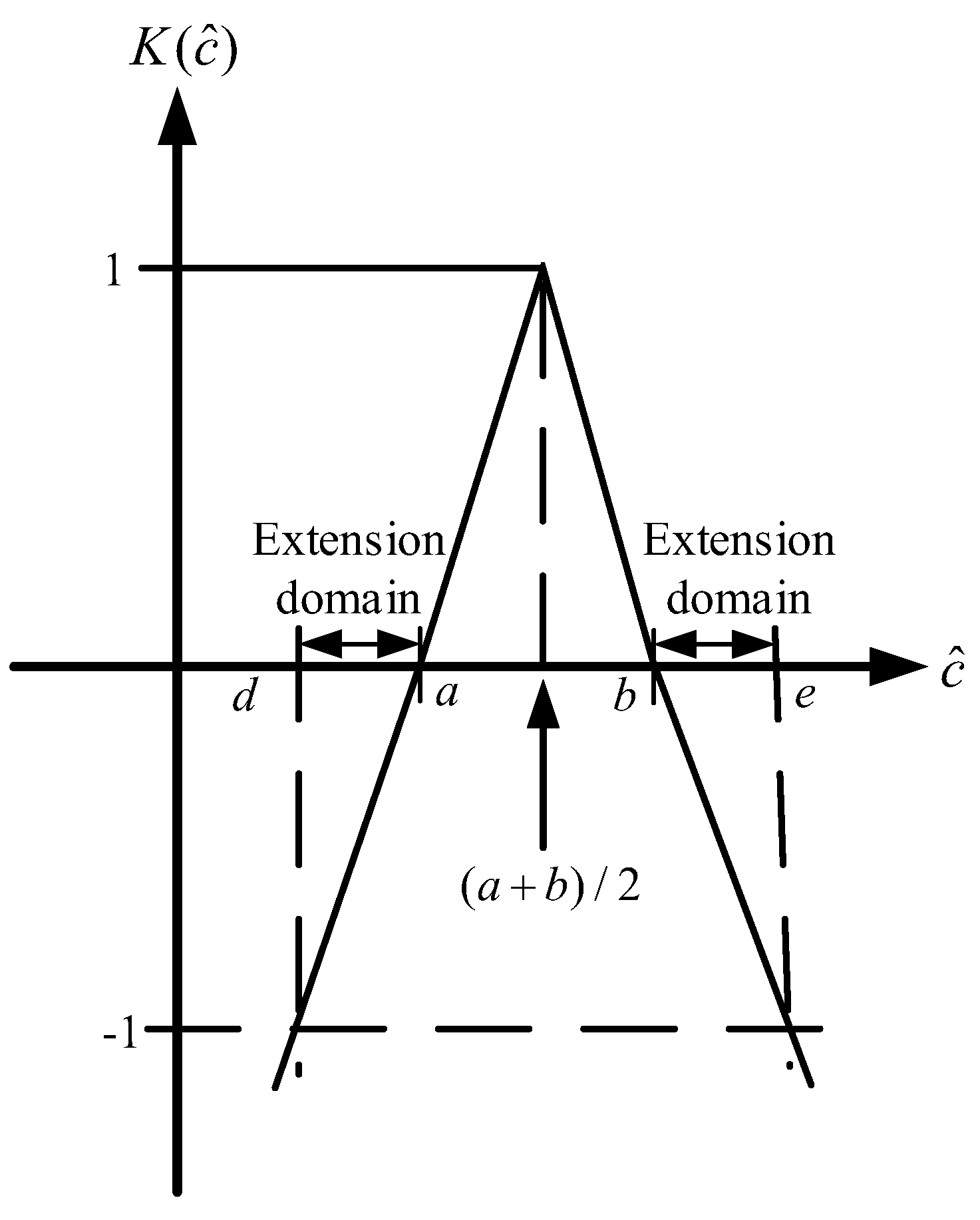

3.1.4. Correlation Function

3.2. Sliding Mode Controller Design

3.2.1. State Variable Design

3.2.2. Sliding Surface Design

3.2.3. Sliding Mode Approach Design

3.2.4. Controller Output Design

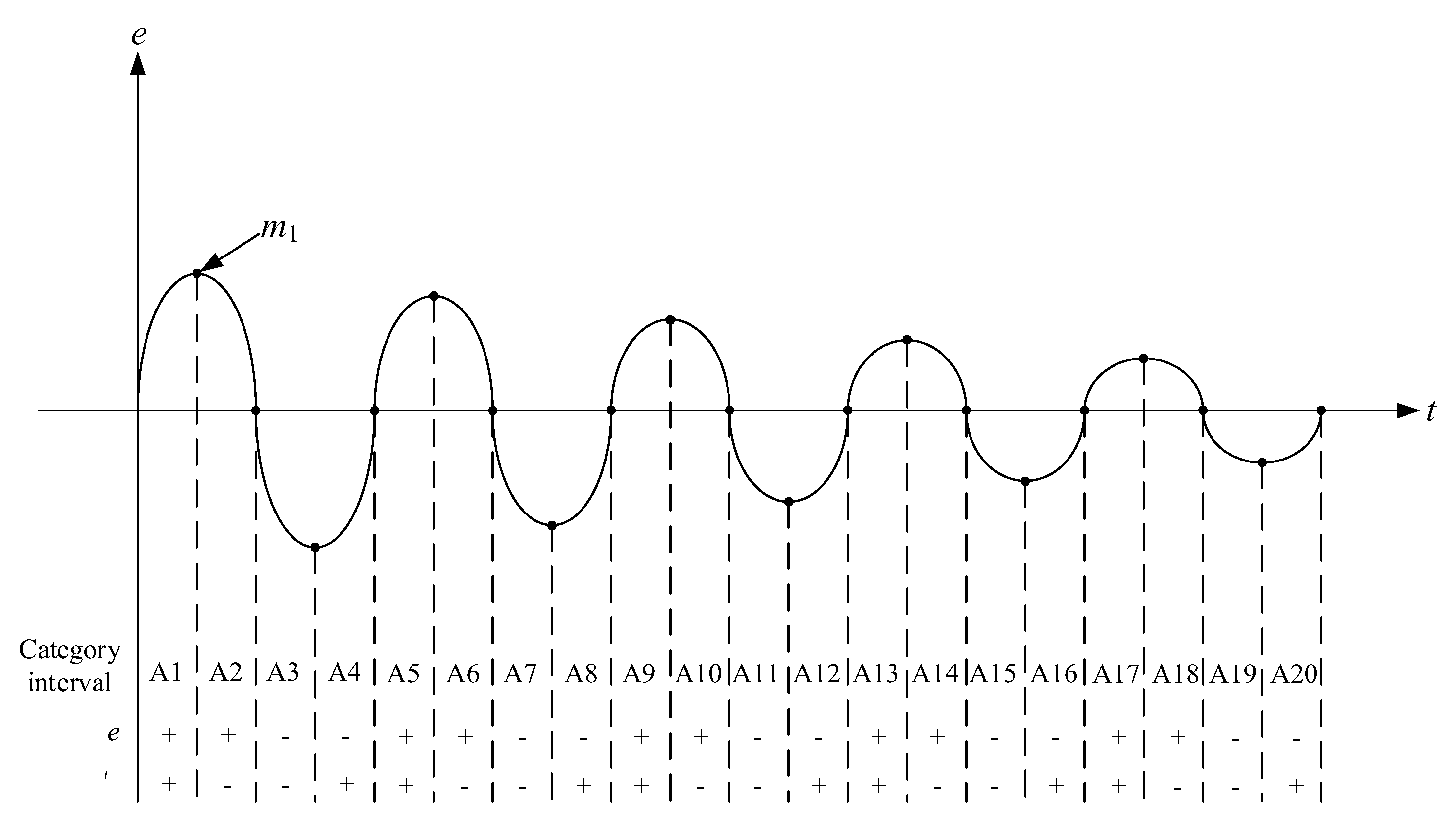

3.3. Feature Selection for ET Integrated SMC of the Drive System

3.4. Integration of ET and SMC for Speed Control

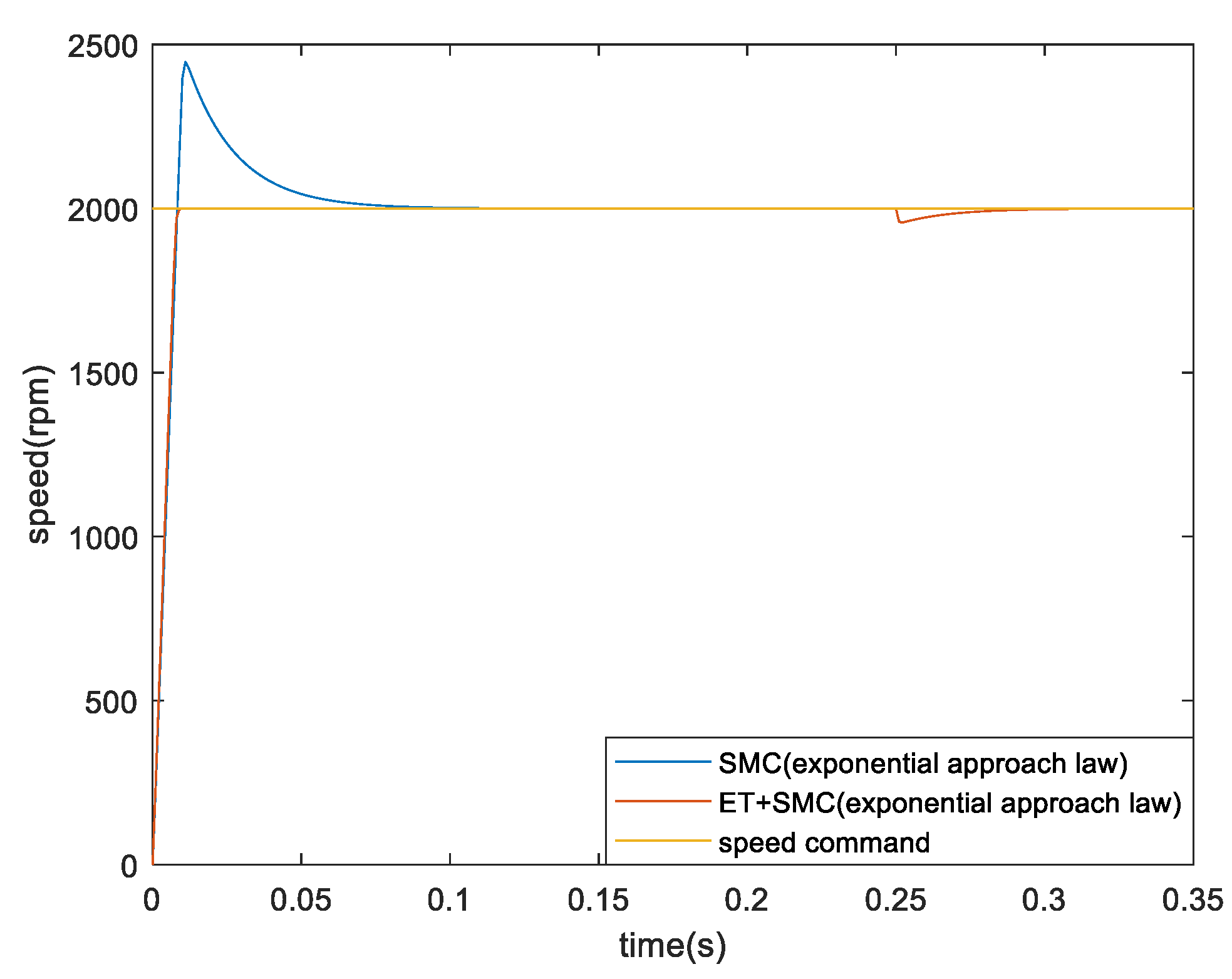

4. Simulation Results

5. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Chen, Z. Research on Permanent Magnet Structure of Permanent Magnet Synchronous Motor for Electric Vehicle. In Proceedings of the 2nd International Conference on Electrical Engineering and Control Science (IC2ECS), Nanjing, China, 16–18 December 2022; pp. 990–993. [Google Scholar] [CrossRef]

- Lee, C. I.; Jang, G. H. Experimental Measurement and Simulated Verification of the Unbalanced Magnetic Force in Brushless DC Motors. IEEE Trans. Magnetics 2008, 44, 4377–4380. [Google Scholar] [CrossRef]

- BV, P.; Balamurugan, A.; Selvathai, T.; Reginald, R.; Varadhan, J. Evaluation of different Vector Control methds for Electric Vehicle Application. In Proceedings of the 2nd International Conference on Power and Embedded Drive Control (ICPEDC), Chennai, India, 21–23 August 2019; pp. 273–278. [Google Scholar] [CrossRef]

- Bhatti, S. A.; Malik, S. A.; Daraz, A. Comparison of P-I and I-P controller by using Ziegler-Nichols tuning method for speed control of DC motor. In Proceedings of the International Conference on Intelligent Systems Engineering (ICISE), Islamabad, Pakistan, 15–17 January 2016; pp. 330–334. [Google Scholar] [CrossRef]

- Murali, S. B.; Rao, P. M. Adaptive sliding mode control of BLDC motor using cuckoo search algorithm. In Proceedings of the 2nd International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19-20 January 2018; pp. 989–993. [Google Scholar] [CrossRef]

- Chao, K.-H.; Chang, L.-Y.; Hung, C.-Y. Design and Control of Brushless DC Motor Drives for Refrigerated Cabinets. Energies 2022, 15, 3453. [Google Scholar] [CrossRef]

- Khanke, P. K.; Jain, S. D. Comparative analysis of speed control of BLDC motor using PI, simple FLC and Fuzzy - PI controller. In Proceedings of the International Conference on Energy Systems and Applications, Pune, India, 30 October–01 November 2015; pp. 296–301. [Google Scholar] [CrossRef]

- Longfei, J.; Yuping, H.; Jigui, Z.; Jing, C.; Yunfei, T.; Pengfei, L. Fuzzy Sliding Mode Control of Permanent Magnet Synchronous Motor Based on the Integral Sliding Mode Surface. In Proceedings of the 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Qi, C.; Xie, J.; Mao, H.; Xie, Q. Condition Assessment of Valve-side Bushing of Converter Transformer Based on Extension Theory. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 06–10 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Wang, J.; Ye, J.; Yan, R. The Magnetostatic Simulation and Determination of Magnetic Components for an External Ventricular Drainage Device. In Proceedings of the 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; pp. 6386–6391. [Google Scholar] [CrossRef]

- Kishore, N.; Shukla, K.; Gupta, N. A Novel Three-Phase Multilevel Inverter Cascaded by Three-Phase Two-Level Inverter and Two Single-Phase Boosted H-Bridge Inverters. In Proceedings of the IEEE PES Innovative Smart Grid Technologies - Asia (ISGT Asia), Singapore, Singapore, 01–05 November 2022; pp. 330–334. [Google Scholar] [CrossRef]

- Xie, T.; Kuai, Z.; Ye, X.; Zhu, L.; Guo, K.; Shi, S. Coordinate Conversions and Deviation Analysis in Multi-source Data Fusion. In Proceedings of the 2nd China International SAR Symposium (CISS), Shanghai, China, 03–05 November 2021; pp. 1–3. [Google Scholar] [CrossRef]

- Yadunandan; Naik, B.; Konduru, R.; Ilkal, B. B.; Kalligudd, S. Terminal Voltage control of BLDC Motor. In Proceedings of the International Conference on Smart Systems for applications in Electrical Sciences (ICSSES), Tumakuru, India, 07–08 July 2023; pp. 1–5. [CrossRef]

- Wu, H.-Q.; Chen, Y.-W.; Liu, R. College Education Outcome Expectation and Proactive Personality as Predictors of Chinese College Students’ Learning Motivation, Career Adaptability as a Mediator. In Proceedings of the International Conference on Modern Education and Information Management (ICMEIM), Dalian, China, 25–27 September 2020; pp. 716–721. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Ma, H.; Ju, P. Power transformer fault diagnosis based on extension theory. In Proceedings of the International Conference on Electrical Machines and Systems, Nanjing, China, 27–29 September 2005; pp. 1763–1766. [Google Scholar] [CrossRef]

- Luo, N.; Zhang, L. Chaos Driven Development for Software Robustness Enhancement. In Proceedings of the 9th International Conference on Dependable Systems and Their Applications (DSA), Wulumuqi, China, 04–05 August 2022; pp. 1029–1034. [Google Scholar] [CrossRef]

- Guo, X.; Huang, S.; Peng, Y. Sliding Mode Speed Control of PMSM Based on A Novel Hybrid Reaching Law and High-Order Terminal Sliding-Mode Observer. In Proceedings of the IEEE 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, B.; Jiang, Z.; Hu, H. The Application of Sliding Mode Control with Improved Approaching Law in Manipulator Control. In Proceedings of the 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–02 June 2018; pp. 807–812. [Google Scholar] [CrossRef]

- Bodur, F.; Kaplan, O. A Novel Sliding Mode Control Based on Super Twisting Reaching Law for PMSM Speed Controller with Fixed-Time Disturbance Observer. In Proceedings of the 12th International Conference on Renewable Energy Research and Applications (ICRERA), Oshawa, ON, Canada, 29 August–01 September 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Zeng, X.; Zeng, X.; Hong, Y. Distributed Computation of Common Lyapunov Functions. In Proceedings of the 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 2418–2423. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, J.; Zhou, Z. Simulation of Sliding Mode Control for PMSM on Account of Variable Exponential Approach Law. In Proceedings of the Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 3518–3521. [Google Scholar] [CrossRef]

| Interval | Extension matter element model | Variation of control gain |

| A1 | 0 | |

| A2 | 0 | |

| A3 | 0 | |

| A4 | 0 | |

| A5 | 15 | |

| A6 | 15 | |

| A7 | 15 | |

| A8 | 15 | |

| A9 | 30 | |

| A10 | 30 | |

| A11 | 30 | |

| A12 | 30 | |

| A13 | 45 | |

| A14 | 45 | |

| A15 | 45 | |

| A16 | 45 | |

| A17 | 60 | |

| A18 | 60 | |

| A19 | 60 | |

| A20 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).