1. Introduction

The necessity for 3D spatial models is evident across various disciplines including architecture, urban design, planning, landscape design, and construction. Consequently, accurate 3D digital or physical models are fundamental in the planning and development phases of these projects. The utilization of 3D models varies from the conceptualization to completion stages, each demanding differing levels of detail. In practical projects, people use 3D models as a means of communication among architects, engineers within a studio, and project stakeholders [

1,

2,

3]. There are two main purposes for developing a 3D digital or physical model for a built environment: prototyping and showcasing projects. Prototyping is aimed at enhancing communication and consensus among designers and decision-makers. The success of projects strongly hinges on this aspect, as the concept design is adjusted based on feedback from discussions about the prototype between the two parties. This process not only helps designers quickly and effectively address the demands of investors or project owners but also eliminates potential problems that may arise during the construction stage. At the same time, showcasing projects can be explained as follows. For instance, a real estate company may require a model of their new apartment projects to provide informative presentations to their customers while marketing their products [

4,

5,

6,

7]. The hologram, a concept dating back to the 19th century, saw significant advancements in the past two decades, driven by significant improvements in hardware. As such, this technology has recently garnered considerable interest from researchers worldwide. However, while there have been some experiments utilizing hologram technology to visualize spatial content in architecture and urbanism, these endeavors have not yet been widely explored and remain largely open. Therefore, the present study aims to conduct experiments utilizing the latest advancements in hologram technology to visualize content in the fields of architecture and urbanism. In this study, we propose a new solution, which is the stereographic hologram visualization created with the CHIMERA hologram printer, as a new approach to solve the problems in the spatial project visualization of both digitalized and physical models. In the study experiment, a 3D architectural model along with the landscape surrounding the building site was visualized using the hologram method on a 30cm × 40cm display. U04 ultra-fine grain silver halide holographic glass plate is used as the display material for the tabletop hologram.

1.1. 3D Visualization in the Field of Architectural and Urban Design

In the past of architectural and urban design practice, physical models were used extensively. These served as prototypes from the earliest time, allowing architects and engineers to communicate their ideas about the future built environment to non-experts such as investors and audiences. This practice has since undergone significant changes following the invention of 3D visualization software, which enables designers to showcase their conceptual project content on a screen. This shift is largely attributed to the significant reduction in processing time, manpower, and production costs associated with digital visualization. Additionally, digital tools offer greater flexibility for modifications during the design process, prompting architecture, urban planning, and landscape design studios to transition their work primarily into the virtual realm of computers. With its efficient performance, digital models have gradually replaced physical models throughout the entire prototyping process, from inception to project completion. In the contemporary era, physical models are typically only used at the end of a project, in response to the requirements of investors or project owners, serving as stable visualizations placed in one location for other audiences. The primary purpose of physical models now lies in showcasing the investments, buildings, and built environment of the project to the public [

1,

2,

4,

5,

7,

8]. Despite the development of 3D digital models and the rapid advancement of 3D visualization programs, the production of 3D physical models has not been replaced totally. In some parts of architectural and urban design projects, 3D physical models are still more effective.

To leverage the strengths of both digital and physical 3D models, a new innovation for creating 3D models with Virtual Reality (VR) and Augmented Reality (AR) is being currently hypothesized by developers. However, both VR and AR have many disadvantages that prevent them from being commercialized in the field of architecture and urbanism, such as high operation and installation costs, low 3D content quality, and the requirement of near eye display devices [

9,

10,

11,

12].

1.2. Hologram as a New Approach for 3D Content Visualization

Hologram is a widely recognized technology known for its ability to make 3D content visible to the naked eye. It is often associated with its depictions in popular culture such as Princess Leia's real-time projection in

Star Wars or Iron Man's suit visualization in the Marvel movies. In real-world applications, many perceive hologram as a form of 3D or even 2D images appearing to hang in the air, which are often encountered in amusement parks, theaters, museums, exhibitions, and stores. However, it is important to note that although this type of visualization resembles a hologram, it typically utilizes projection technology, leading to common confusion between the two [

13,

14,

15]. Holography, a technique based on the principle of light diffraction, began its long history of development when it was first proposed in 1947 by Denis Gabor, who developed the concept while trying to increase the resolving power of electron microscopes [

14,

15,

16]. This achievement later earned him the Nobel Prize in 1971. However, the first successful implementation of holography was pioneered by Emmett Leith and Uris Upatnieks in 1961 in the USA. They utilized a technique known as "off-axis holography," which involved splitting a laser beam into two parts and recording a hologram. This breakthrough was made possible by the invention of the laser beam in 1958 by Charles H. Townes, Nicolay G. Basov, and Aleksandr M. Prokhorov, who were subsequently awarded the Nobel Prize in 1964. This occurred long after Dennis Gabor proposed his theory of holography. In 1963, another successful holographic technique, known as reflection holography, was developed by Yuri Denisyuk. This method involved using a thick emulsion to achieve a significantly higher diffraction efficiency [

15,

17]. This technique was later developed further by various scientists, and with the development of new diode-pumped solid-state lasers used for recording the hologram on newly developed materials such as ultra-fine grain silver-halide emulsions, the recorded analog hologram can now achieve an “ultra-realistic” appearance. Modern holograms are able to achieve full color with 180° full parallax both vertically and horizontally. Thus, it is very difficult to discriminate a recorded hologram with its real-life counterpart when viewed side-by-side [

17,

18,

19].

Despite these technological advances in holograms, hologram products have nevertheless faced challenges in the visualization of other data such as 3D digital models, augmented reality (AR), and projection, which are being developed fast to fit with more difficult contents. For example, the applicability of holographic technology has been limited in the field of architecture, military, urban planning, manufacturing, automotive industry [

19]. To address this and expand the range of visualized content, including digital creations of any size for diverse purposes, techniques for digital holographic stereogram printing have been evolving since the late 20th century, gradually supplanting the tasks handled by analog holograms [

19,

20]. From a proposal of direct-write digital holography technique which using object and reference beams to create a digital hologram divided into a matrix of small holographic elements (hogels) by Yamaguchi in 1995, the first generation of hologram printer was invented by Zebra Imaging Inc. in Austin, Texas, USA [

19,

20]. However, the hologram printing speed was very slow at 2Hz (hogels per second), and took four days to print a 60cm × 60cm hologram with a resolution of 800µm. The second generation that was believed to overcome this limitation was developed by Geola group in Vilnius, Lithuania and XYZ Imaging Inc. in Montreal, Canada [

21]. Using a pulsed laser-based printers, the printing speed can be up to 25Hz. However, due to the used lasers and fast printing, several other problems emerged such as a lack of color accuracy, a lack of diffraction efficiency by reducing visible vertical parallax, and a long and costly manufacturing process for the machine [

19]. Finally, after 15 years of research and development, the most advanced hologram printer was then invented by Yves Gentet in Bordeaux, France. The CHIMERA hologram printer is the newest generation of holographic stereogram printers that uses low-power RGB CW lasers and Ultimate U04 ultra-fine grain silver halide holographic glass plates. This third-generation hologram printer can produce high quality, highly diffractive, large-format, full-color and full-parallax digital reflection holograms. The printing speed is 25 Hz for 500μm hogel resolution and 50 Hz for 250μm hogel resolution [

19].

As mentioned above, 3D spatial models are highly in demand in the fields of architecture and urbanism. Therefore, there are also previous hologram products created for visualization of 3D models and presenting spatial content such as housing, construction, cities, and topography map by Zebra Imaging [

22], Geola group, and Hellenic Institute of holography [

23]. In the case of Zebra Imaging, although the company has stopped providing services in the hologram field and has removed all of its content from the internet, their works can still be found and summarized in existing research, websites, and videos. Using digital holographic stereogram printing techniques, Zebra produced a hologram display from various 3D spatial data, including “.obj” exports from AVEVA Review, 3Ds Max, Maya, and SketchUp; “.dwg” exports from Revit and AutoCAD; and point cloud sources from LiDAR laser scans. The company provided 3D visualizations of digital city models, building information management, and real-world scenes from LiDAR/photogrammetry data [

22,

24]. Besides the model of cities and buildings, holographic maps have been also developed to deliver spatial data for various purposes like military, and construction. This field was developed by the Hellenic Institute of Holography with support from the hologram printing technique of Geola group [

22,

25]. Because of the disadvantages of technology development and the printing quality of the 1st and 2nd generations of hologram printers, the quality of 3D spatial models with holographic displays still needs to be improved. In this study, we discuss how a hologram model can be a competitor for the traditional 3D models used in urbanism and architecture design projects. Additionally, using an experiment, we demonstrate the full parallax hologram visualization using a CHIMERA printer. The name Tabletop Hologram is used for a method of expressing the use of hologram technology for content in the field of architectural and urban design. Instead of displaying hologram content vertically as is often the case, the hologram tabletop is placed on a flat surface and the audience can easily follow the 3D content by moving 360° around the hologram's position. This method will be effective when designers want to visualize the master plan in architectural and urban projects.

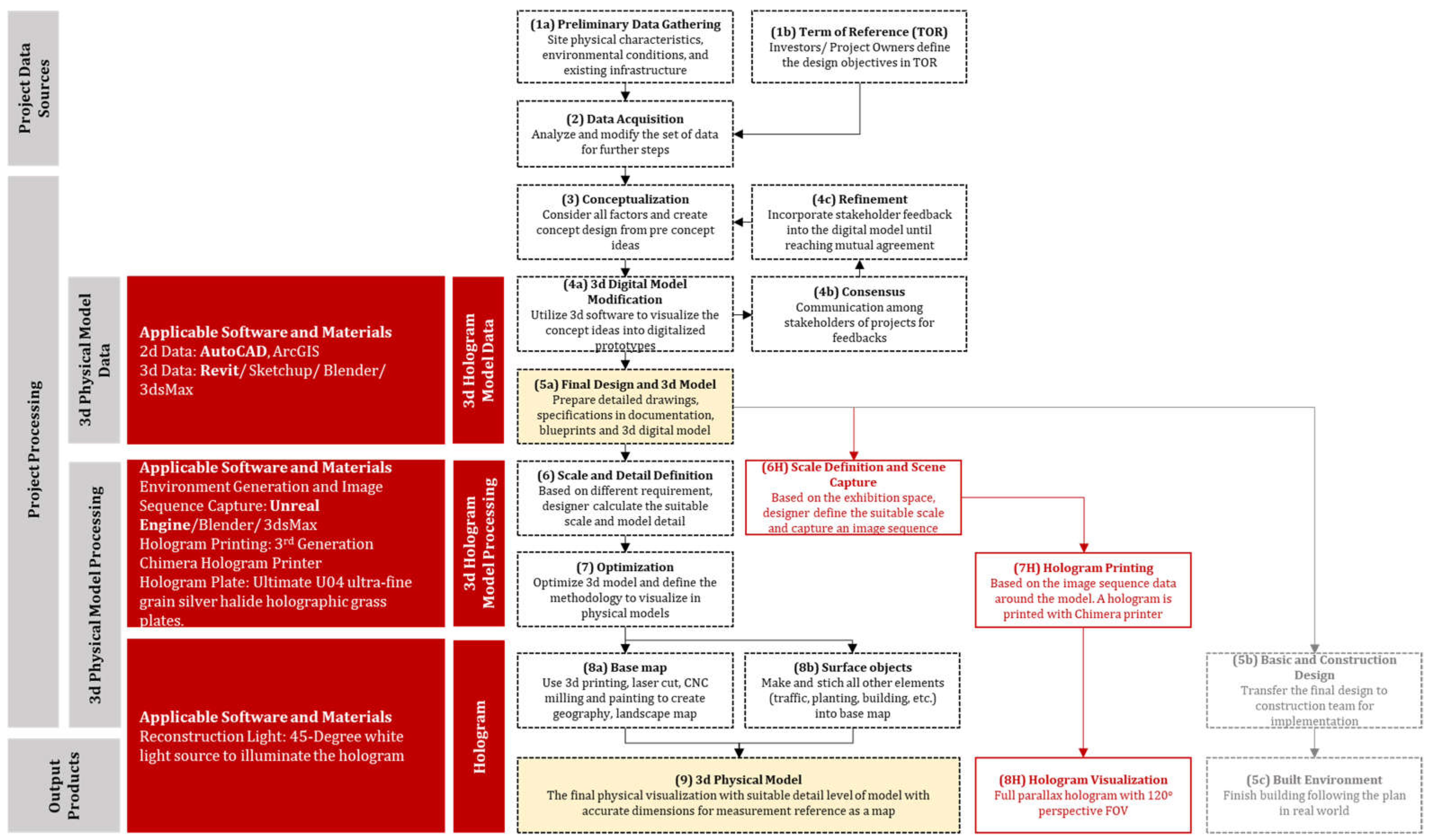

2. The Traditional Procedure of Making 3D Models in the Urbanism and Architecture Projects

2.1. Project Data Source

This is also the input and foundation information of a design project. In the beginning of the workflow, two types of information will be given to the design consultants for a comprehensive understanding of the site.

(1) Preliminary data gathering: This involves gathering all relevant information such as physical characteristics in spatial data (such as contour lines and elevation maps, and green and blue networks in landscape), existing infrastructure (such as road systems, buildings, artificial landscape, etc.), and environmental conditions. Typically, this data is provided by the project owners, investors, or initially collected by consultant companies through site surveys.

(1b) Terms of Reference (TOR): TOR entail different stakeholders articulating their goals and objectives for the projects, followed by an orientation of the site within the local urban planning vision and the regulations.

(2) Data acquisition: Typically, the spatial data for a project are in a 2D format and is stored in various software such as AutoCAD and ArcGIS, which use a vector format, while image data is stored in raster format. As advanced methods for collecting spatial data in the form of point clouds through photogrammetry and LiDAR technology have become prevalent, architects and engineers must take an additional step to synthesize, integrate, and streamline this data to create a cohesive working environment before proceeding with the concept design phase. This transition also presents a challenge for them when transitioning to 3D visualization platforms for their work [

2,

3,

8,

26].

2.2. Project Processing

This is the stage where the design consultant conducts brainstorming by sketching and building 2D drawings and 3D digital models.

(3) Conceptualization: Upon reaching a balance of different factors like the project's goals and objectives, target audience, sustainability, and aesthetic design character, architects and engineers generate their concept ideas with sketches, drawings, and 2D mappings. In this stage, the designers normally consider multiple options for morphology, materials, and structure for the project and space.

(4a) 3D Digital Model: Utilizing software such as Revit, SketchUp, Blender, and 3Ds Max, architects and designers create a digital representation of the conceptualized design idea or design prototype. This step not only allows them to quickly explore design variations and adjustments with a more immersive experience but also provides a platform for communication with other stakeholders such as investors, project owners, and other project departments (e.g., construction, marketing). With advancements in visualization technology, designers can go beyond creating a standard 3D model. There are various applications (such as Vray, Lumion, Unreal Engine, Unity) that enable designers to significantly enhance the realistic appearance of their digital model by implementing digital environments, lighting systems, materials, and textures. Serving as a platform for more interactive and informative discussions, the 3D model plays a significant role in the subsequent steps: (4b) Consensus, where all relevant parties provide comments and feedback for the project, and (4c) Refinement, where architects and engineers collaborate on incorporating received feedback and making modifications to the designs. This entire process is repeated multiple times, typically around three times in practical design projects, until all stakeholders reach a mutual agreement [

2,

4,

7,

27].

(5a) Final design and 3D digital model: In this step, the consultant team prepares all the detailed drawings, specifications, and any necessary input for the construction phase in documentation, blueprints, and 3D digital models. After completing all the required drawings and documents, they will be sent to other departments for making basic and construction designs (5b) and for being used in construction (5c).

2.3. 3D Physical Model Processing

This is the stage where the design consultant conducts brainstorming through sketching and building 2D drawings and 3D digital models. Design visualization is extremely important in the communication between stakeholders.

As explained in the introduction, building 3D physical models today is in fact mostly done to represent works, projects, and areas that will be built in the future. Therefore, a model is considered a final prototype to exhibit to customers. Making 3D physical models also requires professionalism and high artisanship skills to achieve the required level of detail.

(6) Scale and detail definition: One of the most important considerations when creating a 3D physical model is dimensional accuracy. The ability to reference measurements is a key distinction between technical maps and models as opposed to sketches and drawings. Therefore, on the outset of this process, architects and engineers must select a suitable scale for the model based on the project and available space for display. Typically, the appropriate scales for different project types are as follows: architectural models (1:50-1:100), factories or large complexes (1:200-1:300), neighborhoods or districts (1:400-1:1,000), and cities (1:1,000-1:2,000). Additionally, due to the differences in scale, the level of detail for the physical model must also be determined.

(7) Optimization: To ensure the physical model is as effective as possible, designers must devise an optimization plan. This plan includes decisions regarding materials, crafting techniques, the inclusion of necessary and unnecessary objects, and striking a balance between realism and aesthetics. These choices are largely influenced by project owner or investor requirements, scale and detail level, professional standards, and the purpose of the exhibition. For instance, in a 1:50 architectural model created as a prototype for a real estate project targeting potential customers, the housing components, interior furniture, and construction details should be showcased. Conversely, in a city model with a 1:1000 scale, such detailed elements are omitted as they are not crucial. This optimization not only enhances the presentation of 3D physical models but also maximizes manpower and reduces model costs.

(8a) Base Map: The base map, comprising different layers from bottom to top to illustrate topography, can be created first to serve as the foundation for the physical model. Common technologies such as 3D printing, computer numerical control (CNC) milling, and laser cutting can be easily utilized to automatically generate topography layers based on input elevation data. (8b) Surface Objects: Once the ground model is complete, artists can utilize their skills to add objects to it, proceeding from bottom to top according to the detail level decided upon in previous steps. This may include elements such as traffic networks, vegetation, buildings and facilities, lighting systems, vehicles, and people.

(9) The 3D physical model is the output for this procedure. This output model is visualized with a suitable detail level of the model and accurate dimensions for measurement reference as a map.

3. Materials and Methods for Production of Adequate 3D Model for Hologram Printing

3.1. 3D Hologram Model Data

In this study, we use one sample architectural model covered by a landscape area to test the feasibility in using a hologram printer to produce a hologram model. One advantage of a 3D holographic model over the traditional models is that the hologram printer directly reproduces the visualization model captured from the digital model created in previous steps and creates a hologram. Therefore, the optimization step for model crafting methodology and detail-level definition is unnecessary for the hologram model, and practitioners do not have to reproduce any new content.

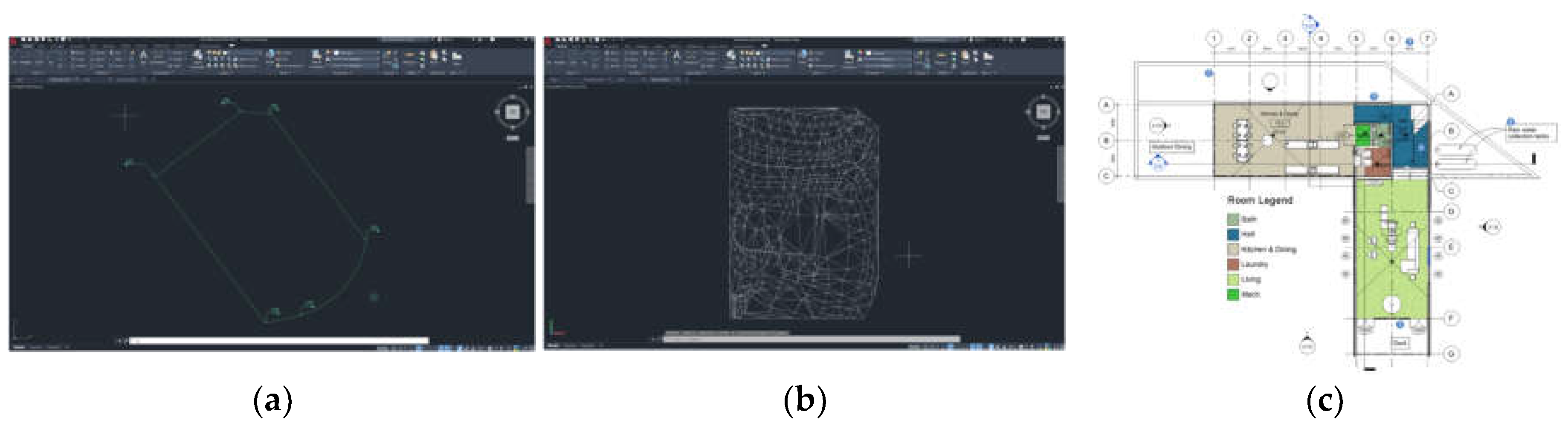

Numerous methods exist for creating 3D models, as discussed earlier. However, for this study, the research team focuses on developing architectural content using Autodesk software, specifically AutoCAD and Autodesk Revit. Revit, a robust 3D modelling software used in building information management, plays a pivotal role in minimizing errors that may arise during utilization and data transfer to other software platforms. As shown in the project construction process (

Figure 1), the source data for a hologram product comes from steps (4a) 3D digital model and (5a) Final design. In this research, we create an example based on the open data of a sample project belongs to Autodesk – “rac_basic_sample,” which can be found in Revit sample project files [

28]. This dataset contains all the essential data required for an architecture project, encompassing elements such as project boundaries, topography including elevation and contours, landscape features, foundations, building construction details, furniture, materials, and other facilities. In terms of 3D computer applications, we employ two software tools: Revit for generating precise 3D models with accurate dimensions, and Unreal Engine for incorporating realistic materials and landscapes, establishing lighting environments, and rendering the final output.

To prepare a good quality digital model for the printing step with CHIMERA, we used Revit for designing 3D prototype from scratch, using spatial and 2D data extracted from the data set of “rac_basic_sample.” In this step, using Revit is ideal to avoid the unnecessary heavy parts and the unwanted errors when transferring into Unreal Engine. According to the spatial information of the project boundary, contours, the construction pad stored in .dwg format that includes both dimensions, elevation, and the matching coordinates (

Figure 2) can be easily input into SketchUp software to produce the digital terrain model (DTM). We then used the construction blueprints of the house to generate the building at the location of the construction pads. In this step, the 3D digital prototype should be built carefully to maintain the accuracy. All the polygons representing different type of surfaces were defined by suitable materials in the Revit library (

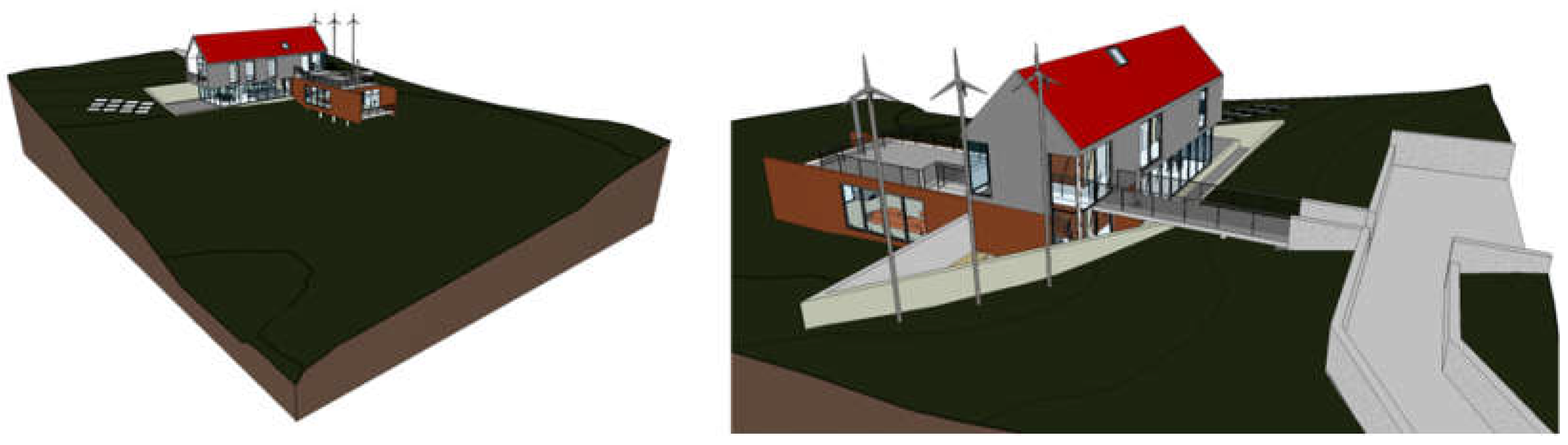

Figure 3). In this step, the model is not required to be realistic, because its main purpose is to simply represent the building’s shape and topography with accurate dimensions and elevation, as well as all the important 3D components and the differences in the prototype material. We then used the plugin Datasmith to bring the whole in construction scenes and models from Revit to unreal engine.

The next step involved crafting our prototype and incorporating additional elements such as vegetation, water surfaces, materials, lighting effects, and special environmental effects in real-time visualizations (

Figure 4). The reason for utilizing Unreal Engine for this stage is twofold: it is easily accessible without any fees, and it offers real-time rendering capabilities. In comparison to other rendering software that relies on traditional offline rendering methods such as 3Ds Max, V-ray, and Lumion, Unreal Engine excels in rendering entire scenes, including special effects of the real environment such as reflections, shadows, and transparency. Traditional offline rendering methods can be time-consuming, especially when dealing with high-detail scenes featuring realistic materials and intricate lighting effects at high resolutions. Moreover, post-editing and environmental adjustments further extend the rendering process. Conversely, real-time editing not only allows us to observe every change in the scene as we work but also significantly reduces rendering times. Instead of rendering, we can record the scene using cameras key-framed in Sequencer along predefined paths defined by the designers [

29,

30]. In real-time ray tracing rendering techniques, the software can render images every few milliseconds (ms), achieving speeds of 16ms per rate for 60 frames per second and approximately 33ms per rate for 30 frames per second. The ability of Unreal Engine to deliver such high speeds in generating final images or video sequences is a game-changer for producing digital content for holograms.

3.2. 3D Hologram Model Processing

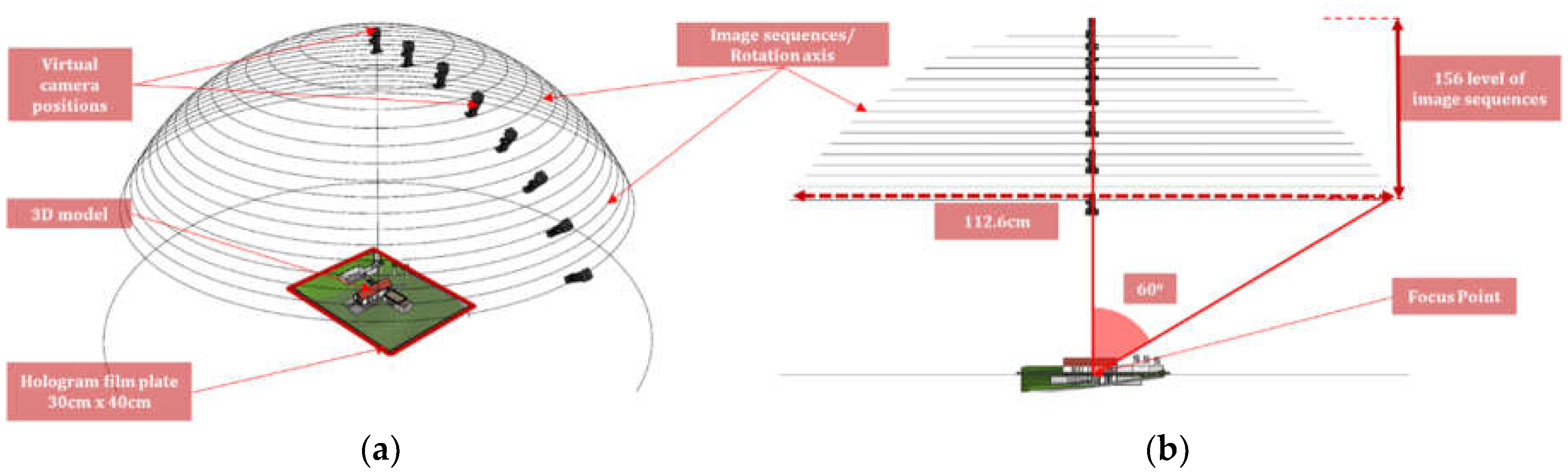

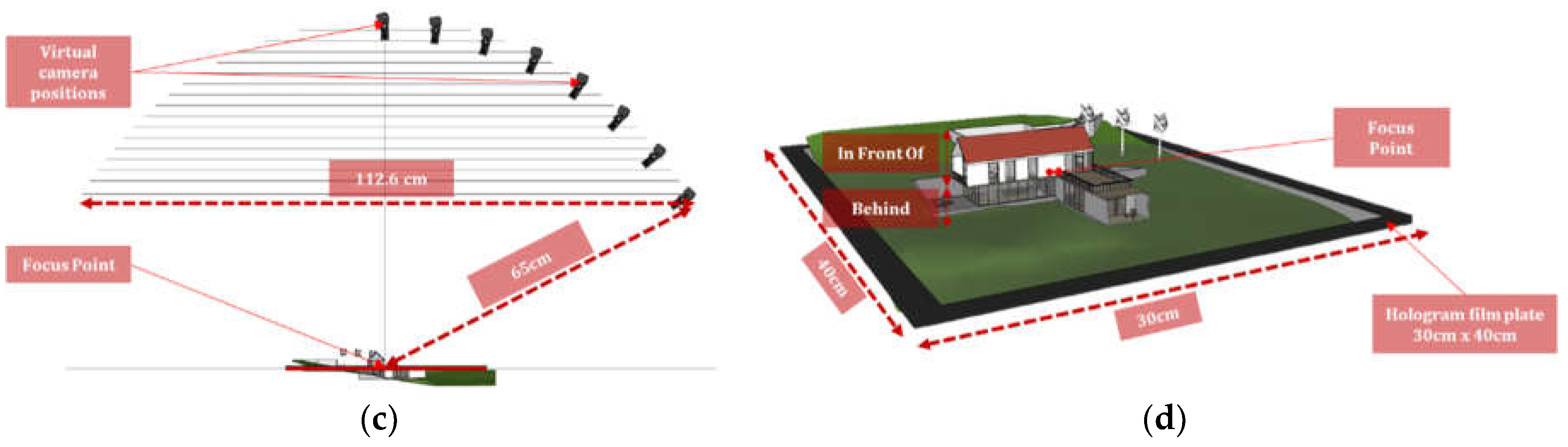

As informed in the

Figure 1 at step (6h) Scale definition and scene capture: Employing the hologram method offers several advantages over physical 3D models at this stage. First, there is no need for optimization as all content displayed in the 3D model within the software, regardless of size, can be visualized uniformly in the tabletop hologram at any desired scale. Performers are relieved of the burden of deciding which details to include or omit based on different scales, streamlining the visualization process significantly. In this research experiment, a holographic display measuring 30cm × 40cm was utilized, necessitating the adjustment of 3D digital content to fit within the same dimensions when determining the camera position in Unreal Engine. In addition to enabling users to observe content from all angles around the hologram tablet, it is possible to create the illusion of elements floating beyond the frame of the object with the correct digital 3D content recording and hologram printing setup. In

Figure 5d, the sections of the building positioned in front of the holographic display will appear to float in the final product, while those situated behind will be depicted below the glass. In prior studies involving the creation of hologram products utilizing the CHIMERA printer, most products were designed to convey content vertically [

19]. The process of recording content in software such as Blender, 3Ds Max, or Unreal Engine involves creating image sequences resembling half cylinders positioned directly in front of the object [

19]. However, in this study, to capture 3D content and obtain a full parallax tabletop hologram, the image sequences are arranged to form a half sphere above the object (

Figure 6). With the orientation of those virtual camera image sequence paths, the field of view of the final tabletop hologram can be up to 120° circular around the model.

The image sequences are set as circles surrounding the building, with a gradually decreasing diameter from low to high level (

Figure 5a–c). These circles lie on a sphere whose center is the selected focus point as shown (

Figure 6d). Therefore, the virtual camera is oriented and rotated based on the rotation axis around a focal point (

Figure 5b). For this experiment, the focal point was selected to be on the first floor of the building at the building's front. This focal point will also be situated on the plane of the hologram film plate on the display. To record and generate a 30cm × 40cm hologram, the configuration of the virtual camera system for rendering the model is established as follows. The distance from the virtual camera positions to the focus point is precisely set at 65cm. The lowest level is calculated from the circle at the position where the virtual camera position is on the image sequence path creating a 60° angle with the line perpendicular to the holographic plate at the focus point position. At this level, the diameter of the circle image sequence is approximately 112.6cm (

Figure 5b,c). The total number of images captured from virtual camera at all levels is set to 120,000, to ensure that the image data collection is equally divided for all perspectives in the sphere's 156 levels. In practice, the number of images gradually increase as the diameter of the circle sequence image increases (note that there are 156 levels of image sequence despite the limited number of levels in the figure). This means that at the highest level at the top of the sphere, the virtual camera only takes one photo from the top view. Conversely, the highest number of photos is taken by the virtual camera located at the lowest level (

Figure 6b,c). At the highest level, the number of images taken by virtual camera around the model is 1 and at the lowest level. The total number of images collected is 21,597.

The cameras rotating 360° around the building and forming a half sphere mirrors the audience's viewing angle for a tabletop. When observing 3D content displayed in a tabletop hologram, such as architectural or urban visualization, the audience tends to move around the hologram's location. The virtual camera's rotation and collection of complete image data aim to create a comfortable viewing experience for the audience and minimize distortion as much as possible. Setting up image sequences for virtual camera is done in the unreal engine software. The resolution of the images is 880 × 880 pixels, and the rendering time to collect image data is approximately around 80 minutes for 120,000 images at 24fps. Before moving on to the hologram printing stage, the final product can be aligned by cropping the printed content again to match. In the case of the experiment in this study, the final hologram product was cropped to a size of 30cm × 40cm.

As informed in the

Figure 1 at step (7h) Hologram printing: With the amount of scene image data collected at the end of this step, countless prints and copies of the hologram visualization can be created with the CHIMERA printer. If there is any adjustment to the digital 3D model, designers can simply adjust and repeat the image sequence rendering with the same settings. Using the hogel generation software, a hologram can be printed at different sizes, resolutions, and printing speeds [

19]. In this experiment, the hologram is printed at a resolution of 250μm with a speed of 60Hz (60 hogels per second). The total time of printing a 30cm × 40cm hologram display is approximately 8.8 hours. According to the methodology been presented by Gentet [

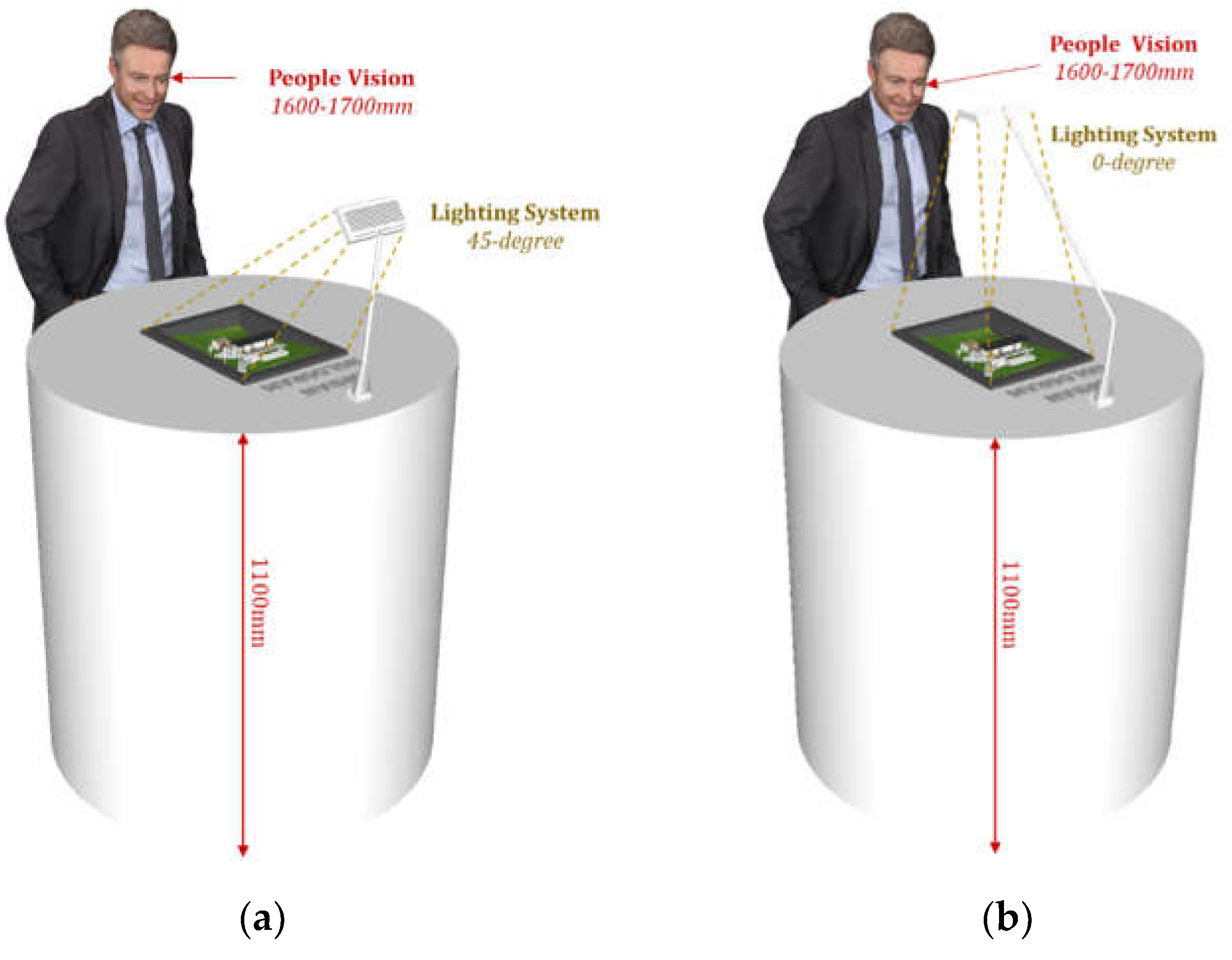

19], the holographic printer uses a recording system that has low-power commercial lasers. The image information corresponding to each hogel is recorded into the holographic plate using 45° reference or zero-degree angle, depending on of the purpose of the 3D content showing. As mentioned earlier in this study, the hologram is recorded on a U04 silver-halide holographic glass plates. After the printing finish, the experiment practitioner has to develop the hologram with a post processing chemical treatment. Finally, the hologram product can be sealed for protection.

3.3. Hologram Output

As informed in the

Figure 1 at step (8h) Hologram visualization: Once the 30cm × 40cm sealed full-color 360° full-parallax CHIMERA, recorded from the image data, is produced, an RGB LED lamp is employed to illuminate and reconstruct the hologram content. The lighting arrangement is positioned at either a 45° angle or directly perpendicular to the plane of the hologram - 0°, as shown in

Figure 6, depending on the angle at which the hologram was recorded in the previous step. This setup allows designers to create the desired exhibition ambiance according to their ideas.

The show case for 0o full parallax hologram can be seen in Video 1.

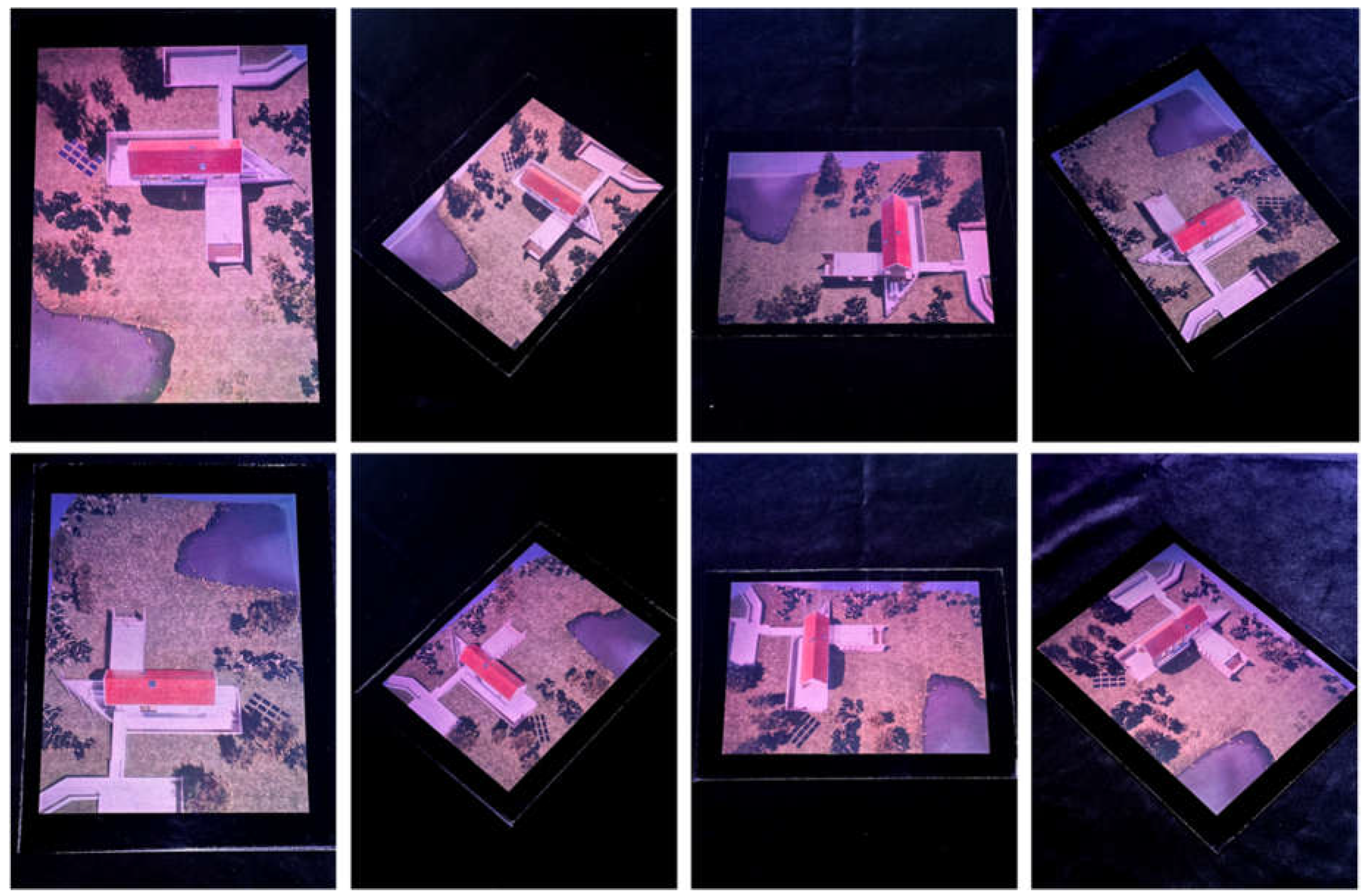

3. Results and Discussions

In this study, the research team conducted an experiment to visualize 3D content of a residential building and its surrounding landscape space using hologram technology. A 30cm × 40cm full parallax tabletop hologram was produced using the newest hologram printer technology operating at a resolution of 250μm and a speed of 60Hz (

Figure 7). The hologram visualization produced using CHIMERA hologram printer technology exhibits remarkable resolution, and color rendition surpassing that of the Geola group's hologram products for architectural and urban projects. Despite its compact size of 30cm × 40cm, intricate details such as blades of grass, rocks, and interior furniture are distinctly visible to the naked eye. Furthermore, environmental effects generated in Unreal Engine, such as sunlight, shadows, reflections, and water surfaces, are faithfully reproduced with high fidelity. The parallax effect remains smooth when observing the hologram from various angles owing to the image interpolation process applied during hologram data generation. The absence of noticeable distortion while navigating around and viewing the holographic 3D content further underscores its impressive quality.

Achieving the same level of expressive quality as a 3D physical model, hologram production offers significantly greater efficiency in terms of time and effort. First, the standardization and utilization of technology minimize the need for manual labor and reduce the risk of human error throughout the entire process. Second, hologram printing takes less time compared to constructing an architectural or urban model with equivalent detail. Moreover, since most of the steps of hologram production are automated, designers can allocate their time to other tasks while the machines handle the production processing time. The hologram display is thin and lightweight, with a thickness comparable to that of a sheet of glass. The hologram is printed on Ultimate U04 ultra-fine grain silver halide glass plage and the 30cm × 40cm version just weigh approximately less than 1kg. Consequently, the flexibility in arranging the hologram presentation layout is notably enhanced. Furthermore, by employing the same hologram placement and RGB LED setup, multiple holograms can be seamlessly interchanged according to the designer's preferences.

4. Conclusions

Hologram technology represents a novel approach to visualizing architectural and urban projects, offering versatility across various applications such as professional projects, education, exhibitions, and heritage conservation. In this study, our research team successfully applied hologram methodology to depict an architectural structure and its surrounding environment. The input data comprised digital 3D content generated from Autodesk Revit and Unreal Engine software. Utilizing Unreal Engine, we created realistic environments and rendered image sequences. This hologram was printed using the latest generation of hologram printers, specifically the CHIMERA model, on Ultimate U04 ultra-fine grain silver halide holographic glass plates. The resulting product is a 30cm × 40cm full-parallax tabletop hologram that provided a circular 120° field of view around the model. The experiment's results highlight the potential of tabletop holograms as a new visualization method for real projects and education in architecture and urban design. Additionally, incorporating this approach into traditional project workflows is highly feasible, as the input data required for hologram technology can be fully accommodated.

While the hologram representation method demonstrates clear advantages in the fields of architecture and urbanism, the research team also identified some challenges associated with this solution. First, there is the limitation of technology. Although creating high-quality holograms, as demonstrated in this experiment, has become more accessible today, the CHIMERA hologram printer remains a new technology and has not yet been commercialized widely in the field of architectural and urban design. Second, there are limitations in real-time interaction capabilities. While hologram products offer immersive visualizations for 3D digital content, once the product is printed, the content becomes fixed and cannot be interacted with. This is in contrast to 3D physical model representation, which allows designers to engage interactively in comprehensive design projects. In the near future, as ICT and hologram technology continue to advance rapidly, successfully commercialized products will make this approach more accessible to designers, architects, and engineers. This study serves as a stepping stone for future research on applying hologram technology in architecture and urban design, aiming to address existing challenges in these fields.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on

Preprints.org.

Author Contributions

Conceptualization, Tam Do Le Phuc; methodology, software, Tam Do Le Phuc and Matteo Coffin and Philippe Gentet; software; validation, Tam Do Le Phuc and Philippe Gentet; formal analysis, Tam Do Le Phuc; investigation, Tam Do Le Phuc; resources, Philippe Gentet and Seunghyun Lee; data curation, Tam Do Le Phuc and Jumamurod Aralov Farhod Ugli; writing—original draft preparation, Tam Do Le Phuc and Narzulloev Oybek Mirzaevich; writing—review and editing, Tam Do Le Phuc and Yi Dongsu; visualization, Tam Do Le Phuc; supervision, Leehwan Hwang; project administration, Leehwan Hwang and Seunghyun Lee; funding acquisition, Seunghyun Lee.

Acknowledgments

This research was supported by the MSIT(Ministry of Science and ICT), Korea, under the ITRC(Information Technology Research Center) support program(IITP-2020-0-01846-003) supervised by the IITP(Institute for Information & Communications Technology Planning & Evaluation), This research is supported by Ministry of Culture, Sports and Tourism and Korea Creative Content Agency(Project Number: R??????????), The present research has been conducted by the Excellent researcher support project of Kwangwoon University in 2023.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Biljecki, F.; et al. Applications of 3D city models: State of the art review. ISPRS International Journal of Geo-Information 2015, 4, 2842–2889. [Google Scholar] [CrossRef]

- Chen, R. The development of 3D city model and its applications in urban planning. 2011 19th International Conference on Geoinformatics; IEEE, 2011. [Google Scholar]

- Sinning-Meister, M.; Gruen, A.; Dan, H. 3D City models for CAAD-supported analysis and design of urban areas. ISPRS Journal of Photogrammetry Remote Sensing 1996, 51, 196–208. [Google Scholar] [CrossRef]

- Al-Kodmany, K. Visualization tools and methods in community planning: from freehand sketches to virtual reality. Journal of planning Literature 2002, 17, 189–211. [Google Scholar] [CrossRef]

- Bowman, D.; et al. 3D User interfaces: theory and practice, CourseSmart eTextbook; Addison-Wesley, 2004. [Google Scholar]

- Ku, K.; et al. 3D model-based collaboration in design development and construction of complex shaped buildings. 2008.

- Lange, E.; Hehl-Lange, S. Making visions visible for long-term landscape management. Futures 2010, 42, 693–699. [Google Scholar] [CrossRef]

- Zhu, Q.; et al. Research and practice in three-dimensional city modeling. Geo-spatial Information Science 2009, 12, 18–24. [Google Scholar] [CrossRef]

- Kensek, K.; et al. Augmented reality: An application for architecture. In Computing in Civil and Building Engineering (2000); 2000; pp. 294–301. [Google Scholar]

- Wang, X. Augmented reality in architecture and design: potentials and challenges for application. International journal of architectural computing 2009, 7, 309–326. [Google Scholar] [CrossRef]

- Chi, H.-L.; Kang, S.-C.; Wang, X. Research trends and opportunities of augmented reality applications in architecture, engineering, and construction. Automation in construction 2013, 33, 116–122. [Google Scholar] [CrossRef]

- Korkut, E.H.; Surer, E. Visualization in virtual reality: a systematic review. Virtual Reality 2023, 27, 1447–1480. [Google Scholar] [CrossRef]

- Gentet, P.; Lee, S.-H. True holographic ghost illusion. Optics Express 2022, 30, 27531–27538. [Google Scholar] [CrossRef] [PubMed]

- Richardson, M.J.; Wiltshire, J.D. The hologram: principles and techniques; John Wiley & Sons: 2017.

- Saxby, G. Practical holography; CRC press, 2003. [Google Scholar]

- Gabor, D. A new microscopic principle. Nature 1948. [Google Scholar] [CrossRef] [PubMed]

- Denisyuk, Y.N. On the reproduction of the optical properties of an object by the wave field of its scattered radiation. II. Optics Spectroscopy 1965, 18, 152. [Google Scholar]

- Bjelkhagen, H.; Brotherton-Ratcliffe, D. Ultra-realistic imaging: advanced techniques in analogue and digital colour holography; CRC press, 2013. [Google Scholar]

- Gentet, Y.; Gentet, P. CHIMERA, a new holoprinter technology combining low-power continuous lasers and fast printing. Applied optics 2019, 58, G226–G230. [Google Scholar] [CrossRef] [PubMed]

- Klug, M.; Holdback, M.; Ferdman, A. Method and apparatus for recording 1-step full-color full-parallax holographic stereograms. U.S. Patent, Editor. 1998.

- Brotherton-Ratcliffe, D.; et al. Digital holographic printing using pulsed RGB lasers. Optical Engineering 2011, 50, 091307–091307-9. [Google Scholar]

- Fuhrmann, S.; Holzbach, M.E.; Black, R. Developing interactive geospatial holograms for spatial decision-making. Cartography Geographic Information Science 2015, 42, 27–33. [Google Scholar] [CrossRef]

- Bjelkhagen, H.I. Color holography: recent improvements and applications. In Practical Holography XXVII: Materials and Applications; SPIE, 2013. [Google Scholar]

- CGarchitectTV. Zebra Imaging Demo at Autodesk University 2009. 2010.

- HiH. Three-dimensional stereoscopic holographically-printed maps; 2012. [Google Scholar]

- Jovanović, D.; et al. Building virtual 3D city model for smart cities applications: A case study on campus area of the university of novi sad. ISPRS International Journal of Geo-Information 2020, 9, 476. [Google Scholar] [CrossRef]

- Kim, D.Y. A design methodology using prototyping based on the digital-physical models in the architectural design process. Sustainability 2019, 11, 4416. [Google Scholar] [CrossRef]

- Autodesk. Revit Sample Project Files.; p. 2024.

- Rodríguez González, E.; Casals, J.R.; Pérez, S.C. Application of real-time rendering technology to archaeological heritage virtual reconstruction: The example of Casas del Turuñuelo (Guareña, Badajoz, Spain). Virtual Archaeology Review 2023. [CrossRef]

- Shannon, T. Unreal Engine 4 for design visualization: Developing stunning interactive visualizations, animations, and renderings; Addison-Wesley Professional, 2017. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).