1. Introduction

Actions to reduce the planet’s temperature by 2º C, or 1.5º C, as recommended by the Intergovernmental Panel on Climate Change (IPCC), have generated a race to decarbonize the world economy. One of the main steps to achieve this goal is the use of non-fossil fuels such as hydrogen, biomass, and electricity, which are emerging as the most viable alternative energy sources on a large scale. Brazil holds a prominent position due to its potential to generate renewable energy from sources such as hydroelectric, wind, photovoltaic, and biomass.

Some countries, especially European ones, are leading the process of decarbonizing supply chain. One of the factors identified for the decarbonization of these chains is the replacement of fossil fuels with low-carbon emission fuels. Brazil seeks to contribute to the decarbonization process through the production of green hydrogen (which uses renewable energy in its production), ethanol (which it is the world leader in vehicle application), and the generation of electrical energy from wind sources, photovoltaic, and hydroelectric plants, which are fundamental for the production of green hydrogen.

The use of fossil fuels for electricity generation represents more than a third of annual CO2 emissions [

1]. Current estimates indicate that emissions from the energy sector are expected to grow by 130% by 2050, based on emissions from 2005, due to a lack of environmental policies or restrictions for future installations of units powered by fossil fuels [

1].

To reduce carbon emissions from the transport sector, the development of low-carbon energy technologies must be accelerated, allowing us to face the challenges of energy security, climate change, and sustainable development [

1].

Another option is CO2 capture and storage (CCS), which is recognized as a technology capable of significantly reducing the volume of greenhouse gases. It is an important part of the portfolio of alternatives necessary to achieve substantial reductions in global emissions [

2].

The traditional logistics chain needs to be restructured to help with this change in the energy paradigm, making the energy matrix of the chains more environmentally friendly, minimizing negative impacts, and improving their operational efficiency. This chain is responsible for the interaction between suppliers of raw materials and industrial productive assets, covering the stages of storage, transportation, distribution, and reverse flow.

The combination of the ability to respond, react, and overcome potential risks, vulnerabilities, and disruptions in the flow of goods, services, and/or information are characteristics of resilient supply chains [

3].

2. Methodology

The first step in the development of this work was the definition of the keywords that would define the topics to be covered. After defining these keywords, research was carried out to gather secondary data about the supply chain, green supply chain, and other topics covered in this work.

To collect the data, several research tools were used, including theses, articles, dissertations, magazines, databases, books, and other reference materials. Among the main sources were the CAPES Journal Portal, Scientific Electronic Library (SciELO), Web of Science, Google Scholar, and Supply Chain Management Review.

The main terms researched were Analysis of Resistance to Logistics Flows, Supply Chain, Green Supply Chain, Green Logistics, and Resilient Supply Chain. With the database ready, the current work was written after reading and understanding the subject, aiming to explain the topic in a practical way.

3. Review of Concepts

According to the Supply Chain Council (2005), the definition of a supply chain covers all efforts involved in supporting the production and movement of a product. Furthermore, monitoring and controlling a chain’s processes are the starting points for its management.

3.1. The Supply Chain

Chopra and Meindl (2010) [

4] explain that the supply chain encompasses all stages involved, directly or indirectly, in fulfilling a customer order. That is, it not only includes manufacturers and suppliers, but also transporters, warehouses, retailers, and customers themselves, managing the different existing flows, such as information, goods, and existing relationships with other companies that are involved in the process.

For Quinn (1997) [

5], a supply chain can be defined as all activities associated with the movement of goods from the raw material stage to the end user. In other words, a supply chain consists of the set of all operations carried out from the first supplier until the product is released to the customer. The structuring of this chain begins with the definition of the focus company and the analysis of the relationship with all suppliers and customers [

6].

3.2. Green Logistics

It refers to the set of policies and measures designed to reduce the environmental impacts generated by activities in the logistics sector [

7]. The global industry had to adapt to changes in legislation and consumer behavior at the end of the 20th century. For some time now, consumers have been giving preference to more sustainable products, seeking to know about the origin and issues related to the sustainability of the production process. For a product or service to be considered sustainable, it must meet the triple bottom line, that is, be environmentally correct, economically viable, and meet social programs. Therefore, green management in the supply chain has become an essential strategy for companies that want to be recognized as sustainable.

The idea of green management is in line with UN trends, as the goals of modern industry align with initiatives that protect and preserve the environment. In other words, we are dealing with production from raw materials to final supply.

To respond to this consumer market trend, supply chains took the following steps:

Focus on converting to a Green Supply Chain;

Adoption of fuels with a green seal;

Greater management of waste generated in the supply chain operation;

Reduction of waste.

Increasingly, consumers have become aware of the need to take care of the environment and how their day-to-day actions can impact it, and this is having an impact on industries. As a result of this change in behavior comes a consequent change in the strategy of operating logistics chains in a way that generates less impact.

The fact is that the industry is adapting, not only to avoid losing customers but also to guarantee compliance with international agreements in the countries where they operate. And it is with this need for adaptation in mind that the traditional logistics chain becomes green.

In practice, what we have are actions that protect and benefit the environment. Companies are investing in this and becoming responsible for having a more beneficial relationship with the environment and transforming this factor into a positive marketing program.

3.3. A Green Supply Chaim—GSC

All links along the chain generate environmental impacts that accumulate until they reach the final consumer, including the disposal of the product after use [

7]. Therefore, it is necessary to expand the vision to the entire chain and understand that it is necessary to identify the environmental impacts and opportunities for cost reduction in each link. Subsequently, a set of procedures can be proposed, which, through partnership policies and operational improvements, will bring benefits to the Green Supply Chain (GSC), in addition to reducing costs and generating new business opportunities.

In general, GSC is an integration that brings together members of the entire supply chain, including suppliers and partners, in the pursuit of better business performance. In other words, it occurs when there is an objective to reduce the impacts generated in the logistics process as a whole.

What are the key elements that make up the Green Supply Chain?

So far, the idea of reducing waste throughout the chain has been mentioned, but this is just one example among many. Supply chain management can also focus on reducing the use of packaging, waste generated during transportation of goods, reducing resistance to flows, etc.

Waste management is also one of the key elements of a Green Supply Chain. According to the UN Food and Agriculture Organization (FAO), a third of global food production is wasted in transportation. Therefore, one industry-wide strategy is to find solutions to reduce waste throughout the supply chain.

3.4. A Green Supply Chaim—GSC

The traffic corridors used by a supply chain that comprise its infrastructure. Regarding classification, distribution channels assume the configuration of a direct channel or an indirect channel:

Direct channel—the organization has greater control over the product, albeit at apparently higher distribution costs.

Indirect channel—external units to the organization take on the risks and burdens of distribution, reducing the manufacturer’s margin.

The traffic corridors consist of roads with traffic flow density and have as their origin/destination the main points of generation and consumption of products. To reduce travel times, traffic lanes prioritize non-resistant flows. To set up a green distribution channel, a study of flow routes should be conducted, which can significantly help in reducing air pollution.

3.5. Flow Resistance Analysis

In fluid mechanics, the layer of fluid in the vicinity of a bounding surface is the layer that limits where diffusive effects and the dissipation of mechanical energy are felt. The concept was introduced at the beginning of the 20th century by Ludwig Prandtl to describe the region of contact between an incompressible fluid moving relative to a solid.

When an object moves through a fluid, or a fluid moves around an object, the movement of liquid molecules near the object is disturbed, and these molecules move around the object, generating aerodynamic forces. The magnitude of these forces depends on the shape and speed of the moving object, as well as the mass, viscosity, and compressibility of the fluid.

In the case of water transport, building faster vessels has always involved hydrodynamics, a science that studies the reduction of drag in contact with a fluid. But things began to change with the return of sailing ships (replacing fossil fuel with wind), where it became necessary to reduce the aerodynamic resistance of ships. According to Donato and Passos (2014) [

9], there are factors proving crucial to reducing resistance to transport flow. One of the factors is aerodynamics, so that large ships can once again use wind propulsion.

The issue is that wind-powered ships are more affected by aerodynamic drag than fossil fuel-powered ships, which rely on the constant power of an engine. In the era of fossil fuel propulsion, the aerodynamic effect was not considered as important compared to the overall resistance of a ship in the water. But when it comes to wind propulsion, techniques often used in aviation and even automobiles can open up new possibilities.

In this way, researchers discovered a way to reduce a ship’s aerodynamic drag by 7.5%, resulting in a gain in energy efficiency and lower fuel consumption that makes all the difference for navigation.

For example, for an oil tanker originating in Saudi Arabia and destined for Japan, this would mean a reduction in fuel consumption of around ten tons, for a ship with hybrid combustion-wind propulsion [

8].

Coanda Effect

In shipping, one of the main sources of aerodynamic drag is the square rear part of the ship’s superstructure (the part that emerges from the deck). Creating a convex-edged design in the ship’s superstructure allows highly compressed air to flow between the “jet slots,” creating the Coanda effect that allows the air pressure in the ship’s hull to balance.

The new designs induce the Coanda effect around this area, which considerably reduces aerodynamic drag, decreasing resistance to flow and making the ship more energy efficient. This aerodynamic innovation in naval transport is based on the Coanda effect [Henri Marie Coanda (1886-1972)], which describes the tendency of a fluid to remain along an externally curved (convex) surface, rather than moving away from it.

The method can be used both in new ship designs and in the upgrade of traditional ships already in operation. These projects aim to reduce drag and consequently resistance to flow [

9].

3.6. Resilient Supply Chain

A resilient supply chain is identified by its resistance and recovery capacity, that is, the ability to resist or even avoid the impact of a disruption and, at the same time, to recover quickly. The risks of disruption for any global supply chain are at an unprecedented level. In an April 2020 survey, the Institute for Supply Management identified that 95% of companies had operational problems in their supply chains due to the COVID-19 pandemic. Risk management has always been a challenge in supply chains. Due to the interdependence between the links, a small problem in an isolated region can compromise an entire global supply chain. Therefore, when major trends and events emerge in the world, there is a potential for widespread disruption of the supply chain [

3].

4. Green Supply Chain Development

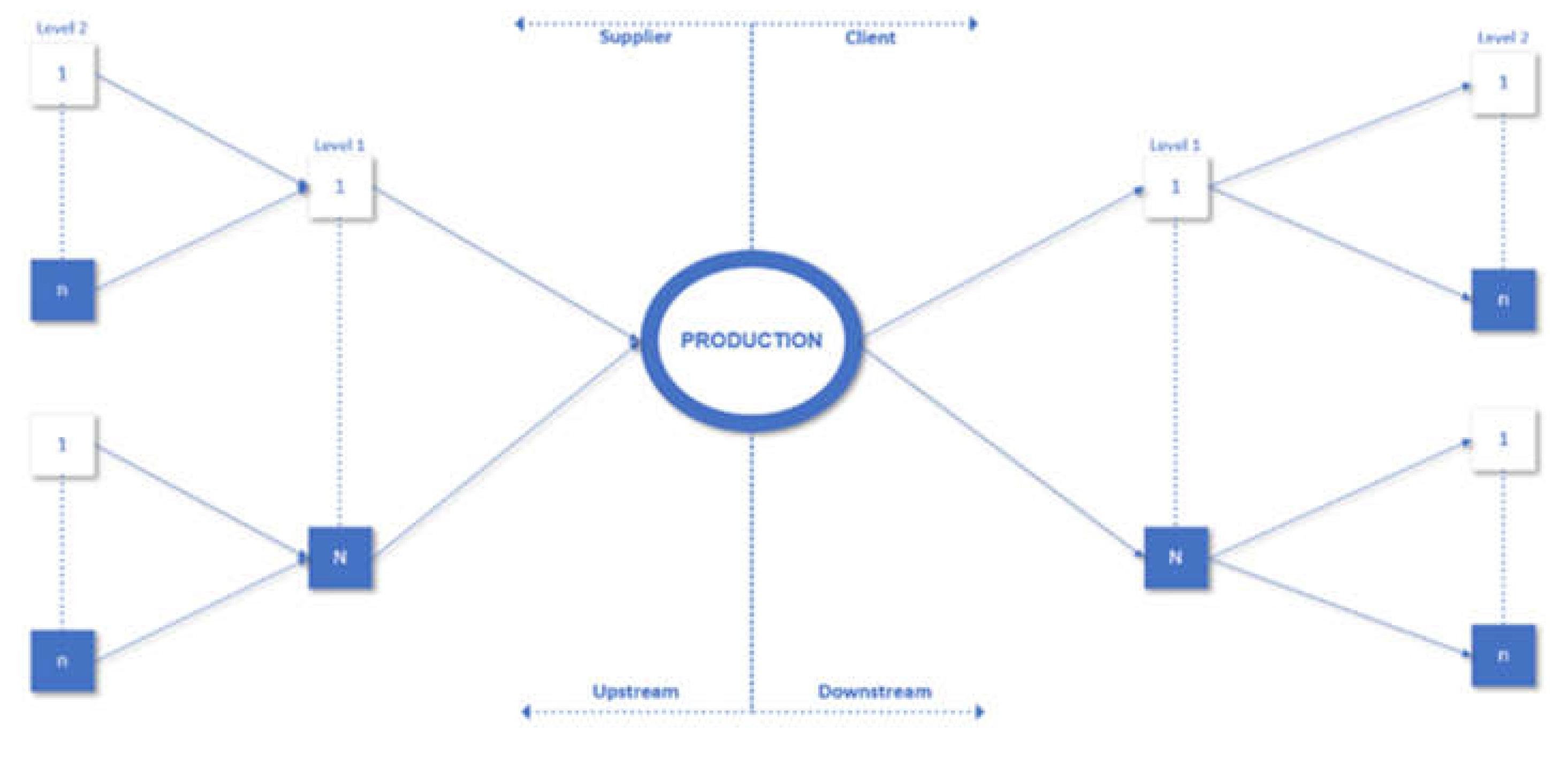

The supply chain must be analyzed in three stages: the Upstream stage, the Midstream stage (intralogistics), and the Downstream stage.

Figure 1.

Green Supply Chain Design [

3].

Figure 1.

Green Supply Chain Design [

3].

Level 2—At this level, industries processing the equipment that will be used for production can be mentioned. It is at this stage that an order is placed with the industry supplier.

Level 1—At this level are the raw material suppliers, where the raw materials used for production are sourced.

Level A—The transformation stage. It is at this stage that the core operations of industries in general occur.

Level B—At this level, the finished product is stored. In some cases, this stage is divided between industry and distributor warehouses. Managing storage areas is one of the biggest challenges in developing effective supply chain management.

Level X—This is the virtual stage, meaning it does not occur in a single link. This activity occurs simultaneously with all the others. It involves the flow of information regarding where and how operations take place. For example, it is at this stage that an order is placed from the distributor to the industry. It is supported by supply chain management software or even e-commerce platforms specialized in B2B.

Level 1—This level involves availability to distributors.

Level 2—This can include inventory in the channel and delivery to the end customer. It is at this stage that the relationship with the greatest asset in this entire chain, the customer, occurs. Without the customer, the logistics chain has no reason to exist.

5. Supply Chain Decarbonization Alternative

If the impact of decarbonizing supply chains is significant, the investment may be lower than expected. In all sectors, 40% of emissions can be eliminated with measures that generate economic returns for companies, either by reducing expenses or using new technologies that allow for greater logistical efficiency. One of the technologies is carbon capture; another is the decarbonization of the agribusiness chain.

5.1. Decarbonization by Carbon Capture

For a long time, techniques for reducing or eliminating CO2 present in the atmosphere were relegated to the background. Today, two are thriving: direct air capture (DAC) and carbon capture and storage (CCS). The DAC method consists of extracting CO2 that is already present in the air. However, as CO2 is dispersed in the air (420 parts per million, that is, around 0.04%), this technique consumes a lot of energy and requires more investment.

The CCS method captures CO2 at the point of generation using carbon capture and storage technology. This technology captures CO2 at the exit of the emission system generated by the combustion of fossil fuels. Once captured, atmospheric carbon can be stored and later used.

The petroleum industry has been using the CCS technique since the 1970s. Originally, this method was created to speed up the oil extraction process, but the climate crisis and public subsidies granted to the sector have revived the fossil fuel industry’s interest in using it to reduce pollutant emissions directly at the source, although this technique is not yet profitable.

Carbon Capture System Installed on Ships

Wärtsilä CCS-Ready scrubbers can adopt CCS onboard as an alternative decarbonization solution for the maritime fleet. Wärtsilä has received an order to supply its CCS-Ready scrubber for the first time, which will be installed on four 8,200 TEU container ships under construction in Asia. The CCS-Ready 35MW scrubbers will be implemented in an open-loop configuration. The scrubbers will also be designed to integrate with a particulate matter filter. According to the International Energy Agency (IEA), at the end of 2022, 35 commercial companies globally used this technology, capturing a total of around 45 million tons of carbon dioxide.

Cost of Technology

CCS technology costs between US$15 and US$20 per ton if CO2 flows are highly concentrated, and between US$40 and US$120 per ton if carbon flows are more diluted, for example, when emitted by power plants. As for the DAC technique, the process is even more expensive, currently costing in the range of US$600 to US$1,000 per ton of carbon extracted. However, according to the 2023 State of Carbon Dioxide Removal report, by 2050, costs are expected to fall to US$100 to US$300 per ton.

5.2. Decarbonizing the Agribusiness Logistics Chain

The use of renewable fuels in agricultural machinery can generate opportunities to reduce emissions for the economy as a whole, and agribusiness is no exception. The use of non-fossil fuels, such as biodiesel and others, is not yet prevalent in the sector’s machinery, in addition to its use in transport, which can contribute to reducing scope 3 emissions in the sector. Opportunities for the sector include the use of biofuels and the electrification of processes.

Generation of Carbon Credits and Payments for Environmental Services

The adoption of more efficient processes and the reduction of deforestation can reduce, avoid, or remove GHG (Greenhouse Gas) emissions, generating carbon credits that can be sold. Agricultural activities have great potential for generating carbon credits, which can represent an opportunity to differentiate companies that adopt more efficient practices. According to consultancy McKinsey, Brazil concentrates 15% of the global potential for generating carbon credits, and this market could reach US$50 billion by 2030.

The main sources of carbon credit generation in agriculture include:

Soil carbon fixation—according to the Intergovernmental Panel on Climate Change (IPCC), the potential for carbon capture by soil can reach 8.6 billion tons of carbon dioxide equivalent (CO2e) per year. Taking advantage of the full potential of carbon capture in the soil may require the adoption of practices such as planting species with deeper roots or the use of agroforestry systems and crop rotation, as well as the addition of organic materials to the soil.

Avoided deforestation—keeping the forest standing and reducing deforestation can also contribute to the generation of carbon credits, particularly considering that, in certain contexts, keeping the forest standing has an additional advantage as it requires adequate protection against possible pressures from logging.

Reforestation—the implementation of large-scale reforestation can contribute not only to the removal of carbon by planted species but also to the guarantee of ecosystem services, such as regulating the microclimate and protecting biodiversity.

The IPCC estimates the potential for CO2 removal through reforestation at between 0.5 billion and 10 billion tons of CO2e. Brazil has privileged conditions, as 80% of the potential for generating carbon credits in the country is concentrated in projects to restore degraded agricultural areas.

Other sources of removing emissions and generating carbon credits in agriculture may include energy efficiency, bioenergy with carbon capture (BECCS), avoided forest conversion (REDD), and, in the case of the biofuels sector, generation of decarbonization credits (CBIOs) in the RenovaBio program.

The process of generating carbon credits in agriculture can have significant costs, and ensuring integrity is extremely important, given the importance of guaranteeing high-quality credits with adequate management of social and environmental risks, in addition to robust mechanisms for negotiation and retirement of credits.

5.1. Use of Alternative Fuels in the Fleet

Fossil fuels used in supply chains are increasingly considered climate change villains (oil and its derivatives and natural gas). Alternative fuels are therefore necessary as they emit low levels of GHG.

Green Hydrogen

Hydrogen is considered green when it is obtained from renewable energy sources that don’t emit GHGs, such as energy generated by wind and photovoltaic equipment, and is sent to an equipment called a water electrolyzer, which decomposes water into hydrogen and oxygen once a certain voltage is applied.

Green hydrogen has been considered the key to global decarbonization. With an energy generation potential three times greater than gasoline, H2 can be used in industry, power generation, and transport, reducing GHG emissions. It is important to note that for hydrogen (H2) to be considered green (H2V), the logistics chain involved in its production and movement must be environmentally friendly [

10].

The Different Types of Hydrogen

The technology to produce hydrogen on an industrial scale is already known. Hydrogen produced industrially is classified, using a color code, according to the process, raw materials, and inputs used, according to chem4us, 2021 [

11]:

Purple hydrogen—hydrogen produced from water via nuclear energy powered electrolysis.

Turquoise hydrogen—hydrogen produced from natural gas by pyrolysis.

Brown and black hydrogen are produced from the gasification of mineral coal.

Gray hydrogen is produced with fossil fuels, especially natural gas. The process is highly polluting, as there are 10 kg of CO2 for every 1 kg of H2 produced.

Blue hydrogen is produced from the capture of CO2 in industrial chimneys. In this case, emissions are 1-3 kg of CO2 for every 1 kg of H2.

Green hydrogen is produced from the electrolysis of water (which can even be from the sea), using energy generated from renewable sources (wind and/or photovoltaic).

Moss hydrogen—hydrogen produced from the decomposition of biomass. In the process of biomass decomposition, GHGs are generated.

Other recent factors with an extremely disruptive effect on traditional supply chain practices are rapid changes in consumer behavior and unpredictable commercial and political climates.

Biomass Energy

Biomasses are hydrocarbons with an OH group. The best-known biomasses are methanol and ethanol; however, methanol is less used due to its toxicity, which can cause blindness and death. Furthermore, ethanol is easy to produce and is therefore more widely used.

The use of ethanol as fuel is a good alternative to fossil fuels. Alcohol fuel is cheaper than gasoline despite having a lower calorific value than gasoline, therefore requiring a greater consumption of alcohol to carry out the same work. Even though it is renewable and environmentally friendly, releasing only around 25% of the pollutants released by gasoline, however, it requires the use of pollutants in the production of the vegetables that give rise to it, such as pesticides and fertilizers (which are less aggressive). Alcohol also has a greater corrosive power than gasoline, dissolving some of the dirt inside the engine cylinders, keeping them clean.

Advantages of ethanol as a fuel:

Releases large amounts of energy when burned.

Has a lower production cost than gasoline.

It is renewable.

Releases only 25% of the pollutants released by gasoline.

Dissolves some of the dirt inside the engines.

Disadvantages:

Requires the use of pollutants in its production, such as pesticides and fertilizers.

Greater consumption is necessary as it does not have as high a calorific value as gasoline.

Large portions of land are needed to grow the vegetables that will create biofuel.

Wind and Photovoltaic Energy

The green Supply Chain operates by understanding and taking advantage of existing resources. In the case of wind energy, it is fundamental in the supply chain decarbonization strategy.

Eco-shipping is a set of actions aimed at decarbonizing maritime transport. The operation of the wind system is through rotor sails, with cylindrical rotors, which rotate to create a pressure difference to move the ship, based on the physical phenomenon of the Magnus effect. The use of this technology reduces fuel consumption to generate energy by the ship’s main engine. To do this, the winds must be favorable.

The use of this technology allows for efficiency gains of up to 6% and a reduction in CO2 equivalent emissions, that is, around 3,000 tons per ship per year.

6. Other Technologies

Other technologies that can be used to contribute to the decarbonization process of supply chains are:

The use of silicone paint on transport vehicles to reduce resistance to movement.

Use of frequency inverters to reduce electrical energy consumption.

Use of hydrodynamic devices to improve propulsion.

Use of real-time data collection systems to monitor energy consumption.

Provide visibility to the entire chain.

Replan geographic supply strategies (search for nearby suppliers) to reduce CO2 emissions from transport [

12].

7. Conclusion

Increasingly it is important for companies (of all production sectors) to master their entire supply chain. The most successful operations (from companies ranging from small to large) are supported by a 100% integrated chain.

In the increasingly competitive market, finding a profitable balance between supply and demand is a major challenge for all managers. Recently, many companies that have reduced expenses on diversification, information technology, and other measures have discovered the real cost of this decision. But, in the current situation of climate change across the planet, companies are rushing to invest in technology to decarbonize the supply chain. There are many possible benefits for business, such as:

More efficient operation: In general, with a higher level of decarbonization, the risk of disruption is minimized.

Greater productivity: Decarbonization of the supply chain contributes to a general increase in productivity throughout the system.

Risk reduction: Traditional supply chain operations typically pose greater risk. By nature, supply chains are dispersed across the world; their functionality is complex, and they are more vulnerable to risks. Supply chain decarbonization reduces risk, enables visibility into all network operations, and empowers companies to optimize and adapt processes and logistics in today’s world.

As can be seen, natural disasters, wars, and epidemic phenomena around the world can cause a global impact and have huge influence on supply chains, impacts caused by phenomena intrinsic to the processes or not. Another moment of disruption comes in the form of climate change with unexpected consequences, sudden market trends, and even rapid changes in exchange rates. The risk of interruption of operations in the fuel industry may threaten other production areas.

Adopting measures towards changing to a green supply chain will be one of the paths towards decarbonization. In addition to overcoming difficult times, companies can use this challenge to innovate and strengthen their business. Decarbonizing the supply chain is about more than surviving operational disruption.

Business leaders around the world agree that to be more resilient and competitive in today’s market will require major changes to supply chain strategies to achieve decarbonization of their supply chains.

References

- IEA. CO2 Emissions from Fuel Combustion. Accessed at http://www.iea.org/statistics; on 12/07/2023.

- SOCOLOW R., H. , PACALA S.W., A Plan to Keep Carbon in Check. Scientific American. v. 295, issue 3, p. 50-57. 2006. [CrossRef]

- DONATO, V. ; VIEIRA, C. S..; ANDRADE, M. S..; ALBUQUERQUE, R. V..; SANTOS, C. C. R.. Resiliência da Cadeia de Suprimento do Hidrogênio Verde. Revista Foco, [S. l.], v. 16, n. 1, p. e821, 2023. Disponível em: https://focopublicacoes.com.br/foco/article/view/821. Accessed on: 9 feb. 2023.

- CHOPRA, S. e MEINDL P. Gestão da Cadeia de Suprimentos: Estratégia, Planejamento e Operações. Pearson Universidades; 4ª edição. 2010.

- QUINN, F. J. What’s the buzz?. Logistics Management, v. 36, nº 2, 1997.

- LAMBERT D., M. COOPER M. C. Issues in Supply Chain Management. Elsevier Science Inc. New York, NY. 2000.

- DONATO, V. Logística verde, uma Abordagem Socioambiental. Ed. Ciência Moderna. Rio de Janeiro, 2008.

- XU, K. , SU X., BENSOW R., KRAJNOVIC S. Large eddy simulation of ship airflow control with steady Coanda effect. Revista Physics of Fluids. Vol.: 35, ed.31. 015112. 2023. [CrossRef]

- DONATO, V; PASSOS, F. U. Proposta e aplicação de um método, baseado no contexto das linhas de transporte de menor resistência, para qualificar cadeias logísticas de distribuição como uma cadeia verde. RECC – Revista Eletrônica Científica do CRA-PR, v. 2, n. 2, p. 47-61, Paraná, 2014.

- MARINHO, C. do B., DONATO, V. VIEIRA, C.S., ANDRADE M. S.. Analysis of the Port Environment for the Export of Green Hydrogen. Global Journal of Science Frontier Research: GBio-Tech & Genetics. v. 23, Issue 1, version 1.0. USA. 2023.

- CHEM.4.US. La chimie pour créer notre futur. Accessed at http://www.chem4us.be/une-question/ on 12/07/2022.

- SANTOS, C.C. R, & DONATO, V. Os impactos decorrentes da pandemia de COVID-19 nas cadeias de suprimentos. Revista de Gestão e Secretariado, 14 (4), 4794–4806. 2023. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).