1. Introduction

According to data provided by the Global Cement and Concrete Association, 14 billion m

3 of Portland cement concrete (PCC) were produced in 2020 [

1], and it is estimated that this production was responsible for 5%–8% of global anthropogenic carbon dioxide emissions [

2]. Because conventional PCC is a mixture of cement, water, admixtures, and mineral aggregates, its most polluting aspect is the Portland cement manufacturing process, with emissions of approximately 866 kg CO2eq per ton [

3], and currently about 4.5 billion tons of cement are yearly produced worldwide [

4]. On the other hand, due to an increase in housing and infrastructure demands, especially in developing countries, it is estimated that cement production will continue to increase to 5–6 billion tons per year by 2050 [

5]. For example, in Chile, the housing shortage in 2020 was 3.3%, equivalent to 641.421 houses [

6], and in other South American countries, similar amounts are demanded. Among them, the Brazilian housing deficit stands out with a shortage of more than 6 million dwellings [

7]. In Colombia, during 2021, the housing deficit was estimated for the first time, and the results showed a deficit of 5.24 million households, equivalent to 31% of the country’s households [

8]. Likewise, in 2015, the Argentine Chamber of Construction estimated the housing deficit based on data from the 2010 census at 1.8 million homes, equivalent to 16.1% of the total housing stock [

9]. It is important to emphasize that, in general, in Latin America, concrete is used in both housing and infrastructure, among other type of construction.

For the previous reasons, the concrete industry must move towards sustainability, and one of the significant measures of such would be reducing CO2 emissions related to the cement content per cubic meter of PCC acting in the reduction of the clinker factor, which may be accomplished by using supplementary cementitious materials (SCMs) because such materials have been shown to be effective in significantly reducing emissions [

10]. These replacements have been used either on site or in cement production and have been extensively studied. Among the best known are industrial by-products such as fly ash, silica fume (SF), ground granulated blast furnace slag, limestone dust, and metakaolin, among others [

11,

12,

13,

14,

15,

16,

17,

18,

19]. Micro silica, for example, is an industrial by-product from ferrosilicon alloys or silicon industries [

20], which has been widely studied and used to improve the physical and chemical properties of concrete because it accelerates the hydration process of cement at early ages given its fine particle size [

21]. Although agricultural as well as industrial wastes are varied, the literature supports that the most-studied such wastes are viable to be used as SCMs in concrete due to their high content of calcium oxide (CaO), silica oxide (SiO2), and alumina (Al2O3), which can react with the chemical components of cement and form hydrated secondary calcium silicates (C-S-H) from the remaining calcium hydroxides (CH) in the cement paste through a pozzolanic reaction [

22]. SCMs improve hydration kinetics, which is mainly favored by the filler effect. Due to the smaller particle size, SCMs provide an extra surface area capable of acting as a nucleation site for C-S-H precipitation, in addition to affecting the acceleration and deceleration periods of hydration, increasing the number of nucleation sites for the generation of hydration products [

10]. Regarding strengthening effects, most SCMs increase the compressive strength of concrete at late ages due to an improved pozzolanic reaction but decrease the strength at early ages due to a decreased amount of cement [

23]. Regarding the durability of concrete, SCMs tend to act positively due to a decrease in or refinement of the pores [

24,

25,

26], decrease in chloride permeability [

27,

28], reduction of expansion due to alkali-silica reaction [

29], or shrinkage reduction [

30,

31], among others. When the excess of CH, which is one of the main factors responsible for the deterioration of the cement matrix, is reduced, the physical and transport properties of the concrete are improved [

32] thereby also improving its durability. In addition, the mixture of SCM with cement results in a more complex combination because the simultaneous hydration can influence the reactivity of the other due to the differences in chemical composition and fineness, among others [

10]. In summary, in addition to the environmental properties, SCMs are also able to improve concrete microstructure, mechanical properties, and durability.

One limitation of SCMs is the fact that they are not always locally available, mainly due to their asymmetric distribution in some regions [

33]; therefore, it is recommended to produce and use SCMs locally available. A major source of waste in the world is agriculture because 9.4 billion tons of primary crops such as sugarcane, corn, wheat, and rice are produced annually to feed the population, and these crops all have by-products [

34]. Many of these by-products can be converted into SCMs, given the large amounts of biomass residues derived from the harvest, such as leaves, stalks, husks, or straw [

35]. Among the best known are rice husk ash [

36,

37,

38], sugarcane bagasse ash [

39,

40,

41], wheat straw ash (WSA) [

42,

43,

44], coconut shell ash [

39,

40,

41,

45], and corn cob ash [

48,

49].

According to cereal production data, wheat is one of the three most-produced cereals, with an estimated production from 2022–2023 of 776.7 million tons, and its consumption is expected to continue increasing as a result of population growth [

50]. On the other hand, to obtain 1 kg of wheat grain, 1.3–1.4 kg of wheat straw is generated [

51]. Although wheat straw is sometimes used to feed livestock, a large amount is still considered waste, so, in many countries, it is typically burned in the fields because it is a fast and economical method to eliminate it. However, method brings negative consequences such as oxidation of soil organic matter; generation of greenhouse gases; increased water erosion; air pollution with particulate matter, which leads to serious health problems; increased risk of fires; and decreased water permeability, among others [

52]. Even though there are alternatives to burning, none have completely solved the problem [

53]. In Chile, this problem persists given that there is a planted area of more than 623,000 ha, which translates into more than 5 million tons of total stubble throughout the country [

54], including crops such as wheat, oats, malting barley, corn, rice, beans, and lentils. One of the most relevant research projects carried out in Chile on the addition of agricultural residues in construction used grapevine shoots with the aim of improving the thermal conductivity of fired clay bricks [

55].

Taking into consideration the previous context, this research considered the use of WSA, started by Biricik et al. (1999) who demonstrated that this material possessed pozzolanic activity and triggered the study of this new potential SCM. It is known that the chemical composition of WSA changes depending on different factors, some related to its place of origin such as variations in soil conditions and climate, thus directly affecting its pozzolanic efficiency [

42]. Furthermore, calcination temperature and particle size are also important when using WSA as an SCM [

42]. Early research investigated the controlled combustion of WSA for 5 hr at temperatures of 570°C and 670°C [

56] and showed that WSA obtained at 670°C had better pozzolanic behavior. It was then reported that the mechanical properties “of autoclaved mortar specimens” were improved with WSA obtained by burning straw at 650°C for 20 hr [

57]. Since those studies, several other similar studies have concluded that the optimum WSA calcination temperature is roughly 600°C, evidencing that upper temperatures tend to transform the amorphous silica into crystalline silica, thus reducing the pozzolanic efficiency [

58,

59].

Although the WSA is a promising material, its incorporation into cement pastes presents some negative impacts such as the loss of strength, which can be improved using another type of SCM such as SF. Additionally, the behavior, properties, and modeling of the incorporation of both WSA and SF so far have not been researched fully.

Therefore, the objective of this study was to set up a model to predict the behavior of concrete with the addition of WSA in order to allow for the utilization of that agricultural waste in the partial replacement of cement. Furthermore, the addition of WSA was investigated in combination with SF. Finally, it is important to highlight that this research was conducted under the umbrella of a larger research project related to timber-concrete composites slabs. Particularly, this type of structures allows concrete with relatively low strength.

4. Conclusions

In this research it was evidenced that the use of agricultural and industrial wastes as SCMs, more specifically wheat straw ash (WSA) and silica fume (SF), was technically feasible in certain proportions. Their utilization as replacements could be maximized using an RSM because this approach effectively achieved cement paste formulations, allowing lower CO2 given a required strength at different ages, namely 7, 28, and 56 days. In addition, the physicochemical characterization of the materials allowed for better understanding and explanation of the resulting design model. The main results and conclusions of this investigation are outlined in the following.

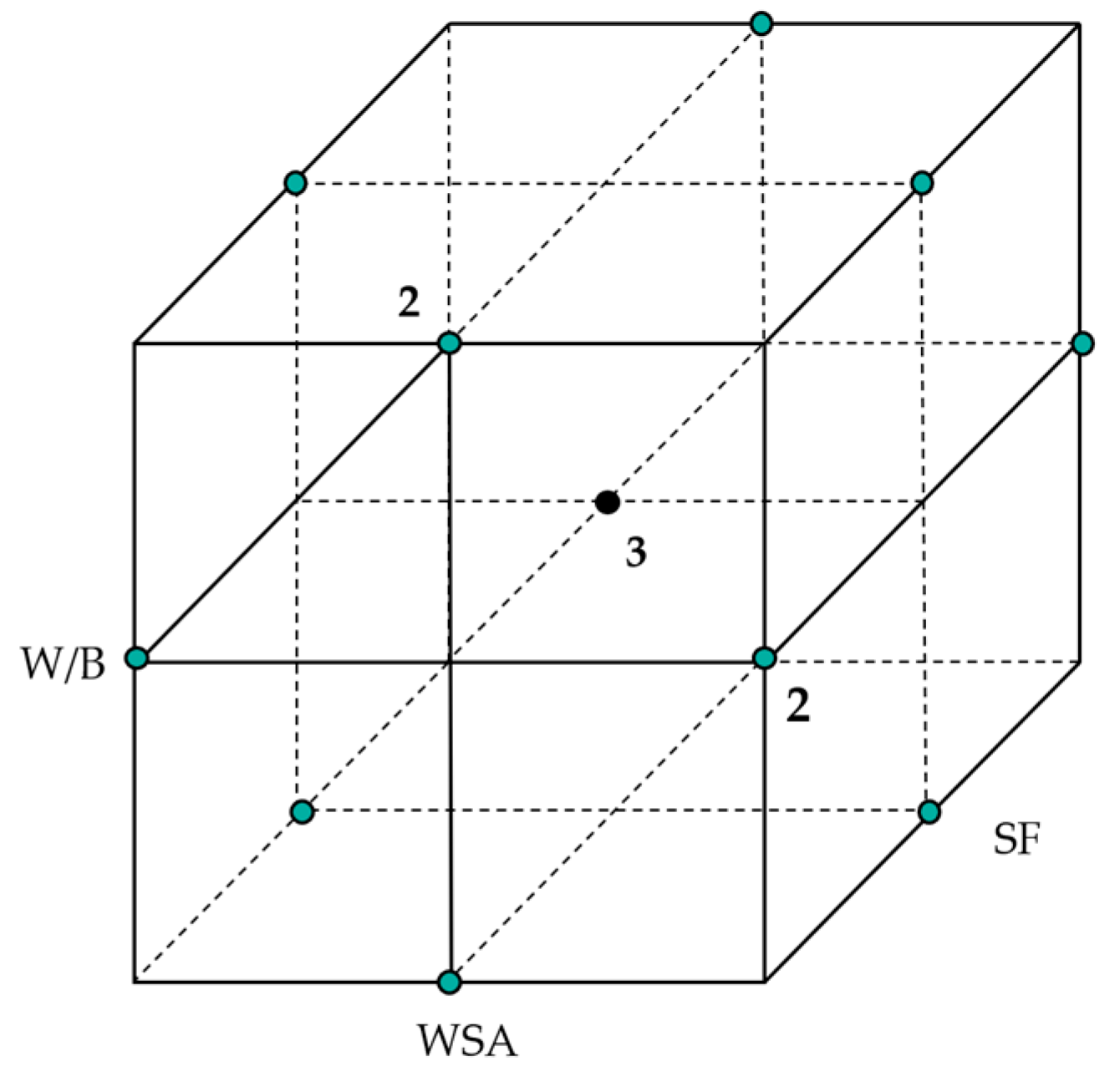

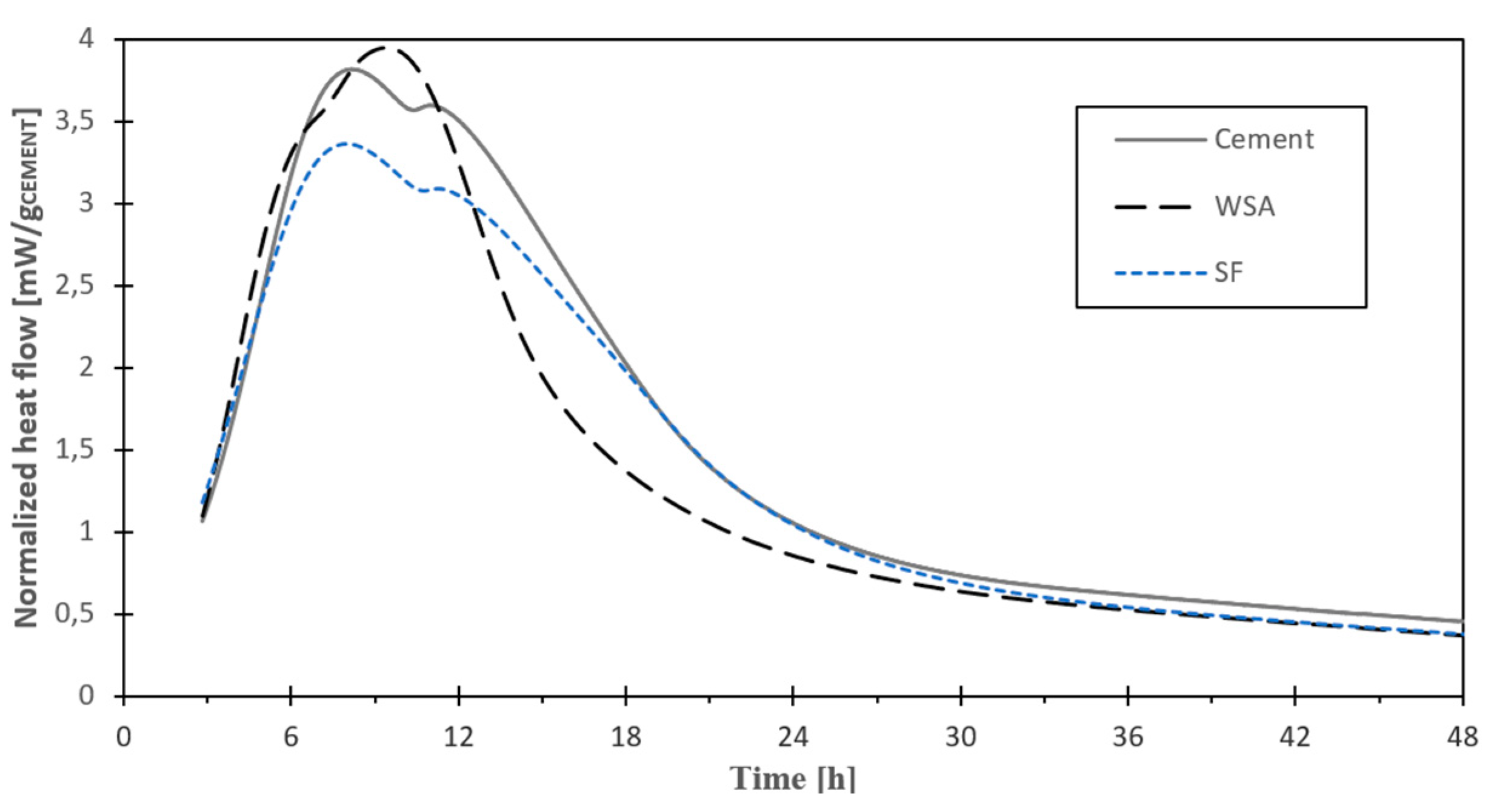

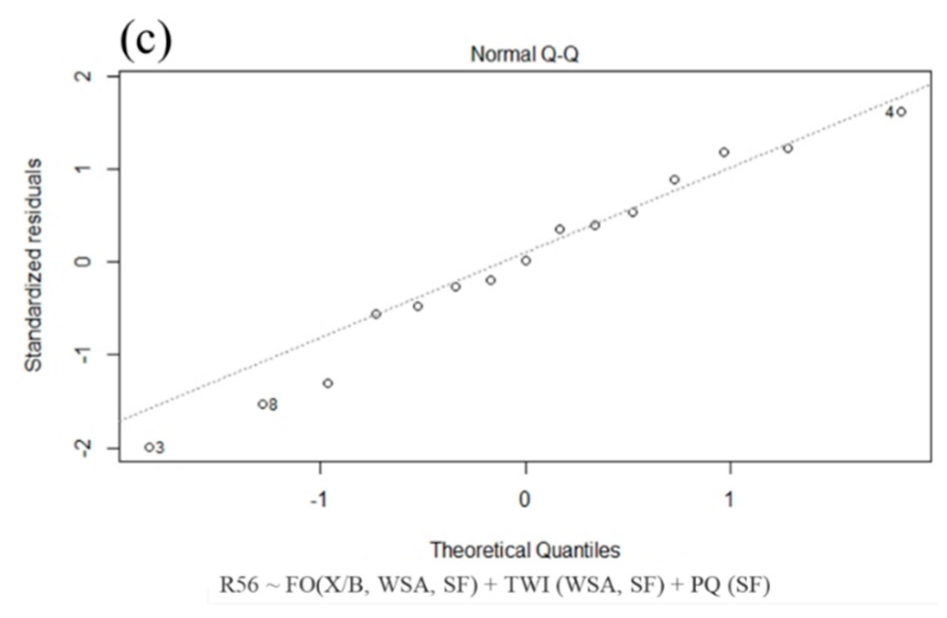

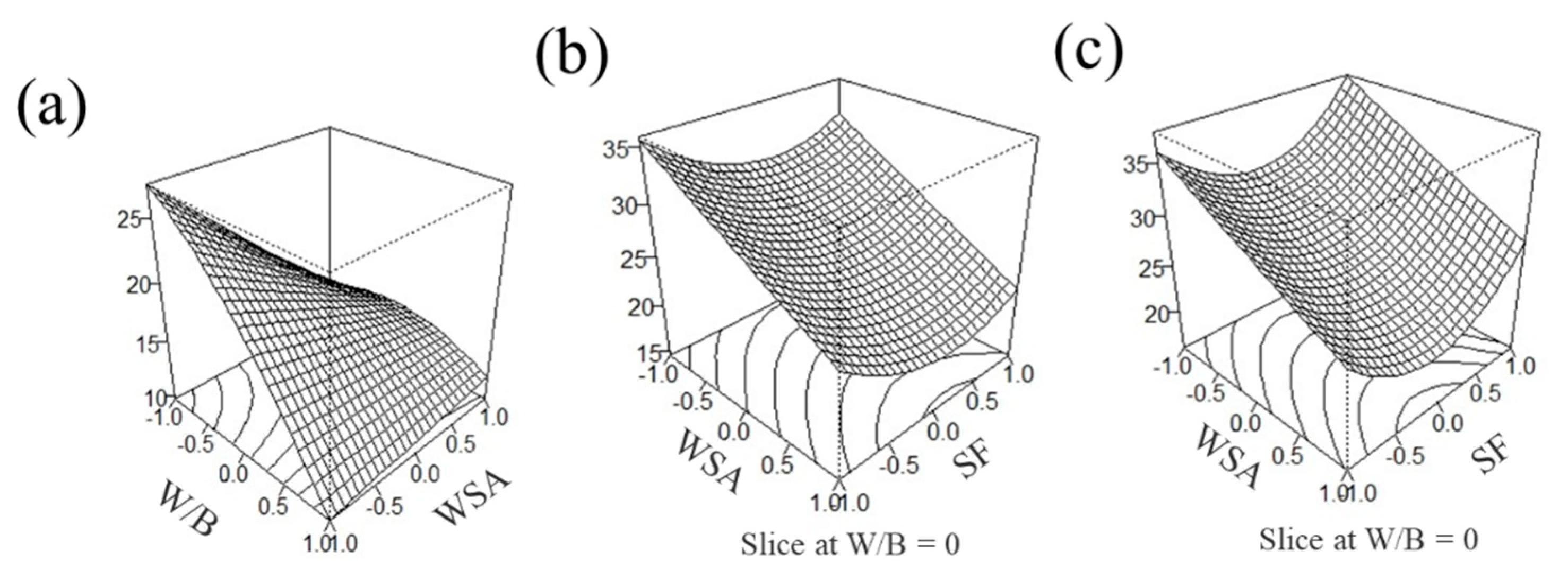

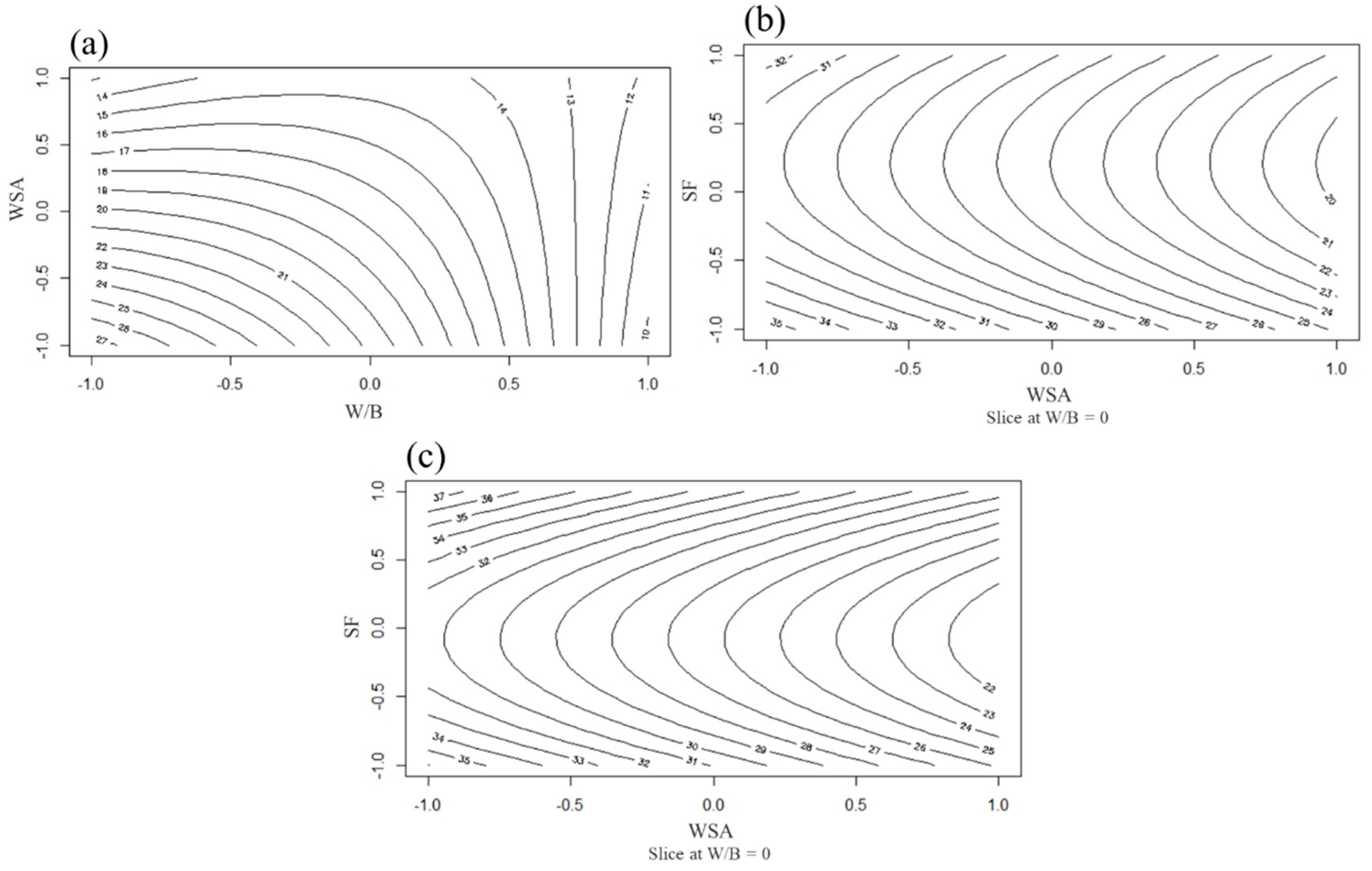

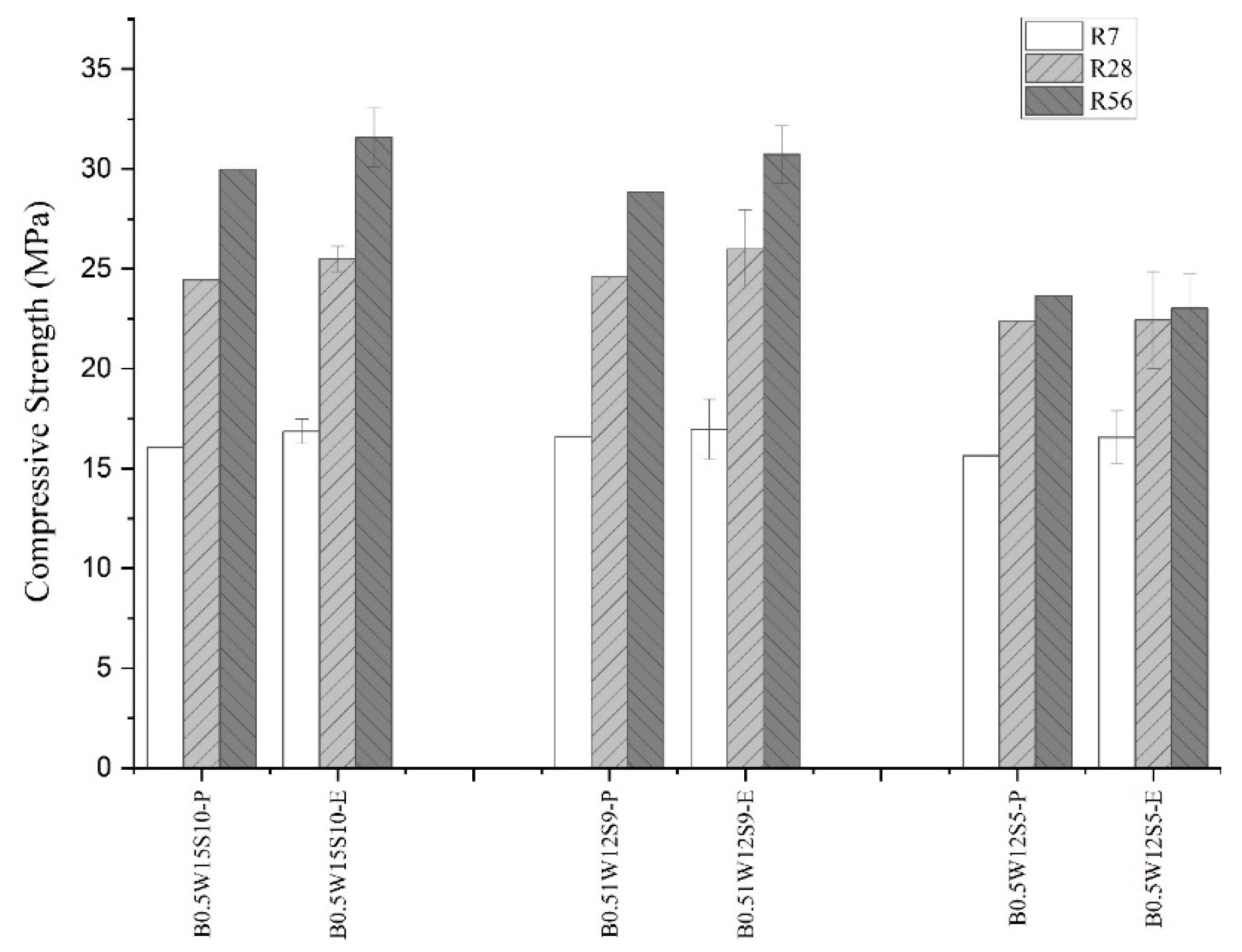

Three statistical models were developed using the BBD, which accurately enabled us to predict the strength of all possible combinations of the variables W/B in the range 0.4–0.6, SF in cement replacement by mass from 0%–10%, and WSA from 0%–20% with good values of (, , and ). This demonstrated that a large part of the variance was explained by the models. In addition, a good fit over the experimental points was prioritized over the whole response surface with the values of the lack of fit, which were non-significant, with p > .05 (, and ). The predictions were as accurate as if additional experiments had been performed, so the regression model showed an excellent fit. To confirm the model, three mixes were tested with different proportions of SCM at a W/B ratio = 0.5 with a high percentage of cement substitution, which resulted in values close to the predicted values, with maximum errors of 6% at the three ages. Therefore, the proposed model may be a suitable means of predicting the strength of this type of mix.

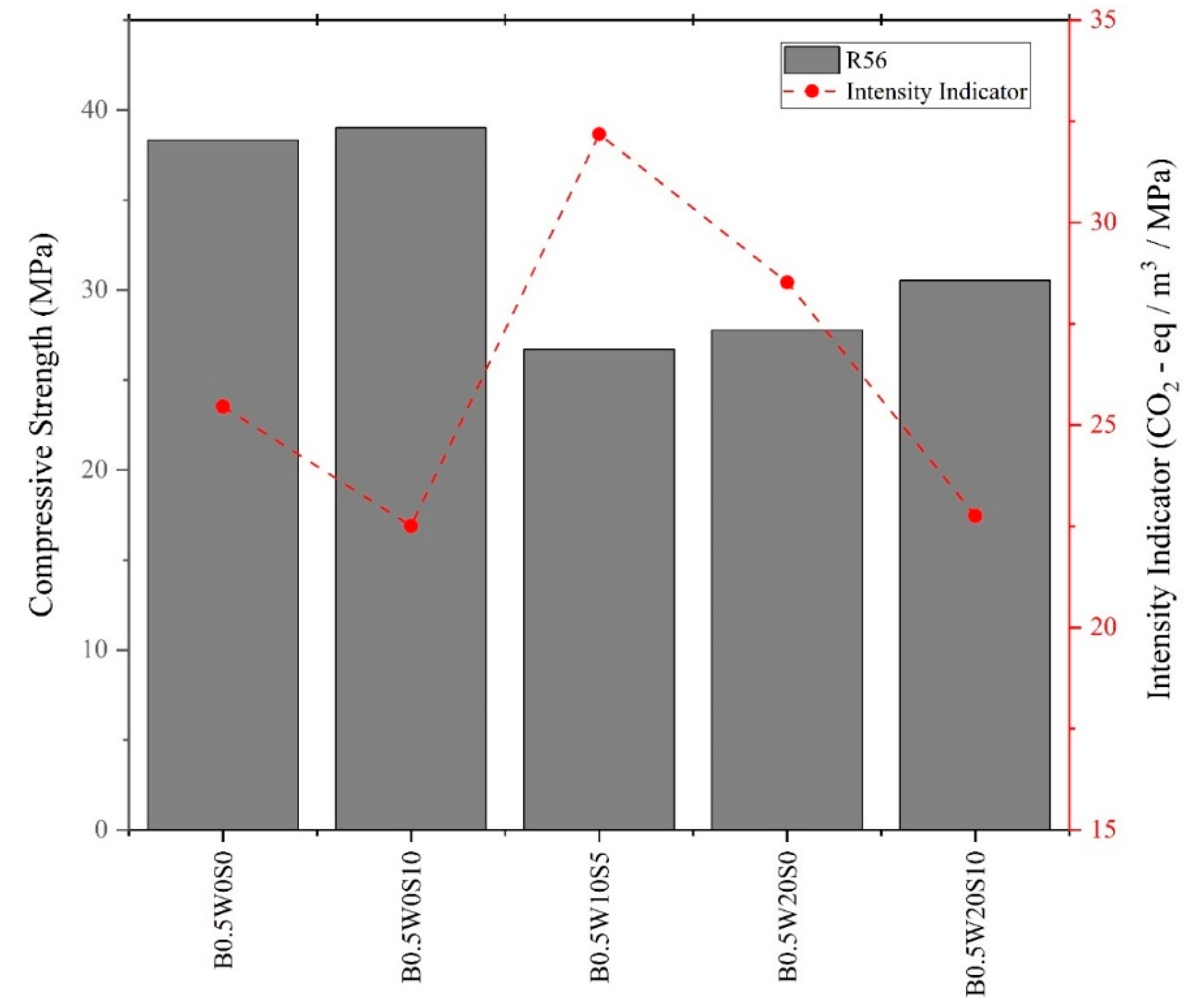

With values based on the models, we established that, for any addition of WSA between 0%–20% and SF between 5%–10%, the mechanical strength losses generated by the incorporation of WSA were reduced, maximizing the incorporation of both SCMs. Furthermore, with this response surface analysis together with the regression equations, it was possible to predict compressive strength at different ages. Therefore, a good strategy for minimizing the carbon footprint may be setting the required strength and calculating the maximum possible cement replacements, which should contribute to making the construction industry more sustainable by utilizing local waste.

Overall, the findings of this research extend the knowledge associated with the possibility of including WSA as a supplementary cementitious material (SCM) that is synergic with other SCMs such as SF; as a result, the clinker factor and the CO2 emissions in the material can be reduced, thus allowing a cement pastes with a lower carbon footprint.

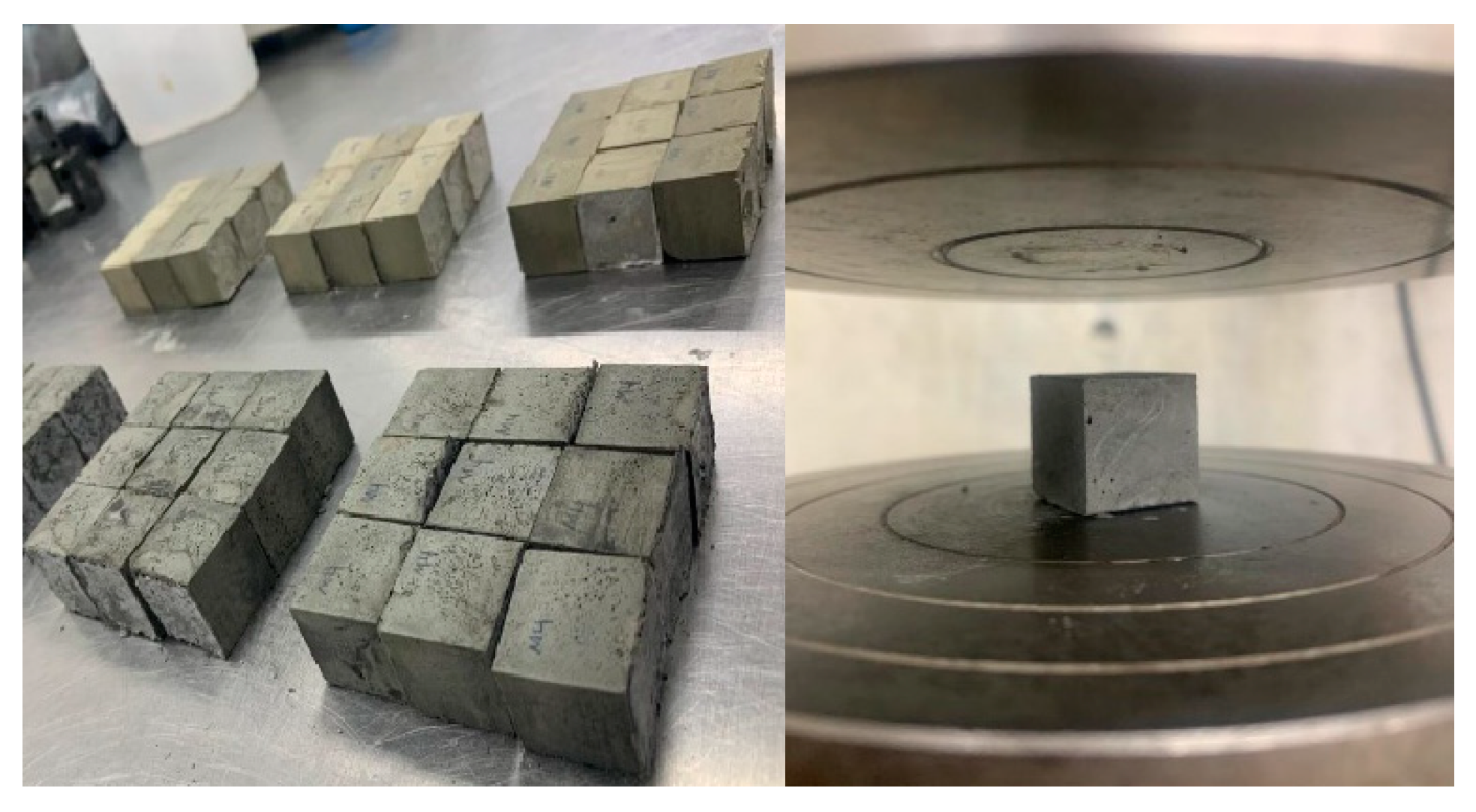

Figure 2.

Curing of specimens in water.

Figure 2.

Curing of specimens in water.

Figure 3.

Compression test of samples.

Figure 3.

Compression test of samples.

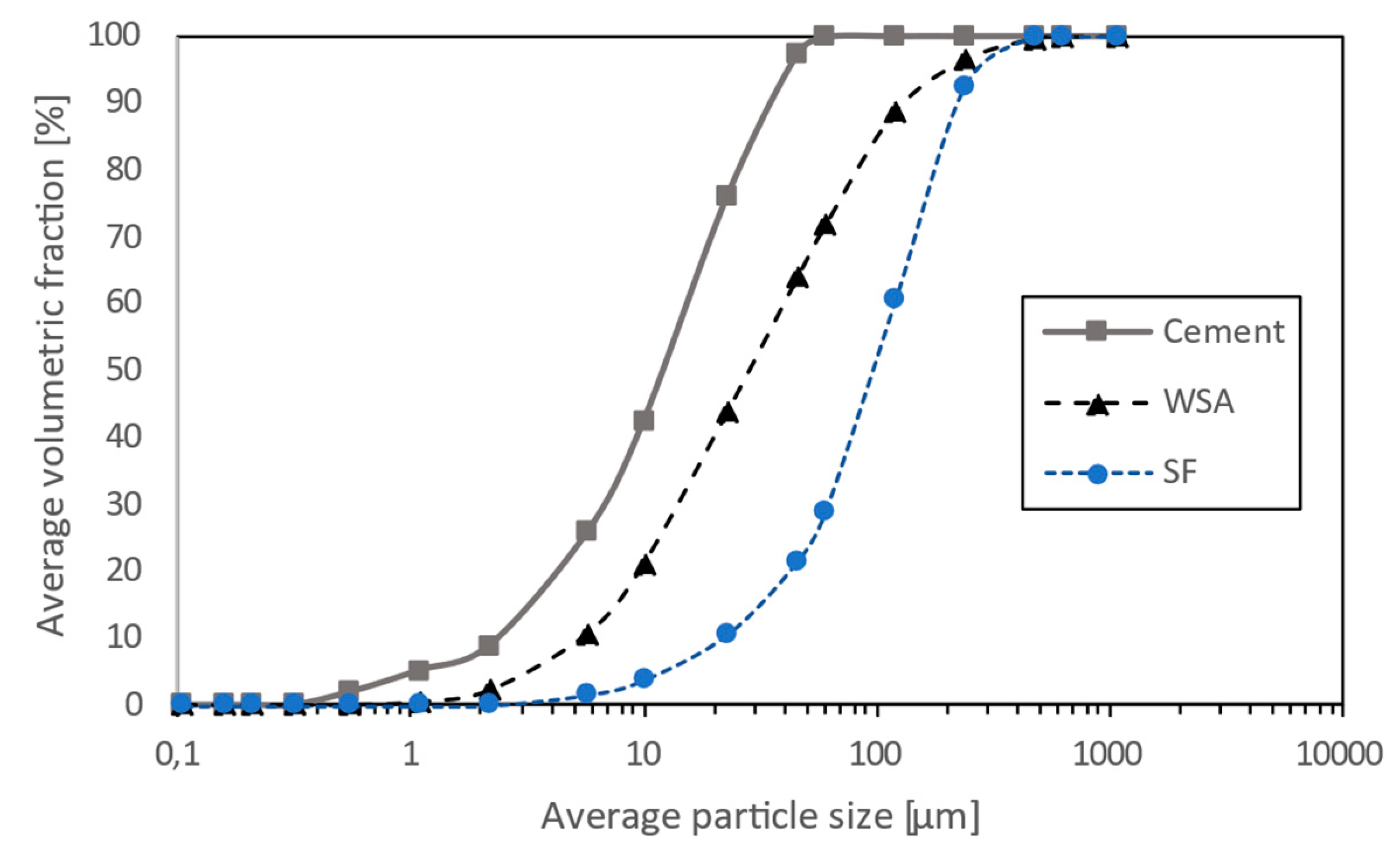

Figure 4.

Particle size distribution of raw materials.

Figure 4.

Particle size distribution of raw materials.

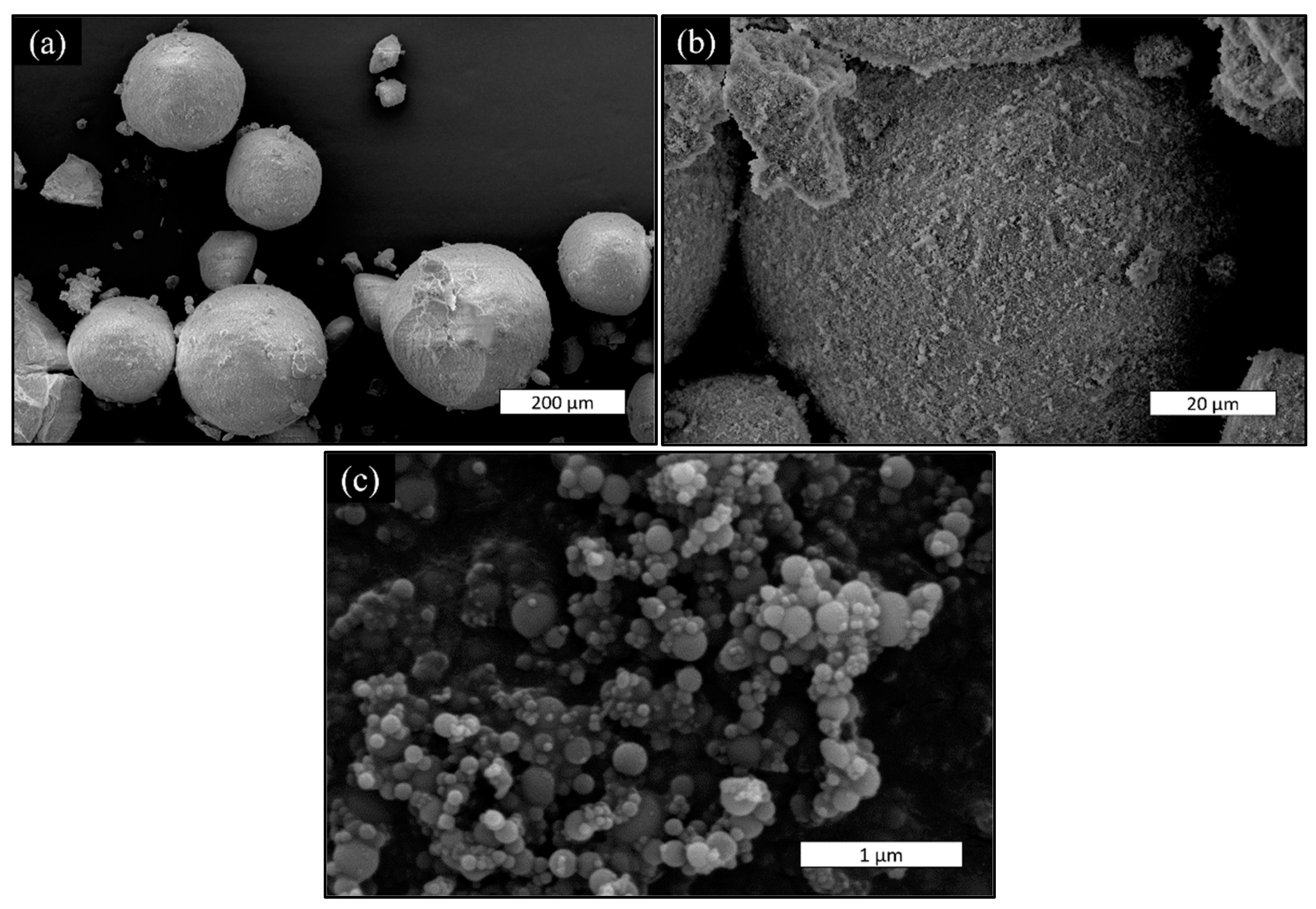

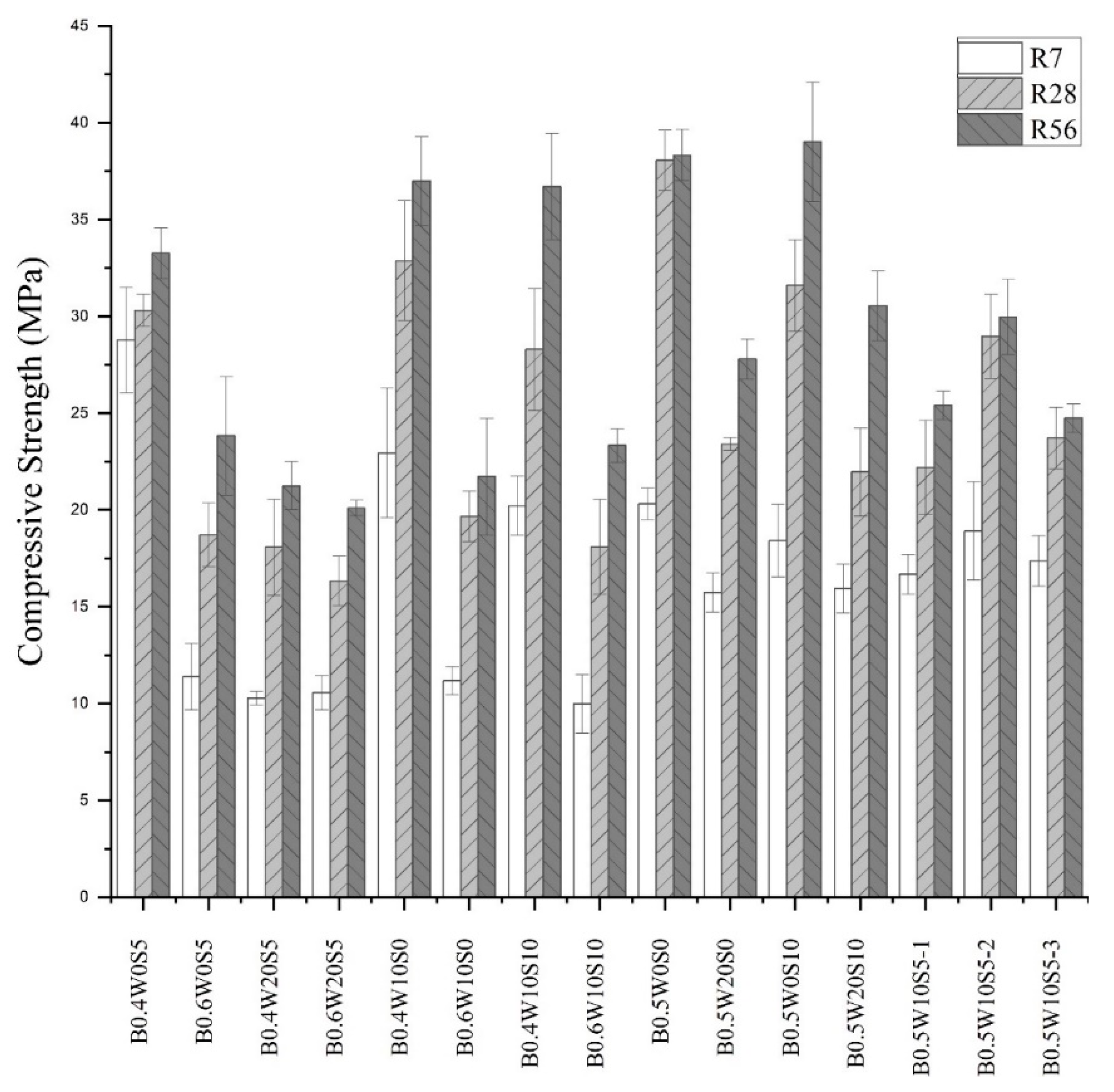

Figure 5.

(a) Morphology of silica fume by electron microscope, (b) agglomeration and (c) silica fume.

Figure 5.

(a) Morphology of silica fume by electron microscope, (b) agglomeration and (c) silica fume.

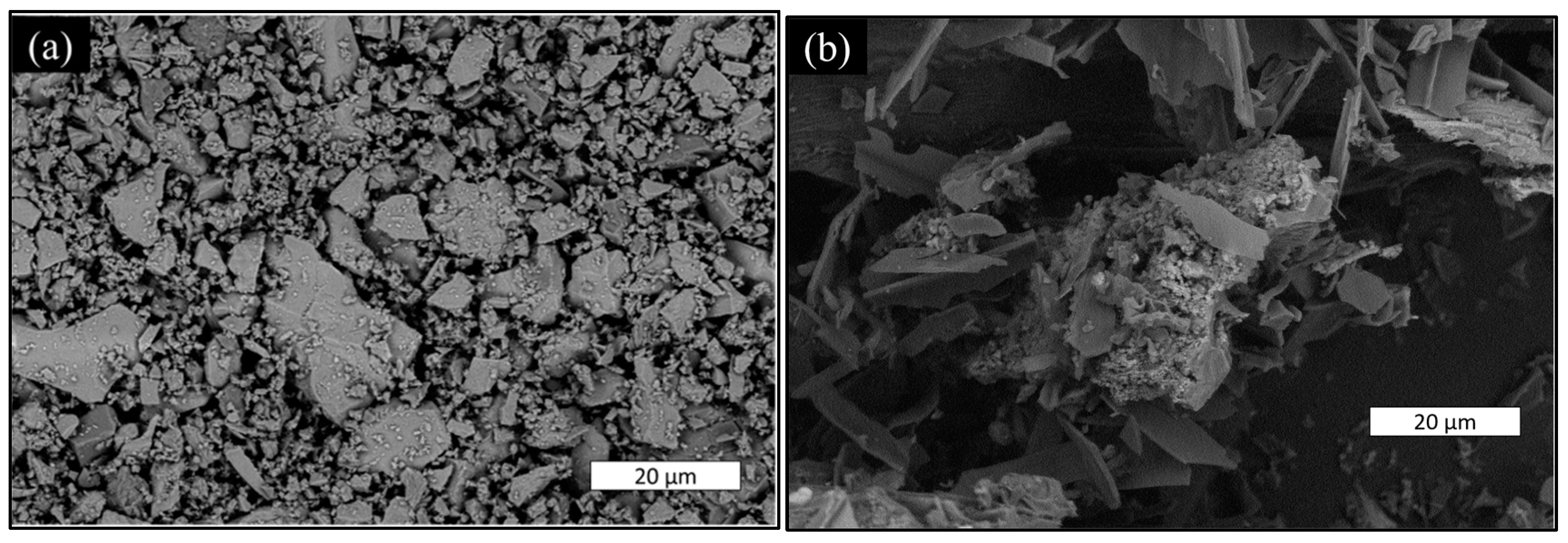

Figure 6.

Morphology of cement and WSA. (a) cement particles, (b) and (c) WSA.

Figure 6.

Morphology of cement and WSA. (a) cement particles, (b) and (c) WSA.

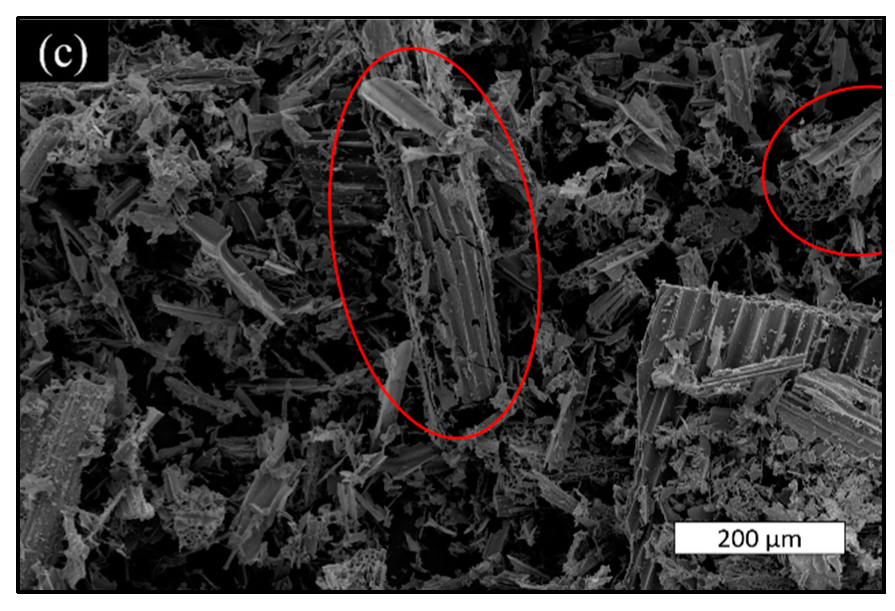

Figure 7.

Normalized hydration heat.

Figure 7.

Normalized hydration heat.

Figure 8.

Normalized heat flow.

Figure 8.

Normalized heat flow.

Figure 9.

Compressive strength.

Figure 9.

Compressive strength.

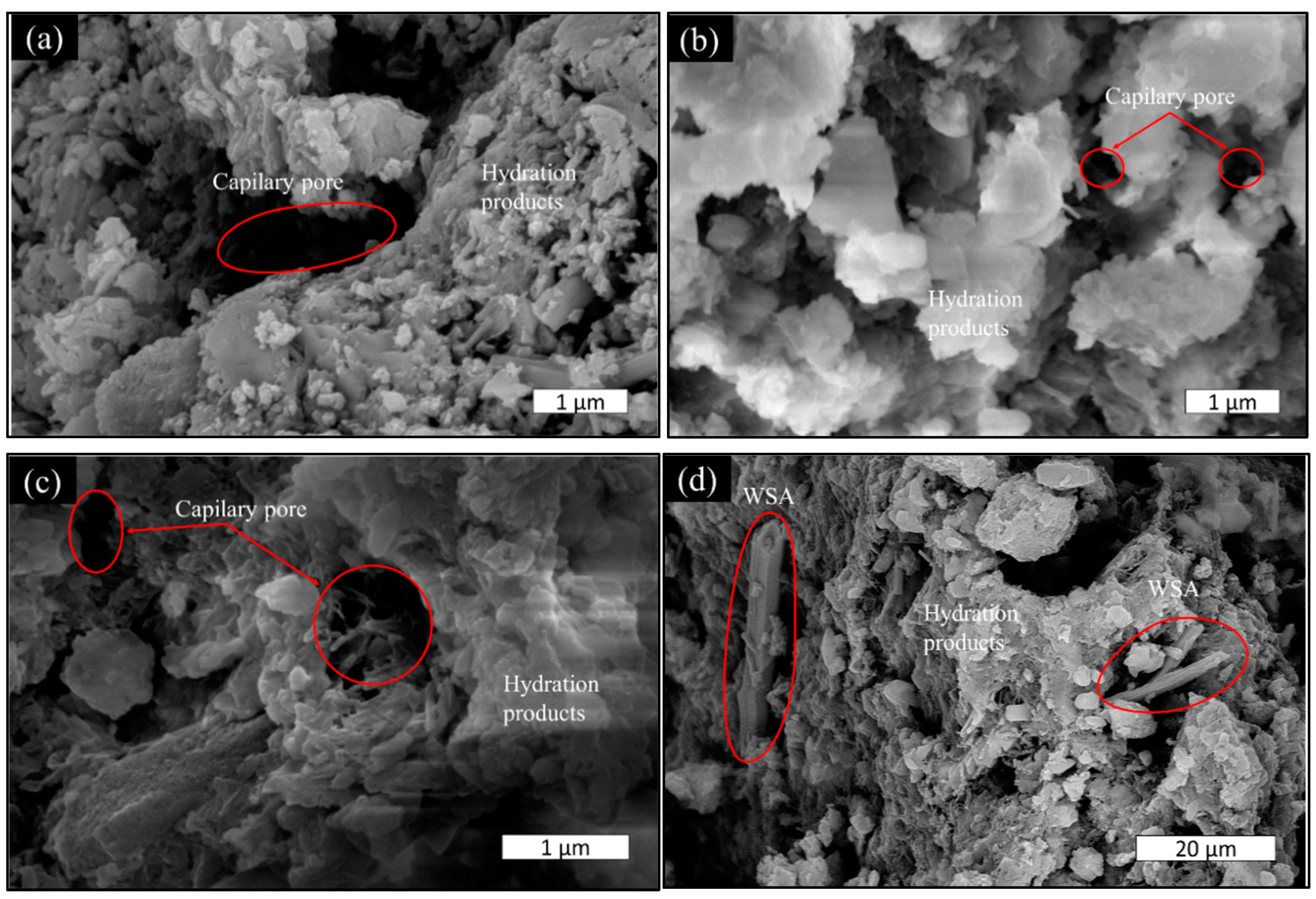

Figure 10.

FE-SEM images of pastes at 56 days. (a) cement, (b) SF and (c) WSA at 1 m, (d) WSA at 20 m.

Figure 10.

FE-SEM images of pastes at 56 days. (a) cement, (b) SF and (c) WSA at 1 m, (d) WSA at 20 m.

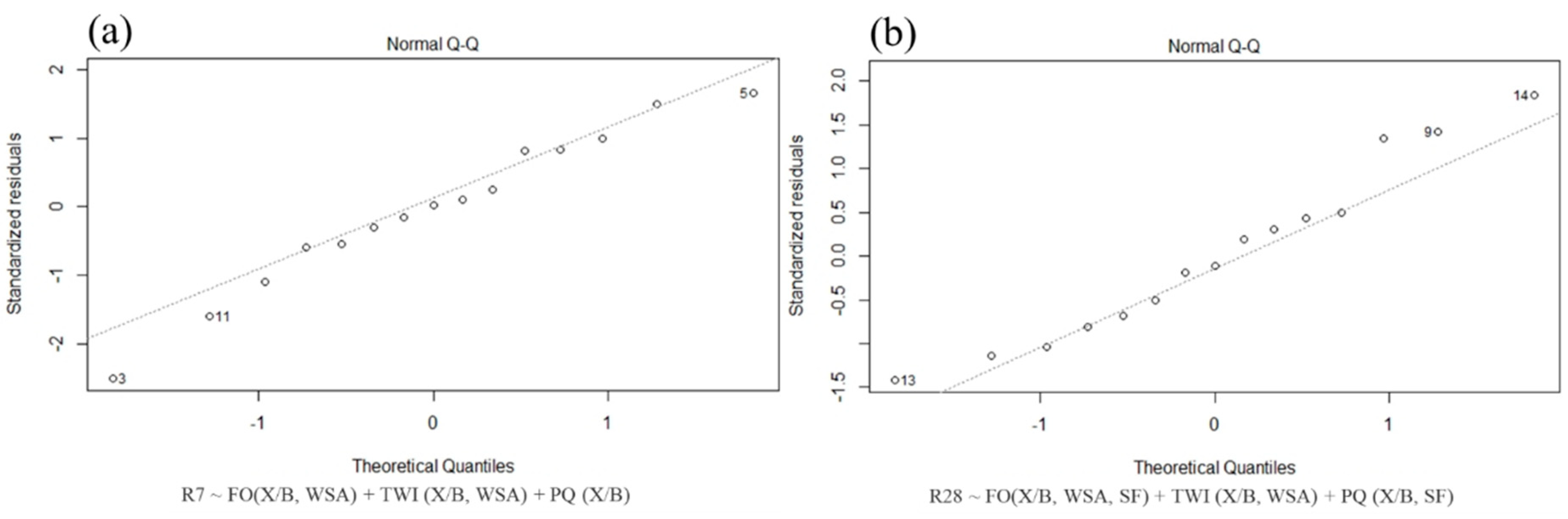

Figure 11.

(a) 7-day, (b) 28-day (c) 56-day quantile-quantile plots.

Figure 11.

(a) 7-day, (b) 28-day (c) 56-day quantile-quantile plots.

Figure 12.

3D model of RSM. (a) 7, (b) 28, and (c) 56 days with W/B=0.5.

Figure 12.

3D model of RSM. (a) 7, (b) 28, and (c) 56 days with W/B=0.5.

Figure 13.

Contour plots for (a) 7, (b) 28, and (c) 56 days with W/B=0.5.

Figure 13.

Contour plots for (a) 7, (b) 28, and (c) 56 days with W/B=0.5.

Figure 14.

Predicted (-P) and experimental (-E) mixes from RSM.

Figure 14.

Predicted (-P) and experimental (-E) mixes from RSM.

Figure 15.

Carbon footprint (intensity index) versus 56-day compressive strength.

Figure 15.

Carbon footprint (intensity index) versus 56-day compressive strength.

Table 1.

Emissions of CO2 in kg per kg of raw material.

Table 1.

Emissions of CO2 in kg per kg of raw material.

| Material |

CO2eq (kg/kg) |

Reference |

| Cement |

0.813 |

[61] |

| Biomass ash |

0.05 |

[62] |

| SF |

0.00001 |

[61] |

Table 2.

Chemical composition of raw materials.

Table 2.

Chemical composition of raw materials.

| Compounds |

Cement (%) |

WSA (%) |

SF (%) |

|

59.0 |

5.33 |

0.18 |

|

24.8 |

27.12 |

94.50 |

|

5.80 |

0.57 |

- |

|

3.29 |

0.15 |

0.14 |

|

2.88 |

0.79 |

- |

|

1.07 |

0.52 |

- |

|

0.79 |

6.81 |

0.45 |

|

0.23 |

- |

- |

|

0.09 |

- |

- |

|

- |

1.18 |

- |

|

- |

0.69 |

- |

|

- |

0.42 |

- |

|

- |

0.17 |

- |

|

2.01 |

- |

4.76 |

Table 3.

Summary of the different paste mixes with cement replacement by WSA and SF.

Table 3.

Summary of the different paste mixes with cement replacement by WSA and SF.

| |

Levels in the BBD model |

Experimental composition |

| Mixes nomenclature |

W/B |

WSA |

SF |

W/B |

WSA (%) |

SF (%) |

| B0.4W0S5 |

-1 |

-1 |

0 |

0.4 |

0 |

5 |

| B0.6W0S5 |

1 |

-1 |

0 |

0.6 |

0 |

5 |

| B0.4W20S5 |

-1 |

1 |

0 |

0.4 |

20 |

5 |

| B0.6W20S5 |

1 |

1 |

0 |

0.6 |

20 |

5 |

| B0.4W10S0 |

-1 |

0 |

-1 |

0.4 |

10 |

0 |

| B0.6W10S0 |

1 |

0 |

-1 |

0.6 |

10 |

0 |

| B0.4W10S10 |

-1 |

0 |

1 |

0.4 |

10 |

10 |

| B0.6W10S10 |

1 |

0 |

1 |

0.6 |

10 |

10 |

| B0.5W0S0 |

0 |

-1 |

-1 |

0.5 |

0 |

0 |

| B0.5W20S0 |

0 |

1 |

-1 |

0.5 |

20 |

0 |

| B0.5W0S10 |

0 |

-1 |

1 |

0.5 |

0 |

10 |

| B0.5W20S10 |

0 |

1 |

1 |

0.5 |

20 |

10 |

| B0.5W10S5-1 |

0 |

0 |

0 |

0.5 |

10 |

5 |

| B0.5W10S5-2 |

0 |

0 |

0 |

0.5 |

10 |

5 |

| B0.5W10S5-3 |

0 |

0 |

0 |

0.5 |

10 |

5 |

Table 4.

Shapiro-Wilk normality test.

Table 4.

Shapiro-Wilk normality test.

| Age |

W |

p value |

| 7 days |

0.97 |

0.86 |

| 28 days |

0.97 |

0.89 |

| 56 days |

0.97 |

0.85 |

Table 5.

Analysis of variance and estimated coefficients of compressive strength for the 7-day model.

Table 5.

Analysis of variance and estimated coefficients of compressive strength for the 7-day model.

| Factor |

Coefficient |

Std. Error |

t value |

Pr ( > |t|) |

| Constant |

17.62 |

0.65 |

27.07 |

0.0000000001093*** |

| W/B |

-4.69 |

0.61 |

-7.7 |

0.01649*** |

| WSA |

-3.3 |

0.61 |

-5.14 |

0.0004356*** |

| W/B:WSA |

4.13 |

0.86 |

4.8 |

0.0007220*** |

| (W/B)2

|

-2.14 |

0.89 |

-2.4 |

0.0373727* |

|

Note: significance codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1 |

Table 6.

Analysis of variance and estimated coefficients of compressive strength for the 28-day model.

Table 6.

Analysis of variance and estimated coefficients of compressive strength for the 28-day model.

| Factor |

Coefficient |

Std. Error |

t value |

Pr ( > |t|) |

| Constant |

25.13 |

1.14 |

22.04 |

0.00001896*** |

| W/B |

-5.31 |

0.84 |

-6.32 |

0.0002274*** |

| WSA |

-5.35 |

0.84 |

-6.38 |

0.0002136*** |

| SF |

-1.53 |

0.84 |

-1.82 |

0.1057541 |

| W/B:WSA |

3.48 |

1.19 |

2.93 |

0.0189174* |

| (W/B)2

|

-3.39 |

1.23 |

-2.75 |

0.0249159* |

| (SF)2

|

3.52 |

1.23 |

2.86 |

0.0211537* |

|

Note. Significance codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1 |

Table 7.

Analysis of variance and estimated coefficients of compressive strength for the 56-day model.

Table 7.

Analysis of variance and estimated coefficients of compressive strength for the 56-day model.

| Factor |

Coefficient |

Std. Error |

t value |

Pr ( > |t|) |

| Constant |

26.21 |

1.25 |

21.04 |

0.000001308*** |

| W/B |

-5.21 |

1.17 |

-4.47 |

0.001203** |

| WSA |

-5.08 |

1.17 |

-4.36 |

0.001423** |

| SF |

0.8 |

1.17 |

0.68 |

0.510685 |

| (SF)2

|

5.52 |

1.71 |

3.23 |

0.008980** |

|

Note. Significance codes: 0 ‘***’ 0.001 ‘**’ 0.01 ‘*’ 0.05 ‘.’ 0.1 ‘ ’ 1 |

Table 8.

Validation mixtures to confirm the predictive model.

Table 8.

Validation mixtures to confirm the predictive model.

| Mixtures |

W/B |

WSA |

SF |

W/B |

WSA (%) |

SF (%) |

| B0.5W15S10 |

0 |

0.5 |

1 |

0.5 |

15 |

10 |

| B0.51W12S9 |

0.1 |

0.2 |

0.8 |

0.51 |

12 |

9 |

| B0.5W12S5 |

0 |

0.2 |

0 |

0.5 |

12 |

5 |

Table 9.

Model prediction errors as per the validation experiments.

Table 9.

Model prediction errors as per the validation experiments.

| Mixtures |

Model error 7 days (%) |

Model error 28 days (%) |

Model error 56 days (%) |

| B0.5W15S10 |

4.8 |

4.1 |

5.1 |

| B0.51W12S9 |

2.2 |

5.4 |

6.1 |

| B0.5W12S5 |

5.6 |

0.3 |

-2.7 |