1. Introduction

It's hard to overstate the crucial role that lasers

play in modern life. From welding, cutting, and drilling in subtractive

manufacturing [

1] to 3D printing in additive

manufacturing [

2], particularly in metal

processing, lasers are indispensable. Besides, they accelerate charged

particles to high energy [

3], produce hard

radiation [

4] crucial for various scientific

and medical applications, and have recently demonstrated breakthroughs such as

achieving breakeven in Confinement Nuclear Fusion [

5]

and enabling Extreme Ultraviolet Lithography [

6].

These are just a few examples showcasing the immense capabilities of high-power

lasers.

Laser systems are broadly classified based on their

operating regimes into two main categories: Continuous Wave (CW) operation,

where the laser is continuously pumped and emits a steady beam of light, and

the pulsed regime, in which the laser produces single or multiple pulses at

various repetition rates.

In CW regime high power fiber lasers are created

from active optical fibers pumped by semiconductor laser diodes, a merger

between two of the most innovative and advanced laser technologies reached the

remarkable output power up to 100s kW [

7] and

feature a wide range of operating wavelengths and record wall-plug efficiency

up to 50% [

8]. Multi-kW carbon oxide (CO

2)

gas lasers present another example of greater reliability, higher output

consistency, which allowed them the widely spread in industry and medicine [

9].

Nevertheless, this paper will primarily focus on

ultrahigh power pulsed laser systems, exploring their various types and recent

technological advancements. High power laser systems possess the ability to

concentrate the energy into extremely small space-time volume. The laser beam

with recently reached 10 petawatts (10

15 Watt -PW) output pulse

power was focused on the few microns spot which allowed to achieve the highest

in the observable universe intensity approaches to 10

24 watts per

square centimeter (W/cm

2) [

10].

With a duration of approximately 20 femtoseconds (10

-15

seconds - fs), this pulse occupies a mere ~7 μm of space during its

propagation. Such a short pulse duration enables the attainment of tremendous

power and intensity with a modest energy input ranging from 300 to 500 Joules. To put this into perspective, consider that the total

power output of all the world's power plants is around 2 terawatts (10

12

watts - TW), while the sunlight reaching the Earth amounts to approximately 90

PW. Achieving an intensity of 10

24 W/cm

2 is feasible by

concentrating this power into a spot with a diameter of just 30 μm.

The light produced by cutting-edge technologies

boasts remarkable specifications, revolutionizing various fields of science and

industry. Take, for instance, the Extreme Light Infrastructure for Nuclear

Physics (ELI-NP) 20PW laser, crafted from sapphire crystals doped with titanium

ions (Ti:Sa). This system generates 600J of output energy with a pulse duration

of 30 fs across two converging channels [

10].

In a different league, the NIF Nd: Glass laser system, pivotal in achieving

thermonuclear fusion breakeven, wields a staggering 4MJ of energy at a

wavelength of 1.053 μm, converted in 1.8MJ of third harmonic at 0.35 μm through

192 channels. Its pulse duration spans a nanosecond, with an output power of

0.5PW [

11]. Furthermore, ASML employs a 1MW CO

2

gas laser within their Extreme Ultraviolet Lithography system, revolutionizing

microchip production [

12], showcasing just a

glimpse of the transformative capabilities of these cutting-edge light sources.

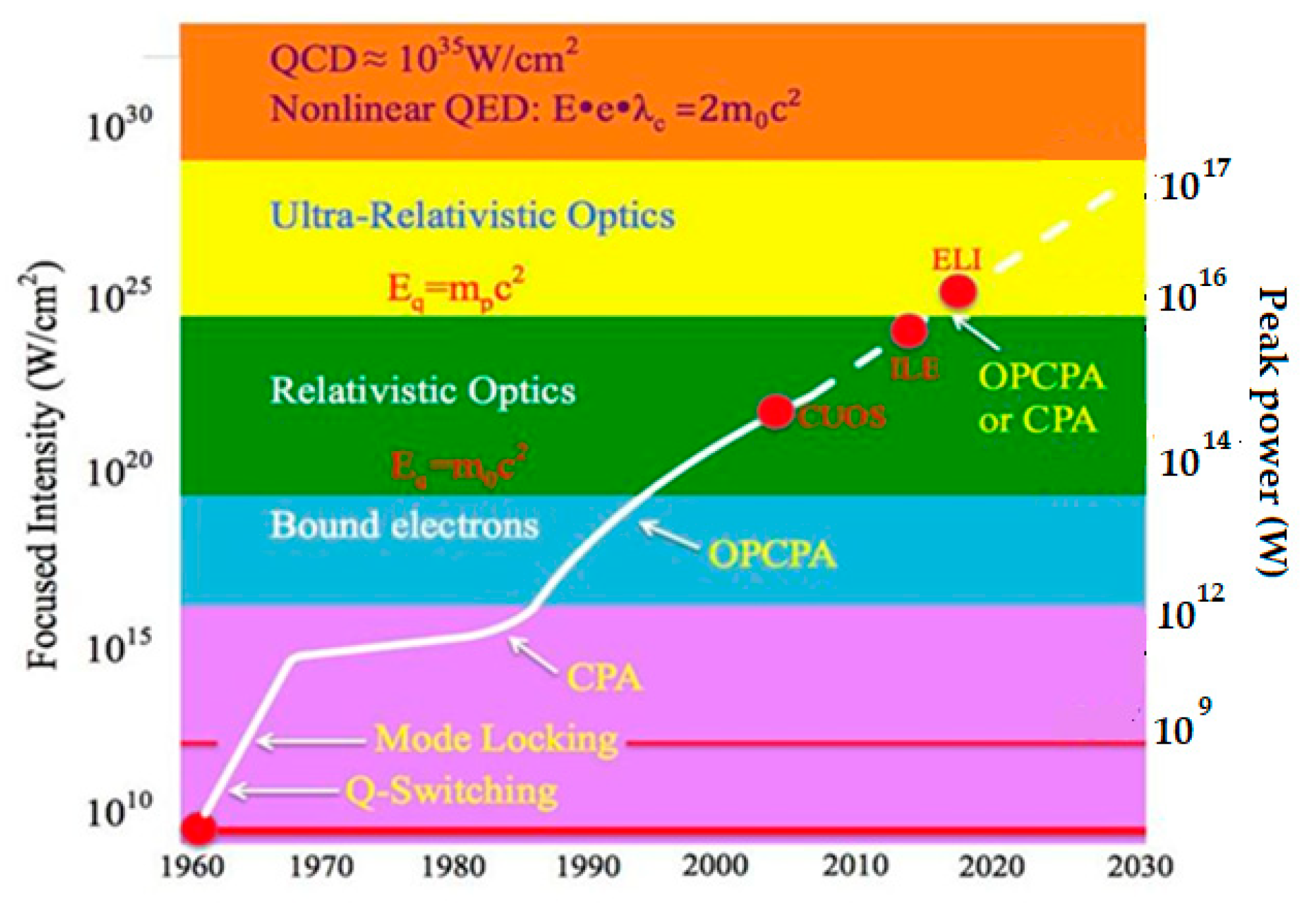

Figure 1

demonstrated the chart of historical development of the laser systems with high

pulse power (intensity).

Since Richard Maiman's groundbreaking invention of

the laser in 1960 [

13], the power of laser

technology has undergone rapid growth, fueled primarily by the discovery of two

pivotal operational regimes: Q-Switching and Mode Locking (a detailed

explanation follows) [

14,

15]. These

breakthroughs, illustrated on the accompanying chart, marked a turning point in

laser development. By implementing these regimes in laser oscillators,

scientists and engineers achieved a remarkable feat: the gradual reduction of

pulse durations from microseconds to nanoseconds, and later, to femtoseconds,

all without significant energy loss. The peak power is determined by dividing

the energy by the pulse duration, thus there are two primary pathways to

increase peak power. The first is extensive, involving increasing the energy

output of the laser by developing Master Oscillator+ Power Amplifiers (MOPA)

scheme. The second is intensive, focusing on reducing the pulse duration.

Intensive improvements, such as pulse duration reduction, are often favored due

to their cost-effectiveness. By enhancing the efficiency and precision of laser

systems, researchers can achieve higher peak powers without significantly

increasing energy consumption or production costs. This approach underscores

the importance of refining pulse duration technologies, which not only boosts

parameters but also promotes accessibility in laser applications across various

new fields.

Following the period of gradual intensity growth

post-1970, a significant technological breakthrough emerged in 1985: Chirped

Pulse Amplification (CPA) [

16,

17]. This

innovation provided a substantial boost to laser capabilities, propelling the

power growth trajectory forward, a trend that continues to evolve to this day

and beyond. The development of Chirped Pulse Amplification (CPA) involved the

collective efforts of numerous scientists over the years. While it's true that

two individuals were awarded the Nobel Prize in 2018 for their contributions to

CPA, namely Jerard Mourou and Dona Strickland, it's essential to recognize the

collaborative nature of scientific progress. Countless researchers worldwide

have dedicated their knowledge, expertise, and resources to advancing CPA

technology, each playing a vital role in its development and refinement. In

this paper, we will delve into a comprehensive explanation of the

aforementioned technologies, elucidating their principles, applications, and

contributions to the evolution of laser science and industry.

2. Ideas and Methods of Laser Power Increasing

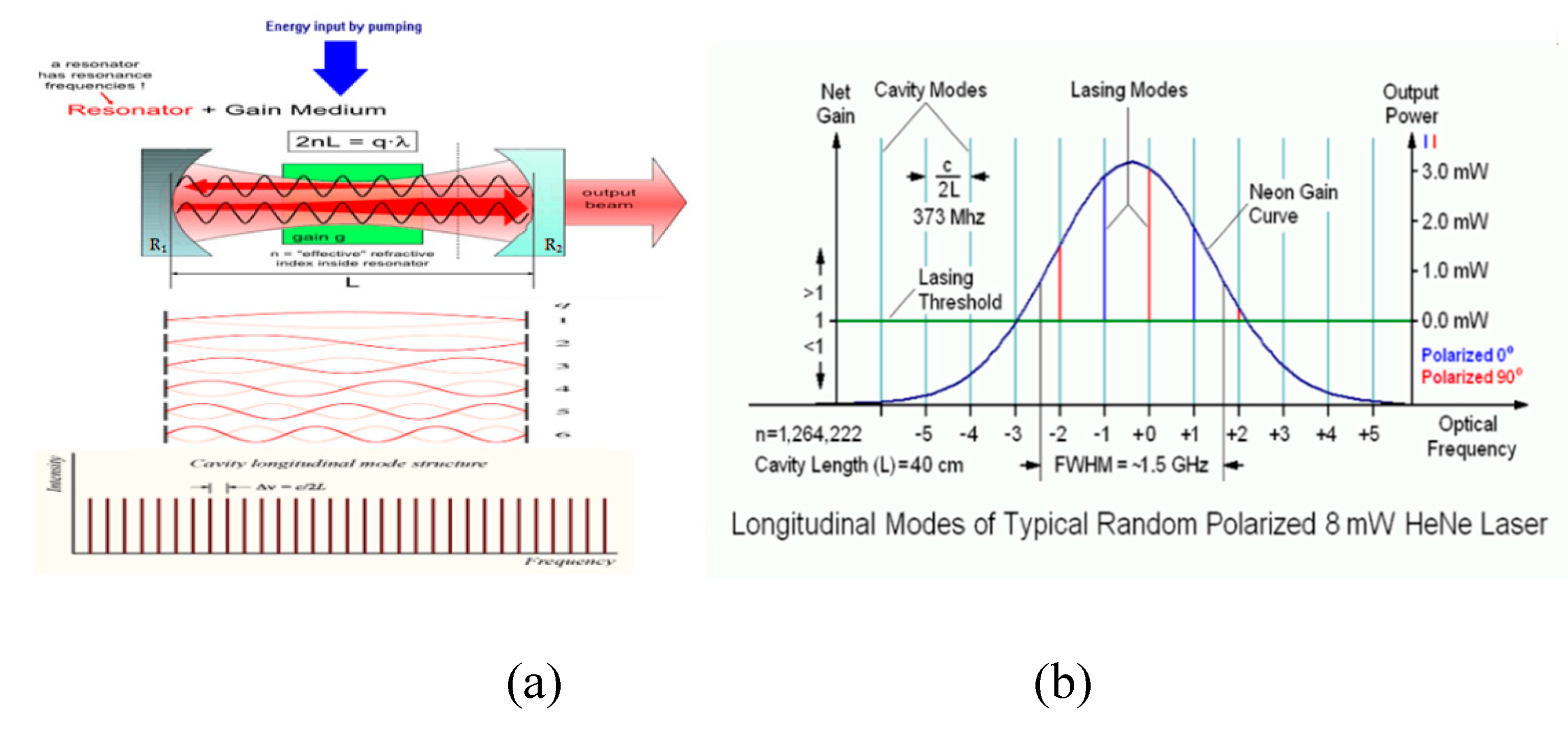

Let's begin with a brief overview of how a laser

oscillator operates. For a deeper understanding, readers can refer to [

18]. In essence, a laser oscillator comprises three

primary components: a resonator or cavity, typically consisting of two mirrors

(one of which is usually partially transparent, serving as the output coupler),

a Gain Medium (GM) that facilitates amplification of light within a specific

spectral range, and a pump system responsible for energizing the gain medium to

enable light amplification (refer to

Figure 2a

top for illustration).

Some of the spontaneous photons generated by GM and

reflected by mirrors of the cavity can produce standing waves or resonance

frequencies (longitude modes) which are able respectively long time exist in

resonator, for example, as standing waves on the guitar string. The condition

for that is the equivalence of number (q) of half-waves (λ/2) to resonator

length (L) multiplied by the index of refraction (n) of the media nL= qλ/2,

similar, the resonance frequencies can also be expressed as ν = qc/2L, where (c)

represents the speed of light.

Initially, the frequency amplitudes are uniform

within the empty cavity, depicted in

Figure 2a

at the bottom, with equidistant spacing calculated by the formula Δ

ν = c/2L, resulting in

an infinite array of frequencies. However, the resonator is not truly empty; it

contains a GM capable of amplifying the frequencies suitable with its

luminescence spectra. In reality, the laser medium (GM) exhibits specific

spectral bandwidths for light amplification, determined by its structure and

condition, as illustrated in

Figure 2b

(blue curve). Only a handful of frequencies align with this curve, as other

frequencies experience limited or no amplification. Additionally, losses occur

within the cavity due to imperfections in optical surfaces, finite apertures,

and output energy (R

1, R

2). Consequently, only a select

few modes persist within the resonator under steady-state conditions, matching

the amplification spectra and surpassing the losses. This condition means

lasing threshold and can be found by formula

R1R2

exp(-aL) exp(bL) =1, where

a is the coefficient of losses in the

cavity material,

b-the coefficient of amplification.

The lasing threshold is shown by the green line on

Figure 2b and only five mod amplitudes were

bigger than it, that means the laser is able generate only these mods. So, a

broader amplification spectrum of a gain medium allows generate the light with

the larger spectral bandwidths (more modes). The spectral bandwidth is directly

linked to the pulse duration produced by the laser, as dictated by the

uncertainty principle. In this context, it can be expressed as

Δν × Δτ = Const,

where

Δν

and

Δτ represent the spectral bandwidth and pulse duration typically

measured at the Full Width Half Maximum (FWHM) of their intensities.

Consequently, the product constant implies that a larger spectral bandwidth

results in a shorter pulse duration.

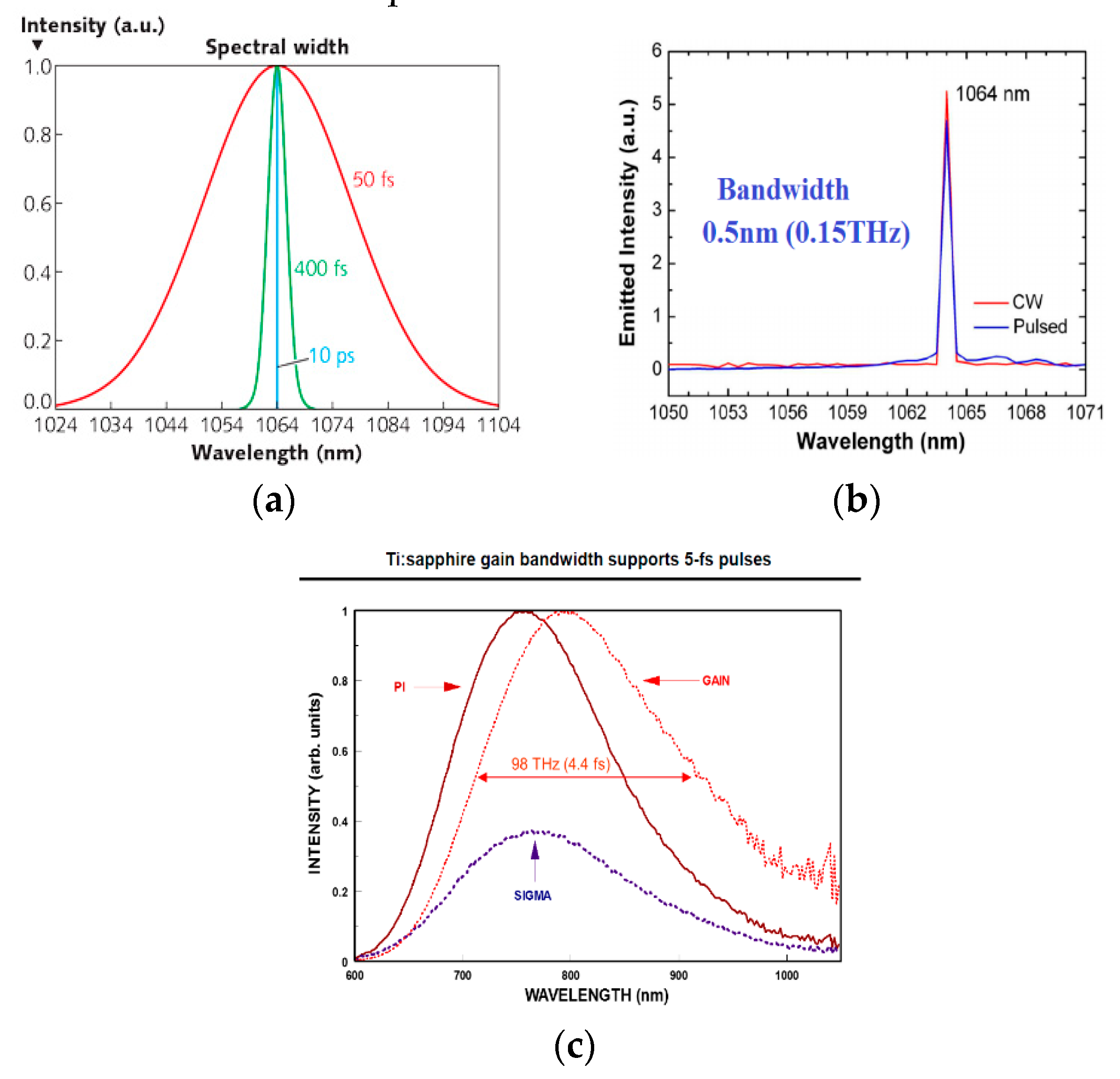

In

Figure 3a,

three spectral widths are depicted alongside pulse durations corresponding to

them. Notably, the pulse duration of 50 fs requires a much larger spectral

width compared to 10 ps (10

-12 seconds). Furthermore,

Figure 3b,c

illustrate the luminescence spectra of two laser crystals, Nd:YAG and Ti:Sa.

Oscillators utilizing these crystals typically generate 4 × 10

3 and

3 × 10

5 longitudinal modes respectively, resulting in spectral

bandwidths of 0.5 nm and 30 nm measured at FWHM.

Now, let's explore the practical methods of

receiving laser pulses. The simplest, albeit not the most effective, method

involves positioning an electromagnetic or mechanical interrupter within the CW

laser output beam. In this scenario, the continuous wave power will match the

pulsed power, despite losing energy. However, as evidenced by the chart in

Figure 1, following the invention of the laser

in 1960, its peak power experienced rapid growth over the subsequent decade, up

to 1970. This advancement can be attributed to the development of two key

technologies: "Q-switching" [

14] and

"Mode-locking" [

15].

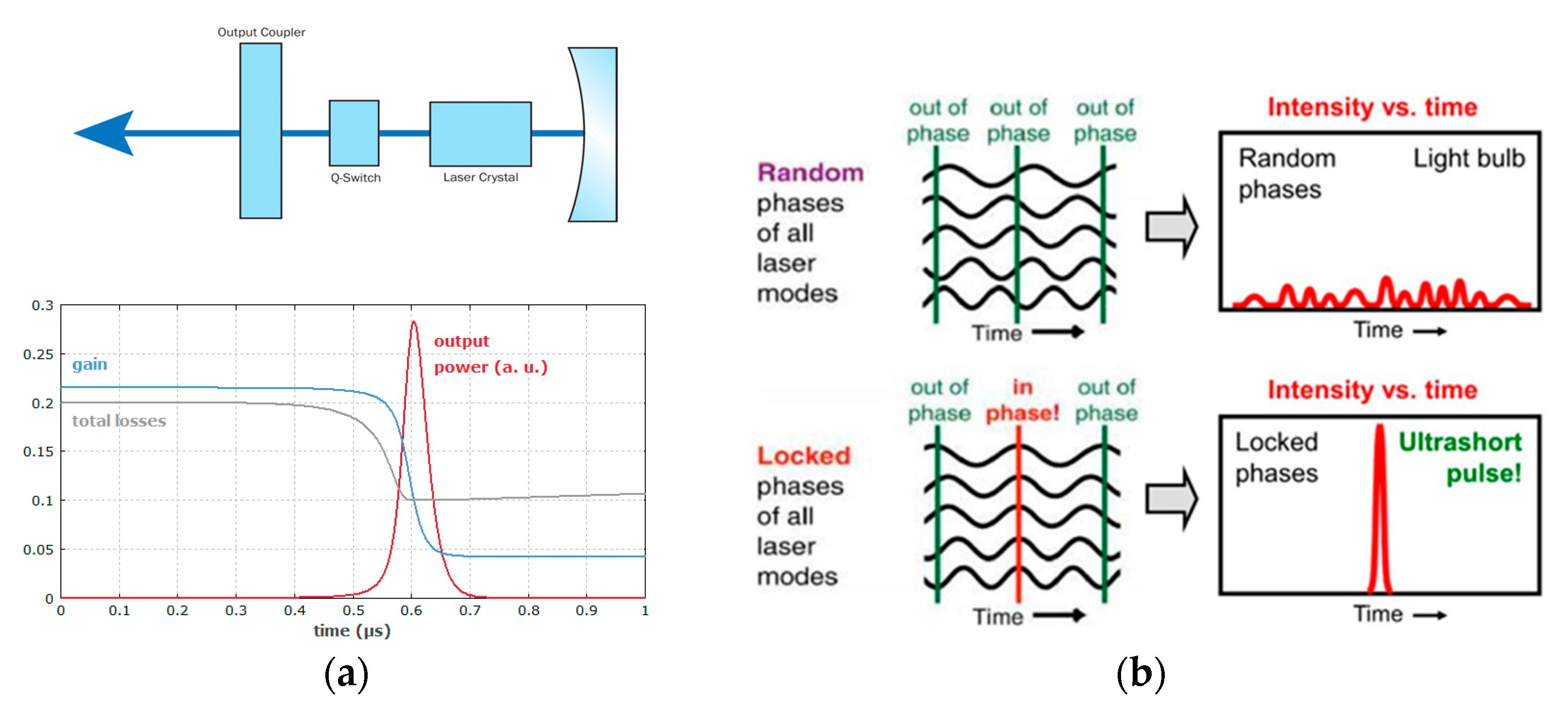

In the first method, unlike the previously

discussed approach, the switcher was positioned inside the laser resonator to

alter its Q-factor (quality factor), as depicted in

Figure 4a (top). The Q-factor in this

context can be defined as the ratio of stored energy to energy dissipated per

oscillation cycle. Essentially, a high Q- factor corresponds to low energy

losses in the cavity, and vice versa. When the Q-switch is closed (low Q-factor),

it prevents light propagation within the cavity during the pumping of the GM,

as illustrated in

Figure 4a (bottom).

Once sufficient energy is accumulated, the Q-switch is opened, allowing the

light photons spontaneously born in GM pass between the resonator mirrors and

undergo amplification in the gain medium by stimulating identical photons

emission, thereby increasing pulse energy.

The duration of the generated pulses is influenced

by several factors, including the resonator round-trip time, the initial gain,

and the resonator losses. A higher initial gain results in a quicker buildup of

pulses, leading to higher energy extraction and typically a faster decay of

power after reaching the pulse maximum. Generally, the duration of pulses is at

least on the order of the resonator round-trip time and often longer than 1

nanosecond (10-9 seconds - ns). Q-switch oscillators typically

produce pulses with a repetition rate in the range below megahertz, boasting

pulse powers up to megawatts (106 Watts - MW).

In the resonator, longitudinal modes exhibit

random phases, as depicted in

Figure 4b

(top). However, laser pulses can be significantly shortened by synchronizing

the cavity modes, as illustrated in

Figure 4b

(bottom). This synchronization, known as Mod-lock operation regime in laser

oscillators, ensures that the maximum amplitudes of all longitudinal modes

coincide at the same point and same time within the cavity. This constructive

summation results in a substantial increase in intensity at this point,

manifesting as a pulse with a duration of a few optical cycles (a few fs).

Furthermore, as more modes concentrate the energy in a smaller area, the pulse

duration becomes even shorter (see

Figure 3).

As the soliton traverses between cavity mirrors, its energy escalates to the

nano - microjoule level upon passing through the GM. A significant number of

modes or a broad spectral bandwidth necessitates a gain medium with a large

fluorescence spectrum, along with devices to compensate for dispersion in

optical elements, such as pairs of prisms [

19].

In practice, like Q-switching, achieving the Mode-locking regime can be

realized through external driving modulators within the laser resonator (active

mode locking) [

20] or by exploiting nonlinear

effects in the cavity elements, such as the Kerr effect or absorption

saturation (passive mode locking) [

21].

Advancements in these techniques, coupled with the integration of laser

oscillators with amplifiers, led to a remarkable increase in output laser pulse

power within a decade following the invention of lasers, achieving peak powers

of up to terawatts (TW) [

22]. However, further

increases in power necessitated significant enlargement of the aperture of

optical elements and gain media. This was due to the approaching of these

elements to their damage threshold and/or the onset of undesired nonlinear

effects, which can distort the laser beam and degrade pulse quality.

An effective method for increasing pulse power

involves reducing its duration rather than simply increasing energy, as

expressed by the equation

P=

E/

τ , where

P is power,

E is energy, and

τ is pulse duration.

However, it's essential to consider the damage threshold, which is proportional

to the square root of pulse duration. For instance, when pulse durations

approach tens of femtoseconds, the damage threshold can be as low as 100

millijoules per square centimeter (mJ/cm

2) of energy fluence.

Moreover, severe nonlinear effects such as self-focusing [

23] can occur even earlier, typically when energy

fluence approaches 1 mJ/cm

2, with critical power levels reaching

gigawatts (10

9 Watts - GW) in most cases. A direct method to

mitigate these undesirable phenomena is by increasing the aperture size, as it

was pointed out above. However, starting from the TW energy level, this

approach becomes exceedingly expensive and even impractical. For instance, to

achieve PW energy levels, a Ti:Sa crystal with a diameter of 3 meters would be

necessary for the final amplifier in the laser system.

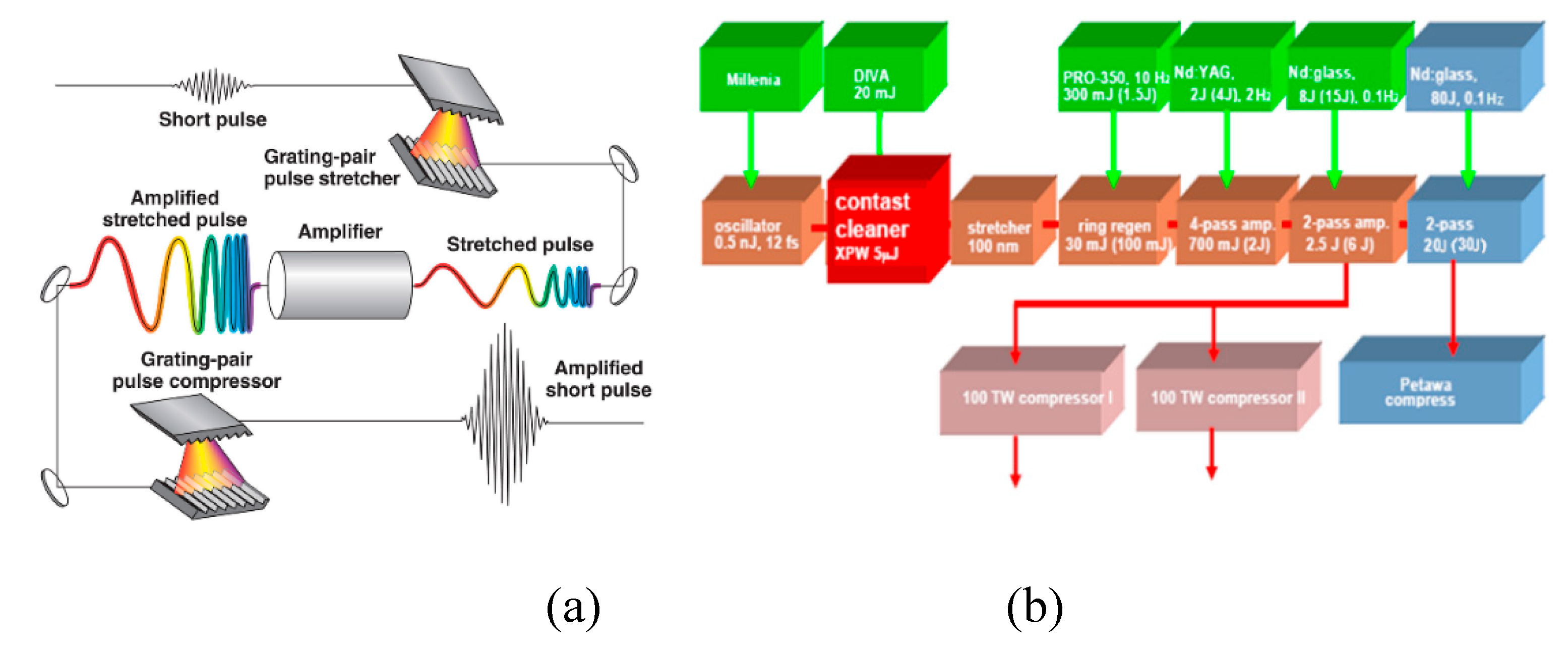

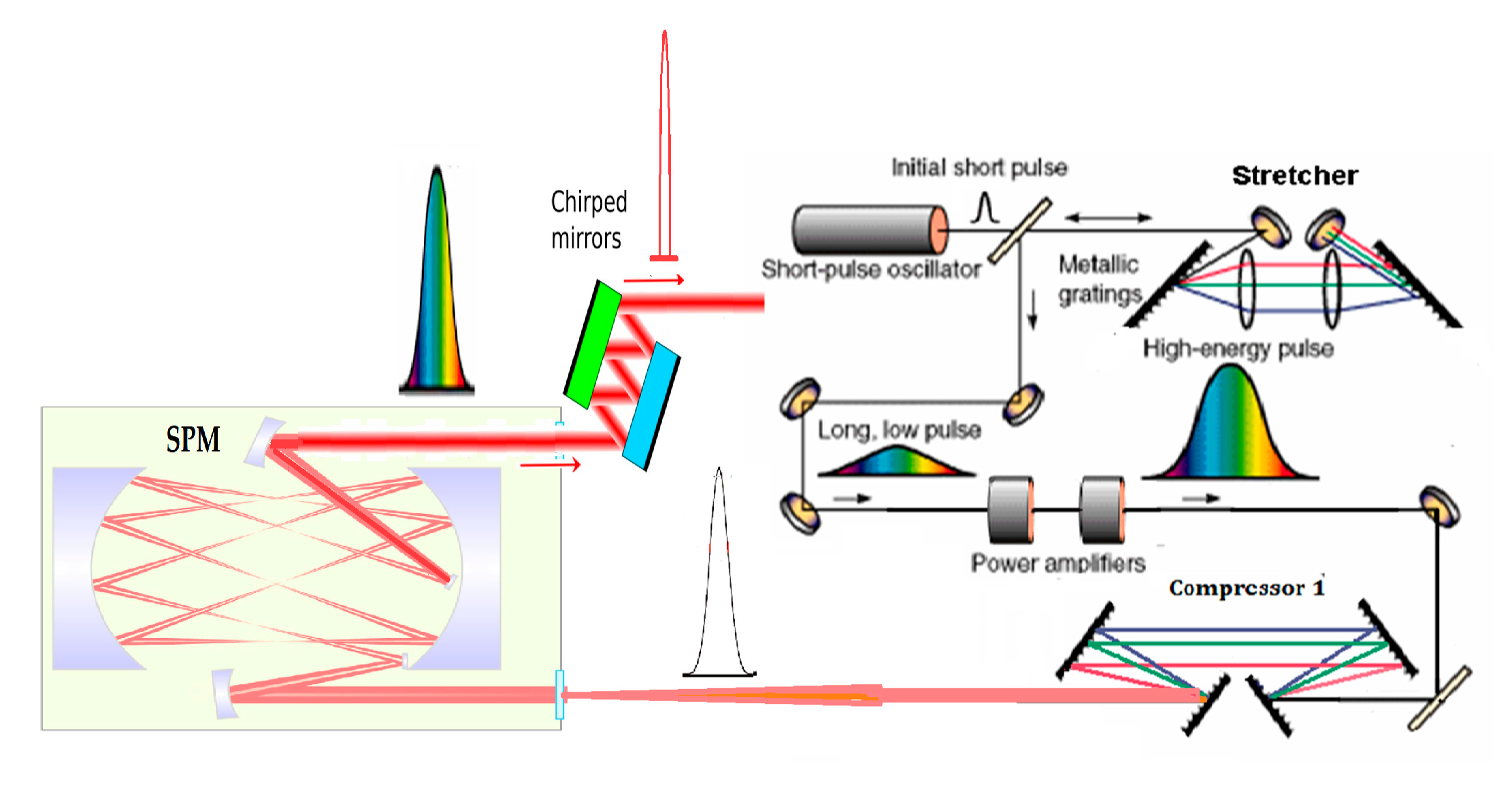

A more creative approach was proposed back in 1985.

Initially, a short pulse with low energy is temporally stretched, resulting in

a longer duration suitable for further amplification. This allows for a

significantly reduced beam aperture. After accumulating a certain energy level

in a chain of amplifiers, the long pulse is then compressed back to its

original short pulse duration, yielding very high power. This groundbreaking

method is known as Chirped Pulse Amplification (CPA) technique [

16,

17]. CPA has proven immensely fruitful in the

development of ultra-high-power lasers, leading to a gradual increase in power

over the years (see

Figure 1). Recently,

it has even enabled the achievement of power levels up to 10 petawatts. The

general scheme of the CPA laser system is presented on

Figure 5 a.

Initiating from the Mod-lock oscillator, which

produces pulses ranging from 10s nJ to 1μJ with durations spanning from a few

ps to few fs, the beam is directed towards a stretcher. This device elongates

the pulse duration by several orders of magnitude, extending it up to the

nanosecond level. The stretcher comprises two diffraction gratings with an

optical telescope positioned between them (messed for simplicity at

Figure 5 (a)). This specific configuration of

the stretcher, proposed by Oscar Martinez in 1985 [

24],

has proven highly effective in facilitating the implementation of the CPA

method. This optical setup disperses the broad spectrum of the short pulse into

multiple narrow harmonics and routes them along different optical paths.

Specifically, it arranges the longer wavelength harmonics (red) to travel

shorter paths compared to the shorter wavelength ones (blue). Upon undergoing

double passes through the stretcher, these harmonics reassemble into a single,

elongated pulse with what is termed a positive chirp, where the red wavelengths

precede the blue ones. In reality, the discretization of the continuous

spectrum into separate harmonics was carried out for the sake of simplicity.

For a more thorough understanding of the stretcher's operation, refer to [

25]. As demonstrated earlier, the longer pulses

possess a higher damage threshold for optics, enabling a significant reduction

in the aperture of the optical elements to a reasonable level, even for high

energy applications. These elongated pulses are then directed, following

stretching, to a chain of multipass amplifiers where they accumulate the

required energy. Subsequently, from the final amplifier, the large energy long

pulses are directed to the compressor, comprised of either two or four

diffraction gratings as depicted in

Figure 5a.

The compressor, as described in [

26], executes

the reverse procedure of the stretcher. It guides the red harmonics with longer

wavelengths along longer paths and the blue ones with shorter wavelengths along

shorter paths, culminating at the compressor output into a short pulse.

Ideally, this pulse equals the initial one but now possesses significantly

higher energy, leading to an exceptionally high pulse power.

Each element of this scheme has undergone

modifications and improvements since 1985. Here, we'll outline the main trends

of this technology. The general modifications applied to two key components of

the CPA system, namely the stretcher and compressor, primarily involved

enhancing pulse stretching [

27], improving the

quality and size of the gratings [

28], and

achieving better alignment and conjugation between the stretcher and compressor

[

29,

30,

31].

Concerning the oscillator and amplifiers, their

initial designs were centered around Nd:glass and Nd:YAG crystals [

32,

33], which typically exhibited a luminescent

spectral bandwidth of 0.5 - 15nm FWHM. These oscillators could generate pulses

with durations of several hundreds of femtoseconds. However, to achieve the

desired output power of 1PW from these laser systems, amplification to the

kilojoule energy level was necessary.

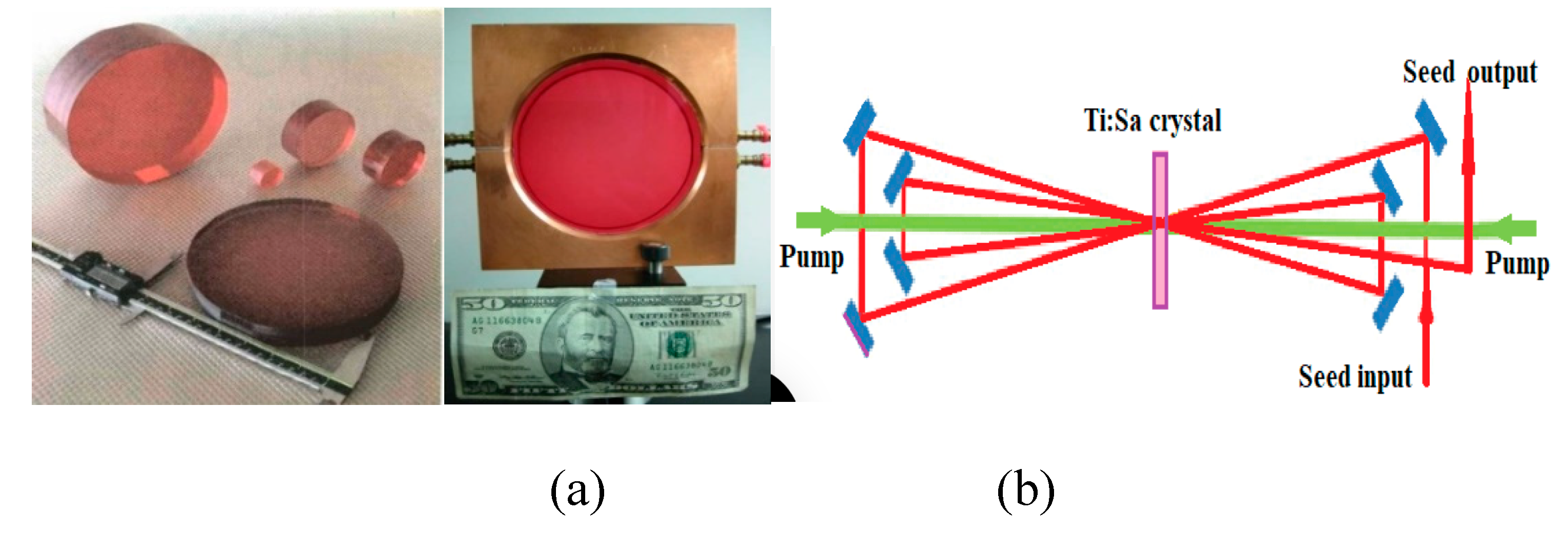

The adoption of Ti: Sapphire crystals [

34] as the gain medium for CPA brought about a

significant reduction in pulse duration, thanks to their much broader

luminescent spectra spanning up to 200 nm, capable of supporting pulse

durations as short as 5fs. Additionally, these crystals possess several unique

properties such as high thermal conductivity for effective heat extraction, low

thermal expansion, and impressive hardness, rendering them suitable for use in

laser oscillators and amplifiers. With the capacity to produce large-aperture

crystals above 20cm [

35] in diameter (

Figure 6 a), they have become the workhorse for

amplifiers in CPA laser systems, ultimately facilitating the achievement of the

current record output power of 10PW [

10].

However, achieving this extraordinary result

demanded numerous technological improvements in laser amplifiers. For instance,

generating the energy required for a 10PW pulse power approaches several

hundreds of joules, necessitating crystal apertures of tens of centimeters in

diameter. Consequently, the gain in the transverse direction far exceeds that

in the longitudinal direction, considering the typical crystal thickness of a

few centimeters. Thus, extracting stored energy by the amplified pulse (seed)

requires a multipass optical scheme and takes considerably longer time compared

to the pulse duration (approximately 100ns for a 1ns pulse). A typical scheme

of a multipass Ti:Sa amplifier is illustrated in

Figure 6b.

The initial method of amplification involved the

full energy crystal pumping before the arrival of the seed pulse, resulting in

substantial energy losses due to amplified spontaneous emission (ASE) and/or

transverse parasitic generation.

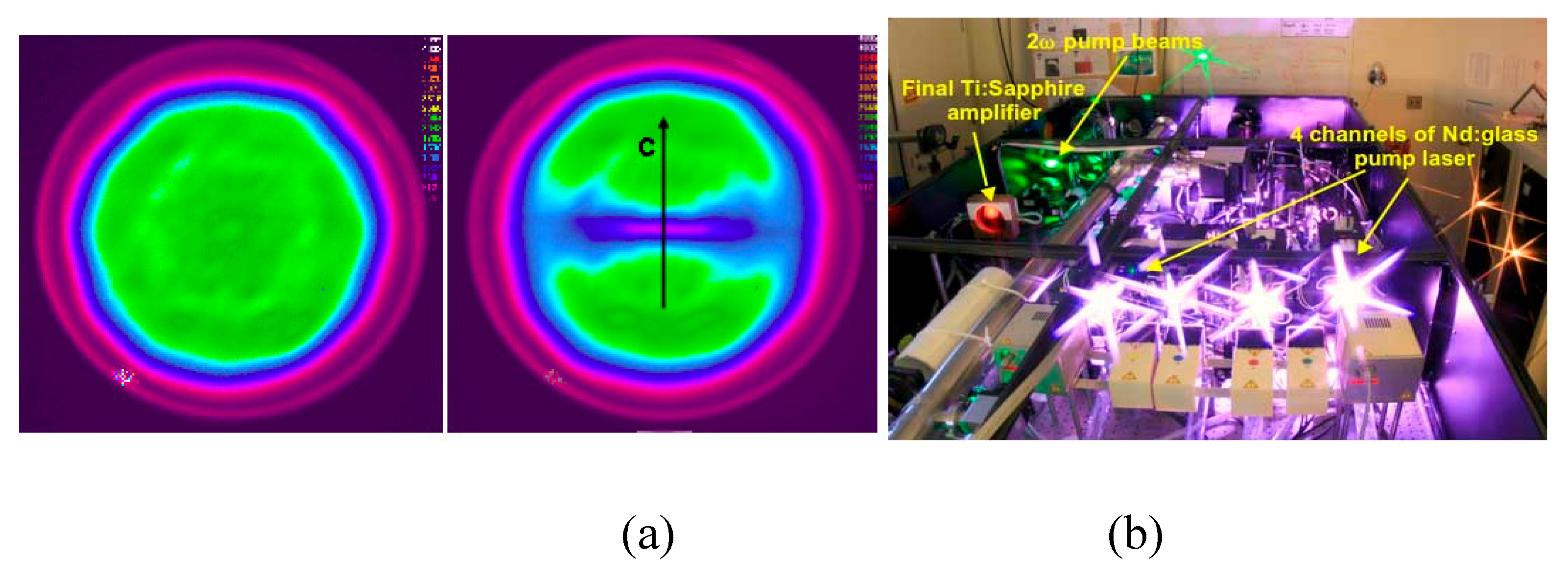

Figure 7a

illustrates the luminescence of the pumped Ti:Sa crystal before and after the

onset of parasitic generation.

One of the methods employed to mitigate these

substantial losses was the cladding of the side surface of the crystal with a

material having a refractive index equal to that of the crystal, thereby

preventing light reflection back into the crystal material and minimizing

further losses [

36]. However, this approach

proved insufficient for truly large crystal apertures due to the significant

transverse gain. In 2003, a new method was proposed to address this challenge,

namely the optimization of timing between crystal pumping and pulse extraction [

37,

38,

39,]. This method, known as Extraction During

Pumping (EDP), enabled the optimization of the energy required for pumping

before and after each seed pulse pass, thereby reducing losses. First time this

method was tested with the Hercules laser system in the Centr for Ultrafast

Optical Science (CUOS) of University of Michigan.

Figure 7b shows the final amplifier of The

Hercules during shot. The laser system reached the record intensity of 2*10

22

W/cm

2 in 2008 [

40]. With EDP, it

became possible to extract up to 0.6 kJ from large-aperture Ti:Sa crystals with

diameters of up to 25cm [

39].

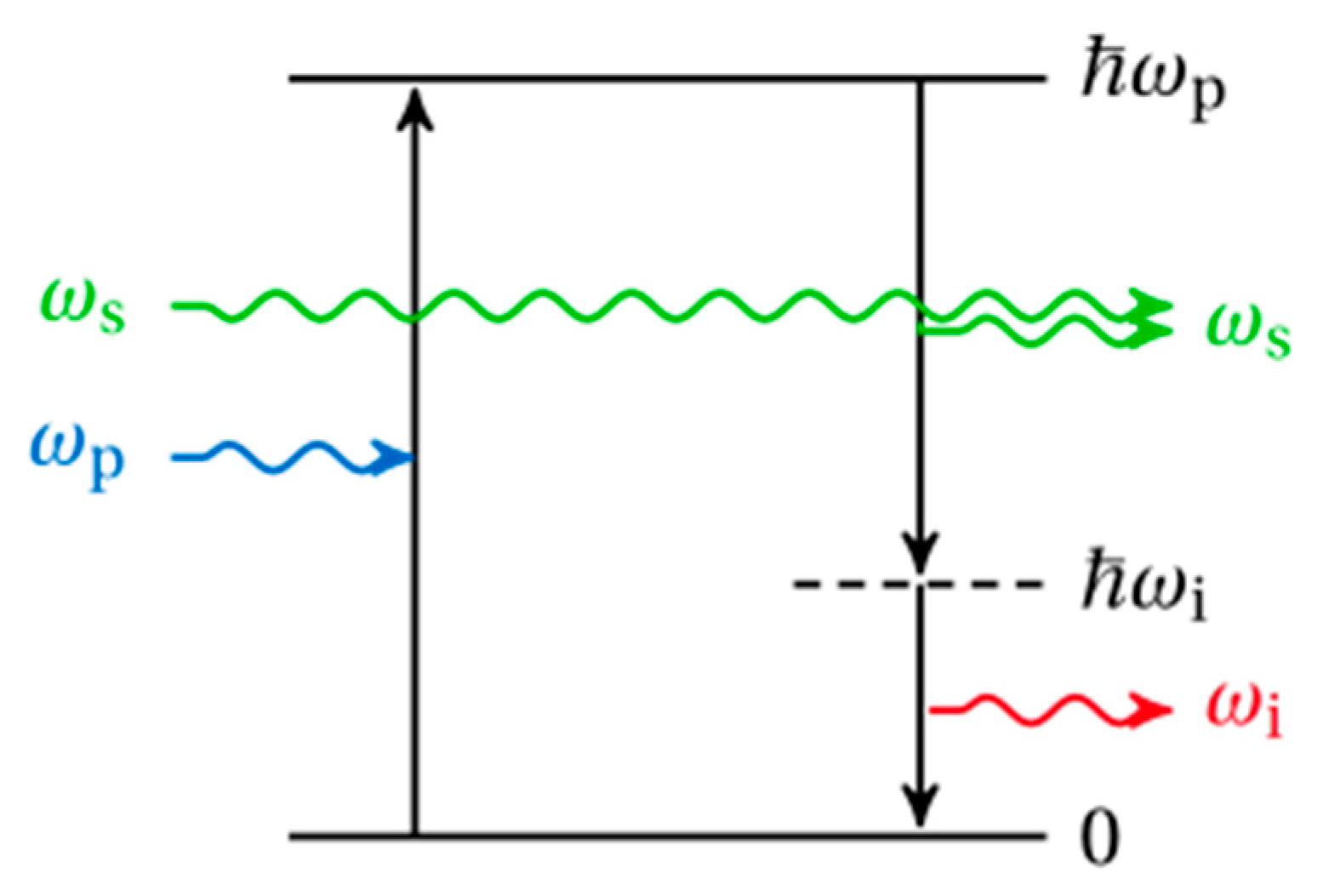

Another type of amplifier utilized in high-power CPA systems is the Optical Parametric Amplifier (OPA) or Optical Parametric Chirped Pulse Amplifier (OPCPA) [

41]. Unlike traditional laser amplifiers, OPAs leverage nonlinear interactions between pump and seed pulses within crystals. In the parametric amplification process, the high-energy quantum state of the crystal, excited by pump photons, undergoes decay stimulated by a seed photon (see

Figure 8). This decay leads to the emission of another seed photon and an idler photon, facilitated by the virtual energy level between the excited and lower states. All three photons adhere to the laws of energy and momentum conservation, necessitating their efficient amplification within a certain distance of the crystal [

42]. To amplify pulses with broad spectral bandwidths, the initially collinear incidence of pump and seed beams on the crystal surface has been replaced with a noncollinear approach (NOPA), enabling the maintenance of synchronization conditions for these broad spectra [

43]. NOPAs offer several advantages over traditional laser amplifiers for their applications in CPA systems, such as improved temporal contrast and energetic efficiency. However, OPCPA systems face challenges, including the necessity for high-quality pump pulses and precise synchronization with the seed pulse, which can be considered disadvantages. It's worth noting that the output power of OPCPA systems now approaches that of laser CPAs [

44]. Used for OPA the KDP and DKDP crystals can be grown with large size clear aperture up to 500 mm diameter, allowing amplification of nanosecond stretched broad-bandwidth laser pulses at kJ-energy-level. Looking ahead, there are ambitious plans to further increase power output, with projects aiming for up to 50 – 100 PW, as demonstrated by initiatives like the OPCPA system development project referenced in [

45,

46].

Industrial, medical, and numerous scientific applications of CPA lasers necessitate a substantial increase in the pulse Repetition Rate (RR), or in other words, the average power. However, the RR of existing high peak power laser systems is typically low, often limited to a few Hz or less [

47]. The primary obstacle to significant RR raising is the escalating heat generation in amplifiers, attributed to the quantum defect, which creates an energy difference between pump and seed photons.

The Thin Disc (TD) geometry of laser amplifier active media, such as Yb:YAG, has proven highly effective for heat dissipation, enabling remarkable achievements in laser power. Continuous Wave (CW) regimes have achieved output powers of up to 10s kW [

48], while in master oscillator - power amplifier (MOPA) systems, several Joules of energy per pulse and high average power have been attained [

49].

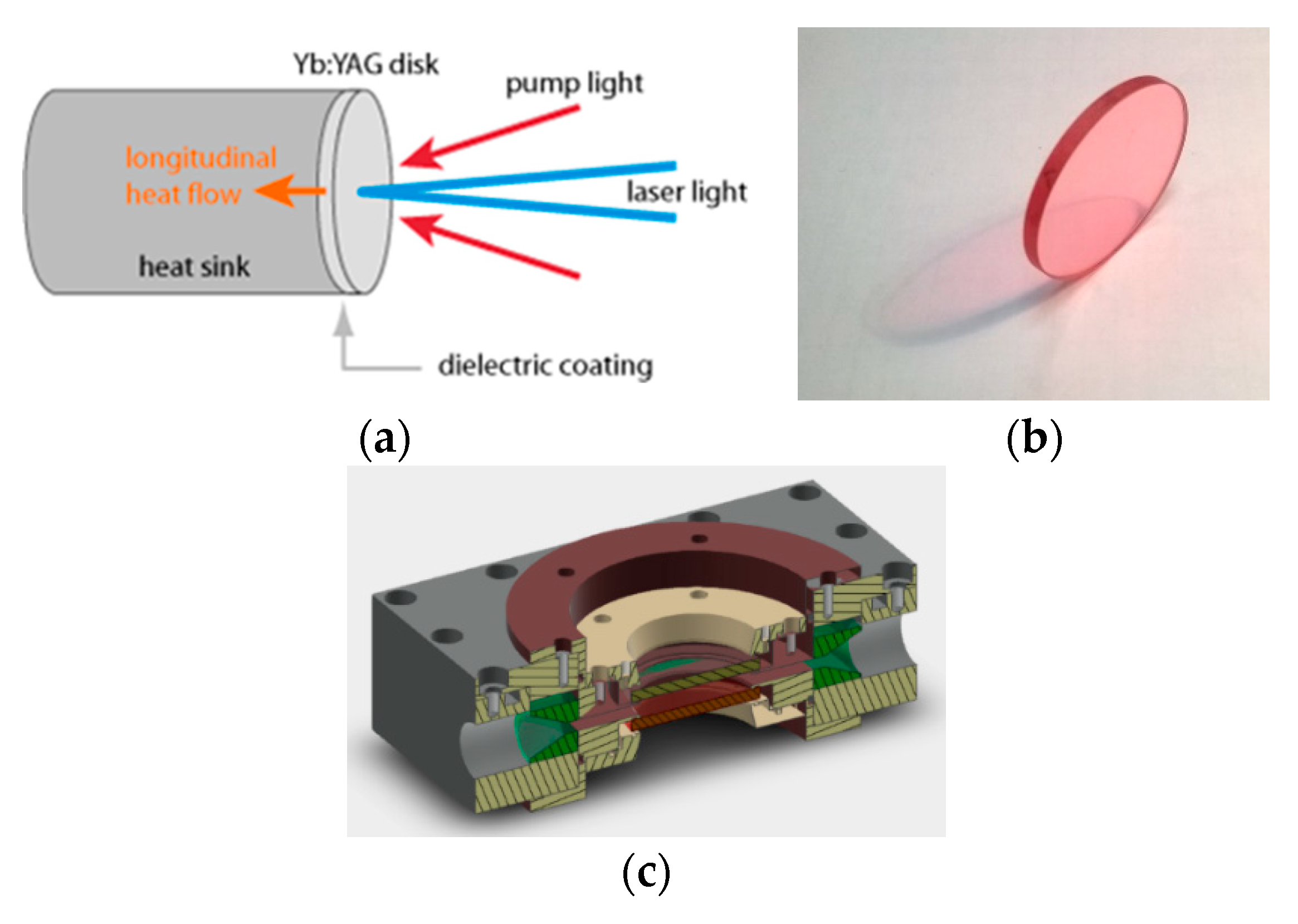

The typical scheme of TD amplifier is shown on

Figure 9 a, the heat is extracted through the largest face of the crystal for efficient and uniform cooling, in opposite to the conventional side-surface heat extraction. The very high thermal conductivity Ti:Sa crystal with combination of TD technology allows to increase this effect, preventing the overheating of the laser crystals and, thus eliminating the beam thermal distortions and possible crystal damage even for an extremely high average power operation regime [

50,

51,

52,

53,

54].

Figure 9b,c demonstrate consequently TD 35*3 mm Ti:Sa crystal and holder with both large surfaces direct contact water chilling.

However, the TD crystal shape represents just one possible geometry for the final amplifier in laser systems, and it may undergo changes depending on the desired output parameters. In paper [

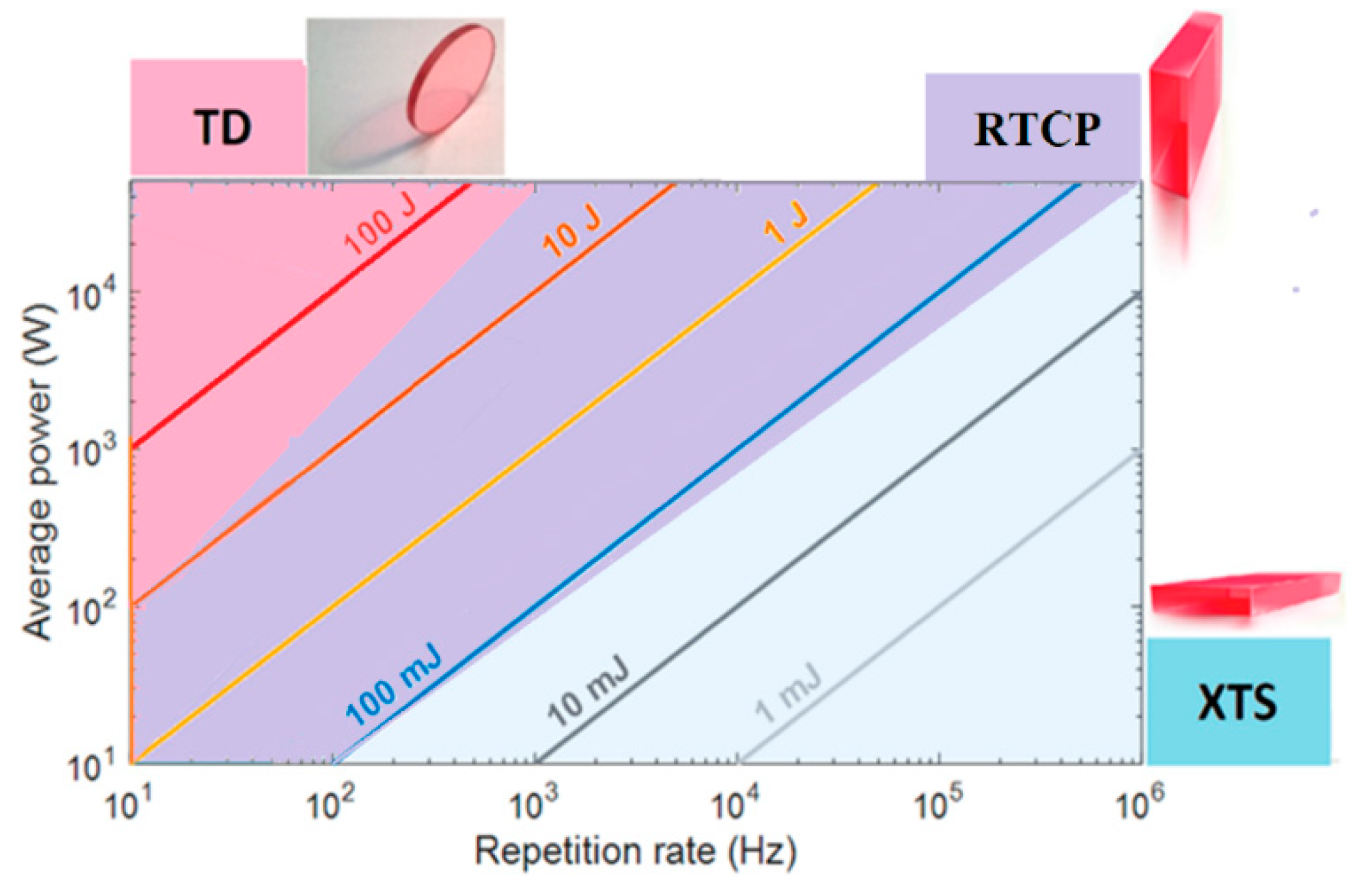

54], simulations were conducted to determine the maximal achievable pump fluence of the amplifier crystal, which was found to depend on the repetition rate (RR). These simulations also highlighted the effect of pump fluences on the selection of crystal shape.

Figure 10 illustrates the relationship between the required output average power and the repetition rate (RR), delineating preferred areas of usage for different Ti:Sa crystal configurations such as Thin Disc (TD), Rectangular Thin Crystal Plate (RTCP), and Cross Thin Slab (XTS). As depicted, the TD crystal configuration is well-suited for systems with an RR below a few hundred Hz, especially if an output pulse energy above 10 Joules is required (red area) [

50,

51]. Conversely, the RTCP geometry demonstrates superiority for Ti:Sa amplifiers operating at an RR above 1 kHz, covering an energy range of 0.1–10 J (violet area). Lastly, the XTS crystal shape emerges as the preferred choice for amplifiers operating at high RR levels above 1 kHz but with a low energy per pulse below 100 mJ (blue area) [

52,

53].

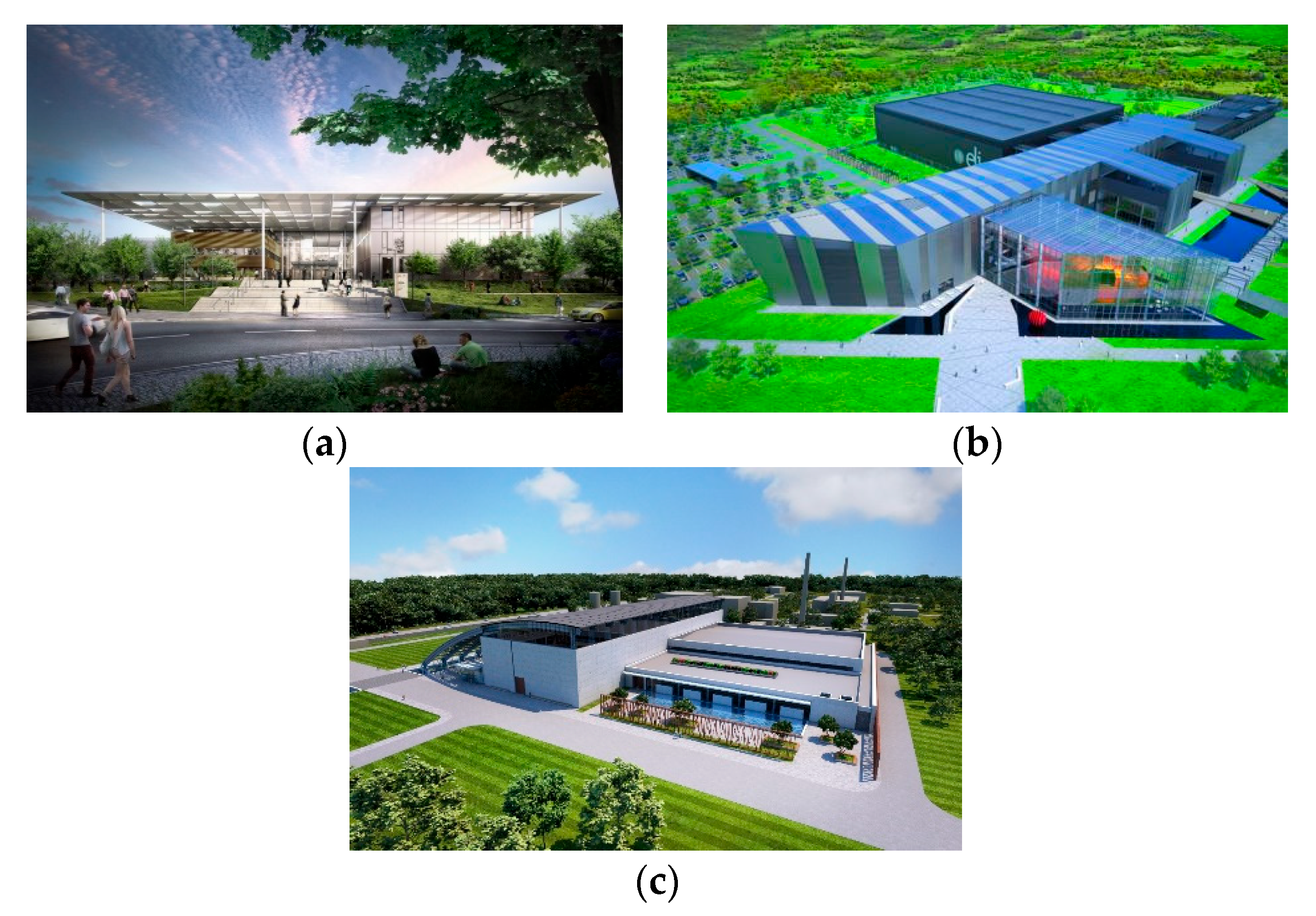

The laser systems utilizing the CPA technique have recently achieved remarkable results and continue to show significant potential for further development. Several facilities have been constructed or are currently under construction. One of the pioneering and notable projects in this field is the Extreme Light Infrastructure (ELI).

Under this project, three laser centers were developed in Eastern Europe (see

Figure 11): ELI-Beamlines in the Czech Republic [

55], ELI-ALPS in Hungary [

56], and ELI-NP in Romania [

57]. These three pillars of ELI include several petawatt-class lasers: ELI-ALPS (HF) Ti:Sa system with a peak power of 2 PW and a pulse duration of 17 fs; ELI-BEAMLINES (L3) Ti:Sa laser with a 30 J pulse energy, 1 PW peak power and a pulse duration ~ 30 fs; ELI-BEAMLINES (L4) Nd: Glass lasers of 2kJ / 10 PW/ 130fs; and ELI-NP with two channels Ti:Sa lasers of 300 J / 10 PW each.

Two other notable high-power laser systems are the Chinese system with an output power of 10 PW [

58] and the South Korean system with an output power of 5 PW. The latter recently achieved the highest intensity of 2×10

23 W/cm

2 [

59].