1. Introduction

1.1. Sustainable Building Materials

The current economy for physical goods relies on extracting valuable resources, often ignoring their life cycle and environmental implications [

1,

2]. The research for sustainable building materials has increased in recent decades, driven by growing environmental concerns and the urgent need to reduce the construction industry's substantial carbon footprint [

3,

4,

5,

6]. Traditional construction materials, while robust, often involve energy-intensive manufacturing processes and contribute significantly to global CO

2 emissions.

The quest to replace synthetic hydrocarbon-based plastics with natural polymeric materials is one of the most critical challenges in the international economy. Cellulose, the most generative biopolymer found in nature, remains the primary raw material for developing biocompatible and biodegradable materials. In conjunction with this, the mycelium of fungi, with its complicated network of tubular filaments known as hyphae, shares a similar structural morphology to cellulose fibrils. This similarity enhances the potential for mycelium to serve as a sustainable alternative in creating new biodegradable composites. These materials have the benefits of biocomposites, particularly their low embodied energy and biodegradability, emphasizing their environmental advantages and sustainability in building applications [

1,

7,

8,

9].

1.2. Mycelium as a Construction Material

Mycelium-based materials show a new approach to fabrication that focuses on growing materials instead of extracting them [

10]. Mycelium's ability to bind organic substrates and its inherent properties as a self-assembling biological material makes it appealing for eco-friendly construction applications. This work explores the potential of FRM composites as innovative and sustainable construction materials that could revolutionize the building industry.

Prototypological research proposed in the realm of architecture involves creating full-scale prototypes as tools for systematic investigation within a broader research context [

11]. They emphasize a holistic and interdisciplinary methodology for developing new materials and construction technologies, mainly aimed at sustainable building practices. Also, [

12] investigate the use of mycelium as a construction material, presenting a classification method that encompasses mycelium type, substrate mixture, supporting structure, and post-treatment. The study features extensive architectural proposals developed with digital design tools, representing diverse approaches and strategies for integrating mycelium composite materials into architecture.

1.3. FRM as a Composite Material

Integrating non-biological or biological materials, such as synthetic fibers or NFs, into the mycelium matrix can improve its structural characteristics. Specifically, the fibers increase tensile strength and the material's resistance to fracture under load by acting as reinforcement.

Mycelium composites are gaining attention as a viable, sustainable material in the construction industry, combining the environmental benefits of NF with the regenerative properties of fungal mycelium. These composites are renewable and biodegradable and offer significant energy savings during production as they grow at ambient temperatures and utilize organic waste as substrates. With excellent thermal and acoustic insulation properties, these materials are ideal for applications such as insulation panels and interior design elements [

13]. Although challenges remain in outdoor durability and large-scale production, continuous research and development enhance their structural integrity and scalability. As the construction industry moves towards greener alternatives, natural FRM composites represent a promising step forward, aligning with global sustainability goals and potentially transforming construction practices to adopt ecological responsibility [

14].

It is well-known that humanity recognizes the significant potential of natural fibers (NFs) as alternatives to petroleum-based materials. In addition, NFs are appealing due to their lower cost, high availability, and diverse feedstock options [

15]. By incorporating NFs to enhance the mechanical properties of mycelium, this research explores the behavior of mycelium composites that are not only environmentally sustainable but also mechanically competitive with conventional materials. This study delves into the properties of these composites, assessing their strength and durability and focusing on their application in non-load-bearing structures and in potential load-bearing structures. Through laboratory experiments and real-world testing, the work aims to demonstrate that FRM composites can offer a viable, sustainable alternative to traditional construction materials, aligning with global sustainability goals and advancing green building technologies.

NFs are increasingly popular for several reasons, including their potential to replace synthetic fiber-reinforced plastics at a lower cost while enhancing sustainability. Many studies [

16,

17,

18] have widely acknowledged the contribution of NFs to enhancing composites. Meanwhile, another study [

19] summarize NFs benefits and drawbacks.

Mycelium composites, with their foam-like properties, are well-suited for non-structural construction applications, such as thermal insulation and door cores. Their inherent structure, even without a specified pore size, makes them effective construction materials [

20].

During the last decades, several different kinds of fibers have emerged to face the demands mentioned above in the construction industry. Experimental studies and modeling have shown that including fibers improves bond characteristics in structural concrete. The addition of short fibers in concrete mass offers a composite material with advanced properties, and fiber-reinforced concrete is a promising alternative in civil engineering applications. The addition of synthetic fibers in concrete results in a new composite material that exhibits different cracking performance and overall behavior than common concrete. A notable influence of the synthetic fibers on improving the post-peak compressive behavior was observed, which indicates the ability of fiber-reinforced concrete to provide increased ductility [

21,

22]. Also, according to the main finding of the paper by Imanzadeh et al, is that increasing the silt-to-binder ratio improves the material's ductility, while the inclusion of flax fibers significantly aids in maintaining cohesion and ductility after the peak stress point [

23].

Meanwhile, the utilization of nondestructive techniques that account for the scattering of fracture energy within the microstructure has proven to be of great importance in understanding crack propagation and damage distribution across the fracture surface [

24]. These methods have shown a strong correlation between the elastic and mechanical properties of fiber composites and can effectively characterize the bonding interactions between fibers and the matrix [

25,

26].

Mycelium is a composite fiber made from natural polymers such as proteins, chitin, and cellulose. Those fibers create the mycelium's structural network, which adds to its flexibility and lightweight properties [

27]. Incorporating wood sawdust into mycelium composites significantly improves material properties, including enhancing mechanical strength and thermal insulation. The mycelium body consists of a complex network of hyphae, which are elongated cells enclosed within a tubular cell wall and separated by internal septa. This structure strengthens the mycelium and supports its growth and ecological functions. The interconnected, fibrous web enhances compressive and tensile strength. Chitin, a natural biopolymer, is essential for creating strong fibers due to its long molecular chains that form tight, stable bonds. This characteristic provides structural integrity and stability to materials like mycelium-based composites, greatly improving their mechanical strength and durability [

28]. Chitin nanofibers from fungal mycelium create a robust network that enhances mechanical properties. Generally, mycelium fibers from fungi like Pleurotus ostreatus offer higher compressive strength than traditional insulators, enhanced structural integrity, and durability. Meanwhile, they have already been applied to construction, furniture, architectural elements, and insulation applications, with a focus on sustainability and functional properties [

29,

30]. Many researchers have focused on the mechanical properties of mycelium structural networks, considering different variables and conditions of loading types of materials and environmental stress. The examination of the mechanical properties of mycelium composites under different stress conditions showed that bamboo microfibers can significantly enhance the material's structural integrity and suitability for various applications where mechanical strength is essential [

31]. Moreover, optimizing the substrate composition for mycelium-based biocomposites (MBCs) maximizes mechanical strength and minimizes the ecological footprint for construction applications [

32]. In this research, mechanical testing has been applied to different material blends to find the optimal balance between mechanical properties and environmental sustainability. Fungi-based binders in composite materials offer an environmentally friendly alternative to synthetic adhesives, reducing harmful emissions and improving mechanical strength [

33].

1.4. Mechanical Properties of the FRM

One of the primary challenges in utilizing mycelium for large-scale structural applications is its inherent weakness, typically exhibiting compressive stress of only 0.1–0.2 MPa without mechanical compaction, and it performs optimally under compression. However, mycelium-based materials are exceptionally lightweight, offering favorable strength-to-weight ratios relative to concrete, which indicates that strategic material placement could enable the construction of large-scale and extended-span structures. Another study [

34] discusses various strategies to strengthen and enhance myco-materials, specifically through the use of mechanical compaction and advantageous and target material placement. Mechanical compaction increases the density and structural integrity of the mycelium composites, enhancing their load-bearing capacity. Additionally, strategic placement of the material in structures optimizes the inherent strength-to-weight ratio of mycelium, making it suitable for larger and more ambitious architectural applications despite its natural limitations in compressive strength. These methods collectively aim to exploit the lightweight nature of mycelium while addressing its structural weaknesses for broader construction uses. The concept of strategic material placement for strengthening and enhancing myco-materials primarily involves designing the mycelium composite's layout and orientation to align with a building project's structural demands. Mycelium can be encouraged to grow in specific directions to align the fibrous network along lines of stress, which can improve the tensile and compressive strength of the material. This is relative to grain direction in wood, where the material is stronger along the grain than across it.

Myco-materials can be compressed or pre-stressed during curing to increase their load-bearing capacity, analogous to pre-stressed concrete. Applying internal pressures to the material enables it to withstand higher external stresses while in use. The strength of myco-materials can also be more effectively exploited through different architectural forms such as arches, domes, or vaults that naturally distribute loads efficiently. These structures are useful for dispersing stresses and lessening the dependency on the intrinsic strength of the material [

35]. The study of [

36] showed that using cold or hot-pressing procedures to create dense panels from mycelium materials can substantially enhance the composite's mechanical characteristics by making it more compact and less porous. Furthermore, it reduces thickness while making it less complicated for fibers to rearrange themselves horizontally in a plane, resulting in more significant interaction between fibers at overlapping points. The pressing temperature significantly impacts the mechanical characteristics of the mycelial-based materials [

28]. In addition, according to another research by [

10] different types of fiber impact the mechanical properties and ability of mycelium composites to be produced. In comparison to cold-pressed and non-pressed samples, heat-pressed samples have greater tensile strength and stiffness and appear to be more brittle. Also, changes in the substrate and type of fungus can affect the thickness of the fungal skin and the homogeneity of the material, which can lead to modifications in the mechanical properties.

The objective of the authors in this study is to provide a detailed review of the properties of FRM composites, including density, compressive strength, and flexural strength. This review synthesizes insights to identify major challenges associated with expanding the use of mycelium-based materials as load-bearing structural components, particularly when integrating natural fibers into the matrix. This analysis will also illuminate potential opportunities and direct future research efforts.

After a standardized and comprehensive review of publications on FRM in engineering and material sciences, the number of publications on this topic was detected to be quite limited. This critical review proposes a novel classification system for these materials to help structure and standardize this emerging transdisciplinary field of knowledge in building construction.

2. Materials and Methods

The methodology investigates the mechanical properties of mycelium-based biocomposites reinforced with NFs, focusing on key properties such as density, compression, and flexural strength. It also investigates how these properties interact with each other in mycelium construction. The review emphasizes the composites' potential as construction material, with an emphasis on the contribution of NFs to the composite. The section mainly focuses on the natural materials used by the researchers to develop FRM composites. [

19]

Research was conducted using four databases: Web of Science, Scopus, Science Direct, and Google Scholar. The search focused on articles using combinations of the keywords "Natural Fiber-reinforced Mycelium Composite for Construction Building Materials". Articles that fell outside the realms of engineering, construction, building technology, or architecture were excluded. The selection process involved reviewing the titles, abstracts, and materials and methods sections of the articles to gather data on mechanical properties such as compressive strength, density, and flexural strength. Subsequently, these data are processed and compared to draw insightful conclusions regarding combining NFs with mycelium to develop robust construction materials.

2.1. Improving Adhesive Characteristics of Mycelium

The process for creating all the different mycelium composites follows the same method of procedure [

37]. As the fungus degrades the substrate to digest its nutrients, it develops its mycelium, which is a highly interconnected network of filaments called hyphae, composed of elongated cells that bind the substrate’s particulates together to yield a mycelium-bound composite. When a fungus grows onto a particulate-based lignocellulosic substrate, fungal cells assemble into filaments called hyphae that form a highly interconnected porous network structure that binds the particulates of the substrate together. Meanwhile, developing mycelium-based adhesives is one area with considerable interest, these types of adhesives have demonstrated promise in various applications, including packaging, textiles, and the construction industry. Nowadays, many researchers [

39,

40,

41] are attempting to enhance mycelium's adhesive abilities and determine the primary challenges and possibilities in this field. Specifically, they utilized the variables influencing the adhesive qualities of mycelium, including the selection of fungal species, substrate composition, and processing procedures.

2.1.1. Type of Mycelium

Different species may influence the material's density, tensile strength, and compressive strength. Hence, the exact kinds of mycelium utilized can vary depending on the bio composite’s planned characteristics. Various fungal species exhibit differences in hyphal characteristics, including diameter, cell wall compositions, and branching patterns, which directly impact the density and tensile strength of the mycelium network and its substrate-binding capacity. Some fungi, like pleurotus ostreatus, form a dense mycelium layer, known as fungal mycelium skin, between the substrate and air, enhancing composite strength. Enzymes secreted by fungi degrade lignocellulosic materials in the substrate, with enzyme type and efficiency varying between species, influencing substrate degradation rates. Additionally, fungal species have distinct growth rates and environmental requirements, further affecting mycelium development and strength. Ultimately, the strength and applicability of mycelium-based composites hinge on the symbiotic relationship between selected fungal species and substrates [

35,

42,

43].

2.1.2. Growing Conditions

The mycelium growing conditions have a major impact on the adhesive strength and durability of materials based on mycelium [

44]. The variation in adhesive effectiveness among various fungal strains and environmental circumstances presents a major obstacle to attaining consistent and dependable adhesive characteristics [

39]. There are several strategies that can be explored to enhance the adhesive properties of mycelium-based materials. The first strategy involves optimizing growth conditions. Meticulously controlling temperature, humidity, and nutrient availability during mycelium's growth can improve its adhesive properties. Machine learning models analyze results from numerous tests to predict specific mechanical properties and recommend processing parameters that enhance strength and performance. This approach is more efficient and less resource-intensive than conducting extensive experimental testing to determine the optimum conditions [

41]. A predictive model establishes the relationship between compressive strength and split tensile strength for engineered cementitious composites [

45]. Based on the aforementioned results, the type and ratio of fibers have a significant impact on the strength of engineered cementitious composites. Research has already indicated that specific combinations of these growth conditions can lead to mycelium with enhanced adhesive characteristics.

To maximize the potential of mycelium-based composites, future research should focus on optimizing growth conditions. Incorporating a vacuum system or an intake airflow system in the incubation chamber can enhance oxygen diffusion during inoculation. However, it is important to maintain optimal relative humidity to prevent the substrate from drying out, which could impede mycelium growth. Additionally, expanding the range of applications for mycelium-based composites and leveraging current study insights will be crucial for advancing this emerging field [

46,

47].

2.1.3. Substrate Selection

The substrate is any material or substance upon mycelium development. It functions as a supportive structure. The composition of the substrate on which the mycelium grows can also significantly determine its adhesive properties. Using substrates rich in cellulose, hemicellulose, and lignin has promoted better adhesion of mycelium-based materials. In the mycelium-based composites, the substrate is the material base that provides nutrients and a structure for the mycelium to colonize and grow, such as sawdust or agricultural waste. For this purpose, optimizing mycelium growth and defining the more suitable characteristics of the composite material requires evaluating the substrate's composition and characteristics. The finalized composite material's density, strength, and growth rate are all significantly impacted by the type of substrate employed, including agricultural waste, sawdust, and straw [

48].

Mycelium-based materials benefit from the strain-hardening properties of intact NF substrates, which provide strength and inhibit shear failure [

40]. Sawdust, straw, jute, hemp fibers, and textile waste are examples of fibrous substrates essential to creating mycelium-based composites. These substrates have special qualities that can greatly influence the final composite material's attributes. Their fibrous structure acts as a scaffold for mycelium's growth and intertwining, enhancing the finished composite's mechanical strength and durability. The final mycelium-based composite's compressive strength and load-bearing capacity will depend on the kind of substrates used [

42].

Summarizing any thin, elongated material that is much longer than it is wide is commonly referred to as a fiber. Fibers may be synthetic, like polyester or nylon, or natural, like cotton, wool, or silk. Fibers are utilized in the context of materials because of their strength, flexibility, and ability to be woven into greater textiles or added to composite materials for enhanced structural integrity. Furthermore, the phrase "fiber" can also refer to additives, including cotton or soy silk fibers, that are merged into the substrate to alter the final composite's physical qualities, increasing characteristics like durability, flexibility, and tensile strength. Researchers found that the mechanical strength is more significantly influenced by the size of the fibers [

10]. Mycelium can grow on a substrate, even on a fiber-substrate. However, incorporating NFs into the substrate can enhance the mechanical properties and structural integrity of the resulting mycelium-based composites, making them more suitable for load-bearing applications [

3].

2.1.4. Genetic Engineering

Genetic engineering of fungal strains to enhance strong adhesive properties can result in better-performing materials [

41]. Using certain chemicals or biological agents during the growth process can enhance the mycelium's inherent adhesive qualities [

40]. Advanced processing techniques like compaction, extrusion, and 3D printing can affect the density and structural integrity of mycelium-based materials, thereby influencing their adhesive strength [

28]. Molecular-level modifications using nanotechnology to alter the mycelium's surface characteristics could improve interface bonding with different materials. Combining mycelium with other natural or synthetic adhesives, fibers, or materials in hybrid composites can exploit synergistic effects to enhance overall adhesive strength. The collaborative interaction between mycelium and other fibers can result in improved mechanical characteristics, such as heightened strength, durability, and resilience to compression [

49].

2.1.5. Additives

The promising approach is the use of additives to enhance the adhesive characteristics of mycelium-based materials. Integration of specific additives during the mycelium growth process has the potential to modify the final adhesive properties, making them more suitable for diverse applications. Nowadays, many researchers are exploring ways to improve mycelium's adherent properties and identify the primary obstacles and potential opportunities in this field [

39,

40,

50,

51]. In addition, by strengthening the internal connections between the hyphae and the NFs inside the composite, adding bacterial cellulose to mycelium composites improves their adhesive properties. Due to its nano-fibrillar form, bacterial cellulose can interlock with the hyphae of mycelium to enhance the contact surface.

Existing research provides substantial evidence for the potential to enhance the adhesive properties of mycelium-based materials by developing advanced processing techniques, investigating additives and pretreatments, and regulating growth conditions. This results in a more cohesive composite material with greater strength and durability, addressing one of the key challenges in developing mycelium-based materials, which is the otherwise weak internal bonding. The incorporation of bacterial cellulose thus results in a strengthening of the mycelium material's overall structure [

52]. Sharma and Sumbia used miscanthus, a C4 grass, as addictive also to enhance the properties of Mycelium [

19].

2.1.6. Manufacturing Processes and Treatments

The development of advanced processing techniques, such as compaction and extrusion methods, can also contribute to improving the adhesive properties of mycelium-based materials [

50], [

19]. Compaction can improve the bond between mycelium and the reinforcement fibers or achieve more satisfactory material homogenization through extrusion, significantly enhancing the composite's structural and environmental performance. These techniques offer the possibility of creating denser and more structurally sound materials, which could lead to enhanced adhesive strength and durability. Investigating the effects of different processing techniques on the adhesive properties of mycelium-based materials would be a valuable prospect for further research.

Once the mycelium has grown through the substrate and around the fibers, halt the growth by drying or heat-treating. This step is crucial to maintaining the material's structural integrity and preventing further biological activity that could compromise its properties. Depending on the application, the composite may need to be post-processed by machining, pressing to the desired density, or applying surface treatments to enhance durability or appearance.

Utilizing mycelium-based bio-composites involves optimizing their substrate composition and production methodology. Primary processing methods typically include drying or heating to complete the formation of mycelium composites [

32]. The main steps can be described by: (i) drying, which typically involves removing moisture from the composite material at room temperature or in an oven at a controlled temperature. This process terminates the growth of the mycelium and solidifies the structure of the material and (ii) heat treatment, which similarly stops the growth of the mycelium but is usually performed at higher temperatures than simple drying. This can also affect the material's structural properties, potentially increasing its strength and stiffness. As for which method is better between drying and heating, it can depend on the desired properties of the final MBCs. Drying at lower temperatures might be less energy-intensive and could preserve more of the natural material properties. Heat treatment might enhance certain properties, such as strength, durability, and resistance to water or pests, but it could also be more energy-consuming and might alter the material's appearance or introduce additional stresses.

Ultimately, the choice of drying or heat treatment would depend on the specified goals for mechanical performance and environmental impact, as well as the nature of the mycelium species and substrates used. Each processing method would need to be evaluated based on the design criteria and environmental considerations for the optimal outcome [

32].

2.1.7. Analytical Tools

Recent studies suggest several potential methodologies for enhancing the adhesive characteristics of mycelium-based materials. Optimizing growth conditions by precisely regulating factors such as temperature, humidity, and nutrient concentrations can improve the adhesive properties of mycelium (Manan et al., 2021). Selecting substrates with high cellulose, hemicellulose, and lignin content, which are known to promote better adhesion, can influence the binding efficiency and mechanical properties of the resulting composite [

10,

40].

To enhance comprehension of the best suitable conditions leading to ideal adhesive properties, simulation and machine learning techniques can be employed [

41]. These techniques take a holistic approach, starting with the first mycelium synthesis and ending with the application in composite production. Combining these techniques can produce mycelium-based polymers with desired adhesive properties in various industrial applications.

2.2. The FRM Composite

To further enhance the material's mechanical properties, the FRM composite, which is an innovative and sustainable material, combines the fungus's root structure and mycelium's inherent growing ability with various reinforcing NFs. In this way, the mixture produces a sustainable and biodegradable composite material, making it an appropriate replacement for traditional synthetic materials in various applications. Modifying the types of fibers induced and the mycelium's growth conditions allows for customizing the composite's mechanical properties, including strength, flexibility, and durability. In general, FRM composites appear to offer many enchanting possibilities for their mechanical properties. Nonetheless, the FRM composites require methodical attention to long-term durability under diverse environmental conditions, property uniformity, and scalability. To conquer these challenges, researchers are working diligently to expand the material's range of applications and solidify its position as an essential part of sustainable manufacturing. Moreover, the distinct characteristics of NFs can be customized to fulfill the demands of various uses. Hemp fibers, for instance, are renowned for having a high tensile strength and are stiff, which makes them appropriate for uses in which structural integrity is crucial. However, flax fibers are highly flexible and resistant to impacts, which makes them perfect for applications where toughness and resilience are critical [

55]. NFs and mycelium improve the composite's mechanical qualities and make it more sustainable by using biodegradable and renewable resources. When combined with NFs, materials built on mycelium can become more robust. While mycelium alone exhibits exceptional adhesive properties and is able to create a cohesive matrix, implementing NFs to the composite enhances its mechanical characteristics, particularly flexural and compressive strength. NFs have a high strength-to-weight ratio and natural toughness. They serve as reinforcement within the composite structure whenever combined with mycelium, propagating stress uniformly while improving overall durability. The material is more resistant to bending, stretching, and impact pressures due to the fibers' additional reinforcement and ability to prevent cracks from spreading all through it. A composite material that is stronger and more resilient than pure mycelium-based materials results from the synergistic interaction between mycelium and NFs.

2.2.1. Fiber Type Selection

NFs are composites with rigid and high-strength cellulose embedded within a lignin matrix. Therefore, high cellulose content corresponds to a high tensile strength. Some fibers, in addition, contain a waxy outer layer that provides a natural protection that guides against bacteria and other potential sources of disease. NFs can be classified according to their origin and grouped into leaf: abaca, cantala, curaua, date palm, henequen, pineapple, sisal, banana; seed: cotton; bast: flax, hemp, jute, ramie; fruit: coir, kapok, oil palm; grass: alfa, bagasse, bamboo and stalk: straw (cereal). The work of Girijappa et al. provided an overview of various sources of NFs, their inherent properties, methods for modifying NFs, and the impact of treatments on their characteristics [

56]. It also summarizes the primary applications of NFs and their efficient utilization as reinforcements for polymer composite materials.

Overall, the key factor is the proper integration of the fibers with the mycelium matrix, which can create a material with markedly improved mechanical properties suitable for various applications, including certain architectural elements [

57].

2.2.2. Fiber Preparation and Surface Modification

The natural fiber-reinforced polymer composite performance depends on several factors, including fiber chemical composition, cell dimensions, microfibrillar angle, defects, structure, physical properties, mechanical properties, and also the interaction of a fiber with the matrix. The primary drawbacks of using NFs as reinforcements in composites include their poor compatibility with the matrix and their tendency to absorb moisture. Consequently, modifications to NFs are often undertaken to enhance their surface properties, thereby improving their adhesion to various matrices. With a robust and well-bonded interface, exceptional strength and stiffness can be achieved, although this may result in a brittle composite that allows cracks to propagate easily through the matrix and the fiber. Conversely, a weaker interface can diminish the efficiency of stress transfer from the matrix to the fiber.

The fibers are prepared by cleaning and sometimes treating them to enhance compatibility with the mycelium. This treatment could involve applying natural binders or adjusting the fiber surface for better adhesion. Treatment of fibers with alkali is also referred to as mercerization and it is one of the most used fiber treatment methods [

58]. Alkaline treatment has the following effect on fibers: Removal of certain amounts of wax, lignin, oil and other impurities. Decomposition of cellulose which leads to exposure of short length crystallites; Increase in the roughness of the fiber surface thereby yielding better mechanical properties; Improves the wettability of fiber surfaces. [

55].

A method for improving the adhesion characteristics of NFs is carried out by treating NFs with a fungus [

59]. Treated fibers showed improved acid-base characteristics and resistance to moisture. Improved acid-base interactions between fiber and resin are expected to improve the interfacial adhesion, whereas improved moisture resistance would benefit the durability of the composites. Finally, composites were prepared using untreated/treated fibers and unsaturated polyester resin. Composites with treated fibers showed slightly better mechanical properties, which is most probably due to improved interfacial adhesion.

Physical methods include stretching, calendaring, thermo-treatment, and the production of hybrid yarns to modify NFs. Physical treatments change the structural and surface properties of the fiber and thereby influence the mechanical bonding of polymers. Physical treatments do not extensively change the chemical composition of the fibers. Therefore, the interface is generally enhanced via an increased mechanical bonding between the fiber and the matrix.

Chemical modifications of NFs aimed at improving the adhesion within the polymer matrix using different chemicals were investigated. Various methods, such as alkaline, silane, or other chemical treatments, have been developed to enhance fiber-matrix compatibility and improve composite quality. Although NF composites are still in development and their applications are limited, they hold great promise as a sustainable alternative to conventional materials [

4].

The physical treatments change the surface and structure properties of the fibers without the application of chemicals and improves the bonding between the polymer matrix and the reinforcement fiber-matrix thus increasing the strength of the fabricated composites [

60]. Physical techniques like corona treatment are used for surface oxidation activation. This process alters the surface energy of cellulose fibers. Corona discharge treatment on cellulose fiber and hydrophobic matrix was found to be effective for the improvement of the compatibilization between hydrophilic fibers and a hydrophobic matrix [

55].

Each treatment type can induce specific changes in the surface layers of NFs. However, the overarching objective is to enhance the physical and chemical interactions between the fiber and the matrix, aiming for exceptional composite material performance [

16].

The decision impacts not only the handling and durability of the material but also its structural integrity and load-bearing characteristics. Drying, which induces dormancy, allows for potential continued growth under suitable conditions, possibly affecting long-term stability and strength. On the other hand, heating permanently halts growth, possibly leading to more consistent characteristics over time. After cultivation, drying or heating is used to stop mycelial growth. If this is done through slow drying, the evaporation of water from the mycelium and the substrate could create a lightweight, porous material with closed-cell structures, much like foam. However, this porosity could compromise compressive strength. Conversely, rapid or uneven drying might create internal stresses that reduce structural integrity. Heating often removes moisture more thoroughly and kills the mycelium, leading to a fixed internal matrix, which might result in increased compressive strength but also potentially greater density due to shrinkage and solidification of the composite components [

53].

If the substrate is dense or the growth conditions do not promote strong binding and development of a robust mycelial network, the resulting material may be dense without being particularly strong in compression [

54].

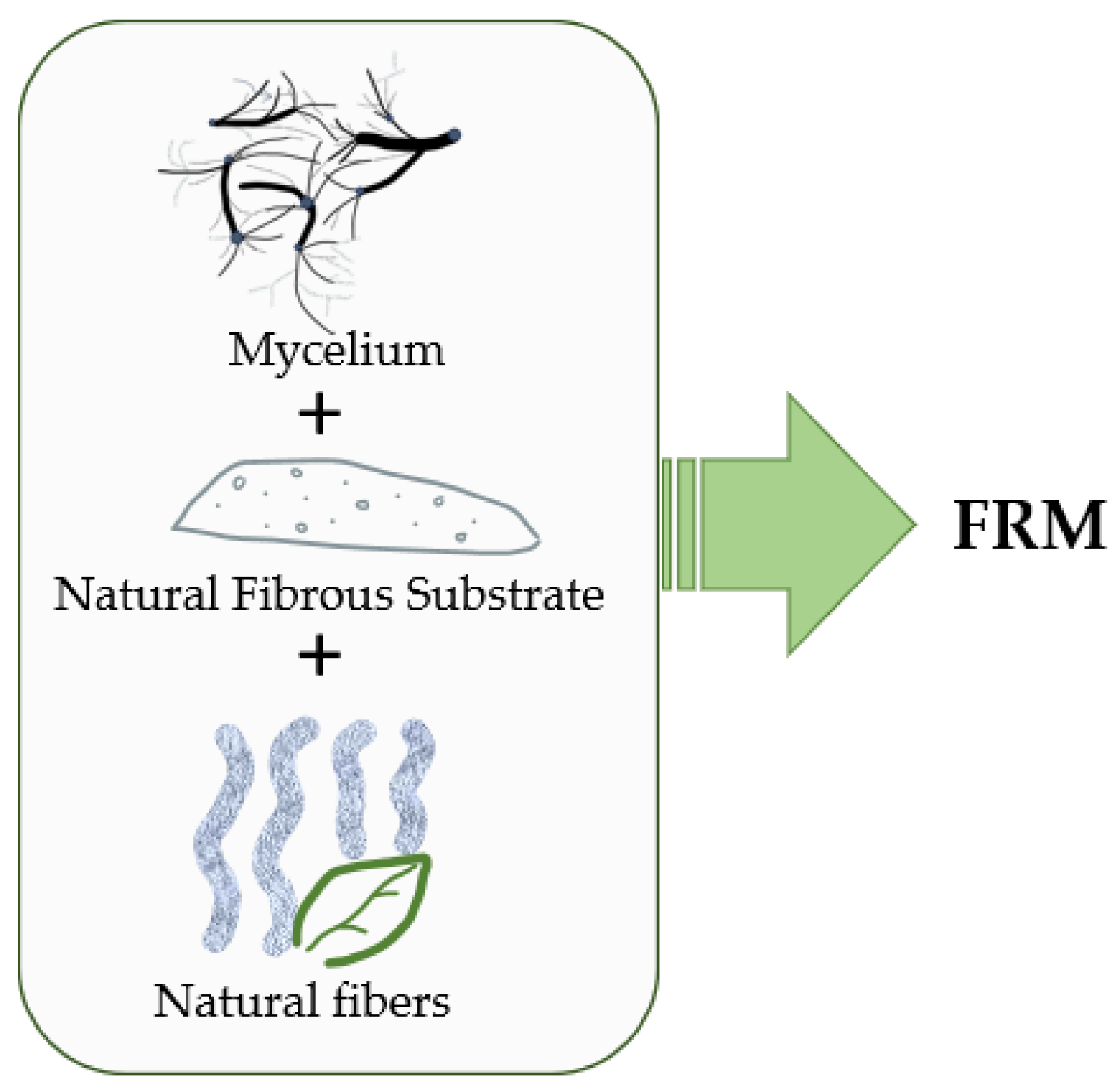

2.2.3. Combining Mycelium and NFs

The fibers blend with the mycelium substrate, typically consisting of mycelium spores and a nutrient base like agricultural waste products. Ensuring a uniform distribution of fibers throughout the matrix is essential to achieve consistent strength. The mixed material is placed into a mold to shape the composite. The mycelium then needs to be adequately inoculated to start the growth process. Integrating fibers with the mycelium matrix correctly is crucial for creating a solid and durable composite. The composite processing ingredients, as depicted in

Figure 1, consist of mycelium, fibrous substrate, and additional NFs.

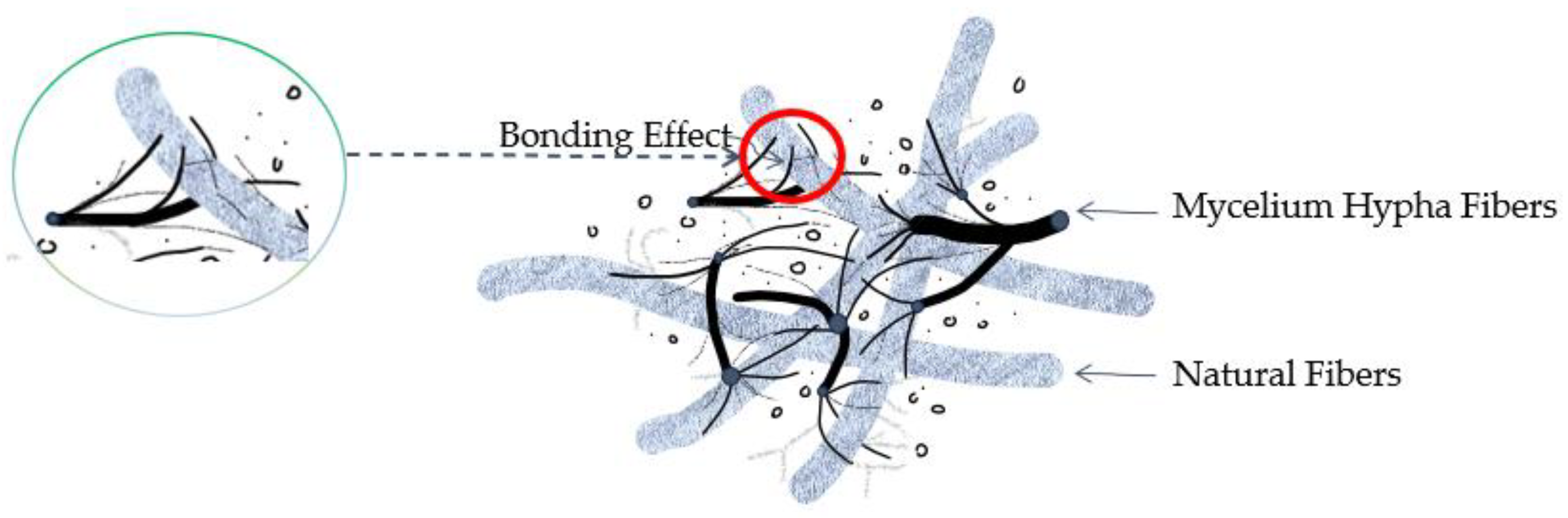

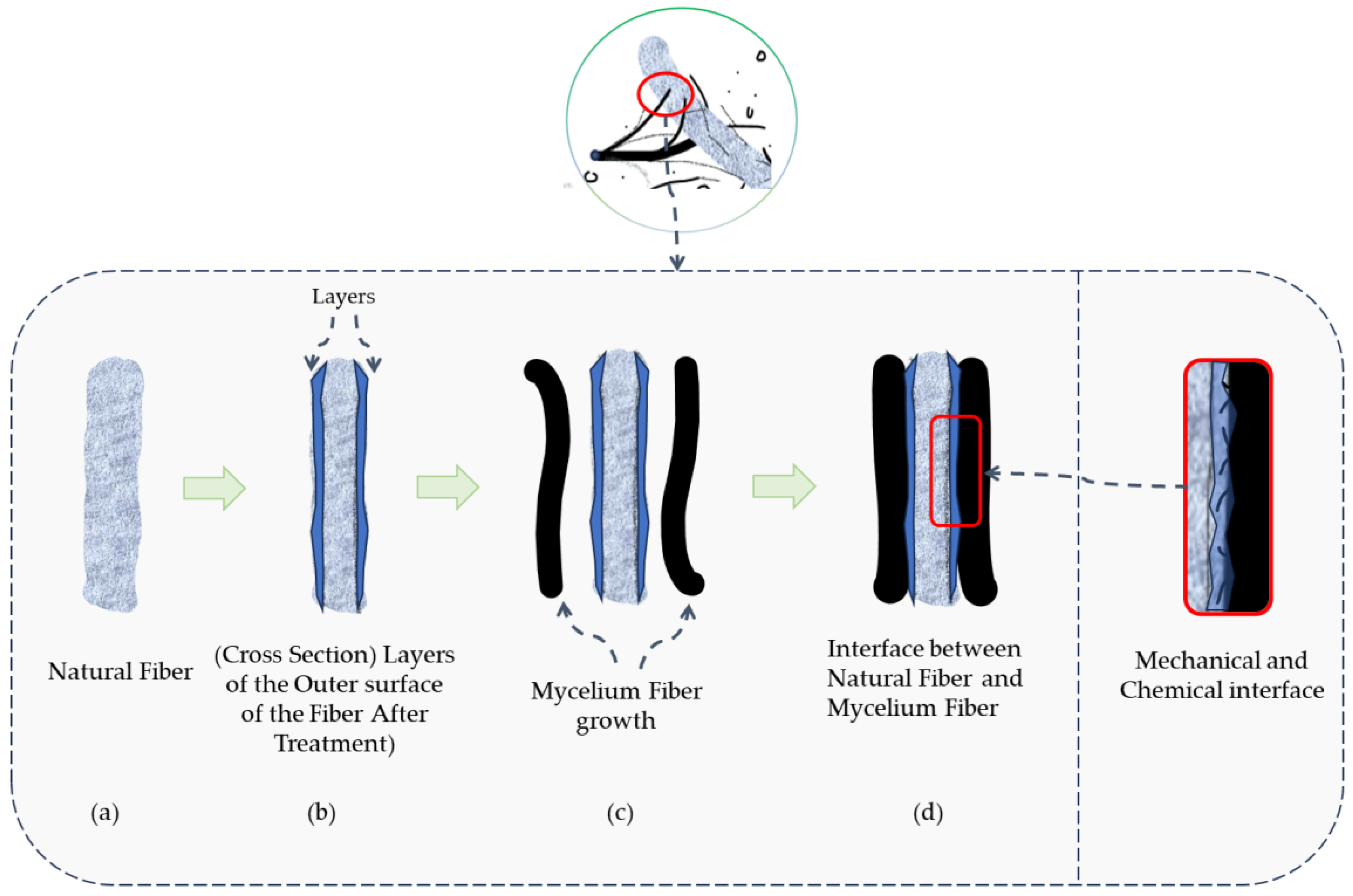

Understanding the mechanisms of the mycelium networking process provides insight into how these composites achieve their unique properties. For optimal coverage, an active surface on both the NF and the mycelium fiber is essential to maximize the bonding effect at the interface between them. As can be depicted in

Figure 2, the bonding effect between mυcelium hypha fibers and NFs. The biological mechanisms of the mycelium networking process enable mycelium-fungal networks to expand in response to their environment, forming complicated, interconnected structures.

The interface, where two distinct materials converge, is crucial for transferring stress and preventing delamination.

Figure 3 shows the bonding effect in the interface zone. Cultivating mycelium hypha fibers enables them to grow and establish connections with the treated NFs. Simultaneously, the mechanical and chemical interface between layers of NFs is developed and strengthened as the mycelium hypha fibers integrate, resulting in a robust composite structure.

The key differences from other traditional fiber-composites are:

Mycelium materials are fully biological and sustainable while other traditional composites often use synthetic polymers,

Mycelium materials are biodegradable and can be grown using less energy and have lower environmental impact compared to the production of synthetic polymers,

Mycelium materials, which contain hyphae—a dynamic growing variable—the precise mix proportion is not initially precisely known, unlike in traditional composites where the mix proportion is defined at the outset.

Traditional composites offer higher strength and durability than mycelium-based materials. However, mycelium composites are continuously being improved and may find appropriate applications where lower mechanical properties are acceptable,

Traditional composites often require high-temperature processing and chemical additives, whereas mycelium materials grow at room temperature and use biological processes.

While the basic principle of creating a composite material is similar — reinforcing a matrix with fibers — the bonding mechanisms and the materials used differ significantly, reflecting their varied applications and environmental impacts.

2.2.4. Fiber Distribution and Bonding

As the fiber content increases, the distribution of fibers within the composite may become less uniform. This can create weak points or areas with less effective stress transfer. Additionally, higher fiber content can interfere with the bonding between the fibers and the matrix (the surrounding material that holds fibers together), which is crucial for transferring loads effectively throughout the composite [

32]. Natural fiber-rich substrates provide properties like hardening of the strains to mycelial products by giving them strength and avoiding failure due to shear [

28,

50]. The impact of the fibrous fiber content on the properties of the mycelium composites results from the interaction between the mycelium's natural network formation and the structural qualities provided by the fibrous materials. The precise effects depend on factors like the type of fibrous material, its proportions within the composite, and the mycelium's growth and processing conditions.

The mechanical characteristics and the durability of the resultant composite can be improved by altering the surface of the fibers using suitable treatments by enhancing the physical and chemical interactions between the fiber and the matrix [

61,

16]. Moreover, NFs have a hierarchical structure comprising primary and secondary layers that control the mechanical behavior of plant fibers and, in turn, the properties of composite materials into which they are included [

17,

62].

Mycelium materials use fungi's root structure to bind natural substrates, which can include plant NFs, agricultural byproducts, or other organic materials. One type of building element is depicted in

Figure 4.

2.3. Problems in the Addition of NFs in MBCs

Although increasing the strength is preferable, the NFs might sometimes stiffen the composites. The mycelium fiber network's inherent structure lowers its deformation and bending capacity, which could diminish its flexibility and increase the material's brittleness and fragility [

61]. The equilibrium between the benefits and the potential drawbacks, such as handling brittleness, water absorption, and the processing difficulties associated with incorporating fibers into the mycelium matrix, is a complex interplay of several variables. These include the fibers' type, quantity, orientation, production method, and mycelium's development properties, all of which significantly influence the final outcome.

3. A Comparative Review of The Mechanical Properties of FRM Composites

The respective mechanical tests evaluate the mechanical characteristics of FRM composites, such as density, compressive strength, and flexural strength, and it is crucial to assess their suitability as a construction material. Compressive strength is a vital characteristic that estimates a material's resistance to direct pressure from an applied compressive force. The value of the material’s compressive strength is a criterion for usage in the building and construction industry. Meanwhile, the mycelium's growth substrate impacts its density. Some substrates might produce a denser mycelium network but do not necessarily enhance the binding quality, which is crucial for compressive strength. Flexural strength is a vital mechanical property indicating a material's deformation resistance under bending loads. FRMs, renowned for their outstanding flexural strength, owe this quality to the blend of a flexible matrix and high-strength fibers. This characteristic renders them well-suited for various structural applications. Recognizing flexural strength is pivotal for discerning both the potential applications and limitations within construction and design when considering mycelium-based composites.

Table 1 shows the mechanical properties of the reviewed FRM composites from different studies. It also indicates the type of mycelium and the corresponding fibrous substrate for each referenced study.

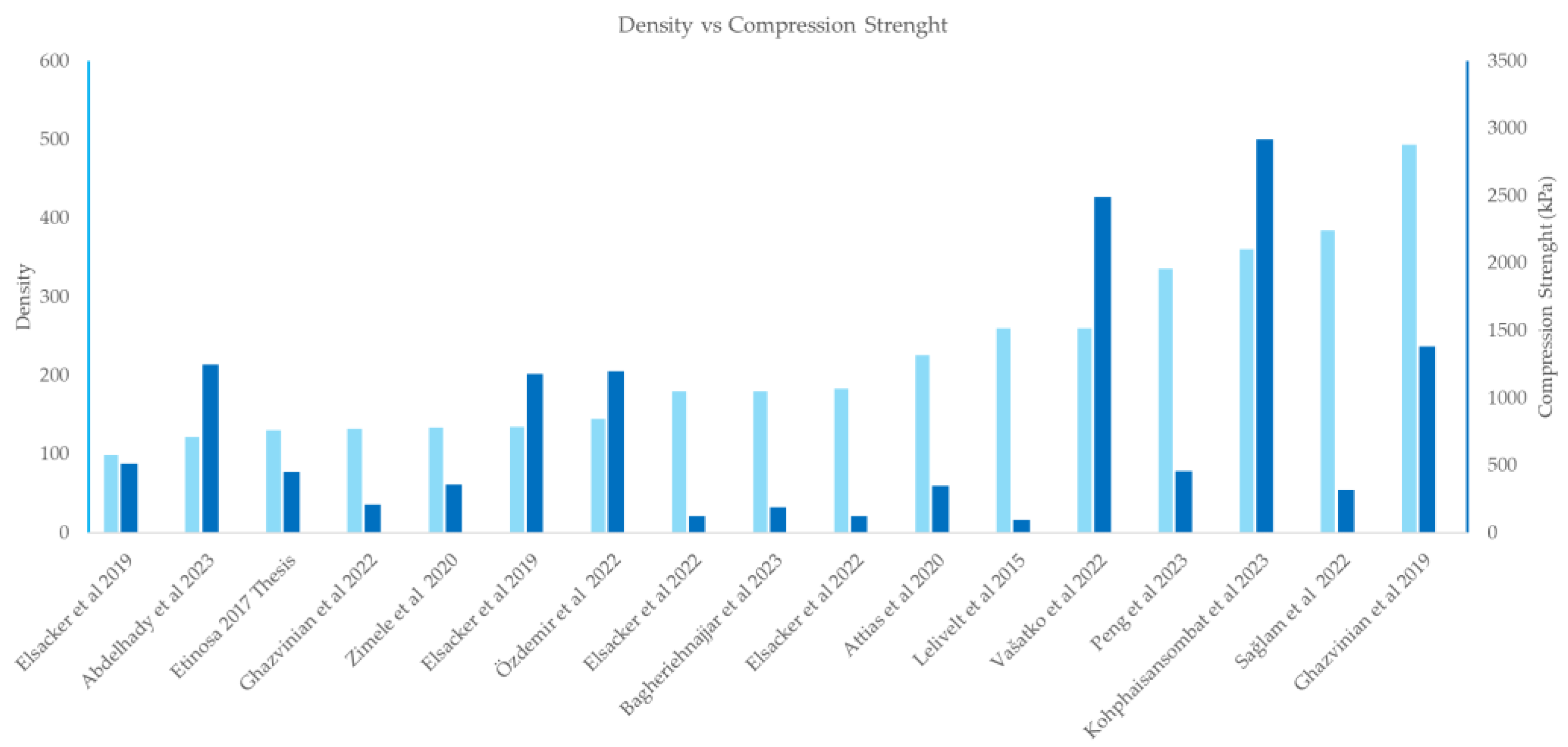

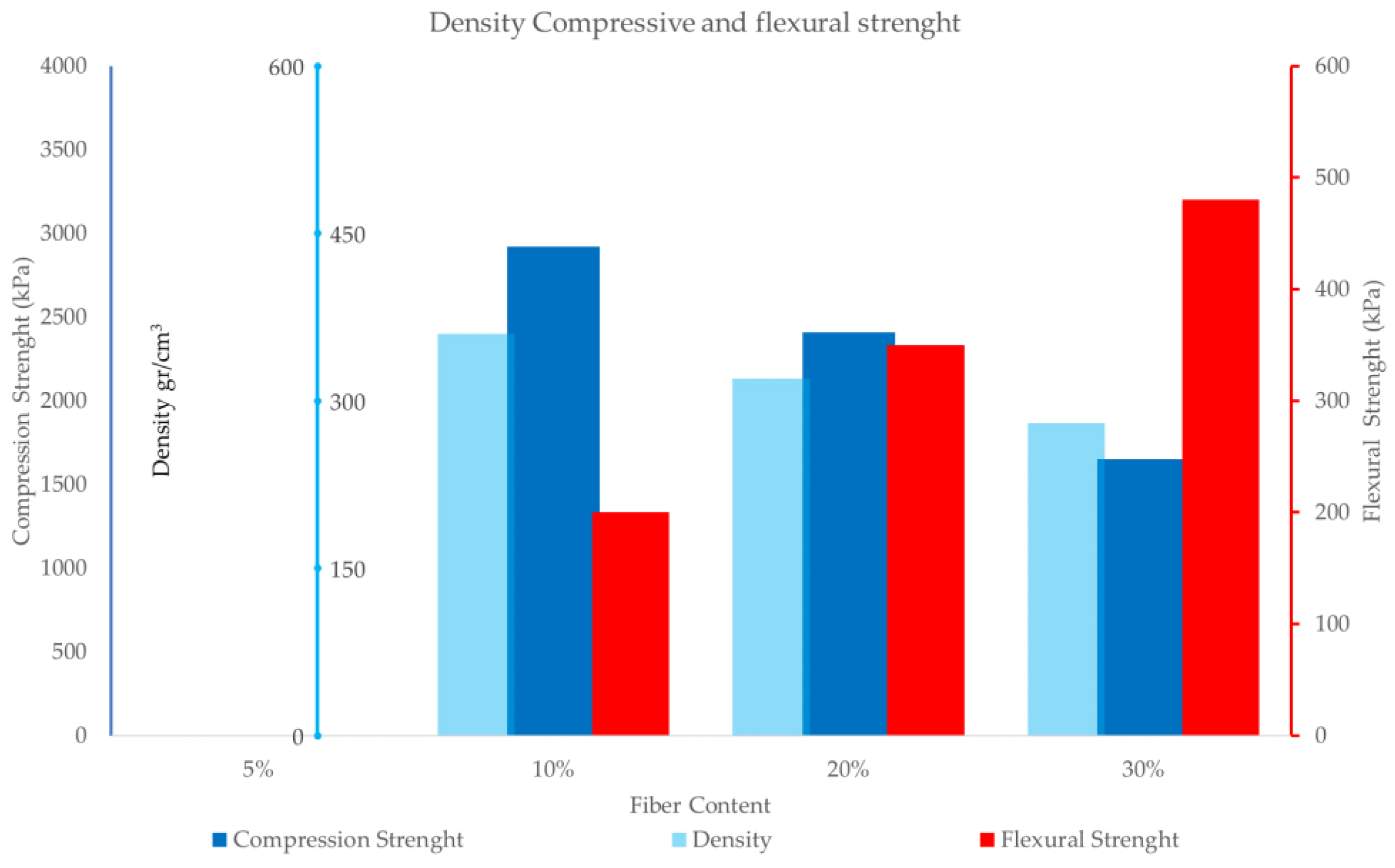

3.1. Density

There is a correlation between compressive strength and density in composite materials. Generally, as the density of a material increases, so does its potential for higher compressive strength because a denser material often indicates that there are fewer voids within the structure, which can increase its ability to withstand compressive forces. However, this relationship can be complex because, at some point, increased porosity or specific configurations of the internal structure might contribute positively to mechanical strength in certain composites. In the context of mycelium-based composites, the study [

76] found that the composite reinforced with 10% natural pineapple fibers exhibited the highest density and, correspondingly, the highest compressive strength. This suggests that within this specific set of materials, there is a direct correlation where increased density, facilitated by the addition of reinforcing fibers, leads to increased compressive strength. Nonetheless, this trend can be influenced by other factors, such as the even distribution of fibers, matrix-to-fiber ratio, and the characteristics of the fiber and matrix materials.

In composite materials, density generally relates to compressive strength, although the relationship can vary depending on the specific material and its structure. Typically, a higher density in a composite material can imply a higher volume of solid material, which often contributes to greater compressive strength since there is more material to resist compression.

However, the correlation is not always linear as illustrated in

Figure 5. If the increased density results from factors such as porosity or the incorporation of low-strength fillers, the impact on compressive strength may be inconsistent, and a clear increase in strength may not be observed. Conversely, if a material's higher density comes from the addition of high-strength reinforcements, the composite's overall compressive strength might increase significantly.

The specific architecture of the composite, including the type of matrix and reinforcement used, the bonding quality between them, and the internal structure (like the presence of voids or the distribution of the reinforcement within the matrix), can all dramatically influence how density and compressive strength are related. Some lightweight composites are engineered to have low density yet maintain high compressive strength through optimized microstructures and material arrangements.

In the cases involving mycelium-based composites, it is crucial to understand that their unique biological structure and the interaction with added substrates will influence both density and compressive strength in different ways compared to more conventional materials [

73,

75,

77].

3.2. Compressive Strength

The compressive strength of mycelium is a vital consideration in numerous applications, particularly in sustainable building materials. Understanding the factors influencing FRM composite compressive strength is essential for optimizing its potential for sustainable construction [

32,

39,

42,

51,

69,

73,

75,

77].

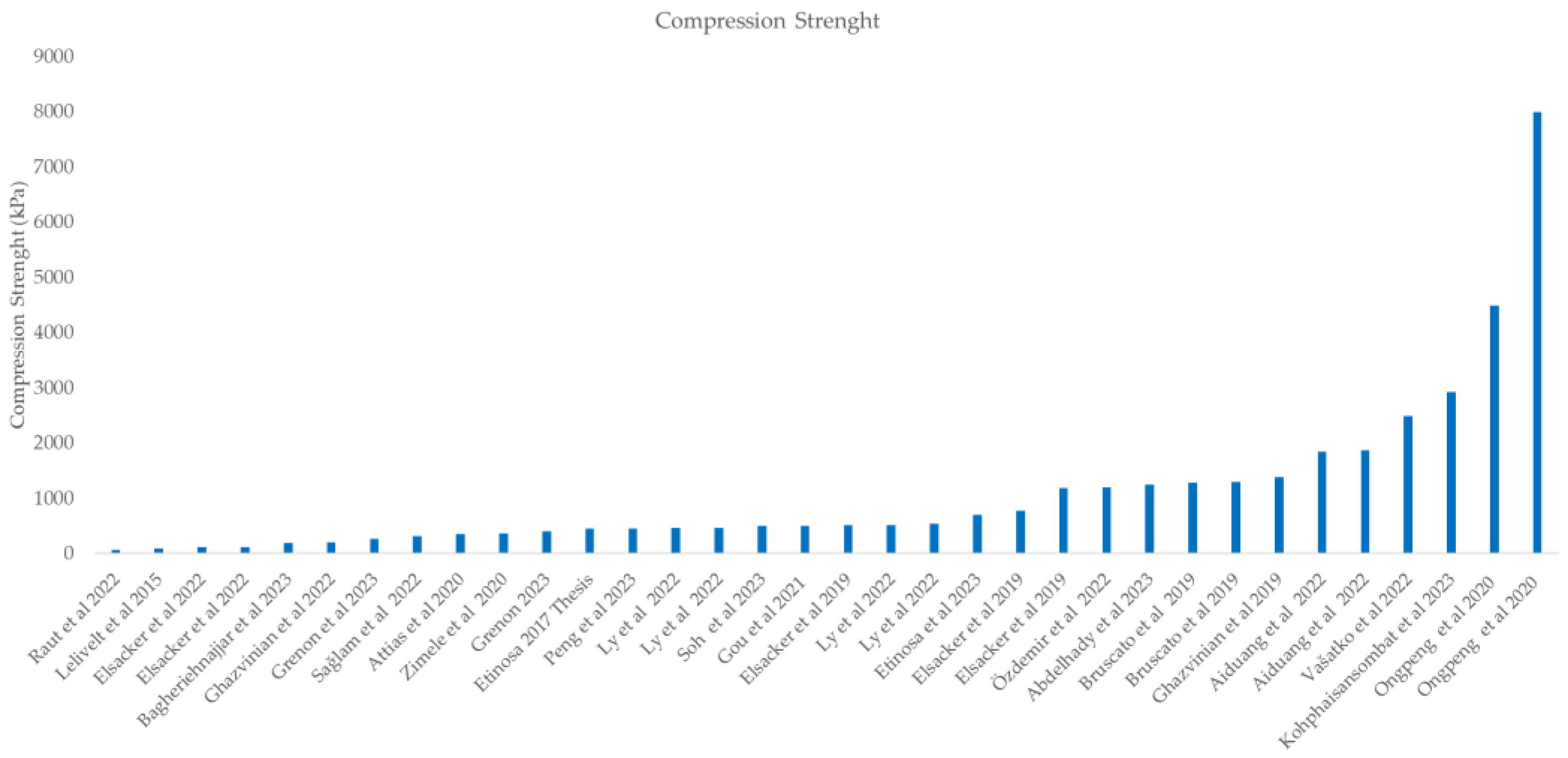

Figure 6 depicts the compression strength of various FRMs studied in the literature arranged from the lower value to the high.

Based on the research presented by Peng et al. [

74] there is a relationship between compression strength and density in mycelium bio-composites. The density of the prepared mycelium bio-composites ranged from 0.249 g/cm

3 to 0.336 g/cm

3. The compression strength of the mycelium bio-composites ranged from 270.31 kPa to 456.70 kPa. The relationship between compression strength and density follows a general trend of higher density leading to higher compression strength.

The relationship between compressive strength and density in mycelium composites shows a slight tendency for compressive strength to increase with density. However, this trend is not consistent and is influenced by factors such as the presence of nanoclay and the specific composition of the composites. Therefore, there is no clear, consistent relationship between compressive strength and density. Other factors, including the inclusion of nanoclay and the composite composition, appear to have a more significant impact on the compressive strength of mycelium composites. [

69]

In mycelium composites, density is directly related to compressive strength. Higher density often correlates with greater compressive strength due to reduced porosity and increased mass per volume, which enhances the material's resistance to compression. As mycelium grows, it binds substrate particles, and densification of this network improves compressive strength. However, this relationship is influenced by factors such as the binding substrate, type of mycelium, and production process.

Effect of the NFs on the Compression Strength of FRM

The recent literature indicates that NFs play a crucial role in creating composite mycelium materials, especially for engineering structural applications. Adding bamboo fibers up to a certain percentage could enhance density and mechanical strength, while above a certain threshold, these properties might start to vary [

32]. This work provides a comprehensive analysis and comparison of studies utilizing only NFs in constructing fiber-reinforced mycelium composite materials.

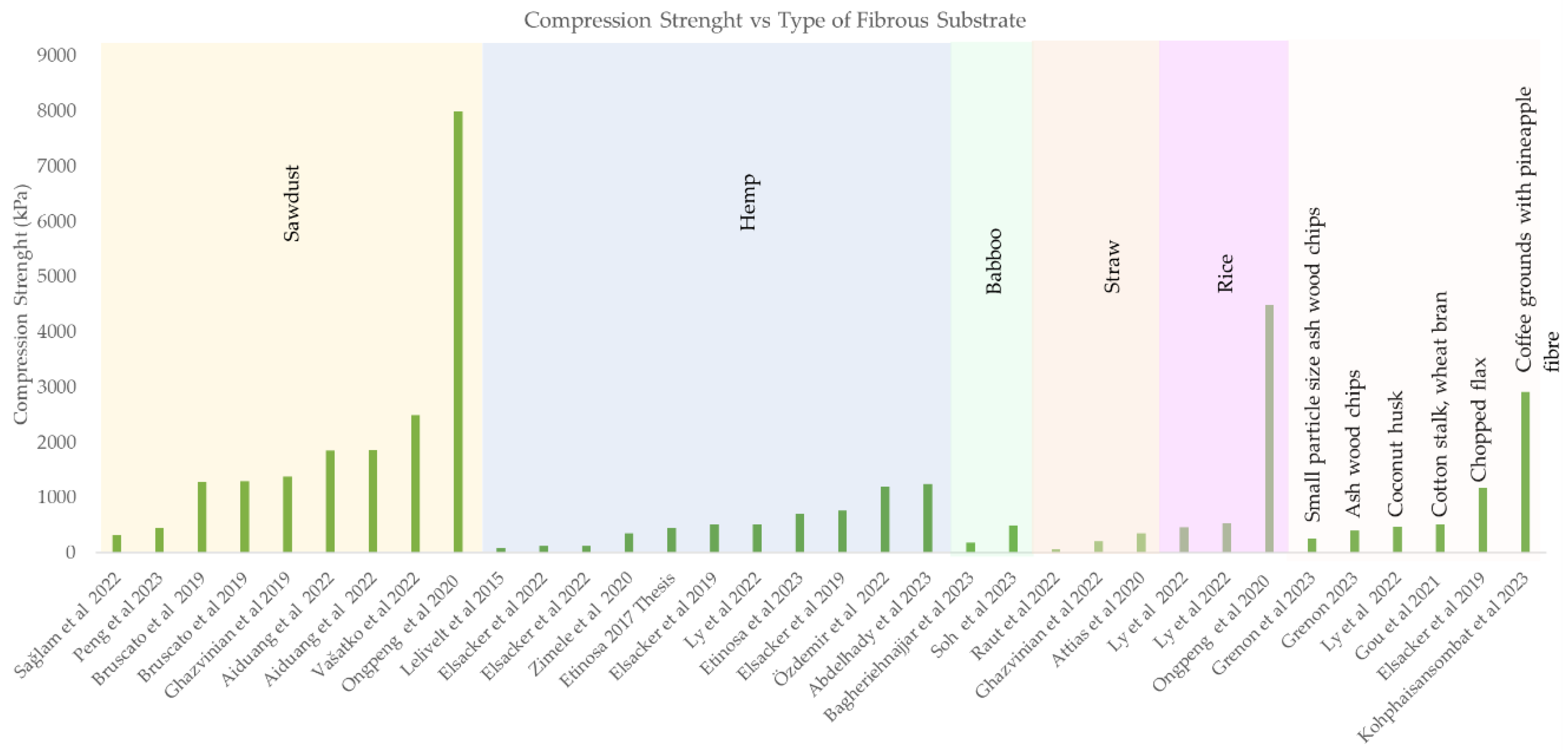

Figure 7 and

Figure 8 depict the compression strength of various FRMs, classified according to the type of fibrous substrate and the type of mycelium, respectively. These visualizations offer insights into how different fibrous substrates and types of mycelium influence the compression strength of FRMs.

Among the various fibers, fine bamboo fibers are particularly effective in increasing the density and mechanical strength of mycelium composites [

32]. Pre-compression further enhances these properties, making it a valuable process in producing high-density, high-strength mycelium-based materials. Conversely, thick bamboo fibers, when added to the substrate mix for mycelium-based composites, led to a reduction in material strength due to their size and rigidity, which resulted in less compactness and more pores within the final material. The sawdust thoroughly incorporates the finer bamboo strands, which are more pliable and may disperse more uniformly in the mold. Furthermore, due to their smaller size, finer fibers might be more readily ingested by fungi, which would facilitate the formation of a denser and more cohesive material structure.

The clear correlation between substrate density, MBC density, and compressive strength highlights the necessity of selecting the optimum substrate to maximize MBC performance in construction applications. Some studies have shown the importance of lignin in determining mycelium-based composites' mechanical properties (2022 Ghazvinian). In addition, the sawdust-to-straw ratio in the substrate mixture can significantly impact the density and compressive strength of mycelium-based materials. The physical and chemical differences between sawdust and straw affect the mycelium's growth behavior and the final composite's structural qualities. Because sawdust usually includes finer particles, it can pack the substrate more densely, increasing the density of the mycelium-based substance. Contrarily, straw is often hollower and more fibrous, with less density when used alone.

The variety of fibers influencing the density originates from the different organic and agricultural waste materials in the mycelium composites. Specifically, in the context of mycelium-based composites, the type of substrate used, such as different types of agricultural waste (like straw or sawdust) and the inherent properties of those fibers, such as their size, porosity, and water absorption capacity, can significantly impact the final density of the composite material [

35]. Additionally, the density of the fibrous additive, such as pineapple fibers or other NFs, can also impact the overall density of the composites [

76].

The addition of hemp fibers enhances the mechanical properties of the Mycelium-Based Foams, including compression strength. The results obtained from the compression test from the study of Picco et al 2024, where it can be observed that the 50% PS-50% hemp fiber and 25% hemp fiber 75% peanut shell combinations improved the compressive, reaching compressive strain values of 0.167 MPa and 0.117 MPa, respectively. Both values were higher than the two expanded polystyrene materials tested for comparison. The 100% hemp fiber and 100% peanut shell materials were less rigid than the tested expanded polystyrene, indicating that mixing is beneficial for achieving better properties [

78].

From the above studies, the inclusion of natural fibers significantly enhances the compression strength of mycelium composites, making them more suitable for construction applications. Fine bamboo fibers and sawdust improve density and strength, while thick bamboo fibers can reduce strength due to increased porosity. The optimal combination of substrates, such as sawdust and straw, is essential for better results. Hemp fibers specifically enhance compression strength. The research highlights the importance of substrate and fiber selection in developing high-performance, sustainable mycelium-based construction materials.

3.3. Flexural Strength

Tensile, flexural, and impact fractural characteristics are reinforced plastic composites' most commonly investigated mechanical properties. Impact strength is one of the undesirable weak points of these materials in terms of mechanical performance. Besides these tensile, flexural, and impact properties, the long-term performance (creep behavior), dynamic mechanical behavior, and compressive properties are also investigated for NF composites. To improve performance to the desired level, much work still needs to be done, considering fiber processing, non-linear behavior, fiber-matrix adhesion, fiber dispersion, and composite manufacturing with optimized processing parameters.

Impact of NFs on the Flexural Strength of FRM

NFs have been widely researched for their impact on the flexural strength of mycelium composites [

36,

52,

61,

69,

71,

75,

79,

80]. The use of NFs in composite materials has gained attention due to their biodegradability, renewability, and low environmental impact. Many studies have investigated the influence of NFs on the flexural strength of mycelium composites. Adding NFs increases the composite material's flexural strength, acting as reinforcement and inhibiting crack propagation. Furthermore, NF distribution and alignment within the mycelium matrix are critical factors in defining the composite's total flexural strength.

Furthermore, the interaction between NFs and the mycelium matrix has been a focal point of investigation, as it directly impacts the composite's mechanical performance. Understanding the bonding mechanisms and interfacial interactions between NFs and the mycelium matrix is essential for optimizing the composite's flexural strength.

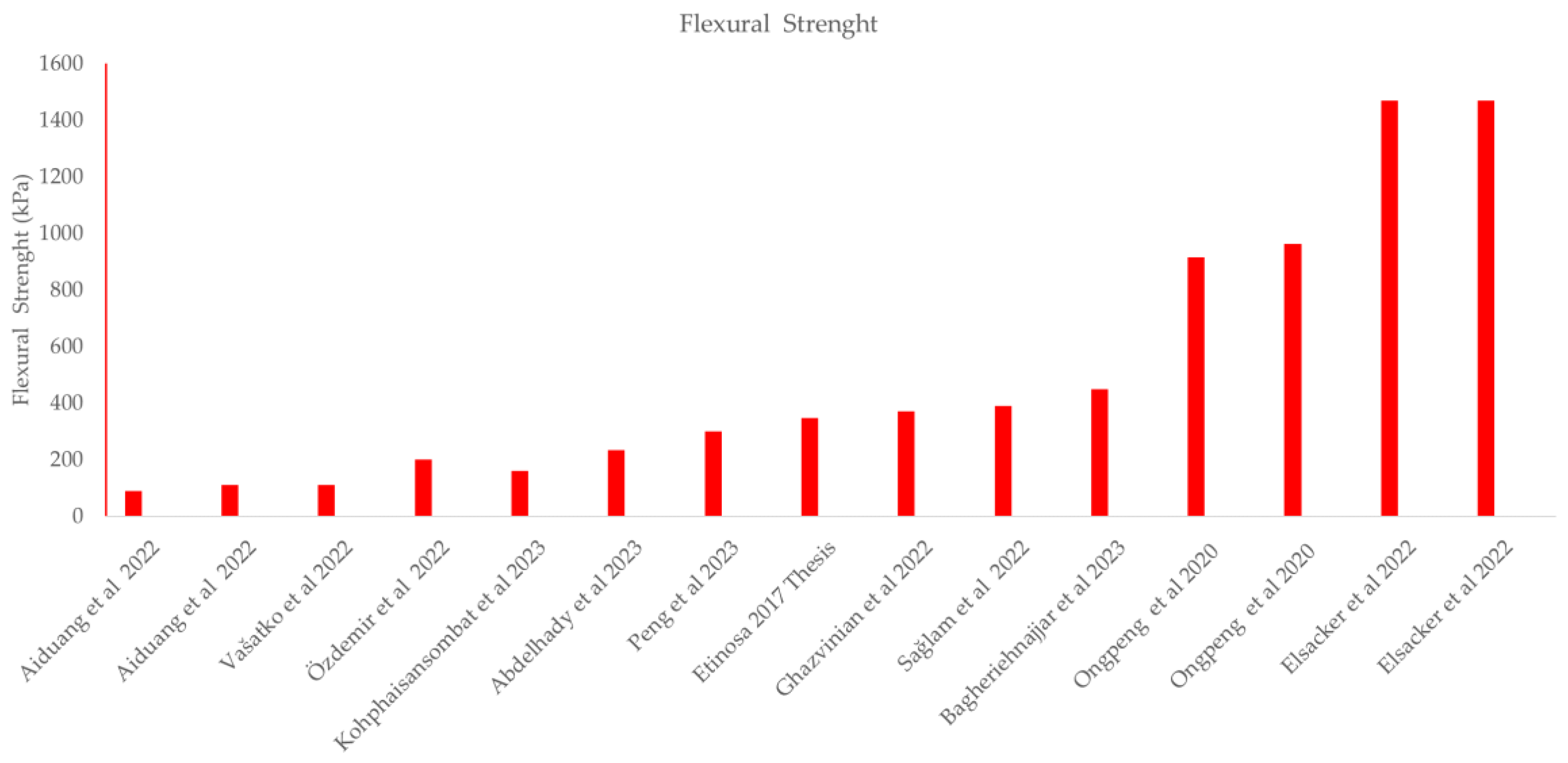

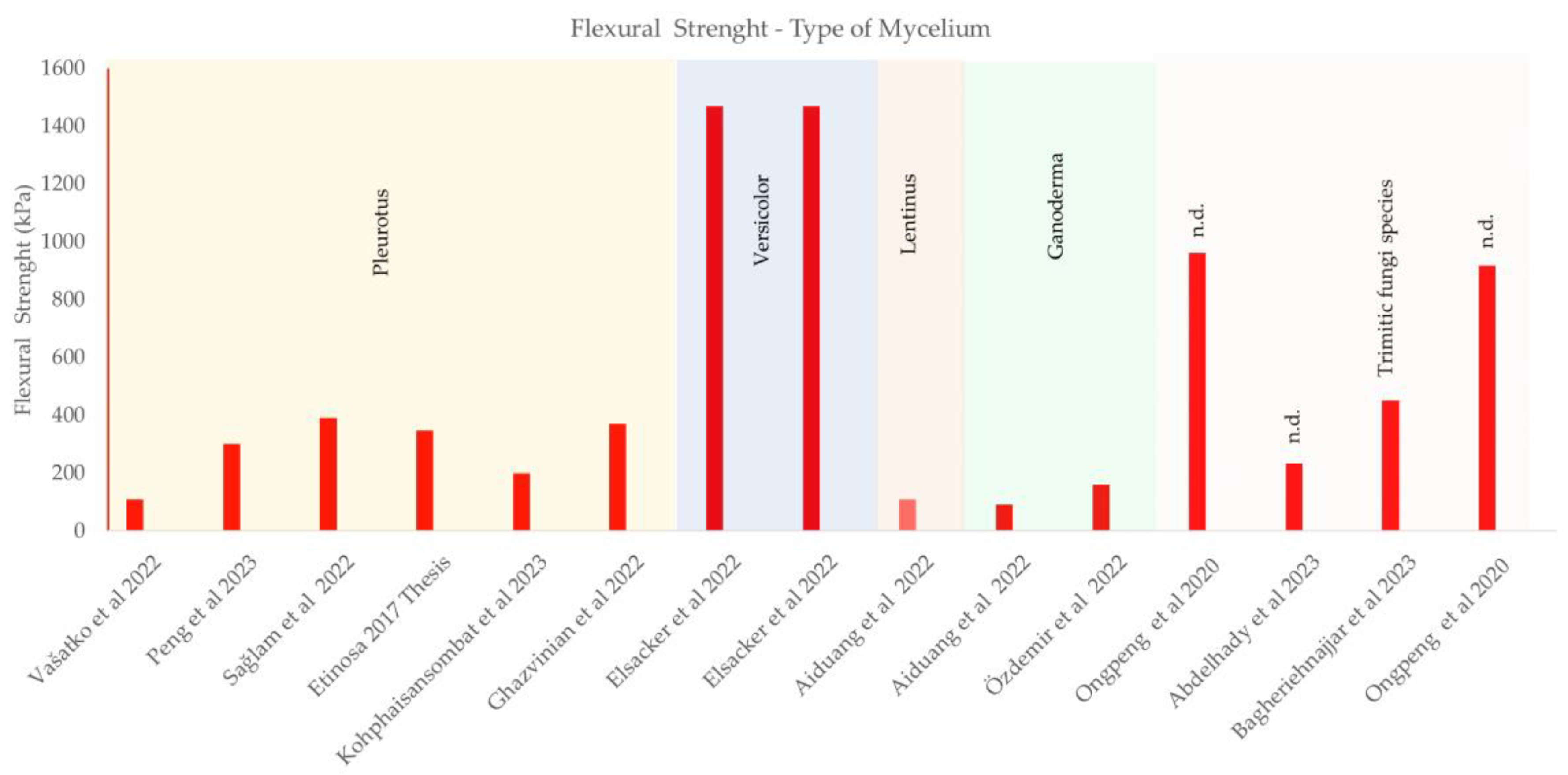

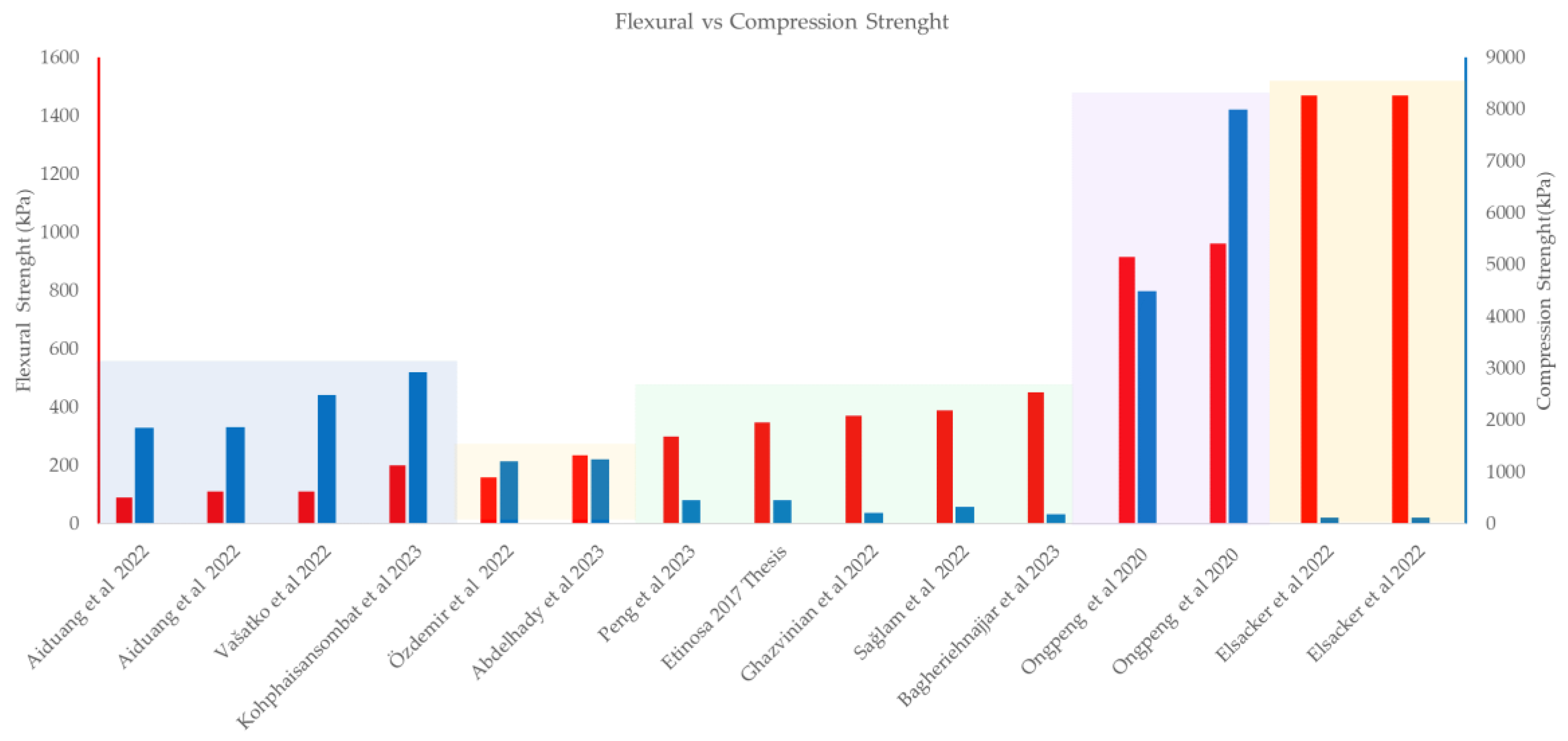

Figure 9 shows the variation of flexural strength values of different FRMs corresponding to the same studies as in the compression results. However, it includes only those that provided data on flexural strength, arranged from the lower value to the high.

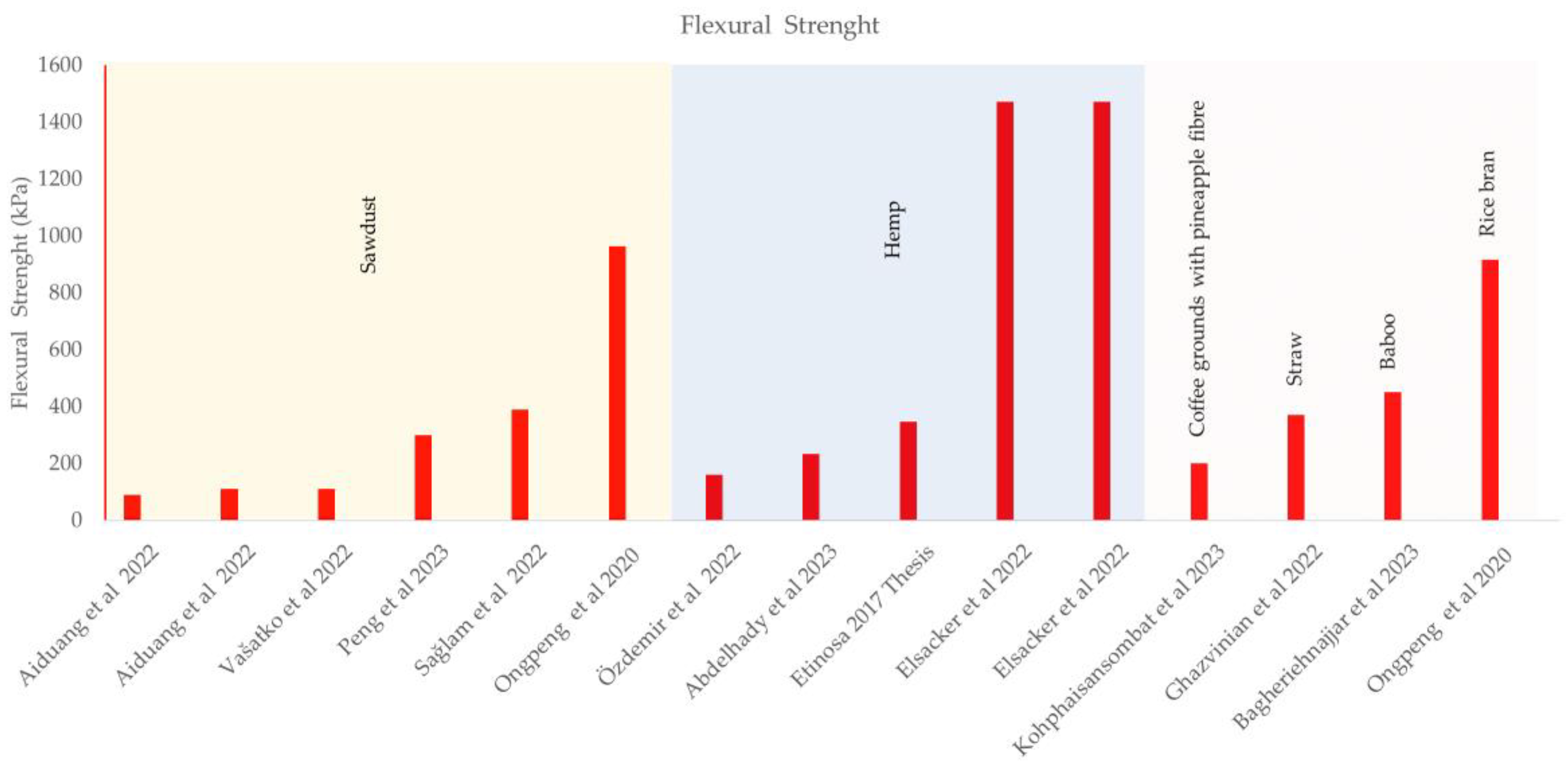

Figure 10 and

Figure 11 depict the flexural strength of various FRMs, classified according to the fibrous substrate type and mycelium type, respectively. These visualizations offer insights into how different fibrous substrates and types of mycelium influence the flexural strength of FRMs.

Figure 12 depicts the compressive and flexural strength comparison of various FRMs arranged by groups. It can be seen the optimum combination of high compression and high flexural strength [

66].

By incorporating mycelium into brick production, particularly with sawdust and rice bran, significantly enhances compressive strength compared to traditional bricks [

66]. Also, the incorporation of mycelium in flexural tests enhances the ductility of brick specimens by reducing crack formation. With increased mycelium content observed in design mixes there's a corresponding increase in linear dimensional change. Microscopic examination reveals the presence of fibers, confirming that natural fibers from mycelium serve as a binding agent in the material.

In addition, the mycelium-based composites with different ratios of natural pineapple fibers exhibit variations in mechanical properties [

76]. It can be seen in the

Figure 13 that as the NF content increased, the flexural strength values aligned well with the ranges documented in previous reports. This highlights the positive impact of fiber reinforcement on the composite's mechanical properties. Meanwhile, the compressive strength and density decreased.

Therefore, the incorporation of NFs in mycelium composites significantly influences their flexural strength. Further exploration and understanding of the intricate relationship between NFs and the mycelium matrix will contribute to the development of high-performance, sustainable composites with enhanced flexural strength.

Several factors contribute to the complex relationship between compressive and flexural strength, including material composition, microstructure, and any potential defects or flaws within the material.

Through further exploration of these variables, scientists and engineers can get a more thorough comprehension of how these characteristics interact and impact the overall performance of materials under different loading scenarios.

For a number of different possible factors, rice bran with mycelium bricks in the study by Ongpeng et al. had higher flexural strength than other mycelium specimen mix designs [

66]. First, rice bran was shown to be a useful substrate for the formation of mycelium. Rice bran's nutrients probably encouraged mycelium growth, strengthening and tightening the brick's fibrous network.

The amount of fiber incorporated into mycelium-based bio-composites significantly influences their flexural strength through various mechanisms. Fibers act as reinforcement, increasing resistance to bending and deformation, and their presence helps distribute stress more evenly across the matrix. Additionally, fibers bridge micro-cracks, preventing their propagation and enhancing strength. The aspect ratio of fibers affects their reinforcing efficiency, with longer fibers relative to their diameter providing better mechanical interlocking. The volume fraction of fibers is critical, as too few fibers may not provide adequate reinforcement, while too many can cause agglomeration and stress concentration, reducing strength. Compatibility between fibers and the mycelium matrix is essential for effective stress transfer, and fiber orientation impacts the direction and magnitude of reinforcement. Maximizing reinforcement without compromising the composite's structural integrity or workability is crucial to achieving an optimal fiber amount. Adding fibers like bamboo increases flexural strength by providing extra support within the matrix, with fine fibers ensuring even distribution and improved binding to the mycelium, thereby enhancing structural integrity. A uniform composite, achieved through the consistent distribution of mycelium and reinforcing materials, enhances flexural strength by evenly absorbing and dissipating stress. Furthermore, the chemical and physical bonds between the mycelium matrix and added fibers or substrates significantly influence the composite's capacity to withstand flexural forces [

32].

The type of mycelium has a crucial effect on the flexural strength of the FRM composite. Besides all the above factors, Pleurotus ostreatus is the optimum. It can be seen in

Figure 11 the distribution of flexural strength among similar mycelium types from the literature.

4. Discussion - Setbacks and Future

The existing literature highlights mycelium composites' potential in architectural and civil engineering due to their sustainability and eco-friendliness. It emphasizes the importance of substrate selection, type of mycelium, and other variables that highly influence the structural behavior in the final product and how the NFs can enhance mechanical properties.

The MBCs produced from corn husk exhibited the highest flexural strength values, followed by MBCs produced from rice straw and sawdust, respectively. The exact values spanned a range from 0.05 to 4.40 MPa, indicating a notable variation in flexural strength that depended on the fibrous substrate used in the production of the composites. Furthermore, the sawdust substrate presents higher compression strength values in different types of mycelium. While the corn husk exhibits higher flexural strength for the same type of mycelium. To conclude the type of substrate is crucial factor for the mechanical properties. Meanwhile, the experimental results highlight that both compressive and flexural strengths are influenced by factors such as the type of substrate and the fungal species used. Therefore, these materials can be tailored for specific mechanical properties by adjusting these variables, which opens up a potential for their use in various sustainable construction applications [

72].

In general, the major setbacks to the wider application of mycelium composites in architectural and civil engineering are the lack of legal design codes, standardized detailing practices, limited ductility, insufficient information on fire and durability performance, and the absence of simplified design manuals for structural engineers. Mycelium composites show great promise in architectural and civil engineering due to their eco-friendliness, lightweight durability, and versatility in shaping. However, their wider application faces challenges such as the lack of standardized testing methods and building codes, which creates uncertainties about their long-term performance. Scalability of production is also a significant issue, as current small-scale methods cannot meet the demands of larger projects. Further research is needed to improve mechanical properties and fire resistance. Collaboration among researchers, industry professionals, and regulatory bodies is crucial to establishing guidelines, conducting testing, and driving innovation, allowing mycelium composites to transform the industry.

For comparison reasons, as shown in

Table 2, the sawdust substrate presents higher compression strength values in different types of fungal, while the corn husk exhibits higher flexural strength for the same type of fungal. To conclude, the type of substrate is a crucial factor for the mechanical properties. No unique type of substrate optimally enhances both compression and flexural strength simultaneously.

While mycelium composites offer significant sustainability benefits, including low cost, low density, low energy consumption, minimal carbon emissions, and biodegradability, their structural limitations deserve consideration. However, because it is a relatively new material, there are currently no established scientific standard protocols.

When mycelium composites are exposed to soil environments, they degrade over time. The decomposition rate depends on factors such as material composition, production method, and characteristics associated with the degradation process [

79]. Additionally, further research is needed to understand the complexities of the degradation process and its implications for long-term sustainability.

5. Conclusions

FRM composites offer a sustainable alternative to traditional materials with their customizable mechanical properties, particularly in compression and flexural strength. The enhancements in natural FRM composites with NFs focus on improving their mechanical properties, mainly compressive and flexural strength, which are crucial for various construction applications. The ability to modify these properties through the choice of reinforcement NFs and composite design highlights the versatility and potential of mycelium-based materials in sustainable building construction materials.

Despite the extensive research on NF treatments and substrate modifications with known materials, the literature does not clearly demonstrate an easy method to enhance the mechanical properties of mycelium composites. The primary reason for this is the complex, multifactorial nature of the type of mycelium and the type of fibrous substrate.

Mycelium materials differ from traditional fiber composites as they are fully biological, sustainable, biodegradable, and have lower environmental impact. The mix proportion in mycelium materials, containing hyphae, is not precisely known initially, unlike traditional composites. FRM composites provide a sustainable alternative to traditional materials, offering customizable mechanical properties, especially in compression and flexural strength.

Factors like porosity, fillers and reinforcements influence the relationship between density and compressive strength in mycelium biocomposites. Higher density from high-strength reinforcements can significantly increase the composite's compressive strength. Adjustments in the ratio of reinforcing fibers can lead to more robust FRM composites with higher compressive strength values compared to other studies using different techniques or materials.

The addition of an optimized quantity of NFs to FRMs positively impacts their flexural strength.

Utilizing simulation and machine learning tools can help understand and predict optimal adhesive properties in mycelium-based materials, enhancing their application in various fields, including the construction realm.

The development of standardized design codes for mycelium composites would not only facilitate their widespread adoption but also pave the way for innovative and eco-friendly structural solutions.

Author Contributions

Conceptualization, M.V.; methodology, M.V and A.M..; validation, M.V and A.M.; investigation, M.V and A.M.; resources, M.V and A.M.; writing—original draft preparation, M.V and A.M.; writing—review and editing, M.V and A.M.; visualization, All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors gratefully acknowledge Stathis Gavrielidis, a student from the Department of Architectural Engineering at the Democritus University of Thrace, for the Figure 1. This figure depicts a building element made from Ganoderma lucidum mycelium cultivated in a hemp fiber substrate. It is one of three types of building elements with different geometries produced as part of Stathis Gavrielidis' diploma thesis.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| NF |

Natural Fiber |

| FRM |

Fiber-Reinforced Mycelium |

| MBCs |

Mycelium-based Bio-Composites |

References

- R. Volk et al., “Life cycle assessment of mycelium-based composite materials,” Resour Conserv Recycl, vol. 205, Jun. 2024. [CrossRef]

- M. Jones, A. Mautner, S. Luenco, A. Bismarck, and S. John, “Engineered mycelium composite construction materials from fungal biorefineries: A critical review,” Materials and Design, vol. 187. Elsevier Ltd, Feb. 01, 2020. [CrossRef]

- Y. Nasr, H. El Zakhem, A. E. A. Hamami, M. El Bachawati, and R. Belarbi, “Comprehensive Review of Innovative Materials for Sustainable Buildings’ Energy Performance,” Energies, vol. 16, no. 21. Multidisciplinary Digital Publishing Institute (MDPI), Nov. 01, 2023. [CrossRef]

- Elfaleh et al., “A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials,” Results in Engineering, vol. 19. Elsevier B.V., Sep. 01, 2023. [CrossRef]

- K. K. Alaneme et al., “Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications,” Alexandria Engineering Journal, vol. 83. Elsevier B.V., pp. 234–250, Nov. 15, 2023. [CrossRef]

- K. Thomoglou, M. E. Voutetaki, J. G. Fantidis, and C. E. Chalioris, “Novel Natural Bee Brick with a Low Energy Footprint for ‘Green’ Masonry Walls: Mechanical Properties †,” Engineering Proceedings, vol. 60, no. 1, 2024. [CrossRef]

- Sayfutdinova, I. Samofalova, A. Barkov, K. Cherednichenko, and D. Rimashevskiy, “Structure and Properties of Cellulose/Mycelium Biocomposites,” Polymers (Basel), vol. 14, no. 8, Apr. 2022. [CrossRef]

- R. Sayfutdinova et al., “Natural Fibrous Materials Based on Fungal Mycelium Hyphae as Porous Supports for Shape-Stable Phase-Change Composites,” Polymers (Basel), vol. 15, no. 23, Dec. 2023. [CrossRef]

- S. N. Jonnala, D. Gogoi, S. Devi, M. Kumar, and C. Kumar, “A comprehensive study of building materials and bricks for residential construction,” Construction and Building Materials, vol. 425. Elsevier Ltd, Apr. 26, 2024. [CrossRef]

- E. Elsacker, S. Vandelook, J. Brancart, E. Peeters, and L. De Laet, “Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates,” PLoS ONE, vol. 14, no. 7, Jun. 2019. [CrossRef]

- F. Heisel and D. E. Hebel, “Pioneering Construction Materials through Prototypological Research,” Biomimetics, vol. 4, no. 3, p. 56, Aug. 2019. [CrossRef]

- D. Almpani-Lekka, S. Pfeiffer, C. Schmidts, and S. il Seo, “A review on architecture with fungal biomaterials: The desired and the feasible,” Fungal Biology and Biotechnology, vol. 8, no. 1. BioMed Central Ltd, Dec. 01, 2021. [CrossRef]

- Rigobello, C. Colmo, and P. Ayres, “Effect of Composition Strategies on Mycelium-Based Composites Flexural Behaviour,” Biomimetics, vol. 7, no. 2, Jun. 2022. [CrossRef]

- Y. H. Arifin and Y. Yusuf, “Mycelium fibers as new resource for environmental sustainability,” in Procedia Engineering, Elsevier Ltd, 2013, pp. 504–508. [CrossRef]

- M. Adamu, F. Alanazi, Y. E. Ibrahim, H. Alanazi, and V. C. Khed, “A Comprehensive Review on Sustainable Natural Fiber in Cementitious Composites: The Date Palm Fiber Case,” Sustainability (Switzerland), vol. 14, no. 11. MDPI, Jun. 01, 2022. [CrossRef]

- D. L. Rocha, L. U. D. T. Júnior, M. T. Marvila, E. C. Pereira, D. Souza, and A. R. G. de Azevedo, “A Review of the Use of Natural Fibers in Cement Composites: Concepts, Applications and Brazilian History,” Polymers, vol. 14, no. 10. MDPI, May 01, 2022. [CrossRef]

- M. J. John and S. Thomas, “Biofibres and biocomposites,” Carbohydrate Polymers, vol. 71, no. 3. pp. 343–364, Feb. 08, 2008. [CrossRef]

- S. M. Sapuan, M. M. Harussani, and E. Syafri, “A short review of recent engineering applications of natural fibres,” in IOP Conference Series: Earth and Environmental Science, Institute of Physics, 2022. [CrossRef]

- R. Sharma and R. Sumbria, “Mycelium bricks and composites for sustainable construction industry: A state-of-the-art review,” Innovative Infrastructure Solutions, vol. 7, no. 5, Oct. 2022. [CrossRef]

- M. C. Naoum, G. M. Sapidis, N. A. Papadopoulos, and M. E. Voutetaki, “An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete,” Fibers, vol. 11, no. 4, p. 34, Apr. 2023. [CrossRef]

- M. C. Naoum, N. A. Papadopoulos, M. E. Voutetaki, and C. E. Chalioris, “Structural Health Monitoring of Fiber-Reinforced Concrete Prisms with Polyolefin Macro-Fibers Using a Piezoelectric Materials Network under Various Load-Induced Stress,” Buildings, vol. 13, no. 10, p. 2465, Sep. 2023. [CrossRef]

- S. Imanzadeh, A. Jarno, A. Hibouche, A. Bouarar, and S. Taibi, “Ductility analysis of vegetal-fiber reinforced raw earth concrete by mixture design,” Constr Build Mater, vol. 239, Apr. 2020. [CrossRef]

- C. Mpalaskas, T. E. Matikas, D. G. Aggelis, and N. Alver, “Acoustic emission for evaluating the reinforcement effectiveness in steel fiber reinforced concrete,” Applied Sciences (Switzerland), vol. 11, no. 9, May 2021. [CrossRef]

- C. Mpalaskas, T. E. Matikas, and D. G. Aggelis, “Acoustic monitoring for the evaluation of concrete structures and materials,” in Acoustic Emission and Related Non-Destructive Evaluation Techniques in the Fracture Mechanics of Concrete, Elsevier, 2021, pp. 257–280. [CrossRef]

- C. Mpalaskas, T. E. Matikas, and D. G. Aggelis, “Acoustic emission of fire damaged fiber reinforced concrete.” [Online]. Available: http://proceedings.spiedigitallibrary.org/.

- R. Ardra, S. Karthik, T. G. Padmakumar, R. Kishnan, S. K. Shukla, and D. Sathyan, “Mycelium-infused geopolymer bricks for non-load-bearing walls: Experimental investigation and life cycle assessment,” Innovative Infrastructure Solutions, vol. 9, no. 3, Mar. 2024. [CrossRef]

- M. Zhang, Z. Zhang, R. Zhang, Y. Peng, M. Wang, and J. Cao, “Lightweight, thermal insulation, hydrophobic mycelium composites with hierarchical porous structure: Design, manufacture and applications,” Compos B Eng, vol. 266, Nov. 2023. [CrossRef]

- N. Verma, S. E. Jujjavarapu, and C. Mahapatra, “Green sustainable biocomposites: Substitute to plastics with innovative fungal mycelium based biomaterial,” Journal of Environmental Chemical Engineering, vol. 11, no. 5. Elsevier Ltd, Oct. 01, 2023. [CrossRef]

- V. Grenon, W. Maref, and C. M. Ouellet-Plamondon, “Multi-property characterization of an experimental material composed of Pleurotus ostreatus mycelium and ash wood chips compared with glass wool and hemp wool,” Constr Build Mater, vol. 409, Dec. 2023. [CrossRef]

- S. Bitting, T. Derme, J. Lee, T. Van Mele, B. Dillenburger, and P. Block, “Challenges and Opportunities in Scaling up Architectural Applications of Mycelium-Based Materials with Digital Fabrication,” Biomimetics, vol. 7, no. 2. MDPI, Jun. 01, 2022. [CrossRef]

- E. Soh and H. Le Ferrand, “Woodpile structural designs to increase the stiffness of mycelium-bound composites,” Mater Des, vol. 225, Jan. 2023. [CrossRef]

- G. Bagheriehnajjar, H. Yousefpour, and M. Rahimnejad, “Multi-objective optimization of mycelium-based bio-composites based on mechanical and environmental considerations,” Constr Build Mater, vol. 407, Dec. 2023. [CrossRef]

- J. Wu et al., “Eco-friendly fiberboard production without binder using poplar wood shavings bio-pretreated by white rot fungi Coriolus versicolor,” Constr Build Mater, vol. 236, Mar. 2020. [CrossRef]

- J. Dessi-Olive, “Strategies for Growing Large-Scale Mycelium Structures,” Biomimetics, vol. 7, no. 3, Sep. 2022. [CrossRef]

- Modanloo, A. Ghazvinian, M. Matini, and E. Andaroodi, “Tilted arch; implementation of additive manufacturing and bio-welding of mycelium-based composites,” Biomimetics, vol. 6, no. 4, Dec. 2021. [CrossRef]

- Javadian, H. Le Ferrand, D. E. Hebel, and N. Saeidi, “Application of Mycelium-Bound Composite Materials in Construction Industry: A Short Review,” 2020, [Online]. Available: www.symbiosisonlinepublishing.com.

- Sayfutdinova, I. Samofalova, A. Barkov, K. Cherednichenko, and D. Rimashevskiy, “Structure and Properties of Cellulose/Mycelium Biocomposites,” Polymers (Basel), vol. 14, no. 8, Apr. 2022. [CrossRef]

- E. Soh and H. Le Ferrand, “Woodpile structural designs to increase the stiffness of mycelium-bound composites,” Mater Des, vol. 225, Jan. 2023. [CrossRef]

- F. V. W. Appels et al., “Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites,” Mater Des, vol. 161, pp. 64–71, Jan. 2019. [CrossRef]

- S. Manan, M. W. Ullah, M. Ul-Islam, O. M. Atta, and G. Yang, “Synthesis and applications of fungal mycelium-based advanced functional materials,” Journal of Bioresources and Bioproducts, vol. 6, no. 1, pp. 1–10, 2021. [CrossRef]

- L. Yang and Z. Qin, “Mycelium-based wood composites for light weight and high strength by experiment and machine learning,” Cell Rep Phys Sci, vol. 4, no. 6, Jun. 2023. [CrossRef]

- Ghazvinian and B. Gürsoy, “Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties,” Biomimetics, vol. 7, no. 2, Jun. 2022. [CrossRef]

- Ghazvinian, P. Farrokhsiar, F. Vieira, J. Pecchia, and B. Gursoy, “Mycelium-Based Bio-Composites For Architecture: Assessing the Effects of Cultivation Factors on Compressive Strength BACKGROUND ON DESIGNING WITH MYCELIUM-BASED BIO-COMPOSITES What is a Mycelium-based Bio-Composite?”.

- Z. Huang, Y. Wei, and S. A. Hadigheh, “Variations in the Properties of Engineered Mycelium-Bound Composites (MBCs) under Different Manufacturing Conditions,” Buildings, vol. 14, no. 1. Multidisciplinary Digital Publishing Institute (MDPI), Jan. 01, 2024. [CrossRef]

- P. Jagadesh, K. S. Amirtavarshini, H. F. Isleem, A. K. Thomoglou, and M. E. Voutetaki, “Development of models for mechanical properties of engineered cementitious composites,” in Production, Properties, and Applications of Engineered Cementitious Composites, IGI Global, 2024, pp. 106–142. [CrossRef]

- M. A. Shakir, M. I. Ahmad, Y. Yusup, and M. Rafatullah, “From waste to wealth: Converting rubber wood sawdust into green mycelium-based composite,” Biomass Convers Biorefin, 2023. [CrossRef]

- M. A. Shakir et al., “Sandwich Composite Panel from Spent Mushroom Substrate Fiber and Empty Fruit Bunch Fiber for Potential Green Thermal Insulation,” Buildings, vol. 13, no. 1, Jan. 2023. [CrossRef]