1. Introduction

Overtopping is a more prevalent concern than other embankment failures worldwide. It is the most common mode of failure, accounting for 40–48% of the reported cases of embankment failure up to 1986 and 34% to date [

1]. Failures caused by overtopping are never predictable, and if not controlled promptly or protected properly, an overtopping event can lead to a catastrophic embankment failure quickly, resulting in huge damage to lives and properties in the communities that are located on the downstream side of the embankment [

2].

1.1. Factors Affecting Scour at Embankment Toe

Scour at the landside toe of the embankment during overtopping flow is one of the main reasons for the fragility of the embankment slope and levee breakage [

3,

4]. The initial scour depth, plunge pool height, and subsequent headcut migration are responsible for the breakage mechanism of the embankment and the total time required for complete failure of the embankment [

5,

6]. Several factors affect this scour, and from previous studies, the energy of the flow (dependent on overtopping depth and velocity) and geometry of the structure are important factors for understanding the extent of the scour hole [

4]. [

7] Ravindra Jayaratne et al. stated that several factors, such as overtopping height, soil permeability, levee geometry, and landside slope, are responsible for toe scour and subsequent levee failure. A mild slope reduces the scour depth and length at the toe [

7]. The tailwater depth and plunge pool adjacent to the scour hole can play vital roles in dissipating energy and the subsequent headcut migration speed [

5,

8]. Farhoudi and Smith investigated the similarity between scour profiles downstream of hydraulic jump. The bed load sediment was removed and deposited adjacent to the scour hole to form a dune and create a plunge pool. The coarser sand caused decrease in dune height gradually over time. However, when using finer materials, the dune is not clearly produced, resulting in no plunge pool formation [

9].

1.2. Local Scour Protection with Ripraps

Riprap is a permanent covering of large, angular stones, cobbles, or boulders used to armour, stabilize, and protect the soil surface against erosion and scour in regions of intense flow or wave activity. By understanding the scour characteristics, scour countermeasures are proposed to prevent the fragility of embankment landside slope in the future. [

10] Johnson et al. compared the effectiveness of four types of scour protection: riprap, coreloc, riprap with underlayer, and coreloc with underlayer to determine the scour characteristics and concluded that riprap combined with underlayer showed a significant improvement in minimizing the scour hole. Researchers have also used grade control structures, block ramps, and other ground improvement techniques to minimize scour and settlement [

11,

12]. One structural measure that has successfully solved the scour problem worldwide is constructing a block ramp structure in a stream [

13]. They also observed that rock sills performed better than other tested sills and dentated sills, and observed that the riprap can significantly affect scour depth and shape. Several studies have been conducted to investigate scouring characteristics and reduce the scour caused by overtopping. Several studies have been conducted on scouring by focusing on different variables, but the combination of several variables in a single study is rare. The tailwater depth and plunge pool adjacent to the scour hole can play vital roles in dissipating energy and the subsequent headcut migration speed [

5,

8]. Farhoudi and Smith investigated the similarity between scour profiles downstream of hydraulic jump. The bed load sediment was removed and deposited adjacent to the scour hole to form a dune and create a plunge pool. The coarser sand caused decrease in dune height gradually over time. However, when using finer materials, the dune is not clearly produced, resulting in no plunge pool formation [

9].

Stein et al. and Dargahi investigated the scour at equilibrium, scour profiles and the rate of scour hole growth by considering the effect of jet diffusion on sediment separation. It was observed from the experiment that the scour depth increased faster in the early stages of scour development and slowed over time. Deposition of sand was observed near the scour hole transported by the reversed flow. However, tailwater depth was not considered for scour depth prediction. Stein et al. and Dargahi concluded that quantity of scour holes was dependent on the bed material and flow discharge [

14,

15].

In this study, the effects of different hydraulic, geotechnical, and geometrical variables on downstream toe scouring and particle deposition were incorporated to better understand the scouring phenomenon and its countermeasures.

2. Materials and Methods

Experiments were conducted at the Hydraulic Engineering Laboratory of Saitama University, Japan. A recirculating flume is used in the laboratory. The flume is 15m long, 0.30m wide, and 0.6m high.

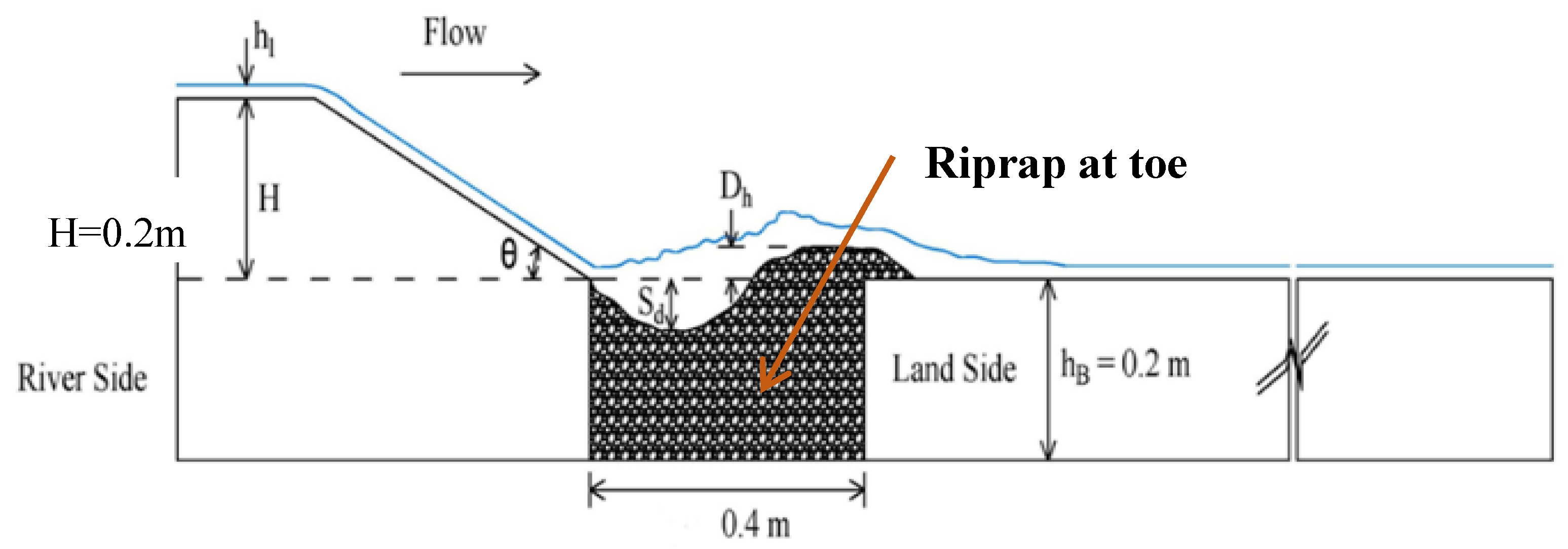

Figure 1 shows a typical diagram of the experimental channel setup.

The embankment model was constructed using plywood. Checking the water level at three different points, namely downstream, in the center, and upstream of the crest, ensures that the crest of the embankment is always completely horizontal. Three different downstream slopes of the embankment were prepared: 1V: 2H, 1V: 3H, and 1V: 4H. The height of the embankments was maintained at 20 cm for all cases, and the overtopping flow depth during all experimental cases was ensured to be 1, 2, and 3 cm. Throughout the experiment, a constant water flow was maintained using an intake pump. The experimental setup used in the laboratory is shown in

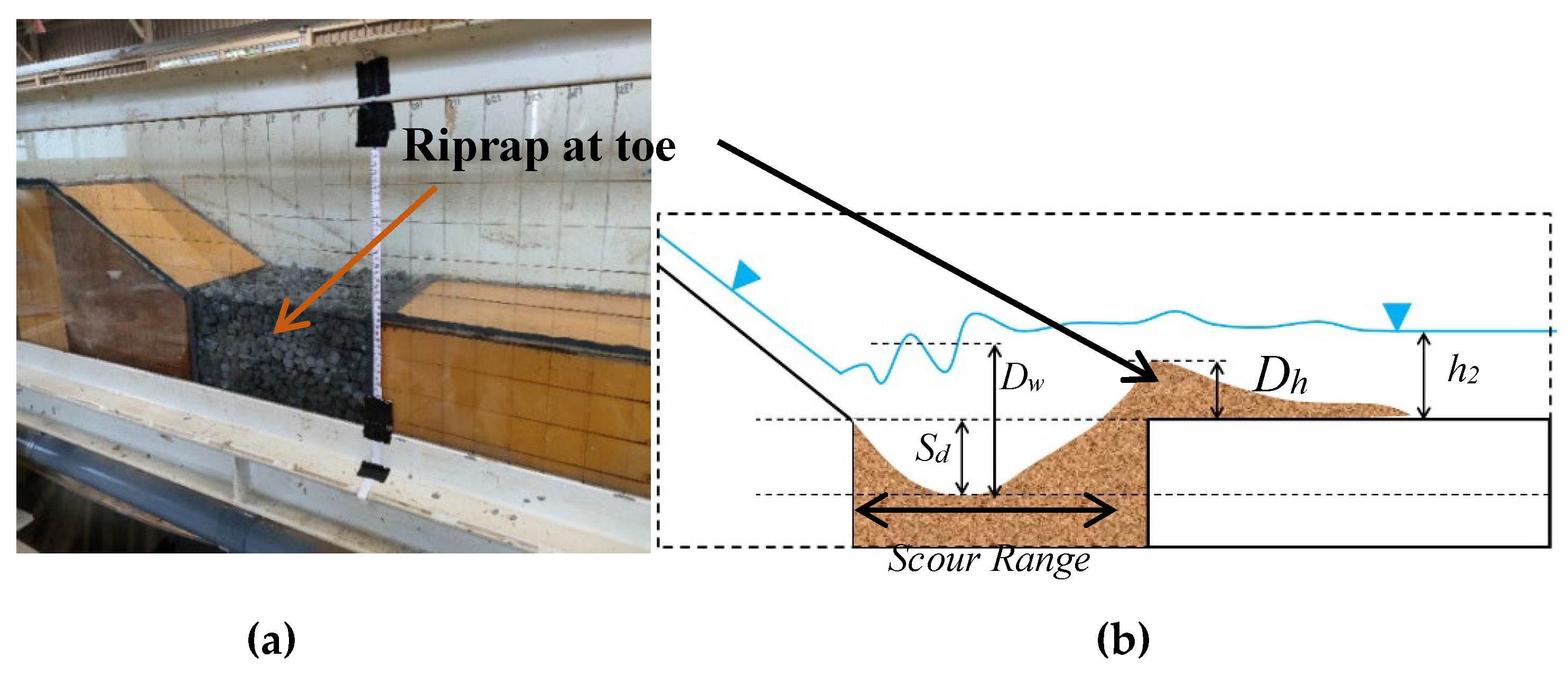

Figure 2a. Ripraps were used at the downstream toe of the embankment model.

To calculate the relative energy loss, the initial energy head

(E1) at the middle of the embankment crest and the final energy head

(E2) after the hydraulic jump were considered. Considering the datum is on the soil surface (across the embankment downstream slope toe), the energy head,

E1 and

E2 were calculated as,

Where,

h2 = water depth at the section after the scour hole

h1=hc = critical water depth

V2 = flow velocity corresponding to h2 and B is the channel width

V1 = flow velocity at the end of the embankment crest

g = gravitational acceleration.

So, velocity (V1) can be expressed in terms of overtopping flow depth, h1, and flow discharge, Q as-

q=Q/b = flow discharge per unit width

b =B= embankment width or channel width.

In addition, the scour hole depth (

Sd), deposition height (

Dh), plunge pool depth (

Dw), and tailwater depth, as shown in

Figure 2b, were measured during and after each experimental run.

2.1. Materials and Equipment

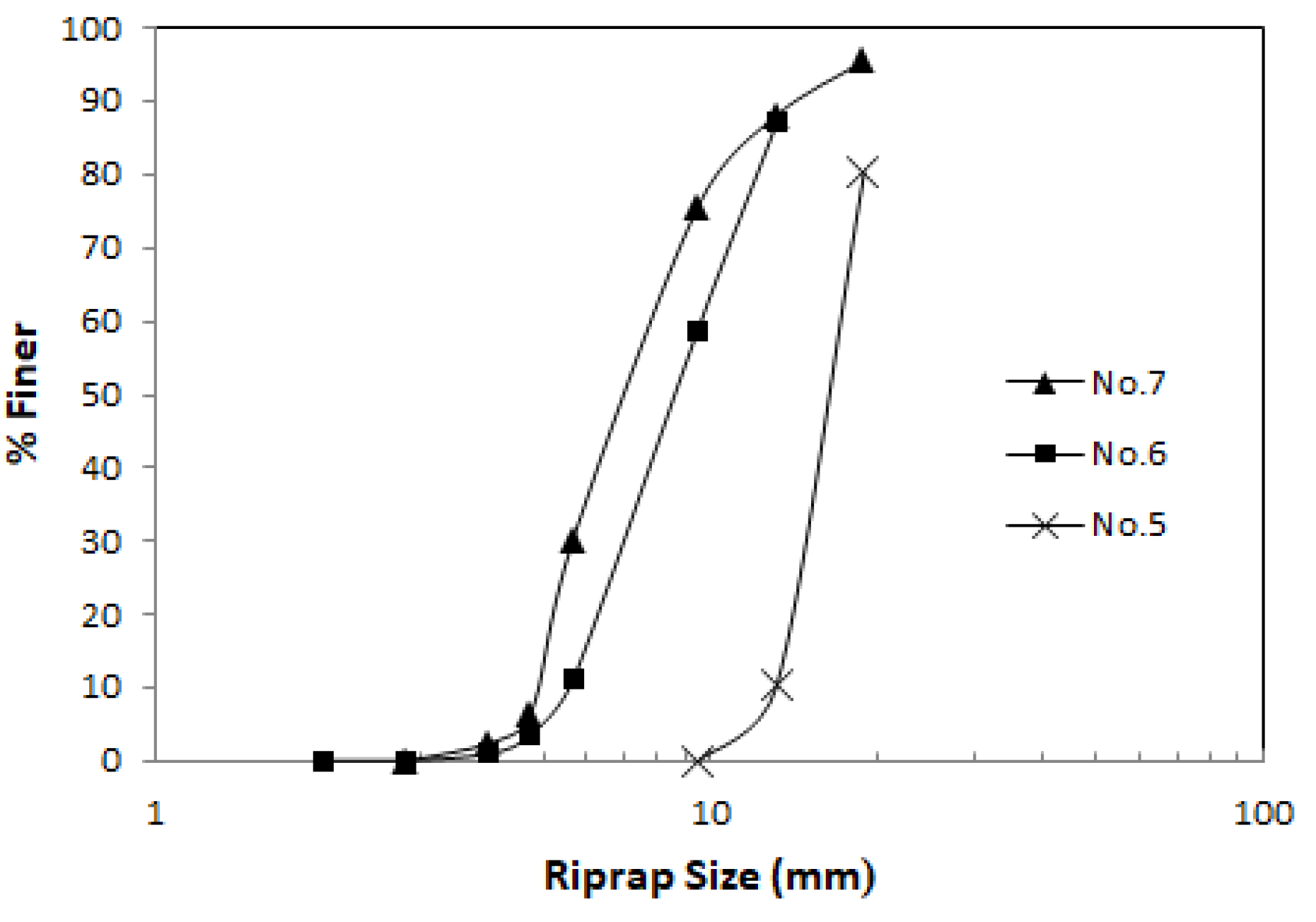

Three different sizes of riprap particles were used at the downstream toe of the embankment model. To determine the median diameter and gradation curve for each riprap particle, three samples were collected. Riprap Particles’ median diameters were found to be 16.41 mm, 8.48 mm, and 3.39 mm and herein referred as No 5 size, No. 6 size, and No. 7 size respectively. The gradation curves of the three types of riprap are shown in

Figure 3.

For this study, a total of 27 experimental cases were performed, as listed in

Table 1, and overflow was continued until equilibrium was achieved. When erosion and deposition reached equilibrium, the water pump was stopped.

The depth of the scour hole (

Sd), plunge pool depth (

Dw), and height of deposition (

Dh), as shown in

Figure 2b, were measured from the 3D contours of the embankment models obtained from the 2D laser scanner with Light Detection & Technology (model: LJ-V7300, manufacturer: Keyence) after every experimental cases. A point gauge was used to measure the tailwater surface profiles inside the channel. The bed profile was measured along the centerline of the channel using 2D laser scanner.

3. Results

3.1. Typical Development of Scour and Deposition Characteristics

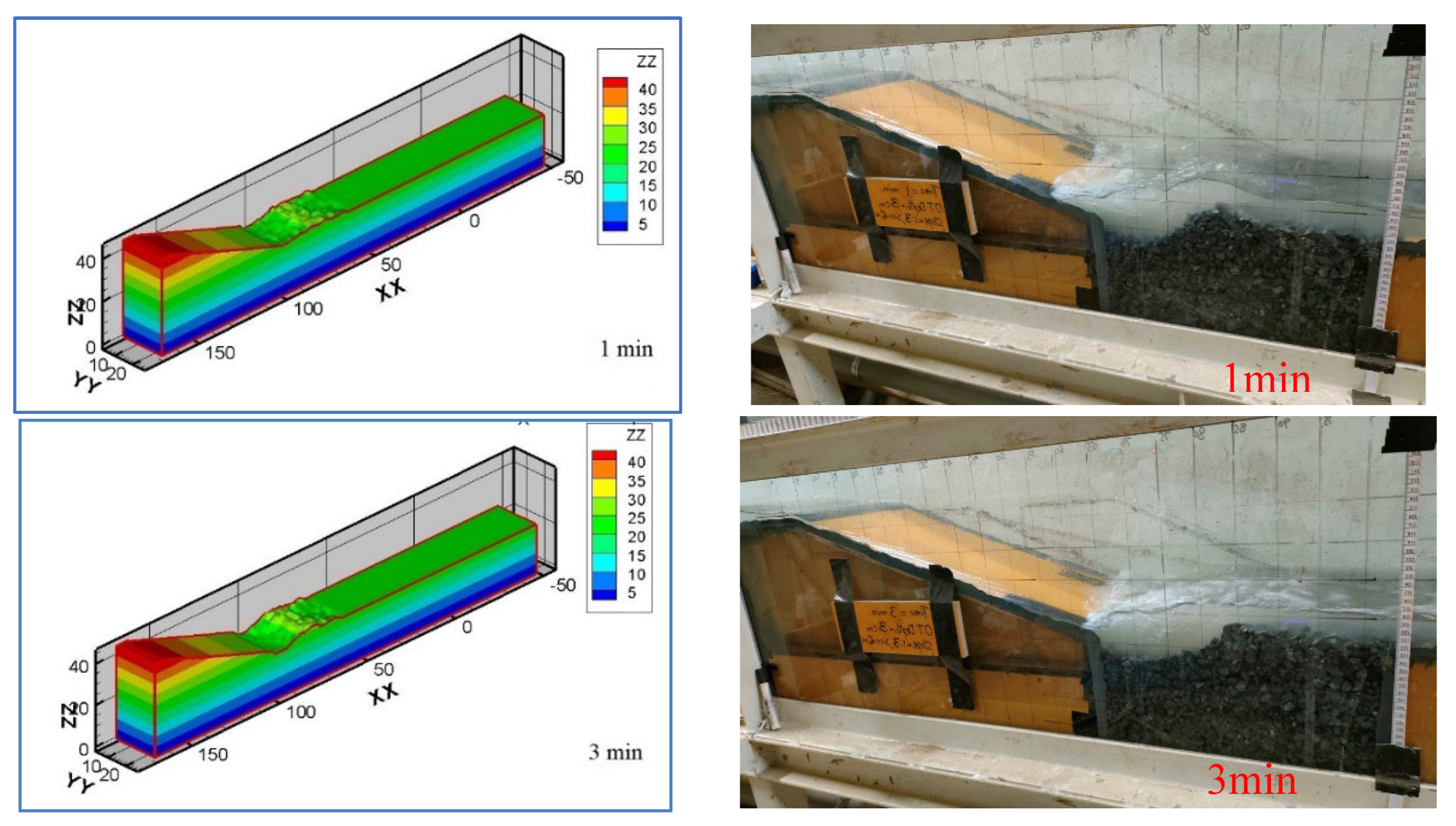

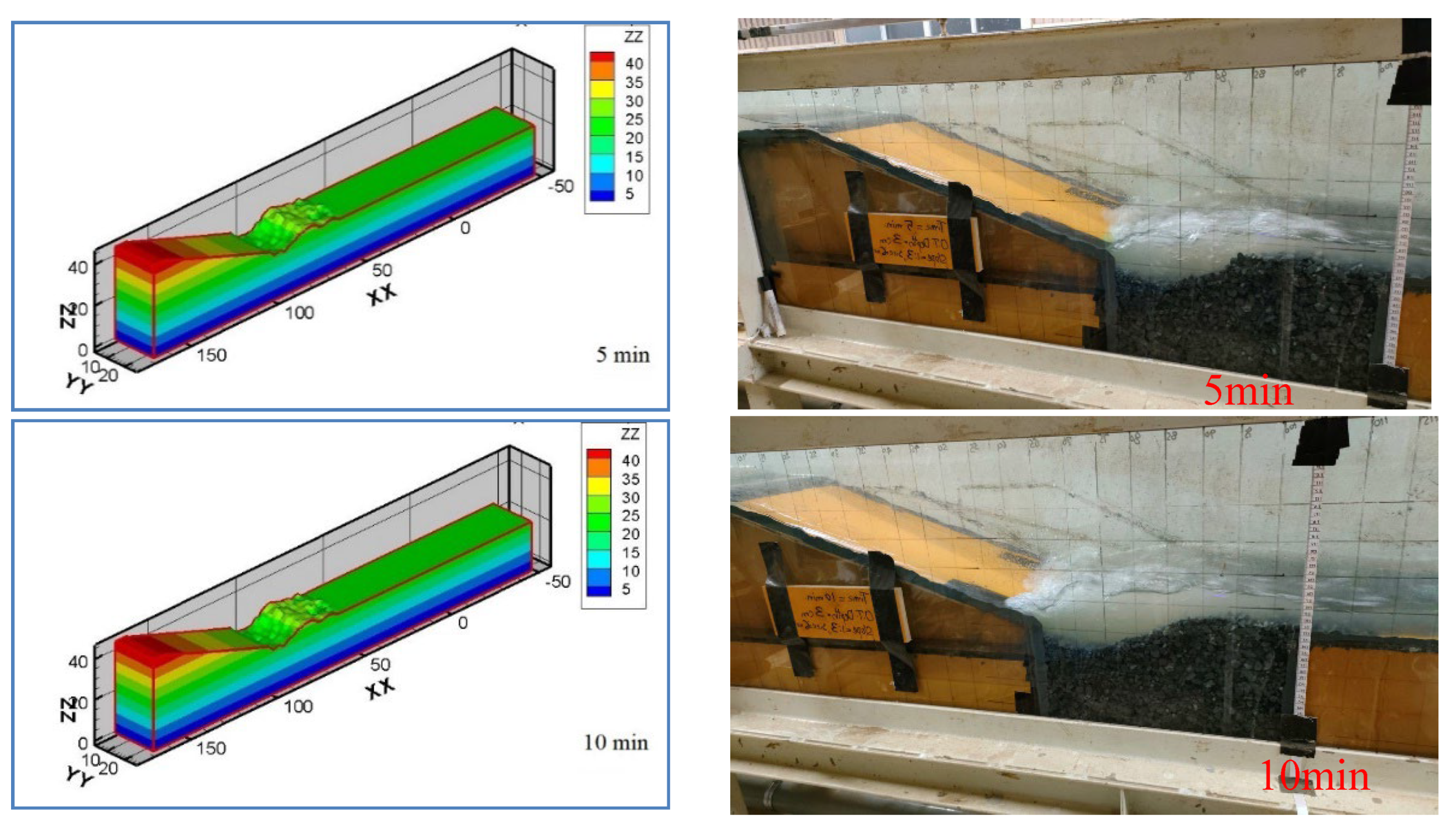

The maximum scour depth and deposition height were monitored and measured over time.

Figure 4 shows the typical development of the scour and deposition. As a representative example, the development process of scour and deposition of ripraps for the M-C-h3 case is shown. The figure shows that the development of scour and deposition was faster in the early stage of the flow (1 minute) and continued up to the second stage (2 minutes). In the third stage (3 minutes), the scour and deposition rates decreased. In the fourth stage (5 minutes), the scour and deposition of the ripraps particles reached an equilibrium state, which was confirmed by the development of the fifth stage (10 minutes). This trend was similar for all the other cases. Based on this, 15 minutes was considered the time required to attain equilibrium.

It was also observed that the maximum scour occurred for a 3 cm overtopping depth, and riprap particle size No. 7 gave the highest scour depth. On the other hand, particle No. 5 had the lowest scouring depth and highest deposition height compared with the other sized particles for all the experimental cases.

3.2. Effect of Energy Head on Scour Depths

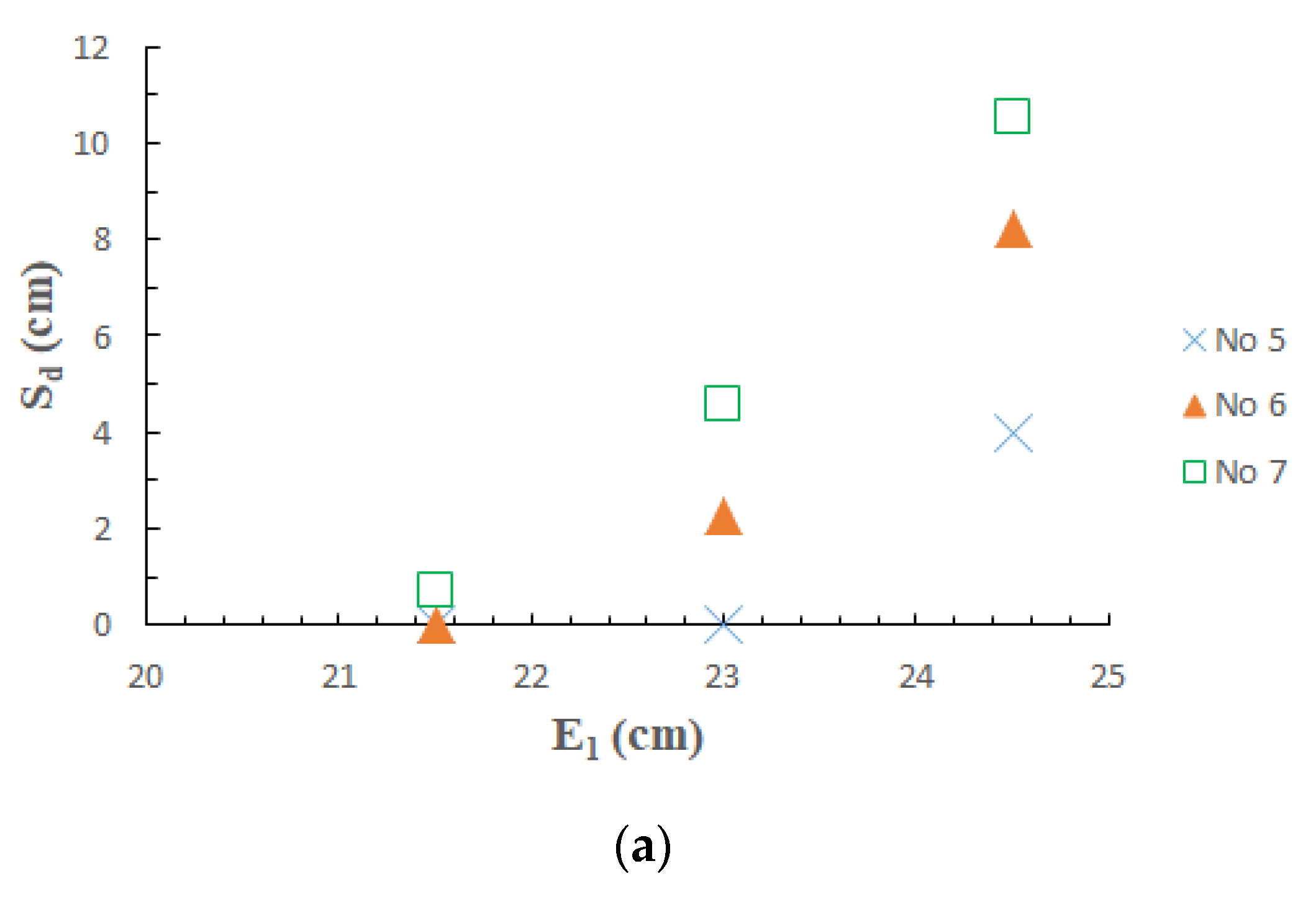

From

Figure 5, it is observed that the scour depth (

Sd) increases with an increase in the energy head for riprap particles of the same size. For the same energy head, the scour depth increased with decrease in particle size

, and the other two slope conditions also showed the same results. For the steep slope (1:2) case, with an increase in

E1 (dependent on overflow depth), the scour depth (

Sd) also increases irrespective of the riprap size. On the other hand, in the case of the gentle slope (1:4), the development of scour depth (

Sd) slowed despite the increase in

E1. The reasons behind this different scenario were the change in flow pattern depending on the steepness or mildness of the downstream slope and the creation of a larger plunge pool depth. On average, for the 1:2 slope case, No. 5 size particle can develop scour upto 62% and 75% less than from No. 6 and No. 7 particles, respectively. Subsequently, for the 1:3 slope case, this is 31% and 46%; and for the 1:4 slope case, this is 39% and 49% less than that for the No. 6 and No. 7 sized particles, respectively.

3.3. Effect of Energy Head on Deposition Height

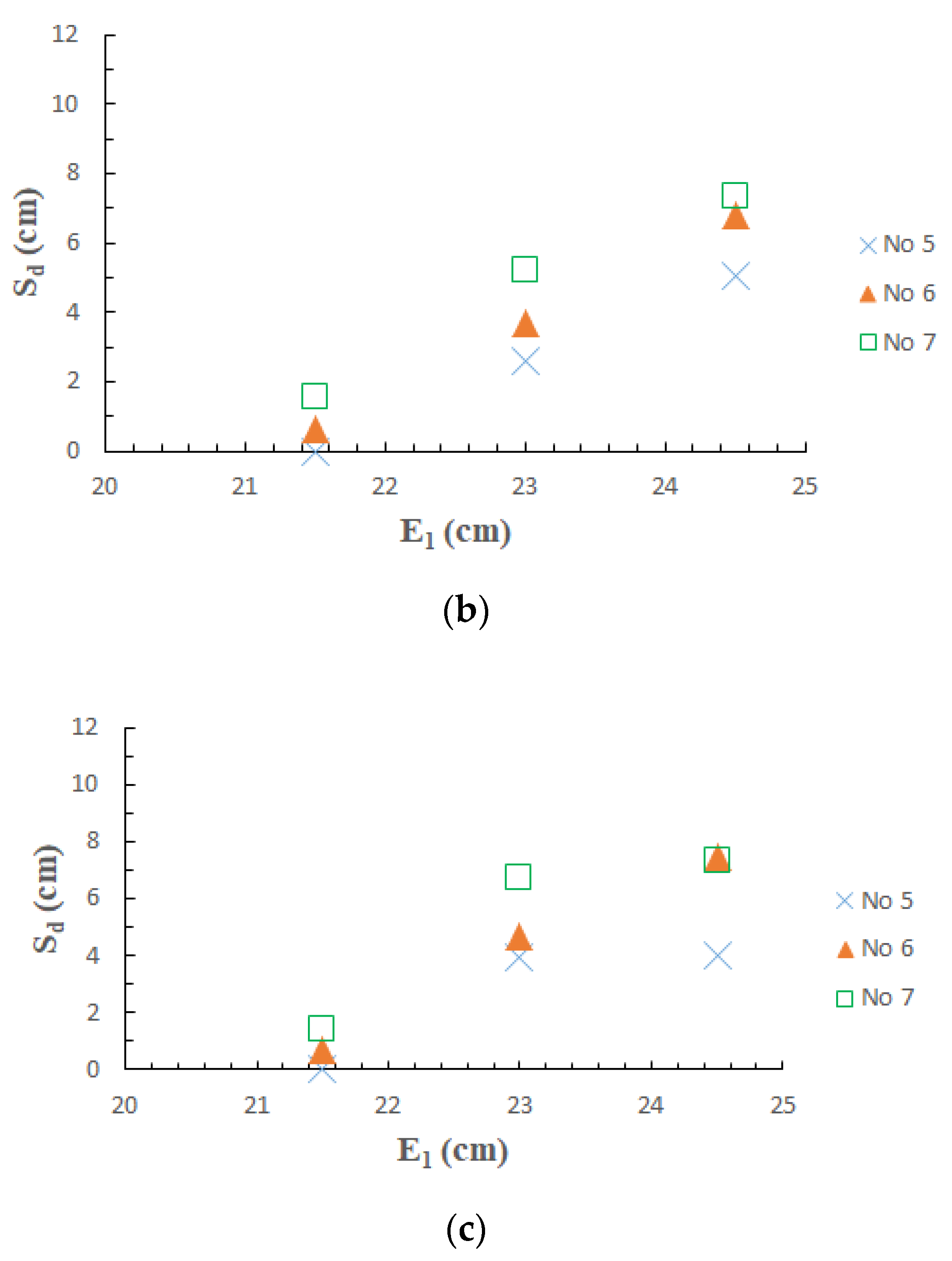

Figure 6 shows that for all particle sizes, the deposition height (

Dh) increases with an increase in the energy head. The deposition height gap between the 2 and 3 cm overtopping depths for the particles was higher for the

1:2 and

1:3 slope conditions. However, for the 1:4 slope condition, this difference is low, and the values are 2 cm and 3 cm for No. 5 size particle; 3.06 cm and 3.46 cm; for No. 6 size particle; 3.19 cm and 3.38 cm for No. 7 size particles, respectively. This is because in this slope, the flow of water is faster, and with scouring, the particle is blown downstream owing to the horizontal component of the flow. This is why the deposition was not very high with the eroded particles. In all slope cases with a 3 cm overtopping depth, particle No. 5 had the highest deposition height. The No. 5 particle size can create 10% and 20% more height of deposition compared to the No. 6 size and No. 7 size particles, respectively.

3.4. Effect of Energy Head on Plunge Pool Depth

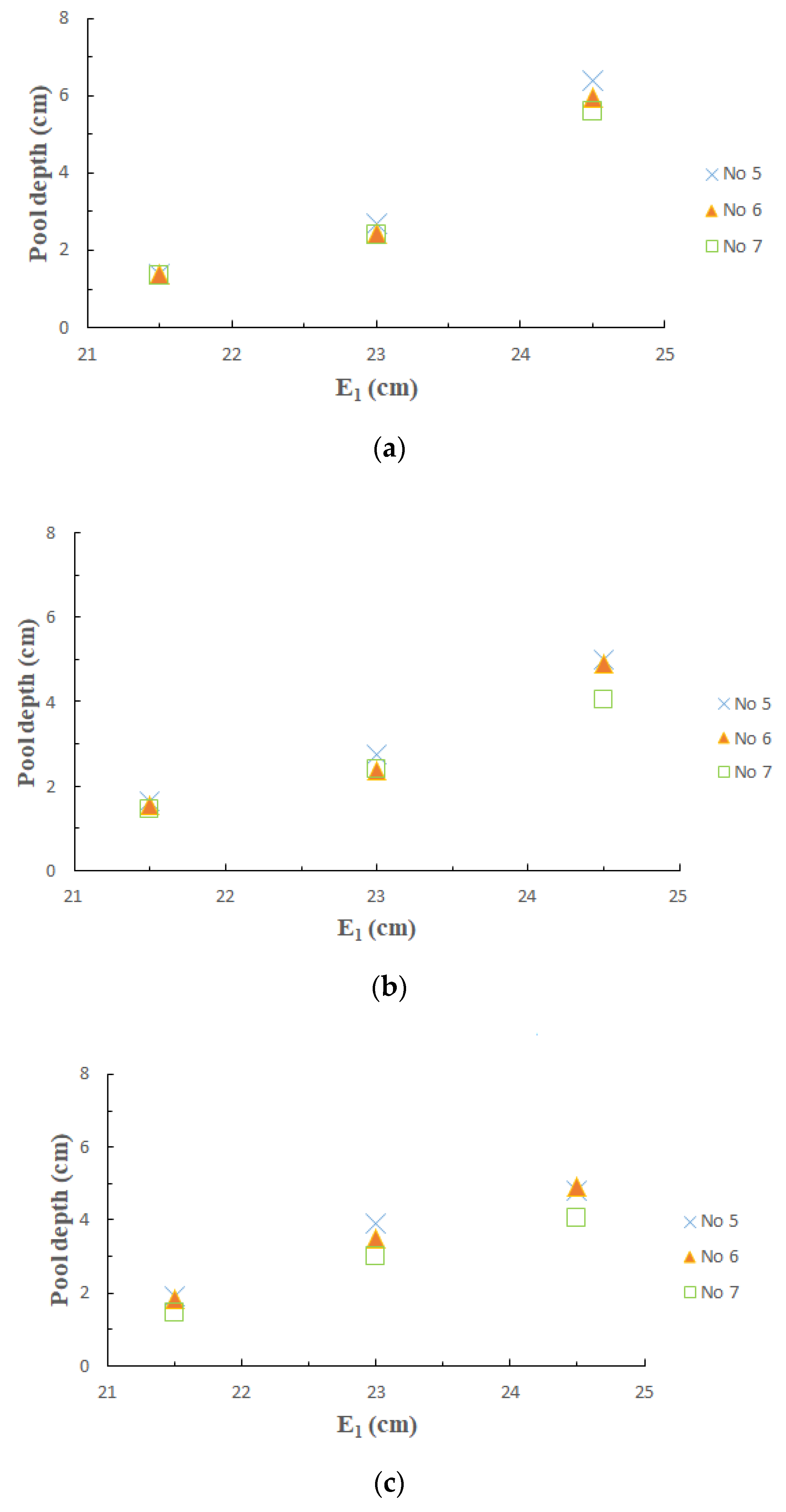

Figure 7 shows that the plunge pool depths increase as the energy heads increase. Among all the slope conditions, particle No. 5 showed the highest depth of the plunge pool, and particle No. 7 had the lowest. The coarser ripraps resisted the water flow as they had a higher critical shear stress to move. Thus, the energy of the water was unable to dislocate the coarser particles and spread over the channel bed, which contributed to creating a heave near the scour hole, resulting in a large pool depth. However, finer particles possess a small critical shear stress

, and the energy of water is sufficient to move the No.7 particles and spread over the channel bed, resulting in smaller pool depths. Therefore, for the same energy head and slope, larger-sized particles create large plunge pool water depths and dissipate more energy than the other two types of particles. On average, No. 5 size particle can create a 5% deeper water pool compared with No. 6 size and 15% more depth of water pool compared with No. 7 size particles for all slopes and overtopping depth conditions.

4. Discussion

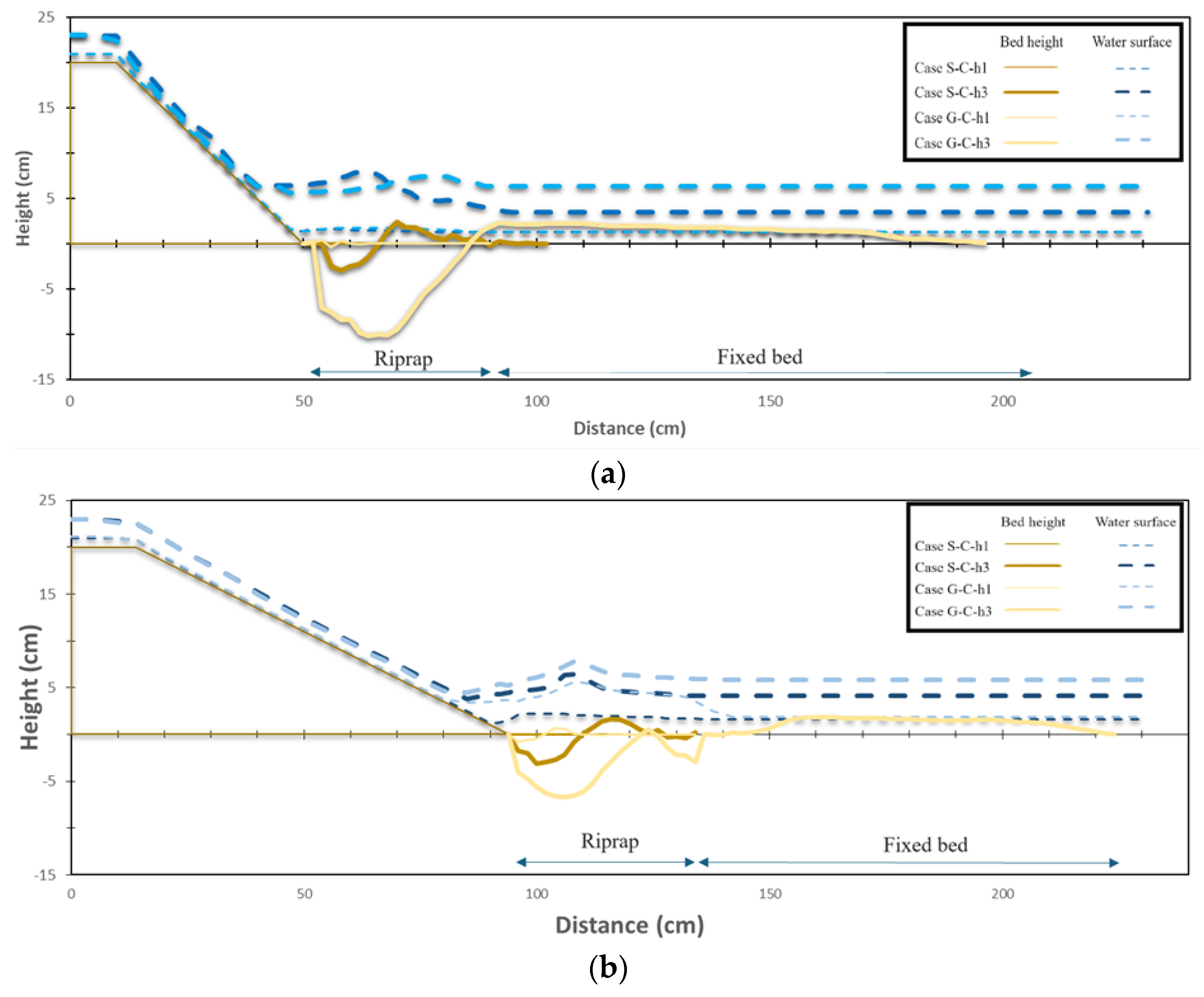

4.1. Effect of Riprap Size, Tailwater and Flow Structure on Scour Phenomenon

Figure 8 shows that the scour depths and extent of scouring differ depending on the downstream slope and riprap size. The steeper slope

(1:2) causes deeper scour depth extending from 2.96 cm to 10.12 cm depending on ripraps size as shown in

Figure 8a. The coarser ripraps showed a lower scour depth. In the

Figure 8b, it is observed that for gentle slope (

1:4) case, the maximum scour depth was found to be 6.74 cm. The scour hole also showed a wider top width with an increase in the flow depth and sharpness of the slopes. It was also observed that the maximum depth of scours appeared closer to the embankment toe for the steeper slope 1:2 case compared with the gentle slope 1

:4 cases because of the sharpness of the impinging angle of the flowing water nappe and positions of hydraulic jumps. Despite the maximum scour depth for the No.7 size ripraps, the pool depth was smaller because the flowing water blew small-sized particles and spread over the channel bed, as shown in

Figure 8. On the other hand, riprap No. 5 showed a shallower scour depth but a higher plunge pool, which caused more energy to dissipate as a heave comprising ripraps was created near the scour hole.

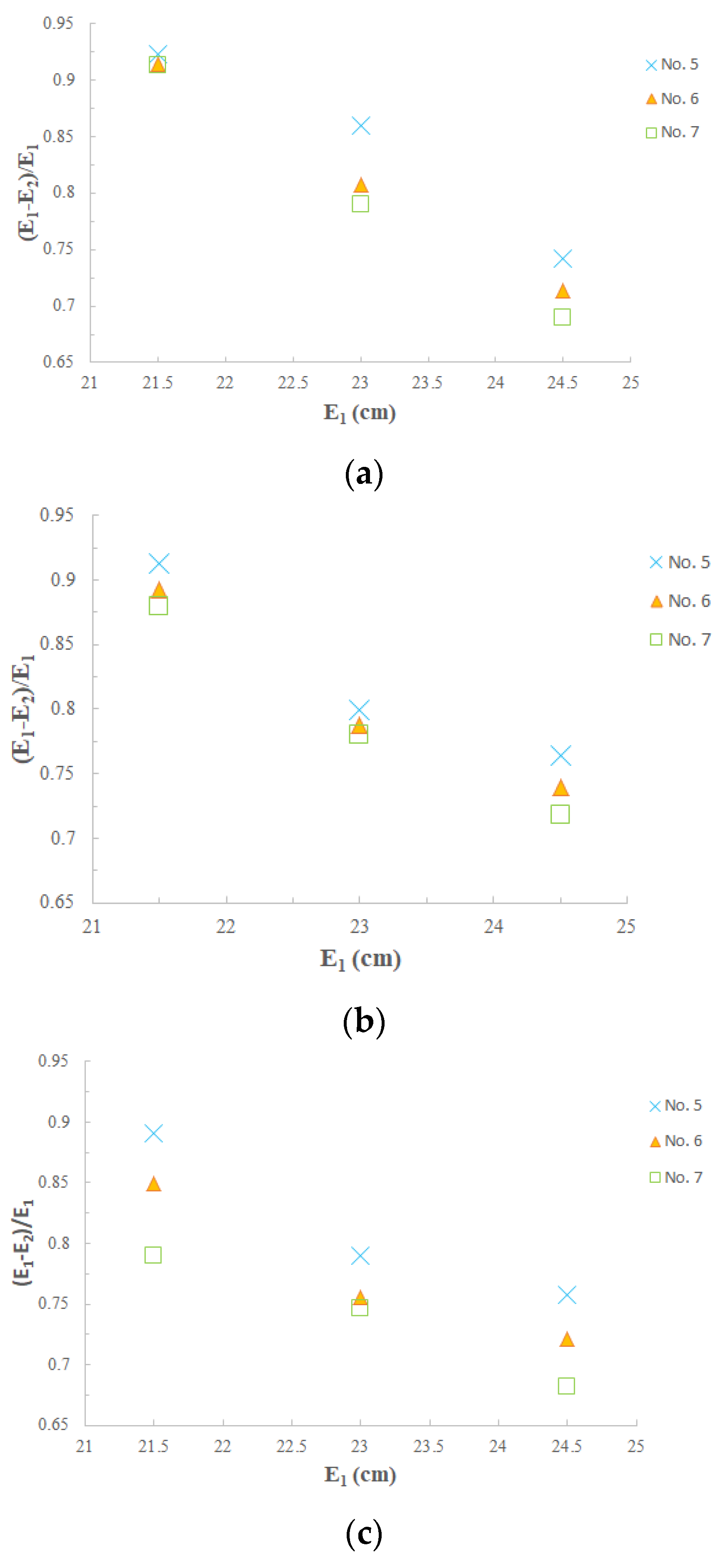

4.2. Relationship between Energy Head and Energy Dissipation

From

Figure 9, it can be observed that for the 1:4 downstream slope condition, the energy dissipation increases with an increase in the size of the particles for the same overtopping depth. A similar relationship was found for the 1:2 and 1:3 slope conditions.

Figure 9 also demonstrates that irrespective of the downstream slopes and E

1 conditions, the energy dissipation was found to be larger in the case with a large riprap grain size (No. 5).

It was also observed that a higher tailwater depth resulting from riprap deposition contributed to more energy dissipation for coarser ripraps (No. 5). In contrast, finer No.7 size ripraps showed the opposite phenomenon, resulting in more scour and lower energy dissipation, irrespective of the downstream slope of the embankment. The difference is particularly large for the 1:4 gradient case compared with the other grain sizes. A possible reason for this can be found in

Section 3.2. For the 1:2 and 1:3 slope cases, when E

l was small, the effect of grain size on energy dissipation was small. On the other hand, as

El increased, the change in energy dissipation with grain size increased. This occurred because, with the increase in initial energy, a large scour depth as well as higher deposition near the scour hole was created, which caused a large plunge pool.

On average, quantitatively No. 5 size particles can dissipate 4% and 7% more energy than No. 6 and No. 7 size particles, respectively, irrespective of the slope and overtopping depth conditions. Therefore, it can be concluded that particle No. 5 has the highest efficiency for energy dissipation.

Hence, it can be concluded that to delay the progression of embankment erosion during overtopping flow, it is important to ensure the plunge pool depth necessary for energy dissipation of overflowing water energy by reducing the amount of scour around the slope and by depositing riprap near the slope.

From this point of view, it was found that the case of a larger grain size (No.5) could control the progression of embankment slope erosion due to overtopping. At the same time, it was also found that coarser grain size ripraps (No.5) were the most stable case in reducing the loss of the embankment body under a wide range of overtopping and embankment slope conditions.

In this study, the influence of different hydraulic, geotechnical, and geometrical parameters on scour, deposition, and energy reduction characteristics were investigated. In the future, different parameter combinations can be used for a clearer understanding. The movable bed may provide different outputs compared to the current study under fixed bed conditions. Therefore, further analysis of movable beds is required in the future.

5. Conclusion

Different particle sizes have different impacts on scour and deposition formation, as well as energy reduction characteristics subject to different slopes and overtopping flow depth conditions. Among these three different sizes of riprap particles, the largest in size (No. 5) reduces the scour depth and generates a higher deposition height to create a larger plunge pool depth, resulting in more energy dissipation. Owing to the overtopping of the embankment during extreme flood events, the toe of the downstream embankment is first affected, and riprap particles can be used to minimize scour at the toe and subsequent headcut migration. Finally, it can be concluded that to protect the embankment from breaching, a riprap with a larger particle size is needed at the downstream toe to decrease the energy of water and minimize the scour depth and subsequent headcut migration.

Supplementary Materials

Not Applicable

Author Contributions

Conducting experiment, data analysis, writing—original draft preparation: Abu Raihan Mohammad Al-Biruni; Data explanation, writing—original draft preparation: Md Masum Billah; Supervision, writing—review and editing: Junji Yagisawa

Funding

This work was supported by JSPS KAKENHI Grant Number 19K04611.

Data Availability Statement

The data supporting the findings of this study are available from the corresponding author upon request.

Acknowledgments

We would like to express our gratitude to all those who supported us in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- L. Schmocker, The failure of embankment dams due to overtopping, vol. 47, no. 2. 2009.

- J. A. Feliciano Cestero, J. Imran, and M. H. Chaudhry, “Experimental Investigation of the Effects of Soil Properties on Levee Breach by Overtopping,” J. Hydraul. Eng., vol. 141, no. 4, p. 04014085, 2015. [CrossRef]

- Z. Liu, T. Li, Y. Ding. A soil tensile strength based headcut migration model of breach side slope. Water (Switzerland) 2020, 12, 1–16. [Google Scholar] [CrossRef]

- T. Afreen, Yagisawa, Binh. Investigation of Scour Pattern Downstream. J. Japan Soc. Civ. Eng. Ser. B1 (Hydraulic Eng. 2015, 59, 175–180. [Google Scholar]

- M. M. Billah and J. Yagisawa. Headcut Migration in Earthen Embankment Induced by Varying Sub-surface and Seepage State under Overflow. Geotech. Geol. Eng. 2023, 41, 4659–4676. [Google Scholar] [CrossRef]

- M. M. Billah and J. Yagisawa. Experimental Investigation on Effect of Initial Phreatic Line Position Inside Earthen Embankment on Headcut Migration During Overtopping Flow. J. Japan Soc. Civ. Eng. Ser. B1 (Hydraulic Eng. 2020, 76, I_565-I_570. [Google Scholar] [CrossRef]

- M. P. R. Jayaratne et al. Failure mechanisms and local scour at coastal structures induced by Tsunami. Coast. Eng. J. 2016, 58. [Google Scholar] [CrossRef]

- G. Zhao, P. J. Visser, P. Peeters, and H. K. Vrijling. Prediction of Headcut Erosion Development on the Breach Slope. ICSE6, August 27-31, 2012, Paris 2012, 1257–1264. [Google Scholar]

- J. Farhoudi and K. V. H. Smith. Local scour profiles downstream of hydraulic jump. J. Hydraul. Res. 1985, 23, 343–358. [Google Scholar] [CrossRef]

- E. B. Johnson, F. Y. Testik, N. Ravichandran, and J. Schooler. Levee scour from overtopping storm waves and scour counter measures. Ocean Eng. 2013, 57, 72–82. [Google Scholar] [CrossRef]

- M.-T. Pham, D.-D. Pham, D.-L. Vu, and D. Dias. Embankments Reinforced by Vertical Inclusions on Soft Soil: Numerical Study of Stress Redistribution. Geotechnics 2023, 3, 1279–2023. [Google Scholar] [CrossRef]

- S. Pagliara, M.; S. Pagliara, M. Palermo, and I. Carnacina. Live-bed scour downstream of block ramps for low densimetric Froude numbers. Int. J. Sediment Res. 2012, 27, 337–350. [Google Scholar] [CrossRef]

- S. Pagliara and S. M. Kurdistani. Scour downstream of cross-vane structures. J. Hydro-Environment Res. 2013, 7, 236–242. [Google Scholar] [CrossRef]

- O. R. Stein, P. Y. Julien, and C. V. Alonso. Mechanics of jet scour downstream of a headcut. J. Hydraul. Res. 1993, 31, 723. [Google Scholar] [CrossRef]

- P. Taylor and B. Dargahi, “Scour development downstream of a spillway,” no. April 2013, pp. 37–41, 2010.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).